Page 1

The Weir Group PLC

Weir Mechatronics

1 Marden St

Artarmon, NSW

2064, Australia

Tel: +61 2 9934 5100

Weir Industrial Gateway

Setup guide

Document ID: 00-40-20-40_20

Revision: 0.5

November 15, 2017

Copyright © Weir Minerals Australia Ltd 2017.

Commercial in Confidence. All rights reserved

Page 2

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

Name

Designation

Date

Signature

Submitted By

C.Strudwicke

Principle Control

Systems Engineer

Accepted By

C.Strudwicke

Principle Control

Systems Engineer

Approved By

B.Baker

Head of

Mechatronics

Document Approval

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page i

Page 3

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

Revision

Date

Author

Details

0.1

9-3-2017

C.Strudwicke

First version

0.2

21-03-2017

C.Strudwicke

Addition of feedback relating to certification

requirements

0.3

08-09-2017

W. Cooke

Addition of feedback relating to certification

requirements

0.4

10-06-2017

W. Cooke

Addition of feedback relating to certification

requirements

0.5

11-15-2017

W. Cooke

Document name change to match regulatory

documents

Document History

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page ii

Page 4

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

Table of Contents

DOCUMENT APPROVAL .................................................................................................................................. I

DOCUMENT HISTORY .................................................................................................................................... II

1 INTRODUCTION AND SAFETY ................................................................................................................. 1

1.1 INTRODUCTION .......................................................................................................................................... 1

1.2 SCOPE ...................................................................................................................................................... 1

1.3 TARGET AUDIENCE ...................................................................................................................................... 1

1.4 SAFETY ..................................................................................................................................................... 1

1.4.1 Safety Terminology and Symbols ...................................................................................................... 1

1.4.2 User Safety ........................................................................................................................................ 1

1.4.3 Warnings ........................................................................................................................................... 2

1.4.4 Determination That Equipment Can be Used Safely in the Intended Area ........................................ 3

2 TRANSPORTATION AND STORAGE ......................................................................................................... 4

2.1 CONSIGNMENT RECEIPT AND UNPACKING ........................................................................................................ 4

2.2 TRANSPORTATION GUIDELINES ...................................................................................................................... 4

2.3 STORAGE .................................................................................................................................................. 4

3 SYSTEM COMPONENTS ......................................................................................................................... 4

4 SYSTEM ARCHITECTURE ......................................................................................................................... 6

5 PSM – POWER SUPPLY MODULE ............................................................................................................ 7

5.1 PARAMETERS RELEVANT TO INSTALLATION AND OPERATION ................................................................................ 7

5.2 INSTALLATION ............................................................................................................................................ 8

6 MPM – MAIN PROCESSING MODULE ..................................................................................................... 9

6.1 PARAMETERS RELEVANT TO INSTALLATION AND OPERATION ................................................................................ 9

6.2 IMAGES .................................................................................................................................................... 9

6.3 CONNECTOR KEYING TYPES ........................................................................................................................ 12

6.4 LED INDICATORS ...................................................................................................................................... 12

6.5 INSTALLATION .......................................................................................................................................... 13

Mounting plate & Hardware ............................................................................................................... 13

6.5.1 .............................................................................................................................................................. 13

6.5.2 MPM & PSM .................................................................................................................................... 14

6.5.3 Hazardous Location Requirements .................................................................................................. 16

6.5.4 Antenna ........................................................................................................................................... 17

7 RSP – REMOTE SIGNAL PROCESSOR ..................................................................................................... 22

7.1 PARAMETERS RELEVANT TO INSTALLATION AND OPERATION .................................................................. 22

7.2 IMAGES ................................................................................................................................................. 22

7.3 CONNECTOR KEYING TYPES ........................................................................................................................ 24

7.4 LED INDICATORS ...................................................................................................................................... 25

7.5 INSTALLATION .......................................................................................................................................... 26

7.5.1 Physical mounting ........................................................................................................................... 26

7.5.2 Hazardous Location Compliance ..................................................................................................... 26

7.5.3 Protective Earth Grounding for Non Hazardous Locations .............................................................. 27

7.5.4 Connection to MPM ........................................................................................................................ 27

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page iii

Page 5

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

8 JUNCTION BOXES AND CABLES ............................................................................................................ 30

8.1 LIST OF CABLES ......................................................................................................................................... 30

8.1.1 Connecting to RSP ........................................................................................................................... 30

8.1.2 Junction Box to sensor ..................................................................................................................... 30

8.2 LIST OF JUNCTION BOXES ........................................................................................................................... 31

8.3 INSTALLATION .......................................................................................................................................... 31

9 SENSORS ............................................................................................................................................. 32

9.1 LIST OF APPROVED SENSORS ....................................................................................................................... 32

9.2 HAZARDOUS LOCATION NON-INCENDIVE SENSORS .......................................................................................... 33

9.3 SENSOR INSTALL LOCATIONS ....................................................................................................................... 33

9.4 INSTALLATION .......................................................................................................................................... 34

9.4.1 Mounting point Preparation ........................................................................................................... 35

9.4.2 Adhesively bonded mounting puck .................................................................................................. 35

9.4.3 Drilled and tapped mount ............................................................................................................... 36

9.5 ACCELEROMETER ATTACHMENT ................................................................................................................... 38

9.5.1 Equipment and materials required .................................................................................................. 38

9.5.2 Installation ...................................................................................................................................... 38

9.5.3 VT-11 ............................................................................................................................................... 38

9.5.4 Removal ........................................................................................................................................... 39

9.6 TEMPERATURE RTD’S ............................................................................................................................... 39

9.6.1 Equipment and materials required .................................................................................................. 39

9.6.2 Hazards ........................................................................................................................................... 40

9.6.3 Installation ...................................................................................................................................... 40

9.6.4 Removal ........................................................................................................................................... 40

9.7 GLAND WATER FLOW METER AND PRESSURE TRANSDUCER .............................................................................. 40

9.7.1 Equipment and materials required .................................................................................................. 40

9.7.2 Possible Hazards .............................................................................................................................. 40

9.7.3 Installation ...................................................................................................................................... 40

9.8 SPEED – PROXIMITY SENSOR ....................................................................................................................... 41

9.8.1 Equipment and materials required .................................................................................................. 41

9.8.2 Hazards ........................................................................................................................................... 41

9.8.3 Installation ...................................................................................................................................... 42

10 CLEANING AND MAINTENANCE ............................................................................................................ 42

11 REGULATORY COMPLIANCE ................................................................................................................. 42

11.1 ELECTROMAGNETIC COMPATABILITY ............................................................................................................. 42

11.2 HAZARDOUS LOCATION COMPLIANCE ........................................................................................................... 43

11.3 SAFETY ................................................................................................................................................... 44

11.4 RADIO APPROVALS .................................................................................................................................... 44

11.4.1 FCC Requirements for Operation in the United States: ............................................................... 45

11.4.2 FCC RF Radiation Exposure: ........................................................................................................ 45

11.4.3 Industry Canada Requirements for Radio Operation in Canada: ................................................ 45

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page iv

Page 6

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

Table of figures

Figure 1-1 Transient Protection Parameters, Line to Line and Line to Ground ........................ 3

Figure 4-1 System diagram ...................................................................................................... 6

Figure 5-1 Iso view of PSM ...................................................................................................... 7

Figure 5-2 PSM Connectors ..................................................................................................... 8

Figure 6-1 MPM perspective view (cables and protective shroud removed) ............................ 9

Figure 6-2 MPM with connector shroud installed ................................................................... 10

Figure 6-3 MPM connector view - protective caps installed ................................................... 10

Figure 6-4 MPM External dimensions .................................................................................... 11

Figure 6-5 Connector view ..................................................................................................... 11

Figure 6-6 Connector Keying, View from MPM Connector .................................................... 12

Figure 6-6 - MPM connector names and locations ................................................................. 12

Figure 6-7 MPM & PSM generic mounting plate .................................................................... 13

Figure 6-8 - MPM & PSU installed on mounting plate ............................................................ 15

Figure 6-9 SIM card receptacle in MPM ................................................................................. 15

Figure 6-10 24Vdc power connection from PSM to MPM ...................................................... 15

Figure 6-11 Mains AC power connection to PSM .................................................................. 16

Figure 6-12 Installation of Locking Clips ................................................................................ 16

Figure 6-13 Location of Protective Earth Grounding on MPM ................................................ 17

Figure 6-14 Antenna mount attached ..................................................................................... 18

Figure 6-15 Installation of Antenna(e) .................................................................................... 19

Figure 6-16 Antenna with and without cable attached ........................................................... 19

Figure 6-17 Antenna connector wrapped in protective tape ................................................... 20

Figure 6-18 Schematic of Wifi and Cellular antennae connections to MPM .......................... 20

Figure 7-2 RSP shown with connector shield installed .......................................................... 23

Figure 7-3 RSP Physical dimensions ..................................................................................... 24

Figure 7-4 RSP Connector layout and descriptions ............................................................... 24

Figure 7-5 Connector Keying, View from RSP Connector ..................................................... 25

Figure 7-5 RSP Connector port descriptions .......................................................................... 25

Figure 7-6 RSP Mounting Dimensions .................................................................................. 26

Figure 7-7 Location of Protective Earth Grounding on RSP ................................................... 27

Figure 7-8 MPM Comms + power connector on RSP ............................................................ 28

Figure 7-9 RSP comms + power connectors on MPM ........................................................... 28

Figure 7-10 PSM, MPM and RSP connected ......................................................................... 29

Figure 8-1 Installation of Locking Clips .................................................................................. 31

Figure 9-1 Sensor Install Locations ........................................................................................ 33

Figure 9-2 Slurry pump installation - mounting puck .............................................................. 34

Figure 9-3 Triblock mounting accessory ................................................................................ 34

Figure 9-4 Slurry pump - Mounting pump adhesively bonded to pump .................................. 36

Figure 9-5 Uni-axial accelerometer with connector and protective tape applied .................... 38

Figure 9-6 Tri-Block ................................................................................................................ 39

Figure 9-7 RTD ....................................................................................................................... 39

Figure 9-8 Gland water sensor installation ............................................................................. 41

Figure 9-9 Speed sensor mount example (new picture required) .......................................... 41

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page v

Page 7

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

1 Introduction and Safety

1.1 Introduction

The purpose of this manual is to provide details on how to install the Weir Industrial Gateway

in a generic sense ie independent of product type.

Read this manual carefully before installing and using the product.

1.2 Scope

The three main items covered in this guide are :

o Power supply Module : PSM

o Main Processor Module : MPM

o Remote Signal Processor : RSP

The important specifications of these devices and the basic installation process will be

covered.

1.3 Target Audience

This document is directed towards maintenance fitters, technicians and any staff involved in

installing this system.

1.4 Safety

1.4.1 Safety Terminology and Symbols

You must observe the instructions contained in this manual. Failure to do so could

result in damage to equipment and/or injury or death.

