Welch Vacuum 8925 User Manual

OWNER’S MANUAL

FOR

DIRECTORR® DIRECT-DRIVE VACUUM PUMP

MODELS:

8905

8907

8912

8917

8920

8925

WARNING

Do not block the exhaust port. Pressure will build up with the

potential of oil case bursting with possible injury to personnel.

WARNING

Pumps being run continuously above 1 torr should use an

exhaust oil recycler.

WARNING

Pumps not recommended for filtration, aspiration or drying

electrophoresis gels.

Gardner Denver Welch Vacuum Technology, Inc.

5621 W. Howard Street

Niles, IL 60714

Phone: (847) 676-8800

Fax: (847) 677-8606 (Technical Support)

E-Mail: welchvacuum@gd-thomas.com Part No. 67-1483R2.5

Web-Page: www.welchvacuum.com Printed in USA

For outside of U.S. and Canada, contact your local

Gardner Denver sales office, see back page

INSTRUCTION

WARNING AND CAUTION

PLEASE READ BEFORE OPERATION

While reading your manual, please pay close attention to areas labeled:

WARNING AND CAUTION.

The description of each is found below.

WARNING

Warnings are given where failure to observe instruction could

result in injury or death to people.

CAUTION

Cautions are found where failure to observe the

instruction could result in damage to the equipment,

associated equipment and process.

These units conrm to the SI International system of units of measurement.

The following symbols (with recommendation of IEC1010 ) of warning will be found on the pump.

Caution - refer to accompanying documents

Caution - risk of electrical shock

Caution - hot surface

WARNING

Motor includes a self resetting thermal cutout and the pump could

restart without actuation under fault condition.

2

TABLE OF CONTENTS

SECTION PAGE

Section 01 - Installation 05

1.01 Unpacking 05

1.02 Pump Mounting 05

1.03 Pump Location / Environmental Conditions 05

1.04 Exhaust Provisions 05

1.05 Electric Power 06

1.06 Vacuum Connections 07

1.07 Vacuum Gauges 07

1.08 Vacuum Pump Oil 07

Section 02 - Pump Features & Principles of Operation 08

2.01 General Description 08

2.02 Principles of Vacuum Pump Operation 09

2.03 Effects of Continued Pressure Reduction 09

2.04 Ultimate Pressure 09

2.05 Pump Mechanism Description 09

2.06 Intake Anti-Suckback Protection 10

2.07 Pump Lubrication 10

2.08 Exhaust Filter 10

2.09 Gas Ballast Valve 10

2.10 UNIBARBTM Intake Fitting 11

Section 03 - Specications 12

3.01 Specication Chart 12

Section 04 - Motor Power Specications / Features 14

4.01 Motor Specications Chart 14

4.02 Changing the voltage setting; 8907, 8912 & 8917 “A” Models 15

4.03 Changing the voltage setting; 8907, 8912 & 8917 “C” Models 15

4.04 Changing the voltage setting; 8905, 8920 & 8925 “A” Models 16

(Includes instructions to attach solenoid valve)

4.05 Other Electrical Congurations 16

4.06 Explosion Proof Pumps 16

Section 05 - Operation 17

5.01 Starting Procedure 17

5.02 High Pressure Operation 17

5.03 Shutdown Procedures 17

3

TABLE OF CONTENTS

SECTION PAGE

Section 06 - Maintenance 18

6.01 Vacuum Problems 18

6.02 Oil Change 19

6.03 Developing a Maintenance Schedule 19

6.04 Lip Seal / Gasket Change 20

Section 07 - Trouble Shooting 24

7.01 Leak Detection Problems 24

7.02 Trouble Shooting Guide 25

Section 08 - Specications 26

8.01 Shaft Seal Replacement 26

8.02 Minor Repair Kits 26

8.03 Major Factory Repair 26

Section 09 - Accessories 27

9.01 Pump Oil 27

9.02 Exhaust Filter 27

Section 10 - Drawings and Speed Curve 28

10.10 Speed Curve 28

10.20 Dimensional Drawing 29

10.30 Pump Exploded Views and Parts List 30

10.40 Module Exploded Views and Parts List 36

10.50 Oil Case Exploded View and Parts List 39

Section 11 - Warranty 40

Section 12 - MSDS Sheet for 8995P 41

4

Section 1: INSTALLATION

1.01 Unpacking

Carefully remove the pump from the shipping carton. Keep all paperwork and inspection tags for future

reference. If shipping damage has occurred, a claim must be led with the carrier immediately; keep the

shipping container for inspection by the carrier.

