Page 1

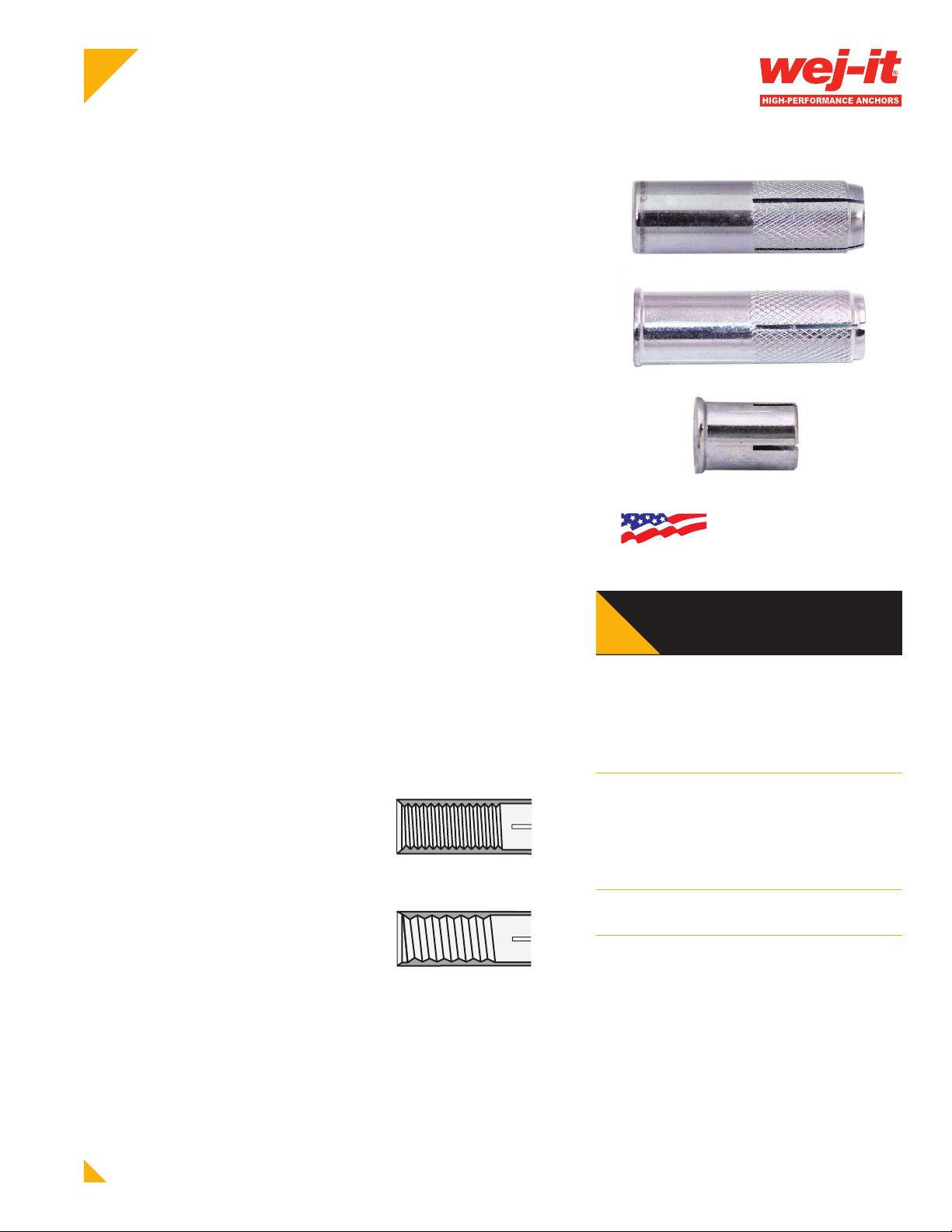

Ultra-Drop™ Drop-In Anchors

USA ENGINEERED

Description

The Ultra-Drop™ Drop-in Anchor is an internally threaded,

ush mount, expansion anchor designed for use in solid

concrete, stone, and solid block based materials. The

Ultra-Drop features a knurled body that increases friction

between the anchor body and the internal walls of the hole.

Options include: standard, coil thread, lipped and mini. The

standard drop-in anchors are also available in 304SS and 316SS.

