Welch Vacuum 2511B-76 User Manual

WELCH-ILMVA

OWNER’S MANUAL

FOR

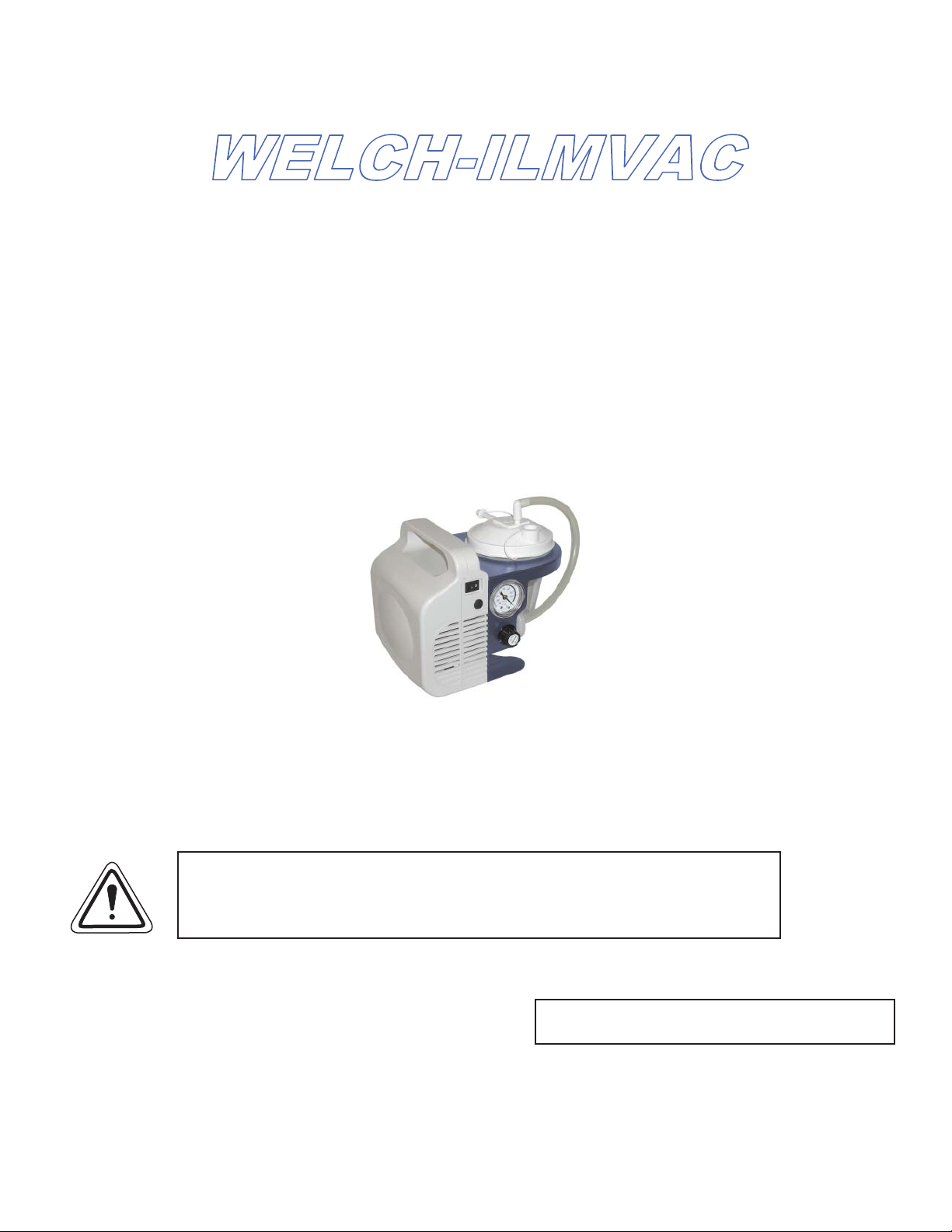

ASPIRATION / FILTRATION

VACUUM SYSTEM

MODEL:

2511

C

Models 2511B-75 / 2511C-75 / 2511C-76 / 2511C-77

Not recommended for pumping acid,

base or organic vapors or gases.

