Page 1

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

83294002 • 2/2014-11

Page 2

60040000

Conformity certification

Manufacturer:

Address:

Product: Combustion Manager

The product described above conforms with

the regulations of directives:

This product is labelled as follows:

Schwendi, 02.09.2014

ppa. ppa.

Dr. Schloen Denkinger

Manager Research Manager Production and

and Development Quality Management

Max Weishaupt GmbH

Max-Weishaupt-Straße

D-88475 Schwendi

W-FM 25

GAD 2009 / 142 / EC

PED

97 / 23 / EC

LVD 2006 / 95 / EC

EMC 2004 / 108 / EC

Sprachschlüssel

02

CE-0085

Page 3

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

1 User instructions ..................................................................................................................... 5

1.1 User guide ............................................................................................................. 5

1.1.1 Symbols ................................................................................................................. 5

1.1.2 Target group ......................................................................................................... 5

1.2 Guarantee and Liability ....................................................................................... 6

2 Safety ............................................................................................................................................ 7

2.1 Designated application ....................................................................................... 7

2.2 When gas can be smelled ................................................................................. 7

2.3 Safety measures .................................................................................................. 7

2.3.1 Normal operation ................................................................................................. 7

2.3.2 Electrical connection ........................................................................................... 7

2.3.3 Gas supply ............................................................................................................ 8

2.4 Alterations to the construction of the equipment ......................................... 8

2.5 Noise emission ..................................................................................................... 8

2.6 Disposal ................................................................................................................. 8

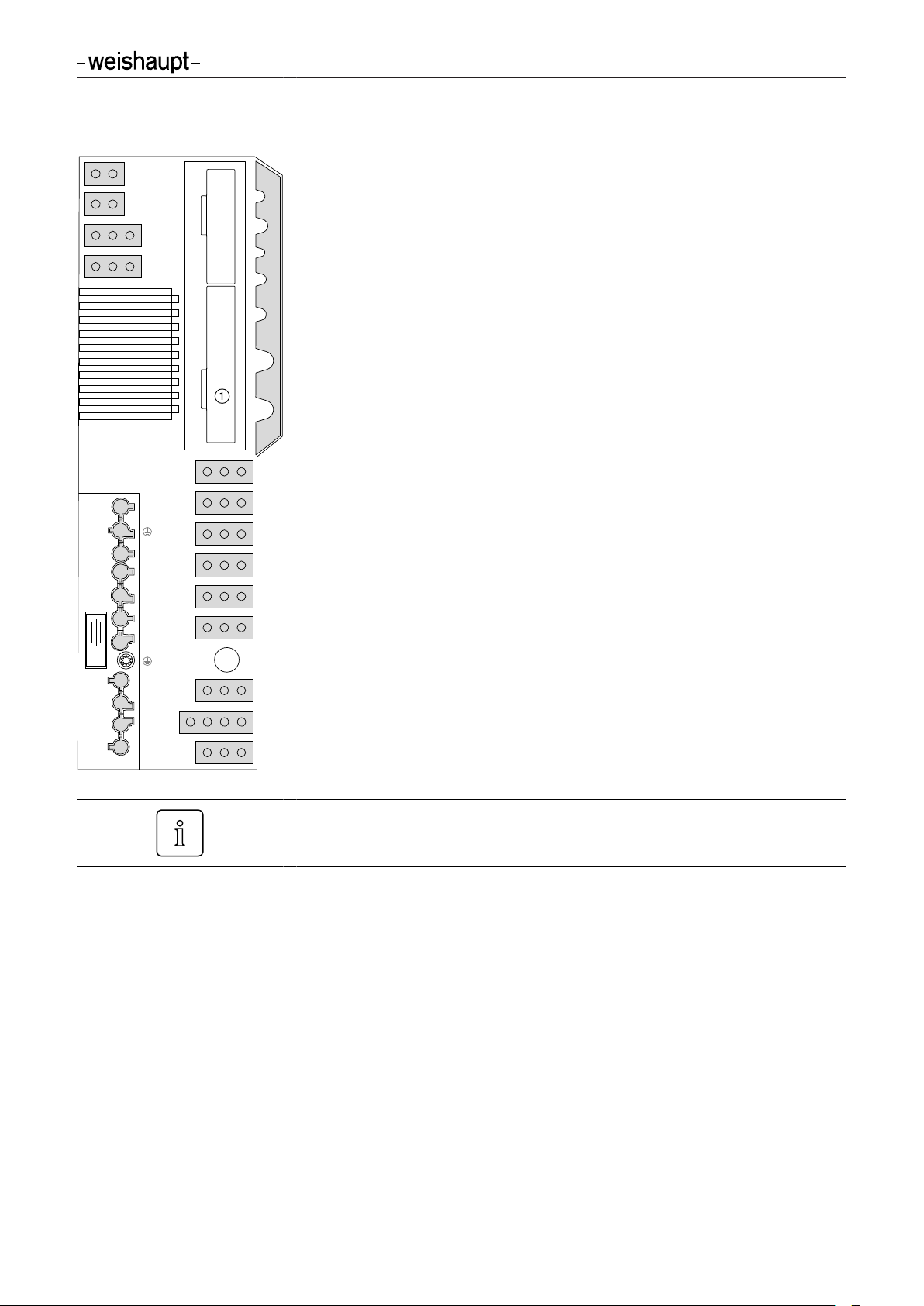

3 Product description ............................................................................................................... 9

3.1 Inputs and outputs ............................................................................................... 9

3.1.1 Gas burner ............................................................................................................ 9

3.1.2 Gas burner with speed control ...................................................................... 10

3.1.3 Oil burner ............................................................................................................ 11

3.1.4 Dual fuel burner ................................................................................................. 12

3.2 Technical data ................................................................................................... 13

3.2.1 Electrical data ................................................................................................... 13

3.2.2 Ambient conditions ........................................................................................... 13

3.2.3 Dimensions ......................................................................................................... 13

4 Operation .................................................................................................................................. 14

4.1 Operating panel ................................................................................................ 14

4.2 Display ................................................................................................................. 16

4.2.1 Info level .............................................................................................................. 17

4.2.2 Service level ....................................................................................................... 20

4.2.3 Parameter level .................................................................................................. 23

4.2.4 Access level ....................................................................................................... 28

4.3 Linearisation ....................................................................................................... 29

5 Installation ................................................................................................................................ 30

5.1 Replacing the combustion manager ............................................................. 30

83294002 • 2/2014-11 • La

6 Commissioning ...................................................................................................................... 32

6.1 Gas burner ......................................................................................................... 32

6.2 Gas burner with speed control ...................................................................... 37

6.3 Oil burner ............................................................................................................ 42

6.4 Dual fuel burner ................................................................................................. 47

6.4.1 Adjusting gas side ............................................................................................ 47

6.4.2 Adjusting oil side ............................................................................................... 52

3-70

Page 4

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

7 Troubleshooting .................................................................................................................... 57

7.1 Procedures for fault conditions ..................................................................... 57

7.1.1 Display off ........................................................................................................... 57

7.1.2 Display flashes ................................................................................................... 57

7.1.3 Detailed fault code ........................................................................................... 58

7.2 Rectifying faults ................................................................................................. 59

8 Spares ......................................................................................................................................... 64

9 Technical documentation ................................................................................................. 66

9.1 Program sequence ........................................................................................... 66

10 Notes ........................................................................................................................................... 68

11 Key word index ...................................................................................................................... 70

83294002 • 2/2014-11 • La

4-70

Page 5

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

1 User instructions

1 User instructions

This installation and operating manual forms part of the appliance and must be kept

on site.

Observe installation and operating manual of the burner.

This installation and operating manual supplements the following chapters in the in-

stallation and operating manual of the burner:

Technical description and/or Product description

▪

Commissioning and operation and/or Commissioning

▪

Cause and rectification of faults and/or Troubleshooting

▪

Technical data.

▪

The chapter Display and operating modes and operation is replaced completely.

1.1 User guide

1.1.1 Symbols

DANGER

WARNING

CAUTION

Immediate danger with high risk.

Non observance can lead to serious injury or death.

Danger with medium risk.

Non observance can lead to environmental damage,

serious injury or death.

Danger with low risk.

Non observance can cause damage to the equipment

and injury to personnel.

Important information

Requires direct action

Result after an action

Itemisation

83294002 • 2/2014-11 • La

Range of values

1.1.2 Target group

These installation and operating instructions are intended for the operator and qualified personnel. They should be observed by all personnel working on the unit.

Work on the unit must only be carried out by personnel who have the relevant training

and instruction.

Persons with limited physical, sensory or mental capabilities may only work on the unit

if they are supervised or have been trained by an authorised person.

Children must not play near or on the unit.

5-70

Page 6

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

1 User instructions

1.2 Guarantee and Liability

Guarantee and liability claims for personal and equipment damage are excluded, if

they can be attributed to one or more of the following causes:

Non approved application,

▪

non-observance of the installation and operating instruction,

▪

operation with faulty safety equipment,

▪

continual operation despite a fault,

▪

improper installation, commissioning, operation and service,

▪

unauthorised modifications made to the unit,

▪

the installation of additional components, which have not been tested with the unit,

▪

the installation of combustion chamber inserts, which impede full flame formation,

▪

repairs, which have been carried out incorrectly,

▪

the use of non original Weishaupt parts,

▪

unsuitable fuels,

▪

defects in the inlet lines,

▪

acts of God.