Standard and Coil Thread

Key Features & Benets

Easy to install using a hammer (or mallet) and a setting tool

Internally threaded anchor allows easy bolt removability

and service work

Two-piece anchor comprised of internally threaded anchor

body and an expansion cone insert

– Case hardened expansion cone insert prevents

galling and binding during expansion

Tapered bottom lip provides maximum depth

and holding power

Anchor design oers consistent holding power

in shallow embedment

Eliminates requirement for rod couplings

in overhead applications

Internal thread* accepts UNC bolts or threaded bolts

– Coil thread style accepts

standard coil thread rod or

coil thread bolts

Available in a variety

of materials:

– Zinc-plated carbon steel

– 304 stainless steel

Internal Threads*

Standard, Lipped and Mini Anchors

accept UNC standard thread

Lipped

Mini

Specications, Listings

and Approvals

Materials:

Carbon steel with zinc plating

– ASTM B633 Type III, SC1 (clear

chromate added)

Type 304 and Type 316 stainless steel

Internal Thread*:

UNC coarse thread or standard

coil thread

– 1/4" - 3/4" UNC Coarse Thread

– 1/2” & 3/4” Coil Thread

Federal Specications:

GSA FFS-325, Group VIII, Type I

– 316 stainless steel

Coil Thread Anchors

accept standard coil thread

Applications

Conduit Suspension

Cable Trays & Strut

Pipe Supports

1-203-857-2200 • www.wejit.com Page 1 of 6

Fire Sprinklers

Utilities

Suspended Lighting

Page 2

Ultra-Drop™ Drop-In Anchors

d

h

v

h

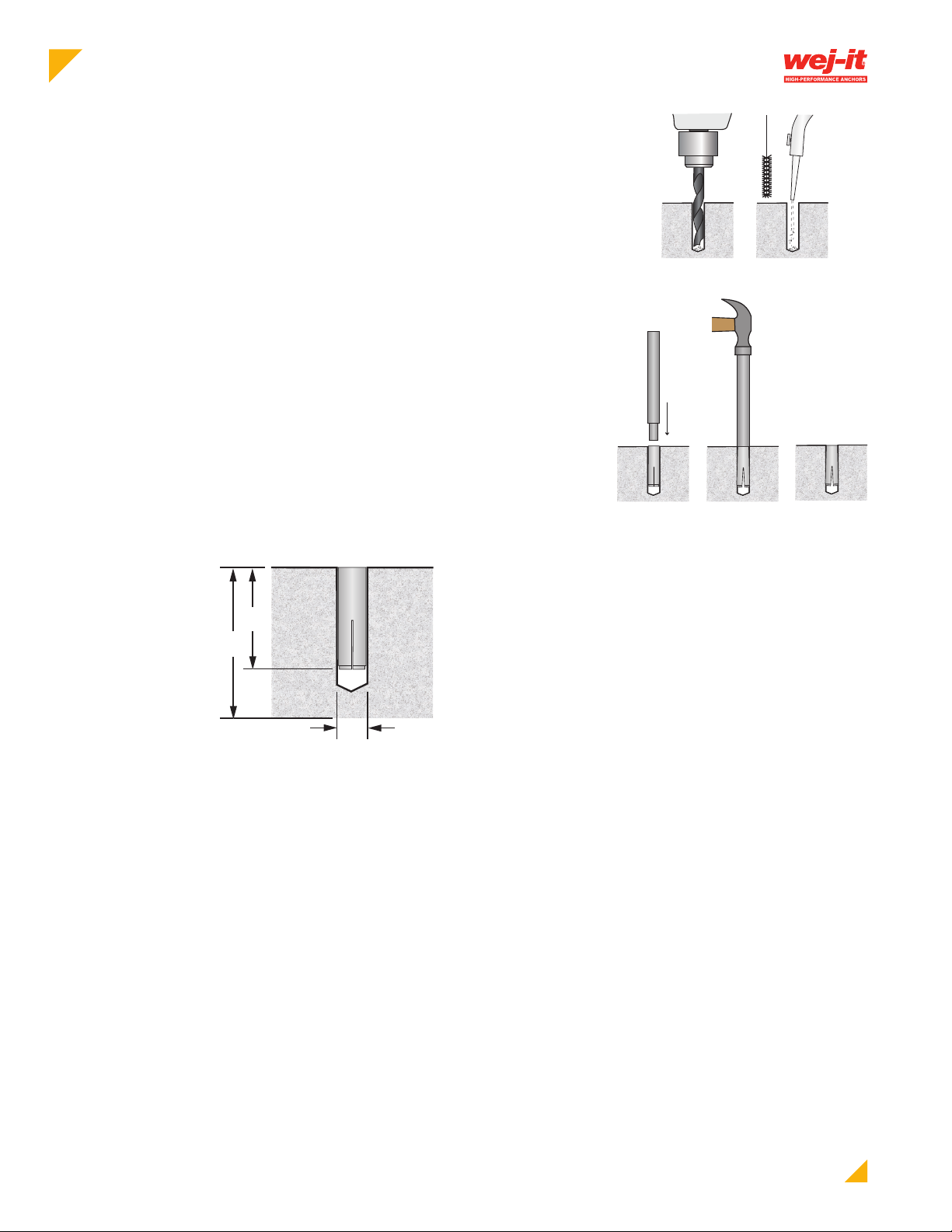

Installation Information

Instructions

1. Drill the hole perpendicular to the work surface at the required

embedment depth. To assure full holding power, do not ream

the hole or allow the drill to wobble.

2. Clean the hole using compressed air and a nylon brush.

3. Place the anchor into the hole. Make sure that the top of the

anchor is ush with, or below, the level of the work surface.

4. Insert the setting tool into the threaded end of the anchor and

