Product User Manual

IdeaWerk™ 3D Printer WT150

Contents

Contents

1. Unpack and checking........................................................................................... 1

1.1 Check the Machine .................................................................................... 1

1.2 Check the Accessories ............................................................................... 3

2. Brief Introduction ............................................................................................... 3

2.1 Precautions and Safety ............................................................................... 3

2.2 Appearance and Structure.......................................................................... 4

2.3 Technical Specifications ............................................................................. 6

3. Software Installation ............................................................................................ 8

3.1 Software Installation .................................................................................. 8

3.2 Port Confirmation ................................................................................... 11

3.3 Python installation ................................................................................... 12

4. Preparations before printing .............................................................................. 15

4.1 Platform Calibration and measuring Z height .......................................... 15

4.2 Select temperature ................................................................................... 22

5. Introduction of main functions ......................................................................... 24

5.1 Introduction of main functions................................................................ 24

6. Forward and reverse the filament ....................................................................... 34

6.1 How to feed material ............................................................................... 34

6.2 How to reverse material ........................................................................... 36

7. Build from SD card and control ........................................................................ 37

7.1 Build from SD card ................................................................................. 37

7.2 Operation on control screen ...................................................................... 3

8. How to fix common problem ............................................................................ 42

8.1 Resolution of filament feeding unsmooth................................................ 42

8.2 Resolution of nozzle blocking ................................................................. 43

Acknowledgements ............................................................................................ 44

1. Unpack and checking

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

1. Unpack and checking

1.1 Check the Machine

1) Open the packing carton box, unwrap the EPE covering, remove the machine and

accessories from the box.

2) Overall observe the machine to make sure there is no serious damage. If any problem,

please contact with the after sale service staff in time.

1.2 Check the Accessories

All of the following accessories are consisted in the box together with the machine.

(Pic 1.1-01)

1

1. Unpack and checking

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

Teflon tube filament guide Nylon cable ties Cut pliers

Tweezers Allen wrench Clips

Power adapter and power cord USB Cable Build plate

2

1. Unpack and checking

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

Spool holder SD card Acupuncture Needle

(Pic 1.2-01)

2. Brief Introduction

2.1 Precautions and Safety

Place the machine in dry environment when operating.

To avoid blocking the nozzle, do not heat up the extruder before feeding the

material

Machine should be away from fire or water.

Use the machine in a ventilated environment, so that to avoid smelling.

Do not touch or remove the power cord or data line when operating.

Never touch the extruder or build bed by any parts of your body or anything

which is easy on fire when machine is operating, for they are very hot to harm

3

1. Unpack and checking

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

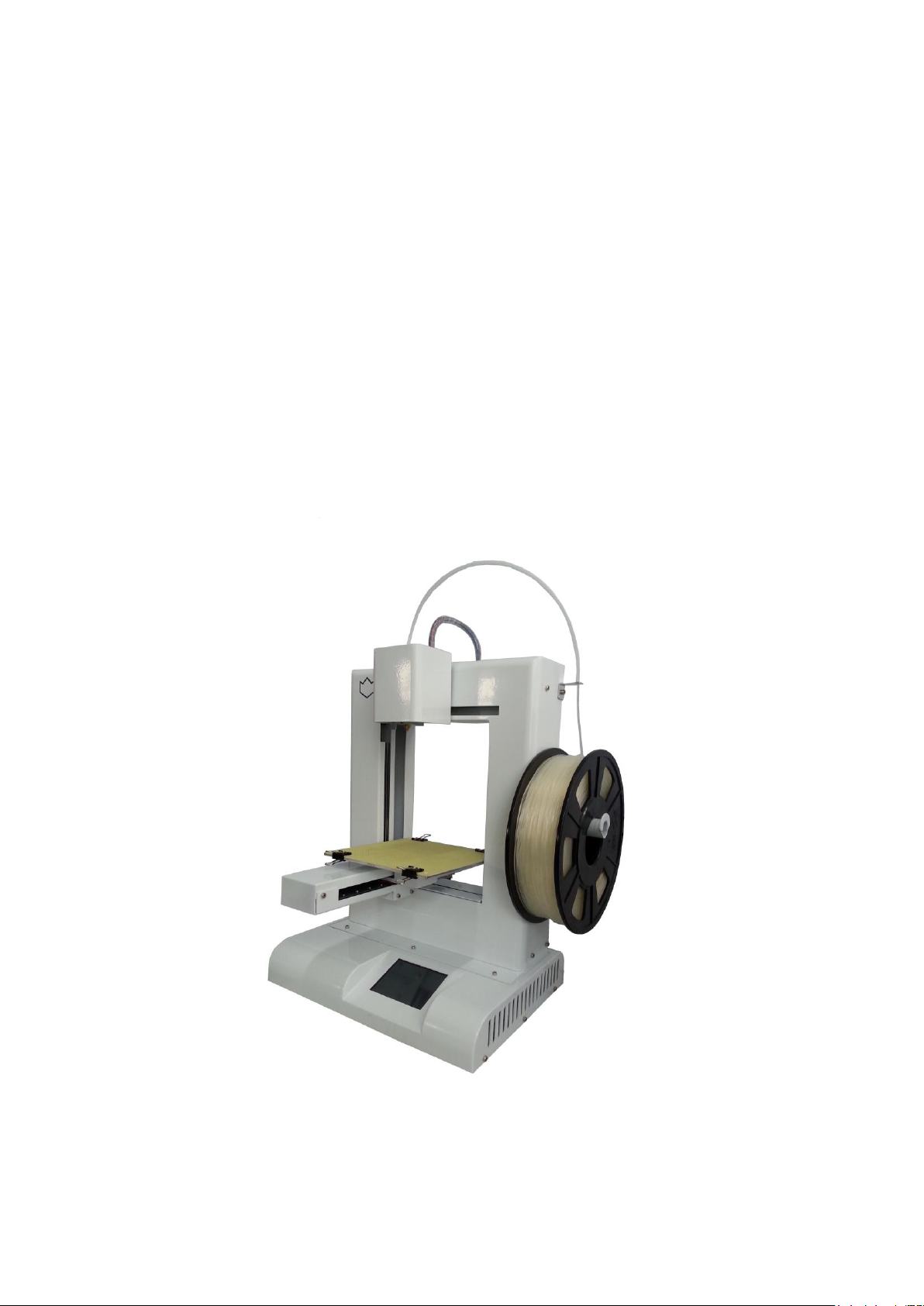

Filament Spool

Extruder

X axis

Z axis

Build Plate

Y axis

your skin or cause fire.

