Page 1

Inject-TITE™ AWF All-Weather Formula

Description

The Inject-TITE (AWF) All Weather Formula is an acrylate

anchoring system made for temperatures ranging from -15°F

to 120°F. The AWF is a styrene-free formula that allows for use

in a wide range of applications like bonding threaded rod and

reinforcing bar hardware into drilled holes in solid (or hollow)

concrete base materials. It won’t shrink or sag, eliminating

expansion forces and avoiding unwanted forces in the joint. It

can be applied in wet or damp holes and can be used in areas

with severe weather conditions.

9.3 .oz. ECA8

28 .oz. ECA28

Key Features & Benets

Allowed at close-edge distances

Bonds to smooth diamond core drilled holes

Working Range: -15°F to 120°F

Sets in water-lled and damp holes

Styrene-free

9.3 oz (275 ml) and 28 oz. (825 ml) cartridges available

Non-sag gel consistency for horizontal and

vertical installations

For both solid and hollow base materials

Styrene Free

Meets ASTM C-881 and AASHTO M-235

Applications

Foundation Anchors

Bonding Threaded Rod &

Reinforcing Bar

Storage

The material should be stored at 40° -95°F (5°-35°C).

Shelf life of properly stored, unopened containers

is 12 months from date of manufacturer.

Health 1

Flammable 3

Reactive 4

Specications, Listings

and Approvals

Properties:

– Mix Ratio (A to B by volume) – 10:1

– Consistency – Non sag-gel

– Gel time (60 GM MASS @ 73°F) – 7.5 Min.

– ASTM D 695 – Compressive Strength

10,000 PSI (68.95 MPa)

– ASTM D 695 – Compressive Modulus

260,000 PSI (1,793 MPa) ASTM D 570 –

Water Absorption – 0.08%

– ASTM D 648 – Heat Deection temp. –

144°F (62.2 C)

– ASTM C 882 – Bond Strength (2-days) –

2,800 PSI (19.31 MPa)

– ASTM C 882 – Bond Strength (14-days) –

3,200 PSI (22.06 MPa)

– ASTM D 638 – Elongation break – 1.3%

– ASTM D 1875 – Density (lb/gal.) Part-A

13.2 lb/gal. (1.58 kg/L)

– ASTM D 1875 – Density (lb/gal.) Part-B

14.1lb/gal. (1.69 kg/L)

VOC: Inject-TITE Standard-Set Formula has

a VOC content of 0 g/L. Compliant with all

US VOC regulations including Federal EPA,

OTC, LADCO, SCAQMD & CARB.

