1

Quick Set Up Guide

Shenzhen Weistek Co., Ltd

Add.: RM2301, Shenzhen Overseas Chinese High-Tech Venture Park, Shenzhen, P. R. China

Email: contact@weistek.net Website: www.weistek.net

Quick Set Up Guide

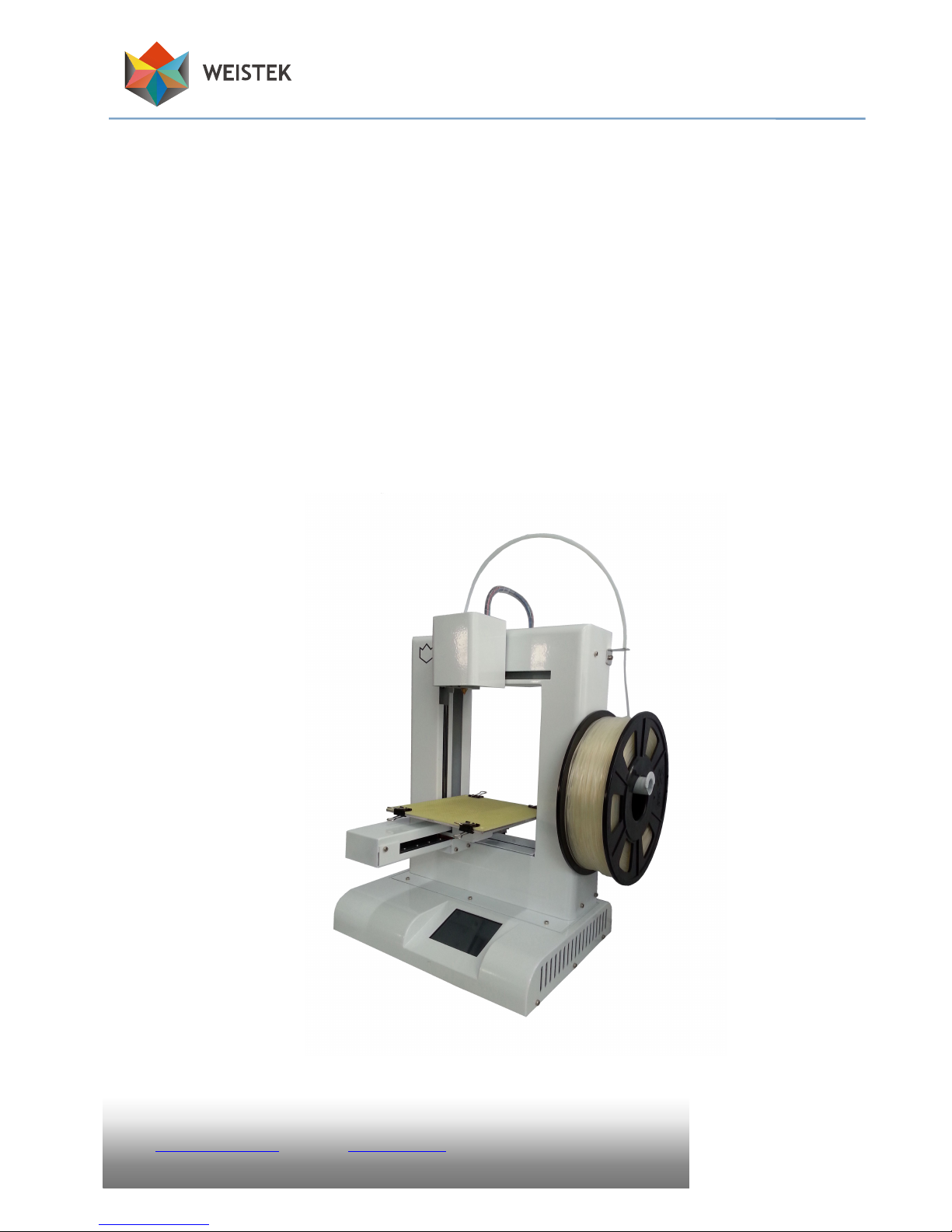

IdeaWerk 3D Printer

2

Quick Set Up Guide

Shenzhen Weistek Co., Ltd

Add.: RM2301, Shenzhen Overseas Chinese High-Tech Venture Park, Shenzhen, P. R. China