Gloves are required when removing the printed part to avoid harm of cutting,

scratching or burning.

2.2 Appearance and Structure

4

(Pic 2.2-01)

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

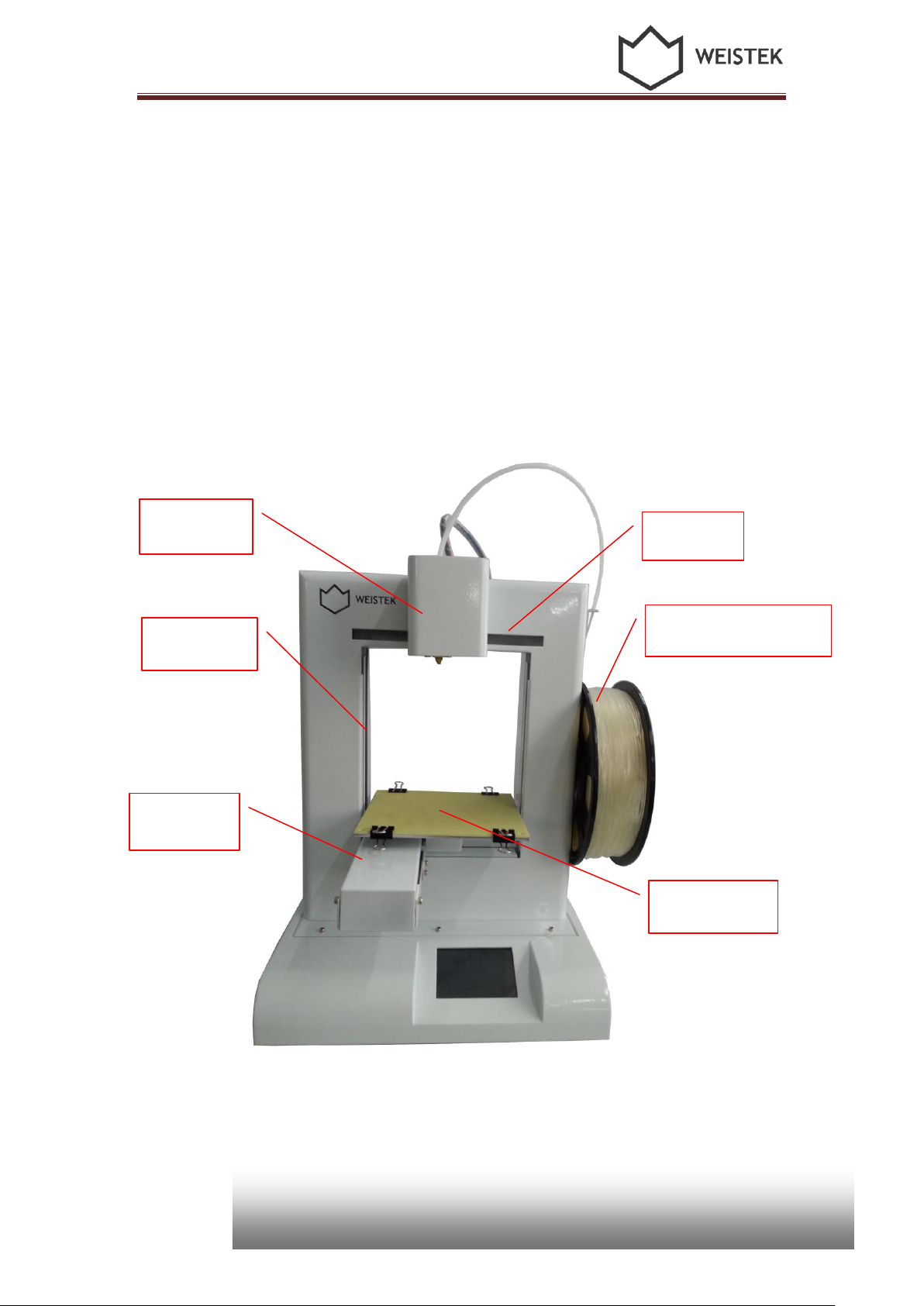

Note: the direction

of the clip must be

parallel to the X

axis

Please note how

to insert SD card

(Pic 2.2-02)