Welch-Ilmvac

5621 W. Howard Street

Niles, IL 60714

Phone: (847) 676-8800 (Technical Support)

Fax: (847) 677-8606

E-Mail: gdwelchvacuum@gardnerdenver.com

Web-Page: www.welchvacuum.com

Warning

For outside of U.S. and Canada, contact your local

Gardner Denver sales offi ce, see back page

Part No. 642781 0510

Printed in USA

INSTRUCTION

WARNING AND CAUTION

PLEASE READ BEFORE OPERATION

While reading your manual, please pay close attention to areas labeled:

WARNING AND CAUTION.

The description of each is found below.

WARNING

Warnings are given where failure to observe instruction could result

in injury or death to people.

CAUTION

Cautions are found where failure to observe the instruction could result

in damage to the equipment, associated equipment and process.

These units confi rm to the SI International system of units of measurement.

The following symbols (with recommendation of IEC1010 ) of warning will be found on the pump.

Caution - refer to accompanying documents

Caution - risk of electrical shock

Caution - hot surface

Double Insulated

OFF (Power)

ON (Power)

WARNING

Motor includes a self resetting thermal cutout and the pump could

restart without actuation under fault condition.

2

TABLE OF CONTENTS

Section 01 - SAFETY INFORMATION

1.10 Caution To Prevent Injury

1.20 Caution To Reduce Risk Of Electrical Shock

1.30 Warning To Reduce Risk Of Electrocution

1.40 Danger To Reduce Risk Of Explosion Or Fire

Section 02 - INSTALLATION

2.10 Introduction

2.20 Unpacking

2.30 Pump Mounting

2.40 Pump Location

2.50 Intake And Discharge Provision

2.60 Electrical Power

2.70 Vacuum Connection

2.80 Vacuum Gauges

2.90 Traps

Section 03 - OPERATION

3.10 Starting Procedures

3.20 Leak Detection

3.30 Operating Pressure Range

3.40 Shutdown Procedures

Section 04 - MAINTENANCE

4.10 Maintenance Procedures

Section 05 - TROUBLESHOOTING

5.10 Vacuum Problems

5.20 Pressure Problems

5.30 Trouble Shooting Guide For 2511 And 2515

Section 06 - SPECIFICATION

6.10 Specifi cation Table

Section 07 - WARRANTY

Section 08 - EXPLODED VIEWS AND PARTS LIST

8.10 Exploded View And Parts List For 2511B-75 / 2511C-75 / 2511C-76

8.11 Exploded View And Parts List For 1475K-20

Section 09 - KITS AND ACCESSORIES

3

SECTION 1: SAFETY INFORMATION

1.10 Caution: To Prevent Injury...

1.11 Never operate this product if it has a damaged cord or plug. If it is not working properly, has been

dropped, damaged or has fallen into water, please return the product to a Welch service center for

examination and repair.

1.12 Keep the cord away from heated surfaces. All electrical products generate heat. To avoid serious burns

never touch unit during or immediately after operation.

1.13 Never block any air openings or place it on a soft surface where the openings may be blocked. The air

openings are for ventilation of the motor inside the housing. Keep all air openings free of lint, dirt and

other foreign objects.

1.14 Model 2511 is thermally protected and can automatically restart when the protector resets. Always

disconnect power source before servicing.

1.15 Never drop or insert fi ngers or any other object into any openings.

1.16 Do not operate this product where oxygen is being administered.

1.17 Wear safety glasses and goggles when operating this product. Never point any air nozzle or air sprayer

toward another person or any part of the body.

1.18 Use only in well ventilated areas.

1.19 Do not use any tools or attachments without fi rst determining maximum air pressure for that tool

or attachment. Be sure to properly identify intake and discharge before using pump. See Section 2.50.

