Welch LVS 300 Z, LVS 302 Z, LVS 301 Z, LVS 310 Z ef, LVS 310 Z ef extern Operating Manual

...

Operation Manual

(EN)

Translation of the german original manual

Laboratory-Vacuum-Systems

Ultimate pressure < 8 mbar

Models:

► unregulated

LVS 300 Z

► manual regulated

LVS 301 Z

LVS 302 Z

► automatic regulated

LVS 310 Z

LVS 311 Z

► ecoflex

LVS 310 Z ef

LVS 310 Z ef extern

► economic

LVS 310 Z en

115041

2017-02-02

We are constantly working on the further

development of all our product models.

Reprinting or reproduction of this manual,

including extracts, is not allowed without the

prior written permission of Co. Gardner

Denver Thomas GmbH.

All rights under the copyright laws are

expressly reserved by Co. Gardner Denver

Thomas GmbH.

We reserve the right to make changes and

amendments.

Gardner Denver Thomas GmbH

Am Vogelherd 20

98693 Ilmenau

Germany

T +49 3677 604 0

F +49 3677 604 131

welch.emea@gardnerdenver.com

www.welchvacuum.com

Customer Support +49 3677 604 0

Contents

115041 3

Contents

1 Important Information ............................................................................................................. 5

1.1 General Information .................................................................................................................. 5

1.2 Target Groups ........................................................................................................................... 5

1.3 Intended Use ............................................................................................................................. 5

1.4 Use for an Unauthorized Purpose ............................................................................................ 5

1.5 Safety Devices .......................................................................................................................... 6

1.6 Meaning of the Warning notes .................................................................................................. 6

1.7 Product Standards, Safety Regulations .................................................................................... 6

2 Basic Safety Instructions ....................................................................................................... 7

2.1 General Information .................................................................................................................. 7

2.2 Electricity ................................................................................................................................... 7

2.3 Mechanical Systems ................................................................................................................. 8

2.4 High Temperatures ................................................................................................................... 8

2.5 Hazardous Substances ............................................................................................................. 9

3 Description ............................................................................................................................ 10

3.1 Design and Function ............................................................................................................... 10

3.1.1 Laboratory-Vacuum-Systems ................................................................................................. 10

3.1.2 Diaphragm pump .................................................................................................................... 11

3.1.3 Vacuum Controller 521, intern ................................................................................................ 12

3.1.4 Built-in – Vacuum Controller 521 ef, extern ............................................................................ 12

3.2 Overview of the variants ......................................................................................................... 13

3.3 Areas of Application ................................................................................................................ 13

3.4 Scope of Delivery .................................................................................................................... 13

3.5 Examples of application .......................................................................................................... 14

3.6 Accessories ............................................................................................................................. 16

4 Technical Data ....................................................................................................................... 18

4.1 View of device and dimensions............................................................................................... 18

4.2 Intake Pressure / Pumping Speed – Diagram ........................................................................ 18

4.3 Device data ............................................................................................................................. 19

4.3.1 Laboratory Vacuum Systems .................................................................................................. 19

4.3.2 Vacuum Controller 521 ........................................................................................................... 21

5 Assembly and Installation .................................................................................................... 22

5.1 Unpacking ............................................................................................................................... 22

5.2 Installation and Connection ..................................................................................................... 22

5.3 General instructions ................................................................................................................ 22

5.4 Storage .................................................................................................................................... 23

5.5 Scrap Disposal ........................................................................................................................ 23

6 Operation ............................................................................................................................... 24

6.1 LVS without vacuum controller ............................................................................................... 24

6.2 LVS with vacuum controller .................................................................................................... 24

6.3 Operating modes of the Controller .......................................................................................... 24

6.3.1 Mode 1, Manual operation ...................................................................................................... 24

6.3.2 Mode 2, Automatic operation .................................................................................................. 24

6.3.3 Mode 3, Ultimate pressure ...................................................................................................... 25

6.3.4 Mode 4, Self cleaning ............................................................................................................. 25

6.4 Monitoring by Level Sensor .................................................................................................... 25

6.5 Calibrating the Pressure Sensor ............................................................................................. 25

6.6 Handling .................................................................................................................................. 25

6.6.1 Control panel ........................................................................................................................... 25

6.6.2 Operating via Buttons and Encoder ........................................................................................ 26

6.6.3 Menu Guidance ....................................................................................................................... 26

Contents

4 115041

6.7 Electrical parameters.............................................................................................................. 31

6.7.1 Printed circuit board – Layout and Connections .................................................................... 31

6.7.1.1 Electrical Interfaces ................................................................................................................ 31

6.7.2 Software-Update .................................................................................................................... 34

6.8 Operation using the "WELCH-Control 521" PC program ....................................................... 35

6.8.1 Menu item: „File“ .................................................................................................................... 36

6.8.2 Menu item: „Settings!“ ............................................................................................................ 37

6.8.3 Menu item: „Calibrate“ ............................................................................................................ 39

6.8.4 Menu item: „Factory settings“ ................................................................................................. 40

6.9 Table of solvents .................................................................................................................... 41

7 Maintenance and Servicing ................................................................................................. 42

7.1 General Requirements ........................................................................................................... 42

7.2 Maintenance Performed by the User ..................................................................................... 42

7.2.1 Maintenance of the diaphragm pump ..................................................................................... 42

7.2.1.1 Disassembly ........................................................................................................................... 43

7.2.1.2 Assembly ................................................................................................................................ 43

7.2.1.3 Test......................................................................................................................................... 44