2. Brief Introduction

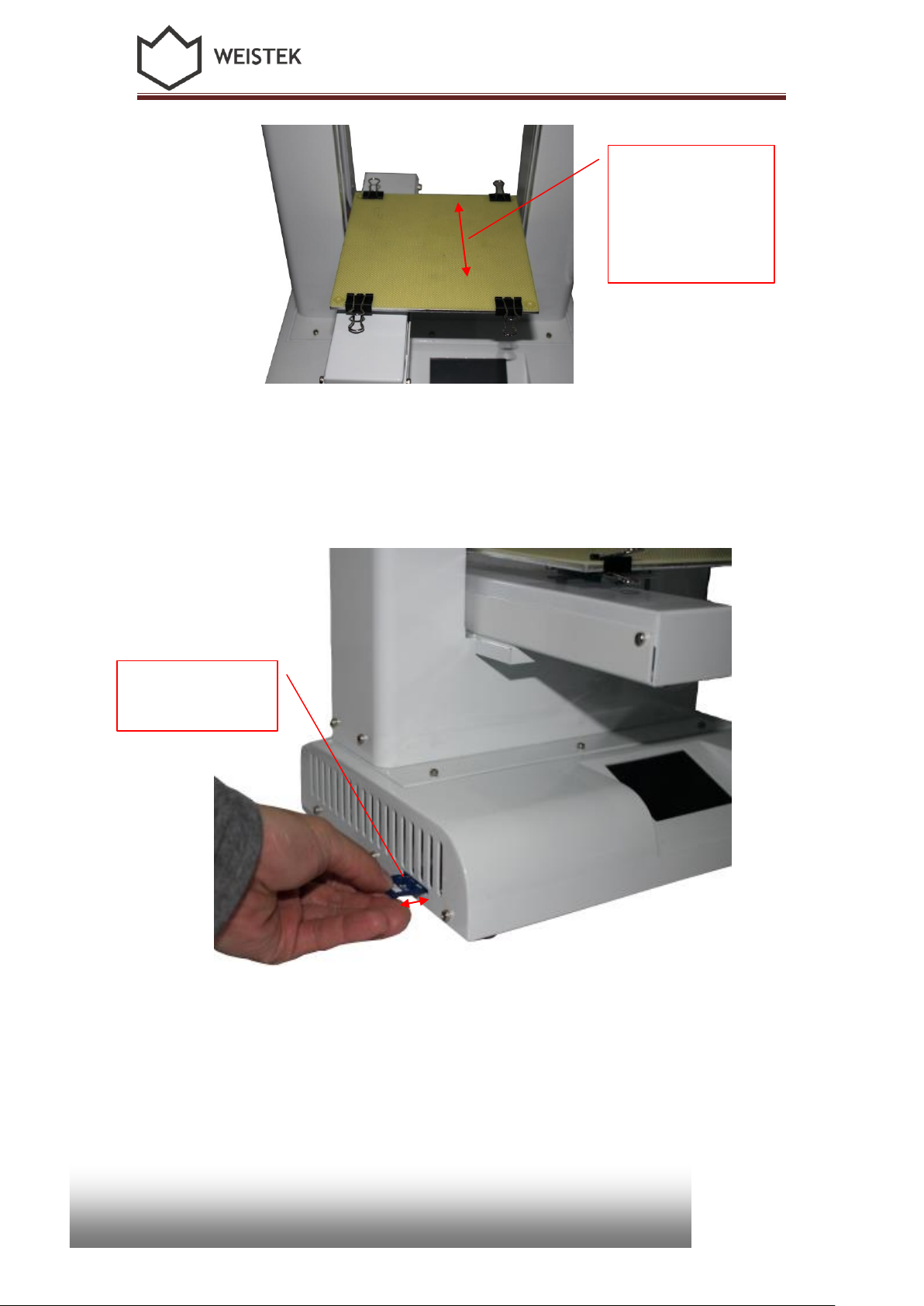

(Pic 2.2-03)

5

2. Brief Introduction

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

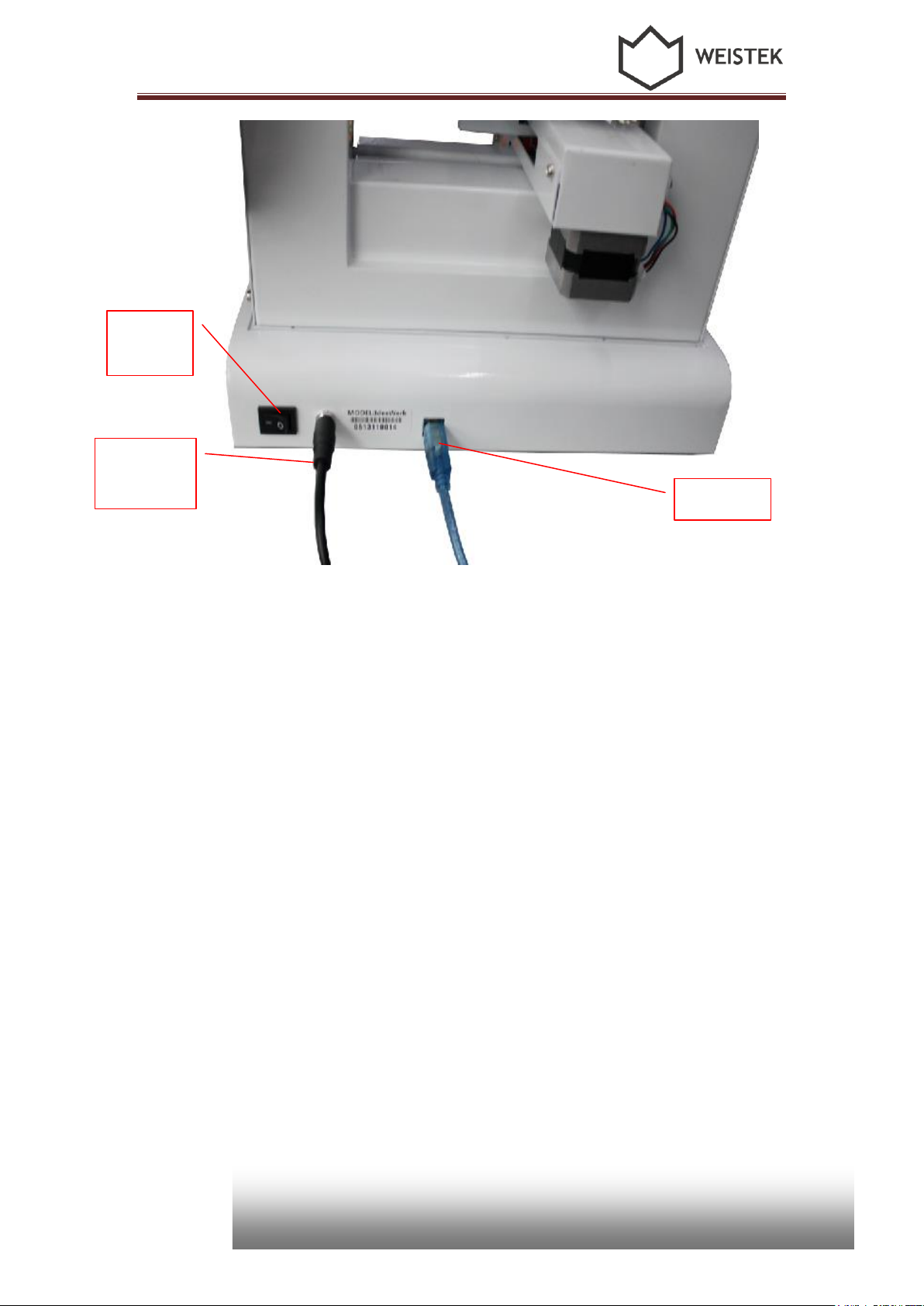

Power

Switch

Power

Input

USB Port

(Pic 2.2-04)

2.3 Technical Specifications

Dimensions: 298mm × 221mm × 403mm

Printing Dimensions: 150mm × 150mm × 140mm

Layer Thickness: 0.18~0.3mm

Speed: 30 – 150cm3/h

Net Weight: 7.5kg

Material: PLA

Materials Printing Temperature: PLA 220 - 230°C

Power: Input: AC 100-240V, 1.6A, 47-63Hz; Output: 12V/DC, 5.3A

6

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

Maximum Operating Power: 63.6W

Input Format: STL/X3G/GCODE

Operating Systems: Windows XP/Vista/Win7/Win8

Operating Software: ReplicatorG-0040(optimized by Weistek1.0)

