Page 1

Wej-it Fastening Systems reserves the right to change designs and specifications without notice or liability for such changes.

arkable trait of concrete: it's plastic and malleable when newly mixed, strong and durable

Please contact Wej-it Fastening Systems or look us up on www.wejit.com for the most current data available.

BASE MATERIAL

CONCRETE

Wej-it Fastening Systems

Technical Manual

Note: the information and data contained herein was current as of November 2008.

However, the material is subject to change and is updated as needed.

In its simplest form, concrete is a mixture of paste and aggregates. The paste, composed of Portland cement and water, coats

the surface of the fine and coarse aggregates. Through a chemical reaction called hydration, the paste hardens and gains

strength to form the rock-like mass known as concrete.

Within this process lies the key to a rem

when hardened. These qualities explain why one material, concrete, can build skyscrapers, bridges, sidewalks, superhighways,

houses and dams.

Proportioning

The key to achieving a strong, durable concrete rests in the careful proportioning and mixing of the ingredients. A concrete

mixture that does not have enough paste to fill all the voids between the aggregates will be difficult to place and will produce

rough, honeycombed surfaces and porous concrete. A mixture with an excess of cement paste will be easy to place and will

produce a smooth surface; however, the resulting concrete is likely to shrink more and be uneconomical.

A properly designed concrete mixture will possess the desired workability for the fresh concrete and the required durability and

strength for the hardened concrete. Typically, a mix is about 10 to 15 percent cement, 60 to 75 percent aggregate and 15 to 20

percent water. Entrained air in many concrete mixes may also take up another 5 to 8 percent.

Portland cement's chemistry comes to life in the presence of water. Cement and water form a paste that

coats each particle of stone and sand. Through a chemical reaction called hydration, the cement paste

hardens and gains strength. The character of the concrete is determined by the quality of the paste. The

strength of the paste, in turn, depends on the ratio of water to cement. The water-cement ratio is the

weight of the mixing water divided by the weight of the cement. High-quality concrete is produced by

lowering the water-cement ratio as much as possible without sacrificing the workability of fresh concrete.

Generally, using less water produces a higher quality concrete provided the concrete is properly placed,

consolidated, and cured.

Other Ingredients

Although most drinking water is suitable for use in concrete, aggregates are chosen carefully. Aggregates comprise 60 to 75

percent of the total volume of concrete. The type and size of the aggregate mixture depends on the thickness and purpose of the

final concrete product. Almost any natural water that is drinkable and has no pronounced taste or odor may be used as mixing

water for concrete. However, some waters that are not fit for drinking may be suitable for concrete.

Excessive impurities in mixing water not only may affect setting time and concrete strength, but also may cause efflorescence,

staining, corrosion of reinforcement, volume instability, and reduced durability. Specifications usually set limits on chlorides,

sulfates, alkalis, and solids in mixing water unless tests can be performed to determine the effect the impurity has on various

properties. Relatively thin building sections call for small coarse aggregate, though aggregates up to six inches (150 mm) in

diameter have been used in large dams. A continuous gradation of particle sizes is desirable for efficient use of the paste. In

addition, aggregates should be clean and free from any matter that might affect the quality of the concrete.

Page 2

Hydration Begins

ic

based materials represent products that defy the label of "concrete," yet

The aggregate used in

ranges from 100 to

Soon after the aggregates, water, and the cement are combined, the mixture starts to harden. All portland cements are hydraul

cements that set and harden through a chemical reaction with water. During this reaction, called hydration, a node forms on the

surface of each cement particle. The node grows and expands until it links up with nodes from other cement particles or adheres

to adjacent aggregates.

The building up process results in progressive stiffening, hardening, and strength development. Once the concrete is thoroughly

mixed and workable it should be placed in forms before the mixture becomes too stiff.

During placement, the concrete is consolidated to compact it within the forms and to eliminate potential flaws, such as

honeycombs and air pockets. For slabs, concrete is left to stand until the surface moisture film disappears. After the film

disappears from the surface, a wood or metal hand float is used to smooth off the concrete. Floating produces a relatively even,

but slightly rough, texture that has good slip resistance and is frequently used as a final finish for exterior slabs. If a smooth,

hard, dense surface is required, floating is followed by steel troweling.

Curing begins after the exposed surfaces of the concrete has hardened sufficiently to resist marring.

Curing ensures the continued hydration of the cement and the strength gain of the concrete. Concrete

surfaces are cured by sprinkling with water fog, or by using moisture-retaining fabrics such as burlap or

cotton mats. Other curing methods prevent evaporation of the water by sealing the surface with plastic or

special sprays (curing compounds).

Special techniques are used for curing concrete during extremely cold or hot weather to protect the

concrete. The longer the concrete is kept moist, the stronger and more durable it will become. The rate of

hardening depends upon the composition and fineness of the cement, the mix proportions, and the

moisture and temperature conditions. Most of the hydration and strength gain take place within the first

month of concrete's life cycle, but hydration continues at a slower rate for many years. Concrete continues

to get stronger as it gets older.

The Forms of Concrete

Concrete is produced in four basic forms, each with unique applications and properties. Ready mixed concrete, by far the most

common form, accounts for nearly three-fourths of all concrete. It's batched at local plants for delivery in the familiar trucks with

revolving drums. Precast concrete products are cast in a factory setting. These products benefit from tight quality control

achievable at a production plant. Precast products range from concrete bricks, paving stones, bridge girders, to structural

components and panels for cladding.

Concrete masonry, another type of manufactured concrete, may be best known for its conventional 8 x 8 x 16-inch block.

Today's masonry units can be molded into a wealth of shapes, configurations, colors, and textures to serve an infinite spectrum

of building applications and architectural needs. Cementshare many of its qualities. Conventional materials in this category include mortar, grout, and terrazzo. Soil-cement and rollercompacted concrete-"cousins" of concrete-are used for pavements and dams. Other products in this category include flowable fill

and cement-treated bases. A new generation of advanced products incorporates fibers and special aggregate to create roofing

tiles, shake shingles, lap siding, and countertops. And an emerging market is the use of cement to treat and stabilize waste.

Reinforced concrete is formed using concrete meeting a certain compressive strength combined with rebar (reinforcing steel).

The function of the concrete is to resist compressive forces while the rebar resists tensile forces. The design and construction

requirements for reinforced concrete buildings are published by the American Concrete Institute (ACI) in document ACI 318,

Building Code Requirements for Structural Concrete. The type of concrete that is used is based upon the requirements of the

structure into which the concrete will be placed. In ASTM 150 (American Society for Testing and Materials) you will find the

requirements for the most commonly used Types of Portland cement. It also contains such things as Terminology, Chemical

Composition, Physical Properties, Sampling, Test Methods and Referenced Documents.

Concrete aggregate is important. Its hardness and strength will affect the life (wear) of your drill bits, drill speed and hole

configuration. ASTM C 33 is another useful document. It outlines the Standard Specification for Concrete Aggregate. Since

concrete mix designs consist of both course and fine aggregates it’s helpful to know what the acceptable limits are in terms of

size and quantity. It also contains Grading requirements for both course and fine aggregate and provides information on

Soundness, Deleterious Substances, Methods of Sampling and Testing and Referenced Documents as well.

normal weight concrete can range from 135 to 165 lb/ft3 however the unit weight for normal weight concrete generally ranges

from 145 to 155 lb/ft3.

Structural lightweight concrete is used when it is beneficial to lower the weight of the structure being built. It

115 lb/ft3 while lightweight aggregate range from 55 to 70 lb/ft3. This information is located in ASTM C 330. It has been

demonstrated that structural lightweight concrete will affect the load bearing capacities of most anchors and fasteners by

lowering their performance by as much as 40%. To determine precisely how an anchor or fastener is affected it is necessary to

conduct on site tests. An upside to structural lightweight concrete is that it provides better fire resistance than normal weight

concrete.

Another form of concrete is lightweight insulating concrete. This is used for thermal insulating and is outlined in ASTM C 332.

Be careful not to confuse it with structural lightweight concrete.

Page 3

of the

While the type of admixtures, cement and aggregate have an effect on the compressive strength of the concrete, the water to

cement ratio is the primary factor affecting the strength. As the water to cement ratio decreases, the compressive strength

cement increases. In order to determine the compressive strength of concrete, test specimens are formed in cylinders according

to ASTM C 31 and crushed at specific time intervals according to ASTM C 39. The resulting strength is documented to the

nearest 10 psi increment.

Any load capacity listed in this manual is for concrete that has cured a minimum of 28 days unless otherwise noted. Job site tests

are recommended for installations in concrete where the material strength or condition is unknown. The load capacities listed in

this manual were conducted in un-reinforced concrete test members to provide data which is useable regardless of the possible

benefit of reinforcement.

Concrete Reinforcing Bar (Rebar)

In the United States, the size designations of these mild steel bars used to reinforce concrete are set by ASTM International.1

Distributors usually stock rebar in 20- and 60-foot lengths. Most bars are “deformed,” that is, a pattern is rolled onto them which

helps the concrete get a grip on the bar. The exact patterns are not specified, but the spacing, number and height of the bumps are.

Between 1947 and 1968, a separate standard (ASTM A 305) covered the deformations. Since 1968 the deformation requirements

have been incorporated in the basic standard. Plain bars are also made, but are used only in special situations in which the bars are

expected to slide (for example, crossing expansion joints in highway pavement).

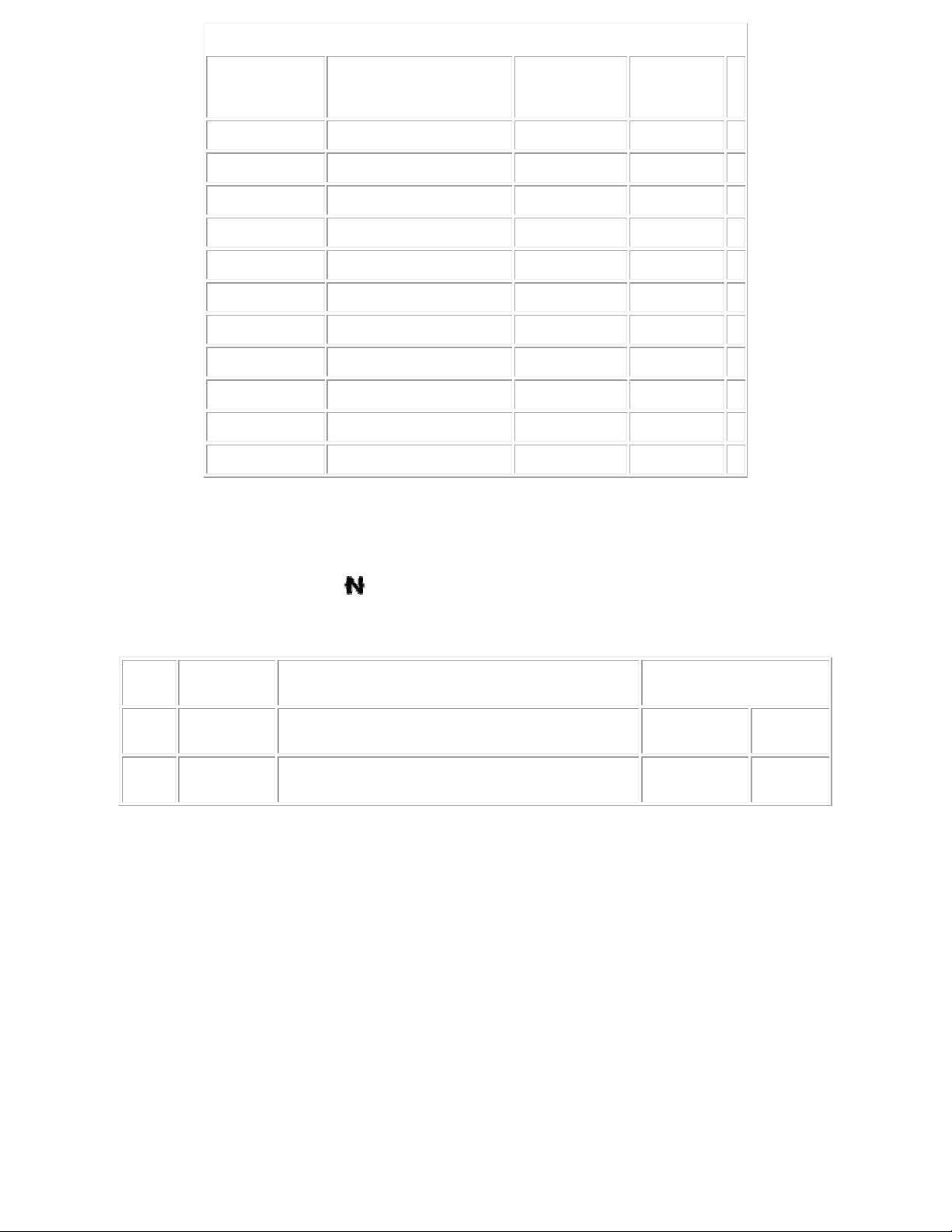

Three grades are defined, with metric equivalents:

Minimum Yield Strength

inch-pound

grade

Grade 40 Grade 280 40,000 280

Grade 60 Grade 420 60,000 420

Grade 75 Grade 520 75,000 520

According to the standard (sec. 20.3.5), "it shall be permissible to substitute a metric size bar of Grade 280 for the

corresponding inch-pound size bar of Grade 40, a metric size bar of Grade 420 for the corresponding inch-pound size bar of Grade

60, and a metric size bar of Grade 520 for the corresponding inch-pound size bar of Grade 75." Nothing is said regarding substituting

inch-pound size bars when the specification is metric.

metric

grade

in pounds

per square inch

in

megapascals

The size designations are the number of eighths of an inch in the diameter of a plain round bar having the same weight per

foot as the deformed bar. So, for example, a number 5 bar would have the same mass per foot as a plain bar 5/8 inch in diameter.

The metric size is the same dimension expressed to the nearest millimeter.

Page 4

Sizes and Dimensions

Bar

designation

number

3 0.375 10 0.376

4 0.500 13 0.668

5 0.625 16 1.043

6 0.750 19 1.502

7 0.875 22 2.044

8 1.000 25 2.670

9 1.128 29 3.400

10 1.270 32 4.303

11 1.410 36 5.313

14 1.693 43 7.650

18 2.257 57 13.60

Specifications require that the producer roll into the bar:

Nominal diameter in

inches (not including

the deformations)

Metric

designation

number

Weight in

pounds

per foot

A letter or symbol identifying the mill that produced the bar.

The bar size.

A symbol indicating the type of steel. for example, means the bar was rolled from a new billet.

If the bar is grade 60 or 75, or metric 420 or 520, a mark indicating its grade. Two styles of marking the grade are used.

o

Grade Metric grade Continuous line system

60 420

75 520

Hard versus Soft Metrification

Various laws2 require federally-funded projects to use materials with metric designations. To meet this requirement, in 1979

ASTM issued standard A 615M-79, which described a set of reinforcing bar sizes in whole number SI units. This standard was

specified in some contracts.

The cost of producing and stocking two different sets of nearly identical sizes proved onerous. In April 1995, the Concrete

Reinforcing Steel Institute and the Steel Manufacturers Association decided to mount a campaign to replace the initial hard metric

sizes with soft. In a soft conversion to metric, the original dimensions are simply restated to the nearest number of SI units. In

1996, ASTM changed A 615M to soft metric sizes. For example, a bar with the metric designation "25", formerly 25 millimeters in

diameter, became 25.4 mm in diameter, the same as a size 8 (1-inch) bar.

1 line running the length of the bar

offset at least five spaces from the center of the bar

2 lines running the length of the bar

offset at least five spaces from the center of the bar

Number system

number stamped onto bar

60 4

75 5

As a result, the metrically-sized bars are identical to the original inch-sized bars, except for the markings and a small

difference in strength (the new metric standard calls for a stronger bar, see the table below).

The grade mark for grade 420 is either a "4" or a single longitudinal grade line. The grade mark for grade 520 is either a "5"

or two longitudinal grade lines.

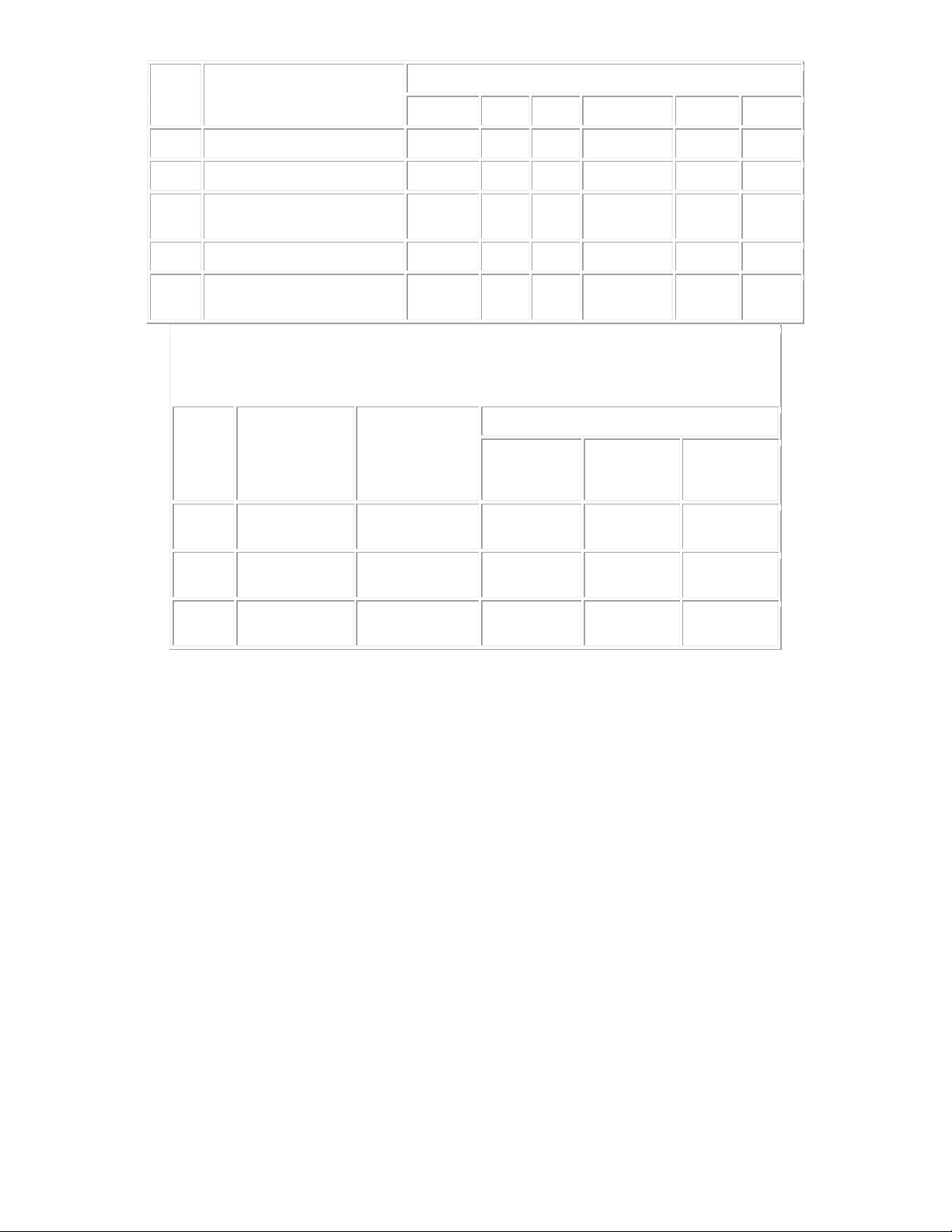

Page 5

Type of steel mark

Mark

S billet A615 A615 A615 A615M A615M A615M

I rail A616 A616 — A996M A996M —

Applicable ASTM Standard by Grade

Meaning

40 & 50 60 75 300 & 350 420 520

IR

A axle A617 A617 — A996M A996M —

W

Rail Meeting Supplementary

Requirements S1

Low-alloy

Grades and Minimum Steel Strength

Corresponding

old US

grade

40 40,000 psi 300

60 60,000 psi 420

75 75,000 psi 520

minimum

yield strength

soft metric

A616 A616 — — — —

— A706 — — A706M —

minimum yield strength

current

grade

original

hard metric

specs

300 MPa

(43,400 psi)

400 MPa

(58,000 psi)

500 MPa

(72,500 psi)

1996

revisions

— —

420 MPa

(60,900 psi)

520 MPa

(75,400 psi)

415 MPa

(60,100 psi)

—

proposal

2. ASTM International issues a series of specifications for rebar:

A615/A615M-05a: Standard Specification for Deformed and Plain Billet-Steel Bars for Concrete Reinforcement. (covers grades 40 and

60/soft metric grades 420 and 520)

A616: Standard Specification for Rail-Steel Deformed Bars for Concrete Reinforcement. (covers grades 50 and 60).

A617: Standard Specification for Axle-Steel Deformed Bars for Concrete Reinforcement. (covers grades 40 and 60)

A706/A706M-96b: Standard Specification for Low-Alloy-Steel Deformed and Plain Bars for Concrete Reinforcement. (grade 60 only)

2. Metric Conversion Act of 1975; Omnibus Trade and Competitiveness Act of 1988 (Public Law 100-418, section 5164); Executive

Order 12770, "Metric Usage in Federal Government Programs."

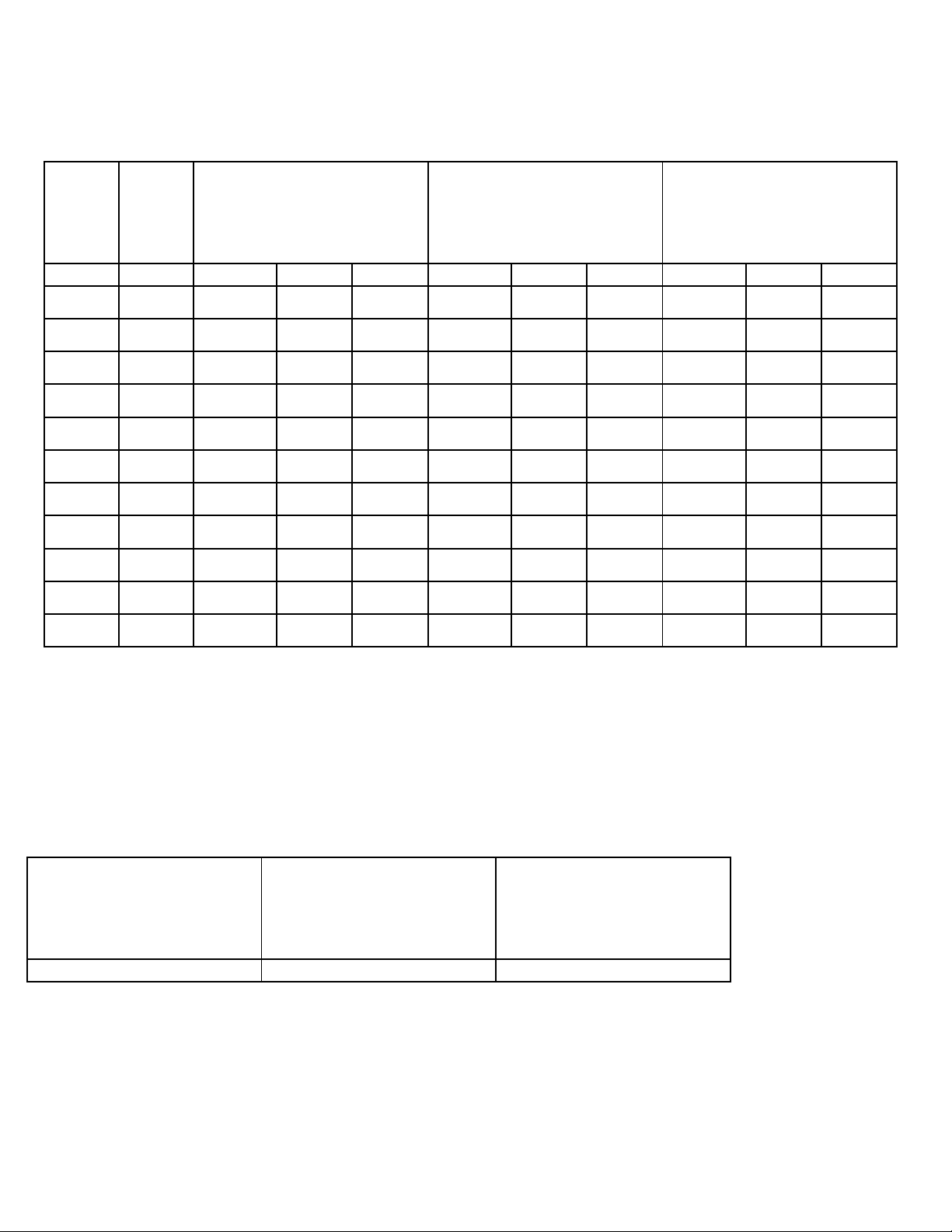

Page 6

Rebar Rebar Grade 40 Rebar Grade 60 Rebar Grade 75 Rebar

Size Area Allowable Yield Ultimate Allowable Yield Ultimate Allowable Yield Ultimate