1.4.2 User Safety

Use Personal Protective Equipment (PPE) according to the site regulations for that work

area. This may include, but is not limited to:

o Hard hat

o Safety goggles

o Protective shoes

o Protective gloves

o Hearing protection

Notice:

Never work on equipment unless the correct lockout procedures have been followed

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 1 of 46

Page 8

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

1.4.3 Warnings

WARNING: THE SAFETY OF ANY SYSTEM INCORPORATING THIS EQUIPMENT IS

THE RESPONSIBILITY OF THE ASSEMBLER OF THE SYSTEM.

WARNING: TO PREVENT FIRE OR SHOCK HAZARD, DO NOT OPEN COVERS. NO

USER SERVICEABLE PARTS INSIDE. REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

WARNING: EXPLOSION HAZARD. DO NOT CONNECT OR DISCONNECT CABLES

WHEN ENERGIZED IN A HAZARDOUS LOCATION ENVIRONMENT. DO NOT

CONNECT OR DISCONNECT ANY CABLES WHILE CIRCUIT IS LIVE OR ULESS THE

AREA IS FREE OF IGNITABLE CONCENTRATIONS.

WARNING: IN HAZARDOUS LOCATION ENVIRONMENTS THE EQUIPMENT MUST

BE OPERATED AT ALL TIMES WITH THE CONNECTOR SHROUDS INSTALLED.

WARNING: DISCONNECTING CABLES IN A HAZARDOUS LOCATION

ENVIRONMENT CAN CREATE A SPARK. CABLES ARE ONLY TO BE

DISCONNECTED BY QUALIFIED SERVICE PERSONNEL.

AVERTISSEMENT: LA SÉCURITÉ DE TOUT SYSTÈME INCORPORANT CET

ÉQUIPEMENT EST LA RESPONSABILITÉ DE L'ASSEMBLÉE DU SYSTÈME.

AVERTISSEMENT: POUR ÉVITER LE RISQUE D'INCENDIE OU DE CHOCS, NE PAS

OUVRIR LES COUVERTURES. AUCUNE PIÈCE DE SERVICE UTILISABLE À

L'INTÉRIEUR. CONSULTER L'ENTRETIEN AU PERSONNEL DE SERVICE QUALIFIÉ.

AVERTISSEMENT: RISQUE D'EXPLOSION. NE PAS CONNECTER OU

DÉCONNECTER DES CÂBLES QUI SONT ENERGISÉS DANS UN ENVIRONNEMENT

DE LOCALISATION DANGEREUSE. NE PAS CONNECTER OU DÉCONNECTER

TOUS LES CABLES, SI LE CIRCUIT EST VIVANT OU ULTÉRIEUR, LA ZONE EST

LIBRE DE CONCENTRATIONS IGNITABLES.

AVERTISSEMENT: DANS LES ENVIRONNEMENTS DE LOCALISATION

DANGEREUSES, L'ÉQUIPEMENT DOIT ÊTRE FONCTIONNÉ À TOUTES LES

HEURES AVEC LE CONNECTEUR SHROUDS INSTALLÉ.

AVERTISSEMENT: LA DÉCONNEXION DES CABLES DANS UN ENVIRONNEMENT

DE LOCALISATION DANGEREUSE PEUT CRÉER UNE SPARK. LES CABLES SONT

SEULEMENT DÉCONNECTES PAR UN PERSONNEL DE SERVICE QUALIFIÉ.

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 2 of 46

Page 9

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

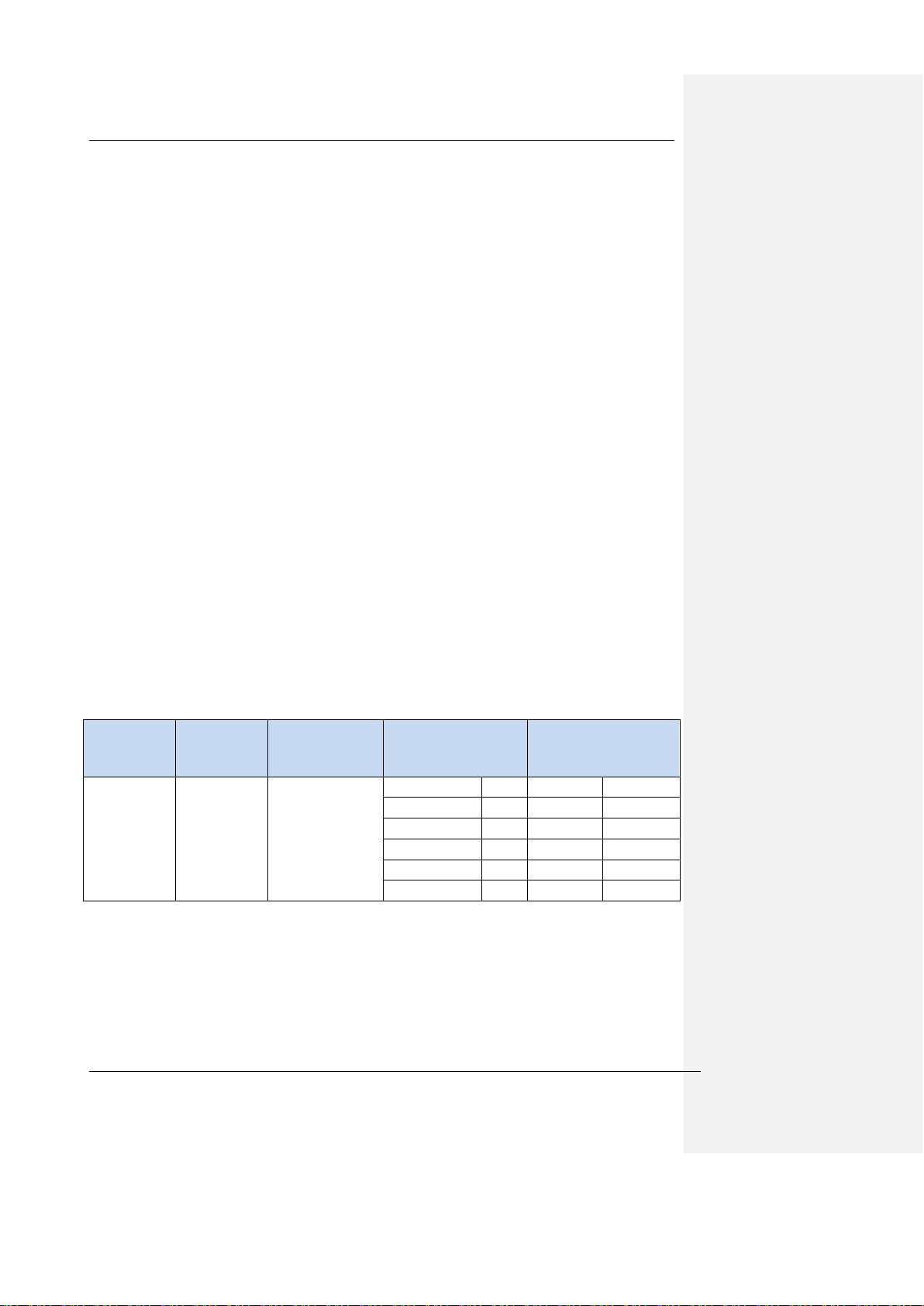

Part No

Varistor

Voltage (V)

Maximum

Allowable

Voltage

Clamping Voltage

At 8/20µs

Max (V) Ip (A)

Maximum Peak

Current at 8/20µs (A)

1 time 2 times

Panasonic

ERZ-V20D431

430

(387 to 473)

275Vac, 350 Vdc

745 5 800

600

710

10

1750

1250

710

25

3500

2500

710

25

3500

2500

710

50

6000

4500

710

100

10000

6500

1.4.4 Determination That Equipment Can be Used Safely in the Intended Area

The installation of this system requires that the equipment be mounted in such a way that it

can withstand impacts from use and vibration from the machinery it is attached to. The

following should be checked to ensure that the installation is safe:

Cables should be supported such that the supports carry the weight of the cable and

the connectors are not being pulled from the weight of the cable.

In hazardous location areas, the air surrounding the equipment should have an

oxygen concentration of not greater than 21 percent by volume; and a pressure of 80

kPa (0.8 bar) to 110 kPa (1.1 bar)

The ambient temperature range is from -30°C ≤ Tamb ≤ 70°C.

The mains that the equipment is attached to have a 15A circuit breaker installed

outside of the hazardous area for hazardous locations.

All connections are tight and in hazardous location areas, all locking mechanisms on

the connectors are attached.

All connections are watertight, with Nitto No 15 self-amalgamating tape used on the

RF connections to ensure that water cannot get into the connector.

The sensors are installed in such a manner that they will not come off from operation,

and the sensor cables will not interfere with equipment operation. It is preferable that

sensor cables do not get very close to electric motor windings, which can generate

significant amounts of magnetic field, which may affect the sensor sensitivity.

The sensor electrical connections are waterproof.

The transient limiting of lightning, surges, and other transients coming from the mains

power is done within the power supply by the use of transient/surge absorbers. These

are connected line to line, as well as line to chassis ground. The characteristics of these

transient absorbers are as follows:

The Continuous operating temperature of the gaskets are as follows:

<ADD GASKET COT INFORMATION HERE>

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 3 of 46

Figure 1-1 Transient Protection Parameters, Line to Line and Line to Ground

Page 10

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

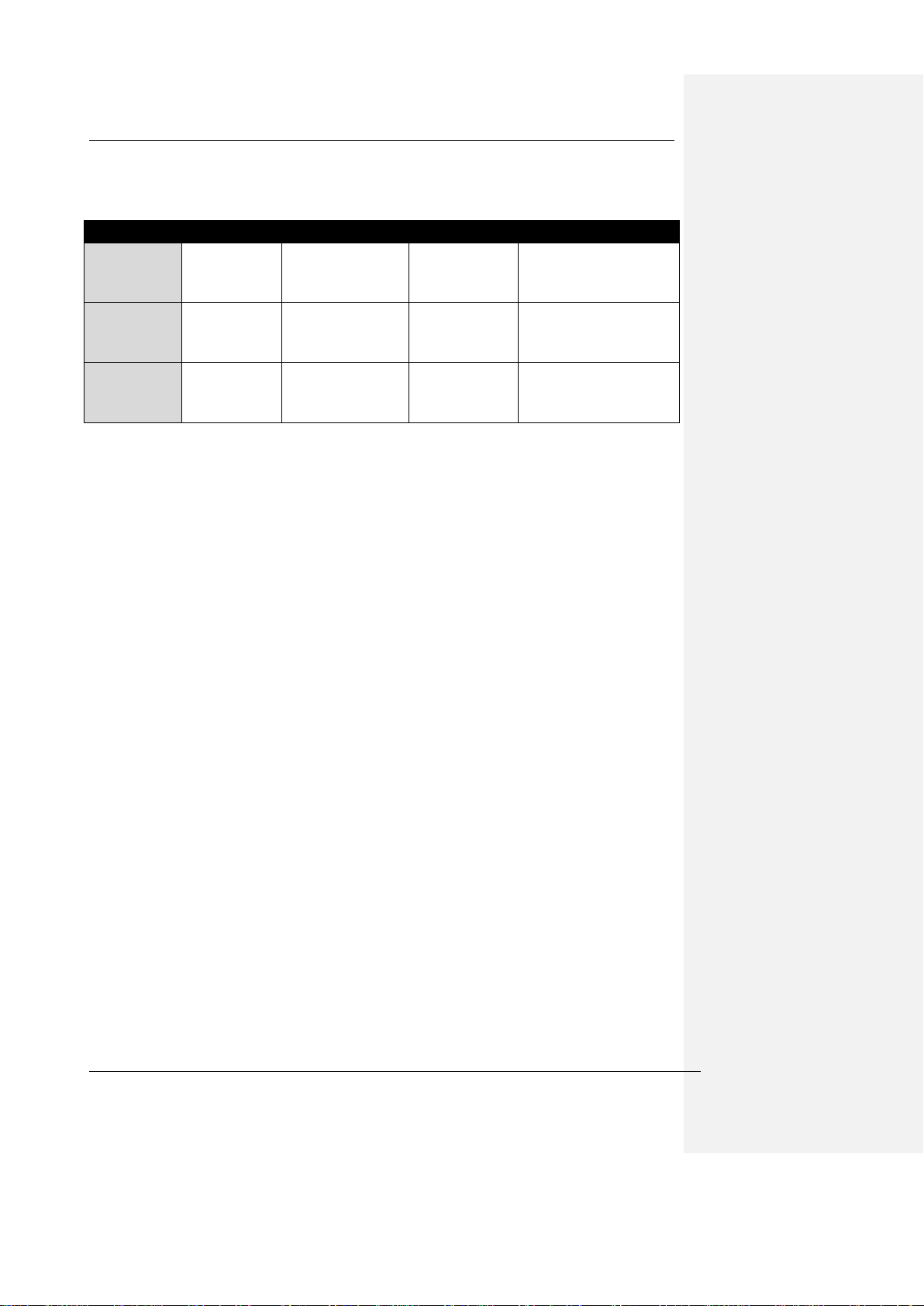

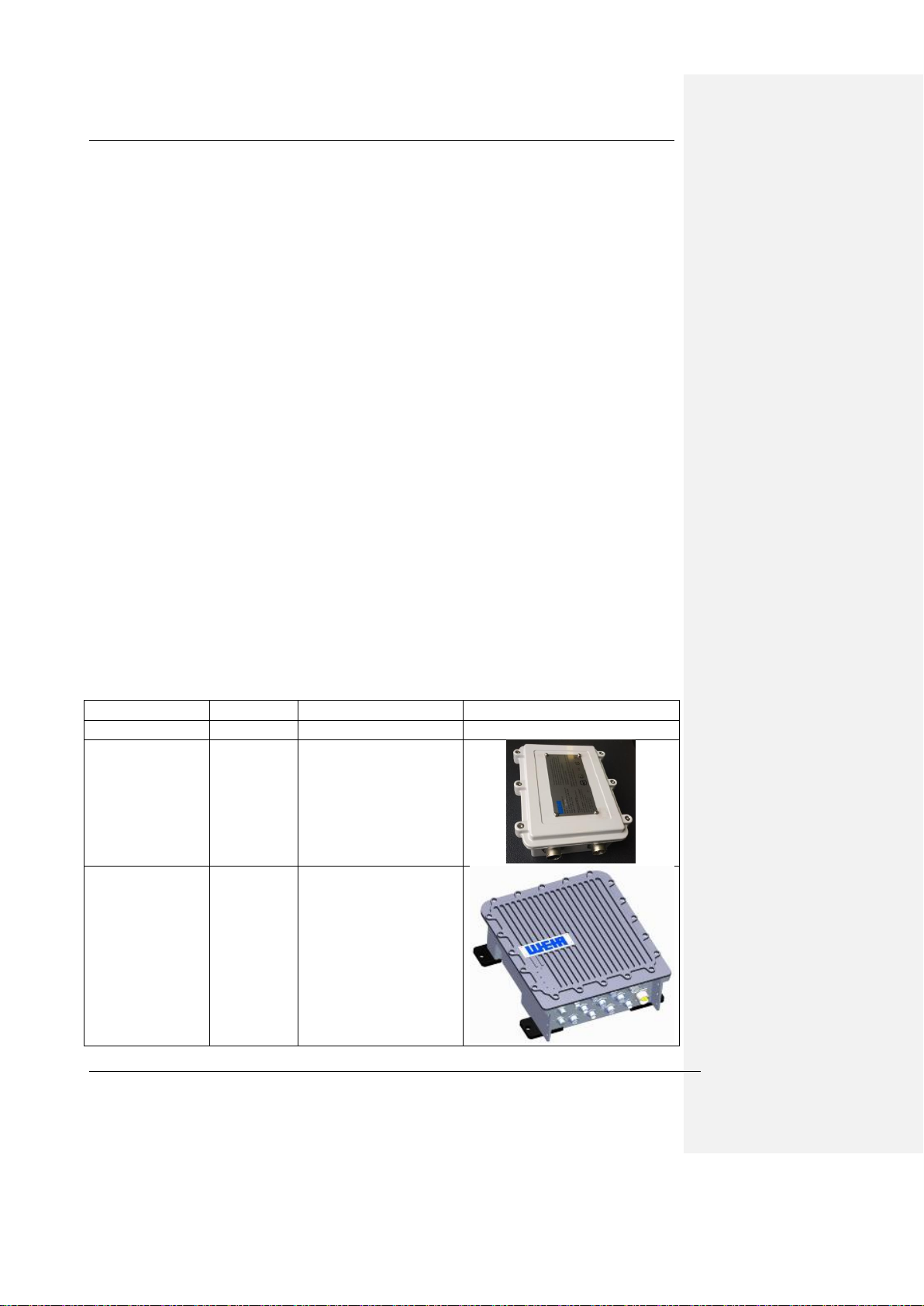

Name

Acronym

Description

Power Supply

Module

PSM

24Vdc 500W power

supply for MPM, able to

supply fully loaded

system at extremes of

environmental ratings

Main Processor

Module

MPM

Module that runs the

Node Engine software,

processes data &

connects to the

enterprise

2 Transportation and Storage

2.1 Consignment receipt and unpacking

o Inspect the package for damaged or missing items upon delivery. All items

should be checked against the delivery note

o Note any damaged or missing items and inform the supplier and relevant

parties

2.2 Transportation Guidelines

o The gateway and its components are designed to be lifted and man-

transported without cranes or other lifting equipment

2.3 Storage

For long term storage, ensure connector caps are firmly secured on the all gateway

connectors

3 System components

A number of main components are common across many of the product implementations.

These are :

o Power Supply Module (PSM)

o Main Processor Module (MPM)

o Remote Signal Processor (RSP)

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 4 of 46

Page 11

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

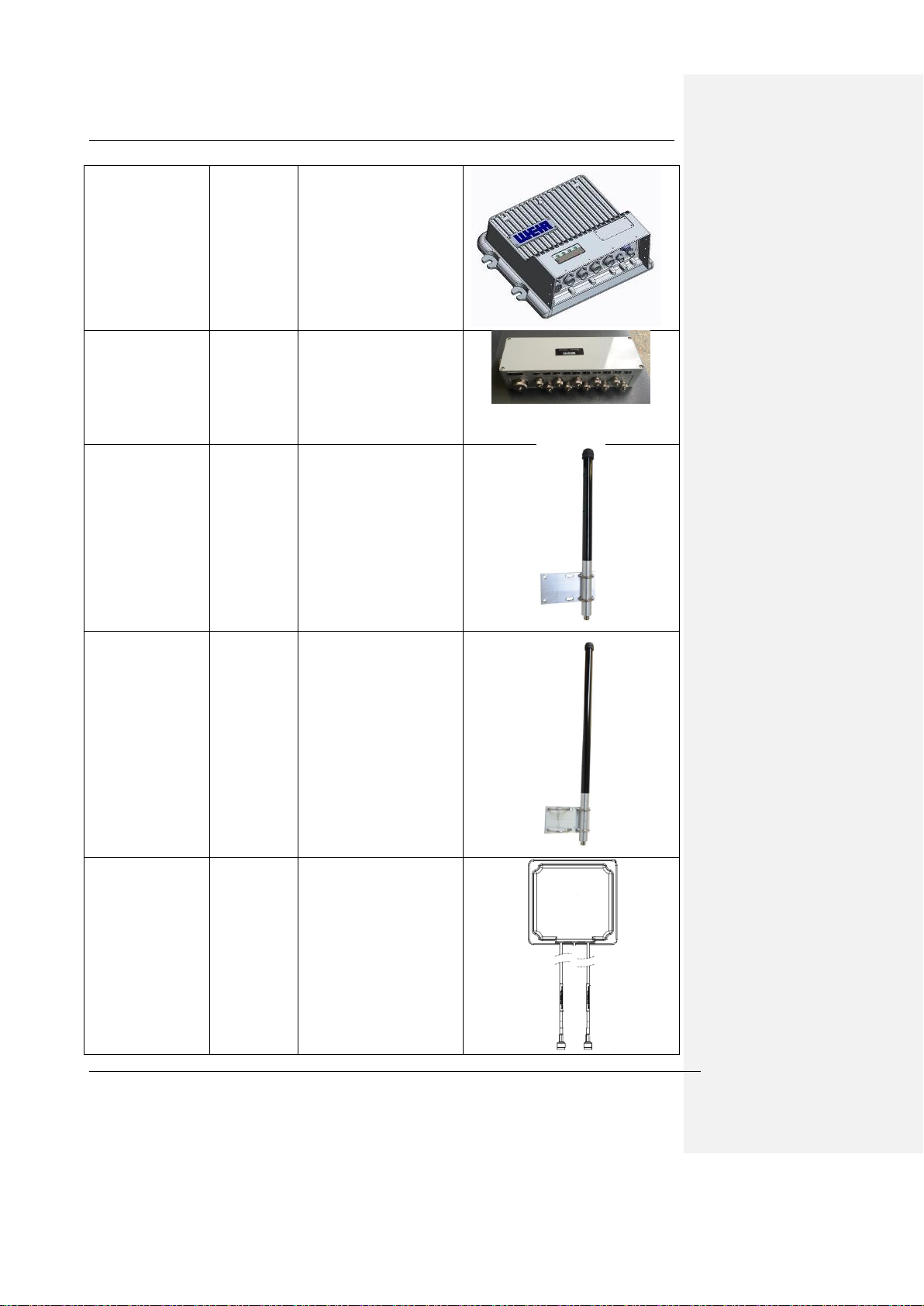

Remote Signal

Processor

RSP

Device that interfaces

with sensors on the

equipment

Junction Boxes

Various

A number of junction

boxes and cables are

used to connect the

RSP to sensors on the

equipment, example

shown to right

WiFi Antenna

(2.4GHz)

Default WiFi antenna

(2.4GHz) 6dB

Omnidirectional

(Mobilemark)

Cellular Antenna

Default Cellular band

Antenna 9dB

Omnidirectional

(Mobilemark)

WiFi Antenna

(2.4GHz/5GHz)

Dual Band Operation

(Laird)

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 5 of 46

Page 12

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

Main Processor Module

(MPM)

Power Supply Box

(PB)

24VDC

RSP

RSP

RSP

RSP

Qpro

Sat/GPS

Sensor

Sensor

Sensor

Sensor

Sensor

Sensor

Sensor

Sensor

Sensor

Sensor

Sensor

Sensor

Sensor

Sensor

Sensor

Sensor

ECA_MR_nn

24VDC, LAN

ECA_RS_nn

Analog

ECA_MQ_01

24VDC, S erial

ECA_PM_01

24VDC

WIFI

Module

ECA_MW_01

POE

Along with these are a range of standard cables that connect these main components to the

sensors on the equipment.