1-203-857-2200 • www.wejit.com Page 1 of 7

Page 2

Inject-TITE™ AWF All-Weather Formula

Installation Data

Instructions

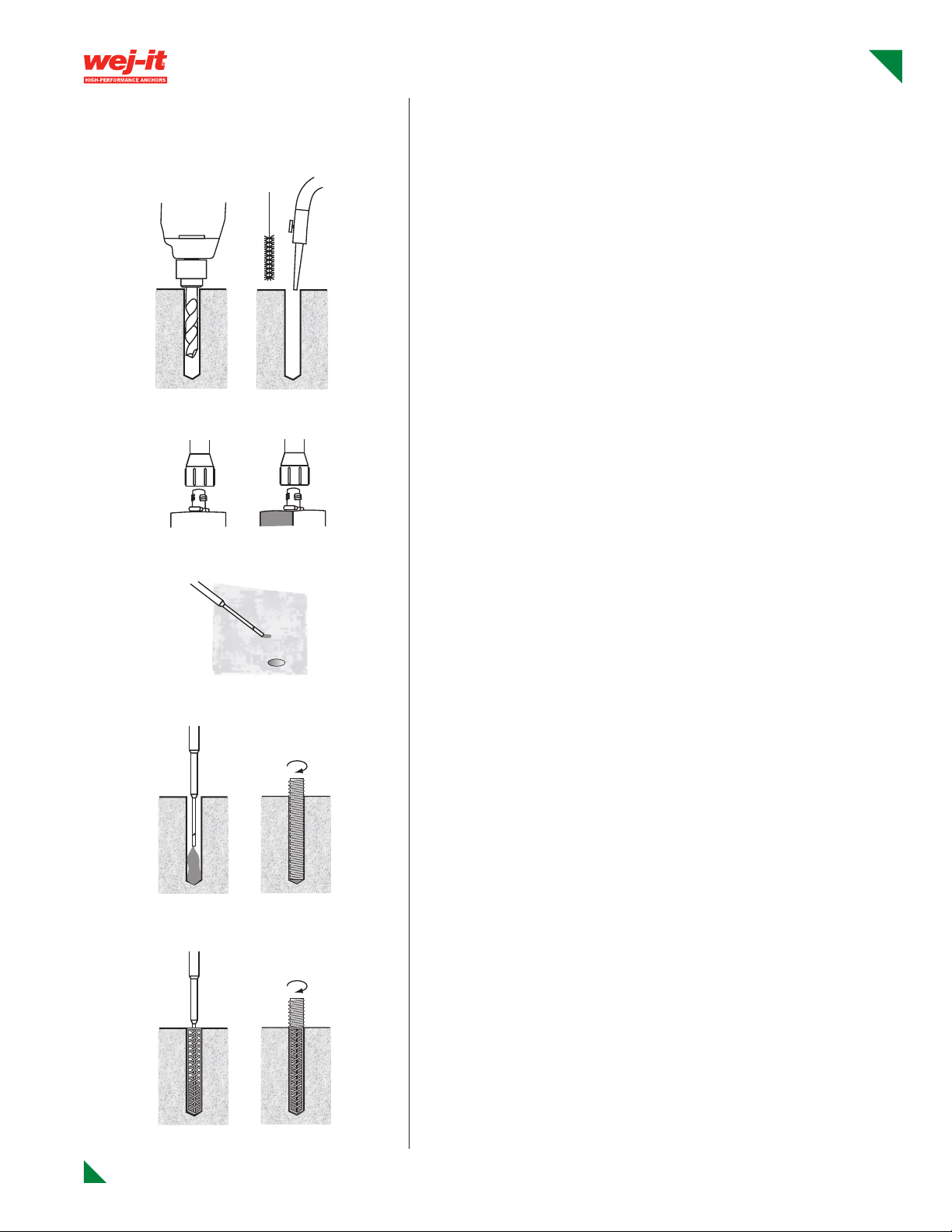

1. Select the proper drill bit. Using only a solid carbide-tipped drill bit that meet the ANSI B212.15 standard

and a hammer drill, proceed to drill the hole perpendicular to the surface and do not allow it to wobble

or to ream out the hole. Always wear safety glasses. Follow the drill manufacturer’s instructions.

2. Cleanliness of all components is very important to the successful use of any adhesive system. Using

clean dry oil-free compressed air or a vacuum, remove the bulk of the dust and debris from the bottom

of the hole. Next — Using a brush that is at least as big as the hole in diameter (sti nylon or wire) or a

combination of multiple brushes that are together more than the hole diameter, brush the hole top to

bottom and back, being very careful to clean the entire bore all the way to the bottom of the hole. This

must be done at least 3 times. The idea is to clear the concrete of dust allowing a good ow of adhesive

into the porosity of the concrete. Using clean dry oil-free compressed air (air nozzle and plastic tube for

extension to the bottom of the hole would work well for this) blow out from the bottom up the dust that

is brushed o of the walls of the hole. Repeated brushings will not signicantly aect hole diameter.

Finally — take the brush and repeat the brushing/blowing procedure until no visible dust or debris is

blown out of the hole. Repeat no less than two more times.

If you do not follow these cleaning procedures, you could signicantly reduce or eliminate the

holding capacity of this anchoring system.

3. For 9.3 oz. cartridges: Remove screw-top lid / cap and end plug from cartridge. Screw static mixing

nozzle onto cartridge. Place assembled cartridge into the dispensing tool. For 28 oz. cartridges: Remove

D-shaped plug from cartridge. Slide retaining nut over static mixer. Secure static mixer to cartridge by

screwing retaining nut onto cartridge. Place assembled cartridge into the dispensing tool.

4. Make sure that adhesive is properly mixed (uniform gray color) when coming out of the end of the

static mixing nozzle before lling any hole. This verication should be done on a piece of disposable

material and not in the hole. Run a bead and check it to be sure.

5. In Concrete: Starting at the BOTTOM of the hole to avoid air pockets, inject Inject-TITE adhesive into the

hole until it’s 1/2 full while pulling static mixer out using constant uniform pressure.

