Weldy Foiler User Manual

FOILER

Automatic hot-air welding machine

Please read operating instructions carefully before use

and keep it for further reference.

OPERATING INSTRUCTIONS

Automatic Overlap Welding Machine

• For overlap welding of industrial fabrics (

PVC, PP, PE, etc…)

•

Welding seam width 20 or 30 mm

GB

Leister Technologies Ltd.

Building A, 1588 Zhuanxing Road

Xinzhuang Industry Park

Shangai 201108 PRC

Tel. +86-21-6442 2398

Fax: +86-21-6442 2338

www.weldytool.com

Optional additional weight with holder

Voltage V~

Frequency Hz

Capacity W

Temperature °C

Air flow (20°C) l/min.

Drive speed m/min.

Noise emission level L

pA(dB)

Dimensions mm

Weight kg

Protection class I

Technical data

230

50 / 60

2100

80 – 530

200 – 270

1.0 – 7.5

76

445×276× 280

10.8

1

2

Danger! Unplug the tool before opening it, as live components and connections are exposed.

Incorrect use of hot air tools can present a fire and explosi-

on hazard, particularly in the proximity of flammable materials and explosive gases.

The tool must be operated under supervision.

Heat can ignite flammable materials which are not in view.

The machine may only be used by qualified specialists or

under their supervision. Children are not authorized to use

this machine.

For personal protection, we strongly recommend the tool to

be connected to an RCCB (Residual Current Circuit Breaker) before using it on construction sites.

The rated voltage stated on the tool must correspond with

the mains voltage.

In the case of a power cut, the Drive switch (11)

and air blower switch (13) has to be set to 0.

Danger of getting burned! Do not touch the end of the

heater tube and nozzle when they are hot. Let the tool

cool down. Do not point the hot air flow in the direction of

people or animals.

Protect the tool from damp and wet.

FI

230

400

Warning

Caution

Connect tool to a receptacle with protective earth terminal.

Any disconnection of the protective conductor in or outside

the tool is dangerous!

Use line/mains extension cables with protective earth/ground

conductor and adequate cross sectional area only!

