Page 1

WELDING INDUSTRIES

A

DIVISION

OF

WELDING

ACN

004

OF

AUSTRALIA

INDUSTRIES

547

l1

1

LTD

Head

Telephone

Office

5

Allan

(08)

8276 6494 Facsimile (08) 8276

OWNERS

and International Sales

Street, Melrose Park

South Australia,

MANUAL

TIGARC 150DC

MODEL

NO. MC86-2,

220V/240V VERSION

10195

5039

REV.

6327

C

QUALITY WELDING PRODUCTS, SYSTEMS AND SERVICE

dw

Page 2

Page

2

TJGARC

150DC

MANUAL

The information contained in this manual is set out to enable you to properly

maintain your new equipment and ensure that you obtain maximum operating efficiency.

in

Please ensure that this information is kept

a safe place for ready reference when

required at any future time.

When requesting spare parts, please quote the serial number of the machine and if

possible, the part number of the item required. All relevant numbers are shown in this

manual. Failure to supply this information may result in unnecessary delays in supplying

the correct parts.

SAFETY

Before this equipment is put into operation, the SAFE PRACTICES section at the

back of the manual must be read completely. This will help to avoid possible injury due to

misuse

PLASTIC HANDLE

or

improper welding applications.

Please note that the handle fitted to the TIGARC 140DC is intended for carrying the

machine by hand only.

DO

NOT

manner.

CONTENTS

use this handle for suspending or mounting the machine in any other

SECTION

1

...........................

2..

.........................

3

...........................

4,

..........................

5..

.........................

...........................

6

7..

.........................

8.

..........................

9..

.........................

Receiving

Specifications..

......................................................

..............................................

Connection To Mains

Operation

Maintenance.

Fault Finding

Service Information

Parts Lists

Safe Practices.

......................................................

................................................

.................................................

......................................

......................................................

..............................................

....................................

PAGE

.3

.4

.5

.5

..8

.8

..9

10

.l3

FIGURE PAGE

1

...........................

2.

..........................

3..

.........................

4.

..........................

5

...........................

6

...........................

6.

..........................

GTAW Welding

Connections For GTAW

Connections For MMAW

MMAW Welding

Circuit Diagram

Power

Source Assembly

GTAW Torch And Accessories

.............................................

.................................

...............................

............................................

.............................................

...............................

.....................

.5

6

.7

.8

.9

l1

.l2

Page 3

TiGARC

1

RECEIVING

150DC

MANUAL

Page

3

l

Check the equipment received against

shipment is complete and undamaged.

please

immediately

The

TIGARC

TIGARC

Sample

8

(This) Owners

The genuine

I

Work lead with sprin ‘Work’ clamp

Electrode

Face

shield

The genuine W1A

D

150

Amp

Torch terminal adaptor

Tungsten electrode,

B

Gas

regulator

II

Gas

hose

a

Heavy duty

notify

150DC

150DC

pack

WIA

lead

GTAW torch

assembly, 2 metre

Work

your

supplier.

carton contains:

Weldin

of

AUSTA

Manuaf

AA32

with

AA47-0

and

W

Acccessory Kit contains:

e

7

ectrode holder

Accessory Kit contains:

2%

ffowguage

lead with spring ‘Work’ clamp.

Power

C

thoriated

12P

Supply

and

the

If

13s

shipping invoice

any

damage

electrodes

has

to

make sure the

occurred

in

transit,

Page 4

2.

SPECfFlCATIONS

INPUT

RATED

MAXIMUM

MAXIMUM KVA

SUPPLY

OPEN

RATED

WELDING

ELECTRODE

MAS$

VOLTAGE

iNPUT

FLEXIBLE

CIRCUIT

OUTPUT

GTAW

MMAW..

CURRENT

SHORT

................................................

............................................

CURRENT

RANGE

..........................................................

........................................

...........................

CIRCUIT

REQUIREMENT

CA5L.E RATJNG

VOLTAGE

CURRENT

RANGE

CURRENT

................

...........

..........................

.....................

..................................

220/240

14

.....