7.2.2 Maintenance of the vacuum controller ................................................................................... 44

7.2.3 Maintenance of other components ......................................................................................... 44

7.3 Maintenance by the Manufacturer .......................................................................................... 44

7.4 Damage Report ...................................................................................................................... 44

8 Troubleshooting ................................................................................................................... 45

9 Spare Parts Overview .......................................................................................................... 46

9.1 Service kit – Diaphragm Pump ............................................................................................... 46

9.2 Spare parts – Laboratory-Vacuum-Systems, unregulated + manually regulated .................. 47

9.3 Spare parts – Laboratory-Vacuum-Systems, automatically regulated ................................... 52

9.4 Spare parts – Laboratory-Vacuum-Systems, ecoflex ............................................................ 55

9.5 Spare parts – Laboratory-Vacuum-Systems, economic ........................................................ 59

9.6 Spare parts – Diaphragm pumps ........................................................................................... 61

- Instructions for certification - Laboratory-Vacuum-Systems LVS -

for use in Zone 2 in accordance with device category 3 per ATEX Directive 2014/34/EU

(Page 1- 3)

- EC Declaration of Conformity

Important Information

115041 5

1 Important Information

1.1 General Information

The Laboratory-Vacuum-Systems conform to the:

2006 / 42 / EC

Machinery Directive

2014 / 30 / EU

Electromagnetic Compatibility Directive

2014 / 34 / EU

ATEX Guideline for use in potentially explosive atmospheres,

Appendix III

The CE sign is located on the rating plate. Observe the binding national and local regulations

when fitting the pump into installations.

Our products are sold worldwide and can therefore be equipped with the typical national

plugs and for the various voltages. You will find more information about the available pump

designs on our web page in the internet.

1.2 Target Groups

This Operating Manual is intended for the personnel planning, operating and maintaining

Laboratory-Vacuum-Systems. This group of people includes:

Designers and fitters of vacuum apparatus,

Employees working on commercial laboratory and industrial vacuum technology applica-

tions and

Service personnel for laboratory-vacuum-systems.

The personnel operating and maintaining the laboratory vacuum systems must have the

technical competence required to perform the work that has to be done.

The user must authorize the operating personnel to do the work that has to be done.

The personnel must have read and understood the complete Operating Manual before using

the laboratory-vacuum-systems.

The Operating Manual must be kept at the place of use and be available to the personnel

when required.

1.3 Intended Use

The laboratory-vacuum-system may only be operated under the conditions stated

– in the "Technical Data" section,

– on the type plate, and

– in the technical specification for the order concerned.

Laboratory-vacuum-systems are approved for extracting, pumping and compressing

gases and vapours. If these gases and vapours are toxic or explosive, then the user must

observe the currently valid safety regulations for this application. Special types of diaphragm pumps are available for aggressive and explosive gas mixtures.

Laboratory-vacuum-systems are intended for generating vacuums with ultimate pressures of around 8 mbar.

The in-built diaphragm pump has been designed to have high resistance to aggressive

gases.

1.4 Use for an Unauthorized Purpose

It is forbidden to use the pump for applications deviating from the technical data stated on

the type plate or the conditions stated in the supply contract, or to operate it with missing or

defective protective devices.

Important Information

6 115041

1.5 Safety Devices

Measures such as the following are for the safety of the operating personnel:

electrical connection with a protective conductor (operating mode S1) and an earthing

plug,

Motor protection switch (thermal),

“Hot Surface" label on the pump body - warning notice

motor hood on the motor fan and

glass components with a transparent plastic coating which protects them against bursting

and cracking

The laboratory-vacuum-system must not be operated without these elements.

1.6 Meaning of the Warning notes

Take note of the warning notices. They are in the following box:

CAUTION ! / WARNING !

Hazard which may lead to serious injuries or material damage.

1.7 Product Standards, Safety Regulations

Laboratory-Vacuum-Systems meet the following product standards:

DIN EN ISO 12100:2011-03

Safety of machinery General principles for design - Risk assessment and risk reduction

DIN EN ISO 13857:2008-06

Safety of machinery - Safety distances to prevent hazard zones being reached

by upper and lower limbs

DIN EN 1012-2:2011-12

Compressors and vacuum pumps - Safety requirements Part 2: Vacuum pumps

DIN EN ISO 2151:2009-01

Acoustics - Noise test code for compressors and vacuum pumps - Engineering

method (grade 2)

DIN EN 60204-1:2014-10

Safety of machinery - Electrical equipment of machines Part 1: General requirements

DIN EN 61000-6-2:2011-06

DIN EN 61000-6-4:2011-09

Electromagnetic compatibility (EMC) Part 6-2: Generic standards - Immunity for industrial environments

Part 6-4: Generic standards - Emission standard for industrial environments

DIN EN 61010-1/A1:2015-04

Safety requirements for electrical equipment for measurement, control and

laboratory use - Part 1: General requirements

DIN EN 50110-1:2014-02

Operation of electrical installations

DIN EN 1127-1:2011-10

Explosive atmospheres - Explosion prevention and protection Part 1: Basic concepts and methodology

DIN EN 13463-1:2009-07

DIN EN 13463-5:2011-10

Non-electrical equipment for use in potentially explosive atmospheres Part 1: Basic method and requirements

Part 5: Protection by constructional safety 'c'

Directive 2012/19/EU

Electrical and electronics - old devices (WEEE)

Directive 2011/65/EU

Dangerous materials in electrical and electronics devices (RoHS II)

China - RoHS II

Environment protection law - China 2016-01

The following additional safety regulations apply in the FR Germany:

BGV A3

Electrical equipment and operating materials

VBG 5

Power-driven machines

BGR 120

Guidelines for laboratories

BGI 798

Hazard assessment in the laboratory

BGG 919 (VBG 16)

Accident prevention regulations for "compressors"

BGR 189 (BGR 195;192;197)

Use of protective working clothes

Observe the standards and regulations applying in your country when you use the laboratory-vacuum-systems.

