Welch LVS 300 Z, LVS 302 Z, LVS 301 Z, LVS 310 Z ef, LVS 310 Z ef extern Operating Manual

...

Operation Manual

(EN)

Translation of the german original manual

Laboratory-Vacuum-Systems

Ultimate pressure < 8 mbar

Models:

► unregulated

LVS 300 Z

► manual regulated

LVS 301 Z

LVS 302 Z

► automatic regulated

LVS 310 Z

LVS 311 Z

► ecoflex

LVS 310 Z ef

LVS 310 Z ef extern

► economic

LVS 310 Z en

115041

2017-02-02

We are constantly working on the further

development of all our product models.

Reprinting or reproduction of this manual,

including extracts, is not allowed without the

prior written permission of Co. Gardner

Denver Thomas GmbH.

All rights under the copyright laws are

expressly reserved by Co. Gardner Denver

Thomas GmbH.

We reserve the right to make changes and

amendments.

Gardner Denver Thomas GmbH

Am Vogelherd 20

98693 Ilmenau

Germany

T +49 3677 604 0

F +49 3677 604 131

welch.emea@gardnerdenver.com

www.welchvacuum.com

Customer Support +49 3677 604 0

Contents

115041 3

Contents

1 Important Information ............................................................................................................. 5

1.1 General Information .................................................................................................................. 5

1.2 Target Groups ........................................................................................................................... 5

1.3 Intended Use ............................................................................................................................. 5

1.4 Use for an Unauthorized Purpose ............................................................................................ 5

1.5 Safety Devices .......................................................................................................................... 6

1.6 Meaning of the Warning notes .................................................................................................. 6

1.7 Product Standards, Safety Regulations .................................................................................... 6

2 Basic Safety Instructions ....................................................................................................... 7

2.1 General Information .................................................................................................................. 7

2.2 Electricity ................................................................................................................................... 7

2.3 Mechanical Systems ................................................................................................................. 8

2.4 High Temperatures ................................................................................................................... 8

2.5 Hazardous Substances ............................................................................................................. 9

3 Description ............................................................................................................................ 10

3.1 Design and Function ............................................................................................................... 10

3.1.1 Laboratory-Vacuum-Systems ................................................................................................. 10

3.1.2 Diaphragm pump .................................................................................................................... 11

3.1.3 Vacuum Controller 521, intern ................................................................................................ 12

3.1.4 Built-in – Vacuum Controller 521 ef, extern ............................................................................ 12

3.2 Overview of the variants ......................................................................................................... 13

3.3 Areas of Application ................................................................................................................ 13

3.4 Scope of Delivery .................................................................................................................... 13

3.5 Examples of application .......................................................................................................... 14

3.6 Accessories ............................................................................................................................. 16

4 Technical Data ....................................................................................................................... 18

4.1 View of device and dimensions............................................................................................... 18

4.2 Intake Pressure / Pumping Speed – Diagram ........................................................................ 18

4.3 Device data ............................................................................................................................. 19

4.3.1 Laboratory Vacuum Systems .................................................................................................. 19

4.3.2 Vacuum Controller 521 ........................................................................................................... 21

5 Assembly and Installation .................................................................................................... 22

5.1 Unpacking ............................................................................................................................... 22

5.2 Installation and Connection ..................................................................................................... 22

5.3 General instructions ................................................................................................................ 22

5.4 Storage .................................................................................................................................... 23

5.5 Scrap Disposal ........................................................................................................................ 23

6 Operation ............................................................................................................................... 24

6.1 LVS without vacuum controller ............................................................................................... 24

6.2 LVS with vacuum controller .................................................................................................... 24

6.3 Operating modes of the Controller .......................................................................................... 24

6.3.1 Mode 1, Manual operation ...................................................................................................... 24

6.3.2 Mode 2, Automatic operation .................................................................................................. 24

6.3.3 Mode 3, Ultimate pressure ...................................................................................................... 25

6.3.4 Mode 4, Self cleaning ............................................................................................................. 25

6.4 Monitoring by Level Sensor .................................................................................................... 25

6.5 Calibrating the Pressure Sensor ............................................................................................. 25

6.6 Handling .................................................................................................................................. 25

6.6.1 Control panel ........................................................................................................................... 25

6.6.2 Operating via Buttons and Encoder ........................................................................................ 26

6.6.3 Menu Guidance ....................................................................................................................... 26

Contents

4 115041

6.7 Electrical parameters.............................................................................................................. 31

6.7.1 Printed circuit board – Layout and Connections .................................................................... 31

6.7.1.1 Electrical Interfaces ................................................................................................................ 31

6.7.2 Software-Update .................................................................................................................... 34

6.8 Operation using the "WELCH-Control 521" PC program ....................................................... 35

6.8.1 Menu item: „File“ .................................................................................................................... 36

6.8.2 Menu item: „Settings!“ ............................................................................................................ 37

6.8.3 Menu item: „Calibrate“ ............................................................................................................ 39

6.8.4 Menu item: „Factory settings“ ................................................................................................. 40

6.9 Table of solvents .................................................................................................................... 41

7 Maintenance and Servicing ................................................................................................. 42

7.1 General Requirements ........................................................................................................... 42

7.2 Maintenance Performed by the User ..................................................................................... 42

7.2.1 Maintenance of the diaphragm pump ..................................................................................... 42

7.2.1.1 Disassembly ........................................................................................................................... 43

7.2.1.2 Assembly ................................................................................................................................ 43

7.2.1.3 Test......................................................................................................................................... 44

7.2.2 Maintenance of the vacuum controller ................................................................................... 44

7.2.3 Maintenance of other components ......................................................................................... 44

7.3 Maintenance by the Manufacturer .......................................................................................... 44

7.4 Damage Report ...................................................................................................................... 44

8 Troubleshooting ................................................................................................................... 45

9 Spare Parts Overview .......................................................................................................... 46

9.1 Service kit – Diaphragm Pump ............................................................................................... 46

9.2 Spare parts – Laboratory-Vacuum-Systems, unregulated + manually regulated .................. 47

9.3 Spare parts – Laboratory-Vacuum-Systems, automatically regulated ................................... 52

9.4 Spare parts – Laboratory-Vacuum-Systems, ecoflex ............................................................ 55

9.5 Spare parts – Laboratory-Vacuum-Systems, economic ........................................................ 59

9.6 Spare parts – Diaphragm pumps ........................................................................................... 61

- Instructions for certification - Laboratory-Vacuum-Systems LVS -

for use in Zone 2 in accordance with device category 3 per ATEX Directive 2014/34/EU

(Page 1- 3)

- EC Declaration of Conformity

Important Information

115041 5

1 Important Information

1.1 General Information

The Laboratory-Vacuum-Systems conform to the:

2006 / 42 / EC

Machinery Directive

2014 / 30 / EU

Electromagnetic Compatibility Directive

2014 / 34 / EU

ATEX Guideline for use in potentially explosive atmospheres,

Appendix III

The CE sign is located on the rating plate. Observe the binding national and local regulations

when fitting the pump into installations.

Our products are sold worldwide and can therefore be equipped with the typical national

plugs and for the various voltages. You will find more information about the available pump

designs on our web page in the internet.

1.2 Target Groups

This Operating Manual is intended for the personnel planning, operating and maintaining

Laboratory-Vacuum-Systems. This group of people includes:

Designers and fitters of vacuum apparatus,

Employees working on commercial laboratory and industrial vacuum technology applica-

tions and

Service personnel for laboratory-vacuum-systems.

The personnel operating and maintaining the laboratory vacuum systems must have the

technical competence required to perform the work that has to be done.

The user must authorize the operating personnel to do the work that has to be done.

The personnel must have read and understood the complete Operating Manual before using

the laboratory-vacuum-systems.

The Operating Manual must be kept at the place of use and be available to the personnel

when required.

1.3 Intended Use

The laboratory-vacuum-system may only be operated under the conditions stated

– in the "Technical Data" section,

– on the type plate, and

– in the technical specification for the order concerned.

Laboratory-vacuum-systems are approved for extracting, pumping and compressing

gases and vapours. If these gases and vapours are toxic or explosive, then the user must

observe the currently valid safety regulations for this application. Special types of diaphragm pumps are available for aggressive and explosive gas mixtures.

Laboratory-vacuum-systems are intended for generating vacuums with ultimate pressures of around 8 mbar.

The in-built diaphragm pump has been designed to have high resistance to aggressive

gases.

1.4 Use for an Unauthorized Purpose

It is forbidden to use the pump for applications deviating from the technical data stated on

the type plate or the conditions stated in the supply contract, or to operate it with missing or

defective protective devices.

Important Information

6 115041

1.5 Safety Devices

Measures such as the following are for the safety of the operating personnel:

electrical connection with a protective conductor (operating mode S1) and an earthing

plug,

Motor protection switch (thermal),

“Hot Surface" label on the pump body - warning notice

motor hood on the motor fan and

glass components with a transparent plastic coating which protects them against bursting

and cracking

The laboratory-vacuum-system must not be operated without these elements.

1.6 Meaning of the Warning notes

Take note of the warning notices. They are in the following box:

CAUTION ! / WARNING !

Hazard which may lead to serious injuries or material damage.

1.7 Product Standards, Safety Regulations

Laboratory-Vacuum-Systems meet the following product standards:

DIN EN ISO 12100:2011-03

Safety of machinery General principles for design - Risk assessment and risk reduction

DIN EN ISO 13857:2008-06

Safety of machinery - Safety distances to prevent hazard zones being reached

by upper and lower limbs

DIN EN 1012-2:2011-12

Compressors and vacuum pumps - Safety requirements Part 2: Vacuum pumps

DIN EN ISO 2151:2009-01

Acoustics - Noise test code for compressors and vacuum pumps - Engineering

method (grade 2)

DIN EN 60204-1:2014-10

Safety of machinery - Electrical equipment of machines Part 1: General requirements

DIN EN 61000-6-2:2011-06

DIN EN 61000-6-4:2011-09

Electromagnetic compatibility (EMC) Part 6-2: Generic standards - Immunity for industrial environments

Part 6-4: Generic standards - Emission standard for industrial environments

DIN EN 61010-1/A1:2015-04

Safety requirements for electrical equipment for measurement, control and

laboratory use - Part 1: General requirements

DIN EN 50110-1:2014-02

Operation of electrical installations

DIN EN 1127-1:2011-10

Explosive atmospheres - Explosion prevention and protection Part 1: Basic concepts and methodology

DIN EN 13463-1:2009-07

DIN EN 13463-5:2011-10

Non-electrical equipment for use in potentially explosive atmospheres Part 1: Basic method and requirements

Part 5: Protection by constructional safety 'c'

Directive 2012/19/EU

Electrical and electronics - old devices (WEEE)

Directive 2011/65/EU

Dangerous materials in electrical and electronics devices (RoHS II)

China - RoHS II

Environment protection law - China 2016-01

The following additional safety regulations apply in the FR Germany:

BGV A3

Electrical equipment and operating materials

VBG 5

Power-driven machines

BGR 120

Guidelines for laboratories

BGI 798

Hazard assessment in the laboratory

BGG 919 (VBG 16)

Accident prevention regulations for "compressors"

BGR 189 (BGR 195;192;197)

Use of protective working clothes

Observe the standards and regulations applying in your country when you use the laboratory-vacuum-systems.