expand the anchor by striking the end of the setting tool with a

hammer. The anchor is set (fully expanded) when the shoulder

of the setting tool touches the anchor. Full expansion is

necessary for proper anchor performance.

5. The anchor is now ready to accept threaded hardware.

NOTE: Always wear safety glasses. Follow the drill manufacturer’s safety instructions. Use only

solid carbide-tipped drill bits meeting ANSI B212.15 diameter standards.

1

3 4

2

5

Length Selection

hv: Minimum embedment depth

h: Base material thickness

d: Anchor diameter

Note: Anchor diameter = drill bit diameter

Page 2 of 6

Page 3

Ultra-Drop™ Drop-In Anchors

Torque Approx.

Torque Approx.

Installation Data

Standard, Lipped and Coil Thread

Anchor

Thread

Dia. (in.)

1/4 3/8 1/4 - 20 7/16 1 5 3 - 1/2 1 - 3/4 3 1 - 1/2

3/8 1/2 3/8 - 16 3/4 1-9/16 10 5 - 1/4 2 - 5/8 4 - 1/2 2 - 1/4

1/2 5/8 1/2 - 13 13/16 2 20 7 3 - 1/2 6 3

1/2 Coil Thread 5/8 1/2 - 6 13/16 2 20 7 3 - 1/2 6 3

5/8 7/8 5/8 - 11 1 - 7/16 2-1/2 40 8 - 3/4 4 - 3/8 7 - 1/2 3 - 3/4

3/4 1 3/4 - 10 1 - 3/8 3-1/4 80 10 - 1/2 5 - 1/4 9 4 - 1/2

3/4 Coil Thread 1 3/4 - 4-1/2 1 - 3/8 3-1/4 80 10 - 1/2 5 - 1/4 9 4 - 1/2

Mini

Anchor

Thread

Dia. (in.)

1/4 3/8 1/4 - 20 3/8 5/8 3 3 1 - 1/2 1 - 7/8 15/16

3/8 1/ 2 3/8 - 16 7/16 3/4 5 4 - 1/2 2 - 1/4 2 - 1/4 1 - 1/8

1/2 5/8 1/2 - 13 5/8 1 10 6 3 3 1 - 1/2

Drill Bit

Dia.

(in.)

Drill Bit

Dia.

(in.)

Thread

Size

(UNC)

Thread

Size

(UNC)

Thread

Depth

(in.)

Thread

Depth

(in.)

Anchor Length/

Min. Embed.

Depth (in.)

Anchor Length/

Min. Embed.

Depth (in.)

Installation

(ft-lb.)

Installation

(ft-lb.)

Critical Edge

Distance

(in.)

Critical Edge

Distance

(in.)

Min. Edge

Dist.

(in.)

Min. Edge

Dist.

(in.)

Critical

Spacing

(in.)

Critical

Spacing

(in.)

Min.

Spacing

Min.

Spacing

(in.)

(in.)

Performance Data – Standard/Lipped/Coil Thread Anchors

Ultimate and Allowable Loads (lbs.) – Normal-Weight Concrete

Anchor

Thread

Dia. (in.)