Basic Safety Instructions

115041 7

2 Basic Safety Instructions

2.1 General Information

CAUTION !

Warning notices must be observed. Disregarding them may lead to damage to health

and property.

The Laboratory-Vacuum-Systems must be operated by personnel who can detect impending

dangers and take action to prevent them from materialising.

The user/operator is responsible for correct installation and safe operation.

Prevent condensate collecting in the pump. When pumping vapours which tend to condense

please ensure that the pump is at operating temperature and that the gas ballast valve is

open when the pump is switched on.

If there is more than one load on one LVS, they must be separated by check valves.

After finishing work with the diaphragm pump, run it for about 10 minutes with an open gas

ballast valve.

The manufacturer or authorized authorised workshops will only service or maintain the Labo-

ratory-Vacuum-System if it is accompanied by a fully completed damage report. Precise information about the contamination (also negative information if necessary) and thorough

cleaning of the Laboratory-Vacuum-Systems are legally binding parts of the contract.

Contaminated Laboratory-Vacuum-Systems and their individual parts must be disposed of in

accordance with the legal regulations.

The local regulations apply in foreign countries.

2.2 Electricity

The Laboratory-Vacuum-Systems are supplied for operating mode S1. Please note that the

testing must be repeated in accordance with DIN EN 0105, DIN EN 0702 and BGV A2 in

case of portable devices.

The local regulations apply in foreign countries.

Please note the following when connecting to the electrical power supply system:

The electrical power supply system must have a protective connector according to DIN

VDE 0100-410 (IEC 60364-4-41).

The protective connector must not have any breaks.

The connecting cable must not be damaged.

All interfaces are under low voltage according to DIN VDE 0100-410.

Basic Safety Instructions

8 115041

2.3 Mechanical Systems

Improper use can lead to injuries or material damage. Observe the following instructions:

Only operate the Laboratory-Vacuum-Systems with hoses of the specified dimensions.

The maximum permissible pressure of 1 bar at the suction connection must not be ex-

ceeded.

Hazardous substances must be separated out as far as this is technically possible before

they reach the pump.

External mechanical stresses and vibrations must not be transmitted to the pump. Only

use flexible laboratory hoses for connecting Laboratory-Vacuum-Systems.

The overpressure generated at the pressure port must not exceed 1 bar.

The pump must not be used to suck up fluids. Lay the exhaust pipe so that it slopes

downwards, so allowing condensate to flow out of the pump. Collect the condensate and

dispose of it in an environmentally compatible manner.

CAUTION !

Solid particles in the pumping medium impair the pumping action and can lead to

damage. Prevent solid particles penetrating into the pump.

When handling glass vessels, pay attention to:

Only use glass vessels with a plastic coating for splinter protection.

Only use vessels which are suitable for use with vacuums (e.g. round-bottomed flasks).

We recommend that only glass components supplied by the manufacturer are used.

Do not use Erlenmeyer flasks.

Before each evacuation, check glass vessels for damage which might impair their

strength, replace them if any such damage is found.

Do not heat glass vessels on one side only.

Retardation of the boiling of the gases to be pumped can lead to a sudden pressure in-

crease. Prevent retardation of boiling by means of suitable measures (e.g. turbulent agitation).

2.4 High Temperatures

The diaphragm pump may heat up as a result of the temperature of the gas being pumped

and through compression heat.

Prevent the following maximum permissible temperatures from being exceeded.

+ 40 °C for the environment, and

+ 60 °C for the gas to be pumped.

The motor for single phase alternating current is protected against overload by an integrated

motor protection switch.

Basic Safety Instructions

115041 9

2.5 Hazardous Substances

The operating company bears the responsibility for the use of the Laboratory-VacuumSystem.

Hazardous and harmful substances must be effectively prevented from escaping.

Ensure that all lines and connections are leak tight.

Handle exhaust gases in accordance with the requirements of the emission protection regulations.

Do not operate the Laboratory-Vacuum-System without a separator and without a emission

condenser. The separator can only be emptied after the apparatus has been vented.

Dispose the condensate in an environmentally compatible manner!

The emission condenser has a safety valve. The air evacuation duct with hose must be kept

clear and lead into a suitable air evacuation duct. Throttling the air evacuation duct can

damage the valves of the diaphragm pump.

Hazardous substances in the gases to be pumped can cause personal injuries and property

damage. Pay attention to the warning notices for handling hazardous substances.

The local regulations apply in foreign countries.

Combustible Gases

Examine before switching on whether that can form gas combustible gas/air mixtures which

can be promoted! Also perform this test with a number of loads connected to one LVS.

Consider the regulations of the guideline 1999/92/EC.

Explosive gases

The diaphragm pumps of the series MPC are certified according to ATEX guidelines

2014/34/EU, device category 3, valid for the gas contacting parts (interior) of the pump.

Aggressive gases

An MPC series diaphragm pump is used for extracting vapours and aggressive gases.

The warranty shall lapse if the LVS is used with diaphragm pumps from other manufacturers.

Especially aggressive gases have to be explicitly checked for material resistance as de-

scribed in chapter 3.1.2 and, if necessary, modified.