Basic Safety Instructions

115041 7

2 Basic Safety Instructions

2.1 General Information

CAUTION !

Warning notices must be observed. Disregarding them may lead to damage to health

and property.

The Laboratory-Vacuum-Systems must be operated by personnel who can detect impending

dangers and take action to prevent them from materialising.

The user/operator is responsible for correct installation and safe operation.

Prevent condensate collecting in the pump. When pumping vapours which tend to condense

please ensure that the pump is at operating temperature and that the gas ballast valve is

open when the pump is switched on.

If there is more than one load on one LVS, they must be separated by check valves.

After finishing work with the diaphragm pump, run it for about 10 minutes with an open gas

ballast valve.

The manufacturer or authorized authorised workshops will only service or maintain the Labo-

ratory-Vacuum-System if it is accompanied by a fully completed damage report. Precise information about the contamination (also negative information if necessary) and thorough

cleaning of the Laboratory-Vacuum-Systems are legally binding parts of the contract.

Contaminated Laboratory-Vacuum-Systems and their individual parts must be disposed of in

accordance with the legal regulations.

The local regulations apply in foreign countries.

2.2 Electricity

The Laboratory-Vacuum-Systems are supplied for operating mode S1. Please note that the

testing must be repeated in accordance with DIN EN 0105, DIN EN 0702 and BGV A2 in

case of portable devices.

The local regulations apply in foreign countries.

Please note the following when connecting to the electrical power supply system:

The electrical power supply system must have a protective connector according to DIN

VDE 0100-410 (IEC 60364-4-41).

The protective connector must not have any breaks.

The connecting cable must not be damaged.

All interfaces are under low voltage according to DIN VDE 0100-410.

Basic Safety Instructions

8 115041

2.3 Mechanical Systems

Improper use can lead to injuries or material damage. Observe the following instructions:

Only operate the Laboratory-Vacuum-Systems with hoses of the specified dimensions.

The maximum permissible pressure of 1 bar at the suction connection must not be ex-

ceeded.

Hazardous substances must be separated out as far as this is technically possible before

they reach the pump.

External mechanical stresses and vibrations must not be transmitted to the pump. Only

use flexible laboratory hoses for connecting Laboratory-Vacuum-Systems.

The overpressure generated at the pressure port must not exceed 1 bar.

The pump must not be used to suck up fluids. Lay the exhaust pipe so that it slopes

downwards, so allowing condensate to flow out of the pump. Collect the condensate and

dispose of it in an environmentally compatible manner.

CAUTION !

Solid particles in the pumping medium impair the pumping action and can lead to

damage. Prevent solid particles penetrating into the pump.

When handling glass vessels, pay attention to:

Only use glass vessels with a plastic coating for splinter protection.

Only use vessels which are suitable for use with vacuums (e.g. round-bottomed flasks).

We recommend that only glass components supplied by the manufacturer are used.

Do not use Erlenmeyer flasks.

Before each evacuation, check glass vessels for damage which might impair their

strength, replace them if any such damage is found.

Do not heat glass vessels on one side only.

Retardation of the boiling of the gases to be pumped can lead to a sudden pressure in-

crease. Prevent retardation of boiling by means of suitable measures (e.g. turbulent agitation).

2.4 High Temperatures

The diaphragm pump may heat up as a result of the temperature of the gas being pumped

and through compression heat.

Prevent the following maximum permissible temperatures from being exceeded.

+ 40 °C for the environment, and

+ 60 °C for the gas to be pumped.

The motor for single phase alternating current is protected against overload by an integrated

motor protection switch.

Basic Safety Instructions

115041 9

2.5 Hazardous Substances

The operating company bears the responsibility for the use of the Laboratory-VacuumSystem.

Hazardous and harmful substances must be effectively prevented from escaping.

Ensure that all lines and connections are leak tight.

Handle exhaust gases in accordance with the requirements of the emission protection regulations.

Do not operate the Laboratory-Vacuum-System without a separator and without a emission

condenser. The separator can only be emptied after the apparatus has been vented.

Dispose the condensate in an environmentally compatible manner!

The emission condenser has a safety valve. The air evacuation duct with hose must be kept

clear and lead into a suitable air evacuation duct. Throttling the air evacuation duct can

damage the valves of the diaphragm pump.

Hazardous substances in the gases to be pumped can cause personal injuries and property

damage. Pay attention to the warning notices for handling hazardous substances.

The local regulations apply in foreign countries.

Combustible Gases

Examine before switching on whether that can form gas combustible gas/air mixtures which

can be promoted! Also perform this test with a number of loads connected to one LVS.

Consider the regulations of the guideline 1999/92/EC.

Explosive gases

The diaphragm pumps of the series MPC are certified according to ATEX guidelines

2014/34/EU, device category 3, valid for the gas contacting parts (interior) of the pump.

Aggressive gases

An MPC series diaphragm pump is used for extracting vapours and aggressive gases.

The warranty shall lapse if the LVS is used with diaphragm pumps from other manufacturers.

Especially aggressive gases have to be explicitly checked for material resistance as de-

scribed in chapter 3.1.2 and, if necessary, modified.

Poisonous gases

Use a separator when pumping poisonous or harmful gases. Prevent such substances from

leaking out of the appliance or pump. Treat these substances according to the applicable

environmental protection regulations.

The diaphragm pump, control valves and hose lines can be damaged by poisonous or aggressive gases.

Test the strength and leak-tightness of the connecting lines and the connected apparatus.

Prevent environmental poisons, e.g. mercury, getting into the diaphragm pumps.

Fulfil the requirements, for example:

German Hazardous Substances Regulation (GefStoffV) of 01. December 2010

Regulations 2016/1179/EU

(classification, packaging and identification of hazardous sub-stances),

Manufacturer's safety data sheets on hazardous substances.

Description

10 115041

3 Description

3.1 Design and Function

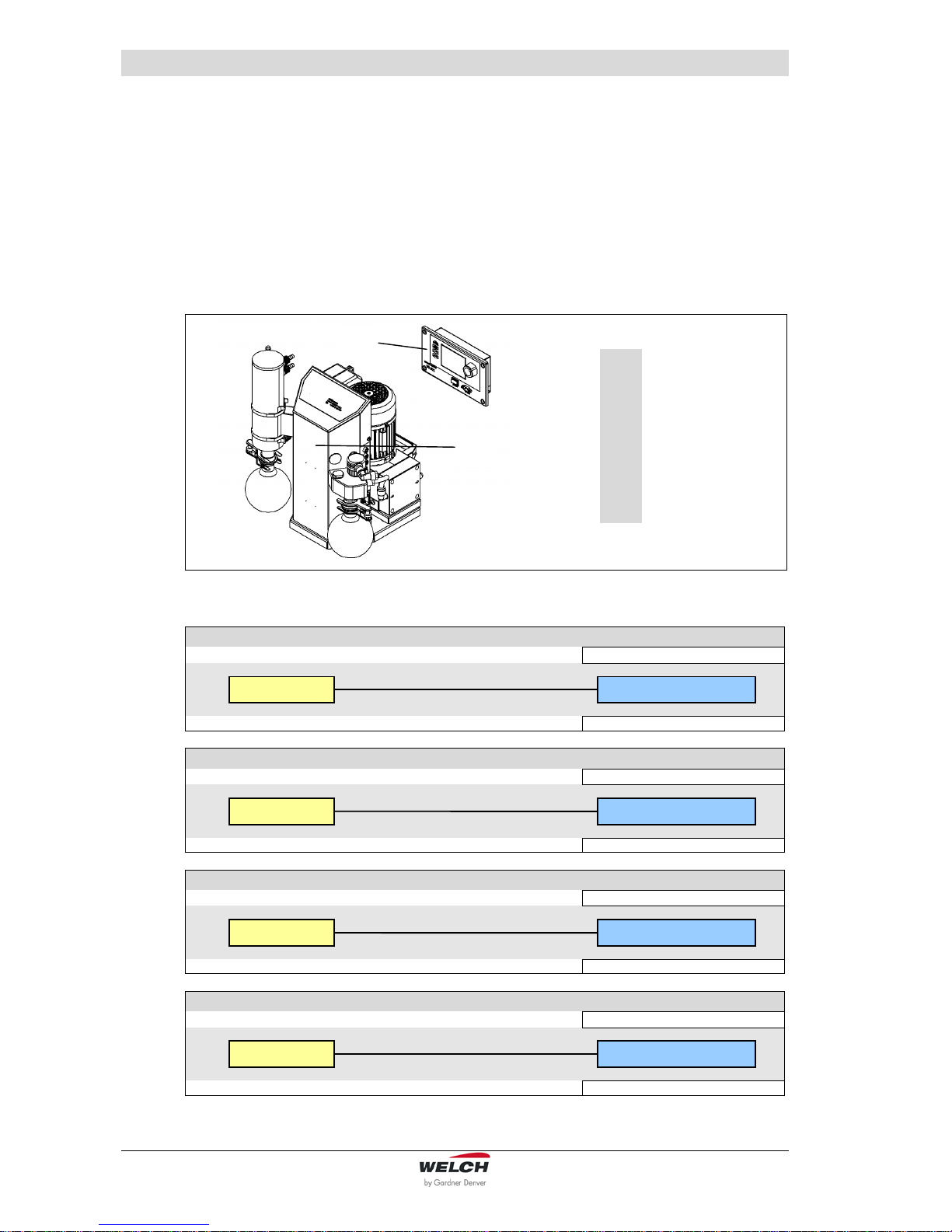

3.1.1 Laboratory-Vacuum-Systems

The Laboratory Vacuum Systems are supplied as a ready-mounted unit.

