WF-255MST

OPERATING INSTRUCTIONS

IMPORTANT!

To qualify for full 36 month warranty, you must register within 30 days of purchase. See inside for details.

Read these Operating Instructions Completely before attempting to use this machine. Save this manual and

keep it handy for quick reference. Pay particular attention to the safety instructions we have provided for

your protection. Contact your distributor if you do not fully understand anything in this manual.

Edition 2.2

© Weldclass 2019 | E.&O.E. | Edition 2.2 1

.

Congratulations & thank you for choosing WeldForce!

The WeldForce range from Weldclass provides market leading value, features and durability. WeldForce

machines have been designed with emphasis on robust construction, with simple and functional operation.

Register Your Warranty Now

Standard warranty without registration is 24 months.

To qualify for an extended full 36 month warranty on your purchase you must register within 30 days of

purchase.

Please register your warranty now by going to:

www.weldclass.com.au/weldforcewarranty

You will need;

a) A copy of your purchase invoice / receipt.

b) Your machine serial number which can be found on the technical data plate on the back of the

machine, or on the outside of the box that your machine came in.

2 © Weldclass 2019 | E.&O.E. | Edition 2.2

WF-255MST

1 CONTENTS ...............................................................................................................................................3

2 BASIC SPECIFICATIONS ............................................................................................................................8

3 KNOW YOUR MACHINE .........................................................................................................................10

3.1 Machine Front ..............................................................................................................................10

3.2 Machine Side ................................................................................................................................10

3.3 Machine Rear ...............................................................................................................................11

3.4 Control Panel ................................................................................................................................11

3.5 LCD Readout .................................................................................................................................12

3.6 Symbols chart ...............................................................................................................................13

4 CONTROLS EXPLAINED ..........................................................................................................................14

4.1 Weld Process Selection ................................................................................................................14

4.1.1 MIG Process: ............................................................................................................................14

4.1.2 Stick & TIG Process: ..................................................................................................................14

4.2 MIG Program Selection ................................................................................................................15

4.3 Function Selection ........................................................................................................................16

4.3.1 Pre-Gas Time (MIG) ..................................................................................................................17

4.3.2 Post-Gas Time (MIG) ................................................................................................................17

4.3.3 Soft-Start Adjustment (MIG) ....................................................................................................17

4.3.4 Burnback Adjustment (MIG) ....................................................................................................17

4.3.5 Spot/Stitch Weld Time (MIG) ...................................................................................................17

4.3.6 Stitch Weld Gap/Interval Time (MIG) .......................................................................................17

4.3.7 Spool Gun On/Off (MIG) ..........................................................................................................18

4.3.8 Post-Gas Time (TIG) ..................................................................................................................18

4.3.9 Slope Down Time (TIG).............................................................................................................18

4.3.10 Hot Start Adjustment (Stick) ................................................................................................18

4.3.11 Arc Force Adjustment (Stick) ................................................................................................18

4.3.12 Optional VRD Function (Stick) ..............................................................................................18

4.4 Trigger Mode Selection ................................................................................................................19

4.4.1 2T (Standard Trigger) ................................................................................................................19

4.4.2 4T (Latch Trigger) ......................................................................................................................19

4.4.3 SP (Spot/Stitch) ........................................................................................................................19

4.5 Inductance Control .......................................................................................................................20

4.6 Test Gas ........................................................................................................................................20

4.7 Feed Wire / Wire Inch ..................................................................................................................21

4.8 Job Memory .................................................................................................................................21

4.8.1 Save or Update a Job ................................................................................................................21

4.8.2 Recall a Job ...............................................................................................................................22

© Weldclass 2019 | E.&O.E. | Edition 2.2 3

.

4.9 Error/Over Temperature Indicator Light.......................................................................................22

5 POWER SUPPLY .....................................................................................................................................23

5.1 Electrical Connection ....................................................................................................................23

5.1.1 Setting machine to 15A Input Mode ........................................................................................23

5.1.2 Setting machine back to Full Output Mode .............................................................................23

5.2 Extension Leads ............................................................................................................................23

5.3 Generator Use ..............................................................................................................................24

5.3.1 Generator Size ..........................................................................................................................24

5.3.2 Generator Quality & Warranty Limitations ..............................................................................24

5.3.3 3 Golden Rules of Generator use .............................................................................................24

6 OPERATING ENVIRONMENT ..................................................................................................................25

6.1 Location ........................................................................................................................................25

6.2 Ventilation ....................................................................................................................................25

7 BASIC OPERATION .................................................................................................................................26

7.1 MIG Welding.................................................................................................................................26

7.1.1 Fitting Wire Spool – 270/300mm Diameter (15kg) ..................................................................26

7.1.1 Fitting Wire Spool – 200mm Diameter (5kg)............................................................................27

7.1.2 Loading Wire Feeder ................................................................................................................28

7.1.3 Gasless Welding Setup .............................................................................................................29

7.1.4 Gas MIG Welding Setup ...........................................................................................................30

7.1.5 Additional Setup for MIG welding with aluminium .................................................................31

7.1.6 Spool Gun Setup .......................................................................................................................31

7.1.7 Adjusting Settings for MIG Welding in Manual Mode (Program 0) ..........................................32

7.1.8 Adjusting Settings for MIG Welding in Synergic (Auto) Mode .................................................32

7.2 Stick (MMA) Welding Operation ..................................................................................................33

7.3 Lift TIG Operation .........................................................................................................................34

8 ACCESSORIES, SPARE PARTS & CIRCUIT DIAGRAMS ..............................................................................35

8.1 MIG Torch and Spares: .................................................................................................................35

8.2 TIG Torch and Spares (Optional Extra): ........................................................................................36

8.3 Optional Accessories ....................................................................................................................37

8.4 Drive Rollers: ................................................................................................................................37

8.5 Machine Spare Parts: ...................................................................................................................38

8.6 Primary Schematic Circuit Diagram ..............................................................................................40

9 CARE & MAINTENANCE .........................................................................................................................41

9.1 Keep your Welding Machine in Top Condition .............................................................................41

9.2 Storing the Welder .......................................................................................................................41

10 GENERAL GUIDE TO WELDING .........................................................................................................42

10.1 Duty Cycle Rating .........................................................................................................................42

10.2 Choosing a Welding Process – MIG, Stick or TIG? ........................................................................42

4 © Weldclass 2019 | E.&O.E. | Edition 2.2

WF-255MST

10.2.1 The Stick (MMA) Process .....................................................................................................42

10.2.2 The TIG Process ....................................................................................................................43

10.2.3 The MIG Process ..................................................................................................................43

10.3 Joint Preparations.........................................................................................................................44

11 MIG BASIC WELDING GUIDE .............................................................................................................46

11.1 MIG Basic Welding Techniques.....................................................................................................46

11.2 Gas Metal Arc Welding (GMAW) ..................................................................................................46

11.3 Flux Cored Arc Welding (FCAW) ...................................................................................................46

11.4 Position of MIG Torch ...................................................................................................................47

11.5 Distance from the MIG Torch Nozzle to the Work Piece ..............................................................47

11.6 Travel Speed .................................................................................................................................47

11.7 MIG Welding (GMAW) Variables ..................................................................................................48

11.7.1 Preselected Variables ...........................................................................................................48

11.7.2 Primary Adjustable Variables ...............................................................................................48

11.7.3 Secondary Adjustable Variables ...........................................................................................48

11.8 Establishing the Arc and Making Weld Beads ..............................................................................50

11.9 MIG Voltage & Wire Speed Settings .............................................................................................50

11.9.1 Setting Wire Speed/Amperage.............................................................................................50

11.9.2 Setting Voltage .....................................................................................................................50

11.9.3 Changing to a different welding wire ...................................................................................50

11.9.4 How to determine correct Wire Speed/Voltage Setting ......................................................51

11.10 Suggested Settings for Typical MIG Applications .....................................................................51

11.11 Welding wire Size Selection .....................................................................................................51

11.12 MIG Welding Troubleshooting .................................................................................................52

11.12.1 Porosity Problems ................................................................................................................52

11.12.2 Wire Feed Problems .............................................................................................................53

11.12.3 Weld Quality Problems ........................................................................................................54

12 STICK (MMA) BASIC WELDING GUIDE ..............................................................................................56

12.1 Size of Electrodes .........................................................................................................................56

12.2 Storage of Electrodes ...................................................................................................................56

12.3 Electrode Polarity .........................................................................................................................56

12.4 Effects of Stick (MMA) Welding on Various Materials ..................................................................56

12.4.1 High Tensile and Alloy Steels ................................................................................................56

12.4.2 Manganese Steels ................................................................................................................56

12.4.3 Cast Iron ...............................................................................................................................56

12.5 Types of Electrodes ......................................................................................................................57

12.5.1 MILD STEEL: .........................................................................................................................57

12.5.2 CAST IRON: ...........................................................................................................................57

12.5.3 STAINLESS STEEL: .................................................................................................................57

© Weldclass 2019 | E.&O.E. | Edition 2.2 5

.