▪

83294002 • 2/2014-11 • La

6-70

Page 7

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

2 Safety

2 Safety

2.1 Designated application

The combustion manager W-FM 25 is suitable for use with:

oil burners

▪

gas burners

▪

dual fuel burners.

▪

Improper use could:

endanger the health and safety of the user or third parties,

▪

cause damage to the appliance or other material assets.

▪

2.2 When gas can be smelled

Avoid open flames and spark generation, for example:

do not operate light switches,

▪

do not operate electronic equipment,

▪

do not use mobile telephones.

▪

Open doors and windows.

▶

Close gas isolating valve.

▶

Warn the inhabitants (do not ring door bells).

▶

Leave the building.

▶

Inform the heating company or gas supplier from outside of the building.

▶

2.3 Safety measures

Safety relevant fault conditions must be eliminated immediately.

2.3.1 Normal operation

All labels on the unit must be kept in a legible condition,

▪

the unit should only be operated with its cover in the closed position,

▪

do not touch moving parts during operation,

▪

stipulated settings, service and inspection work should be carried out at regular

▪

intervals.

2.3.2 Electrical connection

For work carried out on live parts:

Observe the accident prevention instructions BGV A3 and adhere to local direc-

▪

tives,

tools in accordance with EN 60900 should be used.

▪

83294002 • 2/2014-11 • La

7-70

Page 8

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

2 Safety

2.3.3 Gas supply

Only the gas supplier or an approved agent may carry out installation, alteration

▪

and maintenance work on gas appliances in buildings and properties.

Pipe work must be subject to a combined load and valve proving test and usability

▪

testing relative to the pressure range intended (e.g.

DVGW-TRGI, work sheet G 600).

Inform the gas supplier about the type and size of plant prior to installation.

▪

Local regulations and guidelines must be observed during installation (e. g.

▪

DVGW-TRGI, work sheet G 600; TRF Band 1 and Band 2).

The gas supply pipe work should be suitable for the type and quality of gas and

▪

should be designed in such a way that it is not possible for liquids to form (e. g. condensate). Observe vaporisation pressure and vaporisation temperature of liquid

petroleum gas.

Use only tested and approved sealing materials, whilst observing all process in-

▪

formation.

Re-commission the appliance when changing to a different type of gas.

▪

Carry out soundness test after each service and fault rectification.

▪

2.4 Alterations to the construction of the equipment

All conversions require written approval from Max Weishaupt GmbH.

No additional components may be fitted, which have not been tested for use with

▪

the equipment,

use only original Weishaupt replacement parts.

▪

2.5 Noise emission

The noise emissions are determined by the acoustic behaviour of all components fitted

to the combustion system.

Prolonged exposure to high noise levels can lead to loss of hearing. Provide operating

personnel with protective equipment.

Noise emissions can further be reduced with a sound attenuator.

2.6 Disposal

Dispose of all materials used in a safe and environmentally friendly way. Observe local

regulations.

83294002 • 2/2014-11 • La

8-70

Page 9

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

3 Product description

3 Product description

3.1 Inputs and outputs

3.1.1 Gas burner

8

11

-weishaupt-

L

N

X6

F7

X7

T1

T2

S3

B4

B5

T6

T7

T8

15

12

TWI TWI interface (Vision Box)

P free

TWI

NA free

FC free

AM Operating panel of remote reset

L/A Air damper actuator

G Gas butterfly valve actuator

1

Slot analogue module EM3/3 or Fieldbus module EM3/2

1 External liquid petroleum gas valve

G L/A AM FU NA P

3C Burner motor for continuous running fan

3N Burner motor or valve continuous running fan

4 Ignition unit

13

3

N

7

3

C

4

1

5 Multifunction assembly or double gas valve

6 free

7 Bridging plug No. 7

8 Gas meter (impulse generator)

11 Air pressure switch

12 Low / valve proving gas pressure switch

13 Ionisation

14 Remote reset (plug cable No. 14 required)

15 Bridging plug No. 15 or high gas pressure switch

6

5

X6 7 pole connection plug

X7 4 pole connection plug

F7 Internal unit fuse (6.3 AT)

14

83294002 • 2/2014-11 • La

If a digital load converter (DLU) is used, this has to be replaced with the

analogue module EM3/3.

9-70

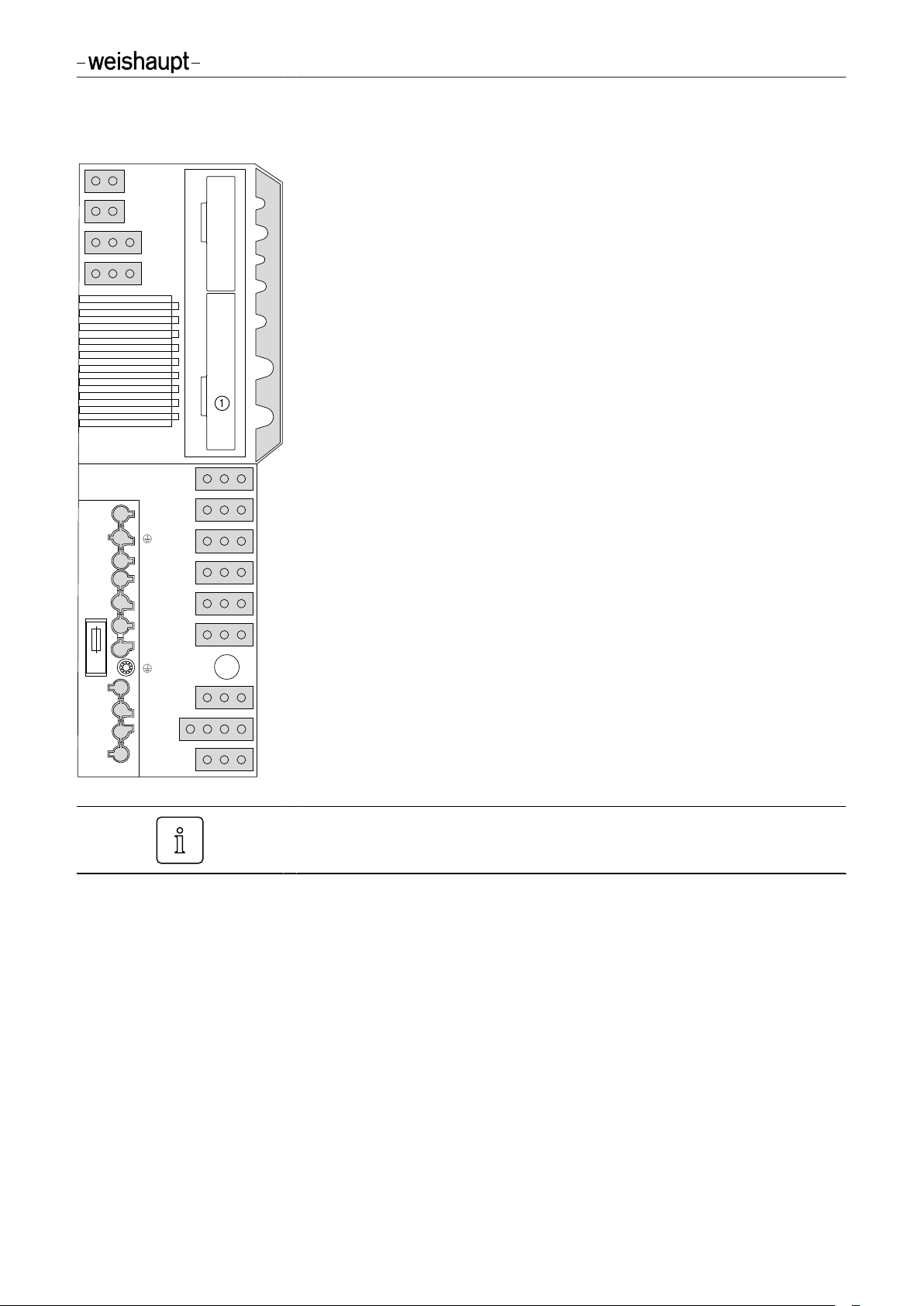

Page 10

8

11

-weishaupt-

L

N

X6

F7

X7

T1

T2

S3

B4

B5

T6

T7

T8

15

12

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

3 Product description

3.1.2 Gas burner with speed control

TWI TWI interface (Vision Box)

P free

TWI

G L/A AM FU NA P

13

3

N

7

3

C

4

1

6

5

14

NA free

FC free

AM Digital/analogue converter (DAU01)

L/A Air damper actuator

G Coded plug (yellow)

1

Slot analogue module EM3/3 or Fieldbus module EM3/2

1 External liquid petroleum gas valve

3C Digital/analogue converter (DAU01)

3N Frequency converter

4 Ignition unit

5 Double gas valve and air pressure switch burner operation

6 free

7 Low gas pressure switch

8 Gas meter (impulse generator)

11 Air pressure switch pre-purge

12 Valve proving gas pressure switch

13 Ionisation

14 Remote reset (plug cable No. 14 required)

15 Bridging plug No. 15 or high gas pressure switch

X6 7 pole connection plug

X7 4 pole connection plug

F7 Internal unit fuse (6.3 AT)

If a digital load converter (DLU) is used, this has to be replaced with the

analogue module EM3/3.