The chemical-resistant diaphragm pump (4) with gas ballast valve (17) is fitted to the base

plate of the column (3) and attached on the suction-side to the separator (7) to protect the

pump from foreign matter and on the pressure-side to the emission condenser (6) to recover

the condensate. This ensures that hazardous substances are separated out. The safety

valve on the emission condenser protects against an impermissibly high operating pressure

on the outgoing air end.

The complete vacuum controller, with sensor, venting valve and power unit (5), is fitted in the

column (3). The LVS 310 Z ef, order no. 115244-04, is an exception. In this case, the vacuum controller is available as an external device for installation in laboratory furniture, see

chapter 3.1.4. The manually regulated LVS-variant does not have a controller.

All exposed glass components (6, 7) are coated with transparent plastic as protection

against bursting. The emission condenser is supplied with insulation.

The power switch (12) and the plug for the power cable (11) as well as the membrane pump

(10), the PC (13) control lead (14), inert gas (16) and the water valve (option) (15) are located on the right of the column.

The LVS types are specially preconfigured according to model.

1

Suction side connection

hose nozzle for hose DN8

Fig. 1a LVS 310 Z - Front view

2

Control valve

(LVS - automatically regulated)

3

Column complete

on swivelling foot

4

Diaphragm pump MPC 301 Z

5

Vacuum controller 521

(in the column or extern)

6

Emission condenser KD 500/5 insulated

at the pressure side with safety valve

and cooling water connections

7

Separator

(round-bottomed flask) suction side

8

Cooling water (feed flow/back flow)

Fig. 1b LVS 310 Z - Rear view

9

Connection outgoing air

hose nozzle for hose DN8

10

Connection Pump (pump)

11

Connection non-heating device power

cable (main in)

12

Main switch (power)

13

Connection PC (RS 232)

14

Connection control cable

LVS - automatically regulated (sensor)

15

Connection water valve

16

Connection inert gas

17

Gas ballast valve

Description

115041 11

3.1.2 Diaphragm pump

► Design:

The diaphragm pump consists of a pump body and a drive motor. The pump body consists

of a drive shaft and two pump heads. Both pump head contains a diaphragm and the work

valves. The two pump heads are arranged opposite each other.

In the two-stage (Z) diaphragm pump, both pump heads are connected in series.

The pump heads are driven via an eccentric shaft with a connecting rod.

► Function:

Motor, eccentric shaft and connecting rod set the diaphragms in stroke movement. This

changes the size of the space between the diaphragms and pump head (pump chamber).

Increasing the size of the pump chamber opens the inlet valve while the outlet valve is

closed (intake process). Decreasing the size of the pump chamber ejects the gas through

the outlet valve.

The valves are actuated by the gas being pumped. A large proportion of fluid in the diaphragm pump minimizes the pumping efficiency.

► Materials of the medium-affecting pump parts:

Component

Materials

Seal

EPDM

Screw fitting / Connecting elements

PP, PVDF

Valve

PEEK

Diaphragm

Elastomer + PTFE layer

Vacuum hose

PTFE

Connection head / pump head

PTFE with carbon-fibre reinforcing

*)

*)

electrically conductive (with manufacturer's certificate of electrical conductivity)

Material resistance to aggressive media see: Publisher Hoppenstedt Publishing

(18. September 2007)

► Gas ballast:

When condensable vapours are pumped,

they may be compressed above the

saturated vapour pressure and condense.

Opening the gas ballast valve (17) in the

suction line of the last pump stage allows

air to flow into the pump chamber.

This prevents condensation and flushes

the pump clear.

Operation leads to increasing the ultimate

pressure and the operating temperature.

Fig. 2 Diaphragm pump MPC 301 Z

Description

12 115041

3.1.3 Vacuum Controller 521, intern

In the case of controlled models for laboratory vacuum systems LVS, the vacuum controller,

complete with sensor, venting valve and power unit, is fitted in the device column. The operating and display elements are on the top surface of the column.

(Description and operation see chapter 6, Technical data see chapter 4.3.1)

3.1.4 Built-in – Vacuum Controller 521 ef, extern

The LVS 310 Z ef (Order no. 115244-04) is equipped with an external vacuum controller for

installation in, for example, laboratory furniture.

Over the cable to the device, the electrical connection is made.

1

Built-in –

Vacuum Controller

extern

2

LaboratoryVacuum-System

LVS

► Electrical Installation - Built-in – Vacuum Controller 521 ef extern:

K1 Sensor + Venting valve

on the pump - rear panel

Controller

Coupling plug 5 pole

Order no. 600052-06

K2 24 V DC + Water valve

on the pump - rear panel

Controller

Coupling plug 4 pole

Order no. 600052-06

K3 Frequency converter

on the frequency converter - motor

Controller

Coupling plug 4 pole

Order no. 600052-06

K4 Fill level sensor o p t i o n

on sensor fill level

Controller

Order no. 600052-06

4 m

4 m

4 m

4 m

2

1

Description

115041 13

It has the same function as the LVS with a standard assembly. It is operated, as similarly described, via an externally installed controller. On the controller is the on / off power switch

and the RS 232 interface. (see also chapter 9.4)

Dimensions for installation

in laboratory furniture:

3.2 Overview of the variants

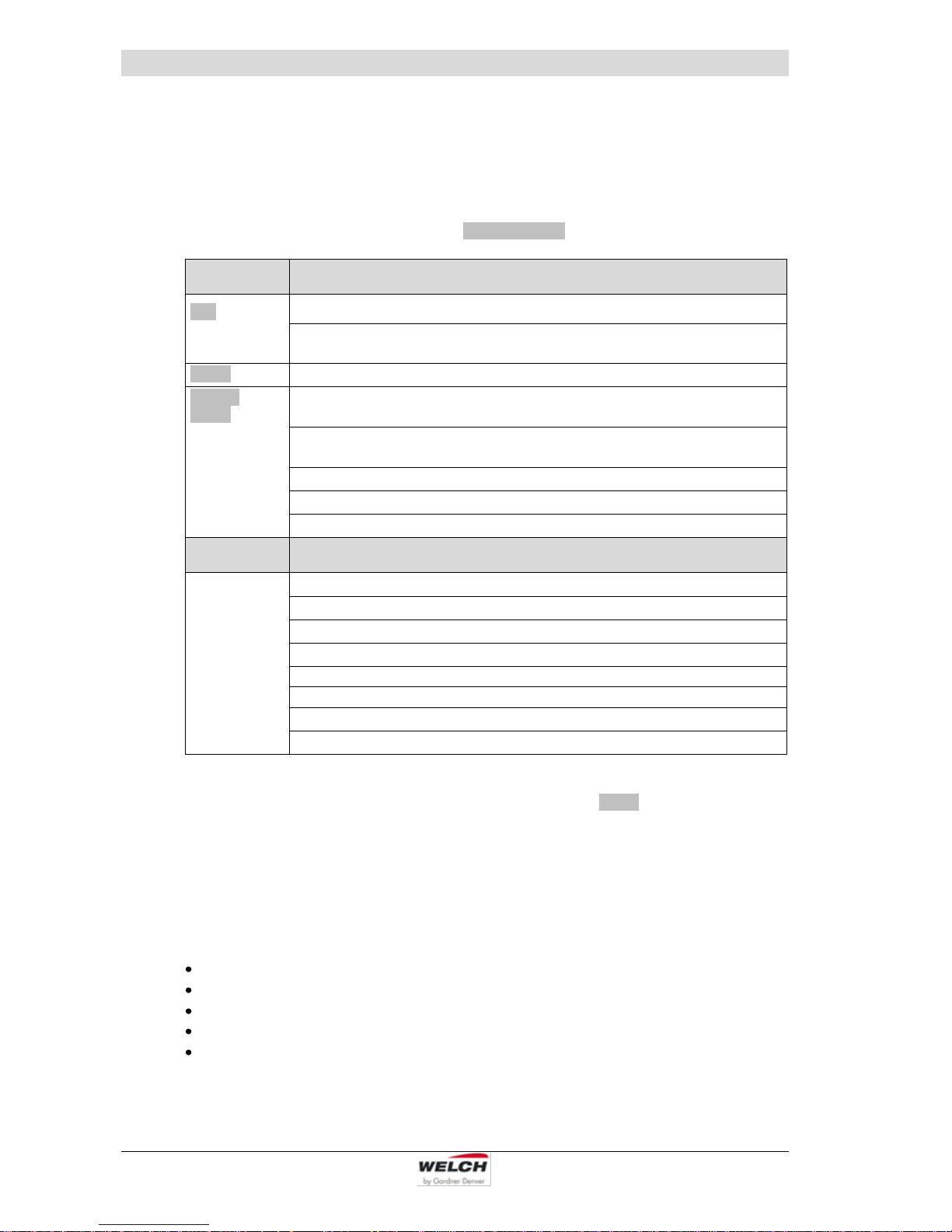

Part

Laboratory-Vacuum-Systems LVS

Piece per LVS

300 Z

301 Z

302 Z

310 Z

311 Z

310 Z ef

310 Z en

Suction side

connections for hose DN 8

1

un-

regulated

1

manually

regulated

2

manually

regulated

1

automati-

cally regu-

lated

1 automatically +

1 manually

regulated

1

ecoflex

regulated

1

economic

regulated

Control valve

- - - 1 1 - -

Column complete

1 1 1 1 1 1 1

Diaphragm pump

1 1 1 1 1 1 1

Vacuum controller 521

- - -

1 (cv)

1 (cv)

1 (ef)

1 (en)

Emission condenser

- 1 1 1 1 1 1

Separator 2 1 1 1 1 1

1

Pressure side

connection for hose DN 8

1 1 1 1 1 1 1

Frequency changer

- - - - - 1 -

Special variants, additional with:

- Dial gauge analog

- 1 - - - - -

- Clamping ring screw

A 10 (netvac 1)

- 1 - 1 - 1 1

- Built-in Controller 521

- - - - - 1 -

3.3 Areas of Application

The Laboratory-Vacuum-Systems is intended for:

vacuum filtration, vacuum distillation and vacuum drying

use in physical and chemical laboratories in trade and industry

pumping and compressing neutral and aggressive gases and vapours

generating a vacuum up to an ultimate pressure of < 8 mbar

► Special designs:

Special LVS can be supplied after consultation with the manufacturer or for a corresponding supply

contract.