Environment Temperature: 5℃~35℃

Relative Humidity: 30%~90%

2. Brief Introduction

7

3. Software Installation

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

3. Software Installation

3.1 Software Installation

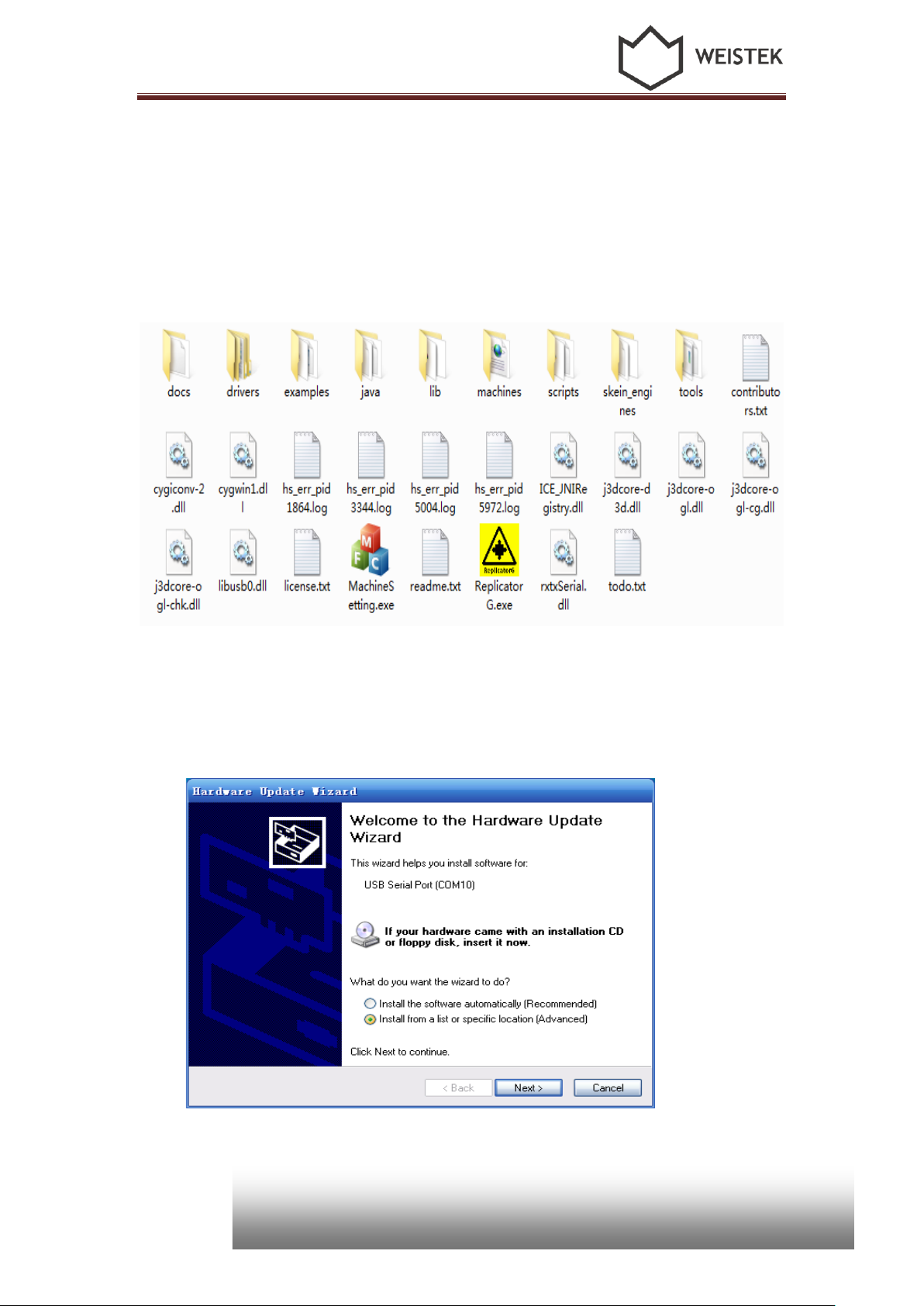

1) Copy the software from the disc before connecting the machine with your computer.

Decompress the file.

(Pic3.1-01)

2) Refer to the power and USB interfaces in the picture 3.1-02. Choosing “install from a

list or specific location (advanced)(S)” when the following interface pops up after

finishing connecting USB cable. Then, click “next” to continue.

8

(Pic 3.1-02)