Email: contact@weistek.net Website: www.weistek.net

Take out the machine after opening the box. In total 5 parts:

1

Extruder part

2

Main frame part

3

Spool holder

4

Y-axis part

5

Main base part

Picture 1.1

Y-axis part

Main frame part

Extruder part

Base part

Spool holder

3

Quick Set Up Guide

Shenzhen Weistek Co., Ltd

Add.: RM2301, Shenzhen Overseas Chinese High-Tech Venture Park, Shenzhen, P. R. China

Email: contact@weistek.net Website: www.weistek.net

Main base part Y-axis part

Picture 1.2 Picture 1.3

Main frame and extruder part Spool holder

Picture 1.4 Picture 1.5

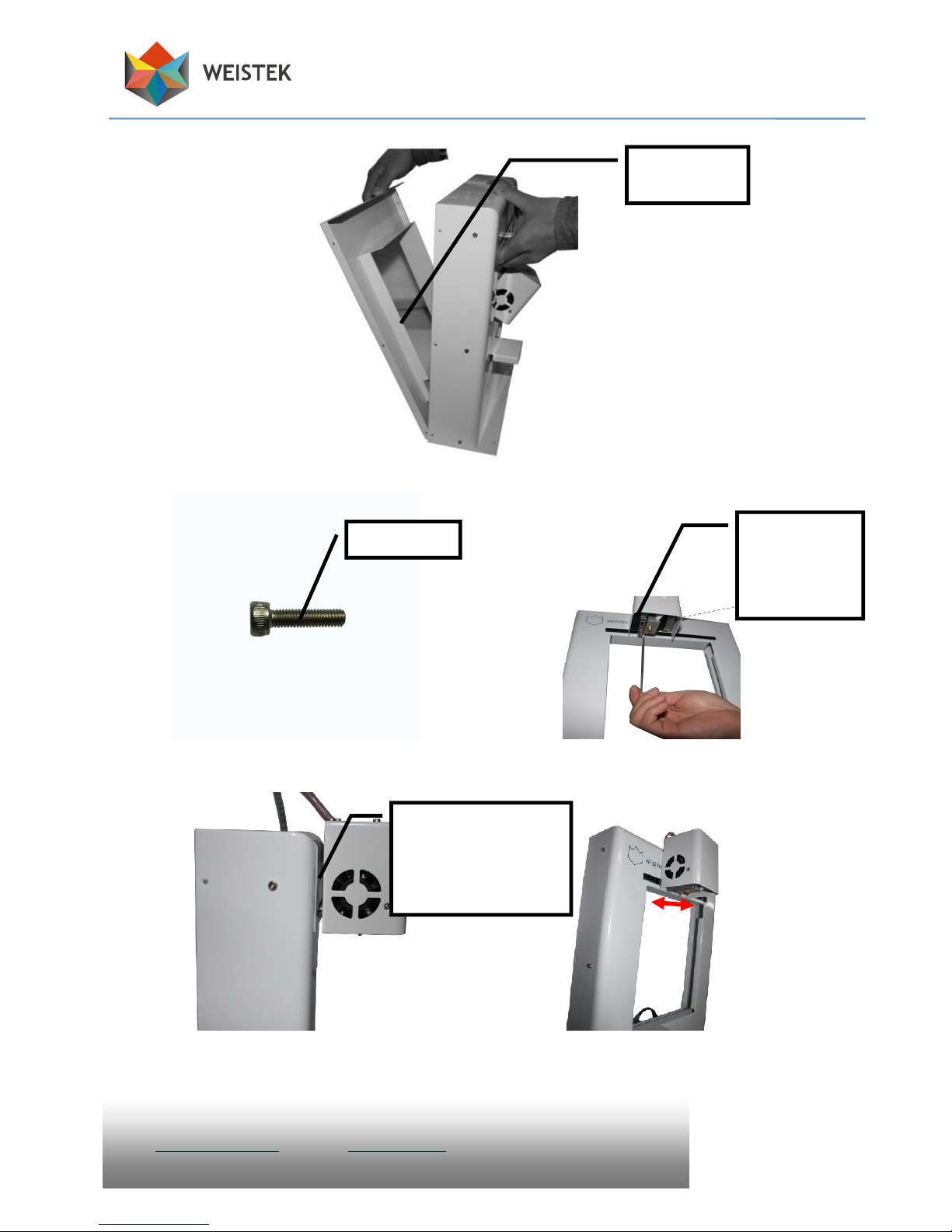

I. Assemble steps:

(1) Take out main frame and extruder part, and fix the extruder part in

the main frame part through a M3*12 screw by Allen wrench. Please

note distance between extruder and main frame part should be

same from top to bottom.