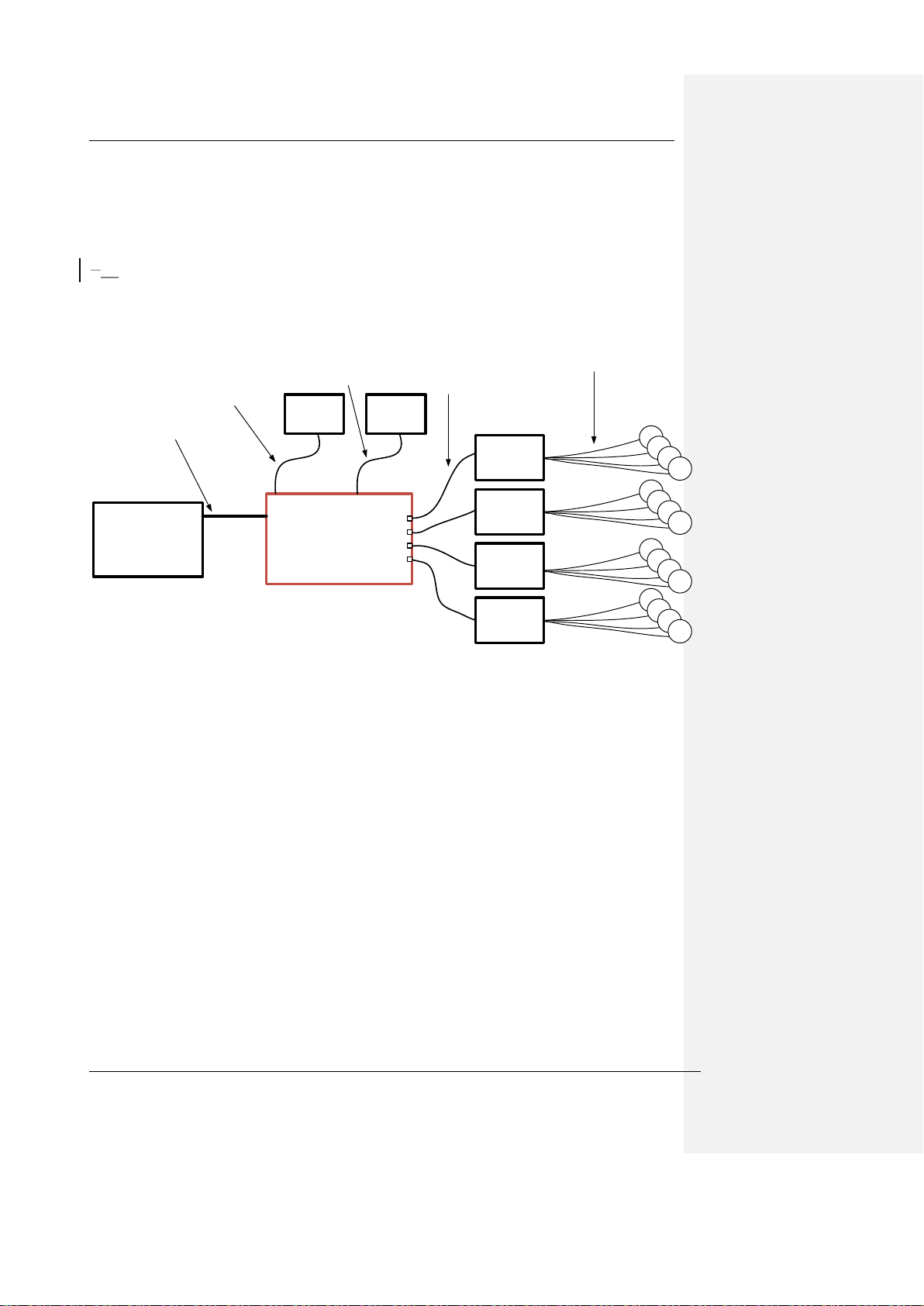

54 System architecture

The Weir Industrial Gateway MPM & RSP system is arranged in a modular manner shown in

the figure below.

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 6 of 46

Figure 4-1 System diagram

o MPM can support 4 x RSPs directly wired via Ethernet

o PSM is rated to support MPM + 4 x RSPs + all other optional items

o Each RSP is located near a piece of equipment being monitored while the

MPM may be remotely located with a maximum of a 100m cable run. Option

to have RSP connected to the MPM via an external WiFi module but this

arrangement requires a local 24Vdc supply to the RSP.

o Qpro amd WiFi module are optional items and not covered in this guide

Page 13

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

Comment [CS1]: Is this a Sanmina part# ?

65 PSM – Power Supply Module

The PSM is a switch mode power supply that operates of mains AC power and provides the

24Vdc that the whole system operates from.

6.15.1 Parameters relevant to installation and operation

o Model # : SPSM-000001

o DELL SKU : IP67IPS500-24

o Supply : 90 to 264 VAC, 47 to 400 Hz

o Output: 20A@24Vdc (Nominal 500W)

o IP rating : 67

o IK rating : 09

o Hazloc : Certified for Class 1 Div 2 environment

o Temperature range (operating) : -30°C ≤ Tamb ≤ 70°C

o Mass : 1.587kg

o MTBF : > 500,000 hours

o Casing material : Powder coated die cast aluminium

o Mounting orientation : Connectors facing downwards

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 7 of 46

Figure 5-1 Iso view of PSM

Page 14

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

J1 – AC

Power in

J2 DC

Power out

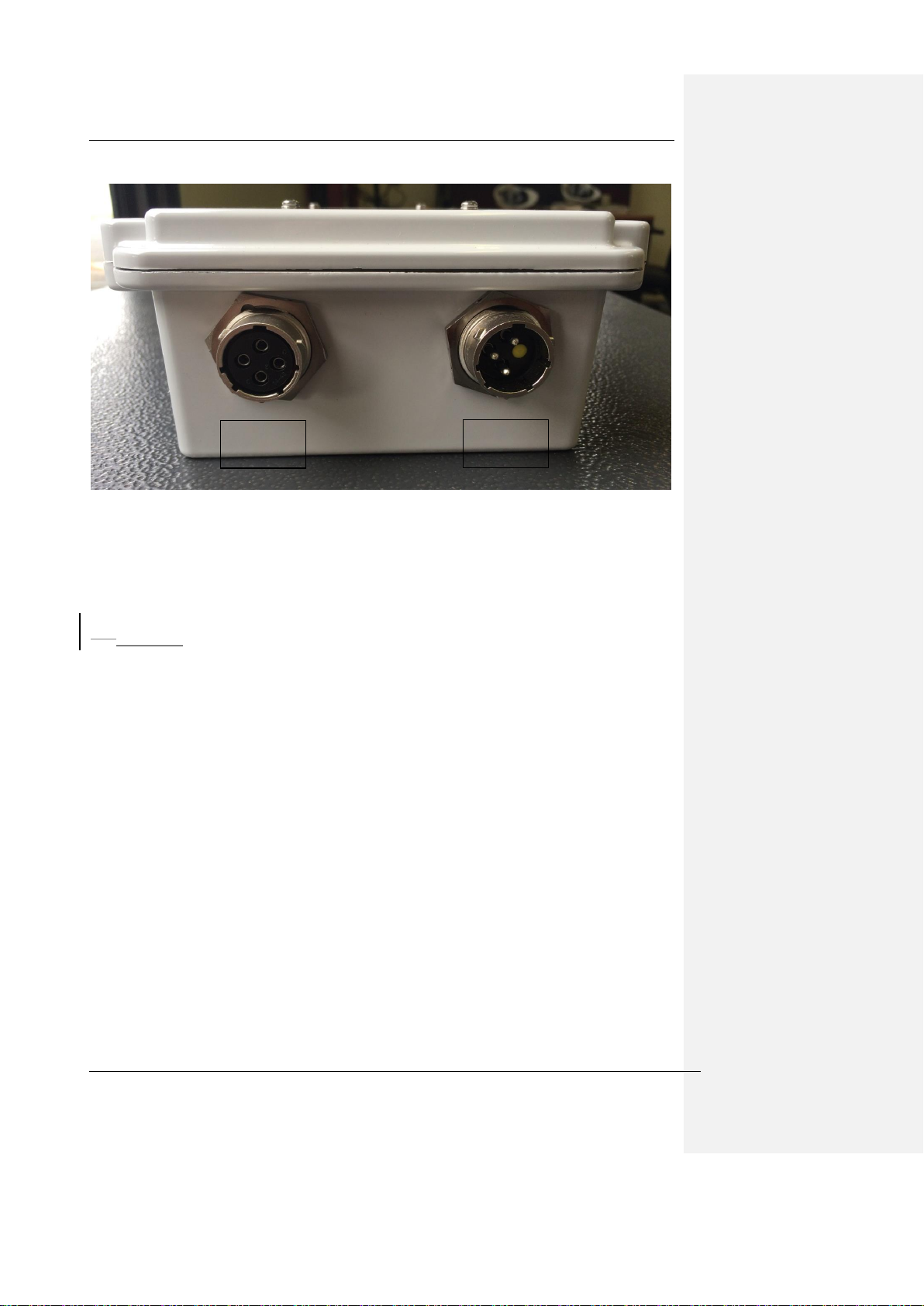

Figure 5-2 PSM Connectors

The cables provided with the power supply are as follows:

AC Cable: PN# LFS04876 connects to the 3 pin port marked "power in".

DC Cable: PN# LFS04875 connects to the 4 pin port marked "power out".

6.25.2 Installation

Physical installation of the PSM is covered in section 6.4. Electrical installation must include

a current limiting device (fuse or circuit breaker) rated to protect the AC supply cable

connected to J1. This circuit breaker should be rated to 15A.

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 8 of 46

Page 15

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

76 MPM – Main Processing Module

The primary functions of the MPM are:

- Run the Node Engine application(s) required for each piece of equipment

o Convert signals captured by the RSP or other devices into TAG Metrics

o Perform secure authentication with the Synertrex Enterprise

o Provide remote access mechanism to allow diagnosis and analysis of issues

on site

The MPM is housed in a rugged enclosure fitted with signal conditioning, data acquisition,

data processing and cloud interfacing systems.