1/4 1 378 458 510 495 528 533 1510 1830 2040 198 0 2110 213 0

3/8 1-1/2 650 1095 1048 114 8 1258 1178 2600 4380 419 0 4590 5030 4710

1/2 2 118 8 156 0 1460 1603 1790 1655 4750 6240 5840 6 410 7160 6620

5/8 2-1/2 134 8 2520 2100 3010 2768 3245 5390 10080 8400 120 4 0 11070 12 9 8 0

3/4 3 -1/4 2275 3670 2588 3868 3125 4085 910 0 14 680 10350 15470 1250 0 16340

*Allowable load capacities are calculated using an applied safety factor of 4:1

Min.

Embed.

Depth (in.)

2,000 psi 4,000 psi 6,000 psi 2,000 psi 4,000 psi 6,000 psi

Ten sio n Shear Ten sio n Shear Ten sio n Shear Ten sio n Shear Ten sio n Shear Ten sio n Shear

Ultimate and Allowable Loads (lbs.) – Structural Lightweight Concrete

Anchor

Thread

Dia. (in.)

1/4 1 278 458 418 495 463 533 1110 1830 1670 198 0 1850 2130

3/8 1-1/2 748 1095 973 114 8 116 0 1178 2990 4380 3890 4590 4640 4710

1/2 2 116 3 156 0 1243 1603 1485 1655 4650 6240 4970 6 410 5940 6620

5/8 2-1/2 1495 2520 2030 3010 2195 3245 5980 10080 8120 12040 8780 1298 0

3/4 3 -1/4 2350 3670 2883 3868 3240 4085 9400 14 680 1153 0 15470 12960 16340

*Allowable load capacities are calculated using an applied safety factor of 4:1

Min.

Embed.

Depth (in.)

2,000 psi 4,000 psi 6,000 psi 2,000 psi 4,000 psi 6,000 psi

Ten sio n Shear Ten sio n Shear Ten sio n Shear Ten sio n Shear Ten sio n Shear Ten sio n Shear

Allowable Ultimate

Allowable Ultimate

1-203-857-2200 • www.wejit.com

Page 3 of 6

Page 4

Ultra-Drop™ Drop-In Anchors

Load Adjustment Factors – Standard/Lipped/Coil Thread Anchors

Spacing in Normal-Weight and Lightweight Concrete (Tension and Shear)

Anchor Thread Dia. 1/4 3/8 1/2 5/8 3/4

Embedment h

Critical Spacing S

Min. Spacing S

Actual

Spacing S

act

v

cr

min

1-1/2 0.50 – – – –

2-1/4 0.75 0.50 – – –

3 1.0 0 0.67 0.50 – –

3-3/4 – 0.83 0.63 0.50 –

4-1/2 – 1.00 0.75 0.60 –

4-7/8 – – 0.81 0.65 0.50

6 – – 1.00 0.80 0.62

7-1/2 – – – 1.00 0.77

9-3/4 – – – – 1.00

1 1-1/2 2 2-1/2 3-1/4

3 4-1/2 6 7-1/2 9 -3/4

1-1/2 2-1/4 3 3-3/4 4 -7/8

For tension and shear anchor loads,

the critical spacing (Scr) is equal

to 3 embedment depths at which

the anchor achieves 100% of load.

Minimum spacing (S

1.5 embedment depths at which the

anchor achieves 50% of load.

) is equal to

min

Edge in Normal-Weight Concrete (Tension)

Anchor Thread Dia. 1/4 3/8 1/2 5/8 3/4

Critical Edge Dist. Ccr3-1/2 5-1/4 7 8-3/4 10-1/2

Min. Edge Dist. C

1-3/4 2-5/8 3-1/ 2 4-3/8 5-1/4

min

Edge in Lightweight Concrete (Tension)

Anchor Thread Dia. 1/4 3/8 1/2 5/8 3/4

Critical Edge Dist. Ccr3-1/2 5-1/4 7 8-3/4 10-1/2

Min. Edge Dist. C

1-3/4 0.90 – – – –

2-5/8 0.95 0.90 – – –

Actual

Edge

Dist.

C

act

3-1/2 1.00 0.93 0.90 – –

4-3/8 – 0.97 0.93 0.90 –

5-1/4 – 1.00 0.95 0.92 0.90

7 – – 1.00 0.96 0.93

Actual

Edge

Dist.

C

act

8-3/4 – – – 1.00 0.97

10-1/2 – – – – 1.00

For tension anchor loads, the critical edge distance (Ccr) is equal to 14 anchor

diameters at which the anchor achieves 100% of load. Minimum edge

distance (C

90% of load.