d Tension Strength Strength Tension Strength Strength Tension Strength Strength

Ø lbs. lbs. lbs. lbs. lbs. lbs. lbs. lbs. lbs.

No. 3 0.110 2209 4418 7731 2651 6627 9940

NO DATA

8284

11045

No. 4 0.196 3927 7854 13745 4712 11781 17672

No. 5 0.307 6136 12272 21476 7363 18408 27612

No. 6 0.442 8836 17672 30925 10603 26507 39761

No. 7 0.601 12026 24053 42093 14432 36079 54119

No. 8 0.785 15708 31416 54978 18850 47124 70686

No. 9 0.999 19987 39973 69953 23984 59960 89940

No. 10 1.267 25335 50671 88674 30403 76006 114009

No. 11 1.561 31229 62458 109302 37475 93687 140531

No. 14 2.251 45023 90046 157581 54028 135069 202604

No. 18 4.001 80017 160035 280061 96021 240052 360078

The strengths listed in the table above are calculated based on the stresses in the following table. The allowable tension is based on

the building code ACI 318. Section 9.4 permits designs based on a yield strength of up to a maximum of 80,000 psi. Currently there

is no ASTM specification for Grade 80 reinforcement. However, deformed reinforcing bars No. 6 through No. 18 with a yield strength

of 75,000 psi (Grade75) are included in the ASTM A 615 specification. “Section 3.5.3.2 requires that the yield strength of greater

than 60,000 psi be taken as the stress corresponding to a strain of 0.35 percent. The 0.35 percent limit is to ensure that the elastoplastic stress-strain curve assumed in 10.2.4 will not result in unconservative values of member strength. Therefore the designer

should be aware that if ASTM A 615, Grade 75 bars are specified, the project specifications need to include a requirement that the

yield strength of the bars shall be determined in accordance with Section 9.2.2 of the ASTM A 615 specification.”

NO DATA

NO DATA

NO DATA

NO DATA

NO DATA

NO DATA

NO DATA

NO DATA

NO DATA

NO DATA

14726

23010

33134

45099

58905

74950

95008

117109

168836

300065

19635

30680

44179

60132

78540

99933

126677

156145

225115

400087

Grade 40 Rebar Grade 60 Rebar Grade 75 Rebar

Allowable Yield Ultimate Allowable Yield Ultimate Allowable Yield Ultimate

Tension Strength Strength Tension Strength Strength Tension Strength Strength

lbs. lbs. lbs. lbs. lbs. lbs. lbs. lbs. lbs.

20000 40000 70000 24000 60000 90000 N/A 75000 100000

(ACC) Autoclaved Concrete is an aerated lightweight material that has been used in other parts of the world but is relatively new to

the market in United States. It’s made of pulverized sand, water, cement and lime however there is no large aggregate in the

mixture. The ingredients are all mixed together to make a paste which is then deposited into molds for forming. The chemical

reaction created creates and traps air bubbles within the solid mix. The batch is allowed to set and then before final hardening

occurs is cut into portions of the desired size. The portions are them hardened & cured in an autoclave utilizing steam under

pressure. ACC is available as you might imagine in a wide variety and combinations of block height, length, thickness’ and

compressive strengths. ACC is used successfully in many applications such as mines, firewalls, shaft wall construction highway sound

walls, exterior wall panels, reinforced panels, load bearing vertical panels, floor and roof panels.

ASTM C 1386 contains specifications for ACC unreinforced block elements and ASTM C 1452 contains those for reinforced panel

elements.

Page 7

MASONRY MATERIALS

Generally speaking, concrete is capable of sustaining higher loads than brick or block. As the embedment depth of an anchor or

fastener increases, the tension load will increase up to a point at which either the capacity of the expansion mechanism or bond is

reached or the concrete fails. The strength of masonry walls is usually less than that of concrete and the consistency of this material

can vary from region to region. To form a wall individual masonry units are bonded together with a cement mortar. The VERTICAL

ROW is called the COURSE and the HORIZONTAL ROW is called a WYTHE.

The strength of the mortar is often the critical factor in product performance. Anchors or fasteners must be installed in the horizontal

mortar joint or in some cases directly into the masonry unit.

In testing products should be installed and loaded to simulate the actual anchor or fastener placement. These tests are usually done

in an unrestrained mode. That is to say that the reaction bridge is spanning the installation without influencing anchor performance.

Hollow base material require special care and consideration as the anchor or fastener must be properly sized to coincide with the wall

thickness or selected to properly expand in the void. This material is very susceptible to reverse spalling thus reducing even further

the normally thin wall thickness’. Manufacturers of hollow block often will specify the maximum load that can be applied to the

material and this must always be kept in mind. Since the strength of masonry materials varies widely, on site testing are

recommended to determine actual load capacities for any critical application that you may have.

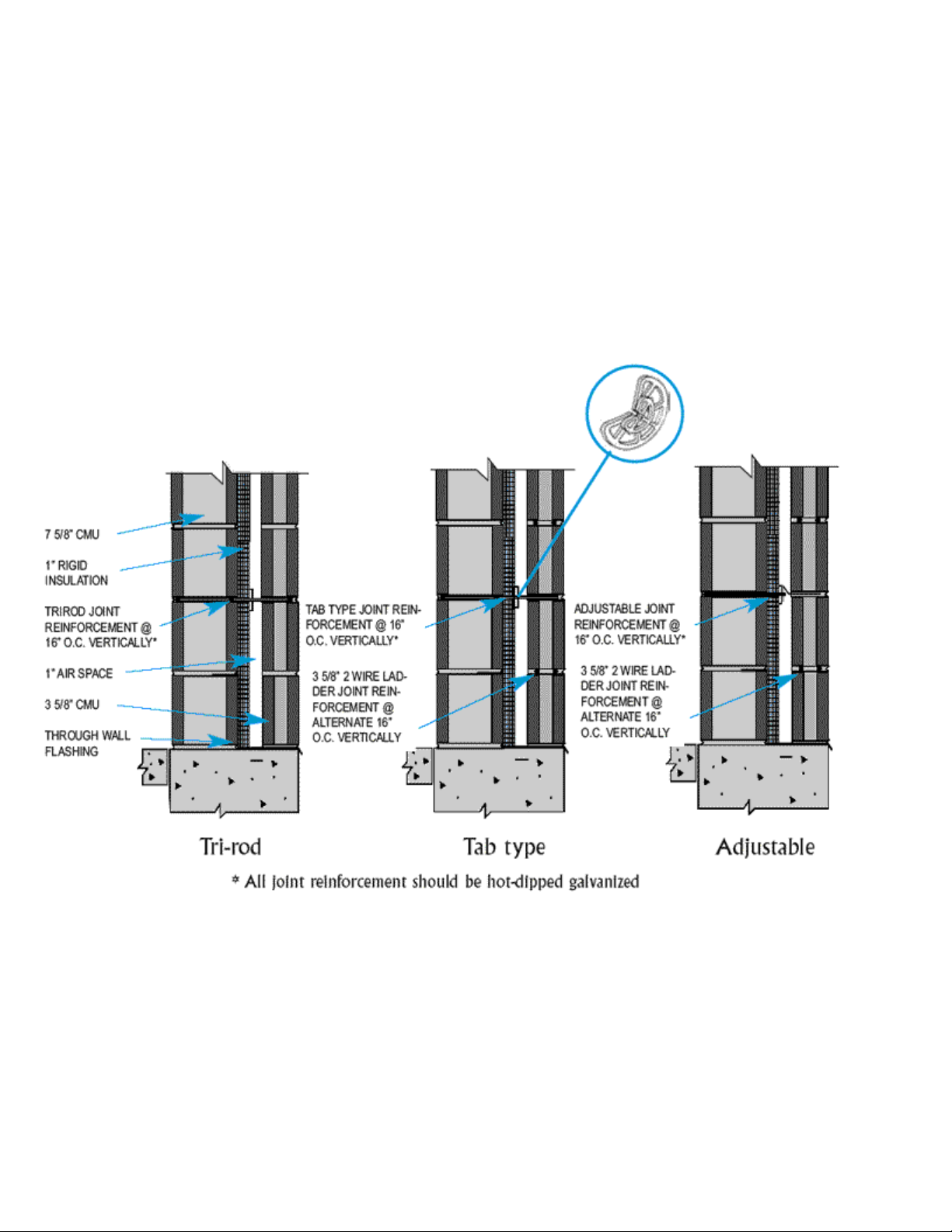

This system is a cavity wall consisting of an exterior concrete masonry veneer and a structural CMU backup. The two wythes are

anchored with horizontal joint reinforcement.. The joint reinforcement can be ladder tri-rod type, tab type, or adjustable. To resist

shrinkage of the concrete masonry veneer, the selection of joint reinforcement should take into account the requirements for

shrinkage control in the veneer. Control joints should be placed in this concrete masonry veneer at the proper spacing and in the

proper locations.

Page 8

CMU Concrete Block Walls

CMUs are

does

. Finally, they are

CMU stands for concrete masonry unit, which is the 8x8x16-inch concrete block that makes up CMU walls. CMUs have been improving in

materials and mixtures since 1882, but their general size and purpose remains the same. Popularly used as a standard building material,

simply precast concrete blocks, meaning that they have been molded to a specific shape and size to build a block or rock retaining wall.

Made from cement, aggregates and water, CMUs are formed in molding equipment and allowed to cure. Curing implies that the concrete CMU

not dry as it hardens but rather retains moisture as it strengthens. Retaining water is part of what gives the concrete block its integrity.

In addition to the ingredients listed above, CMU mixtures may include a host of optional admixtures created to enhance or change the finalized

CMU block’s characteristics. By adding such ingredients, the manufacturer may be able to strengthen, air-entrain, color, accelerate curing speed,

retard or plasticize the CMU. For example, air bubbles disperse in concrete (know as air-entraining) to protect against freezing and thawing

conditions. Plasticizers help make concrete more workable while forming it.

As they are manufactured, CMUs are generally formed in a concrete forming machine that takes moist concrete and quickly pours it into the

desired block dimensions. Placed in chambers that have extremely high temperatures, the CMU blocks undergo accelerated curing

stored for a specific period of time to promote further curing prior to shipment. These CMU blocks are designed to ultimately be the core for walls

and buildings that need to be fabricated economically, efficiently and for fire-resistance.