38

8.2

15

44

05

52.5

100

50

5

to

2.0

27

Volts

Amps@220V,

Amps@220V.

kva

AC

Amps

Volts

A,

Kg

A,

A,

A,

22

120

to

3.2mm

Max.

l4

VDC,

12

Vac,

24

VDC,

VDC,

Amps

100%

diameter

50/60

12.5

Amps@24BV

34

Amps@240V

25%

Duty

180%

25%

Duty

Duty

Duty

Hz

DIMENSIONS

Duty

Cycle

5

minutes

is

defined

in

any

..............................................

in

Australian Standard

5

minute

period, expressed

H

W

AS1966.1

as

365mm(inci.

240mm, D 370mm

as

a

percentage.

handle),

the ratio

of

arcing

time

to

Page 5

TIGARC

3.

CONNECTION

The WELDARC 140 can be set for a supply voltage of either 220 or 240 volts

AC.

terminate the white wire in the appropriately marked connection point. The

machine is factory set for 240 volts.

150DC

To

adjust the supply voltage tapping, remove the machine cover, and

MANUAL

TO

ELECTRICAL MAINS

POWER

SUPPLY

Page

5

The recommended Supply Fuse rating

requirements, the mains supply to welding machines

if

Circuit Breaker may trip frequently

The machine is supplied with

mains power supply cable. If it becomes necessary to replace the mains power

a

supply cable, use only

4.

OPERATION

GAS

between a non-melting tungsten electrode and

molten weld metal and tungsten electrode are protected from contamination by a

shield of inert gas, usually Argon.

the edges of the workpiece together without metal being added to the weld, or filler

metal may be fed into

TUNGSTEN

GTAW is a very clean welding method in which the welding arc is established

cable with equivalent current rating.

ARC

WELDING

the

arc by hand.

used in this application.

a

3

metre,

The

process

is

15

Amps. Due to peak current

is

best protected by a fuse. A

15

Amp Heavy Duty

the

workpiece. The welding

can

be

used

(30/0.25)

to

fusion weld, ie. melt

PVC

zone,

BUTT

JOINT

LAP

JOINT

FIGURE

1.

GAS

TUNGSTEN

30°

ARC

FILLET

JOINT

WELDtNG.

Page 6

The

TIGARC

connected

to

150DC

the

is

GTAW

a Direct Current machine,

(-)

output terminal. Figure

connection of the welding torch and gas supply.

and

for

GTAW

2

illustrates the correct

the torch is

Tungsten electrodes for

provide

the best arc initiation, arc stability and tip shape retention characteristics.

DC

GTAW

should be

Thoriated electrodes can be recognised by

a

electrode is ground to

welding currents less than

for currents greater than

torch, the tungsten should protrude

Before initial use

for

5

minutes at approximately

be

set

rate should

To

initiate the arc, the tungsten electrode

piece

establish

of

copper adjacent to the workpiece, then lifted in a smooth movement

an

arc length slightly larger than the diameter of the electrode. When the

arc is stable,

Use

of

contamination.

A

rod.

contaminated electrode produces an unstable arc.

in the range

it

can

a

copper

The

point, with the grinding marks pointing

20

amps,

20

amps, the recommended angle

of

the welding torch, allow gas to purge the torch and

2-5

be

transferred

striking plate

electrode can

the

included angle

12mm

70

litres/min. For welding purposes, the gas flow

from the ceramic gas nozzle.

litres/min.

to

the workpiece.

is

recommended

also

be contaminated

1 - 2%

a

red

should

Thoriated. This

coded

of

be

touched preferably onto

n

end. The tungsten

towards

the tip. Fqr

the pojnt should

is

60

.

When set in the

to

avoid electrode

by

contact with

type

be

hoses

the

will

30

a

to

filler

,

GTAW

(

-

1

CONNECTION

WORK

(

$-

)

CONNECTION

GAS

0OTTLE

&

RESULATOR

I

l1

FIGURE

2.

CONNECTIONS

FOR

GTAW.

Page 7

TlGARC

150DC

MANUAL

Page

7’

MMAW

consumable electrode

shielded

may

be

smaller sizes are used when welding at lower currents, such

applications. tncreasing the electrode drameter permits higher welding currents to

be selected.