12.6 Suggested Settings for Typical Stick (MMA) Applications ............................................................57

12.7 MMA Welding Techniques ...........................................................................................................58

12.7.1 A Word for Beginners ...........................................................................................................58

12.7.2 The Welder ...........................................................................................................................58

12.7.3 Striking the Arc .....................................................................................................................58

12.7.4 Arc Length ............................................................................................................................59

12.7.5 Rate of Travel .......................................................................................................................59

12.8 Making Welded Joints ..................................................................................................................60

12.8.1 Butt Welds............................................................................................................................60

12.8.2 Fillet Welds ...........................................................................................................................61

12.8.3 Vertical Welds ......................................................................................................................62

12.8.4 Overhead Welds ...................................................................................................................63

12.9 MMA (Stick) Troubleshooting.......................................................................................................64

13 TIG BASIC WELDING GUIDE ..............................................................................................................66

13.1 TIG Electrode Selection and Preparation .....................................................................................66

13.1.1 Electrode Polarity .................................................................................................................66

13.1.2 Preparing Tungsten for DC Electrode Negative (DCEN) Welding .........................................67

13.1.3 Shielding Gas for TIG Welding ..............................................................................................68

13.1.4 Typical TIG Welding Settings ................................................................................................68

13.2 TIG Welding Troubleshooting .......................................................................................................69

14 KNOWLEDGE & RESOURCES .............................................................................................................70

15 SAFETY ..............................................................................................................................................70

15.1 Store and Retain this Manual .......................................................................................................70

15.2 Important Safety Information ......................................................................................................70

15.3 Welding Operation .......................................................................................................................70

15.4 Welding Safety Instructions & Warnings ......................................................................................72

15.4.1 Personal Safety .....................................................................................................................73

15.4.2 Arc Rays can Burn Eyes and Skin ..........................................................................................73

15.4.3 Noise Can Damage Hearing .................................................................................................73

15.4.4 Work Environment Safety ....................................................................................................74

15.4.5 Electricity Can Kill .................................................................................................................74

15.4.6 Fumes And Gases .................................................................................................................75

15.4.7 Fire & Explosive Risks ...........................................................................................................76

15.4.8 Sparks & Hot Metal ..............................................................................................................76

15.4.9 Gas Cylinders ........................................................................................................................77

16 WARRANTY .......................................................................................................................................78

16.1 Warranty period ...........................................................................................................................78

16.2 Warranty Includes and Covers......................................................................................................78

16.3 Warranty Excludes / Does Not Cover ...........................................................................................78

6 © Weldclass 2019 | E.&O.E. | Edition 2.2

WF-255MST

16.4 Warranty Conditions ....................................................................................................................79

© Weldclass 2019 | E.&O.E. | Edition 2.2 7

.

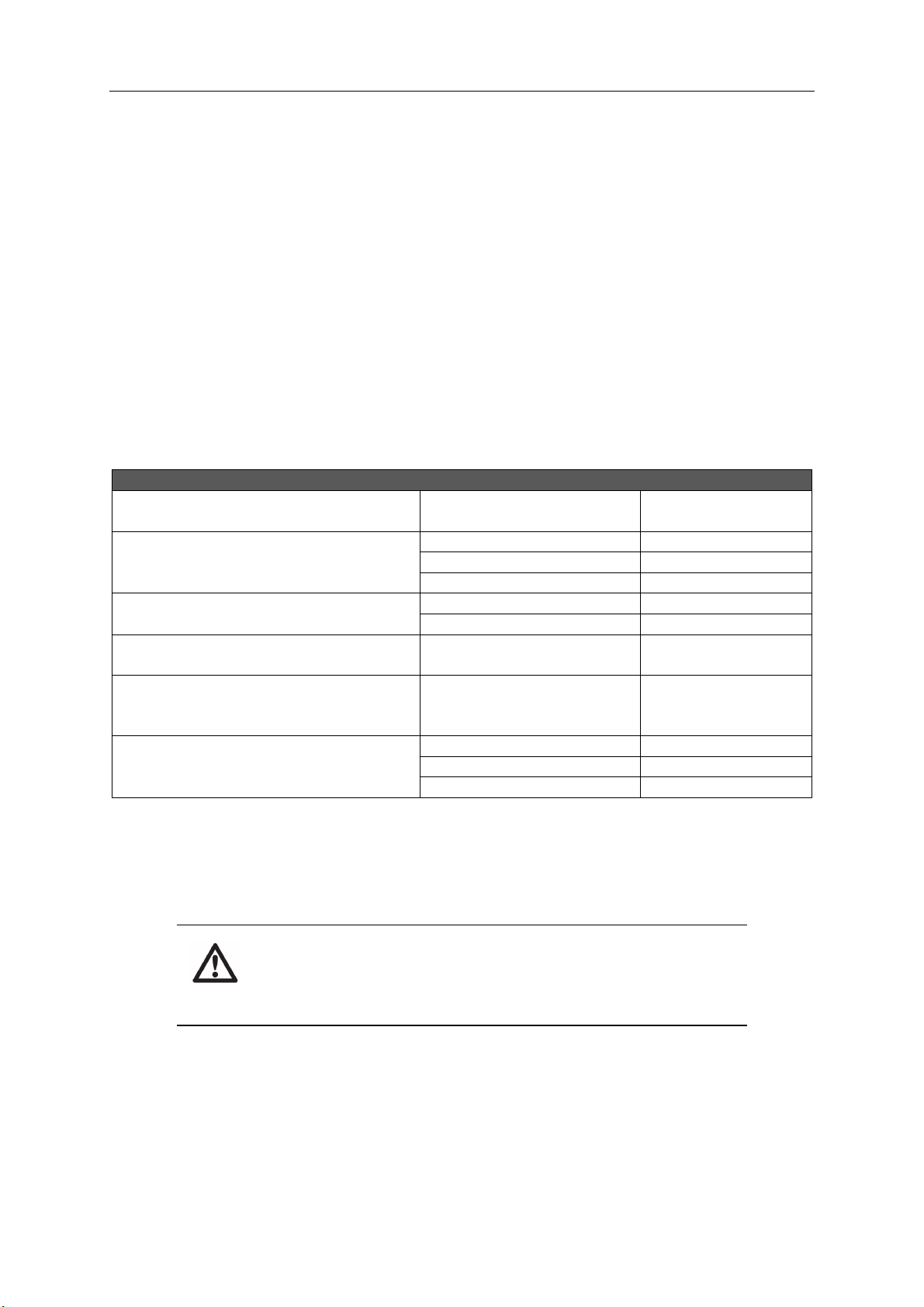

Description

WeldForce WF-255MST

Part Number

WF-06167

Dimensions of Power Source (L x W x H)

680 x 250 x 480mm (including handle)

Weight of Power Source

26.5kg

Standard

AS 60974.1

Power Supply

240V +/- 15% 50hz Single Phase

(See further information under section 5 of this manual)

Factory Fitted Supply Plug Rating

15A

Output Terminals

Dinse™ style 35-50

Protection Class

IP23

MIG Welding

MIG Wire Spool Size

200mm (5kg) & 300mm (15kg)

MIG Wire Sizes

0.6, 0.8, 0.9, 1.0, 1.2mm

Stick (MMA) Welding

MMA Electrode Size

1.6 – 4.0mm

TIG Welding

TIG Tungsten Size

1.6 – 2.4mm

Table 1

8 © Weldclass 2019 | E.&O.E. | Edition 2.2

WF-255MST

This table applies when utilizing the factory fitted 15A plug – Refer to 5.1

Effective Input Current (I

1eff

)