As the finalized CMU blocks are identical, they provide a good material to build a solid wall. The CMU blocks are stacked in layers with mortar

between each block. This process allows for flexible and versatile concrete masonry construction.

CMUs are formed for many different purposes and include various masonry unit types including split face concrete block, slotted and glazed CMUs.

Split face CMUs are formed as one unit and then split revealing the rough aggregate texture. Slotted CMUs offer high sound absorption in places

where a sound barrier wall may be need. Glazed CMUs are primarily used when an aesthetically pleasing finish is desired. Both hollow and solid

types which can be classified as load bearing or non-load bearing are used. CMU blocks are usually considered to be a load bearing masonry unit

and suitable for anchoring and fastening. However on site tests are always recommended for critical applications. ASTM C 90 describes hollow and

solid load bearing concrete masonry unit made from Portland cement, water and mineral aggregates in normal, medium and lightweight

classifications. (Standard Specification for Loadbearing Concrete Masonry Units)

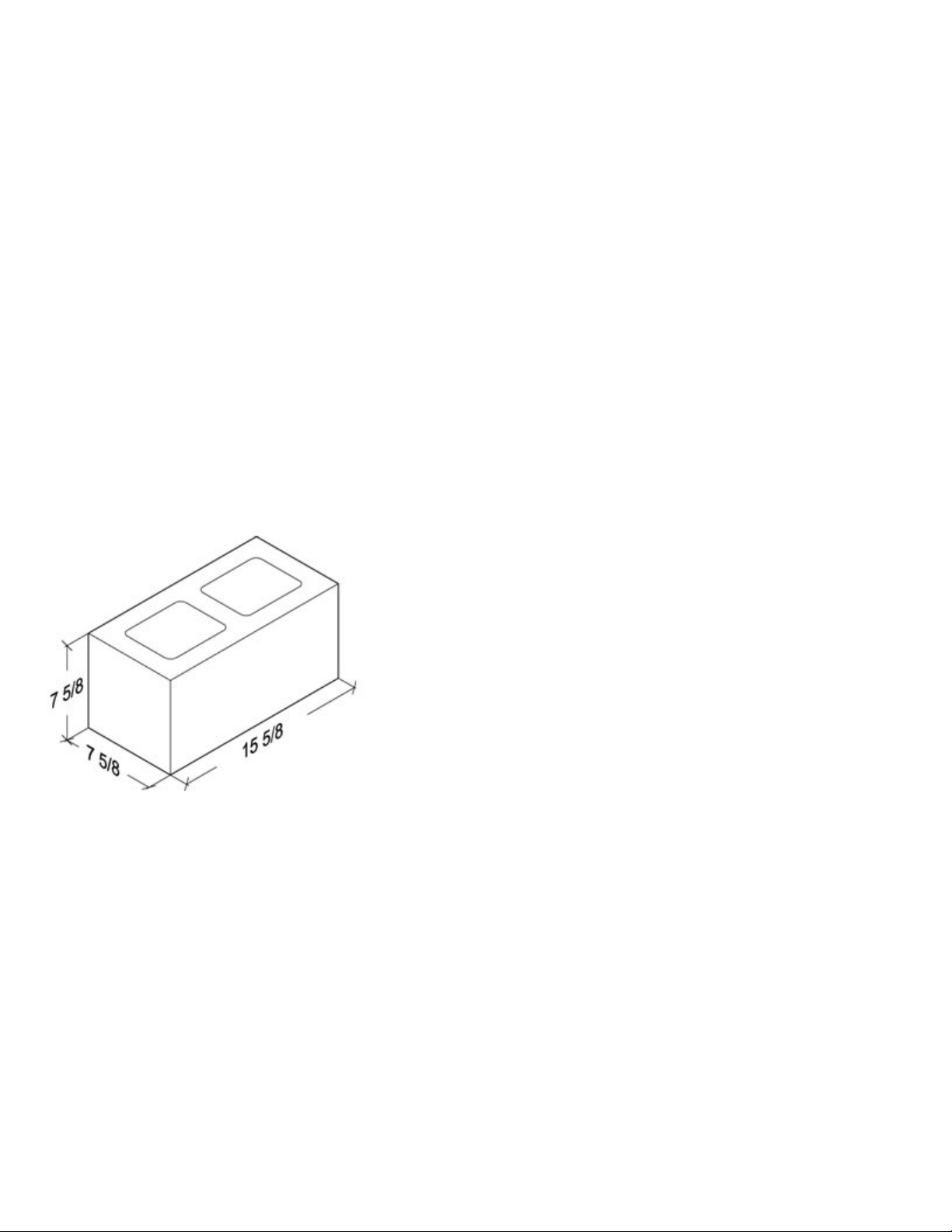

CMU & Blended CMU - 8x8x16 Standard

7 5/8” = Block Width

7 5/8” = Block Height

15 5/8” = Block Face

And the Web cross sections the Hollow Cell

Page 9

CMU Concrete Block Walls cont.

The way to differentiate between hollow and solid block is based on their cross sectional area. Technically, solid block is defined as

having a cross sectional bearing area which is not less than 75% of the gross area of the block when measured in the same plane.

Typical dimensions of the Block face and web based upon ASTM C 90 are as follows:

Nominal CMU Face Web

Width Thickness Thickness

Inches Inches Inches

3 ¾ ¾

4 ¾ ¾

6 1 1

8 1 ¼ 1 ¼

1 3/8 1 1/8

1o 1 ¼ 1 1/8

1 1/2 1 1/8

12 1 ¼ 1 1/8

Mortar Type Compressive

Strength

M 2500psi

S 1800psi

Center – Lime N 750psi

Masonry/Cement O 350psi

Although improving, the consistency of grout filled block walls is variable and on site testing is still the preferred way to determine

more exact performance. Some times when lateral support is needed steel reinforcing rods are installed through the block hollow

and then grouted in place. This allows the unit to act in harmony to resist lateral loads.

Page 10

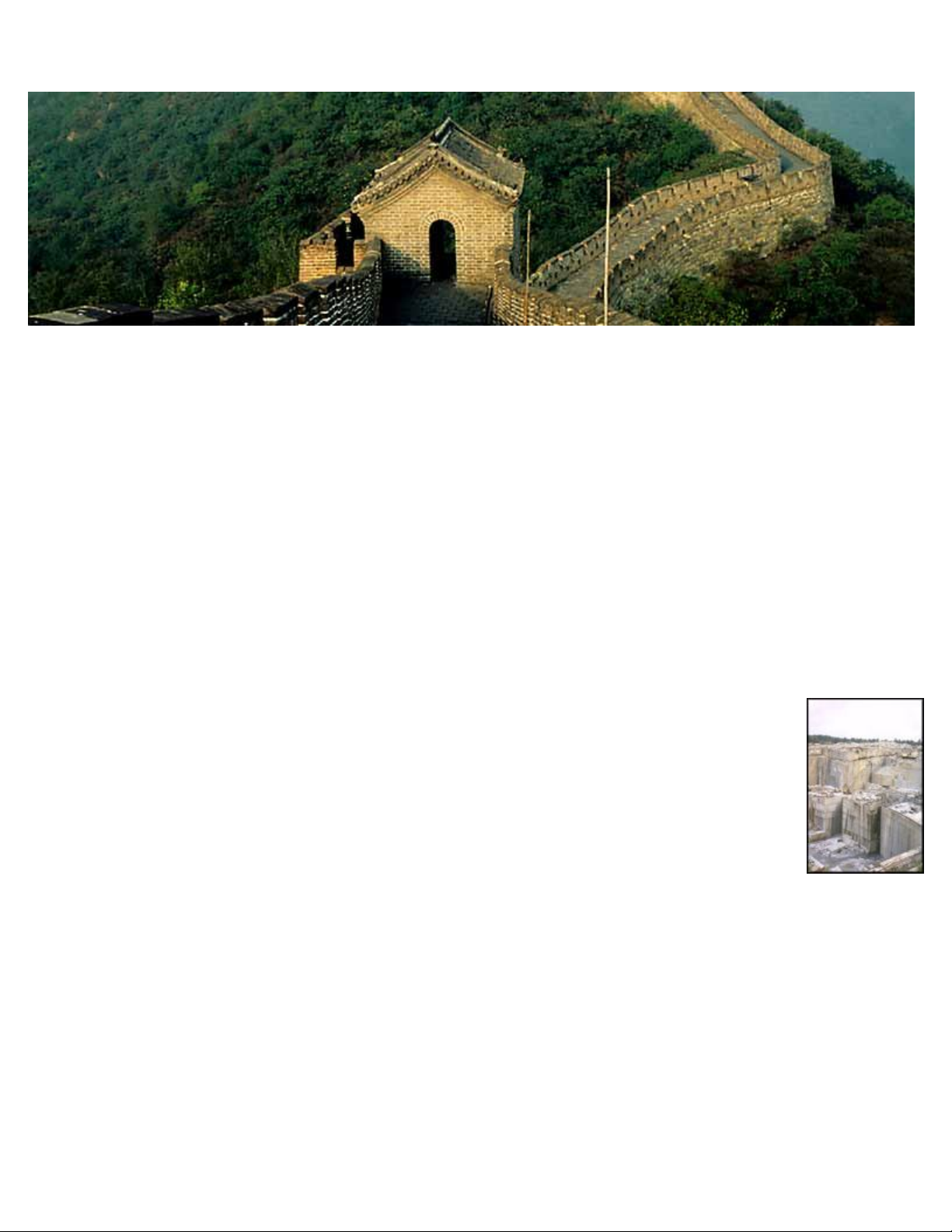

Brick

In 210 BC, the Great Wall of China was constructed of brick — nearly four million of them. And the Romans used kiln-burned brick in

conjunction with an efficient mortar of lime and volcanic ash to construct buildings that were both beautiful and enduring. As the

Roman Empire declined, however, the art of brick making disappeared from most of Europe, only to be revived during the late Middle

Ages by Italian and Byzantine artisans who had kept the technology alive.

Because it is made from the elements, brick stands up to them, like no other building material can. It resists pests and withstands

fire. It buffers sound. It warms us in the winter, and in the summer, helps to keep us cool. For thousands of years, brick has been the

material of choice for strength and beauty. When brick is utilized as a building façade it’s imperative to tie it to the backing wall and

building structure. One should use a non-corrosive anchor made from Stainless Steel when tying these walls together. ASTM C 62

Standard Specification for Building Brick (Solid Masonry Units Made From Clay and Shale) outlines the various grades of brick used in

structural and non-structural masonry applications. Grades such as, Grade SW (Severe Weathering), Grade MW (Moderate

Weathering) and Grade NW (Negligible Weathering). Compressive strength ranges as well as permissible variations in dimensions, a

weathering index and many other helpful pieces of information are located in this ASTM Standard along with other reference

documents such as:

ASTM C 43 – Terminology of Structural Clay Products

ASTM C 67 – Test Methods for Sampling and Testing Brick and Structural Tile

ASTM C 216 – Specification for Facing Brick (Solid Masonry Units from Clay or Shale)

Stone

Dimension stone can be defined as natural rock material quarried for the purpose of obtaining blocks or slabs that

meet specifications as to size (width, length, and thickness) and shape. Color, grain texture and pattern, and

surface finish of the stone are normal requirements. Durability (essentially based on mineral composition and

hardness and past performance), strength, and the ability of the stone to take a polish are other important

selection criteria.

Although a variety of igneous, metamorphic, and sedimentary rocks are used as dimension stone, the principal

rock types are granite, limestone, marble, sandstone, and slate. Other varieties of dimension stone that are

normally considered to be special minor types include alabaster (massive gypsum), soapstone (massive talc), and

various products fashioned from natural stone. Granite is an example of an igneous stone while marble is

metamorphic. Both of these stones tend to be harder than limestone and sandstone which are sedimentary

materials.