When

150DC,

rnanufaeturers’ recommendations for that electrode. Both methods of connection

are shown in Figure

Austarc

is a welding process where

and

the workpiece. The arc and the weld pool are both

by

ases

generated from

use

8

with 2.0mm, 2.5mm, and

using

it

is

12P,

a

DC

(Direct Current) welding machine such

important to select the electrode polarity

3

below.

Classification

AS1553,

A

all

arc makes

applications. Preferred polarity electrode positive.

the

E41

popular general purpose electrode used with ease

positions, vertical up

an

coating

3.2mm

i2.

it

an

ideal

are is struck between B flux-coated

of

the electrode. The

diameter welding electrodes. The

in

accordance with the

or

down.

electrode

for

TIGARC

as

sheet-metal

as

the

TIGARC

The

smooth forceful

all general mild

150DC

in

steel

Austarc

Austarc

Unicord

13S,

Classification AS1553,

16K,

312,

Classification

Classification

E41

13.

A

smooth running electrode with

suited to light sheetmetal

Preferred polarity electrode positive.

AS1553,

A

IOW

out-of-position welding characteristics.

ideal for medium carbon steels, or steels

analysis. Operate electrode positive.

AS2576,

A

high

alectrade specially formulated for joining

and

irons, and for toot and

electrode positive.

R

ELECTROUE NEGATIVE

E4816.

hydrogen

1330-A3

tensile

electrode with

(770

and

MPa),

a

soft

smooth mitre fillet welds,

good

high

die

arc stability and

This

chromium nickel

maintenance. Operate

arc, particularly

electrode

of

unknown

all

alloy steels

ELECTRODE

is

POSITIVE

FIGURE

3.CONNECTIONS

FOR

MMAW.

Page 8

Page

8

TIGARC

f50DC

MANUAL

To strike the arc, drag the end of the electrode

striking a match.

establish an arc length of approximately

feed the electrode into

general rule, the arc should be held

burn off and

flow

of metal with a roug

short leads to

is

electrode

As

along the weld path, aiming to maintain a

Decreasing this rate

increasing

at

the end of a weld deposit, by

electrode to break the arc. Unfilled craters are a point of weakness, and can lead

to weld cracking.

liable to freeze onto the workpiece.

the solidified weld deposit forms, move the

it

will narrow the weld deposit.

good

a

As

the arc initiates,

the

arc in arder to maintain a constant arc length.

weld a pearance. An arc which

R

weld appearance and reduced penetration.

narrow

weld

of

travel will result in a wider

deposit and "stuttery" arc characteristic, and the

lift

3mm.

as

short

pool

Always

pausing

the electrode slightly

As

as

of molten wetd metal behind the arc,

momentarily before withdrawing

possible while

fill the crater which tends to form

along

the electrode

is

too long causes an.unwieldly

end

weld

the workpiece as

away,

end

still

of the electrode slowly

deposit, and similarly

aiming to

is consumed,

giving stable

An

arc too

As

the

if

a

Striking the arc Maintain steady arc kngth

FIGURE

5.

MAINTENANCE

Care

should

welding

prevailing conditions, the machine covers

be

6.

that the fan is running. Check for continuity of the welding current circuit,

lead, work

power source.

removed

FAULT

Check that Mains Supply

clamp

be

by

the use of

FINDING,

and electrode holder.

4.

MANUAL

taken to prevent excessive build-up

It

is

recommended that at regular intervals, according to the

dry,

low

NO

WELDING

is

METAL

pressure compressed air, or

ARC WELDING.

be

removed and any accumulated dust

CURRENT

available at the

T1GARC

of

dust

150DC

a

d

and

dirt within the

vacuum

Power

Source,

cleaner.

i.e.

i.e.,

work

The

TIGARC

device which will

deliver

overload

establish and correct

located on

and

Welding

device cannot

the

If

equipment failure

Service Branch, or quaiified service agent.

15ODC

trip

current until the overload device has been

rear panel, just above the

welding power source incorporates

if

the

unit is overloaded. In this event the machine will not

be

reset immediately after

the

cause

is

suspected, forward the unit to your nearest

of

the overload condition. The reset button is

Supply

an

inbuilt protection

MANUMY

it

has tripped. Before resetting,

Flexible Cable entry.

reset.

