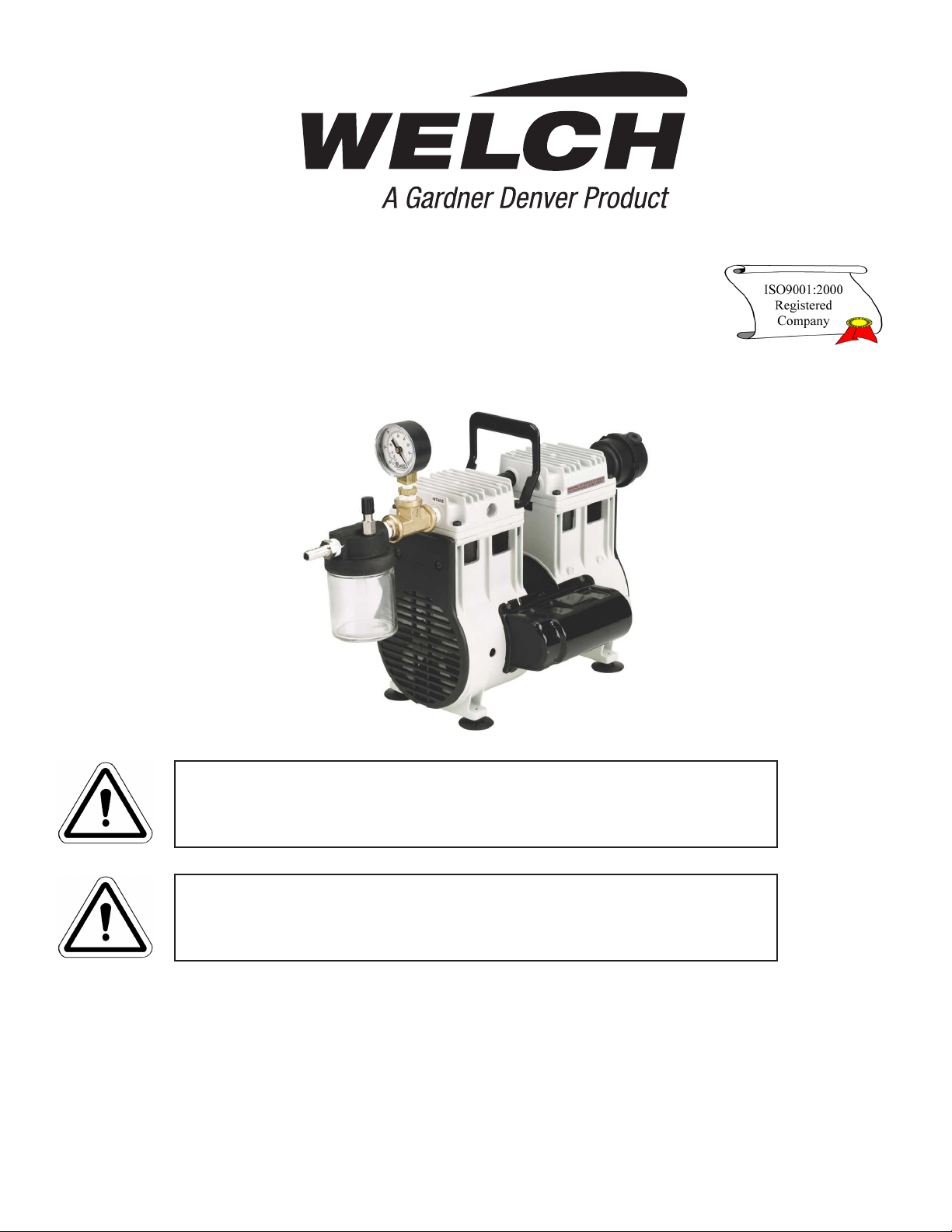

Welch Vacuum 2581B-50 User Manual

OWNER’S MANUAL

FOR

DRY VACUUM PUMP

MODEL: 2581

Warning

Not recommended for pumping acid, base or

organic vapors or gases.