Natural stone is available in a variety of colors, types and textures for use in many building applications as well. But strength and

quality can vary significantly from quarry to quarry and location to location. So when checking anchor capacities be certain that you

know what material the anchors were tested in. Job site testing is recommended because of the wide variation in the strength of

stone.

ASTM C119 – Standard Terminology Relating to Dimensional Stone describes dimensional stone for use in building construction.

ASTM C 503 – Marble

ASTM C 615 – Granite

ASTM C 616 – Quartz and

ASTM C 568 – Limestone

Page 11

Structural Clay Tile

Hollow masonry units, made of burned clay or shale are called variously; structural tiles, hollow tiles, structural clay tiles,

structural clay hollow tiles and structural clay hollow building tiles, but they are most commonly just called building tile.

In building tile manufacture, plastic clay is pugged through a die, and the shape that emerges is cut off into units. The units are then

burned much as bricks are burned. The apertures in a building tile, which correspond to the cores in a brick or a concrete block, are

called CELLS. The solid sides of a tile are called the SHELL and the perforated material enclosed by the shell is called the WEB.

A tile that is laid on one of its shell faces is called a SIDE-CONSTRUCTION tile; one that is laid on one of its web faces is called an

END-CONSTRUCTION tile.

The typical thickness of the outer shell is ¾” with a ½” thick inner web. Structural Clay tile is not an easy material to fasten in safely.

For heavier loads an adhesive anchor utilizing screens as carriers works best For lighter applications use an anchor which has the

ability to open up behind the face and in the web cavity. Grading of Structural Clay tile can be found in ASTM C 212 and ASTM C 34.

Grade LBX is suitable for exposure to weather and Grade LB is suitable for general use` in masonry where not exposed to frost action

or for use in exposed masonry where protected with a facing of 3”.

Steel Decking

Steel deck is used as both a roof deck and for floors. (Composite and non composite) There are many configurations of steel decking

but most are cold formed from a single steel sheet. Steel deck is known by it’s deck type, depth and gage thickness. Steel deck can

be provided uncoated, painted or zinc coated in accordance with ASTM A 525 – Specification for General Requirements for Steel

Sheet.

The yield strength of steel deck varies based on its grade. Steel deck is generally specified by it’s thickness in decimal inches rather

than it’s gage.

Steel Gage Thickness

9 0.1495

10 0.1345

11 0.1196

12 0.1046

13 0.0897

14 0.0747

15 0.0673

16 0.0598

17 0.0538

18 0.0474

19 0.0418

20 0.0359

21 0.0329

22 0.0299

23 0.0269

24 0.0239

25 0.0209

26 0.0179

27 0.0149

Flood decking for construction (composite) with concrete fill typically has rib depths of 1 ½”, 2” and 3”. Other depths up to 7 are also

available. Non-composite steel form deck is used as a permanent form for concrete slabs with rib depths that are typically ½” to 2”.

For steel roof deck, the ribs are classified as narrow, intermediate or wide. They have a 1 1/2” minimum depth that is spaced at 6”

on center. There is also a Deep Rib deck that has a minimum depth of 3” with an 8” on center spacing. There are a variety of other

less common roof decks available as well such as acoustical sound absorbing, long span decks, cellular and sound absorbing floor

decks.

Page 12

Gypsum Concrete Decking

A gypsum concrete roof deck consists of gypsum concrete that is mixed with either wood fibers or mineral aggregate. The density of

dried gypsum concrete varies from 30 to 55 pounds per cubic foot, depending upon the design mix and the type of aggregate. The

mixture forms a slurry that is poured over vapor permeable form boards that are supported by sub purlins and the building's

associated framing system. The sub purlins are installed to support the form boards and to anchor the deck to the building's framing

system. The gypsum concrete mixture shall be reinforced with steel bars or a wire mesh. The reinforcing metal may be either a

welded or woven galvanized wire.

The form boards remains in place after installation of the gypsum concrete, and can provide a finished interior surface. The vapor

permeable form boards allow additional drying of the gypsum concrete to the interior of the building. Various types of form boards

are available to provide enhanced interior light reflection, added fire resistance, insulation, and acoustic control.

Gypsum Concrete Design Requirements: Design requirements from the gypsum concrete manufacturer and from the National

Roof Deck Contractors Association should be obtained for information pertinent to the specifications for gypsum roof decks.

Three general requirements for gypsum decks:

1. The gypsum fill shall be reinforced with steel or a wire mesh, located at

the correct depth within the deck

2. Gypsum decks shall have a minimum compressive strength of 500

pounds per square inch.

3. Gypsum decks shall have a minimum thickness of 2", not including the

form board, and shall extend a minimum of .25" above the top of bulb

tees or other structural supports.

Structural Supports: Gypsum concrete roof decks and their underlying form boards are to be supported by sub purlins that span

the distance between the main purlins or joists. The three common types of steel sub purlins for this installation are:

1. Bulb tees

2. Truss tees

3. Cold rolled steel tees

Venting & Drying: Adequate interior ventilation must be provided below the deck to dry excess moisture from the poured gypsum,

the form board, and other moisture generating construction processes. When possible, the building shall be edge vented to assist in

dissipating residual moisture.

ASTM C 317 – Stand Specification for Gypsum Concrete describes mill mixed gypsum concrete for use in poured in place roof decks.

Traditionally, setting times are assumed to be between 20 minutes to a maximum of 90 minutes and as stated earlier 500 psi for

Class A and 1000 psi for Class B gypsum. Density, strength and physical conditioning of gypsum varies widely so for exact anchor

performance on site testing is always recommended.

Gypsum Wallboard

Ordinary gypsum wallboard is sold in 4’ widths that range from ¼”, 3/8”, ½”, and 5/8” thick and come in lengths that range from 4

feet to 16 feet long. Gypsum wallboard is also available in ¾”, 1” and 2” thickness’ which are normally used as floor underlayment for

acoustical reasons and for other sound deadening applications.

Gypsum wallboard, often referred to as drywall or plaster board, is a building panel consisting mainly of a noncombustible gypsum

core material sandwiched between two durable paper faces.

These panels or sheets are used most often as a simple, cost-efficient interior wall construction material for both residential and

commercial projects. Enhanced with a variety of core additives and/or backer variations, gypsum wallboard can provide a range of

performance characteristics for specialty applications including:

• moisture-resistant tile backing

• heat-resistant fire protection

• sag-resistant ceiling panels

• damage-resistant wall protection

• exterior sheathing and soffit installation

• curved wall surface construction

In addition, properly installed gypsum wallboard adds strength and sound resistance to interior walls improving the living and working

environment of any facility constructed with this versatile material. Originally made entirely from mined gypsum rock, 60% of current

wallboard production capacity is manufactured with a synthetic gypsum core to provide a product that not only performs well but is

also environmentally responsible.

See ASTM C 36 – Standard Specification for Gypsum Wallboard for specifics.

Page 13

Structural Wood Panels

Structural wood panels are manufactured in several grades from a wide variety of wood base materials. Plywood and OSB – Oriented

Strand Board are the most common and have many uses.

Uses for wood panels include wall and roof sheathing, floor underlayments, ceilings, and interior walls. Wood is a renewable product,

and requires less energy than most materials to process into finished products. The invention of plywood helped reduce the amount

of solid lumber and labor required for wood frame construction. Subsequent development and popularity of oriented strand board

(OSB), manufactured from small fast growing trees such as aspen and poplar, has further reduced wood use per square foot of

standard construction. Plywood consists of multiple veneers bound with a resin, usually urea formaldehyde (UF) for interior grade,

and the more water resistant phenol formaldehyde (PF) for exterior grade products.

Plywood has been made for thousands of years; the earliest known occurrence of plywood was in ancient Egypt around 3500 BC

when wooden articles were made from sawn veneers glued together crosswise. This was originally done due to a shortage of fine

wood. Thin sheets of high quality wood were glued over a substrate of lower quality wood for cosmetic effect, with incidental

structural benefits. This manner of inventing plywood has occurred repeatedly throughout history. Many of the great English furniture

makers used veneer as a raw material.

Modern plywood in which the veneer are cut on a rotary lathe from softwood logs is of relatively recent origin, invented by Immanuel

Nobel. The first such lathes were set up in the United States in the mid 19th century. Plywood has been one of the most ubiquitous

building products for decades.

Plywood grades are determined by the veneer quality on the face and back of each panel. The first letter designates quality of face

veneer (best side), while the second letter denotes the surface quality of the back of the panel. The letter "X" simply indicates the

panel was manufactured with exterior type adhesive.

"A" Highest grade quality available. Can be defect free or contain small knots, providing they are replaced with wooden plugs or

repaired with synthetic patch. May contain occasional surface splits that are repaired with synthetic filler. Surface is always sanded

and provides for smooth paintable face quality.

"B" Second highest quality veneer grade. Normally a by-product of downgraded "A" quality veneer. Solid surface, but may contain

small diameter knots and narrow surface splits. Normally repaired with wooden plugs or synthetic filler. Surface normally sanded

smooth.

"C" Considered to be a lower end face quality, but a reasonable choice for general construction purposes. May contain tight knots up

to 1-1/2" diameter, some open knot holes, some face splits, and discoloration. Some manufactures may repair the defects with

synthetic filler. Panels typically not sanded.

"D" Considered to be the lowest quality veneer and often used for the back surface for construction grade panels. Allows for several

knots, large and small, as well as open knots up to 2-1/2" diameter. Open knots, splits, and discoloration are acceptable. "D" grade

veneers are never repaired or sanded. Not recommended for permanent exposure to weather elements.

Oriented strand board, or OSB, or waferboard, is an engineered wood product formed by layering strands (flakes) of wood in

specific orientations. In appearance it has a rough and variegated surface with the individual strips (around 2.5 by 15 cm (~1 inch by

~6 inches) each) lying unevenly across each other in the direction of their grain. It is manufactured in wide mats from cross-oriented

layers of thin, rectangular wooden strips compressed and bonded together with wax and resin adhesives (95% wood, 5% wax and

resin). The layers are created by shredding the wood into strips, these are sifted and then oriented on a belt or wire cauls. The mat is

made in a forming line, the layers are built up with the external layers aligned in the panel direction and internal layers crossoriented. The number of layers placed is determined partly by the thickness of the panel but is limited by the equipment installed at

the manufacturing site, however individual layers can also vary in thickness to give different finished panel thicknesses. Typically a 15

cm layer will produce a 15 mm panel thickness. The mat is placed in a thermal press to compress the flakes and bond them by heat

activation and curing of the resin that has been coated on the flakes. Individual panels are then cut from the mats into finished sizes.

Most of the worlds OSB is made in the USA and Canada in large production facilities. The largest production facilities can make over

1,000,000,000 square feet of OSB per year. Different qualities in terms of thickness, panel size, strength, and rigidity can be

imparted to the OSB by changes in the manufacturing process. OSB panels have no internal gaps or voids, and are water-resistant,

although they do require additional membranes to achieve impermeability to water. The finished product has similar properties to

plywood, but is uniform and cheaper. It has replaced plywood in many environments, especially the North American structural panel

market. The most common uses are as sheathing in walls, floors, and roofs. While OSB does not have grain like a natural wood, it

does have a specific axis of strength. This can be seen by observing the alignment of the surface wood chips. The most accurate

method for determining the axis of strength is to examine the ink stamps placed on the wood by the manufacturer. There is some

debate over the environmental impact of OSB. It allows producers to use tree species such as aspen or poplar that are unfit for

standard veneer plywood or lumber. The production method uses almost all the wood of the harvested trees, and small, young trees

and lower quality fast growing species can be used. Due to the type of resins used in wood-based structural use panels like OSB, they

emit very low levels of formaldehyde. The emission levels have been found to be not more than 10% of the criteria of key national

standards. Some manufacturers add zinc borate, 2ZNO.303.3.5H20, a powder which is toxic to termites and molds and fungus but

not mammals in applied doses. Buyers should ask whether zinc borate is added to their purchase.