1.02 Pump Mounting

Rubber bumpers are supplied with the pump base. They isolate noise and eliminate creeping. For more

rigid mounting requirements the pump base can be bolted directly to a surface by removing the bumpers

from the base and using the mounting holes and slots featured on the base.

1.03 Pump Location / Environmental Conditions

The pump should be located in a clean and well-ventilated area and adequate space should be provided

wherever possible for routine maintenance such as oil changes. For best performance, the pump should

be located as closely as possible to its system. Determining factors for pump location should include

length and size of connections, the number of bends, and the type of exhaust connections.

1.04 Exhaust Provisions

Exhaust connections will be determined by the type of system to be exhausted and the desired

cleanliness of the air surrounding the pump. Under normal pumping conditions the optional exhaust

lter will be adequate. Refer to Section 9, Accessories for available exhaust lters. Where extreme

exhaust conditions are encountered, it is best to pipe the exhaust out of the building. Always use thick

walled rubber vacuum hose, wire reinforced PVC tubing or metal pipe for exhaust lines to avoid the

possibility of the line becoming crimped or collapsing resulting in dangerous exhaust line blockage.

The exhaust connection is a 1”-20 threaded port for all Models except 8905 which is 3/4”-20. The port

is located on top of the oil reservoir. See section 9.02 Exhaust Filters to nd the correct lter for each

pump. If a hose nipple is preferred for the exhaust port, use part number 1393K for models 8907, 8912

and 8917.

Call Welch customer support (847) 676-8800, ext. 1, prior to start-up if you have any questions.

WARNING

Never block or impede air flow from the exhaust port. High

pressure can build up within the oil reservoir if the exhaust port

is blocked. Check frequently, especially if exhaust is piped

out of the building.

5

1.05 Electric Power

For Model 8905

Compare the pump motor rating, printed on a label on the side of the motor and on the serial number tag,

to the power source, to be sure they agree in voltage, phase, and frequency. Pump installation must

comply with local electrical codes which dictate appropriate protection devices such as fuses or circuit

breakers. Know the location of the circuit breaker protecting the electrical outlet for the pump.

For Models 8907, 8912 & 8917

Compare the pump motor rating, printed on a label on the side of the motor and on the serial number tag,

to the power source, to be sure they agree in voltage, phase, and frequency. Pump installation must

comply with local electrical codes which dictate appropriate protection devices such as fuses or circuit

breakers. Know the location of the circuit breaker protecting the electrical outlet for the pump.

Only the Models 8907C, 8912C and 8917C have “global motors” that operate over a wide range of

voltages (100-120V, 200-30V). They also operate at frequencies of 50Hz and 60 Hz.

Power is single phase.

For Models 8920 & 8925

Compare the pump motor rating, printed on a label on the side of the motor and on the serial number tag,

to the power source, to be sure they agree in voltage, phase, and frequency. Pump installation must

comply with local electrical codes which dictate appropriate protection devices such as fuses or circuit

breakers. Know the location of the circuit breaker protecting the electrical outlet for the pump.

CAUTION

Make certain the power settings on the pump match your power

source before attempting to operate the pump.

(Additional information can be found in section 4: Motor Power).

6

1.06 Vacuum Connections

TM

The pump inlet is equipped with a UNIBARB

7/16” and 13/16” hose tting. The inlet is located

next to the pump handle. It contains a screen to collect any debris from getting into the pump. An

extensive line of vacuum pump ISO ttings, hoses, traps, etc. is available from Welch to meet the

requirements of most vacuum systems. For the best vacuum, use a hose clamp in conjunction with a

vacuum hose to hose nipple connections. Welch offers a number of different types of vacuum tubing

and connectors.