15A

Maximum Input Current (I

1max

)

30A

MIG Welding

Welding Current Output

40 – 200A

Welding Voltage Output

16 – 24V

Wire Feed Speed (m/min)

1.5 – 16.5

Duty Cycle

200A / 24.0V @ 25%

145A / 21.3V @ 60%

110A / 19.5V @ 100%

Nominal Open Circuit Voltage

65V

Stick (MMA) Welding

Welding Current Output

10 – 200A

Duty Cycle

200A / 28.0V @ 25%

130A / 25.2V @ 60%

100A / 24.0V @ 100%

Nominal Open Circuit Voltage

VRD on 65V / VRD off 13.5V

TIG Welding

Welding Current Output

10 – 200A

Duty Cycle

200A / 18.0V @ 35%

155A / 16.2V @ 60%

120A / 14.8V @ 100%

Nominal Open Circuit Voltage

65V

This table applies when upgraded plug fitted rated at 25A – Refer to 5.1

Effective Input Current (I

1eff

)

21A

Maximum Input Current (I

1max

)

38A

MIG Welding

Welding Current Output

40 – 250A

Welding Voltage Output

16 – 26.5V

Wire Feed Speed (m/min)

1.5 – 18

Duty Cycle

250A / 26.5V @ 35%

195A / 23.8V @ 60%

150A / 21.5V @ 100%

Nominal Open Circuit Voltage

VRD on 68V / VRD off 13.5V

Stick (MMA) Welding

Welding Current Output

10 – 250A

Duty Cycle

250A / 30.0V @ 30%

180A / 27.2V @ 60%

140A / 25.6V @ 100%

Nominal Open Circuit Voltage

68V

TIG Welding

Welding Current Output

10 – 250A

Duty Cycle

250A / 20.0V @ 35%

195A / 17.8V @ 60%

150A / 16.0V @ 100%

Nominal Open Circuit Voltage

68V

Table 2

Table 3

For full machine specifications, refer to technical data plate on back of machine – or go to:

www.Weldclass.com.au/WF-255MST

© Weldclass 2019 | E.&O.E. | Edition 2.2 9

Figure 1

Figure 2

4

3

5 6 7

2

1

8

11

20

14

12

13

16

10

9

15

19

21

22

18

20

3.1 Machine Front

1. Carry Handle

2. Control panel

3. Positive (+) Welding Power Output Connection Socket

4. MIG Torch Euro Connector

5. Spool Gun/TIG torch Interface Connector

6. TIG Torch Gas Connector

7. Negative (-) Welding Power Output Connection Socket

8. MIG Torch Polarity Change Tail

.

3.2 Machine Side

9. Spool Post

10. Spool Nut

11. Spool Lock Pin

12. Wire Inlet Guide

13. Left Wire Feed Tension Adjustment Lever

14. Left Wire Feed Tension Arm/Top Roller

15. Left Drive Roller

16. Left Drive Roller Retainer Knob

17. Centre Wire Guide Tube

18. Right Drive Roller Retainer Knob

19. Right Drive Roller

20. Outlet Wire Guide Tube

21. Right Wire Feed Tension Arm/Top Roller

22. Right Wire Feed Tension Adjustment Lever

10 © Weldclass 2019 | E.&O.E. | Edition 2.2

23

25

24

Figure 3

3.3 Machine Rear

23. Mains Power Switch

24. 240V AC Mains Power Input Lead

25. Gas Inlet Connection

3.4 Control Panel

26. MIG Program Selection Button (P)

27. Function Selection Button (Fn)

28. Process Indicator Lights

29. Process Selection Button (Process)

30. Gas Test Button (Test Gas)

31. Left Selection Knob (Voltage Dial)

32. Right Selection Knob (Wire Speed/Amperage Dial)

33. Wire Feed/Load Button (Feed Wire)

34. Trigger Mode Selection Button (Trigger)

35. Trigger Mode Indicator Lights

36. Job Recall Button

37. Job Save Button

38. Right LCD Readout

39. Left LCD Readout

WF-255MST

26

27

28

29

30

31

Figure 4

39

38

37

36

35

34

33

32

© Weldclass 2019 | E.&O.E. | Edition 2.2 11

3.5 LCD Readout

Figure 5

40. Power On Indicator Light

41. Error/Over Temperature Indicator Light

42. Spool Gun Mode Indicator Light

43. MIG Program Selection Indicator Light

44. Voltage Setting Indicator Light

45. Inductance Setting Indicator Light

46. Seconds Setting Indicator Light

47. Wire Speed Setting Indicator Light

48. Material Thickness Setting Indicator Light

49. Amperage Setting Indicator Light

50. Job Save/Recall Selection Indicator Light

51. VRD Indicator Light

40 41

43

44

51

45

46

42

47

48 49

.

50

12 © Weldclass 2019 | E.&O.E. | Edition 2.2

I

Power On

O

Power Off

Power On

Indication

Fault Indication

Caution / Hazard

Read Instruction

Manual

MIG Function

TIG Function

Stick/MMA

Function

Material Thickness

Wire Feed

Amperage (current)

output

Voltage output

Variable

Inductance

Increase/Decrease

Save Settings

Recall Settings

Single phase

Inverter power

source DC

MIG (GMAW)

Function

Stick/MMA

(SMAW) Function

TIG (GTAW)

Function

Power Supply

Connection

Single Phase

Direct Current (DC)

–

Negative

+

Positive

Hertz (cycles/sec)

Duty Cycle

Amperage

(Current)

Voltage

3.6 Symbols chart

WF-255MST

Table 4

© Weldclass 2019 | E.&O.E. | Edition 2.2 13

Figure 6

4.1 Weld Process Selection

1. Press ‘Process’ button (29) until the desired Welding Process Indicator Light (28) is lit.

4.1.1 MIG Process:

In Manual MIG mode (Program 0) – before welding the Left Selection Knob (31) adjusts target voltage

output and the Right Selection Knob (32) adjusts Target Wire Speed (m/min). During welding, Left LCD

Readout (39) will display actual weld voltage and Right LCD Readout (38) will display actual amperage

output.

In Synergic (Auto) MIG mode (Programs 1-20) – before welding the Left Selection Knob adjusts voltage

(31) (which will change the performance from the automatic program) and the Right Selection Knob (32)

adjusts target amperage output. Right Selection Knob can be pressed to toggle to adjust Material

Thickness instead of Amperage. During welding, Left LCD Readout (39) will display actual weld voltage

and Right LCD Readout (38) will display actual amperage output.

4.1.2 Stick & TIG Process:

Before welding the Left Selection Knob (31) is disabled and the Right Selection Knob (32) adjusts target

amperage output. During welding, Left LCD Readout (39) will display actual weld voltage and Right LCD

Readout (38) will display actual amperage output.

WF-255MST

MIG Program Chart

Program

Wire Size

Wire Type

Shielding Gas

0

Manual (Non-Synergic)

1

0.6mm

Solid Steel

Mixed (Argon + CO2)

2

0.8mm

3

0.9mm

4

1.0mm

5

1.2mm

6

0.6mm

Solid Steel

CO2

7

0.8mm

8

0.9mm

9

1.0mm

10

1.2mm

11

0.8mm

Flux Cored Steel

Gasless or Gas

12

0.9mm

13

1.0mm

14

1.2mm

15

0.8mm

Stainless Steel

Mixed or Argon

16

0.9mm

17

1.0mm

18

1.2mm

19

0.8mm

Silicone Bronze (CuSi)

Argon

20

0.9mm

21

0.8mm

Aluminium

Argon

22

0.9mm

23

1.0mm

24

1.2mm

Figure 7

2

1, 3

4.2 MIG Program Selection

(Only available in MIG process mode)

1. Press ‘P’ button (26 - MIG Program Selection Button)

2. Rotate Right Selection Knob (32) to choose program (refer to chart below)

3. Press ‘P’ button (26)

NOTE: Program ‘0’ is traditional Manual MIG mode which allows you to manually adjust volts and

wire speed.