OSB is commonly known as Sterling board in the United Kingdom.

Page 14

Structural Cement Wood Fiber – Fiber Cement Faced Panel

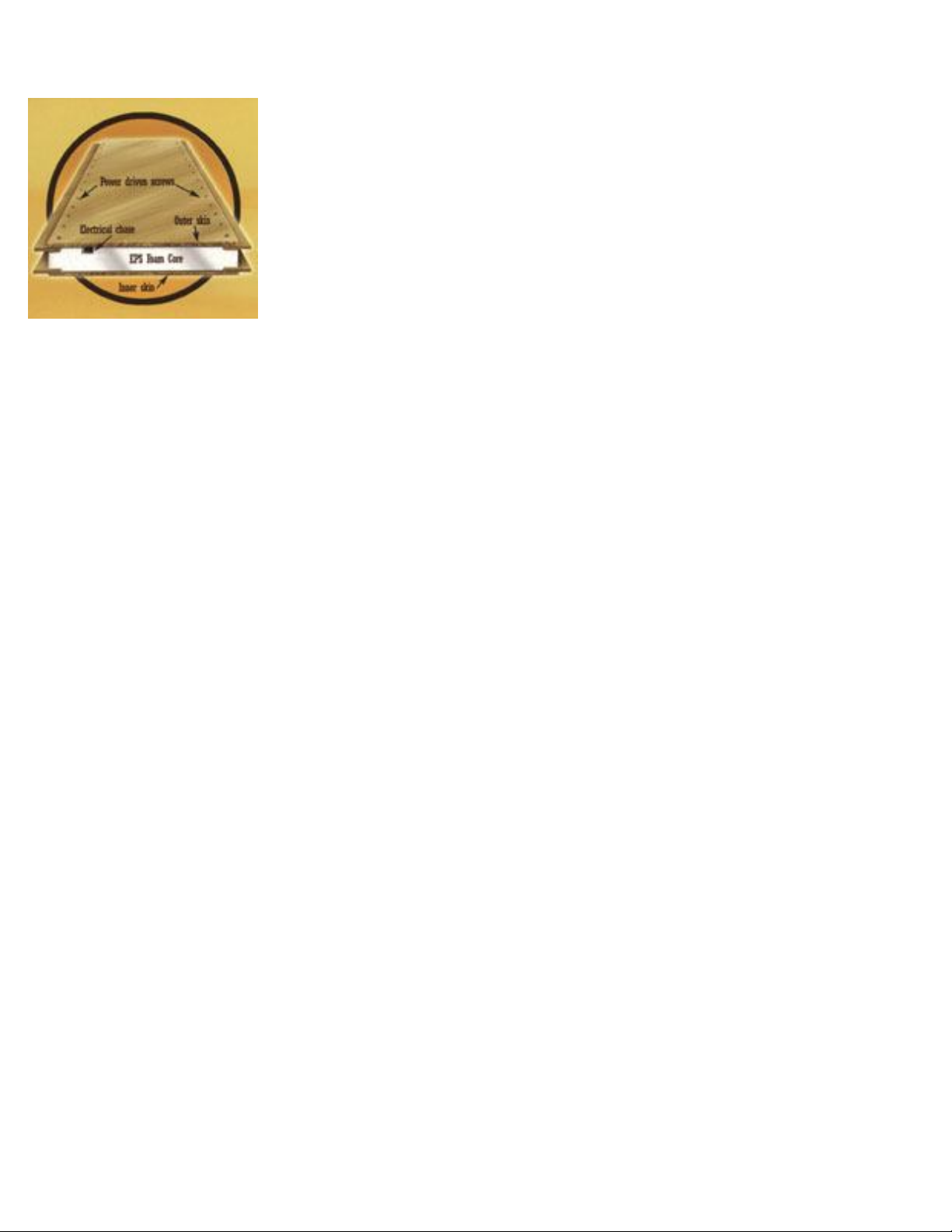

Structural Insulated Panels (SIPs) are prefabricated insulated structural elements for use in building walls, ceilings, floors and roofs.

They are made in a factory and shipped to job sites to replace conventional stud or "stick frame" construction. SIPs may be called

foam-core panels, stress-skin panels, sandwich panels, or structural foam panels. SIPs are engineered laminated panels with solid

foam cores and structural sheathing on each side. The most common types of sheathing or skins materials are oriented strand board

(OSB) and plywood. Some manufacturers produce panels fiber-cement sheathing.

Skin Material

Cementitious SIPs are typically manufactured of cellulose reinforced cement boards, for inside and outside skins. The material can be

taped and finished on the interior surface. The fire-resistive cement board eliminates the need for gypsum drywall. The exterior

surface can be painted or coated with a vinyl or synthetic stucco permanent finish. If siding or brick veneer is to be used, oriented

strand board (OSB) can be applied on the exterior to accept nailing of siding or brick wall ties. It is not necessary to have both OSB

and fiber-cement board on one side for brick and stucco applications. OSB can be used instead of fiber-cement board for such an

application. However, there may be some difficulty in finding a manufacturer that produces this type of SIPs.

Applications

Cementitious SIPs can be used for below and above grade applications. They can be used to construct foundation or basement walls,

floors spanning up to 16 feet between supports, load-bearing walls up to four stories and roof panels up to 20 foot spans.

Details and Connections

Cementitious SIPs are fastened together with power-driven screws through the inner and outer skins into either cement board or

wood splines. Because of the strength of the panels, no headers are needed over standard size doors and windows. Connection

details are similar to those of OSB-sheathed panels.

Thermal Efficiency

Cementitious SIPs are as energy efficient as OSB SIPs. Consumers often think that R-value is of primary importance, but effective air

sealing is also significant. For the best energy performance, a continuous air barrier and uniform insulation coverage, with as few

gaps as possible, are needed. Every air leak and every thermal bridge adds to heating and cooling bills. Cementitious SIP panels are

air-tight and fully insulated.

Durability

Buildings constructed with cementitious SIPs typically will last longer and require less maintenance than other types of SIPs panels.

Fiber-Cement Board used as skins will not rot, burn, or corrode. It has a higher fire rating than OSB faced SIPs, and in most

residential applications no drywall would be necessary. Cementitious boards will not support black mold growth, and they have a high

resistance to moisture absorption. They are rot and vermin resistant, and are not significantly affected by water vapor.

Finishes

Fiber-cement panels can have different finished looks, such as a wood grain, stucco, or smooth. With the smooth finish, stucco, vinyl

siding, brick or stone can be installed

Structural Wood Fiber Decking

A grey area between combustible and noncombustible decking is the structural wood fiber deck system. These fibrous decks generally

have a gypsum-like or cementitious binder and combine the functions of a roof deck, thermal insulation, and finished ceiling. They

also have acoustical value and are oftentimes used in schools and restaurants. Combustibility is generally defined by specific UL or FM

listings.

Because these decks are porous, roofing cannot be adhered directly to the deck. Generally, a base sheet is mechanically fastened,

using a specially designed divergent fastener for wind resistance. While these decks provide some thermal resistance, laminations

with styrene or urethane foam and felt facers are used for the high R-values needed today. Both single-ply and bituminous roofs can

be directly attached to the faced products.

Page 15

Corrosion

Corrosion is deterioration of essential properties in a material due to reactions with its surroundings. In the most common use of the

word, this means a loss of an electron of metals reacting with water or oxygen. Weakening of iron due to oxidation of the iron atoms

is a well-known example of electrochemical corrosion. This is commonly known as rust. This type of damage usually affects metallic

materials, and typically produces oxide(s) and/or salt(s) of the original metal. Corrosion also includes the dissolution of ceramic

materials and can refer to discoloration and weakening of polymers by the sun's ultraviolet light. Most structural alloys corrode

merely from exposure to moisture in the air, but the process can be strongly affected by exposure to certain substances (see below).

Corrosion can be concentrated locally to form a pit or crack, or it can extend across a wide area to produce general deterioration.

While some efforts to reduce corrosion merely redirect the damage into less visible, less predictable forms, controlled corrosion

treatments such as passivation and chromate-conversion will increase a material's corrosion resistance. The corrosive environment

encountered in an anchoring or fastening application therefore must always be given consideration and there are questions to

answer. For example will the anchoring be immersed in a corrosive substance like a liquid or a gas? (aka Chemical Corrosion) For

example a material that would be able to resist chlorine and acids may be what’s needed in an application in a waste water treatment

plant. Or you may ask will the anchorage be in contact with another metal of a dissimilar electric potential in the presence of an

electrolyte?

Galvanic Corrosion Chart - Galvanic corrosion is the corrosion that results when two dissimilar metals with different potentials

are placed in electrical contact in an electrolyte. A difference in electrical potential exists between the different metals and serves as

the driving force for electrical current flow through the corrodant or electrolyte. This current results in corrosion of one of the metals.

The larger the potential difference, the greater the probability of galvanic corrosion. Galvanic corrosion only causes deterioration of

one of the metals. The less resistant, active metal becomes the anodic corrosion site. The stronger, more noble metal is cathodic and

protected. Galvanic corrosion potential is a measure of how dissimilar metals will corrode when placed against each other in an

assembly. Metals close to one another on the chart generally do not have a strong effect on one another, but the farther apart any

two metals are separated, the stronger the corroding effect on the one higher in the table. This table lists the potential differences

for various metals in water. The order of the series can change for different electrolytes (for example, different pH, ions in solution).

The following is the galvanic series for stagnant (that is, low oxygen content) seawater. The order may change in different

environments.

Graphite

Palladium

Platinum

Gold

Silver

Titanium

Stainless steel (316 passive)

Stainless Steel (304 passive)

Silicon bronze

Stainless Steel (316 active)

Monel 400

Phosphor bronze

Admiralty brass

Cupronickel

Molybdenum

Red brass

Brass plating

Yellow brass

Naval brass 464

Uranium 8% Mo

Niobium 1% Zr

Tungsten

Stainless Steel (304 active)

Tantalum

Chromium plating

Nickel (passive)

Copper

Nickel (active)

Cast iron

Steel

Lead

Tin

Indium * Beryllium

Aluminum * Zinc Plating (see galvanization

Uranium (pure) * Magnesium

Cadmium

Page 16

Resistance to corrosion

Some metals are more intrinsically resistant to corrosion than others, either due to the fundamental nature of the electrochemical

processes involved or due to the details of how reaction products form. If a more susceptible material is used, many techniques can

be applied during an item's manufacture and use to protect its materials from damage.

