Page 1

®

TM

Indirect-Fired Water Heaters

Product Manual

®

• Installation

• Startup

• Maintenance

• Parts

User — Read important user safety information found on page 3, page 24 and page 25. Installation and service should

only be performed by a qualified service technician. Retain this manual for future reference.

This manual must only be used by a qualified heating installer/service technician. BEFORE installing, read all instruc-

tions in this manual and all other information shipped with the water heater. Perform steps in the order given. Failure

to comply could result in severe personal injury, death or substantial property damage.

Part number GL-E223-ADOC 0311

Page 2

AQUA PLUS indirect-fired water heaters — Product Manual

Contents

Please read before proceeding 3

When servicing water heater . . . . . . . . . . . . . . . . . . . . 3

Operating restrictions . . . . . . . . . . . . . . . . . . . . . . . . 3

Boiler water restrictions . . . . . . . . . . . . . . . . . . . . . . . 3

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Pre-installation 4

Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Code restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Water heater placement . . . . . . . . . . . . . . . . . . . . . . . 4

Install levelling legs . . . . . . . . . . . . . . . . . . . . . . . . . 4

Domestic water piping requirements. . . . . . . . . . . . . . . . 5

Water heater operating restrictions . . . . . . . . . . . . . . . . . 5

Boiler water restrictions . . . . . . . . . . . . . . . . . . . . . . . 5

Hot Water Can Scald! . . . . . . . . . . . . . . . . . . . . . . . . 5

Domestic water piping 6

Piping overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Recirculation 8

Maintaining domestic water temperature in the supply piping . 8

Time delay at fixtures . . . . . . . . . . . . . . . . . . . . . . . . 8

Balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Components required . . . . . . . . . . . . . . . . . . . . . . . . 8

Connecting to the water heater . . . . . . . . . . . . . . . . . . . 8

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Potential problems . . . . . . . . . . . . . . . . . . . . . . . . . 10

Wiring — zoning with circulators 21

Wiring — zoning with zone valves 22

Water heater filling and start-up 23

Boiler water restrictions . . . . . . . . . . . . . . . . . . . . . . 23

Maximum boiler-side flow rate . . . . . . . . . . . . . . . . . . 23

Filling the domestic water tank . . . . . . . . . . . . . . . . . . 23

Start-up and operation . . . . . . . . . . . . . . . . . . . . . . 23

Start-up checklist . . . . . . . . . . . . . . . . . . . . . . . . . 23

Water heater temperature adjustment 24

Setting the thermostat . . . . . . . . . . . . . . . . . . . . . . . 24

Hot Water Can Scald! . . . . . . . . . . . . . . . . . . . . . . . 24

Water heater maintenance 25

ANNUAL start-up by qualified service technician . . . . . . . 25

Inspect anode and water heater interior . . . . . . . . . . . . . 26

Drain the water heater if necessary during shutdown periods . 26

Troubleshooting 27

Troubleshooting procedures . . . . . . . . . . . . . . . . . . . 27

Preparation for troubleshooting . . . . . . . . . . . . . . . . . 27

Replacement parts 39

AHRI ratings 40

Boiler-side piping 11

Connecting to a low-pressure steam boiler 18

Filling the piping. . . . . . . . . . . . . . . . . . . . . . . . . . 19

Boiler-side wiring and controls 20

Wiring requirements. . . . . . . . . . . . . . . . . . . . . . . . 20

Circulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Zone Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Wiring to the water heater. . . . . . . . . . . . . . . . . . . . . 20

Wiring options . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Use domestic priority . . . . . . . . . . . . . . . . . . . . . . . 20

2

Ratings with 200°F boiler supply water 41

Ratings with 190°F boiler supply water 42

Ratings with 180°F boiler supply water 43

Dimensions 44

Part number GL-E223-ADOC 0311

Page 3

AQUA PLUS indirect-fired water heaters — Product Manual

Please read before proceeding

Hazard definitions

The following defined terms are used throughout this

manual to bring attention to the presence of hazards

of various risk levels or to important information

concerning the life of the product.

Indicates presence of hazards that will

cause severe personal injury, death or

substantial property damage.

Indicates presence of hazards that can

cause severe personal injury, death or

substantial property damage.

Indicates presence of hazards that will

or can cause minor personal injury or

property damage.

Indicates special instructions on installa-

tion, operation or maintenance that are

important but not related to personal

injury or property damage.

This manual provides installation and

operation guidelines for Weil-McLain

AQUA PLUS indirect water heaters.

The installer is responsible for ensuring

that the installation complies with this

manual, the boiler manual and all applicable codes.