Warning

Be sure to properly identify intake and discharge

before using pump. See section 2.5

Gardner Denver Welch Vacuum Technology, Inc.

5621 W. Howard Street

Niles, IL 60714

Phone: (847) 676-8800

Fax: (847) 677-8606 (Technical Support)

E-Mail: gdwelchvacuum@gardnerdenver.com

Web-Page: www.welchvacuum.com

Part No. 642806

Printed in USA

INSTRUCTION

WARNING AND CAUTION

PLEASE READ BEFORE OPERATION

While reading your manual, please pay close attention to areas labeled:

WARNING AND CAUTION.

The description of each is found below.

WARNING

Warnings are given where failure to observe instruction could result

in injury or death to people.

CAUTION

Cautions are found where failure to observe the instruction could result

in damage to the equipment, associated equipment and process.

These units conrm to the SI International system of units of measurement.

The following symbols (with recommendation of IEC1010 ) of warning will be found on the pump.

Caution - refer to accompanying documents

Caution - risk of electrical shock

Caution - hot surface

WARNING

Motor includes a self resetting thermal cutout and the pump could

restart without actuation under fault condition.

2

TABLE OF CONTENT

Section 01 - Installation

1.01 Unpacking

1.02 Pump Mounting

1.03 Pump Location / Environmental Conditions

1.04 Exhaust Provisions

1.05 Electric Power

1.06 Vacuum Connections

1.07 Vacuum Gauges

1.08 Vacuum Pump Oil

Section 02 - Pump Features & Principles of Operation

2.01 General Description

2.02 Principles of Vacuum Pump Operation

2.03 Effects of Continued Pressure Reduction

2.04 Ultimate Pressure

2.05 Pump Mechanism Description

2.06 Intake Anti-Suckback Protection

2.07 Pump Lubrication

2.08 Exhaust Filter

2.09 Gas Ballast Valve

2.10 UNIBARBTM Intake Fitting

Section 03 - Specications

3.01 Specication Chart

Section 04 - Motor Power Specications / Features

4.01 Motor Specication Chart

4.02 Changing the Voltage Settings for

Global Motor Option on “A”-Models

4.03 Changing the Voltage Settings for

Global Motor Option on “C”-Models

4.04 Changing the Voltage Settings on “A”-Models

4.05 Other Electrical Congurations

4.06 Explosion Proof Pumps

Section 05 - Operation

5.01 Starting Procedure

5.02 High Pressure Operation

5.03 Shutdown Procedures

Section 06 - Specications

6.10 Pump Specication Chart

6.11 Pumping Speed Curves

6.12 Dimensional Drawing

6.17 Parts List and Exploded View for Pump Model 2581

Section 07 - Specications

7.20 Vacuum System for Vacuum Chamber, Glove Box, Annular Space & Transfer Line:

7.21 System Components

7.22 Vacuum System for Cell Harvesting

Warranty

3

Section 1: SAFETY INFORMATION

I.10 CAUTION: To prevent injury....

I.11 Never operate this product if it has a damaged cord or plug. If it is not working properly, has been

dropped, damaged or has fallen into water, please return the product to a Welch service center for

examination and repair.

I.12 Keep the cord away from the heated surfaces.

I.13 Never block any air openings or place it on a soft surface where the openings may be blocked.

The air openings are for ventilation of the motor inside the housing. Keep all air openings free of lint,

dirt and other foreign objects.

I.14 The PTFE pump is thermally protected and can automatically restart when the protector resets.

Always disconnect power source before servicing.

I.15 Wear safety glasses or goggles when operating this product.

I.16 Use only in well ventilated areas. The motor is fan cooled enclosed in a shell.

I.17 All electrical products generate heat. To avoid serious burns never touch unit during or immediately

after operation.

I.18 Be sure to properly identify intake and discharge before using pump. See Section II-5.