Table 5

© Weldclass 2019 | E.&O.E. | Edition 2.2 15

4.3 Function Selection

Functions Chart

Display

Drive Roller

Symbol

MIG MODE

PrG

Pre-Gas Time (sec)

PoG

Post-Gas Time (sec)

SFt

Soft Start Adjustment

bUb

Burnback Adjustment

SPt

Spot/Stitch Weld Time (sec)

GAP

Stitch Weld Gap/Interval Time (sec)

SPo

Spool Gun (On/Off)

TIG MODE

PoG

Post-Gas Time (sec)

SLo

Slope Up Time (sec)

STICK (MMA) MODE

Hot

Hot Start Adjustment

ArC

Arc Force Adjustment

1, 4 2 3

1. Press ‘Fn’ button (27)

2. Rotate Left Selection Knob (31) to select Function (refer to chart below)

3. Rotate Right Selection Knob (32) to adjust parameter for the chosen Function

4. If desired, press ‘Fn’ (27) button to exit the Function setting

.

Figure 8

Table 6

16 © Weldclass 2019 | E.&O.E. | Edition 2.2

WF-255MST

4.3.1 Pre-Gas Time (MIG)

Pre-Gas (or Pre-Flow) setting is adjustable from 0 – 2 seconds. This controls the period shielding gas will

flow for when the torch is triggered before the arc starts. This purges the weld zone of atmospheric gas

which could contaminate the weld before the weld starts. In most common welding applications pre-gas is

not critical and can be set to 0.

4.3.2 Post-Gas Time (MIG)

Post-Gas (or Post-Flow) setting is adjustable from 0 – 5 seconds. This controls the period of time the

shielding gas continues to flow after the arc has stopped. This protects the weld area from contamination

while it is still hot enough to react with atmospheric gases, after the weld is finished/trigger is released. In

most common welding applications post-gas is not critical and can be set to 0.

4.3.3 Soft-Start Adjustment (MIG)

Soft-Start setting is adjustable on a scale 0 – 5. Sometimes known as ‘hot start’ or ‘slow feed’. When a weld

is started, the workpiece and the wire will be ‘cold’ compared to welding temperature. This can cause an

uneven and poor start to the weld using the voltage and wire feed speed selected as optimal once the arc

is established. This setting slows the wire speed down at the start of the weld which improves the weld

starting performance. If you find the wire ‘bumping’ the workpiece before the arc is fully established try

increasing Soft-Start setting.

4.3.4 Burnback Adjustment (MIG)

Burn-back setting is adjustable on a scale 0 – 5. Burnback adjustment controls the short period of time that

the wire feed will continue to run for after the main welding current stops. If the wire feed and current is

stopped at exactly the same time, the wire will still be hot and will ‘burn’ back and stick to the welding tip.

If this problem is happening, increasing the burnback adjustment will cause the wire feeder to run for longer

after the arc has stopped. If the burnback adjustment is excessive, after a weld has stopped, the operator

will be left with excess ‘stick out’ wire length from the torch tip that will require correcting before starting

the next weld.

4.3.5 Spot/Stitch Weld Time (MIG)

This setting will ONLY be accessible when Trigger Mode is set to ‘Spot Welding’.

Spot/Stitch Weld Time setting is adjustable from 0 – 5 seconds. This controls the length of time for the weld.

When the trigger is pulled the machine will weld for the set time and then stop. This is great for producing

very precise weld size or ensuring consistent weld size/length when spot welding, tacking or stitch welding.

4.3.6 Stitch Weld Gap/Interval Time (MIG)

This setting will ONLY be accessible when Trigger Mode is set to ‘Spot Welding’ (see 4.4 Trigger Mode

Selection).

Stitch Weld Gas/Interval Time setting is adjustable from 0 – 5 seconds. This controls the length of time

between welds. So when trigger is held on the machine will weld for the ‘Spot/Stitch’ time then it will stop

for the ‘Stitch Weld Gap/Interval’ time and repeat this until the trigger is released. This is great for producing

a very consistent stitch weld or multiple tack welds.

TIP! If you are only doing individual ‘Spot’ welds (single welds, no repeat) it is

suggested to set this Stitch Weld Gap time to maximum and release the trigger before

the weld repeats.

© Weldclass 2019 | E.&O.E. | Edition 2.2 17

.

4.3.7 Spool Gun On/Off (MIG)

This setting turns activates or deactivates Spool Gun mode. See separate section for full explanation of

spool gun operation. The Spool Gun indicator light (42) will be illuminated when Spool Gun Mode is turned

on.

4.3.8 Post-Gas Time (TIG)

Pre-Gas (or Post-Flow) setting is adjustable from 0 – 5 seconds. This controls the period of time the shielding

gas continues to flow after the arc has stopped. This protects the weld area from contamination while it is

still hot enough to react with atmospheric gases, after the weld is finished/trigger is released.

4.3.9 Slope Down Time (TIG)

Slope-Down time setting is adjustable from 0 – 10 seconds. When the trigger is released, the welding

current will reduce gradually over the time selected down to 0. This allows the operator to complete the

weld without leaving a ‘crater’ at the end of the weld pool.

4.3.10 Hot Start Adjustment (Stick)

Hot Start setting is adjustable from 0 – 10. Hot start provides extra power when the weld starts to

counteract the high resistance of the electrode and workpiece as the arc is started. It makes igniting the

electrode easier and prevents it from sticking when cold.

4.3.11 Arc Force Adjustment (Stick)

Arc Force setting is adjustable from 0 – 10. Sometimes called ‘Dig’ or ‘Arc Control’. A Stick welder is designed

to produce constant output current (CC). This means with different types of electrode and arc length; the

welding voltage varies to keep the current constant. This can cause instability in some welding conditions

as Stick welding electrodes will have a minimum voltage they can operate with and still have a stable arc.

Arc Force control boosts the welding power if its senses the welding voltage is getting too low. The higher

the arc force adjustment, the higher the minimum voltage that the power source will allow. This effect will

also cause the welding current to increase. 0 is Arc Force off, 10 is maximum Arc Force. This is practically

useful for electrode types that have a higher operating voltage requirement or joint types that require a

short arc length such as out of position welds.

4.3.12 Optional VRD Function (Stick)

This function is disabled by default. To have this feature enabled please contact your WeldForce

distributor.

When enabled, VRD function reduces the welding machines’ open circuit voltage (OCV, or no-load

voltage) to a much safer level of approximately 13.5V. OCV is the voltage measured across the positive

and negative terminals when welding is not in progress.

The VRD function will turn on full welding power/voltage when the resistance between the electrode and

work piece is less than 200 Ohms (i.e. metal to metal contact).

When the VRD function is active, the VRD Active Indicator Light (51) is illuminated.

Figure 9

18 © Weldclass 2019 | E.&O.E. | Edition 2.2

1

4.4 Trigger Mode Selection

1. Press ‘Trigger’ button (34) until the desired Trigger Mode Light is lit

WF-255MST

Figure 10

4.4.1 2T (Standard Trigger)

2T is available for MIG & TIG processes.

2T stands for Two Touch or ‘Standard Trigger’ mode. In this mode the trigger is pulled and held on to

start welding, when the trigger is released, the welding stops.

4.4.2 4T (Latch Trigger)

4T is available for MIG & TIG processes.

4T stands for Four Touch or ‘Latching’ mode. The trigger is pulled once and released to welding and then

pulled and released again to stop the welding. This function is useful for longer welds as the trigger is

not required to be held on continuously and thus reduced operator fatigue.

4.4.3 SP (Spot/Stitch)

SP is only available for MIG process.

Spot Welding trigger mode is used for Spot, Tacking or Stitch welding. It allows you to set fixed times for

welding time and interval between welding and automatically repeats this process until the trigger is

released.

© Weldclass 2019 | E.&O.E. | Edition 2.2 19

.

1

2

4.5 Inductance Control

Inductance setting is adjustable on scale of -5 to +5.

This setting changes the MIG waveform to simulate changing the inductance of the welding circuit.

Inductance controls the rate of the current rise and fall as the welding wire contacts the workpiece (known

as a short circuit).

More inductance increases the short circuit time and decreases the short circuit frequency rate. This causes

a wider and more penetrating arc, often with better edge wetting, useful for thicker weld joints.