) is equal to 7 anchor diameters at which the anchor achieves

min

For tension anchor loads, the critical edge distance (Ccr) is equal to 14 anchor

diameters at which the anchor achieves 100% of load. Minimum edge

distance (C

80% of load.

Edge in Normal-Weight Concrete (Shear)

Anchor Thread Dia. 1/4 3/8 1/2 5/8 3/4

Critical Edge Dist. C

Min. Edge Dist. C

Actual Edge

Dist.

C

act

cr

min

1-3/4 0.50 – – – –

2 0.57 – – – –

2-5/8 0.75 0.50 – – –

3 0.86 0.57 – – –

3-1/2 1.00 0.67 0.50 – –

4-3/8 – 0.83 0.63 0.50 –

5-1/4 – 1.00 0.75 0.60 0.50

6 – – 0.86 0.69 0.57

7 – – 1.00 0.80 0.67

8 – – – 0.91 0.76

8-3/4 – – – 1.00 0.83

10-1/2 – – – – 1.00

3-1/2 5-1/4 7 8-3/4 10-1/2

1-3/4 2-5/8 3-1/2 4-3/8 5-1/4

1-3/4 2-5/8 3-1/ 2 4-3/8 5-1/4

min

1-3/4 0.80 – – – –

2 0.83 – – – –

2-5/8 0.90 0.80 – – –

3-1/2 1.00 0.87 0.80 – –

4-3/8 – 0.93 0.85 0.80 –

5-1/4 – 1.00 0.90 0.84 0.80

7 – – 1.00 0.92 0.87

8-3/4 – – – 1.00 0.93

10-1/2 – – – – 1.00

) is equal to 7 anchor diameters at which the anchor achieves

min

For shear anchor loads, the critical

edge distance (Ccr) is equal to 14 anchor

diameters at which the anchor achieves

100% of load. Minimum edge distance

(C

) is equal to 7 anchor diameters at

min

which the anchor achieves 50% of load.

Page 4 of 6

Page 5

Ultra-Drop™ Drop-In Anchors

Depth (in.)

Performance Data – Mini Anchors

Ultimate and Allowable Loads (lbs.) – Normal-Weight Concrete

Anchor

Thread

Dia. (in.)

Min.

Embed.

2,000 psi 4,000 psi 6,000 psi 2,000 psi 4,000 psi 6,000 psi

Ten sio n Shear Tension Shear Tension Shear Tens ion Shear Ten sio n Shear Ten sion Shear

1/4 5/8 248 283 285 385 303 405 990 1130 1140 1540 1210 1620

3/8 3/4 445 608 543 945 583 1043 17 8 0 2430 2170 3780 2330 4170

1/2 1 755 990 820 118 8 920 119 8 3020 3960 3280 4750 3680 4790

*Allowable load capacities are calculated using an applied safety factor of 4:1

Load Adjustment Factors – MINI Anchors

Spacing in Normal-Weight and Lightweight Concrete (Tension and Shear)

Anchor Thread Dia. 1/4 3/8 1/2

Actual Spacing

S

act

Embedment h

Critical Spacing S

Min. Spacing S

v

cr

min

15/16 0.50 – –

1-1/8 0.60 0.50 –

1-1/2 0.80 0.67 0.50

1-7/8 1.00 0.83 0.63

2-1/4 – 1.0 0 0.75

Allowable Ultimate

5/8 3/4 1

1-7/8 2-1/4 3

15/16 1-1/8 1-1/2

3 – – 1.00

*For tension and shear anchor loads,

the critical spacing (Scr) is equal

to 3 embedment depths at which

the anchor achieves 100% of load.

Minimum spacing (S

1.5 embedment depths at which the

anchor achieves 50% of load.

is equal to

min)

Edge in Normal-Weight Concrete (Tension)

Anchor Thread Dia. 1/4 3/8 1/2

Critical Edge Dist. C

Min. Edge Dist. C

cr

min

1-1/2 0.90 – –

Actual

Edge

Dist.

C

act

2-1/4 0.95 0.90 –

3 1.0 0 0.93 0.90

4-1/2 – 1.0 0 0.95

6 – – 1.00

Edge in Normal-Weight Concrete (Shear)

Anchor Thread Dia. 1/4 3/8 1/2

Actual

Edge

Dist.