See Section 9 - Accessories or call Welch customer support (847) 676-8800, Extension 1.

The choice of connections and ttings can have a very marked effect on the pumping speed at the

vacuum chamber. Any connection placed between the pump and the chamber creates an impedance to

the ow of gas. This is particularly true at low pressures in the millitorr range where the gas ow is

substantially molecular in character. The gas ow is then dependent upon the kinetic activity of the

molecules to bring it to the pump intake. This impedance is described by the term “conductance”.

The conductance of a tube is proportional to the cube of its diameter and inversely proportional to its

length. Therefore, connecting lines should be as large in diameter and as short in length as practical.

For best results the diameter of the connecting tube should be at least as large as the diameter of the

pump intake. To avoid a large reduction in pumping speed at the vacuum chamber, the conductance of

the line must be considerably greater than the speed of the pump. Sharp bends in vacuum lines also

contribute to conductance. To avoid reductions in pumping speed, minimize the number of 90º angles

in the vacuum system.

1.07 Vacuum Gauges

The type of vacuum gauge to be used in a system is determined largely by the pressure range to be

measured. A thermocouple or pirani gauge is recommended for measuring pressures in the range

produced by these pumps. See Website or call for additional information.

1.08 Vacuum Pump Oil

WARNING

The vacuum pump is shipped witout oil inside to prevent possible

spillage during shipment. Oil must be added prior to use.

Filling with Fresh Oil

Be sure the pump is lled with oil to the level indicated on the oil ll window. When additional oil is

required, use only DIRECTORR® Gold Vacuum Oil , pump performance is not guaranteed with other

brands of oil. Do not overll the pump, and be sure to replace the oil ll plug.

Remove the oil ll plug located on the top of the oil case and add the oil supplied in a bottle packaged

with each pump.

WARNING

Use only DIRECTORR® Premium or Gold Vacuum Pump Oil.

The ll plug has a raised middle section and a center slot for easy turning either by hand or with a

screwdriver. After the pump has been running for at least 15 minutes, check the oil level again. The oil

level should be maintained at the “full” mark on the oil level window while the pump is operating. Do

not overll, excess oil tends to be splashed out the pump exhaust.

Guidelines for the frequency of oil changes and the oil changing procedure can be found in

Section 6-2: Oil Change

7

Section 2: PUMP FEATURES AND PRINCIPLES OF OPERATION

2.01 General Description

All of the Welch Vacuum Pumps are two-stage, rotary-vane, oil sealed vacuum pumps.

These Vacuum Pumps offer a number of features that improve performance, or protect the pump or

vacuum system under specic operating conditions.

2.02 Principles of Vacuum Pump Operation

The main purpose of a vacuum pump is to reduce the pressure in a vessel or a closed system. The

degree of pressure reduction is dependent upon the requirements of the application and the type of

vacuum pump employed. Rotary vane, oil-sealed vacuum pump operation is described in this section.

Pressure reduction in a closed system is accomplished by repeatedly removing a portion of the

original volume of gas contained in the system. Removal is performed by the action of the rotating

elements of the pump which cause a given space to be successfully enlarged and diminished. Figure 2.1

illustrates a section through a typical stage of rotary-vane pump. Note that this gure is not intended to

illustrate exactly the internal components of the pumps; its purpose is to illustrate the general operating

principles of vacuum pumps.

The rotary action of the pump creates a hollow space of chamber (1) which expands as the pump rotates.

As the chamber expands, the pressure in the chamber decreases. As a result, gas is drawn into the

chamber due to the difference in pressure between the chamber and the inlet (4) to the chamber. (The

inlet is the only place where gas can ow into the chamber.) Once the vane (3) moves past the inlet (4),

it seals the inlet against the chamber (1) and the gas becomes trapped between the vanes (2 and 3). The

chamber (1) formed by the enclosed space between the vanes then begins to decrease in volume as the

rotor revolves, compressing the gas. The pressure of the compressed gas becomes greater than

atmospheric pressure. When the vane (2) moves past the exhaust port (5) the compressed gas in the

chamber is forced out through the exhaust port.