4

Quick Set Up Guide

Shenzhen Weistek Co., Ltd

Add.: RM2301, Shenzhen Overseas Chinese High-Tech Venture Park, Shenzhen, P. R. China

Email: contact@weistek.net Website: www.weistek.net

Picture 2.1

Picture 2.2 Picture 2.3

Picture 2.4 Picture 2.5

Screw M3x12

Maintain uniform

clearance between the

two parts to ensure a

good printing accuracy

Push extruder

part to confirm

if it moves

smoothly

Remove the

back cover

5

Quick Set Up Guide

Shenzhen Weistek Co., Ltd

Add.: RM2301, Shenzhen Overseas Chinese High-Tech Venture Park, Shenzhen, P. R. China

Email: contact@weistek.net Website: www.weistek.net

(2) Assemble motor base and main frame by 6 M3x6 screws (each 3

screws on front and back) and fasten with M3 Allen wrench.

Picture 2.6 Picture 2.7

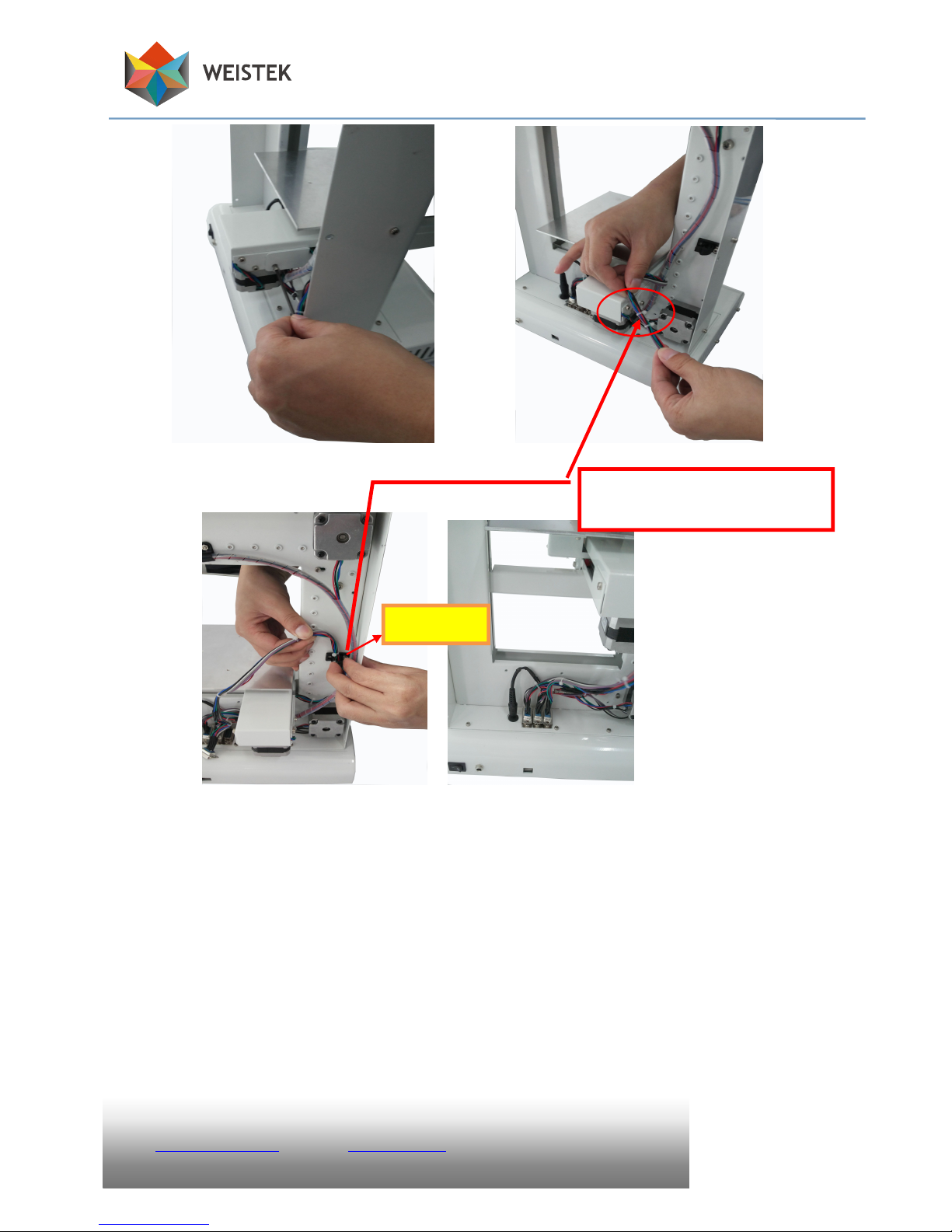

(3) Connect eater cables in picture 2.8, DB 15-pin socket connector in

picture 2.9.

Picture 2.8 Picture 2.9

Screw M3x6

6

Quick Set Up Guide

Shenzhen Weistek Co., Ltd

Add.: RM2301, Shenzhen Overseas Chinese High-Tech Venture Park, Shenzhen, P. R. China

Email: contact@weistek.net Website: www.weistek.net

(4) DB 9-pin socket connector in picture 3.0 and picture 3.1.

Picture 3.0 Picture 3.1

(5) Fix Y-axis in main frame. First, fasten 2 M3x6 side screws, then 2

M6x6 bottom screws, 1 M3x6 side screw at last. After finishing

Y-axis assembly, connector cables should be stuck in the stick-type

wiring holder and also just in between two nylon cable ties in case

of movement caused by loosening.

Picture 3.2 Picture 3.3

7

Quick Set Up Guide

Shenzhen Weistek Co., Ltd

Add.: RM2301, Shenzhen Overseas Chinese High-Tech Venture Park, Shenzhen, P. R. China