Less inductance will create a narrow more focused arc. This effect can also be used to fine tune the arc to

produce less spatter. This is often effective on thin materials.

Wire speed, wire size and type, shielding gas will all change the effect that the inductance setting has on

the welding arc. Inductance change will have no practical effect on MIG spray transfer process (as opposed

to short circuit process).

To adjust inductance (only applied in MIG modes):

1. Press ‘Left Selection Knob’ (31) down. Inductance Setting Indicator Light (45) should illuminate.

2. Rotate ‘Left Selection Knob’ (31) to increase or decrease inductance setting. (Normal setting is

‘0’)

Figure 11

4.6 Test Gas

The ‘Test Gas’ button (30) works in both MIG and TIG process modes.

This simply opens gas flow (without feeding wire or giving arc voltage) to allow user to check that there is

sufficient gas flow coming out of the torch nozzle.

Figure 12

20 © Weldclass 2019 | E.&O.E. | Edition 2.2

WF-255MST

5

3mm Cattle Rail

3

2, 4

4.7 Feed Wire / Wire Inch

The ‘Feed Wire’ button (33) only applies to MIG process mode.

This simply activates the MIG wire drive rollers to feed the wire (without wasting gas or giving arc voltage).

This is very useful when loading a new roll of wire and feeding the wire up the torch.

Figure 13

4.8 Job Memory

The Job Memory can be used to store settings that you want to be able to recall in the future.

This is great if you have several common tasks that you do with your machine. You can save the settings for

each different task in the Job Memory and quickly and easily recall these settings when you change tasks.

This makes it much easier and simpler rather than trying to write down settings or tune correct settings

every time you change tasks.

4.8.1 Save or Update a Job

1. Set all desired settings

2. Press ‘Save Job’ button (37)

3. Rotate Right Selection Knob (32) to choose Job number. The Right LCD Readout (38) will alternate

between displaying the selected Job number and the Amperage setting that was last saved

against the selected Job number.

4. Press ‘Save Job’ button (37) again. [Note: To exit without saving press Right Selection Knob (32)

instead]

5. Write a brief description beside the Job Number on the ‘Job Number Register’ chart on the inside

of the door of the machine so you know what number was allocated to that job.

Figure 14

© Weldclass 2019 | E.&O.E. | Edition 2.2 21

4.8.2 Recall a Job

2

1, 3

Figure 16

1. Press ‘Recall Job’ button (36)

2. Rotate Right Selection Knob to select the desired Job Number (32). The Right LCD Readout (38)

will alternate between displaying the selected Job number and the Amperage setting for that

selected Job number.

3. Press ‘Recall Job’ button again (36)

.

Figure 15

4.9 Error/Over Temperature Indicator Light

Error/Over Temperature Indicator Light (41) illuminates when duty cycle is exceeded and thermal

protection is activated. When thermal protection is activated, welding output will be disabled until

machines cools sufficiently and overload indicator lamp goes out.

This may also activate if there are electronic circuit failure issues.

22 © Weldclass 2019 | E.&O.E. | Edition 2.2

WF-255MST

5.1 Electrical Connection

The WF-255MST is designed to operate on a 25A 240V AC power supply to facilitate full output of the

machine as per Table 3.

However, the WF-255MST is factory-fitted with a 15A 240V plug and 3x2.5mm2 input cable for

commissioning purposes. Whilst this 15A plug is fitted the operator must ensure that the operation of

the machine does not exceed the output and duty cycle limits as per Table 2.

If full output is required, WF-255MST should be fitted with 3x4.0mm2 input cable and 25A or 32A 240V

plug.

Follow the procedure below for Setting machine to 15A Input Mode or Full Output Mode.

WARNING! This machine must be electrically connected by a qualified electrical

trades-person. Personal injury or death or damage to the machine may result from

incorrectly connected power supply or plug.

5.1.1 Setting machine to 15A Input Mode

1. Turn Mains Power Switch (23) Off for at least 10 seconds

2. Press and hold both Left Selection Knob (31) and Right Selection Knob (32) whilst you switch the

Mains Power Switch (23) back On.

3. Machine will now be in 15A Mode - Output will be restricted to 200 Amps as per Table 2.

5.1.2 Setting machine back to Full Output Mode

1. Whilst machine is turned on, press and hold Left Selection Knob (31) for 5 seconds

2. Machine will now be in Full Output Mode which will enable you to select full output welding

current up to 250 Amps, as per Table 3.

To determine which mode the machine is currently in, check the maximum current/Amps setting that the

machine will allow. Max 200A = 15A input mode. Max 250A = Full Output Mode.

5.2 Extension Leads

If using on 15A power supply, a 2.5mm2 heavy duty extension cord may be used, providing the output

and duty cycle limits as per Table 2 are not exceeded.

If using 25A power supply, extension lead should be minimum cable core size 4.0mm2.

Using extension leads of over 100m is not recommended.

© Weldclass 2019 | E.&O.E. | Edition 2.2 23

.

5.3 Generator Use

This machine is designed with generator use in mind and incorporates wide voltage tolerance and

intelligent voltage sensing technology to provide maximum protection from power fluctuations that

can occur with motor generators.

5.3.1 Generator Size

Generator size should be not less than 13kva. A 13kVa generator will not provide enough power to

enable full output and duty of this welder. However, it should provide sufficient power to enable

MIG welding up to approximately 200A.

To enable full output and duty cycle of this welder, minimum recommended generator size is 15kVa

or larger.

5.3.2 Generator Quality & Warranty Limitations

Avoid using poor, low quality generators as these have the greatest risk of power spikes etc. A

suitable quality generator should have a THD (total harmonic distortion) rating of no more than 6%.

Most reputable generator suppliers will be able to specify the THD ratings on their product.

Any damage caused by poor quality generator power supply or incorrect use is not covered under

warranty.

5.3.3 3 Golden Rules of Generator use

When running an inverter welder off a generator there are 3 VERY IMPORTANT Golden Rules that

MUST be followed:

1. Do NOT plug welder into generator until AFTER generator has been started up and is running

smoothly

2. UNPLUG welder from generator BEFORE shutting generator down/turning generator off

3. NEVER let your generator run out of fuel whilst the welder is plugged in.

Following these Golden Rules will significantly reduce the risk of any damage resulting from

generator power supply.

24 © Weldclass 2019 | E.&O.E. | Edition 2.2

WF-255MST

6.1 Location

The machine has electrical components and control circuit boards which may be damaged by excessive

moisture, dust and dirt, so a clean and dry operating environment is important for reliable product life.

The enclosure design of this power source meets the requirements of IP23S as outlined in AS60529.

This provides adequate protection against solid objects (greater than 12mm), and direct protection

from vertical drops. Under no circumstances should the unit be operated or connected in a micro

environment that will exceed the stated conditions. For further information please refer to AS 60529.

6.2 Ventilation

Adequate ventilation is required to provide proper cooling for the machine. Ensure that the machine

is placed on a stable level surface where clean cool air can easily flow through the unit.

© Weldclass 2019 | E.&O.E. | Edition 2.2 25

Spool Tension Bolt

Spool Post

Spool nut

Wire Inlet Guide

7.1 MIG Welding

WARNING! Before changing the feed roller or wire spool, ensure that the mains

power is switched off.

7.1.1 Fitting Wire Spool – 270/300mm Diameter (15kg)

1. Open the wire feeder compartment door.

2. Remove the Spool Nut (10) by threading it anticlockwise.

3. Fit the wire spool to Spool Post (9), ensuring that the wire exits the spool towards the wire feeder

from bottom the spool.

4. Set the Spool Brake Tension by adjusting the Spool Tension Nut in the middle of the Spool Post

(9). Turn clockwise to increase spool brake tension and anti-clockwise to decrease. The spool

brake tension should be set so that the spool can rotate freely, but does not continue to rotate

once the wire feed stops. This may need to be adjusted as the wire is used up and the spool

weight decreases.

.

WARNING! Excessive spool brake tension will cause wire feeding issues and affect

welding performance as well as premature failure/wear of wire feed components.