83294002 • 2/2014-11 • La

10-70

Page 11

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

3 Product description

3.1.3 Oil burner

8

11

-weishaupt-

L

N

X6

F7

X7

T1

T2

S3

B4

B5

T6

T7

T8

15

12

TWI TWI interface (Vision Box)

P free

TWI

NA free

FC free

AM Operating panel of remote reset

L/A Air damper actuator

G Coded plug (black)

1

Slot analogue module EM3/3 or Fieldbus module EM3/2

1 Safety solenoid valve (Y14)(1 or stage 1 solenoid valve (Y11)

G L/A AM FU NA P

3C Burner motor for continuous running fan

(2

3N Burner motor

4 Ignition unit

13

5 Stage 1 solenoid valve (Y11)

3

N

7

3

C

4

1

6 Stage 2 solenoid valve (Y12)

7 Bridging plug No. 7

8 Oil meter (impulse generator)

11 free

12 Bridging plug No. 12 or oil pressure switch

13 Flame sensor

14 Remote reset (plug cable No. 14 required)

(1

15 free

6

5

X6 7 pole connection plug

X7 4 pole connection plug

F7 Internal unit fuse (6.3 AT)

14

(1

Burner with safety solenoid valve

(2

Burner without safety solenoid valve

83294002 • 2/2014-11 • La

If a digital load converter (DLU) is used, this has to be replaced with the

analogue module EM3/3.

11-70

Page 12

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

3 Product description

3.1.4 Dual fuel burner

8

11

-weishaupt-

L

N

X6

F7

X7

T1

T2

S3

B4

B5

T6

T7

T8

15

12

TWI TWI interface (Vision Box)

P free

TWI

NA free

FC free

AM Operating panel of remote reset

L/A Air damper actuator

G Gas butterfly valve actuator

1

Slot analogue module EM3/3 or Fieldbus module EM3/2

1 Stage 1 solenoid valve (Y11)

G L/A AM FU NA P

3C Pump motor and safety solenoid valve Oil (Y14)

3N Burner motor and external LPG valve

4 Ignition unit

13

3

N

7

3

C

4

1

5 Multifunction assembly or double gas valve

6 Stage 2 solenoid valve (Y12)

7 Bridging plug No. 7

8 Fuel change-over

11 Air pressure switch

12 Low / valve proving gas pressure switch and oil pressure switch

13 Flame sensor

14 Remote reset (plug cable No. 14 required)

15 Bridging plug No. 15 or high gas pressure switch

6

5

X6 7 pole connection plug

X7 4 pole connection plug

F7 Internal unit fuse (6.3 AT)

14

If a digital load converter (DLU) is used, this has to be replaced with the

analogue module EM3/3.