3

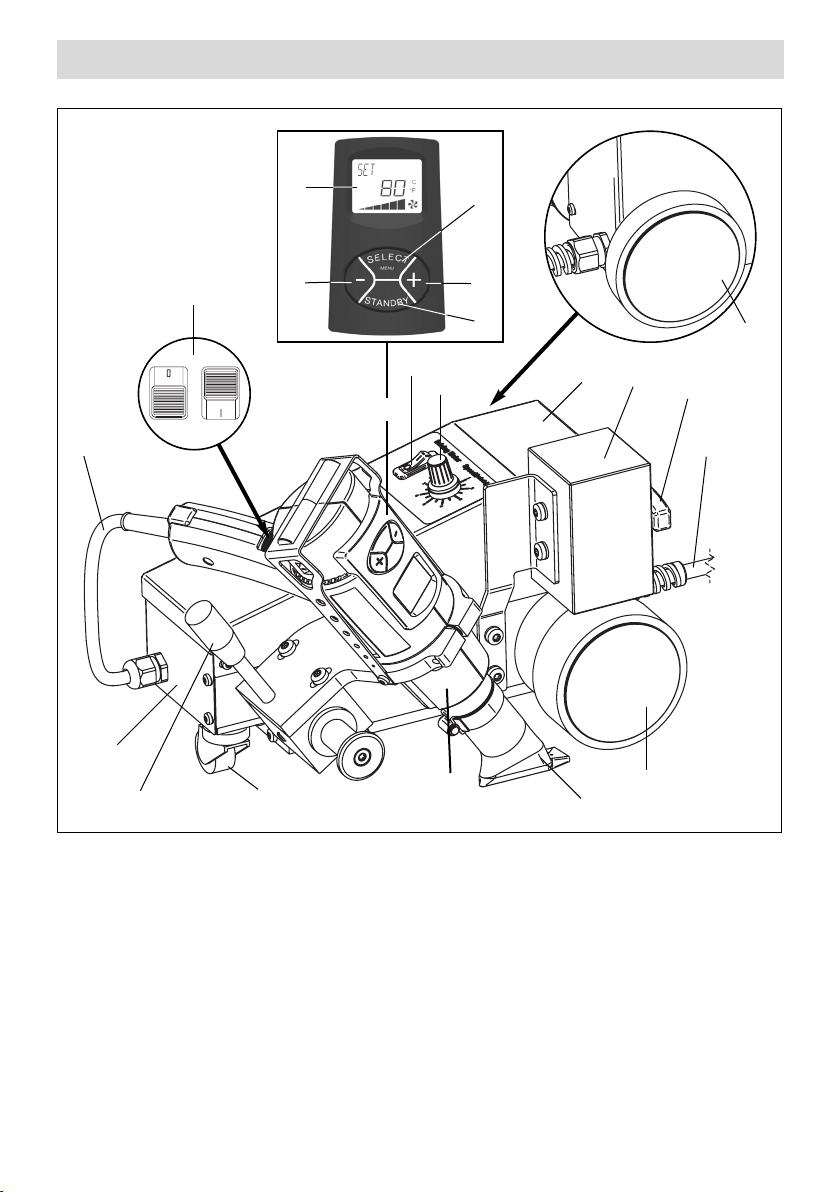

Tool description FOILER

1

2

3

4

6

5

Main components

1. Housing/chassis

2. Power supply cord

3. Hot air blower

4. Welding nozzle

5. Connection cable

6. Drive/pressure roller

7. Drive roller

8. Steering roller

9. Additional weight (optional)

10. Carrying handle

1

11

12

Operating components

11. Drive switch

12. Potentiometer for

welding speed

13. Air blower switch

14. Positioning lever

15. Terminal

16. Display

17. Button SELECT Menu

18. Button STANDBY/COOL DOWN

19. Button MINUS

20. Button PLUS

8

9

10

14

15

16

19

20

17

18

7

13

Observe the mains voltage

The voltage of the power source must correspond with the value given on the nameplate of the unit. Extension cords must have a conductor cross section of 3 × 1.5 mm2min.

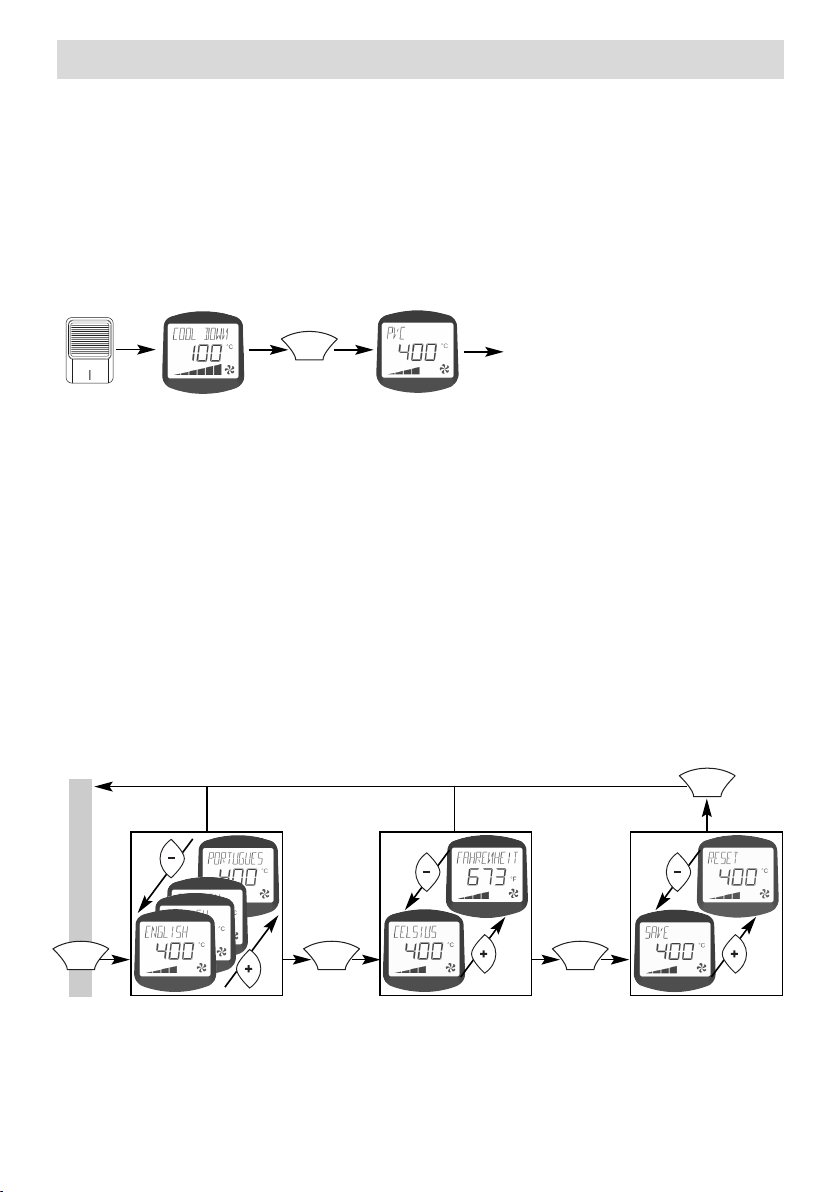

Switching on

Set the

air blower switch

(13) to I. Push 1 x on button SELECT (17).

The heating process starts with the last-saved settings. Select the desired program or

program the temperature and air flow as required.

Language selection, temperature unit °C / °F

2 sec

1 ×

1 ×

1 ×

Putting into Operation FOILER

4

1 ×

Selecting the function

program (see page 5)

or

Language selection

Temperature °C / °F

(see below)

Switching off

To cool down the unit, have it operate on COOL DOWN (see «Settings»).When the

unit has cooled off, set the air blower switch

(13)

to 0.