7.16.1 Parameters relevant to installation and operation

o Supply : 14.6A@24Vdc

o IP rating : 66

o IK rating : 09

o Hazloc : Certified for Class 1 Div 2 environment

o Temperature range (operating) : -30°C ≤ Tamb ≤ 70°C

o Mass : 16.7 kg / 36.8 lb

o Casing material : Powder coating over allodyned aluminium

o Mounting orientation: On vertical plate/wall with all connectors facing down

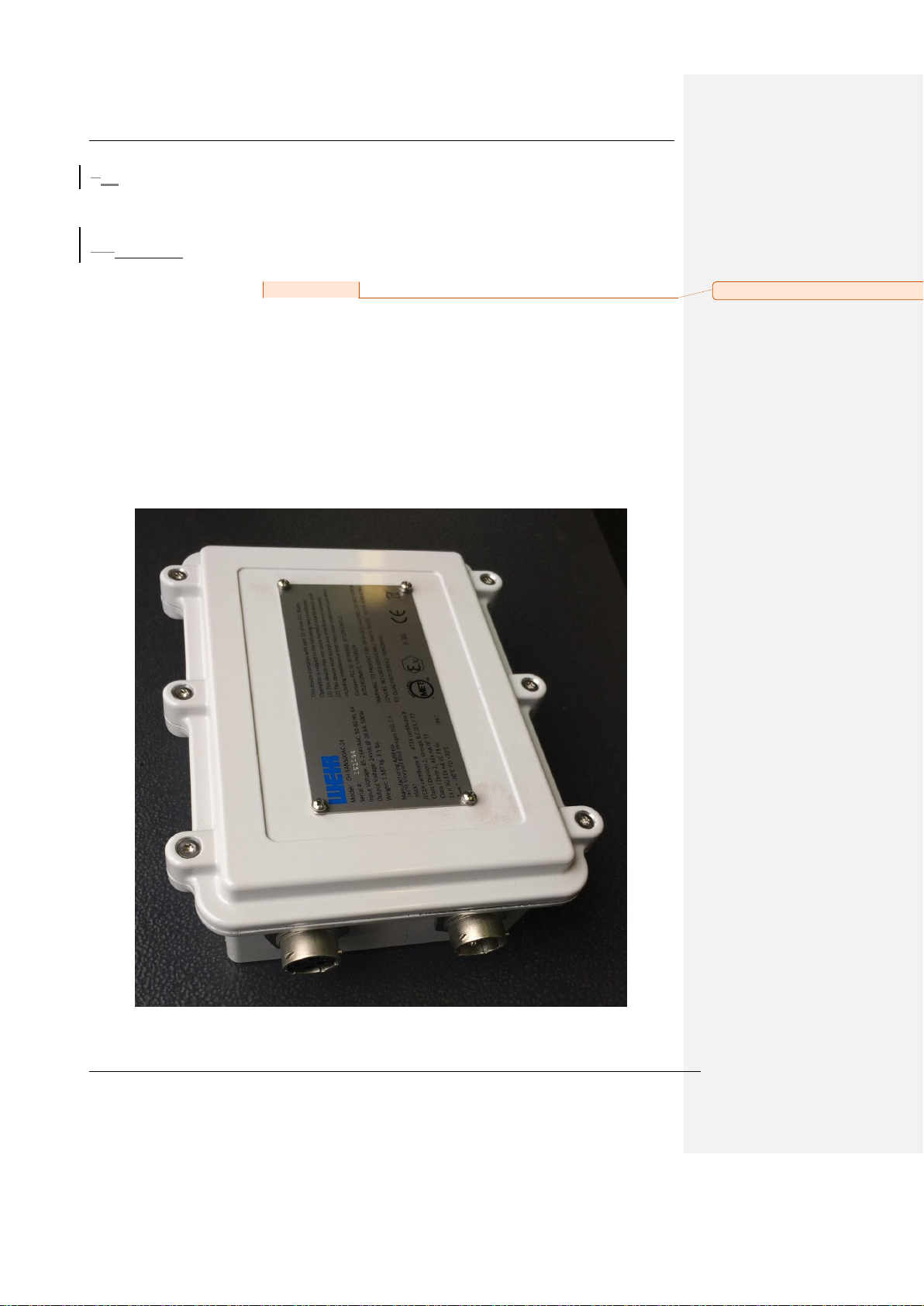

7.26.2 Images

Figure 6-1 MPM perspective view (cables and protective shroud removed)

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 9 of 46

Page 16

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

Figure 6-2 MPM with connector shroud installed

Connector shroud must be installed at all times once connectors are in place to prevent

slurry/mud etc getting onto the connectors AND to meet hazardous location standards.

Figure 6-3 MPM connector view - protective caps installed

Connector caps shown are to be left installed for all connectors without a cable assembly

attached. This is required for hazardous location approvals.

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 10 of 46

Page 17

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

Figure 6-4 MPM External dimensions

Figure 6-5 Connector view

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 11 of 46

Page 18

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

87 Exte

rnal

Nam

e

98 Description

109 Cable Part

Number

1110 Keyi

ng Type

If Used

Wifi 1

WiFi primary connector to EG5100

WiFi

CA120/195-XX

N/A

Wifi 2

WiFi connector to EG5100 WiFi

CA120/195-XC

N/A

3G 1

WWAN primary connector to EG5100

CA120/195-XX

N/A

3G 2

WWAN connector to EG5100

CA120/195-XC

N/A

Qpro

Qpro (GPS receiver) power and signal

LFS04869

SNH

POE

POE Lan port

LFS04870

SWH

LAN

LAN

LFS04870

SWH

RS485

RS485

LFS04880

SNH

CAN

CAN

LFS04872

SWH

RSP 1

RSP #1

LFS04873

SYH

RSP 2

RSP #2

LFS04873

SYH

RSP 3

RSP #3

LFS04873

SYH

RSP 4

RSP #4

LFS04873

SYH

24VDC

Power input

LFS04875

SNH

IO

Analog/Digital IO

LFS048734

SWH

7.36.3 Connector Keying Types

The multi-conductor cables have three different keying types, which are shown below. One

of the tabs is moved in order to provide keying, this tab is shown with the orange arrow.

SNH SYH SWH

Figure 6-6 Connector Keying, View from MPM Connector

11.110.1 LED Indicators

There are 4 LEDs on the MPM front face. The status of these LEDs are as follows::

1.) Green LED 1 – Power

2.) Green LED 2 – System running

3.) Green LED 3 – Wi-Fi Good

4.) Green LED 4 – Enterprise connected.

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 12 of 46

Figure 6-7 - MPM connector names and locations

Page 19

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

Equipment Module

Equipment Module

Power Supply

Power Supply

Weather protector attachment

Weather protector attachment

Weather protector

Weather protector

SIDE VIEW

SIDE VIEW

FRONT VIEW

FRONT VIEW

11.210.2 Installation

11.2.110.2.1 Mounting plate & Hardware

The minimum recommended protective equipment for mounting this equipment would be as

follows: eye protection, gloves, hard hat, steel cap boots, long sleeves and trousers. Danger

tape to cordon off area below if installing at height is also recommended.

The mounting of the MPM, RSP, and power supply needs to be customized to the particular

system that it is intended for. In general a mounting plate made of 16 guage sheet steel

would be sufficient to provide adequate strength. A representative diagram of a mounting

plate is provided below:

Figure 6-8 MPM & PSM generic mounting plate

11.2.1.110.2.1.1 Installation

1. The mounting plate must be mounted in the vertical plane and as level as possible.

2. Fasten or weld the mounting plate to a structure near the equipment with the

following conditions:

a. No more than 50m from the equipment (100m cable run)

b. Attach to a solid structure, relatively free from vibration, ensuring that it is

capable of supporting the combined mass of approximately 30kg and the

additional loading from any vibration.

c. Ensure there is sufficient clearance (~10mm) for bolts to protrude through the

rear of the plate

3. A sun visor/slurry shield is recommended to be added to the mounting plate, which is

shown in the diagram.

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 13 of 46

Page 20

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

11.2.210.2.2 MPM & PSM

11.2.2.110.2.2.1 Equipment and materials required

• Tools

o Allen keys, wrench/spanner to cover sizes 6, 8 & 10mm cap screws and nuts

o Side cutters/scissors or similar to cut self-amalgamating tape

• Consumables

o Self-amalgamating tape : Nitto No 15

o AC supply cable : PN# TBD (note that the mains cable has open wires to

allow connection to a fuse box or the appropriate connector to suit the

customers power outlet)

o DC out cable : DELL SKU: LFS04875-012M00

o 4 - M5 self tapping screws for mounting

• Provisioned SIM card

11.2.2.210.2.2.2 Hazards

- The MPM is relatively heavy (16kg) and requires 2 people to transport and assist

each other during mounting.

- If dropped from height this module is a potentially deadly hazard hence the area

below the installation must be cordoned off with danger tape.

- Mains power is a potentially deadly hazard and hence must only be modified or

connected by a certified Electrician.

11.2.2.310.2.2.3 Installation

1. Ensure the serial number on the MPM and PSM correspond with the equipment to be

monitored and installation location

2. Ensure the protective caps remain on the MPM & PSM connectors until cables are

installed

3. Install the MPM & PSM in the arrangement shown below in Figure 6.8. Ensure a

fastener is used for each mounting hole. The mounting of the PSM is done using M5

self tapping screws.

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 14 of 46

Page 21

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

J2

Figure 6-9 - MPM & PSU installed on mounting plate

4. If SIM card has not been installed, insert this now into J15 on the MPM. The

protective shroud needs to be removed to do this (needs Torx T27 driver). Be sure to

re-install the protective cap afterwards.

Figure 6-10 SIM card receptacle in MPM

5. Connect 24Vdc power lead (PN# LFS04875-012M00) from PSM J2 into DC power

input port (J14) on MPM

Figure 6-11 24Vdc power connection from PSM to MPM

6. Ensure the customer mains outlet is either isolated or turned off and locked

7. Connect the mains power lead from the customer power outlet to the AC input port J1

on the PSM using cable PN# LFS04876.

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 15 of 46

Page 22

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

Figure 6-12 Mains AC power connection to PSM

8. Locking clips need to be installed on the power supply connectors for hazardous

location compliance. These locking clips shall only be removed by qualified service

personnel. The installation of these clips is as follows:

Figure 6-13 Installation of Locking Clips

WARNING: EXPLOSION HAZARD. DO NOT CONNECT OR DISCONNECT CABLES

WHEN ENERGIZED IN A HAZARDOUS LOCATION ENVIRONMENT.

AVERTISSEMENT: RISQUE D'EXPLOSION. NE PAS CONNECTER OU DÉCONNECTER

DES CÂBLES QUI ENERGISES DANS UN ENVIRONNEMENT DE LOCALISATION

DANGEREUSE.

9. Protective earth grounding of the system is provided by the earth ground connection

from the power supply AC cable, and connection of the enclosures of the MPM and

PSM to earth ground is optional.

11.2.310.2.3 Hazardous Location Requirements

The enclosure of the power supply and the MPM will need to be grounded to earth ground

according to local building codes for hazardous location use. The back side of the power

supply is bare metal, allowing it to be grounded to the mounting plate when it is bolted in

place. The mounting plate will need to have no coating where the power supply is installed

in order to provide electrical conductivity.