Poisonous gases

Use a separator when pumping poisonous or harmful gases. Prevent such substances from

leaking out of the appliance or pump. Treat these substances according to the applicable

environmental protection regulations.

The diaphragm pump, control valves and hose lines can be damaged by poisonous or aggressive gases.

Test the strength and leak-tightness of the connecting lines and the connected apparatus.

Prevent environmental poisons, e.g. mercury, getting into the diaphragm pumps.

Fulfil the requirements, for example:

German Hazardous Substances Regulation (GefStoffV) of 01. December 2010

Regulations 2016/1179/EU

(classification, packaging and identification of hazardous sub-stances),

Manufacturer's safety data sheets on hazardous substances.

Description

10 115041

3 Description

3.1 Design and Function

3.1.1 Laboratory-Vacuum-Systems

The Laboratory Vacuum Systems are supplied as a ready-mounted unit.

The chemical-resistant diaphragm pump (4) with gas ballast valve (17) is fitted to the base

plate of the column (3) and attached on the suction-side to the separator (7) to protect the

pump from foreign matter and on the pressure-side to the emission condenser (6) to recover

the condensate. This ensures that hazardous substances are separated out. The safety

valve on the emission condenser protects against an impermissibly high operating pressure

on the outgoing air end.

The complete vacuum controller, with sensor, venting valve and power unit (5), is fitted in the

column (3). The LVS 310 Z ef, order no. 115244-04, is an exception. In this case, the vacuum controller is available as an external device for installation in laboratory furniture, see

chapter 3.1.4. The manually regulated LVS-variant does not have a controller.

All exposed glass components (6, 7) are coated with transparent plastic as protection

against bursting. The emission condenser is supplied with insulation.

The power switch (12) and the plug for the power cable (11) as well as the membrane pump

(10), the PC (13) control lead (14), inert gas (16) and the water valve (option) (15) are located on the right of the column.

The LVS types are specially preconfigured according to model.

1

Suction side connection

hose nozzle for hose DN8

Fig. 1a LVS 310 Z - Front view

2

Control valve

(LVS - automatically regulated)

3

Column complete

on swivelling foot

4

Diaphragm pump MPC 301 Z

5

Vacuum controller 521

(in the column or extern)

6

Emission condenser KD 500/5 insulated

at the pressure side with safety valve

and cooling water connections

7

Separator

(round-bottomed flask) suction side

8

Cooling water (feed flow/back flow)

Fig. 1b LVS 310 Z - Rear view

9

Connection outgoing air

hose nozzle for hose DN8

10

Connection Pump (pump)

11

Connection non-heating device power

cable (main in)

12

Main switch (power)

13

Connection PC (RS 232)

14

Connection control cable

LVS - automatically regulated (sensor)

15

Connection water valve

16

Connection inert gas

17

Gas ballast valve

Description

115041 11

3.1.2 Diaphragm pump

► Design:

The diaphragm pump consists of a pump body and a drive motor. The pump body consists

of a drive shaft and two pump heads. Both pump head contains a diaphragm and the work

valves. The two pump heads are arranged opposite each other.

In the two-stage (Z) diaphragm pump, both pump heads are connected in series.

The pump heads are driven via an eccentric shaft with a connecting rod.

► Function:

Motor, eccentric shaft and connecting rod set the diaphragms in stroke movement. This

changes the size of the space between the diaphragms and pump head (pump chamber).

Increasing the size of the pump chamber opens the inlet valve while the outlet valve is

closed (intake process). Decreasing the size of the pump chamber ejects the gas through

the outlet valve.

The valves are actuated by the gas being pumped. A large proportion of fluid in the diaphragm pump minimizes the pumping efficiency.

► Materials of the medium-affecting pump parts:

Component

Materials

Seal

EPDM

Screw fitting / Connecting elements

PP, PVDF

Valve

PEEK

Diaphragm

Elastomer + PTFE layer

Vacuum hose

PTFE

Connection head / pump head

PTFE with carbon-fibre reinforcing

*)

*)

electrically conductive (with manufacturer's certificate of electrical conductivity)

Material resistance to aggressive media see: Publisher Hoppenstedt Publishing

(18. September 2007)

► Gas ballast:

When condensable vapours are pumped,

they may be compressed above the

saturated vapour pressure and condense.

Opening the gas ballast valve (17) in the

suction line of the last pump stage allows

air to flow into the pump chamber.

This prevents condensation and flushes

the pump clear.

Operation leads to increasing the ultimate

pressure and the operating temperature.

Fig. 2 Diaphragm pump MPC 301 Z

Description

12 115041

3.1.3 Vacuum Controller 521, intern

In the case of controlled models for laboratory vacuum systems LVS, the vacuum controller,

complete with sensor, venting valve and power unit, is fitted in the device column. The operating and display elements are on the top surface of the column.