Figure 2.1

Typical Rotary Vane

Pump, Schematic Diagram

This expansion/compression cycle constitutes one complete cycle of the pump operation. This cycle is

repeated as the vane (2) passes the intake port and seals it against the atmosphere. Therefore, two pump

cycles are performed during each revolution of the pump rotor.

8

2.03 Effects of Continued Pressure Reduction

The quantity of gas in the vessel (6) is reduced with each evacuation cycle. The gas remaining in the

vessel expands to ll the vessel and consequently with each cycle the pressure in the vessel is reduced.

This is a manifestation of Boyle’s Law which states that, for a constant temperature, the volume of a

body of gas is inversely proportional to its pressure; i.e., if the volume is enlarged the pressure must be

reduced.

As the amount of gas in the vessel is steadily diminished, its pressure is correspondingly reduced. The

action of the pump must therefore compress a successively smaller quantity of gas with each cycle to

something greater than atmospheric pressure in order to expel it from the pump.

At the beginning of an evacuation sequence, the compression ratio is very small. In the rst cycle of

operation the pump draws in a volume of gas at atmospheric pressure and expels it at approximately

atmospheric pressure. In contrast, near its ultimate pressure, a pump draws in gas at (for example) 30

millitorr and must compress it to more than 760,000 millitorr (atmospheric pressure) in order to expel it

from the pump. Since the exhaust valve is generally spring loaded to provide a good seal, the pressure

required to open it is somewhat greater than atmospheric pressure. Therefore, at an ultimate pressure

of 1.3 x 10-4 mbar 0.1 millitorr, (1 x 10-4 Torr) the compression ratio performed by the pump is greater

than 1,000,000 to 1.

2.04 Ultimate Pressure

As described previously, a quantity of gas is removed from the system with each cycle of the pump.

Therefore, the pressure of the gas remaining in the system is reduced with each pump cycle. Since the

pump can remove only a small portion of the gas with each pump cycle, it is obvious that this method of

evacuation can never completely remove all the gas in the vessel. In addition to this, all the components

of the system contain minute sources of gas leakage which are impossible to seal completely against

atmospheric pressure. Outgassing of materials within the system provide additional sources of gas.

As a result, after prolonged pumping, a state of equilibrium is reached in which the gas introduced from

all the leakage sources is balanced by the ability of the pump to remove gas from the system. This state

of equilibrium is referred to as the ultimate pressure or blankoff pressure of the pump and its system.

No matter how much additional pumping time is provided, no further reduction in system pressure will

be accomplished once ultimate pressure is attained.

2.05 Pump Mechanism Description

This vacuum pump incorporates two in-line rotary-vane stages with interconnecting ports. When in

operation, the intake stage is at lower pressure and the exhaust stage is at higher pressure relative to each

other. Each stage contains a rotor assembly consisting of a rotor with two vanes and a stator. The two

rotors are combined on one shaft, and the two stators are combined in a common housing. The pump

shaft turns the rotors, causing the vanes in each section to sweep the surface of their stators. The vanes

are pressed against the stators by centrifugal force.

Each stage has an exhaust valve. Gas expelled from the rst stage exhaust passes through an interstage

port to the intake of the second stage. The second stage compresses the gas further, then expels it from

the second stage exhaust valve to the atmosphere.

An adjustable gas ballast valve is located in the pump’s exhaust stage. The purpose of the gas ballast is

to reduce or eliminate vapor condensation in the pump. The function of the gas ballast valve is

described later in this section.

The pump is mounted inside an oil case which is a reservoir for the oil that lubricates the pump. The

electric motor shaft drives the pump shaft via a coupling. There is a coupling body on the end of each

shaft; a coupling spider between the two coupling bodies transfers the power from the motor shaft to the

pump shaft.