Motors for different voltages.

3.4 Scope of Delivery

The scope of delivery is specified in the supply contract.

Description

14 115041

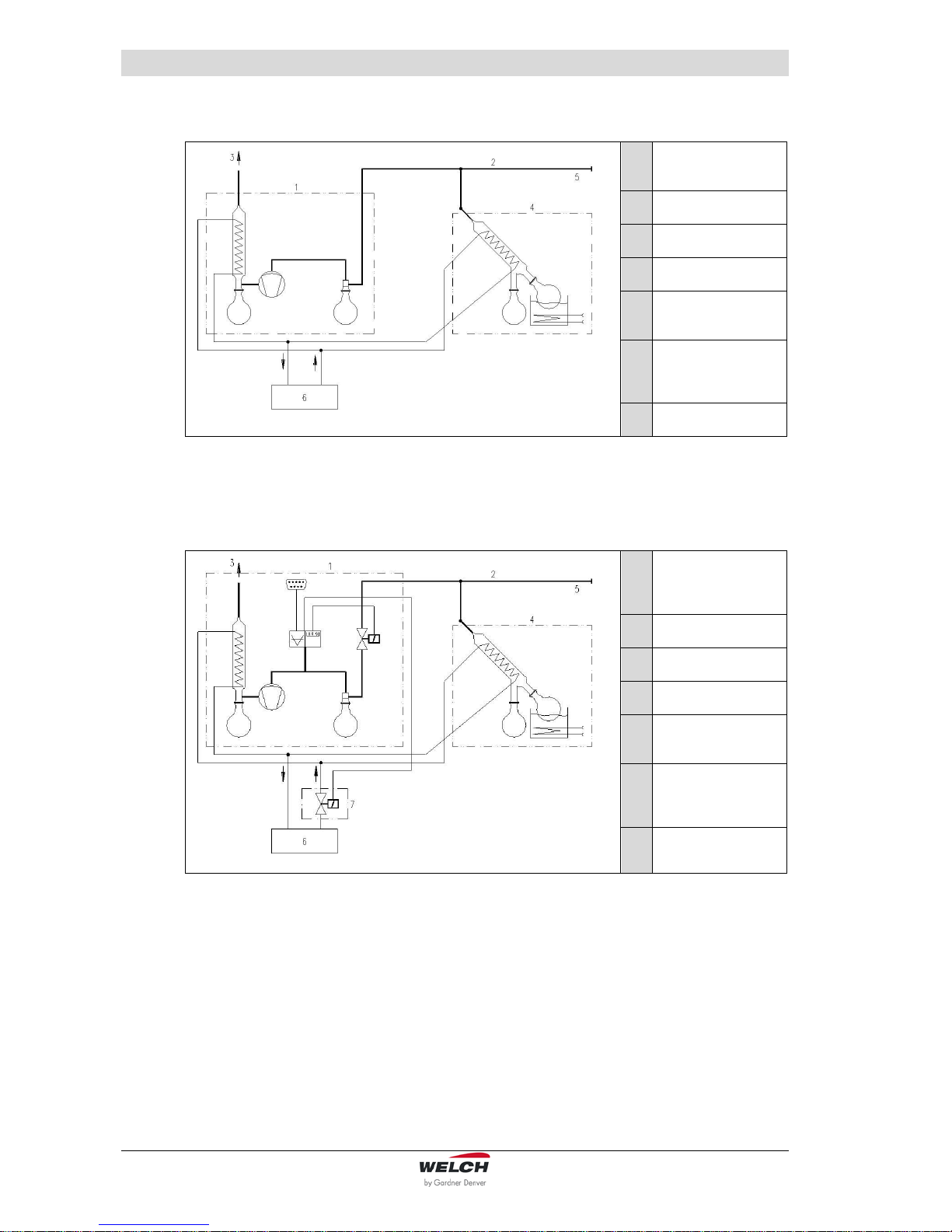

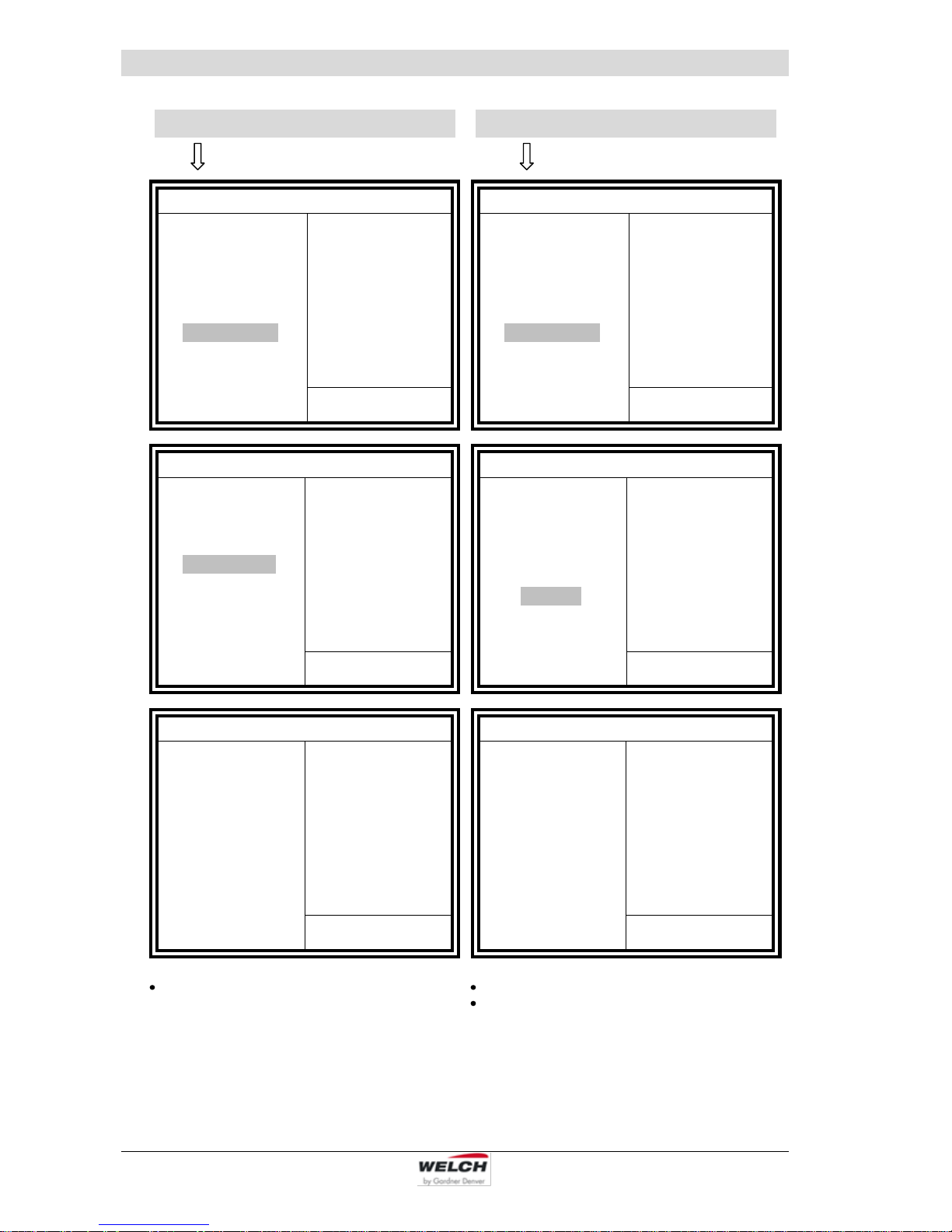

3.5 Examples of application

1

LVS without

vacuum controller

2

Suction line *

3

Outgoing air

4

Rotary vaporizer *

5

Capable of expansion up to 4 loads

6

Coolant system,

un pressurised run

back *

7

Water valve WV *

Fig. 3 Example of application - LVS manually regulated

1

LVS with vacuum

controller and

control valve (cv)

2

Suction line *

3

Outgoing air

4

Rotary vaporizer *

5

Capable of expansion up to 4 loads

6

Coolant system,

un pressurised run

back *

7

Water valve WV *

Fig. 4 Example of application – LVS „cv“ (Control valve) automatically regulated

* Not included in the scope of delivery

Description

115041 15

1

LVS ef (ecoflex)

2

Suction line *

3

Outgoing air

4

Rotary vaporizer *

5

frequency-regulated

pump motor

6

Coolant system,

un pressurised run

back *

7

Water valve WV *

Fig. 5 Example of application – LVS „ef“ ecoflex

1

LVS en (economic)

2

Suction line *

3

Outgoing air

4

Rotary vaporizer *

5

Capable of expansion up to 4 loads

(depending on the

suction capacity)

6

Coolant system,

un pressurised run

back *

7

Water valve WV *

Fig. 6 Example of application – LVS „en“ economic

CAUTION !

The economic Laboratory Vacuum System "LVS ... en" is suitable for slow

processes and central laboratory supplies using a large hysteresis (< 50 mbar).

When installing the switch interval of the diaphragm pump is to be checked.

In practical applications the time-out must be at least 0.5 minutes.

The integrated pressure monitor guarantees immediate activation of the vacuum

generator when required.

This ensures continuous readiness of the vacuum system in the laboratory.