(Description and operation see chapter 6, Technical data see chapter 4.3.1)

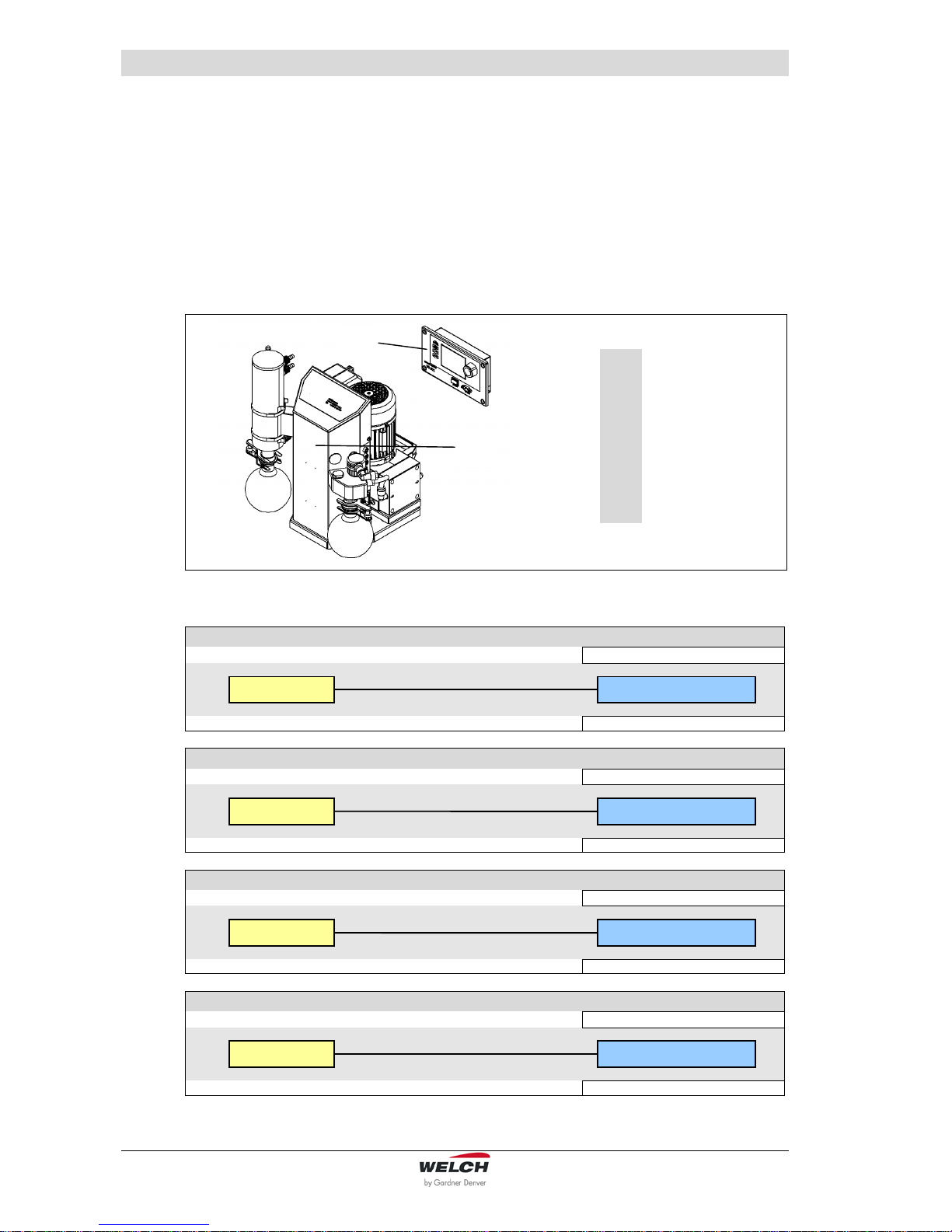

3.1.4 Built-in – Vacuum Controller 521 ef, extern

The LVS 310 Z ef (Order no. 115244-04) is equipped with an external vacuum controller for

installation in, for example, laboratory furniture.

Over the cable to the device, the electrical connection is made.

1

Built-in –

Vacuum Controller

extern

2

LaboratoryVacuum-System

LVS

► Electrical Installation - Built-in – Vacuum Controller 521 ef extern:

K1 Sensor + Venting valve

on the pump - rear panel

Controller

Coupling plug 5 pole

Order no. 600052-06

K2 24 V DC + Water valve

on the pump - rear panel

Controller

Coupling plug 4 pole

Order no. 600052-06

K3 Frequency converter

on the frequency converter - motor

Controller

Coupling plug 4 pole

Order no. 600052-06

K4 Fill level sensor o p t i o n

on sensor fill level

Controller

Order no. 600052-06

4 m

4 m

4 m

4 m

2

1

Description

115041 13

It has the same function as the LVS with a standard assembly. It is operated, as similarly described, via an externally installed controller. On the controller is the on / off power switch

and the RS 232 interface. (see also chapter 9.4)

Dimensions for installation

in laboratory furniture:

3.2 Overview of the variants

Part

Laboratory-Vacuum-Systems LVS

Piece per LVS

300 Z

301 Z

302 Z

310 Z

311 Z

310 Z ef

310 Z en

Suction side

connections for hose DN 8

1

un-

regulated

1

manually

regulated

2

manually

regulated

1

automati-

cally regu-

lated

1 automatically +

1 manually

regulated

1

ecoflex

regulated

1

economic

regulated

Control valve

- - - 1 1 - -

Column complete

1 1 1 1 1 1 1

Diaphragm pump

1 1 1 1 1 1 1

Vacuum controller 521

- - -

1 (cv)

1 (cv)

1 (ef)

1 (en)

Emission condenser

- 1 1 1 1 1 1

Separator 2 1 1 1 1 1

1

Pressure side

connection for hose DN 8

1 1 1 1 1 1 1

Frequency changer

- - - - - 1 -

Special variants, additional with:

- Dial gauge analog

- 1 - - - - -

- Clamping ring screw

A 10 (netvac 1)

- 1 - 1 - 1 1

- Built-in Controller 521

- - - - - 1 -

3.3 Areas of Application

The Laboratory-Vacuum-Systems is intended for:

vacuum filtration, vacuum distillation and vacuum drying

use in physical and chemical laboratories in trade and industry

pumping and compressing neutral and aggressive gases and vapours

generating a vacuum up to an ultimate pressure of < 8 mbar

► Special designs:

Special LVS can be supplied after consultation with the manufacturer or for a corresponding supply

contract.