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 16 of 46

Page 23

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

The MPM has an M6 sized external grounding screw for protective earth grounding.

Insulated 10AWG wiring is needed to connect this grounding screw to the mounting plate,

along with the use of M6 sized ring connectors for 10AWG wire. The connection to the

mounting plate should be made using a lock washer or lock nut to ensure that the connection

cannot loosen from vibration. If this mounting plate is not directly connected to earth ground

through the machinery then the mounting plate will also need to be grounded to earth with

the use of 10AWG wire and ring connectors.

The location of the grounding screw for the MPM is as follows:

Figure 6-14 Location of Protective Earth Grounding on MPM

The connector shroud must be installed at all times once connectors are in place to prevent

slurry/mud etc getting onto the connector threads AND to meet the standards certified

against for Hazardous Location operation.

WARNING: THE POE AND 24 AUX PORTS SHALL NOT BE USED IN HAZARDOUS

LOCATION AREAS.

WARNING: EXPLOSION HAZARD. DO NOT CONNECT OR DISCONNECT CABLES

WHEN ENERGIZED IN A HAZARDOUS LOCATION ENVIRONMENT.

AVERTISSEMENT: LE POE ET LES 24 PORTES AUX AUTRES NE SONT PAS UTILISÉS

DANS LES ZONES DE LOCALISATION DANGEREUSES.

AVERTISSEMENT: RISQUE D'EXPLOSION. NE PAS CONNECTER OU DÉCONNECTER

DES CÂBLES QUI ENERGISES DANS UN ENVIRONNEMENT DE LOCALISATION

DANGEREUSE.

11.2.410.2.4 Antenna

Up to four Antennae may be utilised per MPM :

- Cellular (default)

- Wifi (default)

- Dual Band WiFi (optional)

- GPS module (optional)

The installation position and orientation are crucial to the optimal operation of an antenna –

- Ensure it is mounting in a vertical orientation

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 17 of 46

Page 24

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

- Install away from metal objects such as walls, beams, posts etc

- If mounted on a post, the radiating section of the antenna (above aluminium base)

needs to be level or above the post

11.2.4.110.2.4.1 Equipment and materials required

• Minimum recommended PPE:

o eye protection, gloves, steel cap boots, hard hat, long sleeves and trousers,

danger tape to cordon off area below if installing at height

• Spanner/wrench :

o 7/16” / 11mm (open ended)

• Cellular antenna

o OD-850 (Mobilemark) : Longer antenna (comes with mounting bracket)

o Cable assembly : CA120/195-XX (Mobile Mark)

• Wi-Fi antenna (Default)

o OD-2400 (Mobilemark) shorter antenna

o Cable assembly : CA120/195-XX (Mobile Mark)

• Wi-Fi antenna (Optional)

o Laird PVD24515-DE1

11.2.4.210.2.4.2 Hazards

- If dropped from height the antenna(e) are a potential hazard for people below

- Working from height while installing the antenna(e) is a hazard hence standard

procedures to work at height should be followed to reduce risks.

11.2.4.310.2.4.3 Installation

1. Mount the antenna to the supplied plate using the hardware provided

Figure 6-15 Antenna mount attached

2. Tighten the nuts and lock nuts (thinner of the two) on the two smaller U-Bolts

3. Mount the plate with antenna to your mast/pole using two larger U-bolts

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 18 of 46

Page 25

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

Figure 6-16 Installation of Antenna(e)

4. Remove the red protective cap and connect the antenna cable to the antennas coax

connector

Figure 6-17 Antenna with and without cable attached

5. Wrap connector interface with self-amalgamating tape to protect from slurry, etc.

This is required for hazardous location compliance.

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 19 of 46

Page 26

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

Wifi

Cellular

Figure 6-18 Antenna connector wrapped in protective tape

6. Connect the other end of the cable(s) to the MPM Antenna ports

Figure 6-19 Schematic of Wifi and Cellular antennae connections to MPM

For best results:

- Mount the antenna as high up as the cable length / location permits, with optimal lineof-sight to the receiver

- Attach to a pipe / mast if possible

- If mounted near other antenna, maintain a separation of at least 300mm (~1 foot)

- Avoid placement near close metal objects as unpredictable disturbance can result

- Avoid placing on the side of a building or tower as directivity can be expected

- Mount antenna facing vertically for proper polarization and avoid mounting up-side

down as the antenna will not drain correctly.

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 20 of 46

Page 27

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 21 of 46

Page 28

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

1211 RSP – Remote Signal Processor

The RSP is housed in a rugged enclosure fitted with signal conditioning, data acquisition and

data processing systems.

12.111.1 Parameters relevant to installation and operation

- Supply : 4.2A@24Vdc

- IP rating : 66

- IK rating : 09

- Hazloc : Certified for Class 1 Div 2 environment

- Temperature range (operating) : -30°C ≤ Tamb ≤ 70°C

- Mass : 10.5kg / 23.1 lb

- Casing material : Powder coated die cast aluminium

- Mounting orientation: On vertical plate/wall with all connectors facing down

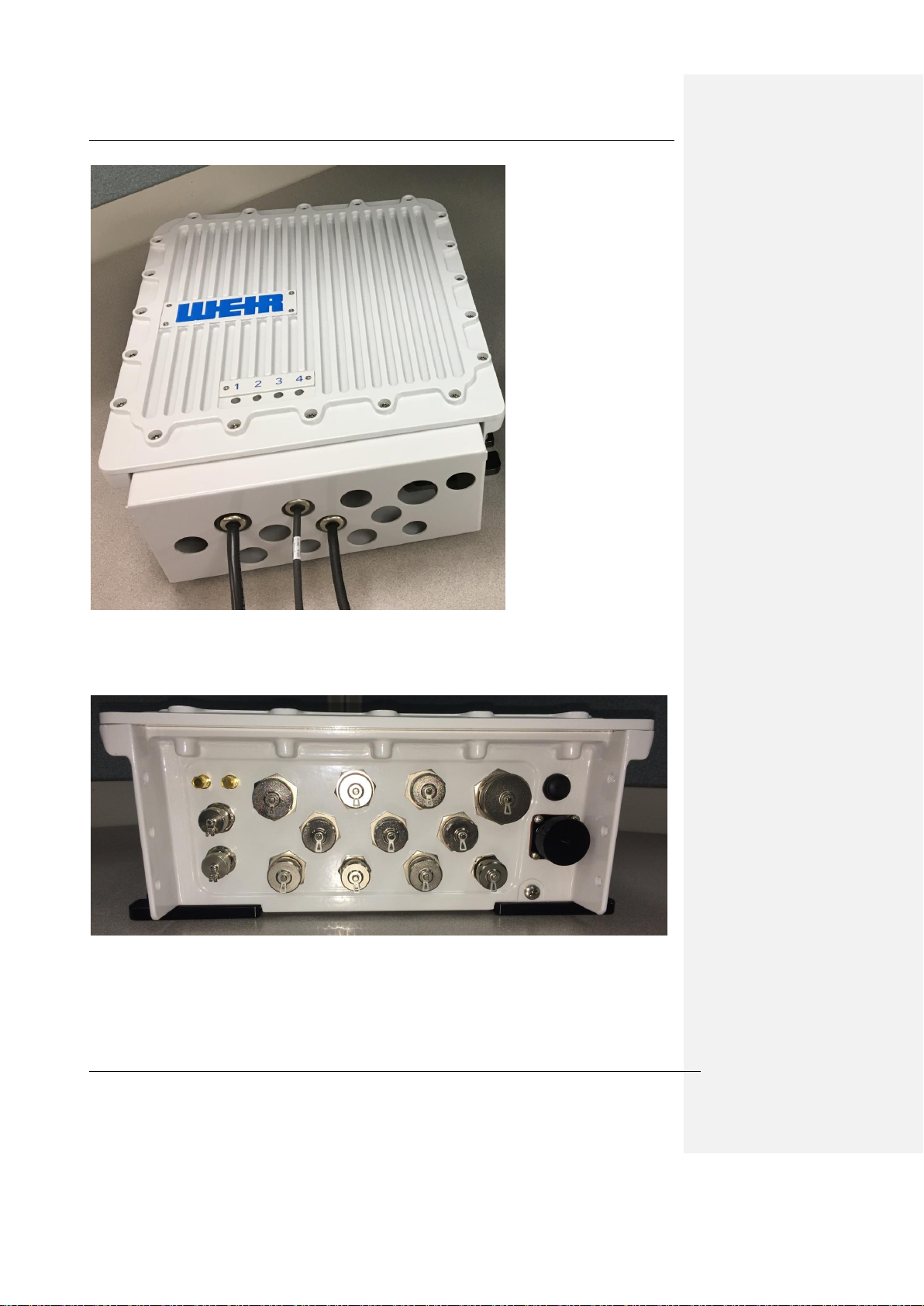

12.211.2 Images

Figure 11-1 RSP Overview

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 22 of 46

Page 29

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

Figure 11-2 RSP shown with connector shield installed

Connector shroud must be installed at all times once connectors are in place to prevent

slurry/mud etc getting onto the connector threads AND to meet the standards certified

against for Hazardous Location operation.

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 23 of 46

Page 30

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

Figure 11-3 RSP Physical dimensions

Figure 11-4 RSP Connector layout and descriptions

12.311.3 Connector Keying Types

The multi-conductor cables have three different keying types, which are shown below. One

of the tabs is moved in order to provide keying, this tab is shown with the orange arrow.

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 24 of 46

Page 31

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

External

Name

Description

Cable Part

Number

Keying Type

If Used

24V Aux

Auxiliary 24V power input

LFS04897

SXH

RS485

RS485/RS232 input

LFS04880

SNH

POE

POE port

LFS04870

SWH

CAN

Can bus port

LFS04872

SWH

MPM

Main MPM connector

LFS04873

SYH

AO0

Analog Output Bank 0

No Application

SZH

AI0

Analog Input Bank 0

LFS05179

SNH

AI1

Analog Input Bank 1

LFS05179

SNH

DO0

Digital Output Bank 0

LFS04879

SNH

DO1

Digital output Bank 1

LFS04879

SNH

DI0

Digital Input Bank 0

LFS04878

SWH

DI1

Digital Input Bank 1

LFS04878

SWH

DI2

Digital Input Bank 2

LFS04878

SWH

AI2

Analog input bank 2

LFS04877

SNH

AI3

Analog input bank 3

LFS04877

SNH

SNH SYH SWH

SXH SZH

Figure 11-5 Connector Keying, View from RSP Connector

12.411.4 LED Indicators

There are 4 LEDs on the MPM front face. The status of these LEDs are as follows::

5.) Green LED 1 – Power

6.) Green LED 2 – System running

7.) Green LED 3 – MPM Communication Status

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 25 of 46

Figure 11-6 RSP Connector port descriptions

Page 32

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

8.) Green LED 4 – I/O Status

12.511.5 Installation

This section covers the generic installation process for the RSP. It is important to note that

product specific installation such as sensors, junctions boxes etc will only be covered

generically and product specific instructions are covered in the IOM Manual.