83294002 • 2/2014-11 • La

12-70

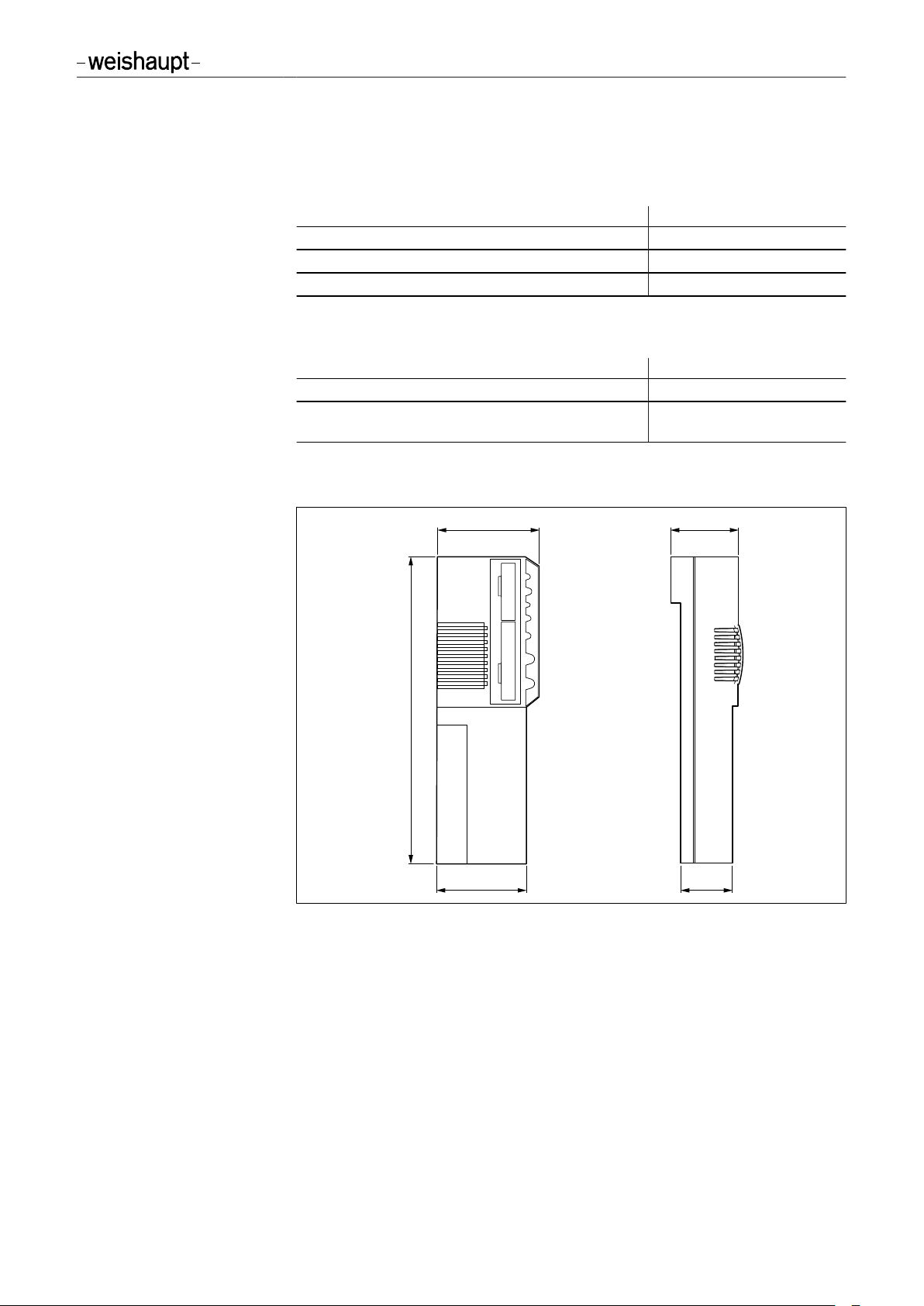

Page 13

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

3 Product description

3.2 Technical data

3.2.1 Electrical data

Mains voltage/frequency 230 V / 50 … 60 Hz

Consumption max 12 W

Internal unit fuse 6.3 A slow

Type of protection IP 40

3.2.2 Ambient conditions

Temperature in operation -20 … +60 °C

Temperature during transport / storage -20 … +70 °C

Relative humidity DIN 60730-1,

no dew point

3.2.3 Dimensions

275 mm

92 mm 60 mm

-weishaupt-

80 mm 46 mm

83294002 • 2/2014-11 • La

13-70

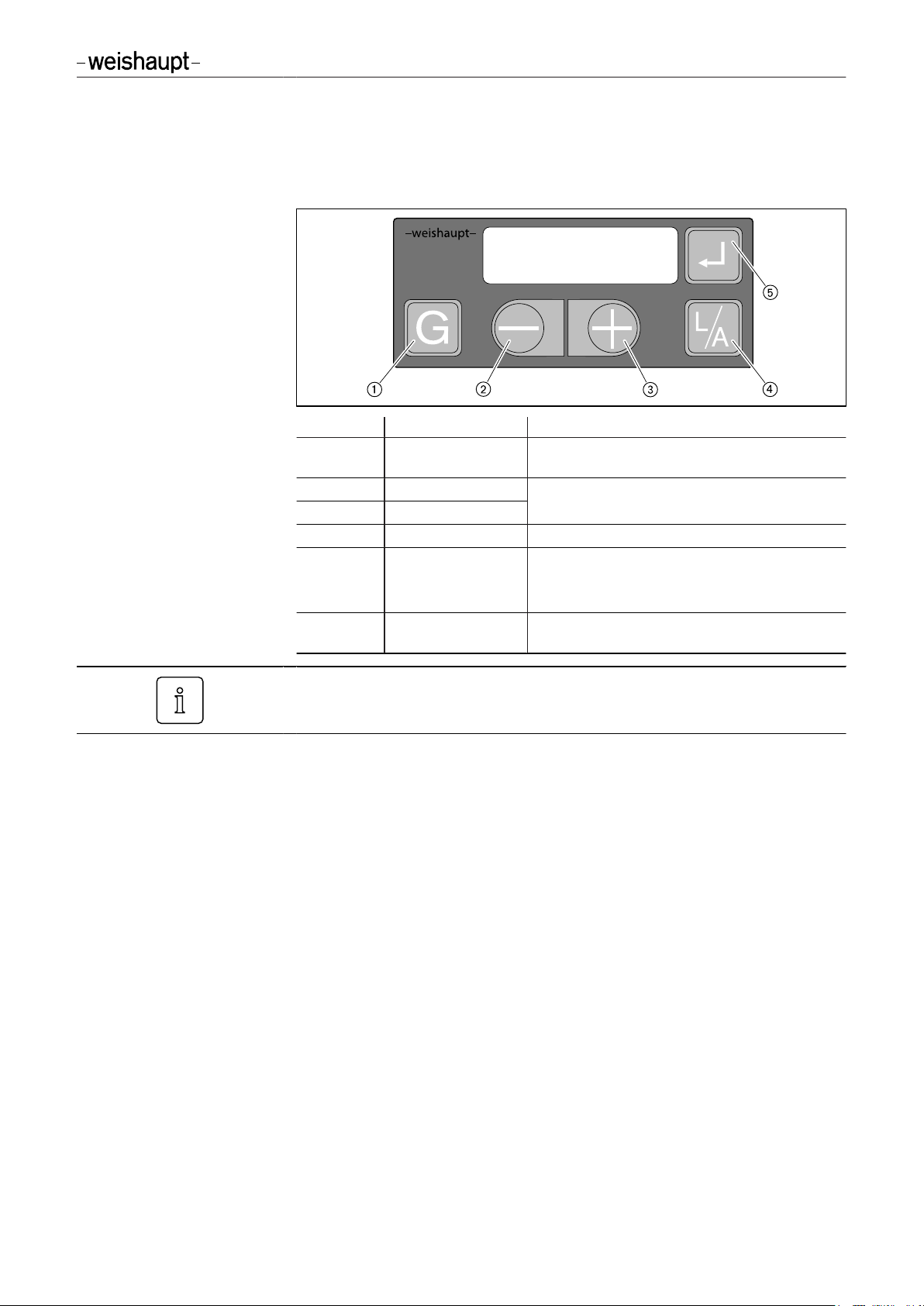

Page 14

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

4 Operation

4 Operation

4.1 Operating panel

No. Key Function

1 [G] Gas Select gas butterfly valve actuator or speed

control

2

3

4

5

3 and 5 [+] and [ENTER] press approx. 2 seconds = Parameter level

[–]

[+]

[L/A] Air Select air damper actuator

[ENTER] Reset burner; call up information

Change values

press approx. 0.5 seconds = Info level

press approx. 2 seconds = Service level

(only possible with display

OFF

)

Various actions (e. g. changing the display, reset) are only triggered when the key is

released.

Operating level

The current actuator position or the fan speed can be displayed by pressing keys in

operating level (10).

Displaying air damper setting:

Press key [L/A].

▶

Displaying gas butterfly valve setting or fan speed:

Press key [G].

▶

Off function

Press keys [ENTER], [L/A] and [G] simultaneously.

▶

Immediate lockout with error

✓

18h

.

83294002 • 2/2014-11 • La

14-70

Page 15

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

4 Operation

Operating phase

The exact operating phase of the combustion manager can also be displayed. This

simplifies determining the cause of the fault during troubleshooting (see Ch. 9.1).

The display can be called up in Standby (

Press and hold keys [+] and [–] simultaneously for approx. 3 seconds.

▶

The combustion manager changes to operating display. In the display, the current

✓

operating phase is shown with a number.

Switching back to standard display:

Press and hold keys [+] and [–] simultaneously for approx. 3 seconds.

▶

OFF

).

83294002 • 2/2014-11 • La

15-70

Page 16

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

4 Operation

4.2 Display

Operating panel

The display shows the current operating status and operating data.

1

Setting level activated

2

Start phase activated

3

Info level activated

4

Actuator runs CLOSED

5

Actuator runs OPEN

6

Burner in operation

7

Lockout

8

Service level activated

No heat demand

No heat demand

(fuel selected: Gas)

No heat demand

(fuel selected: Oil)

Shutdown via contact X3:7 (plug No. 7)

Programming not completed

Programming of gas part not completed

83294002 • 2/2014-11 • La

Programming of oil part not completed

Switch off via Fieldbus

Insufficient gas low gas pressure switch

Low voltage (display flashes)

Connection to Fieldbus faulty (display flashes)

16-70

Page 17

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

4 Operation

4.2.1 Info level

Gas burner / gas burner with speed control

Burner data can be interrogated in the Info level.

Press [Enter] key approx. 0.5 seconds.

▶

The Info level is activated.

✓

Press [Enter] to reach the next information.

▶

l,m³

No. Information

0

1

2

3

4

5

6

7

8

9

11

12

13

Total gas consumption in m³ (via X3:8)

Reset value:

Press [L/A] and [+] keys simultaneously for ca. 2 secs.

▶

Operating hours

- no function Burner starts

Device item number

Index of device item number

Unit number

Production date (DDMMYY)

Fieldbus address

Valve proving behaviour

- no function Current gas consumption (0.1 m³/h)

Analogue module EM3/3 or Fieldbus module EM3/2 available

0

= No

1

= Yes

After information 13 or a waiting time of approx. 20 seconds the combustion manager

changes over to the operating level.

83294002 • 2/2014-11 • La

17-70

Page 18

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

4 Operation

Oil burner

Burner data can be interrogated in the Info level.

Press [Enter] key approx. 0.5 seconds.

▶

The Info level is activated.

✓

Press [Enter] to reach the next information.

▶

l,m³

No. Information

0

1

2

3

4

5

6

7

8

10

11

12

13

Total oil consumption in litres (via X3:8)

Reset value:

Press [L/A] and [+] keys simultaneously for ca. 2 secs.

▶

Operating hours stage 1

Operating hours stage 2

Burner starts

Device item number

Index of device item number

Unit number

Production date (DDMMYY)

Fieldbus address

Oil pressure switch function

- no function Current oil consumption (0.1 l/h)

Analogue module EM3/3 or Fieldbus module EM3/2 available

0

= No

1

= Yes

After information 13 or a waiting time of approx. 20 seconds the combustion manager

changes over to the operating level.

83294002 • 2/2014-11 • La

18-70

Page 19

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

4 Operation

Dual fuel burner

Burner data can be interrogated in the Info level.

Press [Enter] key approx. 0.5 seconds.

▶

The Info level is activated.

✓

Press [Enter] to reach the next information.

▶

l,m³

No. Information

0

1

2

3

4

5

6

7

8

9

10

11

12

13

- no function Operating hours in gas operation or oil operation stage 1

Operating hours in oil operation stage 2

Total burner starts

Device item number

Index of device item number

Unit number

Production date (DDMMYY)

Fieldbus address

Valve proving behaviour

Oil pressure switch function

- no function -

- no function Analogue module EM3/3 or Fieldbus module EM3/2 available

0

= No

1

= Yes

After information 13 or a waiting time of approx. 20 seconds the combustion manager

changes over to the operating level.

83294002 • 2/2014-11 • La

19-70

Page 20

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

4 Operation

4.2.2 Service level

Gas burner / dual fuel burner (Gas operation)

The service level gives information about:

Actuator position of individual operating points

▪

The most recent fault

▪

Flame signal during operation.

▪

Press [ENTER] key for approx. 2 seconds.

▶

The service level is activated.

✓

Press [Enter] to reach the next information.

▶

No. Information

0

1

2

3

4

5

6

7

8

9

10

…

Actuator position in operating point P

Actuator position in operating point P

Actuator position in operating point P

Actuator position in operating point P

Actuator position in operating point P

Actuator position in operating point P

Actuator position in operating point P

Actuator position in operating point P

Actuator position in operating point P

Actuator position in operating point P

18

most recent fault … ninth last occurred fault

Display additional information:

0

1

2

3

4

5

6

7

8

9

1. Detailed fault code / operating phase

Press [+] key.

▶

2. Detailed fault code

Press keys [+] and [-] simultaneously.

▶

3. Detailed fault code

Press key [L/A].

▶

Repetition counter

Press key [G].

▶

19

After information 19 or a waiting time of approx. 20 seconds the combustion manager

changes over to the operating level.

Flame signal:

00

= no flame ... 58 = high intensity

83294002 • 2/2014-11 • La

20-70

Page 21

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

4 Operation

Gas burner with speed control

The service level gives information about:

Actuator position of individual operating points

▪

The most recent fault

▪

Flame signal during operation.

▪

Press [ENTER] key for approx. 2 seconds.

▶

The service level is activated.

✓

Press [Enter] to reach the next information.

▶

No. Information

0

1

9

10

…

Fan speed and air damper setting in operating point P

Fan speed and air damper setting in operating point P

Fan speed and air damper setting in operating point P

18

most recent fault … ninth last occurred fault

Display additional information:

0

1

9

1. Detailed fault code / operating phase

Press [+] key.

▶

2. Detailed fault code

Press keys [+] and [-] simultaneously.

▶

3. Detailed fault code

Press key [L/A].

▶

Repetition counter

Press key [G].

▶

19

After information 19 or a waiting time of approx. 20 seconds the combustion manager

changes over to the operating level.