CAUTION

Do not fi ll the collection jar above the safe fi ll level line

indicated on the jar.

1.20 Caution: To Reduce Risk Of Electrical Shock...

1.21 Do not disassemble. Disassembly or attempted repairs if accomplished incorrectly can create electrical

shock hazard. Refer servicing to qualifi ed service agencies only.

1.22 115V unit is supplied with a three pronged plug. Be sure to connect pump to a properly grounded outlet

only.

1.30 Warning: To Reduce Risk Of Electrocution...

1.31 Do not use this product in or near area where it can fall or be pulled into water or other liquids.

1.32 Do not reach for this product if it has fallen into liquid. Unplug immediately.

1.33 Never operate this product outdoors in the rain or in a wet area.

1.40 Danger: To Reduce Risk Of Explosion or Fire...

1.41 Do not use this pump in or near explosive atmospheres or where aerosol (spray) products are being

used.

1.42 Do not pump anything other than atmospheric air.

1.43 Do not pump combustible liquids or vapors with this product or use in or near an area where

fl ammable

or explosive liquids or vapors may exist.

1.44 Do not use this product near fl ames.

WARNING

Failure to observe the above safety precautions could result

in severe bodily injury, including death in extreme cases.

4

SECTION 2: INSTALLATION

2.10 Introduction

2.11 This manual has been compiled not only for the care and maintenance of the Welch Aspiration/Filtration

Vacuum System now in your possession, but as a helpful reference and guide to prevent many problems

which may occur if used improperly.

2.20 Unpacking

2.21 Carefully remove the Aspiration/Filtration Vacuum System from the shipping case. Preserve all

paperwork for future reference. If damage has occurred from shipment a claim must be fi led with the

carrier immediately; preserve the shipping carton for inspection by the carrier. If you are required to

communicate with your dealer or Welch Vacuum, be sure to include your order numbers for quick

identifi cation. Do not return the pump to the factory without fi lling in the online form for a returned goods

number.

2.30 Pump Mounting

2.31 Rubber feet are attached to the pump. Rubber feet are excellent for applications involving a semi-fl exible

surface such as a bench top; they help to isolate noise and eliminate creeping. All Aspiration/Filtration

Vacuum Systems should be mounted on a horizontal plane.

2.40 Pump Location

2.41 The Aspiration/Filtration Vacuum System should be located preferably in a clean, dry, and well ventilated

area. Please be sure not to block the ventilation holes located on the motor housing. The system should

be placed where the surrounding temperature remains between 10°C and 40°C (50°F and 104°F).

Always check to insure the location chosen is protected from direct or indirect moisture contact.

WARNING

The motor is thermally protected and will automatically restart unexpectedly

when the overload device resets. Don’t pump fl ammable or explosive gases

or vapors or operate this pump in an atmosphere containing fl ammable or

explosive gases or vapors.

5

2.50 Intake And Discharge Provision

2.51 The vacuum regulator and vacuum dial gauge enable control of fl uid aspiration into to the collection jar.

The vacuum regulator allows the vacuum level to be set between roughly a atmospheric pressure and the

maximum vacuum allowed for the pump model. A fl oat valve on the collection jar and, hydrophobic fi lter

keep water from accidentally being drawn into the unit. The regulator allows discharge pressure to be

set between atmospheric and the maximum possible for the pump model. Model 2511 is equipped with a

pressure port.

Note: Adjusting the vacuum regulators will affect the performance of the pump.

IntakePressure / Exhaust

Vacuum GaugeVacuum Regulator

Models 2511B-75 / 2511C-75 / 2511C-76 / 2511C-77

Please contact Welch technical service prior to start up at 847-676-8800 if you have any questions.

WARNING

Never block the discharge port. If the exhaust is blocked, pressure

will build-up in the pump above its rated operating pressure.

6

Loading...

Loading...