Intrinsic chemistry

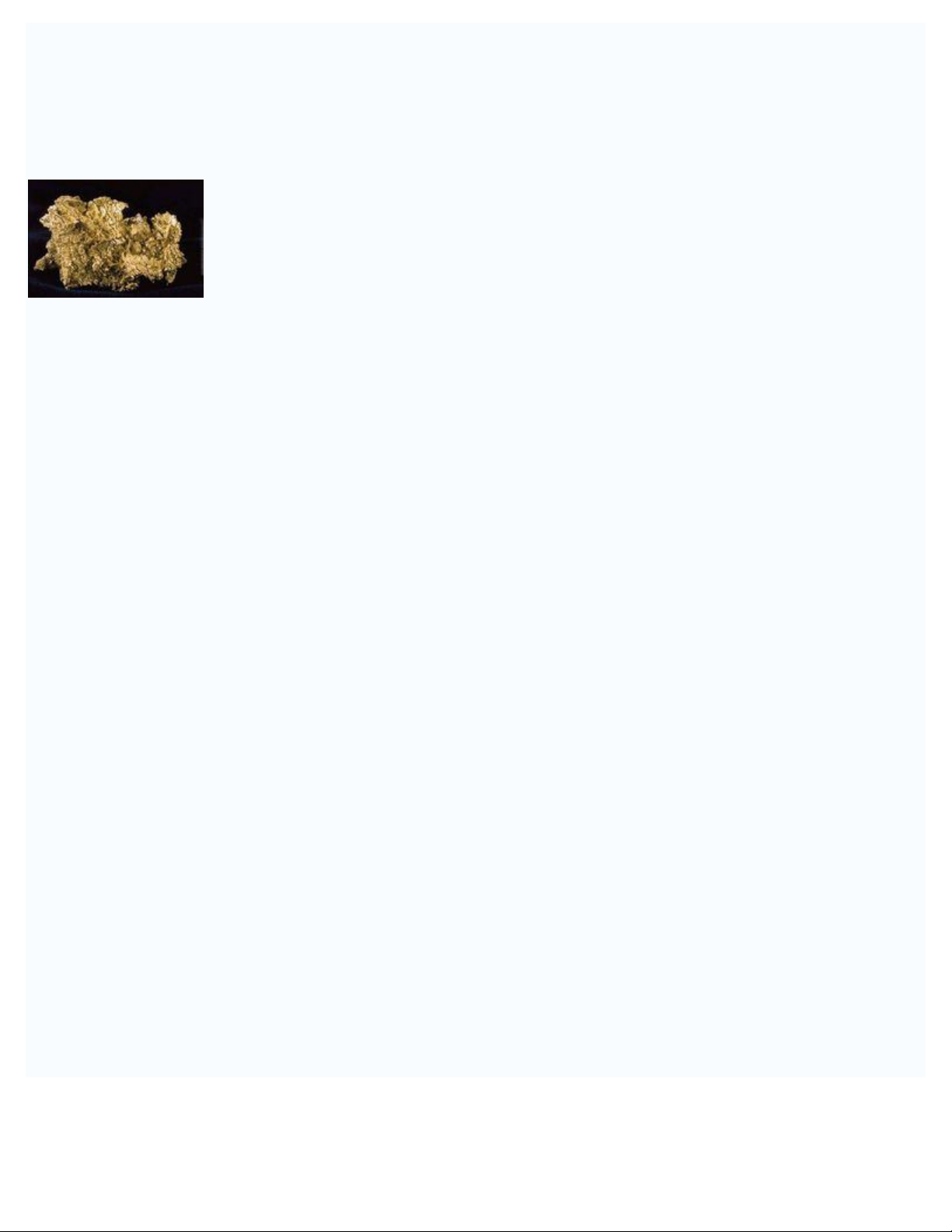

Gold nuggets do not corrode, even on a geological time scale.

The materials most resistant to corrosion are those for which corrosion is thermodynamically unfavorable. Any corrosion products of

gold or platinum tend to decompose spontaneously into pure metal, which is why these elements can be found in metallic form on

Earth, and is a large part of their intrinsic value. More common "base" metals can only be protected by more temporary means.

Some metals have naturally slow reaction kinetics, even though their corrosion is thermodynamically favorable. These include such

metals as zinc, magnesium and cadmium. While corrosion of these metals is continuous and ongoing, it happens at an acceptably

slow rate. An extreme example is graphite, which releases large amounts of energy upon oxidation, but has such slow kinetics that it

is effectively immune to electrochemical corrosion under normal conditions.

Passivation - Given the right conditions, a thin film of corrosion products can form on a metal's surface spontaneously, acting as a

barrier to further oxidation. When this layer stops growing at less than a micrometre thick under the conditions that a material will be

used in, the phenomenon is known as passivation (rust, for example, usually grows to be much thicker, and so is not considered

passivation, because this mixed oxidized layer is not protective). While this effect is in some sense a property of the material, it

serves as an indirect kinetic barrier: the reaction is often quite rapid unless and until an impermeable layer forms. Passivation in air

and water at moderate pH is seen in such materials as aluminum, stainless steel, titanium, and silicon.

The conditions required for passivation are specific to the material. The effect of pH is recorded using Pourbaix diagrams, but many

other factors are influential. Some conditions that inhibit passivation include: high pH for aluminum, low pH or the presence of

chloride ions for stainless steel, high temperature for titanium (in which case the oxide dissolves into the metal, rather than the

electrolyte) and fluoride ions for silicon. On the other hand, sometimes unusual conditions can bring on passivation in materials that

are normally unprotected, as the alkaline environment of concrete does for steel rebar. Exposure to a liquid metal such as mercury or

hot solder can often circumvent passivation mechanisms.

Applied coatings

Plating, Painting, and the application of enamel are the most common anti-corrosion treatments. They work by providing a barrier of

corrosion-resistant material between the damaging environment and the (often cheaper, tougher, and/or easier-to-process)

structural material. Aside from cosmetic and manufacturing issues, there are tradeoffs in mechanical flexibility versus resistance to

abrasion and high temperature. Platings usually fail only in small sections, and if the plating is more noble than the substrate (for

example, chromium on steel), a galvanic couple will cause any exposed area to corrode much more rapidly than an unplated surface

would. For this reason, it is often wise to plate with a more active metal such as zinc or cadmium.

Reactive coatings

If the environment is controlled (especially in recirculating systems), corrosion inhibitors can often be added to it. These form an

electrically insulating and/or chemically impermeable coating on exposed metal surfaces, to suppress electrochemical reactions. Such

methods obviously make the system less sensitive to scratches or defects in the coating, since extra inhibitors can be made available

wherever metal becomes exposed. Chemicals that inhibit corrosion include some of the salts in hard water (Roman water systems are

famous for their mineral deposits), chromates, phosphates, and a wide range of specially-designed chemicals that resemble

surfactants (i.e. long-chain organic molecules with ionic end groups).

Page 17

Fastener Technology

Anchoring – Working Principles

Friction

The applied load N, is transferred to the base material by means of friction, R.

The expansion force, Fexp. is necessary for this to take place.

Bonding

An adhesive bond is produced between the anchor rod and the hole wall by a synthetic resin adhesive. This produces minimal stress

in the base material.

Combination of Holding Principles

There are situations where a combination of holding principles come into play. For example some anchoring systems are expanded

and locally crush the base material with frictional forces when expanded thus creating a keying effect. Others deliberately undercut

the base material to some extent creating a keying and frictional combination of holding forces.

Page 18

Anchoring – Failure Modes

The weakest point in a fastening system determines the way in which it will fail and may determine the most suitable anchor for

an application.

Concrete Cone Failure

The is when the stresses created by the anchor loading cause the concrete to break, usually in the form of a cone with the anchor

expansion section as the apex. Some base materials can also spall in a maze of subsurface cracks as well.

Anchor Pull Out

The anchor may be pulled out of the base material with little or no obvious damage to either the anchor or the base material.

This does not mean to indicate that either the anchor or the hole is re-usable.

Steel Failure

This failure is caused by a fracturing of the anchor or rod material and is generally related to the ductility of the material when the

pull out forces acting on the anchor or the rod are greater than the material’s ability to resist. This may usually be avoided by using a

higher grade of steel.

Page 19

Concrete Edge Breakage

If anchors are set too close to the edge of concrete components, there is a risk that the concrete may break away when loaded. To

avoid this pay close attention to the anchor’s spacing and edge distance requirements listed in the catalog.

Concrete Splitting

If expansion forces and applied load are higher than the base material’s ability to carry the load, splitting as evidenced by cracks may

occur in the base material. This most often happens when the base material component has small dimensions but it can happen in

other situations as well.

Anchoring – Influencing Factors

The base material is critical to the performance of an anchor. Different construction materials will have a major effect on the ability

of an anchor to hold. For most applications the most common base material is reinforced concrete.

Concrete Strength

The concrete strength is usually specified as the design strength at 28 days after pouring. Due to the nature of concrete it continues

to cure even after this time and thus “old” concrete may be much harder than the theoretical design strength.

Page 20

Anchoring Depth

The first mode of failure illustrated was the breakage of concrete, where the concrete fails in more or less a cone shape from the

bottom of the anchor. If the embedment depth of the anchor is increased, the size of the concrete cone is also increased and the

holding power is increased.

Anchor Spacing

The distance between the anchors in a group is important because when they are positioned too close together there will be a loss

of strength due to overlapping of the concrete failure cones. This is illustrated below:

Edge Distance

If an anchor is installed closer to an edge than the recommended distance the capacity will be reduced because the volume of

concrete (the cone) that can resist the load has been reduced.

Page 21

Reinforcement

Most product application data is from testing in un-reinforced concrete, which means that the results may be conservative.

Research work has shown that reinforcement has no significant effect on the ultimate load of an anchor unless the reinforcement is

specifically placed for that purpose. Reinforcement does reduce the effects of edge breakage and also reduces the widths of

concrete cracks where that phenomenon is seen.

Anchoring – Loading

Common engineering usually focuses on static loads however focusing solely on that aspect of loading can yield misleading results

and can cause the under designing of an anchoring system

Static Loads

Static loads can be segregated as follows:

An objects own (dead) weight

Permanent Loads – Loads of non-load bearing components such as floor covering, screed, or from constraint (due to

temperature change or sinking of supports/columns)

Changing Loads – Such as working loads like fitting and furnishings, machines, normal wear, snow, wind, temperature

Dynamic Loads

The main difference between static and dynamic loads is the effectiveness of inertia and damping forces. These forces result in

induced acceleration and must be taken into account when determining section forces and anchoring forces. Dynamic loads can

typically be classified into 3 different groups:

* Fatigue loads

* Seismic loads

* Shock loads

Fatigue loads are normally classified into two sub groupings.

1 – Vibration loading of anchors with very high recurrence and usually low amplitude such as ventilators, production machinery, etc.

2 – Repeated loading and unloading of structures with high loads and frequent recurrence such as elevators, cranes and robots.

Loading that causes fatigue have a large number of load cycles which produce changes in stress in the effected fastening. These

stresses result in a decrease of strength, which is all the greater the larger the change in stress and the larger the number of load

cycles (fatigue). When evaluating loads causing fatigue, not only the type of load but also the planned or anticipated fastening life

expectancy is of major importance.

Seismic loads are a well publicized phenomenon.

Generally, all fastening situated in structures located in seismically active regions and areas can be subject to seismic loading.

However, due to cost considerations, usually only critical fastenings whose failure would result in loss of life or significant weakening

of the over all structure are designed for seismic loads.

Ground movement during an earthquake or seismic tremors lead to relative displacement of a building foundation. The inertia of a

building’s mass makes it difficult or impossible for this movement to occur without deformation or damage. Due to the stiffness of

the structure restoring forces are created and vibration is induced. This results in stress and strain for the structure and the parts

fastened and to the fastener installations. Earthquake frequencies often lead to resonance phenomena which cause larger vibration

amplitudes on the upper floors.

In view of the low ductility of anchor and fasteners, seismic loads generally have to be taken up by a high loading capacity and very

little deformation. A fastening should be able to withstand and be designed for use in earthquake zones without damage.

Determining the forces acting on a fastening is difficult and should be done only by qualified professionals.

Shock loads are mostly unusual loading situations even though they are the only loading a structure may be designed for

withstanding such as crash barriers, avalanches, falling rocks, protection nets, ship or airplane impacts or explosions.

Shock phenomenon generally have a very short duration and tremendously high forces that occur in individual peaks. Since the

probability of one of these occurrences happening in the life expectancy of the building components concerned is relatively small

plastic deformations of fasteners and structural members are usually permitted.

Material Behavior - Material behavior under static loading is described primarily by strength such as tensile and compressive and

the elastic behavior of the material. These properties are generally determined by carrying out simple tests with specimens.

Material behavior under fatigue impact – If a material is subject to a sustained load that changes with respect to time, it can fail after

a certain number of load cycles even though the upper limit of the load withstood up to this time, is clearly lower than the ultimate

tensile strength under static loading. This loss of strength is referred to as material fatigue.

The grade and quality of the steel has a considerable influence on the alternating strength for example: In the case of structural

and heat-treatable steels, the final strength is approximately 25% – 35 % of the static strength after 2 million load

cycles or more.