Flame signal:

00

= no flame ... 58 = high intensity

83294002 • 2/2014-11 • La

21-70

Page 22

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

4 Operation

Oil burner / dual fuel burner (oil operation)

The service level gives information about:

Actuator position of individual operating points

▪

The most recent fault

▪

Flame signal during operation.

▪

Press [ENTER] key for approx. 2 seconds.

▶

The service level is activated.

✓

Press [Enter] to reach the next information.

▶

No. Information

0

1

2

3

9

10

…

Actuator position in operating point P

Actuator position in operating point P

Actuator position in operating point P2 (switch off point stage 2 when

running closed)

Actuator position in operating point P3 (switch on point stage 2 when

running open)

Actuator position in operating point P

18

most recent fault … ninth last occurred fault

Display additional information:

0

1

9

1. Detailed fault code / operating phase

Press [+] key.

▶

2. Detailed fault code

Press keys [+] and [-] simultaneously.

▶

3. Detailed fault code

Press key [L/A].

▶

Repetition counter

Press key [G].

▶

19

After information 19 or a waiting time of approx. 20 seconds the combustion manager

changes over to the operating level.

Flame signal

Oil burner:

255

Dual fuel burner:

00

121

…

= no flame ... 58 = high intensity

= no flame ... 1 = high intensity

83294002 • 2/2014-11 • La

22-70

Page 23

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

4 Operation

4.2.3 Parameter level

Gas burner

The parameter level can only be called up in Standby (

Press [+] and [Enter] keys simultaneously for approx. 2 seconds.

▶

The parameter level is activated.

✓

l,m³

Press [+].

▶

Press [Enter] to reach the next information.

▶

Pno. Information Range of values Factory

1

2

Fieldbus address

Actuator position in Standby

0

254

…

Switch over to

Briefly press [+] and [-] keys simultaneously.

▶

0.0

…

OFF

/

90.0

OFF

and to address:

°

OFF

) mode.

setting

OFF

0.0

Adjust air damper setting:

Press [L/A] and [+] keys or press [-] key.

▶

Adjusting gas butterfly valve setting:

Press [G] and [+] keys or press [-] key.

▶

4

5

6

A

b

C

d

E

F

(1

Post-purge time

Fault history

Factor for gas consumption

Impulse rate of meter per m³

Low / valve proving gas pressure switch (X3:12)

Air pressure switch (X3:11)

(display only, no adjustment

possible)

Operating mode output X3:1

Flame sensor

Display mode

Restart attempts following

flame failure

Following commissioning, set parameter E to

After parameter F or a waiting time of approx. 20 seconds the combustion manager

changes over to the operating level.

0

…

0

= Fault memory is empty

1

= Fault memory contains data

Delete fault memory:

Press [L/A] and [+] keys simultaneously for ca. 2 secs.

▶

1

…

200 impulses ≙ 1 m³

Adjust factor depending on impulse rate of gas meter

▶

0

= not activated

1

= Proof-of-closure (valve 1)

2

= without low gas pressure switch

3

= with low gas pressure switch

0

= not activated

1

= activated

0

= not activated

1

= with pilot valve not interrupted

2

= with pilot valve interrupted

3

= Standard (external LPG valve)

0

= Ionisation electrode / flame sensor FLW

1

= switch input (X3:14)

2

= flame sensor QRB

On

= Parameter E0 … E4 not activated in setting mode

OFF

0

…

4095

s

65535

= Parameter E0 … E4 activated in setting mode

1 1

OFF

.

2

–

200

3

1

3

0

On

(1

83294002 • 2/2014-11 • La

23-70

Page 24

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

4 Operation

Gas burner with speed control

The parameter level can only be called up in Standby (

Press [+] and [Enter] keys simultaneously for approx. 2 seconds.

▶

The parameter level is activated.

✓

l,m³

Press [+].

▶

Press [Enter] to reach the next information.

▶

OFF

) mode.

Pno. Information Range of values Factory

setting

1

2

Fieldbus address

Actuator position in Standby

0

254

…

Switch over to

Briefly press [+] and [-] keys simultaneously.

▶

0.0

…

OFF

/

90.0

OFF

and to address:

°

OFF

0.0

Adjust air damper setting:

Press [L/A] and [+] keys or press [-] key.

▶

Changing the fan speed:

Press [G] and [+] keys or press [-] key.

▶

4

5

Post-purge time

Fault history

0

4095

…

0

= Fault memory is empty

1

= Fault memory contains data

s

Delete fault memory:

Press [L/A] and [+] keys simultaneously for ca. 2 secs.

▶

6

Factor for gas consumption

Impulse rate of meter per m³

A

Low / valve proving gas pressure switch (X3:12)

b

Air pressure switch (X3:11)

(display only, no adjustment

1

65535

…

200 impulses ≙ 1 m³

Adjust factor depending on impulse rate of gas meter

▶

0

= not activated

1

= Proof-of-closure (valve 1)

2

= without low gas pressure switch

3

= with low gas pressure switch

0

= not activated

1

= activated

possible)

C

d

E

F

Operating mode output X3:1

Flame sensor

Display mode

Restart attempts following

0

= not activated

1

= with pilot valve not interrupted

2

= with pilot valve interrupted

3

= Standard (external LPG valve)

0

= Ionisation electrode / flame sensor FLW

1

= switch input (X3:14)

2

= flame sensor QRB

On

= Parameter E0 … E4 not activated in setting mode

OFF

= Parameter E0 … E4 activated in setting mode

0

1 1

…

flame failure

(1

On gas burners with speed control, parameter A must be set to 2.

(2

Following commissioning, set parameter E to

OFF

.

After parameter F or a waiting time of approx. 20 seconds the combustion manager

changes over to the operating level.

2

–

200

(1

3

1

3

0

On

(2

83294002 • 2/2014-11 • La

24-70

Page 25

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

4 Operation

Oil burner

The parameter level can only be called up in Standby (

Press [+] and [Enter] keys simultaneously for approx. 2 seconds.

▶

The parameter level is activated.

✓

l,m³

Press [+].

▶

Press [Enter] to reach the next information.

▶

OFF

) mode.

Pno. Information Range of values Factory

setting

1

2

Fieldbus address

Actuator position in Standby

0

254

…

Switch over to

Briefly press [+] and [-] keys simultaneously.

▶

0.0

…

OFF

/

90.0

OFF

and to address:

°

OFF

0.0

Adjust air damper setting:

Press [L/A] and [+] keys or press [-] key.

▶

4

5

Post-purge time

Fault history

0

4095

…

0

= Fault memory is empty

1

= Fault memory contains data

s

Delete fault memory:

Press [L/A] and [+] keys simultaneously for ca. 2 secs.

▶

6

Factor for oil consumption

Impulse rate of meter per litre

7

8

9

d

E

F

Oil pressure switch (X3:12)

Air pressure switch (X3:11)

Operating mode output X3:1

Flame sensor

Display mode

Restart attempts following

1

65535

…

200 impulses ≙ 1 litre

Adjust factor depending on impulse rate of oil meter

▶

0

= not activated

1

= activated

0

= not activated

1

= activated

1

= safety solenoid valve

2

= tank valve

0

= Ionisation electrode / flame sensor FLW

1

= switch input (X3:14)

2

= flame sensor QRB

On

= Parameter E0 … E4 not activated in setting mode

OFF

= Parameter E0 … E4 activated in setting mode

0

1 1

…

flame failure

(1

If an oil pressure switch is fitted, set parameter 7 and parameter 8 to 1.

(2

If an air pressure switch is fitted, set parameter 8 to 1.

(3

Following commissioning set parameter E to

OFF

.

After parameter F or a waiting time of approx. 20 seconds the combustion manager

changes over to the operating level.

2

–

200

(1

0

(2

0

1

2

On

(3

83294002 • 2/2014-11 • La

25-70

Page 26

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

4 Operation

Dual fuel burner

The parameter level can only be called up in Standby (

Press [+] and [Enter] keys simultaneously for approx. 2 seconds.

▶

The parameter level is activated.

✓

l,m³

Press [+].

▶

Press [Enter] to reach the next information.

▶

OFF

) mode.

Pno. Information Range of values Factory

setting

1

2

Fieldbus address

Actuator position in Standby

0

254

…

Switch over to

Briefly press [+] and [-] keys simultaneously.

▶

0.0

…

OFF

/

90.0

OFF

and to address:

°

OFF

0.0

Adjust air damper setting:

▶

Adjusting gas butterfly valve setting:

▶

4

5

Post-purge time

Fault history

0

0

1

Delete fault memory:

▶

6

7

8

9

A

b

C

(1

- no function - – –

Oil pressure switch (X3:12)

0

1

Air pressure switch for oil operation (X3:11)

Operating mode output X3:1

for oil operation

Low / valve proving gas pressure switch (X3:12)

0

1

1

2

0

1

2

3

Air pressure switch for gas operation (X3:11)

0

1

(display only, no adjustment

possible)

Operating mode output X3:1

for gas operation

0

1

2

3

Set parameter to 1 prior to commissioning.

Press [L/A] and [+] keys or press [-] key.

Press [G] and [+] keys or press [-] key.