9

2.06 Intake Antisuckback Protection

When power to the pump is turned off, this device closes automatically, maintaining vacuum in the

system being evacuated, and vents the inside of the pump to atmospheric pressure.

2.07 Pump Lubrication

To ensure efcient operation and proper maintenance, and to minimize noise and oil vapors, it is

important to use the correct type and quantity of oil. DIRECTORR® Gold Vacuum Oil has been

especially developed to have the proper viscosity, low vapor pressure, and chemical stability needed to

produce peak pumping efciency. The ultimate vacuum guarantee on Welch pumps applies only when

this oil is used. Therefore, DIRECTORR® Gold Vacuum Oil is the only oil recommended for use with

these pumps. Each pump is supplied with sufcient oil for lling. Additional oil is available.

See Section 9: Accessories.

2.08 Exhaust Filter

Any oil-sealed vacuum pump tends to discharge oil mist from its exhaust port when the pump operates

under high-ow conditions, such as when the pump’s intake is at or near atmospheric pressure.

Typically, oil mist in the form of a white puff of “smoke” can be seen from the exhaust port when no

lter is used. Once the vacuum level and the corresponding air ow through the pump are reduced, very

little, if any, oil mist will be emitted.

An exhaust lter is recommended for any vacuum pump installation where the pump operates at high

intake pressures for a prolonged period of time. Oil droplets entrained in the pump’s exhaust are

removed by the exhaust lter element. Use of an exhaust lter typically reduces or bafes pump noise

as well. Exhaust lters are sometimes referred to as Oil Mist Eliminators. See Section 9 - Accessories.

2.09 Gas Ballast Valve

The gas ballast valve can increase the pump’s water vapor tolerance. (The gas ballast valve is sometimes

referred to as a vented exhaust valve.) In many vacuum pump applications the gases being pumped

from a system are a combination of permanent gases and undesirable vapors such as water vapor. Under

some conditions, the vapors condense in the second stage of the pump and contaminate the oil. The gas

ballast valve reduces oil contamination by decreasing or eliminating vapor condensation.

Vapor condensation is most likely to take place when the gas compression ratio is high, i.e. when the

pump compresses a relatively large volume of gas to a small volume. Whether or not condensation takes

place is dependent upon several factors, including the proportion of permanent gases to vapors at the

pump intake. If the gases being pumped consist entirely of vapors, condensation will denitely occur

unless the gas ballast valve is opened. The gas ballast valve adds a small amount of air at atmospheric

pressure to the gas being compressed in the second stage. This reduces the compression required to

push the gas out past the exhaust valve (less reduction in volume is required), and therefore reduces or

eliminates condensation.

When the gas ballast valve is open, the pump has to work a little harder, resulting in a slight increase in

operating temperature. The increase in temperature is small, however, and is not harmful to the pump.

Also, the pump is slightly noisier, and the pump’s ultimate pressure is somewhat reduced. Therefore, the

gas ballast valve should be kept closed when it is not needed. Note that the gas ballast is not equally

effective on all diffrent types of chemical vapors, so it may not always eliminate condensation

completely.

10

2.10 UNIBARB

TM

Intake Fitting - Simplies Small Hose Connections

The Unibarb intake tting allows the user to be able to use either 7/16” or 13/16” ID hose to connect to

this system. However, the choice of hose size can have a very marked difference on pumping speed. It

is the best to have the largest connection I.D.(internal diameters) as possible. However, we recognize

many lab appliances use hose barbs accepting small I.D. hose.

The conductance of a tube is proportional to the cube of its diameter and inversely proportional to its

length. Therefore, connecting line should be as large in diameter and short in length as practical.

Included is a free hose clamp to hold the hose in place.