In Masonry: Insert nylon or stainless steel screen into hole. Starting from the BOTTOM of the screen,

inject Inject-TITE adhesive into the screen until it’s 1/2 full while pulling static mixer out using constant

uniform pressure

NOTE: For both Concrete and Masonry: Dispense under constant uniform pressure. If dispensing is altered, re-establish uniform color prior to

continuing. When using a hand dispensing tool, release pressure from tool by pressing thumb button at every pause in dispensing. Re-establish uniform

color prior to continuing. Do not use adhesive with color streaks.

6. Slowly push anchor into the hole, rotating in a clockwise motion. See appropriate chart for minimum

and full cure times. Anchors are to be undisturbed during the minimum cure time.

NOTE: Always wear safety glasses. Follow drill manufacturer’s instructions. Use only solid carbide-tipped drill bits meeting ANSI B212.15

diameter standards.

Page 2 of 7

1-203-857-2200 • www.wejit.com

Page 3

3x

1 2

3

Inject-TITE™ AWF All-Weather Formula

Important Information

Limitations

– FOR INDUSTRIAL USE ONLY.

– Concrete or masonry surface must be frost free.

– Do not thin. Solvents will prevent proper cure.

– Minimum age of concrete must be 3 – 7 days, depending

on curing and drying conditions.

– NTSB safety recommendations prohibit the use of

adhesive anchors in sustained overhead load

anchoring applications.

Cautions

– Irritant to skin and eyes. Avoid skin contact.

– Use of safety goggles and chemical-resistant gloves

is recommended.

– Avoid breathing vapors. Use of a NIOSH/MSHA organic

vapor respirator recommended if ventilation

is inadequate.

Concrete

Masonry

5 6

Skin Contact

4

– Remove any contaminated clothing.

– Remove product immediately with a dry cloth or

paper towel.

– Wash skin thoroughly with soap and water. Solvents

should not be used as they carry irritant into the skin.

Eye Contact

– Flush immediately with water for at least 15 minutes.

Contact physician immediately. Respiratory Problems

– Remove person to fresh air.

Cleanup

– Collect with absorbent materials. Flush area with water.

Dispose of in accordance with local disposal regulations.

Uncured material can be removed with Unitex Citrus

Cleaner or Xylene. Cured material can only be removed

mechanically.

5 6

1-203-857-2200 • www.wejit.com

Page 3 of 7

Page 4

Inject-TITE™ AWF All-Weather Formula

Embedment Depth (inches)

234567891011121314151617181920

Estimating Guide

Threaded Rod in Concrete: Number of Holes per 28oz. Cartridge*

Rod Size

(in.)

3/8 7/16 244 163 122 98 81 70 61 55 50 45 41 38 36 33 31 29 28 27 26

1/2 9/16 173 116 87 70 59 50 43 37 36 32 29 27 24 23 22 20 19 19 18

5/8 3/4 89 60 45 36 31 25 23 20 18 17 15 14 13 13 11 11 10 10 9

3/4 7/8 71 47 36 29 24 20 18 17 14 13 13 11 10 10 9 9 9 8 8

7/8 1 60 39 31 24 20 15 15 14 13 11 10 10 9 9 8 8 8 6 6

1 1-1/8 48 33 24 20 17 14 13 11 10 9 9 8 8 6 6 6 6 5 5

1-1/8 1-1/4 43 29 22 18 15 13 11 10 9 9 8 8 6 6 6 5 5 5 5

1-1/4 1-3/8 37 25 19 15 13 11 10 9 8 8 6 6 6 5 5 5 5 4 4

1-1/2 1-5/8 29 20 15 13 10 9 8 6 6 6 5 5 5 4 4 4 4 4 4

Hole Size

(in.)

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Rebar in Concrete: Number of Holes per 28oz. Cartridge*

Rebar Size

#3 1/2 207 139 104 84 70 60 52 47 42 38 36 33 31 28 27 25 24 23 22

#4 5/8 162 108 81 65 55 47 41 37 33 31 28 25 24 22 20 19 19 18 18

#5 3/4 131 88 66 52 45 38 33 29 27 24 22 20 19 18 17 15 15 14 14

#6 7/8 104 70 52 41 36 31 27 24 22 19 18 17 15 14 14 13 13 11 11

#7 1 92 61 46 37 31 27 23 20 19 17 15 14 14 13 11 11 10 10 10

#8 1-1/8 79 52 39 32 27 23 20 18 17 15 14 13 11 11 10 10 9 9 9

#9 1-3/8 39 27 20 17 14 11 10 9 9 8 8 6 6 5 5 5 5 5 4

#10 1-1/2 38 25 19 15 13 11 10 9 8 8 6 6 6 5 5 5 5 5 4

Hole Size

(in.)