Insufficient brake tension will cause the spool to ‘freewheel’ and the welding wire will

unravel from the spool (known as a ‘birds nest’)

5. Replace the Spool Nut (10) by threading it back on the Spool Post (9).

6. Feed the wire from the spool through the Wire Inlet Guide (12) into the wire feeder.

26 © Weldclass 2019 | E.&O.E. | Edition 2.2

Figure 17

200mm Spool Spacer

Spool Post

Spool nut

200mm Wire Spool

7.1.1 Fitting Wire Spool – 200mm Diameter (5kg)

Follow the same procedure as for 300mm spool as above however slide the 200mm Spool Spacer

onto the Spool Post before you fit the Wire Spool. Take care to ensure that the Spool Lock Pins

are aligned.

WF-255MST

Figure 18

© Weldclass 2019 | E.&O.E. | Edition 2.2 27

7.1.2 Loading Wire Feeder

1. Release the Wire Feed Tension Arms (14 & 21) by pivoting the Wire Feed Tension Adjustment

Levers (13 & 22) towards you from the vertical ‘locked’ position.

2. Check the wire Drive Rollers’ (15 & 19) groove matches the selected MIG wire type and size. The

drive roller will have two different sized grooves; the size of the groove in use is stamped on the

side of the drive roller. For flux cored ‘soft’ wire, such as that used in gasless MIG welding, the

drive roller groove has a serrated profile (known as knurled). For solid core ‘hard’ MIG wire, the

drive roller groove used has a ‘v’ shaped profile. For Aluminum solid core ‘soft’ MIG wire, the

drive roller required has a ‘u’ shaped groove. If necessary, remove and change the drive rollers by

unthreading the Drive Roller Retainer Knobs (16 & 18). Once the correct drive rollers (15 & 19)

are selected and fitted and the Drive Roller Retainer Knobs (16 & 18) is secured in place, manually

feed the wire through the Wire Inlet Guide (12), through the drive roller grooves & the Centre

Wire Guide Tube (17) and into the Outlet Wire Guide Tube (20).

3. Ensuring that the wire is correctly seated in the drive roller grooves, replace the Wire Feed

Tension Arms (14 & 21) and lock them into place by pivoting the Wire Feed Tension Adjustment

Lever (13 & 22) back to the vertical position.

4. Adjusting wire feed tension. This is accomplished by winding the knob on the Wire Feed Tension

Adjustment Lever (13 & 22). Clockwise will increase tension, anticlockwise will decrease drive

tension.

.

TIP! Ideal tension is as little as possible, while maintaining a consistent wire feed with

no drive roller slippage.

Check all other causes of excess wire feeding friction causing slippage first, such as;

incorrect/worn drive roller, worn/damaged torch consumables, blocked/damaged

torch wire guide liner, before increasing wire feed tension. There is a number scale on

the Wire Feed Tension Adjustment Levers (13 & 22) to indicate the adjustment

position. The higher the number indicated, the higher the tension that is set.

WARNING! The use of excessive feed tension will cause rapid and premature wear of

the drive roller, the support bearing and the drive motor/gearbox.

5. Connect the MIG Torch to the MIG torch Euro Connector (4) on the front of the machine. Secure

by firmly hand tightening the threaded collar on the MIG Torch connector clockwise.

6. Check that the correct MIG torch tip size is fitted to the MIG Torch.

7. Connect the machine to suitable mains power using the mains input power lead (24). Switch the

mains power switch (23) to ‘I’ (On) to power up the machine.

8. Set welding process selector to ‘MIG’ (refer to 4.1)

9. You are now ready to feed the wire through the torch. With the wire feeder cover open, press the

‘Feed Wire’ button (33) to check that the wire is feeding smoothly through the feeder and into

the torch.

10. Remove the contact tip from the torch and lay the torch out as straight as possible.

11. Press the ‘Feed Wire’ button (33) until the wire feeds out through the end of the MIG torch.

12. Replace the tip on the MIG torch and trim off any excess wire.

28 © Weldclass 2019 | E.&O.E. | Edition 2.2

WF-255MST

Wire Feed Tension Adjustment Levers

Wire Feed Tension Arms

Drive Rollers

Wire Inlet Guide

Drive Roller Retainer Knob

Outlet Wire Guide Tube

Centre Wire Guide Tube

Figure 19

7.1.3 Gasless Welding Setup

1. Connect the earth cable quick connector to the Positive Welding Power Output Socket (3)

2. Connect the earth clamp to the work piece. Contact with the work piece must be firm contact

with clean, bare metal, with no corrosion, paint or scale at the contact point.

3. Connect the MIG Torch Polarity Change Tail (8) to the Negative (-) Output Connection (7). Note: if

this connection is not made, there will be no electrical connection to the welding torch!

Figure 20

© Weldclass 2019 | E.&O.E. | Edition 2.2 29

7.1.4 Gas MIG Welding Setup

NOTE: Gas MIG welding will require a gas cylinder. (Argon mix or CO2)

1. Connect the earth cable quick connector to the negative welding power output socket (7).

2. Connect the earth clamp to the work piece. Contact with the work piece must be firm contact

with clean, bare metal, with no corrosion, paint or scale at the contact point.

3. Connect the MIG Torch Polarity Change Tail (8) to the Positive (+) MIG Torch Power Connection

(3).

Note: if this connection is not made, there will be no electrical connection to the welding torch!

4. Connect the gas regulator to a gas cylinder (not included with machine) and connect the gas hose

from the regulator to the gas inlet connection (25) on the rear of the machine. Ensure all hose

connections are tight and clamped with the hose clamps provided.

5. Open gas cylinder valve and adjust regulator. Press ‘Test Gas’ button (30) to initiate flow of gas

through the welding torch. Flow should be between 10-25L/min depending on application.

.

Figure 21

30 © Weldclass 2019 | E.&O.E. | Edition 2.2

WF-255MST

7.1.5 Additional Setup for MIG welding with aluminium

Welding with aluminium provides a unique challenge, due to the low column strength and surface

friction of the wire. This causes the wire to deform more as it is pushed through the feed mechanism

and the torch wire delivery liner, greatly increasing friction. Because good MIG welding results are

dependent on a smooth wire feed, certain changes must be made to the wire feed system to minimise

friction caused issues.

1. A shorter MIG Torch will minimize friction and issues. If possible limit length to no longer than 3m

2. Replace the liner in the MIG Torch with a special Graphite/Teflon/PVC liner (rather than the

conventional steel liner). The Weldclass Universal Graphite liner kit is recommended (P3-CTUL09)

3. Choose the largest dimeter wire possible that can but used by your machine for your application.

(Ideally 1.0mm or above)

4. Ensure the wire drive system is fitted with the correct size U-groove drive roller to suit the wire

being used.

5. Ensure specific Aluminium contact tip to suit chosen wire (or a standard tip in one size oversize,

e.g. 1.0mm aluminium wire, use standard 1.2mm contact tip).

TIP! For above reasons, it is quite common for operators to have an extra MIG torch

specifically set up for aluminium use, if the machine is used for welding steel as well.

TIP! Another option to overcome the friction issues is using a spool gun, which will

give better results and much less frustration than a standard MIG torch when welding

aluminium. The WF-255MST is spool gun capable, refer following section for use with

a spool gun on the WF-255MST.

7.1.6 Spool Gun Setup

NOTE: Spool Gun is an optional extra for the WF-255MST.

The spool gun is a very useful addition to a MIG welder. It can be used for all types of MIG welding, but

it has two primary advantages over a conventional ‘push’ wire feeder…

The main advantage is that distance that the wire has to travel from the spool to the welding tip is very

short, compared with a conventional torch. This greatly reduces the wire feeding friction and improves

the wire feed speed smoothness and consistency, thus the welding quality is greatly improved. This is

especially so with ‘soft’ wires such as Aluminium. It is difficult to get Aluminium to feed smoothly in

welding machines equipped with standard design wire feeders, even with special torch liners and short

torch lengths.

The second advantage is that the gun can allow the use of the small 100mm wire spools at a distance

from the power source (This distance is only limited by the length of the spool gun lead). This is

advantageous for high cost wire, that is not used commonly such as Stainless Steel or MIG brazing wire.

It saves the outlay cost for a much more expensive, larger 200mm spool.