C

act

Critical Edge Dist. C

Min. Edge Dist. C

cr

min

1-1/2 0.75 – –

2-1/4 0.88 0.75 –

3 1.0 0 0.83 0.75

4-1/2 – 1.0 0 0.88

6 – – 1.00

3 4 -1/2 6

1-1/2 2-1/4 3

3 4 -1/2 6

1-1/2 2-1/4 3

*For tension anchor loads, the critical

edge distance (Ccr) is equal to 12

diameters at which the anchor achieves

100% of load. Minimum edge distance

(C

) is equal to 6 anchor diameters at

min

which the anchor achieves 90% of load.

*For shear anchor loads, the critical

edge distance (Ccr) is equal to 12

diameters at which the anchor achieves

100% of load. Minimum edge distance

(C

) is equal to 6 anchor diameters at

min

which the anchor achieves 75% of load.

1-203-857-2200 • www.wejit.com

Page 5 of 6

Page 6

Ultra-Drop™ Drop-In Anchors

®

Order Information

Standard: Zinc-Plated Carbon Steel

Catalog No.

WD14 3/8 1/4 - 20 1 10 0 1000

WD38 1/ 2 3/8 - 16 1-5/8 50 500

WD12 5/8 1/2 - 13 2 50 500

WD58 7/8 5/8 - 11 2-1/2 25 200

WD34 1 3/4 - 10 3-1/4 25 150

Drill Bit

Dia.

(in.)

Thread

Size

(UNC)

Anchor

Length

(in.)

Box

Quantity

Quantity

Lipped: Zinc-Plated Carbon Steel

Catalog No.

WDL14 3/8 1/4 - 20 1 10 0 1000

WDL38 1/2 3/8 - 16 1-5/8 50 500

WDL12 5/8 1/2 - 13 2 50 500

Drill Bit

Dia.

(in.)

Thread

Size

(UNC)

Anchor

Length

(in.)

Box

Quantity

Quantity

Coil Thread: Zinc-Plated Carbon Steel

Catalog No.

WD CT12 5/8 1/2 - 6 2 50 500

WDCT34 1 3/4 - 4-1/2 3-1/4 25 150

Drill Bit

Dia.

(in.)

Thread

Size

(UNC)

Anchor

Length

(in.)

Box

Quantity

Quantity

MINI: Zinc-Plated Carbon Steel

Catalog No.

WDM14 3/8 1/4 - 20 5/8 100 1000

WDM38 1/2 3/8 - 16 3/4 50 500

WD M12 5/8 1/2 - 13 1 50 400

Drill

Bit Dia.

(in.)

Thread

Size

(UNC)

Anchor

Length

(in.)

Box

Quantity

Quantity

Carton

Carton

Carton

Carton

Standard: Type 304 Stainless Steel

Catalog No.

WDS14 3/8 1/4 - 20 1 100 1000

WDS38 1/2 3/8 - 16 1-5/8 50 500

WD S12 5/8 1/2 - 13 2 50 500

WDS58 7/8 5/8 - 11 2-1/ 2 25 200

WDS34 1 3/4 - 10 3 -1/4 25 150

Drill Bit

Dia.

(in.)

Thread

Size

(UNC)

Anchor

Length

(in.)

Box

Quantity

Standard: Type 316 Stainless Steel

Catalog No.

WDSS14 3/8 1/4 - 20 1 10 0 1000

WDSS38 1/2 3/8 - 16 1-5/8 50 500

WD S S12 5/8 1/2 - 13 2 50 500

WDSS58 7/8 5/8 - 11 2-1/2 25 200

WDSS34 1 3/4 - 10 3-1/4 25 150

Drill Bit

Dia.

(in.)

Thread

Size

(UNC)

Anchor

Length

(in.)

Box

Quantity

Setting Tools

Catalog No.

ST14 STM14* 1/4 1

ST38 STM38* 3/8 1

ST12 STM12* 1/2 1

ST58 - 5/8 1

ST34 - 3/4 1

* Mini Ultra-Drop Drop-In Anchor Setting Tools

Sets Anchor

Thread Size (in.)

Quantity

Carton

Quantity

Carton

Quantity

Page 6 of 6

For more information, please contact:

Divisions of Mechanical Plastics Corp.

110 Richards Avenue • Norwalk, CT 06854

Phone: 203-857-2200

Fax: 203-857-2201 • E-mail: sales@wejit.com

www.toggler.com • www.wejit.com

Ultra-Drop™, TOGGLER logo and typeface, Wej-It® and High-Performance Anchors®

are trademarks of Mechanical Plastics Corp. ©2014 Mechanical Plastics Corp. Rev. 6/15

Loading...

Loading...