Adjusting the settings on the terminal (15)

Begin the selection with the button SELECT Menu (17). Note: When an indication

flashes in the display (16), a change can be initiated with either button PLUS (20)

or button MINUS (19). Repeated actuation of button SELECT (17) leads to the next

step.

L

E

S

M

E

C

T

N

E

U

L

E

S

M

E

C

T

N

E

U

E

C

L

E

S

N

E

U

M

E

C

L

T

E

T

S

N

E

U

M

L

E

S

M

E

C

T

N

E

U

Putting into Operation FOILER

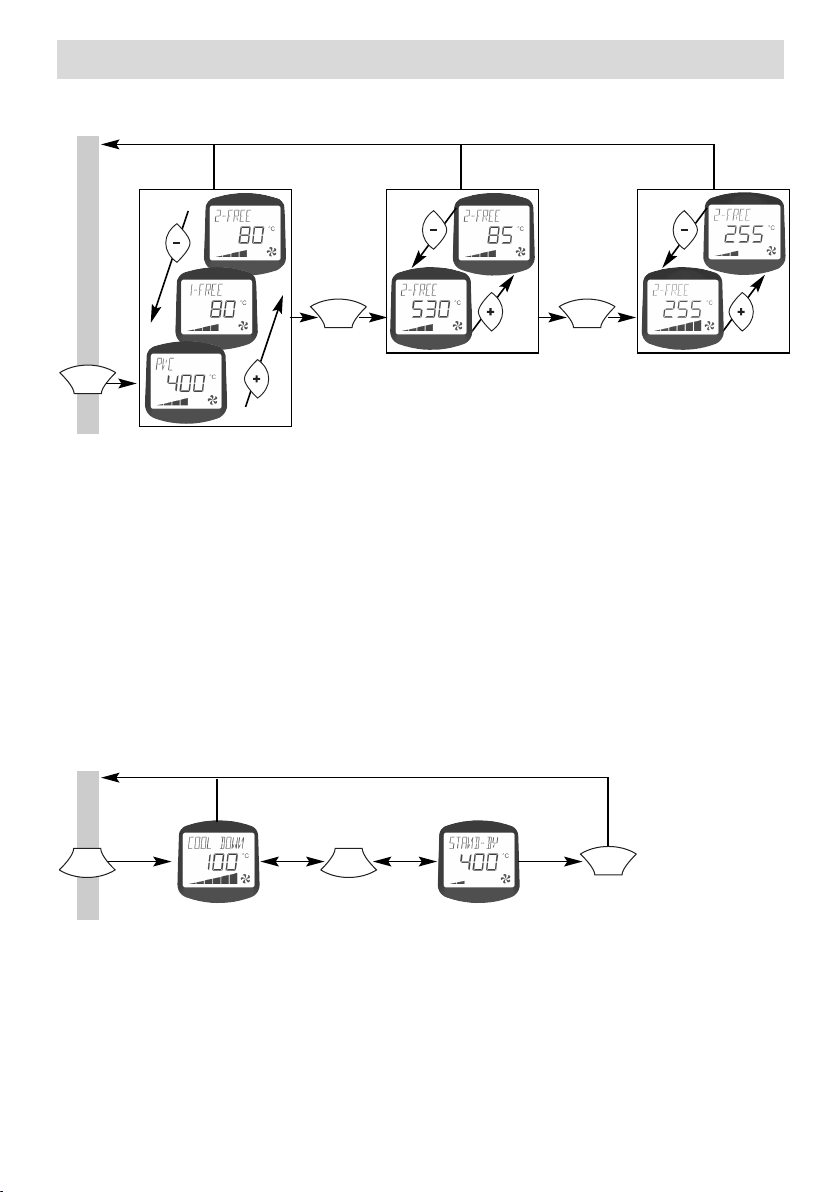

The buttonword of the selected function program is indicated by flashing. Longer

text begins to move after 2 seconds and returns to the buttonword after 2 passes.

Within this period, the button SELECT Menu (17) can be pressed again to adjust the

temperature or the air flow.

– Press 2 × button STANDBY (18) when interrupting your work for short time. The ener-

gy absorption is reduced.

– At the end of your work, always select COOL DOWN with button STANDBY (18).

When the unit has cooled off, switch it off with the air blower switch (13) and pull

the plug from the receptacle.

1 ×

1 ×

1 ×

1 ×

Selecting the function program

1. Welding PVC

2. 1-Free setting

3. 2-Free setting

5

Selecting STANDBY or COOL DOWN

1 ×

1 ×

E

S

M

E

C

L

T

N

E

U

E

S

M

E

C

L

T

N

E

U

E

C

L

E

T

S

N

E

U

M

S

T

Y

A

B

N

D

S

T

A

E

C

L

E

T

S

N

E

U

Y

B

N

D

M

Loading...

Loading...