1. Follow above steps for either ‘Gasless Welding Setup’ or ‘Gas MIG Welding Setup’ (whichever is

relevant) using the spool gun for the torch

2. Connect the spool gun interface plug to the Spool Gun Interface Connection Socket (5).

3. Set welding process selector to ‘MIG’ (refer to 4.1)

4. Set the MIG Program to ‘0’ (refer to 4.2)

Note: Spool Gun cannot be used with Synergic MIG programs.

5. Set Spool Gun Function setting to ‘On’ (refer to 4.3)

6. Set the welding voltage adjustment, wire speed control knob and inductance control to the

desired positions.

7. You are now ready to weld!

© Weldclass 2019 | E.&O.E. | Edition 2.2 31

7.1.7 Adjusting Settings for MIG Welding in Manual Mode (Program 0)

1. Follow above steps for either ‘Gasless Welding Setup’, ‘Gas MIG Welding Setup’ or ‘Spool Gun

Setup’ (whichever is relevant)

2. Set welding process selector to ‘MIG’ (refer to 4.1)

3. Set the MIG Program to ‘0’ (refer to 4.2)

4. Set the desired Voltage output using the Left Adjustment Knob (31). Voltage setting will show on

Left LCD Readout (39).

5. Set the desired Wire Speed using the Right Adjustment Knob (32). Wire Speed setting will show

on Right LCD Readout (38) in meters per minute (m/min).

6. Adjust Inductance if required (refer to 4.5)

7. Adjust special Function settings if required (refer to 4.3)

7.1.8 Adjusting Settings for MIG Welding in Synergic (Auto) Mode

1. Follow above steps for either ‘Gasless Welding Setup’ or ‘Gas MIG Welding Setup’ (whichever is

relevant)

2. Set welding process selector to ‘MIG’ (refer to 4.1)

3. Set the MIG Program to the relevant Program number (refer to 4.2)

4. To set output by Amperage: Rotate Right Adjustment Knob (32) to choose amperage

OR

To set output by Material Thickness: Press Right Adjustment Knob (32) in then Rotate Right

Adjustment Knob (32) to choose material thickness

5. You can use the Left Adjustment Knob (31) to fine tune the voltage if the standard synergic

program does not suit your exact welding application.

6. Adjust Inductance if required (refer to 4.5)

7. Adjust special Function settings if required (refer to 4.3)

.

32 © Weldclass 2019 | E.&O.E. | Edition 2.2

WF-255MST

7.2 Stick (MMA) Welding Operation

1. Connect the earth cable quick connector to the Negative (-) Welding Power Output Socket (7)

2. Connect the earth clamp to the work piece. Contact with the work piece must be firm contact

with clean, bare metal, with no corrosion, paint or scale at the contact point.

3. Insert an electrode into the electrode holder and connect the electrode holder and work lead to

the Positive (+) Welding Power Output Socket (3).

NOTE: This polarity connection configuration is valid for most GP (General Purpose)

MMA electrodes. There are variances to this. If in doubt, check the electrode

specifications or consult the electrode manufacturer.

4. Connect the machine to suitable power. Switch the mains power switch (23) to ‘on’ to power up

the machine.

5. Set welding process selector to ‘Stick’ (refer to 4.1)

6. Select the required output current using the Right Adjustment Knob (32). The Right LCD Readout

(38) will display the set amperage output.

7. Adjust special Function settings if required (refer to 4.3)

8. You are now ready to weld!

Figure 22

© Weldclass 2019 | E.&O.E. | Edition 2.2 33

.

7.3 Lift TIG Operation

NOTE: Lift TIG operation requires an optional trigger control TIG torch, argon gas cylinder & regulator.

NOTE: The WF-255MST is a DC (Direct Current) output welder only, this means that it is unable to TIG weld

reactive metals such as Aluminium alloys and Brass (which require AC output). DC TIG output is suitable for

steel, stainless steel and copper.

1. Connect the earth cable to the Positive (+) Welding Power Output Socket (3)

2. Connect the earth clamp to the work piece. Contact with the work piece must be firm contact

with clean, bare metal, with no corrosion, paint or scale at the contact point.

3. Insert TIG torch power connection into the Negative (-) Welding Power Output Socket (7)

4. Connect TIG multi-pin connector to the TIG Control/Spool Gun connection socket (5)

5. Connect TIG torch gas line to the TIG Torch Gas Connection (6) on the front of the machine.

Ensure all connections are tight.

6. Open gas cylinder valve and adjust regulator. Press ‘Test Gas’ button (30) to initiate flow of gas

through the TIG torch. Flow should be between 5-10 l/min depending on application.

7. Connect the machine to suitable power. Switch the mains power switch (23) to ‘I’ to power up

the machine.

8. Set welding process selector to ‘TIG’ (refer to 4.1)

9. Select the required output current using the Right Adjustment Knob (32). The Right LCD Digital

Readout (38) will display the set amperage output.

10. Adjust special Function settings if required (refer to 4.3)

11. You are now ready to weld!

Figure 23

34 © Weldclass 2019 | E.&O.E. | Edition 2.2

WF-255MST

BZL 25 Torch Parts

Ref.

Part No.

Description

WC-03614

Complete BZL 25 Torch – 3m

WC-03615

Complete BZL 25 Torch – 4m (Standard)

1

P3-B25SN

Neck

2

P3-B25NS

Nozzle Spring Pk2

3

P3-B25TH

Tip Holder Pk2

4

P3-BT6066

Tip 0.6mm Pk5

4

P3-BT6086

Tip 0.8mm Pk5

4

P3-BT609

Tip 0.9mm Pk5

4

P3-BT610

Tip 1.0mm Pk5

4

P3-BT612

Tip 1.2mm Pk5

4

P3-BTA610

Tip 1.0mm Alu Pk5

4

P3-BTA612

Tip 1.2mm Alu/Flux Core Pk5

5

P3-B25N

Nozzle Pk2

6

P3-BRSL4

Liner – Steel wires

6

P3-CTUL12

Liner – Aluminium wire

8.1 MIG Torch and Spares:

The MIG Torch supplied with the WF-255MST is a BZL 25 (Binzel 25 style) model.

To view parts for this torch, see below table or go to: www.weldclass.com.au/BZL25parts

Table 7

© Weldclass 2019 | E.&O.E. | Edition 2.2 35

8.2 TIG Torch and Spares (Optional Extra):

Part No.

Description

WC-06234

Complete TIG Torch – Remote Control 150A 4m

P3-TB17

Torch Body - 17 Standard (No Valve)

P3-TB17F

Torch Body - 17F Flexible (No Valve)

WC-57Y02P

Back cap – Long Pk2

WC-57Y05P

Back cap – Medium Pk2

WC-57Y04P

Back cap – Short Pk2

P3-10N23

Collet – 1.6mm

P3-10N24

Collet – 2.4mm

P3-10N25

Collet – 3.2mm

P3-10N31

Collect Body – 1.6mm Pk2

P3-10N32

Collect Body – 2.4mm Pk2

P3-10N28

Collect Body – 3.2mm Pk2

P3-10N49

TIG Ceramic Cup - #5 7.9mm Pk2

P3-10N48

TIG Ceramic Cup - #6 9.5mm Pk2

P3-10N47

TIG Ceramic Cup - #7 11.1mm Pk2

P3-10N46

TIG Ceramic Cup - #8 12.7mm Pk2

P3-10N45

TIG Ceramic Cup - #10 15.8mm Pk2

WC-05192

TIG Tungsten RE4 – 1.6mm Pk10

WC-05193

TIG Tungsten RE4 – 2.4mm Pk10

WC-05194

TIG Tungsten RE4 – 3.2mm Pk10

Figure 24

The compatible TIG torch for this machine is the Weldclass WC-06234 torch.

To view this torch and parts, go to: www.weldclass.com.au

.

Table 8

36 © Weldclass 2019 | E.&O.E. | Edition 2.2

Optional Accessories

Part No.

Drive Roller

WC-06234

TIG Torch – Remote Control 150A 4m

WC-06235

Welding Trolley

WC-01775

Welding Gloves

P6-MPLY

MIG Pliers

WC-06203

MIG Spool Gun 8m (BZL 25)

Drive Rollers

Part No.