In the non-loaded state, concrete already has micro cracks in the zone of contact of the aggregate and the cement paste which are

attributable to the aggregate hindering shrinkage of the cement paste. The fatigue strength of concrete is directly dependent on the

grade of concrete. Concrete strength is reduced to about 55% - 65% of the initial strength after 2 million load cycles.

The material strength is not influenced so much under fatigue impact. Other factors such as inertia, cracks etc. influence the

behavior much more in this case.

Page 22

Material Behavior - Fatigue When a large number of load cycles are involved it is usually the anchor in single fastenings that are

critical due to steel fatigue and failure. The concrete generally only fails when the depth of embedment is shallow and subjected to

tensile loading or if an anchor is at a reduced edge distance and exposed to a shear load. Individual anchors in a multi-anchor

fastening such as a group can have a different elastic stiffness and a displacement behavior (slip) that differs from one anchor to

another. This leads to a redistribution of forces in the anchors during the load cycle. Stiffer anchors are subjected to higher loads

whereas the loads in the weaker anchors are reduced. A reduction factor for multiple anchorage or groups is generally used to allow

for this phenomenon. Both mechanical and chemical anchors are basically suitable for fastenings subject to fatigue loading.

Seismic Quake - Anchors (fasteners) subjected to seismic loading can under certain circumstances be stressed far beyond their

static loading capacities. Due to this, the respective suitability tests are carried out using a loading that is considerably higher than

the working load level. The behavior of anchors under seismic conditions depends on the magnitude of loading, the direction of the

loading, the base material and the type of anchor. After an earthquake the loading capacity is generally considerably reduced. With

any earthquake design of fasteners, concrete cracks resulting from the seismic activity should be taken into consideration.

When designing anchor fastenings it is important to remember that they can not be regarded as isolated fixings to take up seismic

forces but should be considered in the overall context of the design.

Chemical anchors do well under most other seismic loading conditions. However a mechanical fastening may be more suitable under

certain external conditions such as where there is a risk of fire and so on.

Shock – Shock can be simulated by mimicking load increase times and amplitude in the range of milliseconds during tests using

servo-hydraulic test equipment. The main effects observed during this testing has been:

deformation is greater when the breaking load is reached

energy absorbed by the anchorage is higher

breaking loads are roughly the same magnitude during static loading and shock loading tests

Suitability for shock is something that the designer must take into consideration when demanding a fastening for their application.

Some adhesive and mechanical systems will work quite well and are quite suitable when load considerations and risk is properly

considered during the designing phase of the application.

Bending – It is frequently necessary to place shims or spacers between the fixture and the base material for alignment or leveling.

When this occurs it is often the strength of the anchor material which determines the strength of the connection. The load is applied

a distance from the base material creating a lever like action on the anchorage. The allowable bending load should be calculated by

the design engineer based upon the material from which the anchor is manufactured and not necessarily the tension and shear

capacity of the anchor. In concrete the bending arm should be increased by ½ to 1 anchor diameter to allow for spalling around the

top of the anchor hole.

Cracked Concrete – Anchoring

Many factors cause cracking in concrete and these cracks can reduce the anchor loading capacity by splitting the concrete cone that

resists the applied load. For anchoring the cracks may be considered “dead” or “live” depending upon their cause. A dead crack is

one that usually occurs during the curing process or settling process of the structure. This not a “moving” crack.

A live crack one that is still able to move and may be caused by the imposed load or foundation problems. Cracks of less than

approximately .012” are normally considered non-structural. Wej-it has developed an anchoring system made specifically to address

the need for fastenings in zones where cracking is likely. This system has been tested to AC 193, ACI 335,2 and met the most

stringent requirements of both acceptance criteria.

Corrosion

We dealt with corrosion in a more general way earlier in this manual. Here we shall discuss the specifics as it relates to fasteners.

The most common and basic coating for our fasteners is electro-plated zinc. Some still use the old reference to this process as

electro-galvanizing. Zinc is a sacrificial coating which will “heal” itself if damaged making it a desirable coating for anchors which are

not generally treated with much care in the field. Electro-plated material coating thickness is governed by ASTM B-633, Type II, SCI.

Improved corrosion resistance can be provided by the use of hot-dip galvanizing. This is a process which is exactly what its name

purports it to be, a dip in a hot bath of molten zinc. This process coats the anchor with a significantly more robust shell than other

methods afford. Hot-dip (HDG = Hot Dip Galvanizing and NOT Heavy Duty Galvanizing which is misleading and often used when

referring to mechanical plating) galvanizing thickness is governed by ASTM A 183, B-454 and B-695-82.

303/304 Stainless Steel affords increased corrosion protection than zinc plated & galvanized coatings.

316 Stainless Steel are for fastening that face even greater risks of a higher corrosive environment. Your designer should identify the

specific level of needed protection. But generally speaking 316 SS does well in places like tunnels, seawater, swimming pools, water

treatment, power plants and so on. But all metals have their limits, especially in chemically aggressive environments.

Page 23

Drill Bits

A drill bit of the correct nominal diameter should always be used. Detailed below are nominal drill bit sizes that have been

coordinated with most anchor fastenings in the U.S. to provide the published anchor performance.

Anchors are designed to be used in holes in concrete and masonry base materials with carbide tipped drill bits meeting the ANSI

B212.15 standard as shown above.

The actual hole diameter is larger than the nominal diameter. For example, a ¾” nominal drill bit diameter has an OD (outer

diameter) of .775” to .787”. When selecting the diameter of the hole to be pre-drilled, the diameter of the hole selected should allow

for proper anchor installation.

When going through a fixture be sure that the pre-punched or drilled hole is big enough to allow the carbide tipped masonry bit to

pass through. This is usually 1/16” over for sizes up to 7/8”. For sizes of 1” or larger it’s usually plus 1/8”.

Page 24

Introduction to Anchoring Design

The design of fastenings is becoming increasingly important for both design professionals and the construction community. PostInstalled mechanical anchors on the market today offer the potential to routinely transfer loads of relatively large magnitude into

various base materials. Optimum use of anchors is only possible if the design explicitly considers not only the direction of the load

(tension, shear or combined tension and shear) but the modes of failure as well.

Effective anchor design requires careful consideration to the required loading capacity and required level of safety of the anchorage.

Risk analysis is used to determine the necessary level of safety that will be required along with consideration to the use of safety

factors. These are usually specified in national or company standards and codes of practice. For example: Wej-it recommends a 4 to

1 safety factor when using it’s mechanical anchorages such as Ankr-Tite and Original Wej-it installations.

The load capacity of an anchorage is normally determined in accordance with recognized standards or building codes, e.g. The

International Building Code (IBC), International Residential Code (IRC), Building Standards Law in Japan or the Eurocodes in Europe.

Most codes identify the holding power of an anchor installation in terms of “resistance” and the loads acting on the anchorage as

“actions” which are simply a convenient way to describe how an anchor works. But in any case, both resistance and actions must be

considered when designing an anchor installation (or as our European friends like to call it, a “fixing”).

Design Philosophy

An anchor installation should be designed giving careful consideration to the maximum known resistance that may be applied and the

minimum likely resistance that may be obtained. These values can then be combined to enable a probability of failure of the

anchorage to be estimated and the appropriate reliability to be achieved.

Risk Analysis - Basics

The design of an appropriate anchor installation can only be achieved if the effects of anchorage failure are considered. Most

anchorage installations can be divided into 3 classes, depending on the significance of a failure:

CLASS 1

Light loads, non structural anchorages, usually multiple anchor points. Sometimes referred to redundant fastening systems, where

the failure of one or two individual anchors is not a problem and is of little cost.

CLASS 2

Failure of these anchors may involve a risk to human life or considerable economic consequences. Safety anchors must be used and

designed in accordance with the relevant engineering design codes.

CLASS 3

In this installation any failure may involve risk to many lives and/or serious economic or social consequences. Advice should be

obtained from a licensed and qualified engineer who will have all of the latest information.

Variation in Base Material Performance

Due to the variations in material performance in both the anchor and base material e.g. concrete, the exact or absolute performance

of an anchorage can only be determined by carrying out destructive testing. Usually, the load applied to an anchor during its life is

not known. To allow for these unknowns, “Safety Factors” and “Characteristic Values” are applied in the design process.

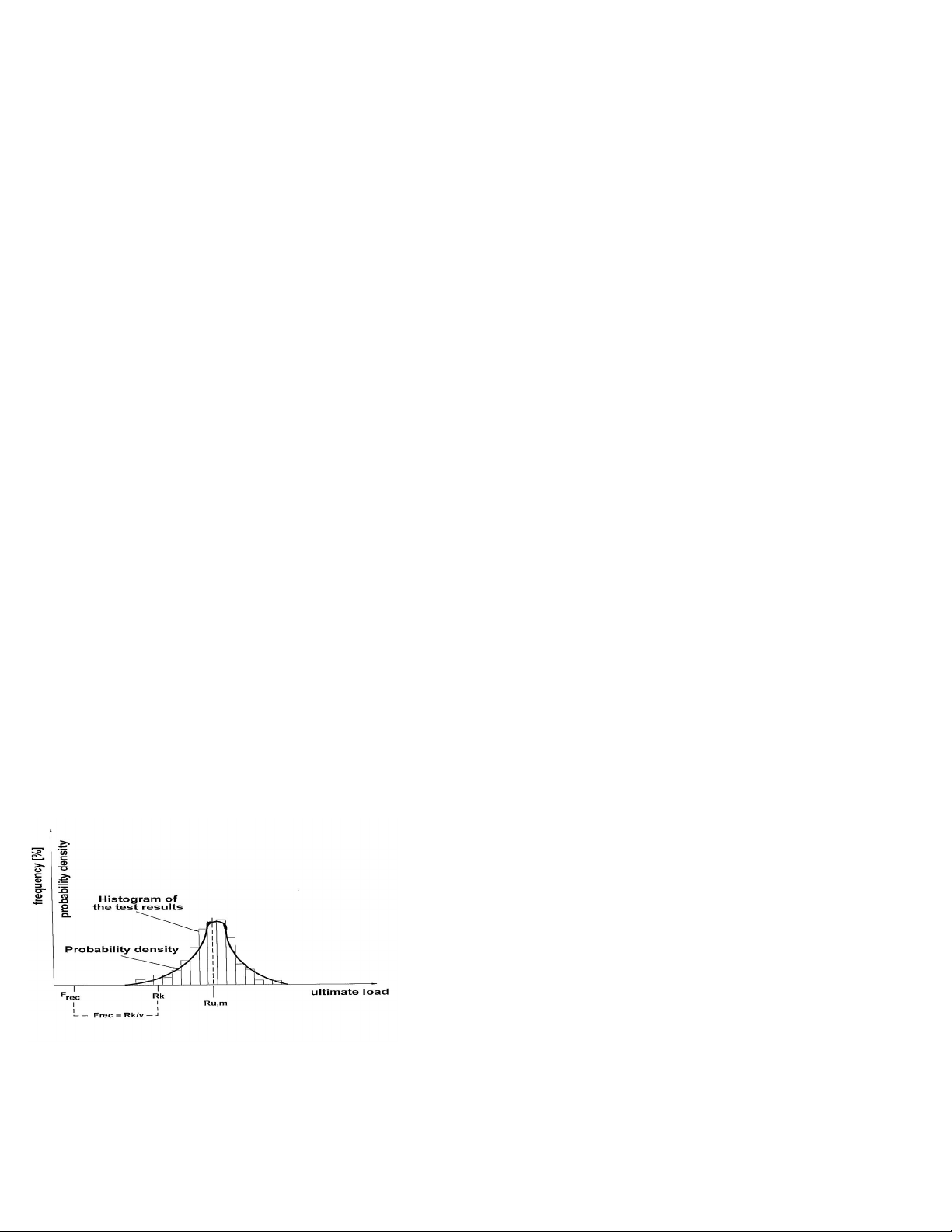

Values - Basics