WIA

The

Sales

Page 9

TIGARC

7.

SERVICE

150DC

MANUAL

INFORMATION.

Page

9

The electrical components

diagram below. The output of the welding transformer

with the

based phase shift circuit. Adjustment

open

ACTIVE

-

NEUTRAL

-

GTAW

Primary voltage to the Welding Transformer is controlled by means

circuit output

-

-

output current

voltage

of

the

TIGARC

smoothed

of

the Welding Transformer.

by

a

of

the front panel potentiometer will vary

150DC

DC

inductance coil.

are shown

is

full-wave bridge rectified,

.

!I

l- l

in

the

of a Triac

circuit

the

PRlMARY

AUXILLIARY

TRANSFORMER

CPlO2-0116

AUXILLIARY

RECTIFIER

I

CURRENT LIMITING RESISTORS

I

L-J

PRIMARY

I

SECONDARY

~~82-15110

FIGURE

5.

'il"""""

I

TfGARC

L

OVERLOAD DEVICE

MC84-013

,

150DC

CIRCUIT

BTA40-6008

INDUCTANCE

MC86-20

MAIN

RECTIFIER

CPlO4-012

DIAGRAM

MC86-11

-VE

GTAW

+VE

-

Page 10

page

current limiting resistors. The current from these components maintains the GTAW

are during periods when the triac

assembly provides

incorporates specialized components,

Replacement assemblies obtained from WIA are supplied complete with Triac

Potentiometer.

retaining pop-rivets. Clean the mounting surface to remove swarf and any

remaining heat-sink compound. Always apply clean heat-sink compound to the

new triac prior to assembly.

10

The

TIGARC

Replacing the Triac requires removal of the original part by first drilling out the

To correctly adjust the phase-shift range of a replacement circuit board:

m

Rotate the Current Control potentiometer knob to

position, (fully anti-clockwise).

II

Disconnect the red wire from

(CP38-31/5).

U

Connect a

"-ve MMAW".

P

With the PIGARC energised, but not welding, adjust the potentiometer

on the printed circuit board to obtain a voltmeter reading of

U

Reconnect the red wire to the positive terminal of the auxilliary rectifier.

150DC

the

DC

also includes an auxilliary transformer, rectifier, and

is

not conducting.

appropriate trigger pulses to

it

is not intended to be repaired in the field.

the

positive terminal

Voltmeter to the welding output terminals

TIGARC

The

the

of

J50DC

printed circuit board

Triac. AS

the

minimum current

the auxilliary rectifier

"+VB

12

MANUAL

this

circuit

WORK"

volts.

and

and

RV2

8.

PARTS

TlGARC

ITEM

1

..................

Includes

2..................MC86-23...................Transformer

3

..................

4

..................

5..................SA140-0/1

6

..................

Includes

7

..................

8..................CP27-0/15

9..................CP101-0/17

10

11

12

13

15

17

I8

19

20

21

22

23

24

25

26

31

LISTS

150DC

.................

.................

.................

.................

.................

.................

.................

.................

.................

.................

.................

.................

.................

.................

.................

.................

POWER

-#........PART#

MC864

CP101-11/8

CPlO1-11/2

MC86-13

MC84-14

MC84-16

MCI1-41/1

MC66-Q/8

W1

MK6/4

H390W

H285

CP102-0/18

WIN199

HF200-1

MC84-0

MC84-0/2

MC&4-0/4

MC86-20

CP104-0/2

CP102-0/16

eP38-31/5

MC82-15/10

MC84-24

SOURCE

......................

1

...................

..............

..............

...................

...................

................

...................

...............

.................

................

..............

1-0/16

..................

......................

......................

.........................

..............

labe^ labe^ be^

75

..............

/

3

.................

.................

.................

...................

................

..............

................

.............

...................