Motors for different voltages.

3.4 Scope of Delivery

The scope of delivery is specified in the supply contract.

Description

14 115041

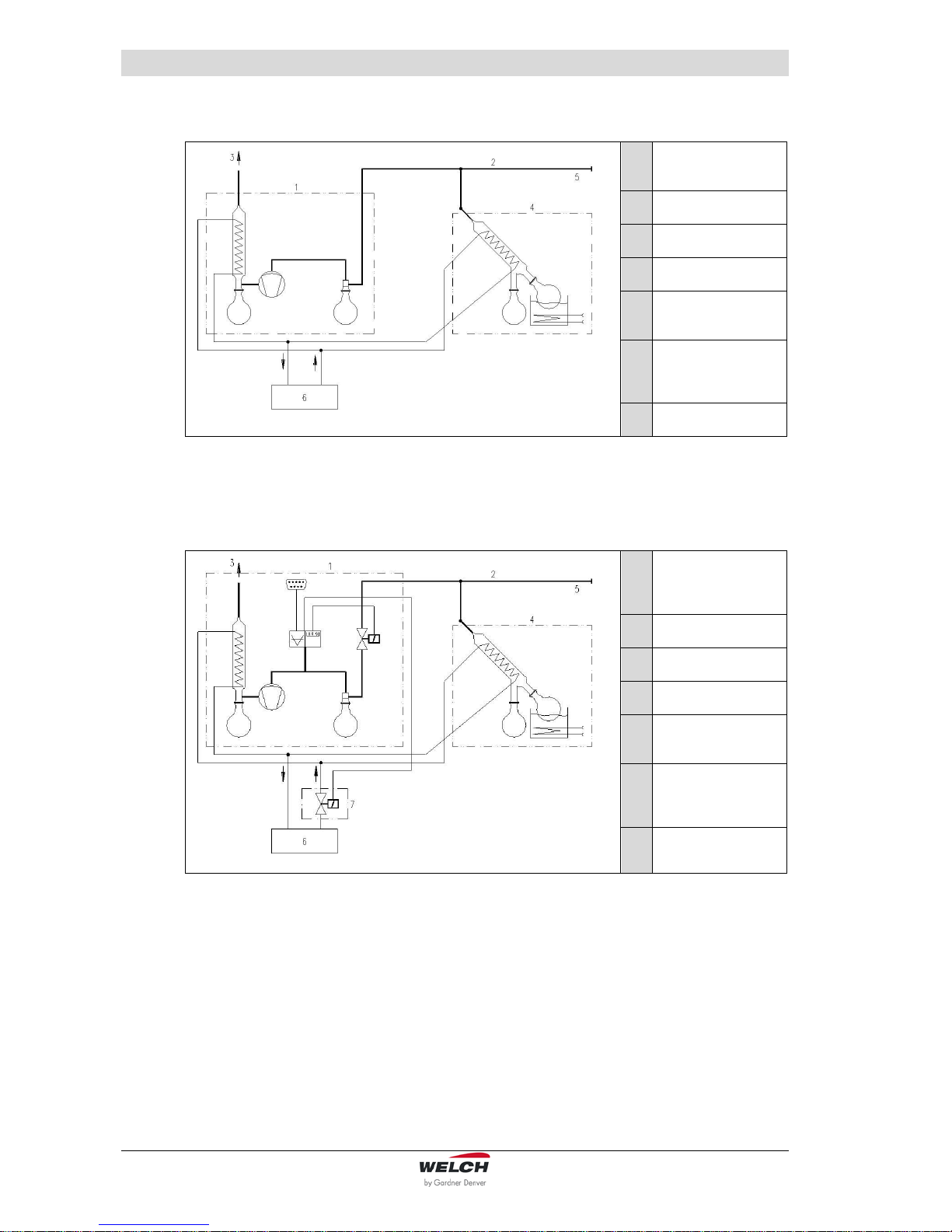

3.5 Examples of application

1

LVS without

vacuum controller

2

Suction line *

3

Outgoing air

4

Rotary vaporizer *

5

Capable of expansion up to 4 loads

6

Coolant system,

un pressurised run

back *

7

Water valve WV *

Fig. 3 Example of application - LVS manually regulated

1

LVS with vacuum

controller and

control valve (cv)

2

Suction line *

3

Outgoing air

4

Rotary vaporizer *

5

Capable of expansion up to 4 loads

6

Coolant system,

un pressurised run

back *

7

Water valve WV *

Fig. 4 Example of application – LVS „cv“ (Control valve) automatically regulated

* Not included in the scope of delivery

Description

115041 15

1

LVS ef (ecoflex)

2

Suction line *

3

Outgoing air

4

Rotary vaporizer *

5

frequency-regulated

pump motor

6

Coolant system,

un pressurised run

back *

7

Water valve WV *

Fig. 5 Example of application – LVS „ef“ ecoflex

1

LVS en (economic)

2

Suction line *

3

Outgoing air

4

Rotary vaporizer *

5

Capable of expansion up to 4 loads

(depending on the

suction capacity)

6

Coolant system,

un pressurised run

back *

7

Water valve WV *

Fig. 6 Example of application – LVS „en“ economic

CAUTION !