Description

16 115041

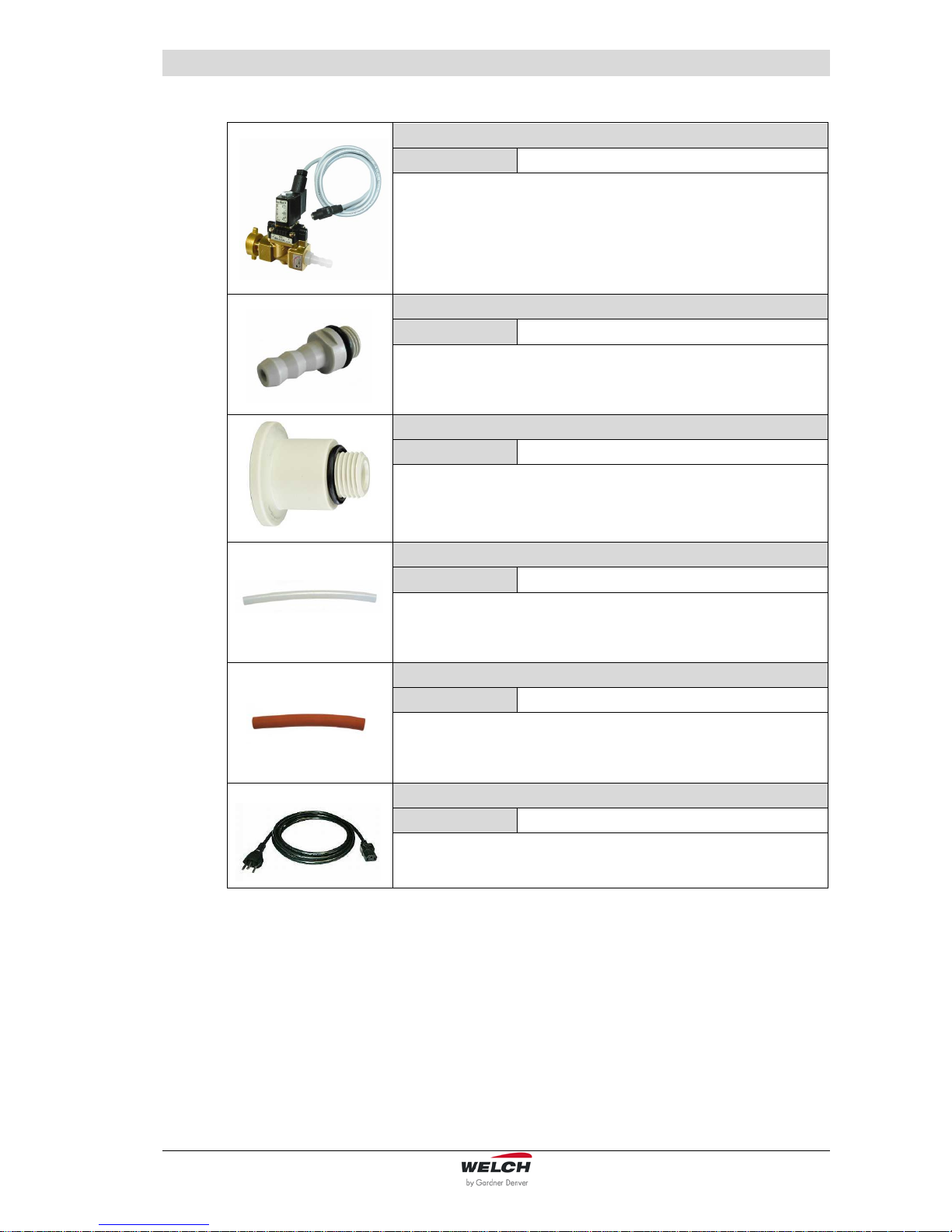

3.6 Accessories

The use of chemical-resistant vacuum connections “netvac +” is recommended for extending the application range of a vacuum generator to several workstations.

netvac +

Set BC1 - 63

Order no. 700563

for mounting

on wood furniture

Set BC2 - 63

Order no. 700563-01

for mounting

on sheet metal wall

with integrated FFKM-Check valve, Dosing valve, Hose nozzle

and Ball valve

Area of application: Laboratory

Suction connection: Hose DN 8-10

Connection thread: 1/4 "- outside

Material of valve body: Polypropylene (PP)

Dimensions (W/D/H): Ø 69 / 161 / 82 mm

Mounting hole: Ø 25 to Ø 35 mm

netvac +

Set BC1 - 62

Order no. 700562

for mounting

on wood furniture

Set BC2 - 62

Order no. 700562-01

for mounting

on sheet metal wall

with integrated FFKM-Check valve, Dosing valve and Hose nozzle

Area of application: Laboratory

Suction connection: Hose DN 8-10

Connection thread: 1/4 "- outside

Material of valve body: Polypropylene (PP)

Dimensions (W/D/H): Ø 69 / 69 / 82 mm

Mounting hole: Ø 25 to Ø 35 mm

Vacuum Control-Box

VCB 521 cv

Order no. 600053

Table model as digital, chemical-resistant vacuum regulator.

With integrated sensor, airing -, control- and check valve.

Connection vacuum apparatus: DN 8

Connection vacuum pump: DN 8

Connection inert gas: DN 4

Connection water valve: Binder plug 4-pole 24V DC

Operating software „WELCH-Control 521“

on CD

Order no. 620637

to connect the vacuum controller to the PC

Description

115041 17

Water valve

WV 2

Order no. 700300-02

2 way water flow valve for the demand-responsive cooling water

supply, mounting possible in any direction.

Input: G 3/4 inch sleeve nut

Output: Hose nozzle for hose inside diameters 8 mm

Hose nozzle with FKM - O-Ring

DN 10

Order no. 710955

Material: PP

Male thread: ¼“

Inlet fitting

DN 16 KF

Order no. 710116

Material: PP

Male thread: ¼“

Vacuum hose

10 / 8x1

Order no. 828332

Material: PTFE

Please state the length you want to order!

Vacuum hose

18 / 8x5

Order no. 828310-4

Material: Rubber, red

Please state the length you want to order!

Mains connection cable IEC with plug

Type 12 (CH)

Order no. 825877

for LVS … in 23O V

Technical Data

18 115041

4 Technical Data

4.1 View of device and dimensions

The main dimensions are identical for all types stated here.

Fig. 7 View of device (Model LVS 301 Z, dimensions see chapter 4.3

4.2 Intake Pressure / Pumping Speed – Diagram

Fig. 8 Intake Pressure / Pumping Speed – Diagram

(W)

(H)

(D)

Technical Data

115041 19

4.3 Device data

4.3.1 Laboratory Vacuum Systems

Parameter

Unit

LVS

300 Z

301 Z

302 Z

310 Z

311 Z

Pumping speed 50/60 Hz

DIN 28432

at speed of 1500 rpm

m3 / h

2.3 / 2.5

Ultimate pressure

at speed of 1500 rpm

mbar

8

Ultimate pressure

with gas ballast

at speed of 1500 rpm

18

Max. inlet pressure

bar

1

Max. outlet pressure

1

Intake and pressure ports

-

Hose nozzle DN 8

for hose inside diameter 8 mm

Ambient temperature

°C

+ 10 to + 40

Max. Operating

gas temperature

+ 60

Bearing

-

maintenance-free

Reference surface

sound pressure level

DIN EN ISO 2151

dB (A)

44

Voltage / Frequency

(different data upon

customer request)

V, Hz

230, 50/60 (115, 50/60)

(generally with motor protection switch, switch and cable)

Motor power

W

180

Operating mode

-

S 1

Motor / Type of protection

DIN EN 60529

IP 54

Motor / Class of insulation

DIN EN 600034-1

F (160°C)

Type Examination

Certificate no.

WELCH_ATEX_03-01

Designation EX

II3G IIC T3 X (internal Atm. only)

Dimensions (W/D/H)

mm

360 / 310

/ 395

360 / 310 / 445

Weight

kg

16.1

16.3

16.9

17.8

18.1

Order numbers for :

-

in 230 V

inclusive mains connection cable

IEC with plug CEE, UK

- LVS …

- LVS … with dial gauge analog

- LVS … netvac 1

115041

-

-

115047

115047-10

115047-02

115043

-

-

115044

-

-

115045

-

-

in 115 V

inclusive mains connection cable

IEC with plug US

- LVS …

- LVS … with dial gauge analog

- LVS … netvac 1

115041-01

-

-

115047-01

115047-11

115047-03

115043-01

-

-

115044-01

-

-

115045-01

-

-

in 100 V

inclusive mains connection cable

IEC with plug J

- LVS …

- LVS … with dial gauge analog

115041-05

-

115047-05

115047-12

115043-05

-

115044-05

-

115045-05

-

Technical Data

20 115041

Parameter

Unit

LVS 310 Z ef

LVS 310 Z en

Pumping speed 50/60 Hz

DIN 28432

at speed of 1500 rpm

m3 / h

2.6

2.3 / 2.5

Ultimate pressure

at speed of 1500 rpm

mbar

8

Ultimate pressure

with gas ballast

at speed of 1500 rpm

18

Max. inlet pressure

bar

1

Max. outlet pressure

1

Intake and pressure ports

-

Hose nozzle DN 8

for hose inside diameter 8 mm

Ambient temperature

°C

+ 10 to + 40

Max. Operating gas temperature

+ 60

Bearing

-

maintenance-free

Reference surface sound

pressure level

DIN EN ISO 2151

dB (A)

44

Voltage / Frequency

(different data upon customer request)

V, Hz

230, 50/60 (115, 50/60)

(generally with motor protection switch, switch and cable)

Motor power

W

180

Input Frequency changer

(Apparent power)

W / A

680 / 4.5

-

Operating mode

-

S 1

Type of protection (motor)

DIN EN 60529

IP 54

Motor / Class of insulation

DIN EN 600034-1

F (160°C)

Type Examination Certificate

no.