3. Software Installation

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

Check this out

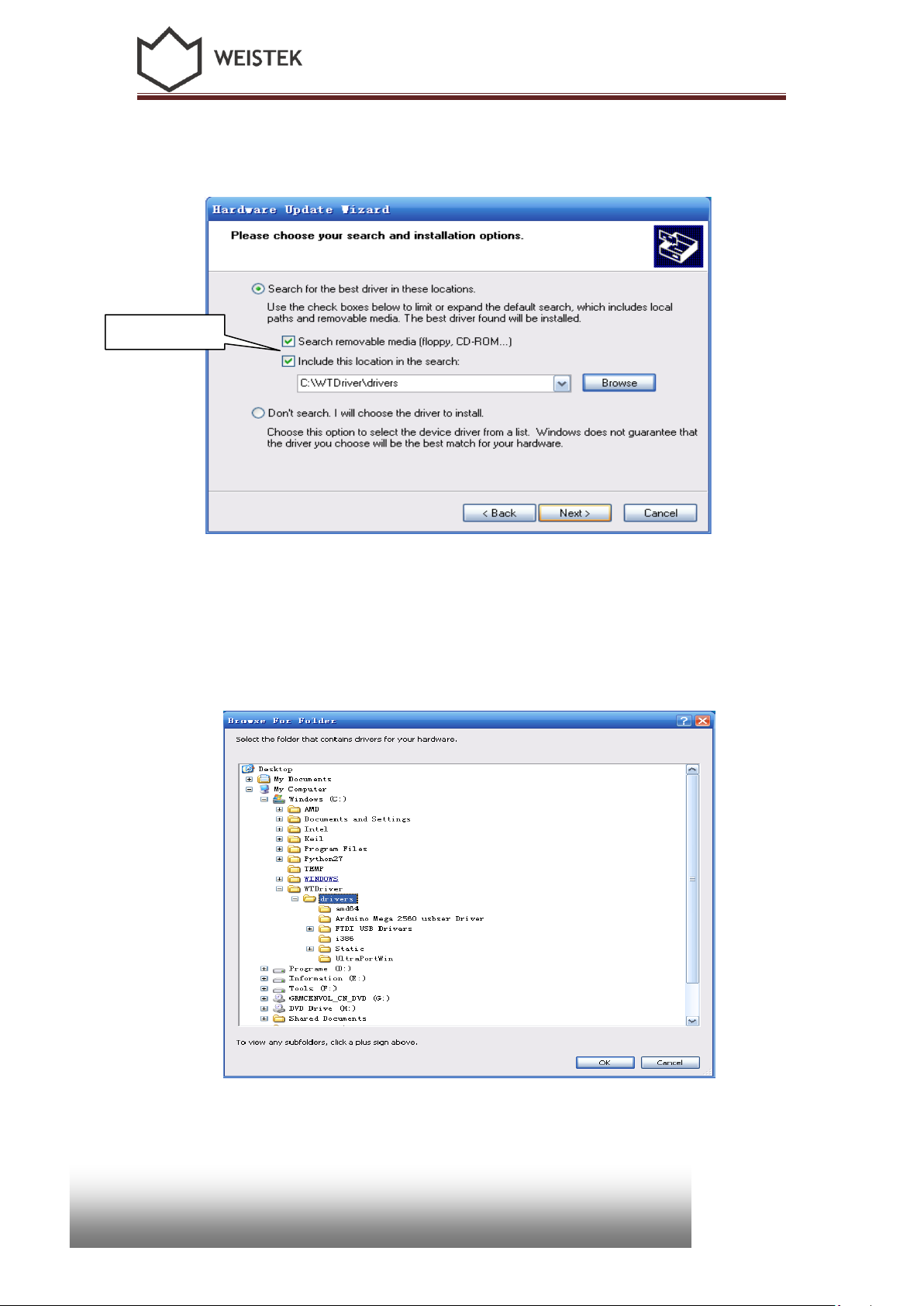

3>Select “Include this location in the search” in the below pop-up window, then clicking

“Browse”

(Pic 3.1-03)

4> Select a folder for WAY in the pop-up window Browse For Folder, and find

“drivers” folder, then clicking [OK]. Then, click [Next] in the window of Hardware

Update Wizard.

(Pic 3.1-04)

9

3. Software Installation

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

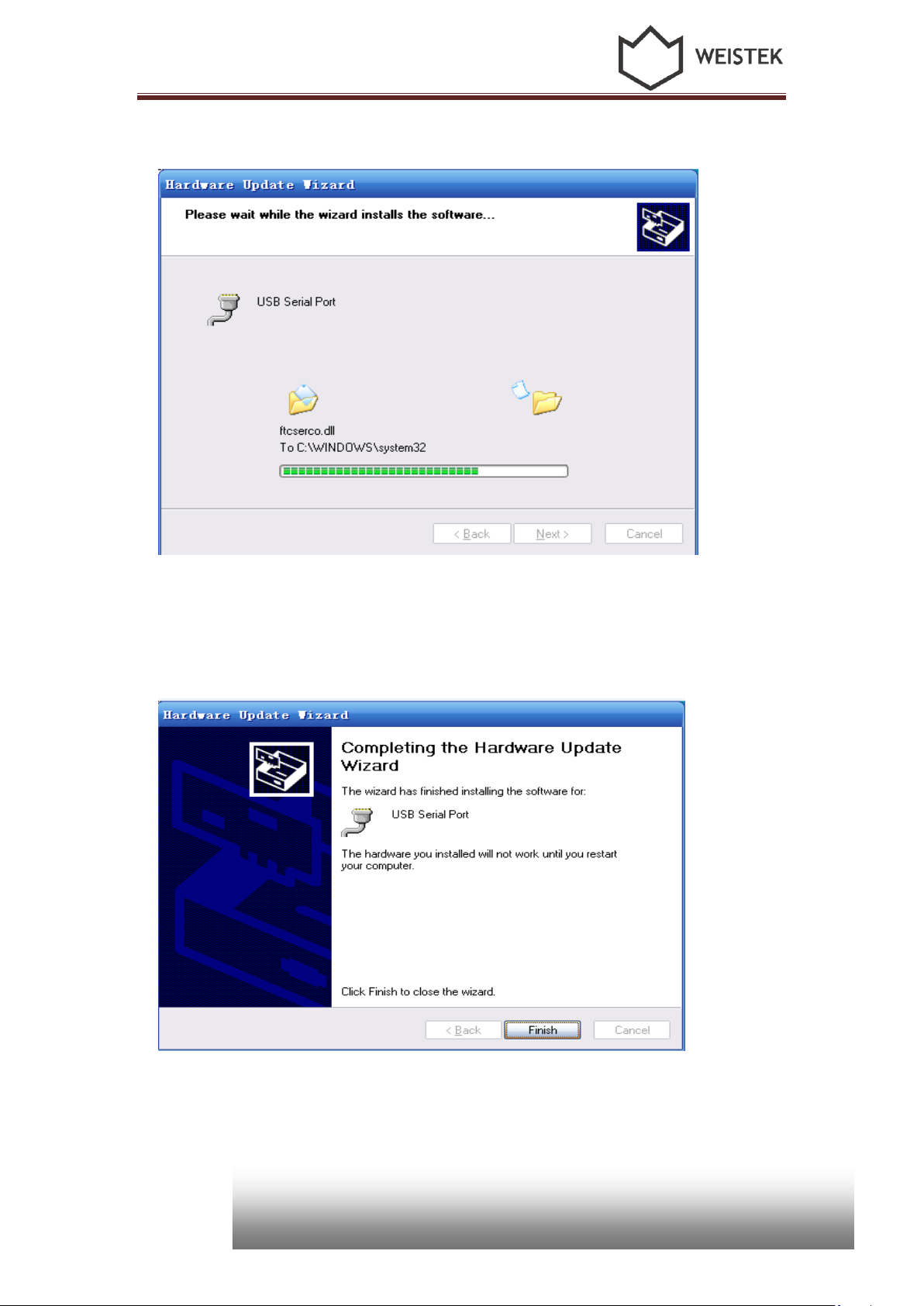

5> Click [next] when the following interface pops up.