4095

…

s

= Fault memory is empty

= Fault memory contains data

Press [L/A] and [+] keys simultaneously for ca. 2 secs.

= not activated

= activated

= not activated

= activated

= safety solenoid valve

= tank valve

= not activated

= Proof-of-closure (valve 1)

= without low gas pressure switch

= with low gas pressure switch

= not activated

= activated

= not activated

= with pilot valve not interrupted

= with pilot valve interrupted

= Standard (external LPG valve)

2

–

(1

0

(1

0

1

3

1

3

83294002 • 2/2014-11 • La

26-70

Page 27

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

4 Operation

Pno. Information Range of values Factory

setting

d

E

F

Flame sensor

Display mode

Restart attempts following

0

= Ionisation electrode / flame sensor FLW

1

= switch input (X3:14)

2

= flame sensor QRB

On

= Parameter E0 … E4 not activated in setting mode

OFF

= Parameter E0 … E4 activated in setting mode

0

1 1

…

0

On

(2

flame failure

(2

Following commissioning, set parameter E to

OFF

.

After parameter F or a waiting time of approx. 20 seconds the combustion manager

changes over to the operating level.

83294002 • 2/2014-11 • La

27-70

Page 28

Parameters

E0

E1

E2

E3

E4

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

4 Operation

4.2.4 Access level

The configuration can be adapted relative to the burner type or version in the access

level.

In the parameter level, the display mode must be set to On to enable access to parameters E0 … E4.

Press [G] and [L/A] simultaneously.

▶

The access level is activated.

✓

Press [+].

▶

Set the required value using [ENTER] and [+] or [-] keys.

▶

Press [+] key to reach the next information.

▶

Information Range of values

0

Burner type

Type of operation

(display only, no adjust-

ment possible)

Flame sensor type

Fan configuration

Pre-ignition for oil burner

= Single fuel burner

1

= Dual fuel burner

0

= intermittent operation

1

= continuous operation

0

= Ionisation electrode / flame sensor FLW

1

= switch input (X3:14)

2

= flame sensor QRB

0

= Off

1

= Fan control

2

= Fan control with fan monitoring

3

= Speed control

4

= Fan control according to modulation degree specified

5

= DAU control

6

255

…

0

…

ignition is started)

OFF

= Off

4094

seconds (the time runs down from operating phase No. 09, then

= Ignition only from operating phase No.

l,m³

15

83294002 • 2/2014-11 • La

28-70

Page 29

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

4 Operation

4.3 Linearisation

During commissioning it is possible to carry out linearisation of the operating points

for gas burners or for gas operation.

During linearisation a straight line is generated from the operating point displayed to

P9. The values on the straight are adopted as the new operating points.

Initiate a calculation after P9:

Press [ENTER] key.

▶

Combustion manager changes to linearisation mode.

✓

The linearisation mode can be interrupted using the [-] key.

Confirm with [+] key.

▶

Linearisation is initiated.

✓

Example:

P1 P2 P3 P4 P5 P6 P7 P8 P9 P1 P2 P3 P4 P5 P6 P7 P8 P9

1

Calculation from P1 to P9

2

Calculation from P5 to P9

83294002 • 2/2014-11 • La

29-70

Page 30

DANGER

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

5 Installation

5 Installation

5.1 Replacing the combustion manager

Risk of electric shock

Working on the unit when voltage is applied can lead to electric shock.

Isolate the unit from the power supply prior to starting any work.

▶

Safeguard against accidental re-start.

▶

The conversion must only be carried out by qualified electricians. Observe local regulations.

Removing W-FM 20 … 24

Unplug all plugs.

▶

Undo screws 1.

▶

Push combustion manager upwards and remove.

▶

83294002 • 2/2014-11 • La

30-70

Page 31

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

5 Installation

Fitting W-FM 25

On sizes W30 and W40, the burner motor should be fed via contactor (except when

using variable speed drive).

If the boiler control is protected by an internal 10 A fuse, the plug cable for separate

motor power supply can be used. This means it is not necessary to install a separate

voltage supply for the motor.

Pre-fusing of separate supply line:

min 10 AT

▪

max 16 AT

▪

Observe inputs and outputs of combustion manager W-FM 25 (see Ch. 3.1).

▶

If required, remove contactor and snap it on to the carrier rail 1 of the bracket

▶

supplied.

If required, fit bracket 2 supplied.

▶

Fit combustion manager.

▶

Plug in all plugs, if necessary use extension cable No. 4.

▶

On gas and dual fuel burners, plug in bridging plug No. 15 supplied

▶

(see Ch. 3.1).

If necessary, connect supply line for burner motor or plug cable for motor voltage

▶

supply to the connection plug of the contactor.

W10/20

W30/40

83294002 • 2/2014-11 • La

31-70

Page 32

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

6 Commissioning

6 Commissioning

In addition to this chapter, the installation and operating manual of the burner should

be observed.

6.1 Gas burner

1. Preset combustion manager

Unplug bridging plug No. 7 on combustion manager.

▶

Switch on voltage supply.

▶

The unprogrammed condition of the combustion manager is indicated by a flashing

✓

display.

The burner goes to lockout.

l,m³

Press [ENTER] key.

▶

Burner has been reset.

✓

Combustion manager drives to Standby.

✓

Press [G] and [L/A] simultaneously.

▶

Combustion manager changes to access level.

✓

l,m³

Press [+].

▶

Setting level (parameter E0) is displayed.

✓

l,m³

Adopt value 0 (single fuel burner), if necessary adjust using [ENTER] and [-] key.

▶

Press [+].

▶

E1

is displayed.

✓

l,m³

The value of parameter E1 can not be altered.

0

= intermittent operation (Standard)

▪

1

= continuous operation (if W-FM 21 was used previously)

▪

83294002 • 2/2014-11 • La

32-70

Page 33

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

6 Commissioning

Press [+].

▶

E2

is displayed.

✓

l,m³

Adopt value 0 (ionisation electrode), if necessary adjust using [ENTER] and [-] key.

▶

Press [+].

▶

E3

is displayed.

✓

l,m³

Adopt value 1 (fan control), if necessary set using [ENTER] and [-] or [+] key.

▶

Press [+].

▶

Combustion manager changes into the setting level for step points.

✓

Determine the air damper and gas butterfly valve setting for operating points P0,

▶

P1 and P9 from the sticker for burner setting.

The operating points are preset using these values:

Press [+].

▶

Factory setting operating point P9 (Full load) is displayed.

✓

Press and hold [L/A] and set air damper setting using the [–] or [+] key.

▶

Press and hold [G] and set gas butterfly valve setting using the [–] or [+] key.

▶

Press [+].

▶

Factory setting operating point P1 (partial load) is displayed.

✓

Press and hold [L/A] and set air damper setting using the [–] or [+] key.

▶

Press and hold [G] and set gas butterfly valve setting using the [–] or [+] key.

▶

83294002 • 2/2014-11 • La

33-70

Page 34

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

6 Commissioning

Press [+].

▶

Factory setting operating point P0 (ignition load) is displayed.

✓

Press and hold [L/A] and set air damper setting using the [–] or [+] key.

▶

Press and hold [G] and set gas butterfly valve setting using the [–] or [+] key.

▶

Press [+].

▶

Combustion manager is preset.

✓

2. Check sequence of operation

Open gas isolating valve.

▶

Gas pressure in gas valve train increases.

✓

Close isolating valve.

▶

Plug in bridging plug No. 7 on combustion manager.

▶

Burner starts.

✓

Check sequence of operation:

▶

Valves open.

▪

Gas pressure switch reacts.

▪

Burner start is interrupted.

▪

Low gas program starts.

▪

Unplug 7 pole connection plug and plug it in again.

▶

Low gas program is interrupted.

✓

3. Adjusting the operating points

If a controlled shutdown or lockout occurs during setting:

Press [–] and [+] simultaneously.

▶

Then press [+] key.

▶

Combustion manager changes to setting level.

✓

Open gas isolating valve.

▶

Press [–] and [+] simultaneously.

▶

The display shows

✓

E ACCESS

.

l,m³

83294002 • 2/2014-11 • La

34-70

Page 35

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

6 Commissioning

Press [+].

▶

Burner starts according to the sequence of operation and stops at operating

✓

point P0 (ignition load).

Check combustion and if necessary adjust via air damper or gas butterfly setting.

▶

Press [+].

▶

Burner drives to P1.

✓

Check combustion and if necessary adjust via air damper or gas butterfly setting.

▶

Press [+].

▶

Burner drives to P2.

✓

Determine the air damper and gas butterfly valve setting for operating point P2.

▶

Preset P2 with these values.

▶

Check combustion and if necessary adjust via air damper or gas butterfly setting.

▶

Repeat steps for each operating point until P9 has been reached.

▶

4. Adjust full load

Press [G] and [L/A] simultaneously.

▶

Burner drives to full load.

✓

The upper operating limit (bo) is displayed.

✓

If necessary, full load can be adjusted using [–] or [+] keys.

l,m³

83294002 • 2/2014-11 • La

35-70

Page 36

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

6 Commissioning

5. Adjust partial load

Press [G] and [L/A] simultaneously.

▶

Burner drives to partial load.

✓

The lower operating limit is displayed (bu).