WELCH_ATEX_03-01

Designation EX

II3G IIC T3 X (internal Atm. only)

Dimensions (W/D/H)

mm

360 / 310 / 445

Weight

kg

19.9

17.8

Order numbers for LVS:

-

in 230 V

inclusive mains connection cable

IEC with plug CEE, UK

- LVS …

- LVS … netvac 1

- LVS … with built-in controller

VC 521 extern

115244

115244-03

115244-04

115248

-

in 115 V

inclusive mains connection cable

IEC with plug US

- LVS …

115244-01

115248-01

Technical Data

115041 21

4.3.2 Vacuum Controller 521

Parameter

LVS 310 Z

LVS 311 Z

LVS 310 Z ef

LVS 310 Z en

Unit

Sensor

integrated

Sensor type

ceramic sensor

-

Measuring range

1 - 1100

mbar

Measuring uncertainty

< ± 0.3 % FS

Controller

Sensor interface :

3 conductor interface

-

- Scan frequency

10

Hz

- Resolution ADC

12

Bit

- Power supply

+ 5 stabilized

V

- Sensor signal

0.5 to 4.5 (optionally also 4..20 mA per jumper possible)

Pressure indicator

digital and graphic

-

Switching accuracy / control

accuracy

±1

digit

Switching outputs :

digital

-

- Voltage level

0; 24

V

- Control power, single

2 x 6

W

- Control power, total

24

Switching outputs used :

3 2 3

-

- Control valve

x - -

- Ventilation valve

x x x

- Water valve x x

x

- Pump net connection

- - x

Frequency converter output :

-

analog

-

- Voltage level

-

0 to 10

-

V

- Resolution DAC

- 8 -

Bit

Communication interface

RS 232

-

Power consumption -

controller in normal operation

max. 15 (depends upon the control power)

W

Fuse (internal controller)

5

A

Power pack

integrated

Operating voltage

90 .. 260

V AC

Operating frequency

50 / 60

Hz

Output voltage

24

V DC

Output current

1.25

A

Output power

100

W

Entire unit

Protective system

IP 20

-

Working temperature

15 - 40

°C

Connections

IN/OUT: RS 232

SUB-D plug 9-pole

-

OUT: Control line for

frequency changer

-

Binder socket 4-

pole

0 - 10 V DC

-

OUT: Control valve

Control valve

integrated

-

-

OUT: Water valve

Binder socket 4-pole, 24 V DC

Connection: Inert gas

integrated, hose nozzle DN 4

The information presented in this material is based on technical data and test results of nominal units. It is believed

to be accurate and reliable and is offered as and aid to help in the selection of products.

It is the responsibility of the user to determine the suitability of the product for the intended use and the user assumes all risk and liability whatsoever in connection therewith. Gardner Denver Thomas GmbH does not warrant,

guarantee or assume any obligation or liability in connection with this information.

Assembly and Installation

22 115041

5 Assembly and Installation

5.1 Unpacking

Carefully unpack the Laboratory-Vacuum-System.

Check the system for:

Transport damage,

Conformity with the specifications of the supply contract (type, electrical supply data),

Completeness of the delivery.

Please inform us without delay if there are discrepancies between the delivery and the contractually agreed scope of delivery, or if damage is detected.

Please take note of the general terms of business of the manufacturing firm.

In case of a claim under warranty, the device must be returned in packaging that is

suitable for protecting it during transport.

5.2 Installation and Connection

Set the Laboratory-Vacuum-System on a flat and horizontal surface.

Remove the protective caps on the connections.

Connect the intake connector of the LVS to your apparatus with vacuum hose DN 8.

Connect the cooling water tube to the emission condenser.

The cooling water return flow must be unpressurized.

Connect the air exhaust to the central air exhaust system.

Connect the Laboratory-Vacuum-System to the power supply.

Check that the connections are properly seated.

5.3 General instructions

Observe the basic safety instructions when using the LVS.

The pressure device regulation 2014/68/EU must be observed if devices with an overpressure of 0.5 bar or more are connected.

The pressures at the intake and exhaust sides of the diaphragm pump at the time it is

switched on must correspond to the specifications of DIN 28432.

In order to avoid pumping speed losses, all the vacuum connecting hoses used should have

a large nominal diameter and should be laid out so that the lengths are as short as possible.

Avoid rigid connections. They must be assembled carefully in order to achieve a low leak

rate.

We recommend fitting non-return valves (order no. 720327) for applications with several

consumers.

The upstream separator on the intake-side serves to protect the diaphragm pump and the

vacuum sensor from condensates and mechanical contamination. It must be used for an application. The level in the separator must be monitored and the separator emptied regularly.

The currently valid regulations must be observed when disposing of waste. The separator on

the intake-side can only be removed and emptied after the system has been vented.

Assembly and Installation

115041 23

The emission condenser enables a 100 per cent recovery of the solvents led through the

vacuum pump. Cooling takes place via the DN 8 hose nozzles. Ensure that the outflow is

clear. The safety valve is located at the gas inlet. The rubber valve seal must be checked

for cracks at regular intervals and exchanged when necessary. The exhaust connection is

unpressurized. It can be led off through a DN 10 hose into a suitable evacuation duct. There

is common solvent reclamation for all the connected systems. Mixing media must not lead to

a hazard for persons, the environment of for the equipment.

Condensable vapours may only be extracted when the pump is at operating temperature.

When doing so, the gas ballast valve should be opened and/or a quantity of air, which is to

be calculated by the user, allowed to enter via the intake port valve. The pressure values

may be increased when doing so. The diaphragm pump's maximum tolerance of water vapour pressure can be improved or a cleaning run can be made after finishing work by opening the gas ballast valve (this significantly reduces the pumping speed and ultimate pressure). The vacuum ducts must always be laid sloping downwards so that condensates can

flow into the relevant separators.

In case of soiling by solid matter, the pump heads must be opened and the entire interior

space, including valves and diaphragm, cleaned mechanically (see chapter 7.2.1).

5.4 Storage

The pumps are to be stored in a low-dust, interior room within the temperature range from

+ 5 to + 40 °C and at a relative air humidity < 90%.

Leave the protective elements on the intake and exhaust ports. Another equally good protection may be used.

5.5 Scrap Disposal

CAUTION !

The Laboratory-Vacuum-Systems must be disposed of in accordance with the

2012/19/EU guideline and the specific national regulations.

Contaminated pump systems must be decon taminated according to the laws.

Operation

24 115041

6 Operation

6.1 LVS without vacuum controller

Switch the device (LVS 300 Z, LVS 301 Z, LVS 302 Z) on using the main switch. Vacuum is

generated immediately and without regulation. Over the regulating valves on the LVS 302 Z

it is possible two customers concomitant to connect.

6.2 LVS with vacuum controller

The LVS is switched on by the rocker switch POWER located on the device.

The device is ready for operation after a short initializing routine, during which a signal tone

sounds and all light elements light up briefly.

In the version LVS with external controller (Order no. 115244-04) is the on / off power

switch on the controller.

6.3 Operating modes of the Controller

The following modes are available:

0 -

STOP

Controller is inactive and can be configured

1 -

Manual operation

With specification of the setpoint and, if required, lowering

2 -

Automatic operation

The setpoint is detected automatically from the pressure development

3 -

Ultimate pressure

Pumping out at maximum motor output

4 -

Self cleaning

Motor runs for 2 minutes at open ventilation valve

6.3.1 Mode 1, Manual operation

The vacuum valve is closed when the pressure reaches the setpoint. Closed-loop control between the set hysteresis and the setpoint has been started.

For operation with a frequency converter, an analog voltage is output, which controls the

speed according to the standard tolerance. If the set pressure is not reached, the speed is

automatically adjusted to the pressure loss.

If the pressure is actively lowered, after the setpoint has been reached for the first time, it is

lowered still further within a settable timeframe. The number of ramps can be set up to a

maximum of 3. Each ramp starts with a holding time. The setpoint then falls in one step to

the defined starting pressure. The setpoint then falls to the final value over the set time.

After the last ramp, there is a waiting time until the automatic STOP

(0 – the last set pressure is held indefinitely until STOP is pressed manually).

CAUTION !

When setting the ramps make sure that the set value is greater than or equal to the

starting value of the first ramp.

The closed-loop control and hysteresis are always related to the current (reduced) setpoint.

The changed setpoint always applies until the STOP button is pressed, then the configuration value applies once more. When the pressure reduction has finished, the control is

stopped, and the system waits until the STOP button is pressed.

6.3.2 Mode 2, Automatic operation

After selection of the operating mode, the controller starts the evacuation. The pressure drop

per minute is determined during this process. If increases during distillation by incipient boiling of the pressure, then this pressure value is taken as the setpoint and proceeds in the

normal control operation.

Operation

115041 25

6.3.3 Mode 3, Ultimate pressure

By pressing of the key P min evacuation takes place at maximum pump speed until the user

presses STOP.

6.3.4 Mode 4, Self cleaning

The Mode "Self cleaning" is used for flushing the pump and can, if desired, also be carried

out several times in succession. After a waiting period of 5 seconds, the evacuation for 2

minutes (at maximum pump power and open vent valve) is carried out. A aborting the process at any time by pressing the encoder (4) possible.

Self cleaning for Controller-version „cv“: The control valve (cv) remains closed when the

mode Manual or Automatic the "ventilation at STOP" parameter = "0".

6.4 Monitoring by Level Sensor

If the level sensor input is activated (optional), the device goes into STOP status when "Tank

full" is signalled.

6.5 Calibrating the Pressure Sensor

A two-point calibration is made with a comparison measurement device.

Calibration at ambient pressure:

Calibration at ultimate pressure:

- The diaphragm pump is switched off.

- The diaphragm pump is switched on.

- The venting valve is open.

- The venting valve will be closed.

- The vacuum valve is closed.

- The vacuum valve will be open.

- The ambient pressure to set.

- The ultimate pressure to set.

CAUTION !

Instead of measuring the pressure with a comparison measurement device, the ultimate pressure of the pump used may also be input if this is known with sufficient

accuracy (take note of evacuation time).

Ensure that the set pressure is also present at the sensor.

6.6 Handling

6.6.1 Control panel

1

START - STOP

4

2

AIR - ventilation

3

P min - pressure drop

5

Encoder (turn / press)

with marking point on encoder

Display

Fig. 9 Control panel

Operation

26 115041

6.6.2 Operating via Buttons and Encoder

The menu is operated with the encoder.

The menu option is selected by turning the encoder anticlockwise, and then confirmed by

pressing.

A pop-up window is provided for changing numerical values. They are accepted by pressing

the encoder.

The process can be cancelled by pressing START - STOP.

Key:

Meaning

AIR

- Switches the venting valve on if the control is inactive.

- Opens the venting valve as long as the button remains pressed while

control is active.

P min

- Starts "ultimate pressure" mode directly.

START

STOP

- Starts the operating mode currently selected in the main menu and the

corresponding set value.

- Starts the operating mode manually with the currently selected setpoint

in the solvent table, see chapter 6.9.

- Stops the active mode

- Cancels the input in the pop-up window.

- Jumps back to the main menu from submenus.

Encoder:

Meaning

- Turn to select the operating mode.

- Press to select the setting menu for the corresponding operating mode.

- Turn to select menu items.

- Press to open Change pop-up window.

- Turn to change values.

- Press to confirm the changed value.

- When active: Turn to change setpoint.

- When active: Press to accept current value as setpoint.