The economic Laboratory Vacuum System "LVS ... en" is suitable for slow

processes and central laboratory supplies using a large hysteresis (< 50 mbar).

When installing the switch interval of the diaphragm pump is to be checked.

In practical applications the time-out must be at least 0.5 minutes.

The integrated pressure monitor guarantees immediate activation of the vacuum

generator when required.

This ensures continuous readiness of the vacuum system in the laboratory.

Description

16 115041

3.6 Accessories

The use of chemical-resistant vacuum connections “netvac +” is recommended for extending the application range of a vacuum generator to several workstations.

netvac +

Set BC1 - 63

Order no. 700563

for mounting

on wood furniture

Set BC2 - 63

Order no. 700563-01

for mounting

on sheet metal wall

with integrated FFKM-Check valve, Dosing valve, Hose nozzle

and Ball valve

Area of application: Laboratory

Suction connection: Hose DN 8-10

Connection thread: 1/4 "- outside

Material of valve body: Polypropylene (PP)

Dimensions (W/D/H): Ø 69 / 161 / 82 mm

Mounting hole: Ø 25 to Ø 35 mm

netvac +

Set BC1 - 62

Order no. 700562

for mounting

on wood furniture

Set BC2 - 62

Order no. 700562-01

for mounting

on sheet metal wall

with integrated FFKM-Check valve, Dosing valve and Hose nozzle

Area of application: Laboratory

Suction connection: Hose DN 8-10

Connection thread: 1/4 "- outside

Material of valve body: Polypropylene (PP)

Dimensions (W/D/H): Ø 69 / 69 / 82 mm

Mounting hole: Ø 25 to Ø 35 mm

Vacuum Control-Box

VCB 521 cv

Order no. 600053

Table model as digital, chemical-resistant vacuum regulator.

With integrated sensor, airing -, control- and check valve.

Connection vacuum apparatus: DN 8

Connection vacuum pump: DN 8

Connection inert gas: DN 4

Connection water valve: Binder plug 4-pole 24V DC

Operating software „WELCH-Control 521“

on CD

Order no. 620637

to connect the vacuum controller to the PC

Description

115041 17

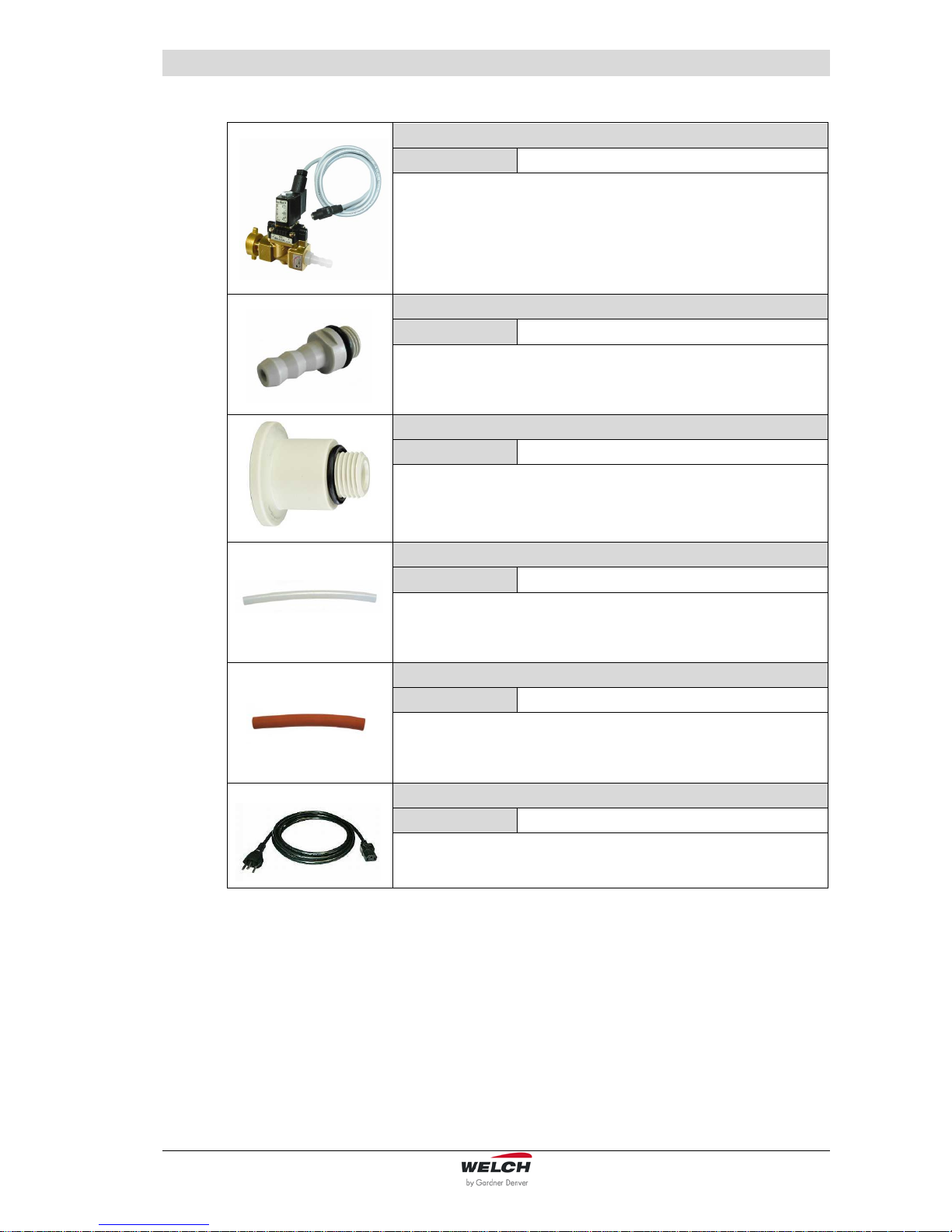

Water valve

WV 2

Order no. 700300-02

2 way water flow valve for the demand-responsive cooling water

supply, mounting possible in any direction.