✓

The value bu is given in percent on the W-FM 25, on the W-FM 20 … 24 bu corresponds with the air damper setting.

Determine gas throughput for partial load from test sheet.

▶

Set bu using [–] or [+] key.

▶

Determine gas throughput and adjust value.

▶

Press [G] and [L/A] simultaneously.

▶

Combustion manager changes to operating level (10).

✓

Combustion manager is programmed.

✓

6. Check start behaviour

Switch off and restart burner.

▶

Check start behaviour and if necessary correct ignition load (P0).

▶

If the ignition load set has been changed:

Re-check start behaviour.

▶

7. Deactivate E-Parameters

OFF

.

OFF

).

Burner must be in Standby (

Press [Enter] and [+] keys simultaneously for approx. 2 seconds.

▶

The parameter level is activated.

✓

Press [+].

▶

Press [Enter] key until parameter E is displayed.

▶

Set parameter E to

▶

E

-Parameters are not shown in the setting level.

✓

Press [Enter] key twice.

▶

Combustion manager returns to the operating level.

✓

83294002 • 2/2014-11 • La

36-70

Page 37

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

6 Commissioning

6.2 Gas burner with speed control

1. Preset combustion manager

Unplug plug No. 7 from combustion manager.

▶

Switch on voltage supply.

▶

The unprogrammed condition of the combustion manager is indicated by a flashing

✓

display.

The burner goes to lockout.

l,m³

Press [ENTER] key.

▶

Burner has been reset.

✓

Combustion manager drives to Standby.

✓

Parameter A must be set to value2.

Press [Enter] and [+] keys simultaneously for approx. 2 seconds.

▶

The parameter level is activated.

✓

Press [+].

▶

Press [Enter] key until parameter A is displayed.

▶

Set parameter A to value 2 (without low gas pressure switch).

▶

Press [Enter] key until parameter

▶

Press [G] and [L/A] simultaneously.

▶

Combustion manager changes to access level.

✓

Press [+].

▶

Setting level (parameter E0) is displayed.

✓

l,m³

l,m³

OFFUPr

is displayed again.

83294002 • 2/2014-11 • La

Adopt value 0 (single fuel burner), if necessary adjust using [ENTER] and [-] key.

▶

37-70

Page 38

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

6 Commissioning

Press [+].

▶

E1

is displayed.

✓

l,m³

The value of parameter E1 can not be altered.

0

= intermittent operation (Standard)

▪

1

= continuous operation (only if W-FM 21was used previously)

▪

Press [+].

▶

E2

is displayed.

✓

l,m³

Adopt value 0 (ionisation electrode), if necessary adjust using [ENTER] and [-] key.

▶

Press [+].

▶

E3

is displayed.

✓

l,m³

Adopt value 1 (fan control), if necessary set using [ENTER] and [-] or [+] key.

▶

Press [+].

▶

Combustion manager changes into the setting level for step points.

✓

Determine the air damper setting and fan speed for operating points P0, P1 and

▶

P9 from the sticker for burner setting.

The operating points are preset using these values:

Press [+].

▶

Factory setting operating point P9 (Full load) is displayed.

✓

83294002 • 2/2014-11 • La

Press and hold [L/A] and set air damper setting using the [–] or [+] key.

▶

Press and hold [G] and set fan speed using [–] or [+] key.

▶

38-70

Page 39

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

6 Commissioning

Press [+].

▶

Factory setting operating point P1 (partial load) is displayed.

✓

Press and hold [L/A] and set air damper setting using the [–] or [+] key.

▶

Press and hold [G] and set fan speed using [–] or [+] key.

▶

Press [+].

▶

Factory setting operating point P0 (ignition load) is displayed.

✓

Press and hold [L/A] and set air damper setting using the [–] or [+] key.

▶

Press and hold [G] and set fan speed using [–] or [+] key.

▶

Press [+].

▶

Combustion manager is preset.

✓

Unplug 7 pole connection plug and plug it in again.

▶

Low gas program is interrupted.

✓

2. Check sequence of operation

Open gas isolating valve.

▶

Gas pressure in gas valve train increases.

✓

Close isolating valve.

▶

Plug in plug No. 7 on combustion manager.

▶

Burner starts.

✓

Check sequence of operation:

▶

Valves open.

▪

Gas pressure switch reacts.

▪

Burner start is interrupted.

▪

Unplug 7 pole connection plug and plug it in again.

▶

83294002 • 2/2014-11 • La

39-70

Page 40

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

6 Commissioning

3. Adjusting the operating points

If a controlled shutdown or lockout occurs during setting:

Press [G] and [L/A] simultaneously.

▶

Then press [+] key.

▶

Combustion manager changes to setting level.

✓

Open gas isolating valve.

▶

Press [–] and [+] simultaneously.

▶

The display shows

✓

Press [+].

▶

Burner starts according to the sequence of operation and stops at operating

✓

point P0 (ignition load).

E ACCESS

.

l,m³

Press [+].

▶

Burner drives to P1.

✓

Check combustion and if necessary adjust combustion values via N-correction on

▶

the double solenoid valve.

Press [+].

▶

Burner drives to P2.

✓

Press [+] key until P9 is reached whilst checking combustion at each point and

▶

adjust via V-correction on double solenoid valve.

Press [-].

▶

Burner drives to P8.

✓

Press [-] until P1 is reached.

▶

83294002 • 2/2014-11 • La

Check combustion and if necessary adjust combustion values via N-correction on

▶

the double solenoid valve.

40-70

Page 41

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

6 Commissioning

4. Adjust full load

Press [+] key until P9 is reached whilst checking combustion at each point.

▶

Press [G] and [L/A] simultaneously.

▶

Burner drives to full load.

✓

The upper operating limit (bo) is displayed.

✓

If necessary, full load can be adjusted using [–] or [+] keys.

l,m³

5. Adjust partial load

Press [G] and [L/A] simultaneously.

▶

Burner drives to partial load.

✓

The lower operating limit is displayed (bu).

✓

If necessary, partial load can be adjusted using [–] or [+] keys.

Press [G] and [L/A] simultaneously.

▶

Combustion manager changes to operating level (10).

✓

Combustion manager is programmed.

✓

6. Check start behaviour

Switch off and restart burner.

▶

Check start behaviour and if necessary correct ignition load (P0).

▶

If the ignition load set has been changed:

Re-check start behaviour.

▶

7. Deactivate E-Parameters

OFF

.

OFF

).

Burner must be in Standby (

Press [Enter] and [+] keys simultaneously for approx. 2 seconds.

▶

The parameter level is activated.

✓

Press [+].

▶

Press [Enter] key until parameter E is displayed.

▶

Set parameter E to

▶

E

-Parameters are not shown in the setting level.

✓

Press [Enter] key twice.

▶

Combustion manager returns to the operating level.

✓

83294002 • 2/2014-11 • La

41-70

Page 42

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

6 Commissioning

6.3 Oil burner

1. Preset combustion manager

Unplug bridging plug No. 7 on combustion manager.

▶

Switch on voltage supply.

▶

The unprogrammed condition of the combustion manager is indicated by a flashing

✓

display.

The burner goes to lockout.

l,m³

Press [ENTER] key.

▶

Burner has been reset.

✓

Combustion manager drives to Standby.

✓

If an oil pressure switch is fitted, set parameters 7 and 8 to 1 (see Ch. 4.2.3.3).

If an air pressure switch is fitted, set parameter 8 to 1 (see Ch. 4.2.3.3).

Press [G] and [L/A] simultaneously.

▶

Combustion manager changes to access level.

✓

l,m³

Press [+].

▶

Setting level (parameter E0) is displayed.

✓

l,m³

Adopt value 0 (single fuel burner), if necessary adjust using [ENTER] and [-] key.

▶

Press [+].

▶

E1

is displayed.

✓

l,m³

83294002 • 2/2014-11 • La

The value of parameter E1 can not be altered.

0

= intermittent operation (Standard)

▪

1

= continuous operation (only if W-FM 21was used previously)

▪

42-70

Page 43

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

6 Commissioning

Press [+].

▶

E2

is displayed.

✓

l,m³

Set value 2 (flame sensor QRB) using [ENTER] and [+] key.

▶

Press [+].

▶

E3

is displayed.

✓

l,m³

Adopt value 1 (fan control), if necessary set using [ENTER] and [-] or [+] key.

▶

Press [+].

▶

E4

is displayed.

✓

l,m³

Adopt value 0 (no ignition delay), if necessary set using [ENTER] and [-].

▶

Press [+].

▶

Combustion manager changes into the setting level for step points.

✓

Determine the air damper setting for operating points P9, P1 P0and P2 from the

▶

sticker for burner setting.

The operating points are preset using these values:

Press [+].

▶

Factory setting operating point P9 (Full load) is displayed.

✓

83294002 • 2/2014-11 • La

Press and hold [L/A] and set air damper setting using the [–] or [+] key.

▶

43-70

Page 44

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

6 Commissioning

Press [+].

▶

Factory setting operating point P1 (stage 1) is displayed.

✓

Press and hold [L/A] and set air damper setting using the [–] or [+] key.

▶

Press [+].

▶

Factory setting operating point P9 (ignition position) is displayed.