Drive Roller

WC-06191

0.6 / 0.8mm V-Groove (Steel)

WC-06192

0.9 / 1.2mm V-Groove (Steel)

WC-06193

0.8 / 0.9mm Knurled (Flux Cored)

WC-06194

0.9 / 1.2mm Knurled (Flux Cored)

WC-06195

1.0 / 1.2mm U-Groove (Aluminium)

8.3 Optional Accessories

Table 9

8.4 Drive Rollers:

WF-255MST

Table 10

© Weldclass 2019 | E.&O.E. | Edition 2.2 37

8.5 Machine Spare Parts:

Ref.

Description

1

Handle

2

Right panel

3

Assembly sheet

4

Air switch protection part

5

Cooling fan grill

6

Air switch assembly part

7

Inlet gas fitting

8

Power cable clip

9

Rear panel

10

Air switch

11

Rear panel assembly sheet

12

Cooling fan assembly sheet

13

Cooling fan

14

Left panel

15

Locker

16

Spool holder

17

Wire feeder protection part

18

Wire feeder

19

Wire feeder holder

20

Base panel

21

Transformer

22

Insulation part

23

Front panel

24

Wire connector

25

Euro socket

26

9 Pin socket

27

Power cable clip

28

Gas fitting

29

Central socket

30

Gas fitting

31

Connector

Ref.

Description

32

Knob

33

Front panel assembly sheet

34

Front PCB

35

Inductor

36

Assembly sheet

37

Shunt

38

Power PCB

39

Control PCB

40

Transformer holder

41

PFC inductor

42

Gas valve

43

Valve assembly sheet

44

3 way connector

A1

Assembly sheet

A2

Heatsink

A3

Support pillar

A4

Heatsink

A5

MUR PCB

A6

Heatsink

A7

Main PCB

A8

Heatsink

A9

Rectifier

A10

Insulation part

A11

Insulation part

A12

Recovery diode

A13

Insulation part

A14

IGBT

A15

Heatsink

A16

Thermistor

A17

Heatsink

A18

Heatsink

A19

Recovery Diode

For machine parts, go to www.weldclass.com.au/machines or contact your Weldclass distributor.

.

Table 11

38 © Weldclass 2019 | E.&O.E. | Edition 2.2

WF-255MST

Figure 25

© Weldclass 2019 | E.&O.E. | Edition 2.2 39

8.6 Primary Schematic Circuit Diagram

.

Figure 26

40 © Weldclass 2019 | E.&O.E. | Edition 2.2

WF-255MST

9.1 Keep your Welding Machine in Top Condition

The WF-255MST does not require any special maintenance, however the user should take care of the

machine as follows:

1. Regularly clean the ventilation slots

2. Keep the casing clean

3. Check all cables before use

4. Check electrode holders, work lead/clamps and welding torches before use

5. Replace worn electrode holders and earth clamps, which do not provide a good connection

6. Replace worn torch consumable parts in a timely manner

7. Replace worn wire drive components in a timely manner

8. Use a soft cloth or brush to clean electrical components. Do not use liquid cleaning products,

water or especially solvents

9. Do not use compressed air to clean electrical components as this can force dirt and dust further

into components, causing electrical short circuits

10. Check for damaged parts

WARNING! Before performing cleaning/maintenance, replacing cables/connections,

make sure the welding machine is switched off and disconnected from the power

supply.

If damaged, before further use, the welder must be carefully checked by a qualified person to determine

that it will operate properly. Check for breakage of parts, mountings and other conditions that may affect

its operation.

Have your welder repaired by an expert. An authorised service centre should properly repair a damaged

part.

This appliance is manufactured in accordance with relevant safety standards. Only experts must carry out

repairing of electrical appliances, otherwise considerable danger for the user may result.

Use only genuine replacement parts. Do not use modified or non-genuine parts.

9.2 Storing the Welder

When not in use the welder should be stored in the dry, dust-free and frost-free environment.

© Weldclass 2019 | E.&O.E. | Edition 2.2 41

.

10.1 Duty Cycle Rating

WeldForce welding machines are fitted with thermal overload protection which means the machine will

cut out when it reaches a certain temperature, to prevent damage to components. The machine will then

re-start when it returns to a safe temperature.

Duty cycle is a measure of the percentage of time a machine will operate within a certain time period at a

given amperage. For example a duty cycle of 160A @ 25% means that a machine will operate at 160A for 2

½ minutes in a 10 minute time period. The machine will have to rest for the remaining 7 ½ minutes to

enable it to cool down.

The international standard for duty cycle rating is based on an ambient air temperature of 40°C with 50%

humidity, over a 10 minute period. In an environment with temperatures exceeding 40°C, the duty cycle

will be less than stated. In ambient temperature less than 40°C, duty cycle performance will be higher. There

are numerous other factors that can influence actual duty cycle performance.

10.2 Choosing a Welding Process – MIG, Stick or TIG?

10.2.1 The Stick (MMA) Process

10.2.1.1 Description

The acronym MMA (or MMAW) stands for Manual Metal Arc Welding. ‘Manual’ refers to the fact

that the MMA process requires the operator to apply filler metal (in contrast to MIG ‘semi-automatic’

welding where the machine feeds the filler metal into the weld). ‘Metal’ refers to the fact that the

filler metal itself (the stick electrode) is used to conduct the welding current to the job. MMA welding

is commonly known as ‘stick-electrode’ or ‘arc’ welding.

10.2.1.2 Process

The MMA process involves the electrode being touched on the job to ignite the arc. The electrode is

held in the electrode holder and must be continually replaced as it is consumed. The electrode

consists of a metal core, which is the filler metal, covered by a flux coating which shields the weld

and prevents it from oxidising. During welding the flux forms into a slag covering the weld which is

chipped off after the weld has formed.

10.2.1.3 Advantages

MMA welding offers several advantages over alternative welding processes. Primarily it has a greater

capacity than MIG welding, or in other words it can weld heavier materials with the same amperage

output. For this reason small, portable inverter welders like the WeldForce machines, have the

capacity to weld with up to 3.2mm or 4mm electrodes making it suitable for a vast range of

applications without the complication of shielding gas or wire feeding. Moreover, MMA welding is

typically more ‘forgiving’ than MIG or TIG when welding rusty or dirty materials (which makes it ideal

for maintenance applications).

10.2.1.4 Limitations

Traditionally, welding thin materials whilst avoiding “blow-through” can be tricky with the MMA

process. This being said, however, welding thin materials with a WeldForce machine will be

noticeably easier because the arc is so stable and the output can be very finely adjusted down to

very low amps.

10.2.1.5 Materials

MMA welding can be used with a wide variety of electrodes including general purpose, low

hydrogen, stainless steel, iron powder, hard facing & cast iron just to name a few.

42 © Weldclass 2019 | E.&O.E. | Edition 2.2

WF-255MST

10.2.2 The TIG Process

10.2.2.1 Description

The acronym TIG stands for Tungsten Inert Gas. Tungsten refers to the type of conductor (a tungsten

electrode) that is used to transfer the welding current to the job and create the arc. Inert Gas refers

to the fact that the process relies on an inert gas to prevent weld oxidisation.

Also referred to as Gas Tungsten Arc Welding (GTAW).

10.2.2.2 Process

In simple terms, TIG welding is probably most similar to oxy flame welding. However, instead of a

flame it uses an electrical arc to melt the job and filler metal, and instead of a preheat flame it uses

inert gas to prevent weld oxidisation. Like oxy flame welding, the filler metal is fed into the weld by

hand as required. Due to the fact that the current is not conducted to the job via the filler metal, (as

it is in MIG and MMA welding), the arc is much more controllable.

10.2.2.3 Advantages

Very low amperages can be achieved making this process ideal for welding thin materials. Also, due

to the independence of the arc and the filler metal application, TIG welding is very controllable and

can therefore achieve very high quality welds with excellent appearance. Unlike MIG and MMA

welding, TIG welding does not produce spatter so clean up is very minimal. It is typically used where

weld appearance is critical (e.g. handrails) or where weld quality is vital (e.g. pressure vessels or

pipes).

10.2.2.4 Limitations

Whilst TIG welding is very controllable, it can also be slower and more tedious than MIG or MMA

welding and it will generally not operate well on dirty or rusty materials meaning that additional