(Pic 3.1-05)

6>waiting till the below window pops up, then clicking [Finish]. Until now a serials of

ports were installed successfully

(Pic 3.1-06)

10

3. Software Installation

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

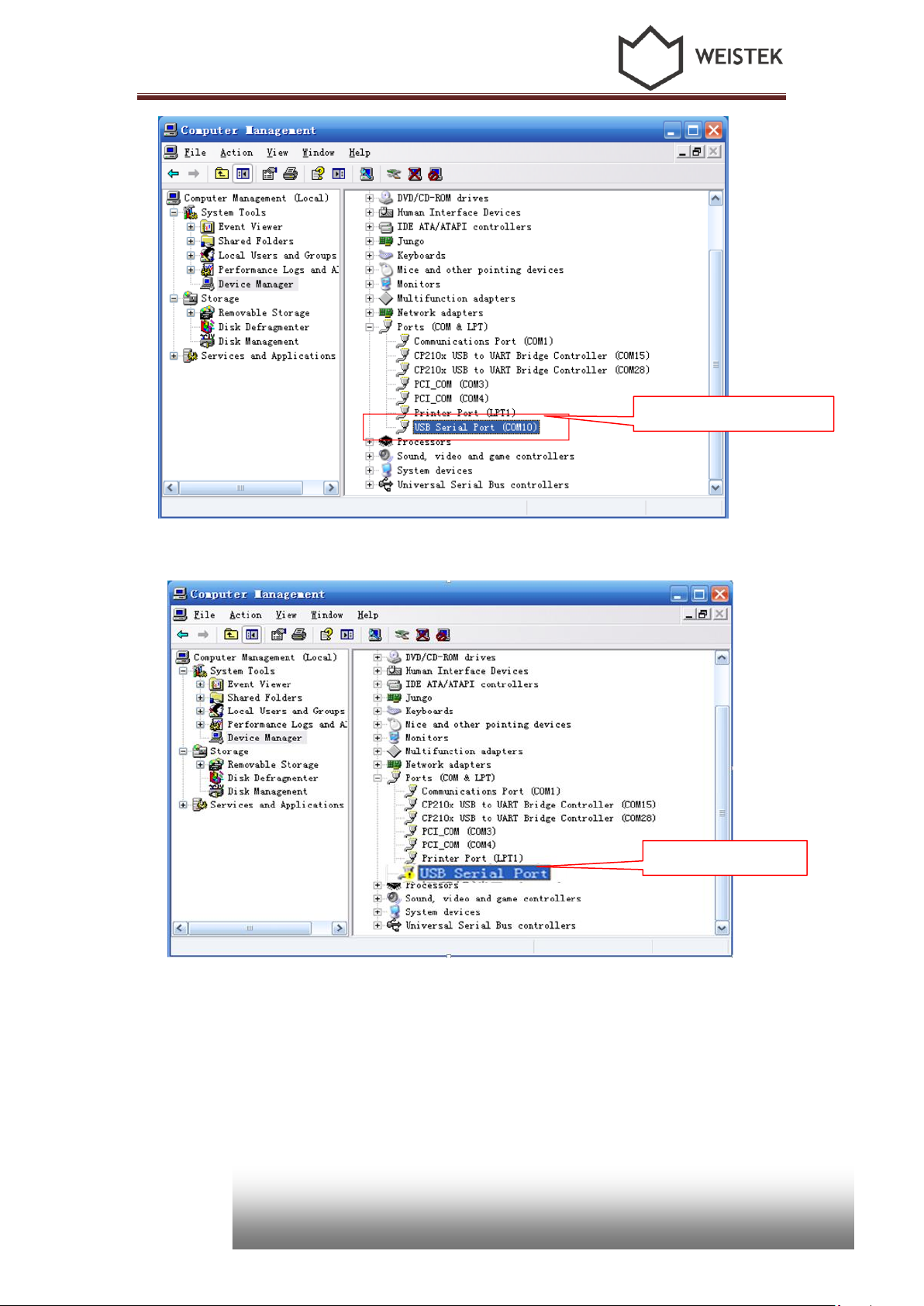

3.2 Port Confirmation

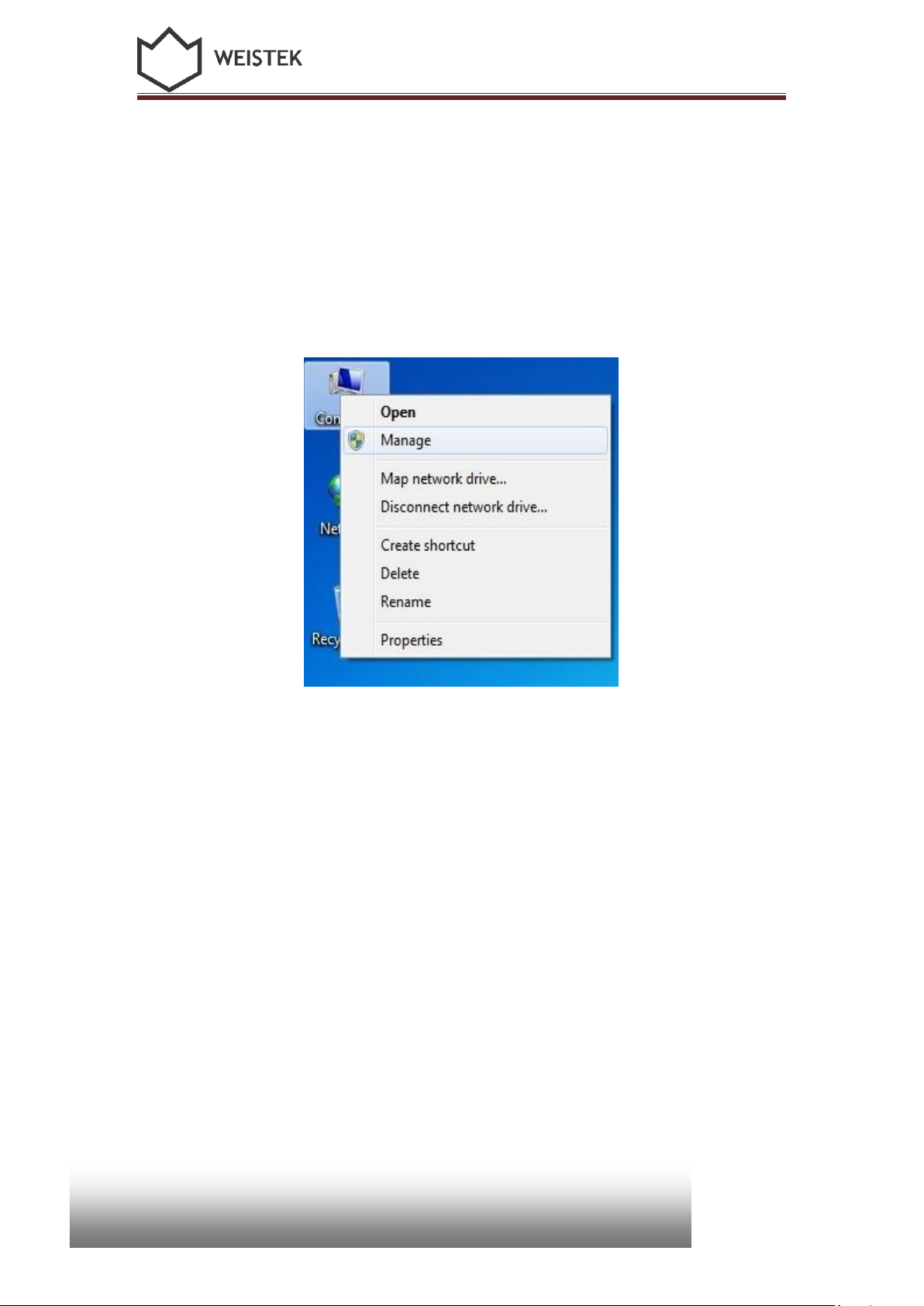

After finishing drives installation, please use the below methods to confirm whether it is

successful or not

1> right click「Computer」, choose「Manage」, and then choose「Device Manager」

(Pic 3.2-01)

2> Select “Ports (COM&LPT)”in the below pop-up window,. If no ? or ! ahead of

“USB Serial Port” shows the USB Serial Port Drive is installed successfully.

11

3. Software Installation

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

Installation succeeded

Installation failed

(Pic 3.2-02)

(Pic 3.2-03)

3.3 Python installation

as following:

12

Install Python software after finishing driver installation. The installation steps are

3. Software Installation

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

1>Double-click software ,click [next] in the following windows.

(Pic 3.3-01)

2> Disk C is the default destination. Don’t change anything, just click [next] as

following:

3> Click [next] in the following windows.

(Pic 3.3-02)

13

3. Software Installation

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

(Pic 3.3-03)

4> Click [finish] to complete Python installation.

(Pic 3.3-04)

14

3. Software Installation

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

(Pic 3.3-05)

4. Preparations before printing

Before start to print the SD card should insert in the 3D printer, or software will not

able to connect the printer.

4.1 Platform Calibration and measuring Z height

The plate should be calibrated before printing. Make sure the plate to be flat and level,

and appropriate distance to the extruder.

4.1.1 Place the platform at the bottom of Z axis. Start [Machine Setting], choose the

correct serial port and connect the printer.

15

4. Preparations before printing

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

Start this

program

(Pic 4.1-01)

(Pic 4.1-02)

4.1.2 Click [Connect], Connecting devices.

16

4. Preparations before printing

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

Green

arrows

indicate

equipment

connection

(Pic 4.1-03)

4.1.3Click [Roughly measure], the platform will go up and measure the height of Z axis

automatically and stop at the height of 138mm.

(Pic 4.1-04)

17

4. Preparations before printing

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

(Pic 4.1-05)

4.1.3 Select accurately measure step distance on the right of the [Accurately measure]

button, then click [Accurately measure] to move the platform step by step, till only

0.3mm between the platform and the extruder.

(Pic 4.1-06)

18

4. Preparations before printing