12.5.111.5.1 Physical mounting

The mounting dimensions are as follows. Use M10 bolts to fasten the RSP to the

mounting location.

Figure 11-7 RSP Mounting Dimensions

12.5.211.5.2 Hazardous Location Compliance

The enclosure of the RSP will need to be grounded to earth ground according to local

building codes for hazardous location use. The RSP has an M6 sized external grounding

screw for protective earth grounding. Insulated 10AWG wiring is needed to connect this

grounding screw to the mounting plate, along with the use of M6 sized ring connectors for

10AWG wire. The connection to the mounting plate should be made using a lock washer or

lock nut to ensure that the connection cannot loosen from vibration. If this mounting plate is

not directly connected to earth ground through the machinery then the mounting plate will

also need to be grounded to earth with the use of 10AWG wire and ring connectors.

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 26 of 46

Page 33

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

The location of the grounding screw for the RSP is as follows:

Figure 11-8 Location of Protective Earth Grounding on RSP

The connector shroud must be installed at all times once connectors are in place to prevent

slurry/mud etc getting onto the connector threads AND to meet the standards certified

against for Hazardous Location operation.

WARNING: EXPLOSION HAZARD. DO NOT CONNECT OR DISCONNECT CABLES

WHEN ENERGIZED IN A HAZARDOUS LOCATION ENVIRONMENT.

AVERTISSEMENT: RISQUE D'EXPLOSION. NE PAS CONNECTER OU DÉCONNECTER

DES CÂBLES QUI ENERGISES DANS UN ENVIRONNEMENT DE LOCALISATION

DANGEREUSE.

12.5.311.5.3 Protective Earth Grounding for Non Hazardous Locations

Protective earth grounding of the system is provided by the earth ground connection from the

power supply AC cable, and connection of the enclosures of the RSP to earth ground is

optional.

12.5.3.111.5.3.1 Hazards

The RSP may be difficult to mount without the assistance of a second person; there is a

significant risk of dropping the unit without help. This could be a significant hazard for

bystanders if installing at height.

12.5.411.5.4 Connection to MPM

12.5.4.111.5.4.1 Equipment & materials required

Recommended minimum PPE

o Gloves, long sleeve shirt, trousers, eye protection

MPM to RSP Ethernet + power cable :

o 5m : SKU# LFS04873-015M00

o 20m : SKU# LFS04873-0120M00 TBC

o 50m : SKU# LFS04873-0150M00 TBC

MPM with spare RSP port

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 27 of 46

Page 34

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

Tools required to remove and replace slurry guards

o Torx T27 driver

12.5.4.211.5.4.2 Hazards

No direct hazards of note

12.5.4.311.5.4.3 Installation

1. Run the cable between the MPM and RSP

2. RSP : Remove connector shroud

Images needed showing screw locations

3. RSP : Remove the connector cap from J5

Figure 11-9 MPM Comms + power connector on RSP

4. RSP : Pass the MPM -> RSP comms + power cable through the hole in the shroud

associated with J5 and make the connection by pushing and turning the bayonet

fitting.

5. RSP : Ensure that all other connectors not being utilised have their protective caps

installed

6. RSP : Re-install the connector shroud per Fig 7.2

7. MPM: Remove the connector shroud, ensuring that the retaining screws are secured

ie do not lose these (no spares are shipped)

8. MPM: Feed the MPM<->RSP cable through the shroud hole associated with the port

being used for this RSP ie one of the four shown below

Figure 11-10 RSP comms + power connectors on MPM

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 28 of 46

Page 35

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

9. MPM: Mate the connectors with a push and twist motion (bayonet style)

10. MPM: Reinstall the shroud

11. MPM: Turn on power to the MPM

12. MPM: Confirm that the following LEDs are lit

a. LED 1 – power

b. LED 2 – System running

13. RSP: Confirm that the following LEDs are lit

a. LED 1 – power

b. LED 2 – System running

14. If all above LEDs are lit, the configuration process may begin, if not contact the

Synertrex Operations team for assistance with troubleshooting and/or refer to the

troubleshooting guide within the IOM Manual.

Figure 11-11 PSM, MPM and RSP connected

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 29 of 46

Page 36

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

Description

Part #

RSP mating

connectors

Junction box

connector type

High speed Analog input

TBD

AI2, AI3

32pin

Low speed Analog input

TBD

AI0, AI1

32 pin

Digital Input

TBD

DI0, DI1, DI2

19 pin

Digital output

TBD

DO0, DO1

19 pin

Analog Output

TBD

AO

TBD

Sensor type

Sensor connector

Cable Part number (example

where XX is length in m)

Lengths

available

(m)

Gland water flow

meter

M12x1 4 pin

IndProx_8_DigitalInJB_Cable_XXm

10, 20

Inductive Prox

M12x1 4 pin

IndProx_8_DigitalInJB_Cable_XXm

10, 20

Uniaxial

accelerometer

2 pin Amphenol

MS3106F10SL-4S

Accel_8_AnalogInJB_Cable_XXm

3, 6, 10, 20

Triaxial

accelerometer

4 pin Amphenol

PT06W8-4S(SR)

TriAccel_8_AnalogInJB_Cable_XXm

10, 20

Glandwater

pressure

transducer

6 pin Amphenol

PT06W10-6S(SR)

GlandPressure_8_AnalogJB_Cable_XXm

10

Temperature RTD

3 pin Marlin

1211U 3 PIN MINI JACK

2, 5, 10

Comment [CS2]: Require part numbers from

Sanmina

1312 Junction boxes and cables

The RSP has a generic signal interface designed to support a wide range of product types.

Therefore to match the RSP to any particular product a specific set of cables, junction boxes

and sensors are needed.

The complete list of junction box types and how they connect to the RSP is described in this

section.

13.112.1 List of cables

13.1.112.1.1 Connecting to RSP

13.1.212.1.2 Junction Box to sensor

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 30 of 46

Page 37

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

Description

Part#

RSP cable(s)

Sensor cables supported

4 Channel AI

4_AnalogIn_JB

32 <-> 24 pin (part# TBD)

32 <-> 32 pin (part# TBD)

All single channel analog

8 Channel AI

8_AnalogIn_JB

32 <-> 24 pin (part# TBD)

32 <-> 32 pin (part# TBD)

All single channel analog

4 Tri + 4 GP AI

4Tri-4GP_AnalogIn_JB

32 <-> 32 pin (part# TBD)

2 cables required

4 x Tri-axial Accelerometers + 4 x

single channel analog

3 Tri + 7 GP AI

3Tri_7GP_AnalogIn_JB

32 <-> 32 pin (part# TBD)

2 cables required

3 x Tri-axial Accelerometers + 7 x

single channel analog

4 x DI

4_DigIn_JB

19 <->19 pin (part# TBD)

IndProx_8_DigitalInJB_Cable_XXm

8 x DI

8_DigIn_JB

19 <->19 pin (part# TBD)

IndProx_8_DigitalInJB_Cable_XXm

4 x DO

4_DigOut_JB

19 <->19 pin (part# TBD)

TBD

8 x DO

8_DigOut_JB

19 <->19 pin (part# TBD)

TBD

2 x AO

TBD

13.212.2 List of Junction Boxes

13.312.3 Installation

This section covers the generic installation process for the junction boxes.

Locking clips need to be installed on the power supply connectors for hazardous location

compliance. These locking clips shall only be removed by qualified service personnel. The

installation of these clips is as follows:

Figure 12-1 Installation of Locking Clips

WARNING: EXPLOSION HAZARD. DO NOT CONNECT OR DISCONNECT CABLES

WHEN ENERGIZED IN A HAZARDOUS LOCATION ENVIRONMENT.

AVERTISSEMENT: RISQUE D'EXPLOSION. NE PAS CONNECTER OU DÉCONNECTER

DES CÂBLES QUI ENERGISES DANS UN ENVIRONNEMENT DE LOCALISATION

DANGEREUSE.

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 31 of 46

Page 38

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

Type

details

Manufacturer

Part #

Accelerometer

Tri-axial: 500mV/g

PCB

604B32

Accelerometer

Uni-axial: 500mV/g

(cylindrical)

PCB

601A02

Accelerometer

Uni-axial: 500mV/g RA

connector

PCB

602D02

Accelerometer

Tri-axial: 50g, 100mV/g

PCB

604B31

Accelerometer

Uni-axial: 100mV/g

(cylindrical)

PCB

601A01

Accelerometer

Uni-axial: 100mV/g RA

connector

PCB

602D01

Accelerometer

mounting block

Tri-axial mounting cube

GVS

GVS-TB

Accelerometer

mounting pad

Glue on mounting pad ¼”

UNF

GVS

GVS-MP05-11

Temperature RTD

Donut style RTD with 1m

flying lead and connector

Temperature

Controls

TC10933

Speed

Inductive prox sensor for

shaft speed measurement

Allen Bradley

872C-N8NP12-D4

Flow rate

Magnetic flow meter for

Gland water

Omega

FMG94-PVDF

1413 Sensors

A wide range of sensors are supported by default by the RSP and Junction box system.

14.113.1 List of Approved Sensors

The following is the current list of supported sensors for non-hazardous location

environments. For hazardous location environments a sensor approved for hazardous

location use in the country of operation will need to be purchased.

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 32 of 46

Page 39

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

Parameter

Value

Voltage VO 24V

Current I

O

Power P

O

Capacitance C

O

Inductance L

O

14.213.2 Hazardous Location Non-Incendive sensors

The RSP provides non-incendive field wiring outputs for Class 1 Division 2 hazardous

location environments, groups B, C, D, E, and F. The non-incendive field wiring outputs are

rated to the following parameters:

WARNING: EXPLOSION HAZARD. DO NOT CONNECT OR DISCONNECT SENSORS

WHEN ENERGIZED IN A HAZARDOUS LOCATION ENVIRONMENT.

AVERTISSEMENT — NE PAS CONNECTER OU DÉCONNECTER LES CAPTEURS DE

SONDAGE QUAND IL EST ENERGISE DANS UN ENVIRONNEMENT DE LOCALISATION

DANGEREUSE.

14.313.3 Sensor Install Locations

The following diagram shows the locations that sensors can be placed on a liquid pump.

Figure 13-1 Sensor Install Locations

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 33 of 46

Page 40

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

Figure 13-3 Triblock mounting accessory

14.413.4 Installation

Vibration and Temperature sensor mounting options:

There are two options available for mounting vibration and temperature sensors to the pump.

Choose the option that best suits your needs:

A. Directly to the pump via a drilled and tapped hole – typically used for bearing

assembly locations and ductile iron parts, intended to be created at time of

manufacture for all products where possible

B. Via an adhesively bonded mounting pad (fig 5.6 below). To be used when it is not

possible to drill and tap.

It is also possible to change the orientation of a single axis sensor by placing a placing a triblock mounting accessory in between the pump and the sensor. This is exclusively used for

single axis sensor VT-10 as described in section x.x below.