After the current operating mode has been stopped by pressing STOP, the vacuum valve is

closed.

The venting valve takes the selected status (Option: AIR_ON_STOP).

The originally selected values are retained on start.

6.6.3 Menu Guidance

After the start, the main menu appears with its 5 submenus, which are shown below:

Manual

Automatic

Low pressure

Configuration

Self cleaning

Operation

115041 27

Configuration: language

Configuration: display settings

MAIN-MENU

Manual

Automatic

Low pressure

Configuration

Self cleaning

VCZ 521

V 1.15

P = 960 mbar

Configuration

language

display settings

pressure unit

calibrate

back

VCZ 521

V 1.15

P = 960 mbar

language

English

Deutsch

Français

Español

back

VCZ 521

V 1.15

P = 960 mbar

MAIN-MENU

Manual

Automatic

Low pressure

Configuration

Self cleaning

VCZ 521

V 1.15

P = 960 mbar

Configuration

language

display settings

pressure unit

calibrate

back

VCZ 521

V 1.15

P = 960 mbar

display settings

contrast

brightness

display interval

min. pressure

max. pressure

back

VCZ 521

V 1.15

P = 960 mbar

Select one of the available languages

Select contrast in the display

Select brightness in the display

Graphic display:

– Number of measurements per second

– Display of min. pressure

– Display of max. pressure

Operation

28 115041

Configuration: pressure unit

Configuration: calibrate

MAIN-MENU

Manual

Automatic

Low pressure

Configuration

Self cleaning

VCZ 521

V 1.15

P = 960 mbar

Configuration

language

display settings

pressure unit

calibrate

back

VCZ 521

V 1.15

P = 960 mbar

pressure unit

mbar

torr

psi

hPa

back

VCZ 521

V 1.15

P = 960 mbar

MAIN-MENU

Manual

Automatic

Low pressure

Configuration

Self cleaning

VCZ 521

V 1.15

P = 960 mbar

Configuration

language

display settings

pressure unit

calibrate

back

VCZ 521

V 1.15

P = 960 mbar

calibrate

Cal. Start pressure

Cal. Low pressure

back

VCZ 521

V 1.15

P = 960 mbar

Select measured values for display

Selection of the upper pressure value

Calibration of the lower pressure value

The current value of the comparison measurement

device must always be entered for calibration. The

correction values are then calculated from this. It is

recommended to always make both calibrations.

Operation

115041 29

Self cleaning:

Low pressure:

MAIN MENU

Manual

Automatic

Low pressure

Configuration

Self cleaning

VCZ 521

V 1.15

P = 960 mbar

MAIN MENU

Manual

Automatic

Low pressure

Configuration

Self cleaning

VCZ 521

V 1.14

P = 960 mbar

MAIN MENU

Manual

Automatic

Low pressure

Configuration

Self cleaning

VCZ 521

V 1.14

P = 960 mbar

MAIN MENU

Manual

Automatic

Low pressure

Configuration

Self cleaning

VCZ 521

V 1.15

P = 960 mbar

Selection self-cleaning -

for flushing the pump (Process several

times in succession possible)

Starting the pump system

All control settings are ignored (P min).

Self cleaning

Attention: system is aired

Start in seconds

5

Cancel with <OK>

Self cleaning

Cleaning in action

Remaining seconds

120

Cancel with <OK>

Operation

30 115041

Automatic:

Manual:

MAIN-MENU

Manual

Automatic

Low pressure

Configuration

Self cleaning

VC 521

V 1.15

P = 960 mbar

Parameter for mode: Automatic

Parameter

Value

Unit

start graphic

start numeric

auto limit

auto speed

hysteresis

auto stop time

No. of pressure ramps

VENTILATE on STOP

Auto Restart

back

-----

----100

50

0

0

0

0

0

-----

%

mbar

sec

Parameter for mode: Automatic

Parameter

Value

Unit

start graphic

start numeric

auto limit

auto speed

hysteresis

auto stop time

No. of pressure ramps

start cycle 1

cycle time 1

cycle pressure 1

VENTILATE on STOP

Auto Restart

back

-----

----100

50

0

0

1

2

600

600

0

0

-----

%

mbar

sec

mbar

sec

mbar

MAIN-MENU

Manual

Automatic

Low pressure

Configuration

Self cleaning

VC 521

V 1.15

P = 960 mbar

Parameter for mode: Manual

Parameter

Value

Unit

start graphic

start numeric

Setpoint numeric

setpoint table

hysteresis

auto stop time

No. of pressure ramps

VENTILATE on STOP

Auto Restart

back

-----

----123

123

0

0

0

0

0

-----

mbar

mbar

mbar

sec

Parameter for mode: Manual

Parameter

Value

Unit

start graphic

start numeric

Setpoint numeric

setpoint table

hysteresis

auto stop time

No. of pressure ramps

start cycle 1

cycle time 1

cycle pressure 1

VENTILATE on STOP

Auto Restart

back

-----

----123

123

0

0

1

2

600

600

0

0

-----

mbar

mbar

mbar

sec

mbar

sec

mbar

Select and set the displayed values.

Values that are not required are not displayed.

Parameter display: "Hysteresis" only when

operating without a FU-Motor (Factory settings!)

Select and set the displayed values.

Values that are not required are not displayed.

Parameter display: "Hysteresis" only when

operating without a FU-Motor (Factory settings!)

Operation

115041 31

6.7 Electrical parameters

6.7.1 Printed circuit board – Layout and Connections

Fig. 10 Positions of components and interfaces

6.7.1.1 Electrical Interfaces

Location of interfaces, see Figure 6

The device is supplied with 24 V DC.

X1 Power supply input

Spring contact clamp Wago type 236 / 2-pole

Pin no.

Function

Specification

Comment

1

GND

reverse polarity protected /

blue

2

Primary power supply

24V DC ± 10%, 1.5 A

reverse polarity protected /

orange

X7

X9

X2

Operation

32 115041

X2 LCD Display BP320240E / INTERNAL

FFC Würth 686124144 24-pole / RM 1mm

Pin no.

Function

Specification

Comment

1

RESET

2

/RD

3

/WR

4

/CS

5

A0

6

D0 7 D1 8 D2 9 D3

10

D4

11

D5

12

D6

13

D7

14

VDD

15

VSS

16

VLCD

17

free

18

SK/X1

19

D0/X2

20

D1/Y1

21

CS/Y2

22

INT

23

LED+

24

LED-

X3 PLC input 1- Level sensor

Spring contact clamp Wago type 236 / 3-pole

Pin no.

Function

Specification

Comment

1

GND

bl

2

SENSOR 1 or PCL input 1

I in approx. 10 mA /

U

threshold

approx. 13 V

gn

3

Sensor supply

Corresponds to the voltage at

X1 / protected by 200 mA

self-resetting circuit-breaker

orange

X4 Pressure sensor 1 input

Spring contact clamp Wago type 236 / 4-pole

Pin no.

Function

Specification

Comment

1

GND

blue

2

SENSOR 1 Signal

0..5 V or 0..20 mA

Resolution 5 mV / green

3

Sensor supply

5 V ± 5% or

Corresponds to the voltage at

X1 / protected by 200 mA

self-resetting circuit-breaker

Not fused / beige

Operation

115041 33

The input can be configured with jumper J2:

J2 open: (Default) Voltage: 0..5 V

J2 plugged: current 0..20 mA

The sensor supply voltage can be configured with jumper J3:

J3 1-2: 24 V needed for current output

J3 2-3: 5 V (Default) needed for voltage output (depending on sensor data sheet)

X5 PLC output 1 – vacuum valve

X6 PLC output 2 – venting valve

Spring contact clamp Wago type 236 / 2-pole

Pin no.

Function

Specification

Comment

1

GND output

bl

2

Output

Corresponds to the voltage

infeed at X1 / pnp max. 0.5 A

with freewheeling diode /

orange

X7 RS232 to the PC

Tub plug connector, 10 pin via FB to

Sub-D-plug, 9-pin (Würth 618009221823)

Function

Pin at tub plug connector

Pin at SUB - D

Comment

RXD 3 2

TXD 5 3

GND 9 5

X8 Analog output 1 – Frequency converter pump speed

Spring contact clamp Wago type 236 / 2-pole

Pin no.

Function

Specification

Comment

1

GND

bl

2

Output 1

0..10 V max. 10 mA

Resolution 2 mV / gr

X9 DEBUG / INTERNAL

Tub plug connector, 10 pin / RM 2.5mm

Pin no.