I.20 CAUTION: To reduce risk of electrical shock....

I.21 Do not disassemble. Disassembly or attempted repairs if accomplished incorrectly can create

electrical shock hazard. Refer servicing to qualied service agencies only:

Call (847) 676-8800 Ext. 1

I.22 Unit is supplied with a three pronged plug. Be sure to connect pump to a properly grounded

outlet only.

I.23 WARNING: To reduce risk of electricution…

I.24 Do not use this product in or near area where it can fall or be pulled into water or other liquids.

I.25 Do not reach for this product if it has fallen into liquid. Unplug immediately.

I.26 Never operate this product outdoors in the rain or in a wet area.

I.27 DANGER: To reduce risk of explosion or re…

I.28 Do not use this pump near explosive atmospheres or where aerosol (spray) products are being used.

I.29 Do not use this product near ames.

Do not operate the pumps in an atmosphere containing

flammable or explosive gases/vapors.

Never block the exhaust port. If the exhaust is blocked, pressure

will build-up in the pump with the potential of the pump head

bursting and causing possible injury to personnel in the area.

WARNING

WARNING

WARNING

Failure to observe the above safety precautions could result

in severe bodily injury, including death in extreme cases.

4

Section 2: INSTALLATION

2.10 Introduction

This manual has been compiled not only for the care and maintenance of the Welch Dry Vacuum System

now in your possession, but as a helpful reference and guide to prevent many problems which can occur

if used improperly.

2.11 Unpacking

Carefully remove the Dry Vacuum System from the shipping carton. Preserve all paperwork for future

reference. If damage has occurred from shipment a claim must be led with the carrier immediately;

preserve the shipping carton for inspection by the carrier. If you are required to communicate with your

dealer or Welch Vacuum be sure to include your order numbers for quick identication. Do not return

the system to the factory without rst calling for a returned goods number. Call (847) 676-8800

2.12 System Mounting

Rubber feet are attached to the pump. Rubber feet are excellent for applications involving a

semi-exible surface such as a bench top; they help to isolate noise and eliminate creeping.

2.13 System Location and Enviromental Condition

The Dry Vacuum System should be located preferably in a clean, dry and well ventilated area. Please

be sure not to block the ventilation ports located on the metal shell. The pump should be placed where

the surrounding temperature remains between 10°C and 40°C (50°F and 104°F). Always check to insure

the location chosen is protected from direct or indirect moisture contact. The pump should be located as

closely to its system in order to utilize it most efciently. The pump is rated for indoor use only.

Maximum altitude 2000 meters. Operating temperature range 5°C to 40°C. Maximum relative humidity

of 80% for temp. up to 31°C decreasing to 50% at 40°C. Rated for ±10% of supply voltage.

Pollution Degree2, Installation Category II.

WARNING

2.14 Inlet and Outlet Provisions

A inlet hose barb which accepts ¼” I.D. hose makes it easy to connect the system to your concentrator,

rotary evaporator or gel dryer. Since the vacuum system operates in the viscous ow regime, the small

diameter of the hose will generate minimal conductance loss. For best results, Welch recommends the

length of the tubing between the pump and the apparatus be kept as short as possible. Hose clamps

should be used to hold the hose in place.

The hose barb in the outlet port of the pump accepts ¼” ID hose. A vent line can be attached to the

outlet hose barb which allows gases and vapors pumped through the pump to be piped to a fume hood.

Be sure to call Welch technical service prior to start-up at (847) 676-8800 if you have any questions.

Never Block The Outer Port. If the outlet is blocked, pressure will

buildup in the pump which can lead to the pump head bursting

The motor is thermally protected and will automatically

restart unexpectedly when the overload device resets.

Don’t operate this pump in an atmosphere

containing flammable or explosive gases or vapors.

WARNING

WARNING

creating the potential of serious injury.

Remove plug from outer port.

5

Loading...

Loading...