DESeRIFSPION

Printed Circuit Assembly

Potentiometer

Triac

Assembly (220J240V)

Base

Cover

Handle

Terminal Assembly

Terminal Knob

Primary Flex and

Fan

and Motor

Fan Finger Guard

Potentiometer Knob

Terminal Block

Cup Terminal and Washer

Earth Tab

Circuit Board Support

Set

Foot

Overload Device

Cable Gland

Cable Gland Nut

Inductance Assembly

Rectifier Assembly

Auxilliary Transformer

Diode

Resistor

Heatsink to

Bridge

suit

220/240V

Plug

Page 11

TIGARC

150DC

MANUAL

\n

Page

ITEM

INSIDE

J?

1

i

25

FITTED

BACK

COVER

1

r

IU

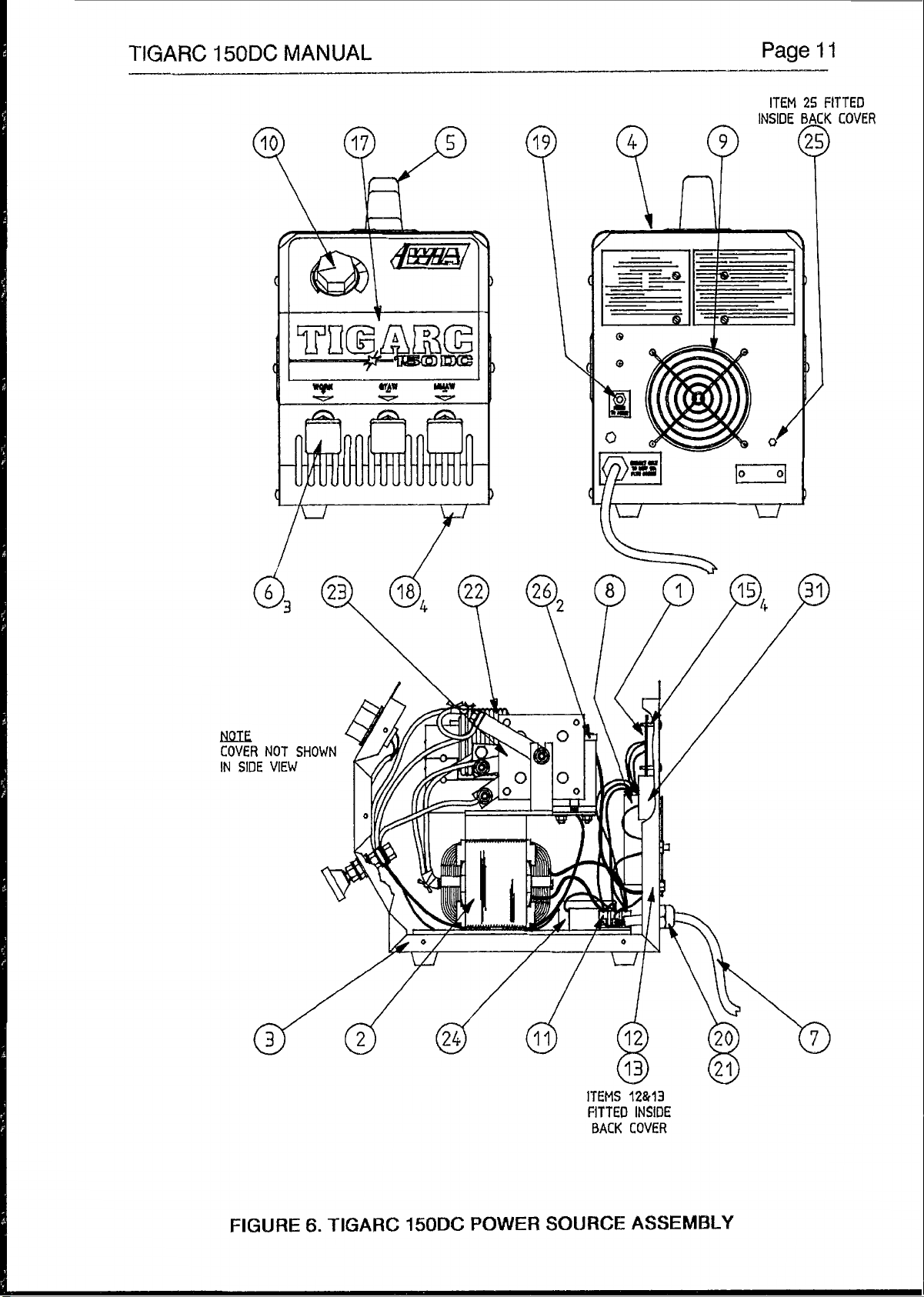

FIGURE

6.