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

0.3mm between

the platform and

the extruder

Put a card here.

(Pic 4.1-07)

Tip: How to estimate the distance: put a card between the extruder and the platform,

while no more distance’s left, make sure the card can slice between extruder and platform

smoothly without any damage.

(Pic 4.1-08)

4.1.4 Now you can check if the platform is flat or not. Move the platform forward and

backward, to check the distances. Also, move the extruder to the left and right, to

check the distance.

19

4. Preparations before printing

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

(Pic 4.1-09)

Use the wrench to fasten or loosen the screws beneath the platform to adjust the

platform if somewhere distance is not around 0.3mm.

20

(Pic 4.1-10)

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

(Pic 4.1-11)

X axis

Y axis

4. Preparations before printing

4.1.5 After adjusting the platform, click [Meter Z], platform will go down again and

stop when it touches the Limit Switch. This process is measuring the Z height.

New data will be shown on the program.

(Pic 4.1-12)

Note: It is not necessary to measure Z height each time before printing. The program

will memorize the data for your next printing. It is suggested to adjust the platform every

3-4 months after using.

4.1.6 Click [Apply] and exit the program.

21

4. Preparations before printing

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

Start this program

Target temperature

4.2 Select temperature

4.2.1 Open the tool showed below.

(Pic 4.2-01)

4.2.2 How to select temperature: Extruder target temperature, 220~230oC.

22

(Pic 4.2-02)

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

4.2.3 Click [Apply] and exit the program.

Click Apply

4. Preparations before printing

(Pic 4.2-03)

23

5. Introduction of main functions

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

5. Introduction of main functions

5.1 Introduction of main functions

5.1.1 Software interface

Please choose [Skeinforge] before printing, as picture shows.

(Pic 5.1-01)

Then choose Machine Type [Replicator 2] before printing, as picture shows.

24

(Pic 5.1-02)

5. Introduction of main functions

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

Six main function bottoms: File, Edit, GCode, Machine, Thingiverse, Help

(Pic 5.1-03)

5.1.2 When user firstly starts the software, the software will show a blank area without

any model like below picture shows.

(Pic 5.1-04)

25

5. Introduction of main functions

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

5.1.3 Click「file」, choose「Open」to open an STL file of the model. The model will show

up on the center of the interface.

(Pic 5.1-05)

5.1.4 If your model does not show correctly on the virtual plate, use the bottoms on the

right side of the interface to edit the model.