Input: G 3/4 inch sleeve nut

Output: Hose nozzle for hose inside diameters 8 mm

Hose nozzle with FKM - O-Ring

DN 10

Order no. 710955

Material: PP

Male thread: ¼“

Inlet fitting

DN 16 KF

Order no. 710116

Material: PP

Male thread: ¼“

Vacuum hose

10 / 8x1

Order no. 828332

Material: PTFE

Please state the length you want to order!

Vacuum hose

18 / 8x5

Order no. 828310-4

Material: Rubber, red

Please state the length you want to order!

Mains connection cable IEC with plug

Type 12 (CH)

Order no. 825877

for LVS … in 23O V

Technical Data

18 115041

4 Technical Data

4.1 View of device and dimensions

The main dimensions are identical for all types stated here.

Fig. 7 View of device (Model LVS 301 Z, dimensions see chapter 4.3

4.2 Intake Pressure / Pumping Speed – Diagram

Fig. 8 Intake Pressure / Pumping Speed – Diagram

(W)

(H)

(D)

Technical Data

115041 19

4.3 Device data

4.3.1 Laboratory Vacuum Systems

Parameter

Unit

LVS

300 Z

301 Z

302 Z

310 Z

311 Z

Pumping speed 50/60 Hz

DIN 28432

at speed of 1500 rpm

m3 / h

2.3 / 2.5

Ultimate pressure

at speed of 1500 rpm

mbar

8

Ultimate pressure

with gas ballast

at speed of 1500 rpm

18

Max. inlet pressure

bar

1

Max. outlet pressure

1

Intake and pressure ports

-

Hose nozzle DN 8

for hose inside diameter 8 mm

Ambient temperature

°C

+ 10 to + 40

Max. Operating

gas temperature

+ 60

Bearing

-

maintenance-free

Reference surface

sound pressure level

DIN EN ISO 2151

dB (A)

44

Voltage / Frequency

(different data upon

customer request)

V, Hz

230, 50/60 (115, 50/60)

(generally with motor protection switch, switch and cable)

Motor power

W

180

Operating mode

-

S 1

Motor / Type of protection

DIN EN 60529

IP 54

Motor / Class of insulation

DIN EN 600034-1

F (160°C)

Type Examination

Certificate no.

WELCH_ATEX_03-01

Designation EX

II3G IIC T3 X (internal Atm. only)

Dimensions (W/D/H)

mm

360 / 310

/ 395

360 / 310 / 445

Weight

kg

16.1

16.3

16.9

17.8

18.1

Order numbers for :

-

in 230 V

inclusive mains connection cable

IEC with plug CEE, UK

- LVS …

- LVS … with dial gauge analog

- LVS … netvac 1

115041

-

-

115047

115047-10

115047-02

115043

-

-

115044

-

-

115045

-

-

in 115 V

inclusive mains connection cable

IEC with plug US

- LVS …

- LVS … with dial gauge analog

- LVS … netvac 1

115041-01

-

-

115047-01

115047-11

115047-03

115043-01

-

-

115044-01

-

-

115045-01

-

-

in 100 V

inclusive mains connection cable

IEC with plug J

- LVS …

- LVS … with dial gauge analog

115041-05

-

115047-05

115047-12

115043-05

-

115044-05

-

115045-05

-

Technical Data

20 115041

Parameter

Unit

LVS 310 Z ef

LVS 310 Z en

Pumping speed 50/60 Hz

DIN 28432

at speed of 1500 rpm

m3 / h

2.6

2.3 / 2.5

Ultimate pressure

at speed of 1500 rpm

mbar

8

Ultimate pressure

with gas ballast

at speed of 1500 rpm

18

Max. inlet pressure

bar

1

Max. outlet pressure

1

Intake and pressure ports

-

Hose nozzle DN 8

for hose inside diameter 8 mm

Ambient temperature

°C

+ 10 to + 40

Max. Operating gas temperature

+ 60

Bearing

-

maintenance-free

Reference surface sound

pressure level

DIN EN ISO 2151

dB (A)

44

Voltage / Frequency

(different data upon customer request)

V, Hz

230, 50/60 (115, 50/60)

(generally with motor protection switch, switch and cable)

Motor power

W

180

Input Frequency changer

(Apparent power)

W / A

680 / 4.5

-

Operating mode

-

S 1

Type of protection (motor)

DIN EN 60529

IP 54

Motor / Class of insulation

DIN EN 600034-1

F (160°C)

Type Examination Certificate

no.

WELCH_ATEX_03-01

Designation EX

II3G IIC T3 X (internal Atm. only)

Dimensions (W/D/H)

mm

360 / 310 / 445

Weight

kg

19.9

17.8

Order numbers for LVS:

-

in 230 V

inclusive mains connection cable

IEC with plug CEE, UK

- LVS …

- LVS … netvac 1

- LVS … with built-in controller

VC 521 extern

115244

115244-03

115244-04

115248

-

in 115 V

inclusive mains connection cable

IEC with plug US

- LVS …

115244-01

115248-01

Loading...

Loading...