TIGARC

150DC

POWER

ITEMS

FITTED

BACK

SOURCE

12&13

INSIDE

COVER

ASSEMBLY

Page 12

page

12

TIGARC

158DC

MANUAL

GTAW

ITEM

Includes

TORCH AND

#.............PART

1

.................

1

.

1

.............

1.2

..............

l

,3.

.............

1.4

..............

1.5

..............

-I

..............

2.....

............

3.................CKi5PCA..................Porch

4..........,......AA47-0/1

5..

...............

ACCESSORIES

#.....................DESCRIPTION

CK1512VR

.300M..

3OOH-13

3C332

3CB332

3A7

IBQVK

"fWNGTH2.4

.......................

.......................

.......................

.....................

...........................

.......................

..................

HA101-185

................

GTAW

Medium

Heatshield

Collet

Collet

Alumina

Gas

..............

................

2.4mrn

Gas

Gas

Torch,

bac

kcap

body

Nozzle

Valve

diam.

Terminal

Hose

Regulator

Assembly

Rigid

2%

Thoriated

Adaptor

and

Tungsten

ftowgauge

FIGURE

7.

GTAW

TORCH

AND

ACCESSORIES

Page 13

TIGARC

9.

SAFE

150DC

MANUAL

PRACTICES

WHEN USING WELDING

EQUIPMENT

Page

l3

These notes are provided in the interests

to

only as a basic guide

the Standards Association of Australia, also various State Electricity Authorities, Departments of Labour and

Industry or Mines Department and other Local Health or Safety Inspection Authorities may have additional

requirements. WTlA Technical Note TN7-98

welding.

EYE

PROTECTION

NEVER

with side shields underneath, with appropriate filter lenses protected by clear cover lens. This is a MUST for

welding, cutting, and chipping

lens when broken, pitted, or spattered.

LOOK

Amps

0-100

700-150

150-200

200-300

300-400

400-500

500

+

Safe Working Habits. A full list of Standards pertaining

AT AN ARC WITHOUT PROTECTION. Wear a helmet with safety goggles or glasses

to

protect the eyes from radiant energy and flying metal. Replace the cover

Recommended

TIG MMAW MIG Pulsed MIG

.............

...................................................

10

..................

.........

l1

..................

.........

12

..................

.........

13..

................

.........

14

..................

............................

"

"

shade

9

10

10-11

1 1

12

13

"

of

improving operator safety. They should be considered

also

provides a comprehensive guide

filter

lens.

...................

.................

............

.................

.................

.................

10

10

11-12

12-1 3

13

14

14

.................

.................

............

............

.................

.................

.................

12-13

12-13

12-13

12-1

14

14

14

3

to

industry is available from

to

safe practices in

BURN PROTECTION.

The welding arc is intense and visibly bright.

clothing, reflect from light-coloured surfaces, and burn the skin and eyes. Burns resulting from gas-shielded

arcs resemble acute sunburn, but can be more severe and painful.

Wear protective clothing

collar and pocket flaps, and wear cuffless trousers

Avoid oily or greasy clothing.

pieces should never be handled without gloves.

Ear plugs should be worn when welding in overhead positions or in a confined space. A hard hat

should be worn when others are working overhead.

Flammable hair preparations should not be used by persons intending to weld or cut.

TOXIC

vapours, heat, or oxygen depletion that welding or cutting may produce. NEVER ventilate with oxygen.

produce harmful concentrations of toxic fumes. Adequate local exhaust ventilation must be used, or each

person in the area as well as the operator must wear an air-supplied respirator. For beryllium, both must be

used.

removed from the work surface, the area is well ventilated, or the operator wears an air-supplied respirator.

respirator.

FUMES.