(Pic 5.1-06)

26

5. Introduction of main functions

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

5.1.5 When the interface turns green and shows like the picture below, that means the

software has connected to the right serial port.

(Pic 5.1-07)

5.1.6 After editing the model, click「Generate Gcode」. Wait a few minutes till the Gcode

is finished.

How to deal with this problem: Choose [Defaults], then [Load Parameter]. After this step,

(Pic 5.1-08)

27

5. Introduction of main functions

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

Parameter

settings

the parameters will be correct as default.

(Pic 5.1-09)

5.1.7 Please operate some more times to get skills of printing.

28

5. Introduction of main functions

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

(Pic 5.1-10)

Setting Parameters Description

A: Choose slicing profile: IdeaWerk。

B: If your model contains vacant part, you need to select support.

None: None support

Exterior support: select to generate GCode with exterior support

Full support: select to generate GCode with full support

C: Infill percentage. If you want to print the model as a complete solid one, best

selection will be 95%. As your wish, you can select smaller percentage to save time and

material.

D: Layer Height should be 0.15mm-0.3mm. It decides smoothness of model surface and

printing speed. Thinner layer makes the surface smoother, and estimated time will be

longer.

E: Number of shells should be ≥1. Usually between 1 and 3.

29

5. Introduction of main functions

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

F: Feed rate should be 30-80mm/s. Best selection is 60mm/s.

G: Travel feed rate should be 60-150mm/s. Best selection is 80mm/s.

5.1.8 Confirm the settings and generate Gcode. Click「OK」to continue.

(Pic 5.1-11)

5.1.9 Wait several minutes till generation finished.

30

5. Introduction of main functions

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

(Pic 5.1-12)

5.1.10 Click to start building. Click「Proceed anyway」to continue.

(Pic 5.1-13)

31

5. Introduction of main functions

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

Click here

Click(Yes)

If GCode warning is shown, please ignore it. Do not cancel and choose “Proceed any

way”.

(Pic 5.1-14)

5.1.11 Click「Yes」to continue.

(Pic 5.1-15)

32

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

5.1.12 Model is printing.

5. Introduction of main functions

(Pic 5.1-16)

Warning: Do not cut down power during printing process, or the printing plate will

drop down without any tip.

5.1.13 Printing plate will drop down slowly when printing finishes. Caution not to pinch

your hands.

Remove the model from the plate with the shovel. Remember to wear your gloves.

33

5. Introduction of main functions

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

Filament feeding hole

(Pic 5.1-17)

6. Forward and reverse the filament

6.1 How to feed material

6.1.1 To avoid material stuck inside the extruder, please make sure the filament is fed

through the center of the hole.

34

(Pic 6.1-01)

7. Build from SD card and control

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

Correct

Error

6.1.2 First step, put the filament free end through the holder guide, and feed the filament

through the guiding tube. Second, push the free end into the extruder feeding hole.

6.1.3 Select Extruder Target Temperature at 220oC. Heat up extruder. After heating up,

click 「Forward」until the material string comes out from the nozzle. Click「Stop」when

finish this step.

(Pic 6.1-02)

The filament free end must be cut to be flat.

(Pic 6.1-03)

35

6. Forward and reverse the filament

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

Forward

Feed the materials end to end.

(Pic 6.1-04)

(Pic 6.1-05)

6.2 How to reverse material

To reverse material, the extruder should be heated up first. Then click 「Reverse」until

the filament is totally reversed from the extruder. Click「Stop」to finish this step.

36

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

(Pic 6.2-01)

Reverse

7. Build from SD card and control

7. Build from SD card and control

7.1 Build from SD card

After generating Gcode of the model, click bottom to create an .x3g file. Save

the .x3g file in your SD card.

Note: 1. SD card capacity should be no larger than 2D.

2. .x3g file name should be made up from English or Arabic number only.

37

7. Build from SD card and control

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

Should be .x3g

format

Click here (Yes)

Click here (OK)

(Pic 7.1-01)

(Pic 7.1-02)

7.2 Operation on control screen

Control should be done on the screen when building from SD card.

7.2.1 Click anywhere on the screen to start operating.

38

7. Build from SD card and control

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

(Pic 7.2-01)

7.2.2 Scan the file as the guide shows.

(Pic 7.2-02)

39

7. Build from SD card and control

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

7.2.3 Click on the name of the file to start building.

(Pic 7.2-03)

7.2.4 The picture (Pic 7.1-04) shows the condition of the machine when building. Click

Light to switch on the light inside the machine box, in order to observe the printing

process more clearly.

(Pic 7.2-04)

40

7. Build from SD card and control

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

7.2.5 Click Stop to end the process of building if needed.

(Pic 7.2-05)

7.2.6 Error alert shows up if anything wrong when building.

(Pic 7.2-06)

41

8. How to fix common problem

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

8. How to fix common problem

8.1 Resolution of filament feeding unsmooth

What is unsmooth: During printing, the extruder can’t extrude filament or

extrude intermittently, at this situation,

1: Check the extruder temperature if is too low or not, increase 5-10oC each time to see

if the problem is solved or not. See Pic8.1- 01

2: Check the gear of the extruder, if there are a lot of filament waste pellet, just clean it

and then print again to see if situation get better or not.

(Pic 8.1-01)

42

8. How to fix common little problem

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

8.2 Resolution of nozzle blocking

If the extruder is still not able to work, then you have to check if the nozzle of the

extruder is blocked or not. This is always due to wrong operation of machine and

use wrong filament or wrong operation of joining the filament.

Solutions:

1) Heat the extruder temperature to appropriate temperature (only for PLA. PLA:

220°C -230°C).

Click Reverse, if needed, at the same time have to pull back the filament with hand

(some time the filament was bite a breach by the gear, the gear can’t touch the

filament, need to pull the filament to the gear so the reverse will work)

2)Change a new filament, the temperature of extruder can be selected a little

high(around 250oC).

3)Then Start to extrude, use your needle (or any of your needle like tools) insert into

the hole of nozzle, dredge up and down, at the same time, press the filament which is

extruding. Keep doing this until the filament comes out from the nozzle.

43

8. How to fix common problem

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str.1

D-92240 Hirschau

(Pic 8.2-01)

Acknowledgements

Thanks for using IdeaWerk™ 3D printer and thanks for your supports for Weistek.

For after sale service please contact with your retailer.

44

Loading...

Loading...