✓

Press and hold [L/A] and set air damper setting using the [–] or [+] key.

▶

Press [+].

▶

Factory setting operating point P

✓

(switch off point stage 2 when running closed) is displayed.

2

Press and hold [L/A] and set air damper setting using the [–] or [+] key.

▶

Press [+].

▶

Factory setting operating point P3 (switch on point stage 2 when running open) is

✓

displayed.

Press and hold [L/A] and set the same values as for P2 using the [–] or [+] key.

▶

Press [+].

▶

Combustion manager is preset.

✓

83294002 • 2/2014-11 • La

44-70

Page 45

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

6 Commissioning

2. Adjusting the operating points

Open oil shut off devices.

▶

If a controlled shutdown or lockout occurs during setting:

Press [G] and [L/A] simultaneously.

▶

Combustion manager changes into the setting level of operating points.

✓

Plug in bridging plug No. 7 on combustion manager.

▶

Burner starts in accordance with program sequence and stops in operating

✓

point P0 (ignition position).

Check combustion and if necessary adjust combustion values via air damper set-

▶

ting.

Press [+].

▶

Burner drives to P1.

✓

Check combustion and if necessary adjust combustion values via air damper set-

▶

ting.

Press [+].

▶

Burner drives to P9.

✓

Check combustion and if necessary adjust combustion values via air damper set-

▶

ting.

Press [+].

▶

Switch off point stage 2 when running closed (P2) is displayed.

✓

Set switch off point stage 2 when running closed (P2) to approx. 1/3 of the setting

movement between P1 and P9.

83294002 • 2/2014-11 • La

Press and hold [L/A] key and set P2 using [–] or [+] key.

▶

45-70

Page 46

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

6 Commissioning

Press [+].

▶

Switch on point stage 2 when running open (P3) is displayed.

✓

Press and hold [L/A] and set the same values as for P2 using the [–] or [+] key.

▶

Press [G] and [L/A] simultaneously.

▶

Combustion manager changes to operating level (10), depending on heat demand

✓

stage 1 or stage 2 is displayed.

3. Check start behaviour and on/off switch points

Switch off and restart burner.

▶

Check start behaviour.

▶

Check on and off switch point stage 2:

▶

excess air phase prior to switch over must not be too long,

▪

flame must not fail.

▪

If necessary correct ignition position P0.

▶

If necessary correct switch on and point P3 or switch off point P2.

▶

If the existing settings have been changed:

Re-check start behaviour and on and off switch points.

▶

4. Deactivate E-Parameters

OFF

.

OFF

).

Burner must be in Standby (

Press [Enter] and [+] keys simultaneously for approx. 2 seconds.

▶

The parameter level is activated.

✓

Press [+].

▶

Press [Enter] key until parameter E is displayed.

▶

Set parameter E to

▶

E

-Parameters are not shown in the setting level.

✓

Press [Enter] key twice.

▶

Combustion manager returns to the operating level.

✓

83294002 • 2/2014-11 • La

46-70

Page 47

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

6 Commissioning

6.4 Dual fuel burner

6.4.1 Adjusting gas side

1. Preset combustion manager

Set fuel selection switch to GAS.

▶

Unplug bridging plug No. 7 on combustion manager.

▶

Switch on voltage supply.

▶

The unprogrammed condition of the combustion manager is indicated by a flashing

✓

display.

The burner goes to lockout.

l,m³

Press [ENTER] key.

▶

Burner has been reset.

✓

Combustion manager drives to Standby.

✓

Press [G] and [L/A] simultaneously.

▶

Combustion manager changes to access level.

✓

l,m³

Press [+].

▶

Setting level (parameter E0) is displayed.

✓

l,m³

Set value 1 (dual fuel burners) using [ENTER] and [+] key.

▶

Press [+].

▶

E1

is displayed.

✓

l,m³

Adopt value 0 (intermittent operation) using [+] key.

▶

E2

is displayed.

✓

83294002 • 2/2014-11 • La

l,m³

47-70

Page 48

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

6 Commissioning

Adopt value 0 (flame sensor FLW), if necessary set using [ENTER] and [-] key.

▶

Press [+].

▶

E3

is displayed.

✓

l,m³

Adopt value 1 (fan control), if necessary set using [ENTER] and [-] or [+] key.

▶

Press [+].

▶

Combustion manager changes into the setting level for step points.

✓

Determine the air damper and gas butterfly valve setting for operating points P0,

▶

P1 and P9 from the sticker for burner setting.

The operating points are preset using these values:

Press [+].

▶

Factory setting operating point P9 (Full load) is displayed.

✓

Press and hold [L/A] and set air damper setting using the [–] or [+] key.

▶

Press and hold [G] and set gas butterfly valve setting using the [–] or [+] key.

▶

Press [+].

▶

Factory setting operating point P1 (partial load) is displayed.

✓

Press and hold [L/A] and set air damper setting using the [–] or [+] key.

▶

Press and hold [G] and set gas butterfly valve setting using the [–] or [+] key.

▶

83294002 • 2/2014-11 • La

48-70

Page 49

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

6 Commissioning

Press [+].

▶

Factory setting operating point P0 (ignition load) is displayed.

✓

Press and hold [L/A] and set air damper setting using the [–] or [+] key.

▶

Press and hold [G] and set gas butterfly valve setting using the [–] or [+] key.

▶

Press [+].

▶

Combustion manager is preset.

✓

2. Check sequence of operation

Open gas isolating valve.

▶

Gas pressure in gas valve train increases.

✓

Close isolating valve.

▶

Plug in bridging plug No. 7 on combustion manager.

▶

Burner starts.

✓

Check sequence of operation:

▶

Valves open.

▪

Gas pressure switch reacts.

▪

Burner start is interrupted.

▪

Low gas program starts.

▪

Unplug 7 pole connection plug and plug it in again.

▶

Low gas program is interrupted.

✓

3. Adjusting the operating points

If a controlled shutdown or lockout occurs during setting:

Press [–] and [+] simultaneously.

▶

Then press [+] key.

▶

Combustion manager changes to setting level.

✓

Open gas isolating valve.

▶

Press [–] and [+] simultaneously.

▶

The display shows

✓

E ACCESS

.

l,m³

83294002 • 2/2014-11 • La

49-70

Page 50

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

6 Commissioning

Press [+].

▶

Burner starts according to the sequence of operation and stops at operating

✓

point P0 (ignition load).

Check combustion and if necessary adjust via air damper or gas butterfly setting.

▶

Press [+].

▶

Burner drives to P1.

✓

Check combustion and if necessary adjust via air damper or gas butterfly setting.

▶

Press [+].

▶

Burner drives to P2.

✓

Determine the air damper and gas butterfly valve setting for operating point P2.

▶

Preset P2 with these values.

▶

Check combustion and if necessary adjust via air damper or gas butterfly setting.

▶

Repeat steps for each operating point until P9 has been reached.

▶

4. Adjust full load

Press [G] and [L/A] simultaneously.

▶

Burner drives to full load.

✓

The upper operating limit (bo) is displayed.

✓

If necessary, full load can be adjusted using [–] or [+] keys.

l,m³

83294002 • 2/2014-11 • La

50-70

Page 51

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

6 Commissioning

5. Adjust partial load

Press [G] and [L/A] simultaneously.

▶

Burner drives to partial load.

✓

The lower operating limit is displayed (bu).

✓

The value bu is given in percent on the W-FM 25, on the W-FM 20 … 24 bu corresponds with the air damper setting.

Determine gas throughput for partial load from test sheet.

▶

Set bu using [–] or [+] key.

▶

Determine gas throughput and adjust value.

▶

Press [G] and [L/A] simultaneously.

▶

Combustion manager changes to operating level (10).

✓

Combustion manager is programmed.

✓

6. Check start behaviour

Switch off and restart burner.

▶

Check start behaviour and if necessary correct ignition load (P0).

▶

If the ignition load set has been changed:

Re-check start behaviour.

▶

83294002 • 2/2014-11 • La

51-70

Page 52

Installation and operating instruction

Replacing combustion manager W-FM 20 … 24 with W-FM 25

6 Commissioning

6.4.2 Adjusting oil side

1. Preset combustion manager

Set fuel selection switch to OIL.

▶

Unplug bridging plug No. 7 on combustion manager.

▶

Switch on voltage supply.

▶

The unprogrammed condition of the combustion manager is indicated by a flashing

✓

display.

The burner goes to lockout.

l,m³

Press [ENTER] key.

▶

Burner has been reset.

✓

Combustion manager drives to Standby.

✓

Parameters 7 and 8 must be set to value 1.

Press [Enter] and [+] keys simultaneously for approx. 2 seconds.

▶

The parameter level is activated.

✓

Press [+].

▶

Press [Enter] key until parameter 7 is displayed.

▶

Set parameter 7 (oil pressure switch) to value 1 (activated).

▶

Press [Enter] key.

▶

Set parameter 8 (air pressure switch) to value 1 (activated).

▶

Press [Enter] key until parameter

▶

Press [G] and [L/A] simultaneously.

▶

Combustion manager changes to access level.

✓

Press [+].

▶

Setting level (parameter E0) is displayed.

✓

l,m³

l,m³

OFFUPr

is displayed again.