Function

Specification

Comment

1 2 3 4 5

Level converter supply

5 V ± 5%

not fused 6 7

8

TXD

5 V level

9

RXD

5 V level

10

GND

Operation

34 115041

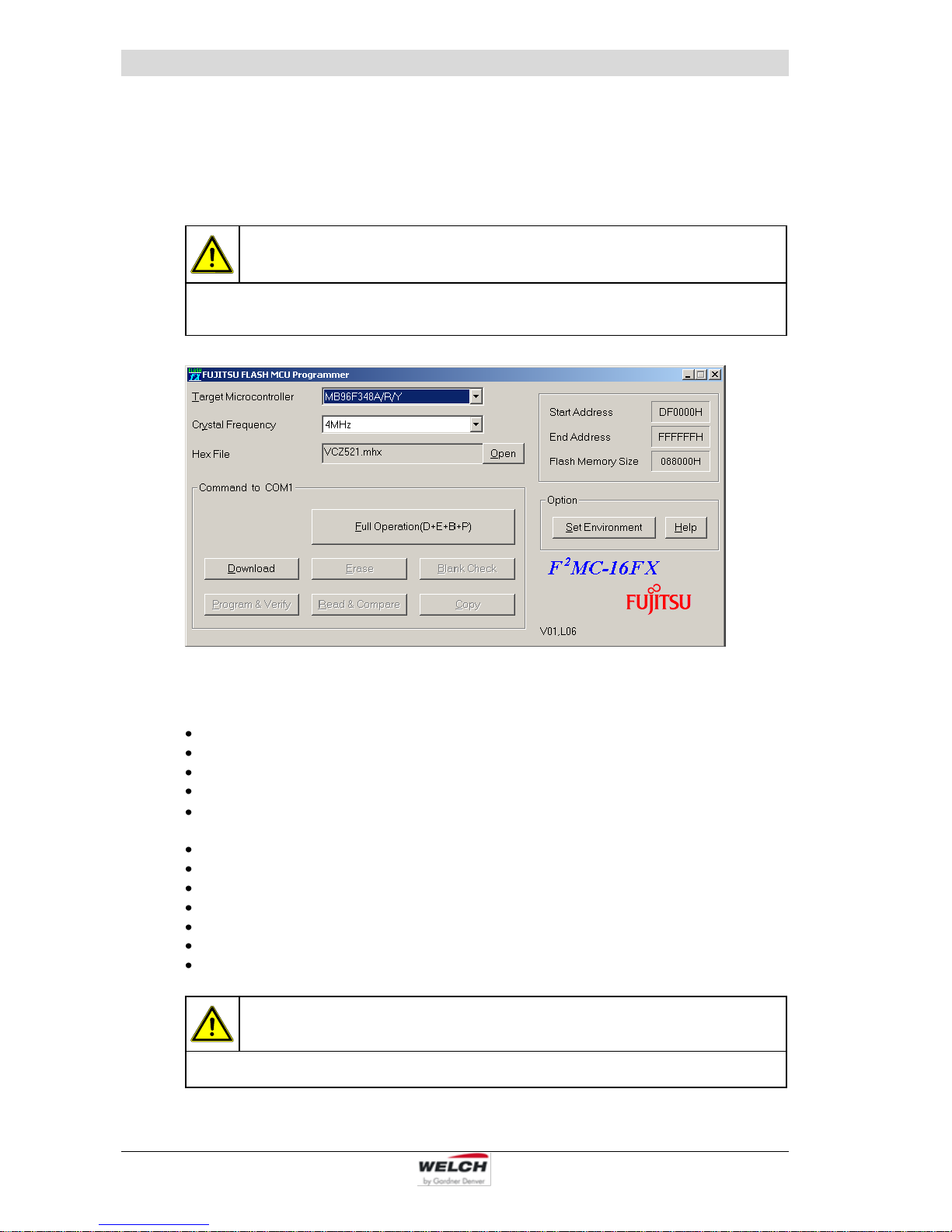

6.7.2 Software-Update

The software in the controller can be updated.

It can be re-input by the user. The Fujitsu Flash tool must be used for the Fujitsu 16FX CPU

range.

The factory default settings can be made with a corresponding sequential number input again (VCZ521_XXX.mhx).

NOTE !

The highest sequential number VCZ521_XXX.mhx is always the most current software version. (currently: VCZ521_115.mhx)

The following steps must be carried out:

Switch off the controller

Call the flash program.

Select the processor MB96F348A/R/Y

Select the quartz frequency 4 MHz

Select the program file

(Most Current Version = Highest Sequential Number, VCZ521_XXX.mhx)

Select the serial interface used (Option / Set Environment)

Start the programming with "Full Operation"

Confirm the Box (PC) „Reset ...“ with OK

Switch on the controller quickly (don't forget timeout of approx. 15 seconds!)

The programming runs automatically.

Switch off the controller again after the OK message

Switch on the controller, and check the functions of the controller

CAUTION !

The controller should be switched off during each interruption.

Operation

115041 35

6.8 Operation using the "WELCH-Control 521" PC program

The "WELCH-Control" enables the vacuum controller to be operated simply and easily from

the PC. The program can be purchased and installed as an option.

Make the cable connection (O-Modem) between PC and controller.

PC program

Most Current Version

Order no.

WELCH-Control 521

V 1.15

620637

CAUTION !

1.) "WELCH-Control 521" is currently version V 1.15.

2.) Flash software is also currently version VCZ521_115.mhx.

3.) Version 1.) and 2.) need not be identical!

The program attempts to find a switched-on controller on COM1 to 20. A COM-Port 1..255

can also be defined as a command line parameter: VCZ521.EXE 2 -> select COM2

If a controller cannot be found, the program goes into offline mode.

Here, a previously saved curve can be reloaded and printed out.

Internal wiring of the controller RS 232 port

PIN

Cable colour

Connection on the main board

2

white

16

RS 232 - RXD

3

brown

17

RS 232 - TXD

5

green

18

GND

9

yellow

19

Flash - sets software update mode if on GND (18)

The following screen appears after the start:

The graph shows the pressure development. Both the chronological and the pressure display range can be set. Data can also be recorded in the PC memory, which can then be

stored as an ASCII file in the "File / Save memory" menu.

Operation

36 115041

In the PSI pressure range, the pressure values for the curve are multiplied by 100 to remain

with integers.

The curve can be printed out by the system printer via the "File / Print curve" menu.

The buttons largely correspond to the buttons on the controller. However, the buttons cannot

be held down.

In active mode, the AIR button can be used with the mouse like on the controller.

Pressing the mouse button opens the valve, releasing it closes the valve again.

However, this only works if the mouse pointer is still on the AIR button.

The Up and Down arrow buttons change the temporary setpoint in active mode.

The OK button only works in active mode, and sets the current pressure as the new set

value.

The Start button starts or ends in the current operating mode.

The Pmin button functions the same as without a controller.

The following menu items can be selected from the menu bar:

File

Measure!

Settings!

Calibrate!

Factory settings!

6.8.1 Menu item: „File“

File

Save settings

Saving the Settings dialog settings in a file

Load settings

Loading the Settings dialog settings from a file

Print settings

Printing out an image of the Settings dialog on the standard printer

Save memory

Saving the pressure data in a file

Load memory

Load the print data from a file

Print curve

Printing out the current pressure curve on the standard printer

Password

Changing the basic setting of the controller is password-protected.

Release is given by inputting the date as a hex number.

Example : 25.03.2015 = 250315 = 3D1CB

(Required for activating the "Calibrate" and "Factory settings" menus and the direct input

of pressure offset und pressure factor in the „Calibrate“ Dialog)

Info

Information about the program version

Exit <ESC>

Exit program

Operation

115041 37

6.8.2 Menu item: „Settings!“

CAUTION !

Settings not required for the selected operating mode are disabled and grayed out in

the display. Appropriate error messages are displayed if the data ranges are exceeded or if inputs are illogical.

Operation

38 115041

Settings required for the control behaviour of the controller:

Designation

Explanation

Software

WELCH-Control

521

Control panel

at the controller

mode

MAIN MENU

1 - manual

(manual pressure setting for boiling pressure)

2 - automatic

(automatic finding of the boiling pressure)

3 - low pressure

Operation without regulation

There are only the modes meaningful for their application adjustable.

language

-

english, german, french, spain

-

Configuration,

language

English, Deutsch, Français, Español

pressure unit

pressure unit

mbar, torr, psi, hPa

VENTILATE

on STOP

-

ON - automatic venting after STOP is on

OFF - automatic venting after STOP is off

-

VENTILATE

on STOP

0 - closed

1 - open

Auto Restart

-

OFF - no function

ON - The program works automatically continues

after power failure or shutdown.

-

Auto Restart

0 - no function

1 - The program works automatically continues

after power failure or shutdown.

manual, setpoint

setpoint

Enter a setpoint pressure value between 0 and 1100

mbar.

manual, hysteresis

hysteresis

Enter a hysteresis value between 0 and 1100 mbar.

pressure drop,

ramp num

No. of pressure

ramps

Number of possible ramps 1, 2 , 3

P start, ramp 1 – 3

start cycle 1 – 3

in adjusted pressure value (example: mbar)

P lower, ramp 1 – 3

cycle time 1 – 3

in second absolute

T lower, ramp 1 – 3

cycle pressure 1 – 3

in adjusted pressure value absolute (example: mbar)

auto stop time

auto stop time

Hunting time in second

auto limit

auto limit

Threshold value for detecting the boiling point

(selected pressure unit / min)

auto speed

auto speed

0 ... 100%

Reduces the frequency of rotation / rotational speed

to a percentage of the maximum speed

of the pump motor in order to determine the

boiling point smoothly.

read config

-

Read out current parameter values from the

controller and display in the Settings dialog.

send config

-

Values changed in the Settings dialog are stored in

the controller. The controller confirms reception with

a signal tone.

Operation

115041 39

6.8.3 Menu item: „Calibrate“

Calibration:

When search lower point (Pmin) is activated, evacuation is to the lower point. If the pressure does not fall any further, the value can be entered by using a comparison measurement

device and confirmed with Ok. The system is vented and the ambient barometric pressure

entered as the upper point (Pmax). Do not confirm until the value has been established.

If the controller is integrated in a complete system or pump system (LVS), evacuation and

venting take place automatically when the stated buttons are pressed.

The calculated correction values are displayed and can be stored with save.

CAUTION !

Ensure that the set pressure is also present at the sensor.

Designation

Explanation

Software

WELCH-Control 521

Control panel

at the controller

Lower point

CL

at low pressure -

pressure of comparison measurement device

(at lowest possible pressure, e.g. 10 mbar)

Upper point

CH

at normal pressure (high) -

barometric pressure

Operation

40 115041

6.8.4 Menu item: „Factory settings“

Designation

Explanation

Software

WELCH-Control 521

Control panel

at the controller

FU motor

not settable

analog output active

calibration allowed

not settable

= present

= not present

read

not settable

Reading the set values

Confirmation of acceptance by signal tone

send

not settable

Transmission of changed values to the controller

Confirmation of acceptance by signal tone

CAUTION !

These settings are adapted by the manufacturer to match the supplied configuration.

The user can change the settings after inputting the password (“File” menu item).

Operation

115041 41

6.9 Table of solvents

Solvent

Formula

Vacuum (mbar)

for boiling point at 40 °C

Acetone

C3H6O

556

n-amyl alcohol, n-pentanol

C5H12O

11

Benzole

C6H6

236

n-butanol

C4H10

25

tert-butyl alcohol, 2-methyl-2-propanol

C4H10O

130

Tetrachlorometane

CCl4

271

Chlorobenzene

C6H5Cl

36

Chloroform

CHCl3

474

Cyclohexane

C6H12

235

Diethyl ether

C4H10O

no vacuum

1, 2, -dichlorethane

C2H4Cl2

210

1, 2, -dichlorethylene (cis)

C2H2Cl2

479

1, 2, -dichlorethylene (trans)

C2H2Cl2

751

Diisopropyl ether

C6H14O

375

Dioxan

C4H8O2

107

DMF

C3H7NO

11

Ethanol

C2H6O

175

Ethyl acetate

C4H8O2

240

Heptane