Email: contact@weistek.net Website: www.weistek.net

Picture 3.4 Picture 3.5

Picture 3.6 Picture 3.7

(6) Recover the back cover, be careful not to press or stuck the cables.

Then fasten 7 M3x6 screws, among which 2 on the top, 3 on one

side and 2 on the other side.

The part between two nylon cable

ties is design to be clamped

The clamp

8

Quick Set Up Guide

Shenzhen Weistek Co., Ltd

Add.: RM2301, Shenzhen Overseas Chinese High-Tech Venture Park, Shenzhen, P. R. China

Email: contact@weistek.net Website: www.weistek.net

Picture 3.8 Picture 3.9

Picture 4.0

9

Quick Set Up Guide

Shenzhen Weistek Co., Ltd

Add.: RM2301, Shenzhen Overseas Chinese High-Tech Venture Park, Shenzhen, P. R. China

Email: contact@weistek.net Website: www.weistek.net

(7) Assemble the spool holder on the side with 2 M3x6 screws.

Picture 4.1

(8)Assemble the filament passing-through assistant. (Attention the

direction.)

Picture 4.2

10

Quick Set Up Guide

Shenzhen Weistek Co., Ltd

Add.: RM2301, Shenzhen Overseas Chinese High-Tech Venture Park, Shenzhen, P. R. China

Email: contact@weistek.net Website: www.weistek.net

(9)Connect the motor cable on Y axis.

Picture 4.3

(10) Set the build bed, fix it with 4 clips.

Picture 4.4

Note: the long tail of the clips

should be parallel to Y-axis

11

Quick Set Up Guide

Shenzhen Weistek Co., Ltd

Add.: RM2301, Shenzhen Overseas Chinese High-Tech Venture Park, Shenzhen, P. R. China

Email: contact@weistek.net Website: www.weistek.net

(11)Place the filament spool and feed the filament with the Teflon

filament guide.

Picture 4.5

II. Acknowledgements

Thanks for using IdeaWerk 3D printer.

For after sale service please contact with your retailer.

Loading...

Loading...