Massachusetts installations — The

water heater must be installed by a licensed plumber. The installation must

follow all Massachusetts code requirements. The domestic water piping must

comply with the piping shown in this

manual. See “Domestic water piping,”

page 6, for details and code requirements.

Failure to adhere to the guidelines on this page can

result in severe personal injury, death or substantial

property damage.

Read all instructions before installing. Failure to follow all instructions in proper order can cause severe personal injury, death or

substantial property damage.

When servicing water heater

• To avoid electric shock, disconnect electrical supply before

performing maintenance.

• To avoid severe burns, allow water heater to cool before performing maintenance.

Operating restrictions

• Maximum domestic hot water temperature: residential sizes

— 160°F, commercial sizes — 180°F. Pay attention to the

water temperature warnings throughout this manual.

• Maximum boiler water temperature — 200°F.

• Maximum working pressure for tank — 150 PSIG.

• Water chemistry limits:

• hardness — less than 6 grains/gal.

• pH — above 6 and less than 8.

• chlorides — less than 200 ppm.

Boiler water restrictions

• Thoroughly flush the boiler system (without water heater

connected) to remove sediment.

• The water heater heat exchanger can be damaged by build-up

or corrosion due to sediment.

• Boiler water (including additives) must be practically nontoxic, having toxicity rating or class of 1, as listed in Clinical

Toxicology of Commercial Products.

• If antifreeze is used in boiler system:

• Local codes may require a backflow preventer on cold

water supply line.

• Use antifreeze specifically intended for hydronic heating

systems. Inhibited propylene glycol is recommended.

• Follow boiler manual instructions for antifreeze usage.

• Do not use automotive, ethylene glycol or petroleum-

based antifreeze. Do not use any undiluted antifreeze.

When calling or writing about the water

heater — Please have the water heater serial number from the serial number label,

located on the back side of the water

heater, adjacent to the rating plate.

Any claims for damage or shortage in

shipment must be filed immediately

against the transportation company by

the consignee.

Part number GL-E223-ADOC 0311

Location

• This water heater is not intended for outdoor installation.

• Install the water heater so if the tank or any connections

should leak, the water flow will not cause damage to area

near water heater, or to lower floors of structure. When such

locations cannot be avoided, install a suitable drain pan under

water heater. Drain pans are available at your local plumbing

supply store.

• This product is designed for vertical installation only.

3

Page 4

AQUA PLUS indirect-fired water heaters — Product Manual

Pre-installation

Codes

1. Installation must conform with instructions in this

manual and, where applicable:

• local, state, provincial, and national codes, laws,

regulations and ordinances.

• in Canada — B149.1 or B149.2 Installation

Code.

2. AQUA PLUS water heaters are exempt from ASME

Section VIII, Division 1 Code construction per Interpretation VIII-1-86-136. Check with local codes

for applicability.

3. Where recommendations in this manual differ from

local or national codes, local or national codes take

precedence.

Code restrictions

National Standard Plumbing Code

1. Single-wall heat exchanger in water heater complies

with National Standard Plumbing Code, provided

that:

a. boiler water (including additives) is practically

non-toxic, having toxicity rating or class of 1,

as listed in Clinical Toxicology of Commercial

Products, and

b. boiler water pressure is limited to maximum 30

PSIG by approved relief valve.