11

Section 3: PUMP SPECIFICATIONS

SPECIFICATION 8905 8920 8925

Free Air Displacement

CFM (L/min) @ 60Hz 1.8 (52) 7.7 (218) 11.3 (320)

(L/min) m3h @ 50Hz (43) 1.5 (182) 10.8 (266) 16.0

Normal Pumping Speed

CFM (L/min) @ 60Hz 1.5 (43) 7.4 (210) 10.0 (283)

(L/min) m3h @ 50Hz (36) 1.3 (175) 10.5 (236) 14.2

Guaranteed Ultimate Pressure* Torr

2 x 10

-3

3 x 10

-4

4 x 10

-4

Water Vapor Tolerance (capacity), Torr 6 15 15

Water Vapor Tolerance (capacity), g/hr 30 180 180

Sound Level dBA 56 54 55

Motor/Pump Speed

RPM @ 60Hz 3450 1725 1725

RPM @ 50Hz 2875 1425 1425

Motor Voltage 50/60Hz Single Phase

Current 115V (230V) @ 60Hz 3.8A (1.9A) 6.8A (3.4A) 10.0A (5.0A)

Current 230V @ 50Hz 1.2A 3.4A 5.0A

Motor Horsepower 1/4 1/2 3/4

Oil Capacity , quarts (liters) 0.42 (0.4) 1.3 (1.2) 1.2 (1.1)

Unibarb for Unibarb for Unibarb for

3/16" and 7/16" 9/16" and 13/16" 9/16" and 13/16"

Intake Connection I.D. Hose, I.D. Hose, I.D. Hose,

Threaded for Threaded for Threaded for

3/4"-20 1-1/8"-20 1-1/8"-20

Tubing needed, I.D.

in inches 3/16 or 7/16 9/16 or 13/16 9/16 or 13/16

in mm 5 or 11 14 or 20 14 or 20

Exhaust Connection 3/4"-20 Thread 1"-20 Thread 1"-20 Thread

Gas Ballast Connection 10-32 Thread 10-32 Thread 10-32 Thread

Pump Weight

lbs. 24.5 58.5 63

Kg. 11.1 26.6 31.3

Overall Dimensions

Length (inch / cm) 14.5 / 36.8 20.8 / 52.8 22.2 / 56.4

Width (inch / cm) 5.1/ 13 7.1 / 17.9 7.1 / 17.9

Height (inch / cm) 8.4 / 21.3 11.0 / 27.9 11.0 / 27.9

Shipping Weight

lbs. 26 71 77

Kg. 11.8 32.2 34.6

Shipping Carton Dimensions

Length (inch / cm) 21 / 53.3 29 / 73.7 29 / 73.7

Width (inch / cm) 6.5 / 16.5 10 / 25.4 10 / 25.4

Height (inch / cm) 11.2 / 28.6 14 / 35.6 14 / 35.6

Exhaust Filter (Optional) Cat. No. 1416B / 1417 1417P-10 / 1416C 1417P-10 / 1416C

Oil Type Cat. No. 8995P / 8995G 8995P / 8995G 8995P / 8995G

3.01 Specication Chart

* Partial measurement based upon the American Vacuum Society Test Procedure No. AVS 5.1-1963

using a trapped McLeod Gauge.