Adequate ventilation with air is essential. Severe discomfort, illness or death can result from fumes,

Lead, cadmium, zinc, mercury, and beryllium bearing and similar materials when welded or cut may

Metals coated with or containing materials that emit fumes should not be heated unless coating is

Work in a confined space only while it is being ventilated and, if necessary, while wearing air-supplied

-

leather or heat resistant gloves, hat, and safety-toe boots. Button shirt

A

spark may ignite them.

Its

radiation can damage eyes, penetrate lightweight

to

avoid entry of sparks and slag.

Hot

metal such as electrode stubs and work

Page 14

page

supplied respirator.

14

Work

in

a confined space

only

while

it

is being ventilated and,

TtGARC

if

necessary, while Wearing air-

15QDC

MANUAL

Vapours from chlorinated solvents can be decomposed by the heat of the arc (or flame)

PHOSGENE,

energy of the arc can also decompose trichlorethylene and perchlorethylene vapors to form

phosgene.

atmosphere or where the radiant energy can penetrate

amounts

FIRE

windows or doors, and through watl or floor openings, out of sight of the operator. Sparks and slag

can travel up to

particles that can cause short circuits.

to

work can not be moved, move combustibles at least

or protect against ignition with suitable and snug-fitting fire-resistant covers or shields.

and floor near work should be protected

durlng and for some time after welding or cutting

AND

Be

Keep equipment clean and operable, free

If

combustibles are present in the work area, do

an area free of combustibles. Avoid paint spray rooms, dip tanks, storage areas, ventilators.

Walls

A

person acting

a highly toxic gas, and

Do

not weld or cut where solvent vapors can be drawn into

of

trichlorethylene or percholorethylene.

lung

and eye irritating products. The ultra-violet (radiant)

the

welding

to

atmospheres containing even minute

EXPLOSION PREVENTION.

aware that flying sparks or falling slag can pass through cracks,

10

metres from the arc.

of

oil, grease, and (in electrical parts) of metallic

NOT

weld or cut. Move the work

10

metres away out

touching combustibles on opposite sides should not be welded on or cut. Walls, ceilings,

by

heat-resistant covers or shields.

as

Fire Watcher must be standing by with suitable fire extinguishing equipment

if;

along

of

reach of sparks and heat;

pipes, through

to

form

or

cutting

if

practicable,

If

the

U

Combustibles (including building construction) are within

U

Combustibles are further than

U

Openings (concealed or visible)

combustibles to sparks.

a

Combustibles adjacent

radiant or conducted heat.

is

After work

An

tank or drum which has contained combustibles can produce flammable vapors when

heated. Such a container must never be welded on or cut, unless

described

steam

followed by purging and inerting wlth nitrogen or carbon dioxide, and using protective equipment as

recommended In

Never weld

SHOCK

equipment can fatally shock a person whose body becomes a conductor. Ensure that the machine

correctly connected and earthed.

mobile or portable equlpment, regularly inspect condition of traillng power teads and connecting

plugs. Repair or replace damaged leads.

in

or

caustic cleaning (or a solvent or water washing, dependlng on the combustible’s solubility),

Hollow castings or containers must be vented before weldlng or cutting. They can explode.

PREVENTION.

Exposed conductors or other bare metal

done, check that area

AS.1674-1974,

AS.1674-1974.

or

cut where the air may contain flammable dust, gas, or liquid vapours.

the

S.A.A.

Water-filling just below worktng level may substitute for inerting.

10

metres but can be ignited

in

floors or walls within

to

walls, ceilings, roofs,

is

free

of

sparks, glowing embers, and flames.

Cutting and Welding Safety Code. This includes a thorough

in

the welding circuit, or ungrounded electrlcally alive

If

unsure have machine installed by a qualified electricfan. On

or

10

metres.

by

sparks.

10

metres may expose

metal partitions can be ignited by

it

has first been cleaned as

is

Fully insulated electrode holders should be used.

Fully insulated lock-type connectors should be used to join welding cable lengths.

Terminals and other exposed parts of electrical unlts should have insulated knobs or covers

secured before operation.

Do

not use holders with protruding screws.

Loading...

Loading...