Figure 13-2 Slurry pump installation - mounting puck

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 34 of 46

Page 41

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

Insert picture of cleaned surface

ready for bonding. Note area to

be cleaned is ~= 30 mm and flat

Insert picture of puck back

surface, cloth and isopropyl

14.4.113.4.1 Mounting point Preparation

The first step in the installation is to determine what type of sensor mounting method is to be

used for each sensor. There are 7 locations that need to be drilled and tapped, or have a

mounting puck affixed. These locations are summarised in the quick start guide. As

mentioned before, cast iron parts can be drilled and tapped; white iron parts require a

mounting puck.

14.4.213.4.2 Adhesively bonded mounting puck

This approach is used where it is not viable to create a drilled and tapped hole. The mounting

pads provided a threaded hole to mount the sensor and a small magnet that assists in

keeping the pad in place whilst the adhesive cures.You must wait a minimum of 24 hours for

the adhesive to cure before attaching the sensor to the mounting puck.

14.4.2.113.4.2.1 Equipment and materials required

• Minimum PPE : eye protection, gloves, hard hat, long sleeves and trousers

• Wire brush

• Clean cloth

• Adhesive : Loctite Hysol 9461

• Abrasive paper eg 120grit

o A suitable portable drill tool can be used if approved by site

• Cleaning solvent eg isopropyl alcohol

• Plastic card or similar for mixing 2 part epoxy components

14.4.2.213.4.2.2 Hazards

- Epoxy represents a minor hazard needs to be handled with recommended PPE and

following manufacturer’s instructions

- Solvents can be skin irritants. Wear protective gloves in addition to standard PPE

14.4.2.313.4.2.3 Process

1. Clean area to be bonded using scraper and wire brush such that no paint, loose

material or large particles of debris remain. All paint, oils and solvents must be

removed for a good bond.

2. Wipe are down with degreasing/cleaning spirit to remove all traces of oils, grease,

dirt, water etc

3. Wipe mounting puck back surface and edges with cleaning sprit impregnated cloth

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 35 of 46

Page 42

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

Show pictures of unmixed and

mixed epoxy, make note to even

amounts of A and B

Show picture of puck covered

with correct amount of epoxy

Insert picture of sensor held in

place with Denso tape

4. Allow both surfaces to dry such that no cleaning spirit/fluid/residue remains

5. Dispense epoxy onto mixing card and mix thoroughly

6. Apply enough epoxy to mounting puck such that the entire back surface will be

covered to at least 1mm thick

7. Place puck onto casing allowing magnet to hold in position during cure

Figure 13-4 Slurry pump - Mounting pump adhesively bonded to pump

8. Allow 24 hour cure time before installing sensors. Denso tape can be used to help

secure vertically mounted pucks if needed.

14.4.313.4.3 Drilled and tapped mount

This method is most often utilised for bearing assemblies but can also be used on suction

covers and casings made of cast iron. In this case, an official drawing will be provided by the

DCO indicating approved locations and depths of the tapped holes.

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 36 of 46

Page 43

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

14.4.3.113.4.3.1 Equipment and Materials required

• Minimum recommended PPE: eye protection, hard hat, long sleeves and trousers –

do not wear gloves when using rotating

equipment.

• Drill, tap and facing kit HS-AA031 Series is

available from Hansford Sensors. The

product range includes all the necessary tools

needed to accurately mount a vibration sensor

onto the rotating machine. The packaged kit

includes; tapping drill, taps, tap wrench and a

spot facing tool. There are three versions of

the kit available to allow for different mounting

threads; ¼, M6 and M8. See

http://www.hansfordsensors.com/wp-content/uploads/datasheets/TS161U.pdf for

more information.

• Tapping compound/cutting fluid

• Battery drill

14.4.3.213.4.3.2 Hazards

- Swarth associated with drilling can be sharp. Do not brush away with your hands.

- Ensure that any electrical equipment is in good condition and meets site requirements

- Do not wear gloves whilst using rotating machinery

14.4.3.313.4.3.3 Process

1. Clean area to be tapped using scraper and wire brush such that no paint, loose

material or large particles of debris remain

2. Measure and mark locations as per the DCO drawing

3. Drill hole(s) and face mounting location with combined drill and facing tool

4. Tap hole to ¼” UNF using the hand tap. Ensure thread extends to a depth of

10mm

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 37 of 46

Page 44

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

14.513.5 Accelerometer attachment

14.5.113.5.1 Equipment and materials required

• PPE: gloves, eye protection, hard hat, long sleeves and trousers

• Spanner/wrench – 7/16” (ring or open ended)

• 3/16” Allen key

• 2x uni-axial accelerometers (part # 602D02)

• 3x Tri-axial accelerometers (part # 604B32)

• 1x tri-axial mounting block

14.5.213.5.2 Installation

1. Ensure mounting puck or tapped hole and surrounding surface is clean and free of

debris/particles

2. Connect each sensor cable to the allocated sensor making sure to use the correct

cable and observe keyways (cables have stamped metal labels)

3. Wrap connector interface including nut and exposed thread with Nitto No.15 tape, as

shown in Figure 13-5Figure 9-5.

Figure 13-5 Uni-axial accelerometer with connector and protective tape applied

4. Screw Accelerometer thru-bolt or cap screw into mounting puck or prepared threaded

5. Tighten to approximately 3 Nm using 3/16” allen key (tri-axial sensors) or 7/16”

spanner/wrench (uni-axial sensors)

14.5.313.5.3 VT-11

A tri-axial mounting block is used to mount the cutwater vibration sensor at right angles to the

surface. This mounting block is fitted in between the pump and the sensor in order to change

the orientation of the sensor.

1. Mount the tri-block to the pump as shown, using a 3/16” allen key.

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 38 of 46

Page 45

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

Figure 13-6 Tri-Block

14.5.413.5.4 Removal

1. Release cap screw or retaining bolt and remove sensor from mounting point

2. If required to disconnect sensor from cable :

a. Unwrap protective tape

b. Remove connector

c. Install plastic bung/cap on both sensor and cable connectors

14.613.6 Temperature RTD’s

14.6.113.6.1 Equipment and materials required

• Minimum recommended PPE : gloves, eye protection, hard hat, long sleeves and

trousers

• Allen key. 3/16”

• Small Philips screwdriver

• ¼” UNF x 1” long cap screw and washer x qty 4

• RTD leads (part # SD014-3M) x qty 4

Figure (left): RTD ring at end of 3m lead

Figure (right): RTD fastened to magnetic mount

Figure 13-7 RTD

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 39 of 46

Page 46

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

14.6.213.6.2 Hazards

- No task specific hazards of note

14.6.313.6.3 Installation

1. Ensure mounting puck/location surface is clean and free of debris/particles

2. Fasten the RTD’s to the mount locations specified in section x.x

3. Screw cap-screw into mounting puck

4. Tighten to approximately 3 Nm using 3/16” allen key

14.6.413.6.4 Removal

1. Release cap screw and remove sensor from mounting point

2. Install screw back into mounting hole to prevent slurry/crud from entering thread

14.713.7 Gland Water Flow Meter and Pressure Transducer

14.7.113.7.1 Equipment and materials required

• Minimum recommended PPE : gloves, eye protection, hard hat, long sleeves and

trousers

• Spanner/wrench to suit pipe fittings

• 1 ¼” open end spanner/wrench (for Pressure transducer)

• 1x Flow Meter (part # xxxxxxx)

• 1x Pressure Tranducer (part # xxxxxxxx)

• Protective tape – Nitto Self-fusing Butyl Rubber Tape – No.15

• Plumbers thread tape

14.7.213.7.2 Possible Hazards

- Water within the gland supply system may be at elevated pressure, enough to cause

eye damage if accidentally directed into the eye

- Gland water supply is not likely potable water hence should not be ingested or

allowed to come into contact with the face

14.7.313.7.3 Installation

1. Ensure the gland supply is depressurised and the pump is not running

2. The pressure transducer and flow meter must be installed in series with the gland

water supply

3. Fittings to install the pressure and flow sensors are site specific and not supplied.

These should have been identified in the site survey and purchased ahead of

time. This will include a suitable T fitting for the pressure sensor.

4. The suggested installation location is after an isolation valve (shown in image

below).

5. Connect pressure and flow sensors to main cable harness.

6. Wrap connector interfaces with protective tape (Nitto No.15).

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 40 of 46

Page 47

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

Replace image with new hardware

Figure 13-8 Gland water sensor installation

14.813.8 Speed – Proximity sensor

14.8.113.8.1 Equipment and materials required

• Spanner/wrench – as required for particular mounting bracket and bearing assembly

• Fasteners

• 1x Speed Sensor (Part # 872C-N8NP12-04)

• Mounting bracket (dwg xxxxx)

• Target bracket (dwg xxxxxx

• Protective tape – Nitto Self-fusing Butyl Rubber Tape – No.15

• Gap measurement tool

• Speed sensor integrity check tool

14.8.213.8.2 Hazards

- The Pump Shaft speed sensor is mounted off the motor end of the bearing assembly.

- To install the speed sensor the motor must be turned off and tagged out for safety

- There may also be pinch or crush hazards when/if the shaft is rotated during the

alignment process

Figure 13-9 Speed sensor mount example (new picture required)

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 41 of 46

Page 48

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

14.8.313.8.3 Installation

1. Clean shaft and bearing housing mount points of all slurry/debris

2. Loosely mount the target on the shaft.

3. Mount the sensor bracket onto the bearing assembly

4. Loosely secure the speed sensor into the sensor bracket

5. Align the speed sensor and the shaft target bracket so that the speed sensor is

directly above the target

6. Tighten both the target collar to the shaft and the lateral adjustment of the speed

sensor

7. Adjust the vertical motion of the speed sensor so that the gap is no more than 2mm

and tighten

8. Rotate the shaft to the edge of target and measure the gap. Ensure it is no more than

1mm and that it is not touching the corner.

9. Connect the speed sensor to the test box. Rock the shaft back and forth, ensuring

that the indicator LED on the test box illuminates each time the target passes under

the sensor

10. Remove the test box from the sensor and connect the regular cable

11. Wrap connector interface with protective tape (Nitto No.15)

1514 Cleaning and Maintenance

The enclosure of the system is able to withstand slurry. This slurry should be removed

periodically with the use of water and a stiff brush. The use of pressurized water can also used to

clean the system.

There are no user serviceable parts inside the system. Technical support issues with this system

are available at:

Attn: Richard Smith

Sanmina

Unit 3, Cherrywood, Chineham, Basingstoke, UK RG24 8WF

United Kingdom

Telephone: +44 1256 637371

1615 Regulatory Compliance

The Weir Industrial Gateway system comprising of the PSM, MPM, and RSP are designed

and tested to comply with/meet the following standards:

16.115.1 Electromagnetic Compatability

o FCC Part 15 Subject B class A

o CISPR 22 Class A, EN55022 Level B

o ICES-003 Class A

o AS/NZS CISPR 32:2013

Copyright © Weir Minerals Australia Ltd 2017. Commercial in Confidence. All rights reserved. Page 42 of 46

Page 49

The Weir Group PLC Weir Industrial Gateway setup guide rev 0.5

Note: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired operation.

These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own expense.

This Class A digital apparatus complies with Canadian ICES-003.