12

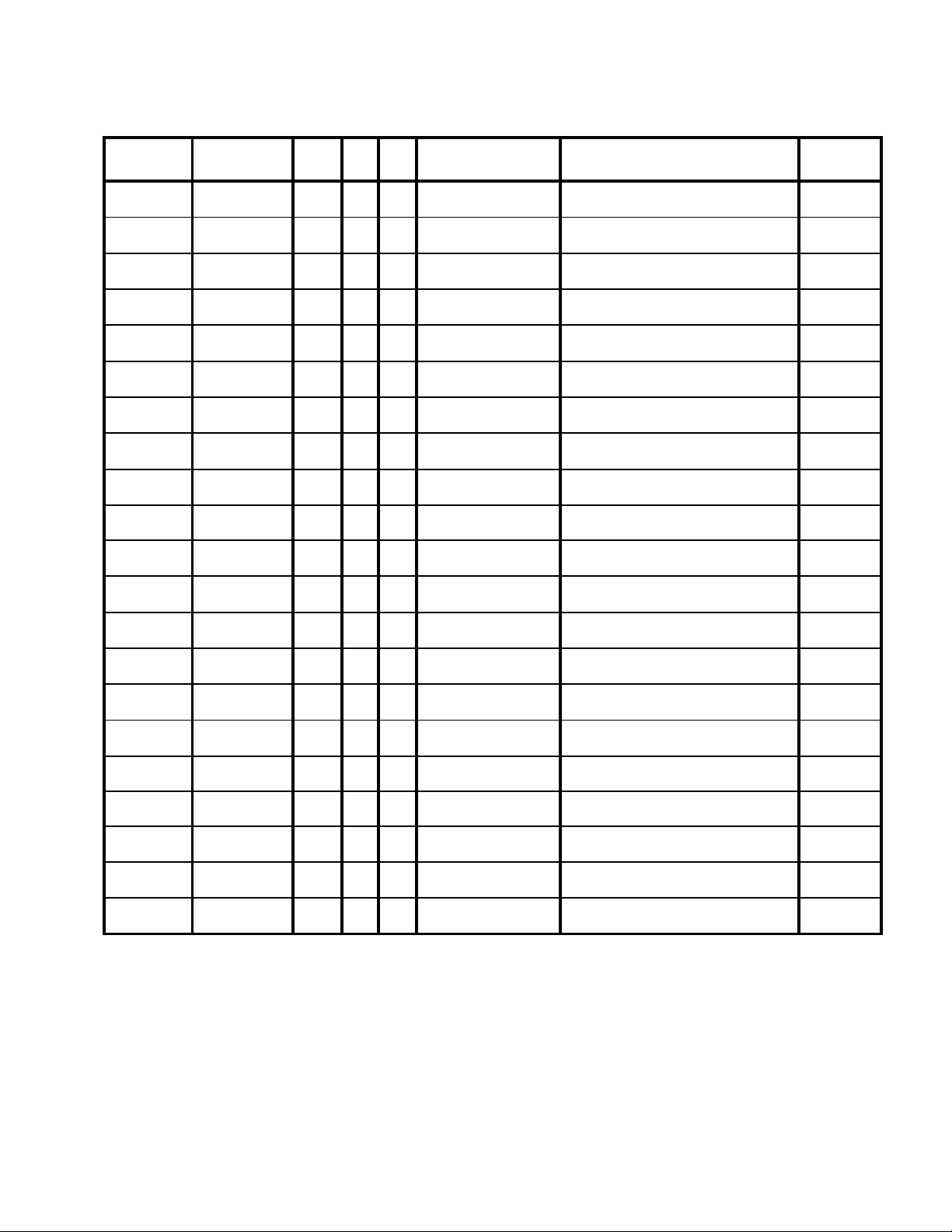

SPECIFICATION 8907 8912 8917

Free Air Displacement

CFM (L/min) @ 60Hz 2.6 (70) 3.8 (108) 6.1 (173)

(L/min) m3h @ 50Hz (56) 3.68 (86) 5.37 (138) 8.63

Normal Pumping Speed

CFM (L/min) @ 60Hz 2.3 (64) 3.4 (96) 5.3 (150)

(L/min) m3h @ 50Hz (53) 3.2 (80) 4.78 (125) 7.51

Guaranteed Ultimate Pressure* Torr

1 x 10

-4

1 x 10

-4

1 x 10

-4

Water Vapor Tolerance (capacity), Torr 19 12 12

Water Vapor Tolerance (capacity), g/hr - - -

Sound Level dBA 50 50 50

Motor/Pump Speed

RPM @ 60Hz 1725 1725 1725

RPM @ 50Hz 1425 1425 1425

Motor Voltage 50/60Hz Single Phase

Current 115V (230V) @ 60Hz 4.6A (2.3A) 4.6A (2.3A) 4.6A (2.3A)

Current 230V @ 50Hz 2.1A 2.1A 2.1A

Motor Horsepower 1/2 1/2 1/2

Oil Capacity , quarts (liters) 1.0 (0.95) 0.9 (0.86) 0.8 (0.76)

Unibarb for Unibarb for Unibarb for

7/16" and 13/16" 7/16" and 13/16" 7/16" and 13/16"