Embedment Depth (in.)

Embedment Depth (in.)

Rebar in Concrete: Number Holes Per 9.3 oz Cartridge*

Rebar Size

#3 1/2 69 46 35 29 23 20 18 15 14 13 12 11 10 10 9 9 8 8 8

#4 5/8 54 36 28 22 19 15 13 12 11 10 10 9 8 8 7 7 7 6 6

#5 3/4 44 30 22 18 15 13 11 10 9 8 8 7 7 6 6 6 6 4 4

#6 7/8 35 23 18 13 12 10 9 8 8 7 6 6 6 4 4 4 4 3 3

#7 1 31 21 15 12 10 9 8 7 7 6 6 4 4 4 3 3 3 3 3

#8 1-1/8 26 18 13 11 9 8 7 6 6 6 4 4 3 3 3 3 3 3 3

#9 1-3/8 13 9 7 6 4 3 3 3 3 2 2 2 2 2 2 2 2 2 1

#10 1-1/2 13 9 7 6 4 3 3 3 2 2 2 2 2 2 2 2 2 2 1

Hole Size

(in.)

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Embedment Depth (inches)

All Thread in Concrete: Number Holes Per 9.3 oz Cartridge*

Size (in.)

3/8 7/16 81 54 41 33 28 23 21 19 17 15 13 13 12 11 10 10 10 9 9

1/2 9/16 58 39 29 23 20 17 14 12 12 11 10 9 8 8 8 7 7 7 6

5/8 3/4 30 20 15 12 10 9 8 7 6 6 6 4 4 4 3 3 3 3 3

3/4 7/8 24 15 12 10 8 7 6 6 4 4 4 3 3 3 3 3 3 2 2

7/8 1 20 13 10 8 7 6 6 4 4 3 3 3 3 3 2 2 2 2 2

1 1-1/8 17 11 8 7 6 4 4 3 3 3 3 2 2 2 2 2 2 2 2

1-1/8 1-1/4 14 10 8 6 6 4 3 3 3 3 2 2 2 2 2 2 2 2 2

1-1/4 1-1/2 12 9 7 6 4 3 3 3 2 2 2 2 2 2 2 2 2 1 1

1-1/2 1-5/8 10 7 6 4 3 3 2 2 2 2 2 2 2 1 1 1 1 1 1

Page 4 of 7

Hole Size

(in.)

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

1-203-857-2200 • www.wejit.com

Page 5

Inject-TITE™ AWF All-Weather Formula

Substrate Temp.

Dowel in Concrete: Number Holes Per 9.3 oz Cartridge*

Dowel Size

(in.)

3/4 7/8 35 24 18 14 12 10 9 8 8 7 6 6 6 4 4 4 4 3 3

7/8 1 31 21 15 12 10 9 8 7 7 6 6 4 4 4 3 3 3 3 3

1 1-1/8 26 18 13 11 9 8 7 6 6 4 4 4 3 3 3 3 3 3 2

1-1/4 1-3/8 21 14 11 9 8 6 6 4 4 3 3 3 3 3 3 2 2 2 2

1-1/2 1-5/8 18 12 9 8 6 6 4 4 3 3 3 3 2 2 2 2 2 2 2

* The number of anchoring installations is based upon calculations of hole volumes using ANSI tolerance carbide tipped drill bits, the nominal areas of the

reinforcing bars and the stress areas of the threaded rods. These estimates do not account for waste.

Hole Size

(in.)

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Cure Times

Minimum

-15° F (-26°C) 8 hrs 36 hrs

0°F (-18°C) 4 hrs 24 hrs

40°F (5°C) 45 min 90 min

65°F (18°C) 8 min 45 min

70°F (21°C) 7 min 35 min

80°F (32°C) 6 min 30 min

100°F (38°C) 5 min 25 min

Gel Time Cure Time

NOTES:

1. Cure Time is time required before epoxy reaches ultimate strength.

2. Anchors are to be undisturbed during the minimum cure time.

3. Gel time = time limit for installation and positioning for anchor element.

4. All surfaces using AWF must be free of frost and ice.

Embedment Depth (inches)

Resistance to Chemicals

Chemical Chemical Tested Behavior

Concentrate -

Sulphuric Acid

Hydrochloric Acid

Nitric Acid

Phosphoric Acid

Acetic Acid

Formic Acid

Citric Acid 10% +

Lactic Acid

Sodium Hydroxide 40% *

Caustic Soda

30% *

10% +

Concentrate -

10% +

Concentrate -

10% *

Concentrate +

10% +

Concentrate *

10% +

Concentrate -

10% *

Concentrate +

10% +

20% +

5% +

Chemical Chemical Tested Behavior

Ammonia

Soda Solution 10% +

Common Salt Solution 10% +

Chlorinated Lime

Solution

Sodium Hypochlorite 2% +

Hydrogen Peroxide 10% +

Carbolic Acid Solution 10% -

Ethanol -

Sea Water +

Glycol +

Acetone -

Carbon Tetrachloride -

Tol ulene *

Petrol/gasoline *

Machine Oil *

Diesel Oil *

Key:

- Non-Resistant

+Resistant

* Limited Resistance

Concentrate *

5% +

10% +

1-203-857-2200 • www.wejit.com

Page 5 of 7

Page 6

Inject-TITE™ AWF All-Weather Formula

Performance Data

Ultimate Loads (lbs.) – Reinforced Bar in Normal-Weight Concrete

Rebar

Size

#3 7/16 3-3/8 4-1/2 1-1/2 6220 8800 10560

#4 5/8 4-1/2 6 2 16430 16000 1920 0

#5 3/4 5-5/8 7-1/2 2-1/2 23310 24800 29760

#6 7/8 6-3/4 9 3 31145 35200 42240

#7 1 7-7/ 8 10-1/2 3-1/ 2 36975 48000 57600

#8 1-1/8 9 12 4 43320 62400 74880

#9 1-3/8 11-1/4 13-1/2 5 6134 0 - -

Drill Bit

Dia. (in.)

Embed.

Depth (in.)

Critical Edge

Dist. (in.)

Min. Edge

Dist. (in.)

Ultimate Loads (lbs.) – A-36 Threaded Rod in Normal-Weight Concrete

Rod Dia.

(in.)

3/8 7/16

1/2 9/16

5/8 3/4

3/4 7/8

7/8 1

1 1-1/8

1-1/4 1-3/8

*Allowable load capacities are calculated using an applied safety factor of 4:1

Warning: NTSB safety recommendations prohibit the use of adhesive anchors in sustained overhead load anchoring applications

Drill Bit

Dia. (in.)

Embed. Depth

(in.)

1-11/ 16

3-3/8 10685 10785

2-1/4

4-1/2 154 05 19985

2-13/16

5-5/8 29465 32730

3-3/8

6-3/4 28995 43460

3-15/16

7-7/8 40235 56865

4-1/2

9 54715 54945

5-5/8

11-1/4 74125 80180

Critical Edge

Dist. (in.)

4-1/2 1-1/2

6 2

7-1/2 2-1/2

9 3

10-1/2 3-1/2

12 4

13-1/2 5

Min. Edge

Dist. (in.)

Ten sio n Shear

2,300 psi Grade 40 Grade 60

Ten sio n

2,300 psi 4,300 psi

3520 5330

6435 9780

10600 17 315

15780 24285

1742 5 317 95

22980 35400

33220 54230

Shear

4500

7720

12000

17440

23600

26000

48000

Page 6 of 7

1-203-857-2200 • www.wejit.com

Page 7

Order Information

®

Inject-TITE AWF All-Weather Formula

Inject-TITE™ AWF All-Weather Formula

Catalog No. Description

ECA8 9.3 . oz. (275 ml) Cartridge 1 12

ECA28 28 . oz. (825 ml) Cartridge 1 8

* Each adhesive tube is supplied with one nozzle

Box

Quantity

Carton

Quantity

Inject-TITE™, TOGGLER logo and typeface, Wej-It® and High-Performance Anchors®

are trademarks of Mechanical Plastics Corp. ©2015 Mechanical Plastics Corp. Rev. 6/15

1-203-857-2200 • www.wejit.com

For more information, please contact:

Divisions of Mechanical Plastics Corp.

110 Richards Avenue • Norwalk, CT 06854

Phone: 203-857-2200

Fax: 203-857-2201 • E-mail: sales@wejit.com

www.toggler.com • www.wejit.com

Page 7 of 7

Loading...

Loading...