Intake Connection I.D. Hose, I.D. Hose, I.D. Hose,

Threaded for Threaded for Threaded for

1-1/8"-20 1-1/8"-20 1-1/8"-20

Tubing needed, I.D.

in inches 7/16 or 13/16 7/16 or 13/16 7/16 or 13/16

in mm 11 or 20 11 or 20 11 or 20

Exhaust Connection 1"-20 Thread 1"-20 Thread 1"-20 Thread

Gas Ballast Connection 10-32 Thread 10-32 Thread 10-32 Thread

Pump Weight

lbs. 40 41 48

Kg. 18 18 22

Overall Dimensions

Length (inch / cm) 18.8 / 47.7 18.8 / 47.7 18.8 / 47.7

Width (inch / cm) 6.5 / 16.6 6.5 / 16.6 6.5 / 16.6

Height (inch / cm) 9.6 / 24.4 9.6 / 24.4 9.6 / 24.4

Shipping Weight

lbs. 46 46 53

Kg. 21 21 24

Shipping Carton Dimensions

Length (inch / cm) 28.9 / 73.5 28.9 / 73.5 28.9 / 73.5

Width (inch / cm) 10.8 / 27.5 10.8 / 27.5 10.8 / 27.5

Height (inch / cm) 13.7 / 35.0 13.7 / 35.0 13.7 / 35.0

Exhaust Filter (Optional) Cat. No. 1416C / 1417P-7 1416C / 1417P-7 1416C / 1417P-7

Oil Type Cat. No. 8995P / 8995G 8995P / 8995G 8995P / 8995G

* Partial measurement based upon the American Vacuum Society Test Procedure No. AVS 5.1-1963

using a trapped McLeod Gauge.

13

Section 4: MOTOR SPECIFICATIONS, POWER / FEATURES

Cat. No.

V

oltage Freq. Ph. H.P. Factory Wired fo

r

Special Feature

A

pproval

8905A 115 / 230 60 1 1/4 115V 60Hz Standard Model CSA

8905C-01 115 / 230 60 1 1/4 115V 60Hz 230V US Cord Plug CSA

8905C-02 230 50 1 1/4 230V 50Hz European "Schuko" Cord Plug CE

8905C-10 115 / 230 60 1 1/4 230V 60Hz European "Schuko" Cord Plug CSA

8907A 115 / 230 60 1 1/2 115V 60Hz Standard Model CSA

8907C-02 230 50 1 1/2 230V 50Hz European "Schuko" Cord Plug CE

8907C-05 100 50/60 1 1/2 100V For Japan with US Cord Plug -

8912A 115 / 230 60 1 1/2 115V 60Hz Standard Model CSA

8912C-02 230 50 1 1/2 230V 50Hz European "Schuko" Cord Plug CE

8912C-05 100 50/60 1 1/2 100V For Japan with US Cord Plug -

8917A 115 / 230 60 1 1/2 115V 60Hz Standard Model CSA

8917C-02 230 50 1 1/2 230V 50Hz European "Schuko" Cord Plug CE

8917C-05 100 50/60 1 1/2 100V For Japan with US Cord Plug -

8917W 115 60 1 1/2 115V 60Hz To be wired by qualified electrician -

8920A 115 / 208-230 50/60 1 3/4 115V 60Hz Standard Model CSA

8920C-01 115 / 208-230 50/60 1 3/4 230V 60Hz 230V US Cord Plug CSA

8920C-02 115 / 208-230 50/60 1 3/4 230V 50Hz European "Schuko" Cord Plug CE

8925A 115 / 208-230 50/60 1 3/4 115V 60Hz Standard Model CS

A

8925C-01 115 / 208-230 50/60 1 3/4 230V 60Hz 230V US Cord Plug CSA

8925C-02 115 / 208-230 50/60 1 3/4 230V 50Hz European "Schuko" Cord Plug CE

8925W 115 60 1 1/2 115V 60Hz To be wired by qualified electrician -

4.01 Motor Specication Chart

14

Loading...

Loading...