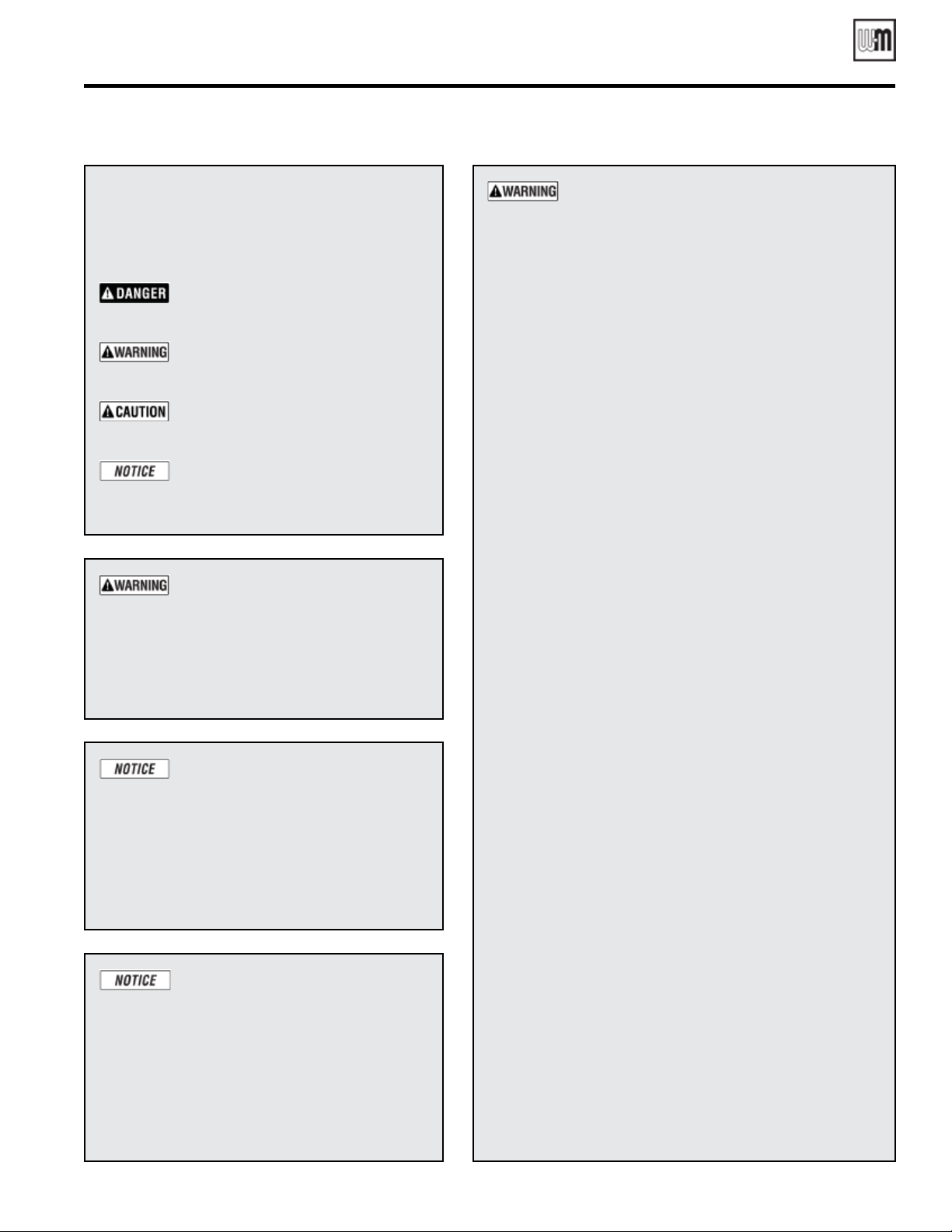

Figure 1 Clearance recommendations

Recommended clearances

Installation location must provide adequate clearances for servicing and

proper operation of the water heater. See Figure 1.

• 1” clearance is permissible to either side of water heater, but the Instruction label or other labels may be hidden.

• Top (vertical) clearance is 12” minimum.

• Refer to boiler manual for boiler clearances.

Uniform Plumbing Code

1. Single-wall heat exchangers are permitted if they

satisfy all of the following requirements —

a. The heat transfer medium is potable water or

contains only substances which are recognized

as safe by the U. S. Food and Drug Administration.

b. The pressure of the heat transfer medium is

maintained less than the normal minimum op-

erating pressure of the potable water system.

c. Exception: Steam complying with #a, above.

d. The equipment is permanently labeled to

indicate that only additives recognized as safe

by the FDA shall be used in the heat transfer

medium.

2. Other heat exchanger designs may be permitted

where approved by the Administrative Authority.

Clearance to combustible materials

1. Provide at least ½” clearance between all hot water pipes and combustible materials.

Water heater placement

1. Read and comply with “Location,” page 3 of this manual.

2. Select a convenient location for the water heater, based on domestic

and boiler piping hook-ups.

3. Keeping the distance between boiler and water heater short will:

• reduce piping heat loss.

• provide minimum friction loss.

Install levelling legs

1. Carefully tip the water heater onto its side.

2. Screw the four levelling legs into the base.

3. Return the water heater to the upright position and set in place.

4. Adjust the legs as necessary to level the water heater.

4

Part number GL-E223-ADOC 0311

Page 5

AQUA PLUS indirect-fired water heaters — Product Manual

Pre-installation

(continued)

Domestic water piping requirements

1. Install unions on all piping for easy removal of water heater.

2. Use

3.

4. If the water heater will replace a tankless coil in the boiler, discon-

dielectric unions or couplings to protect hot and cold water

fittings from corrosion when connecting dissimilar materials such

as copper and galvanized iron pipe.

When the supply pressure is higher than 70 PSIG, install a

pressure reducing valve on cold water supply line to prevent water

loss through T&P relief valve. A thermal expansion tank is also

required.

nect piping to coil or remove coil from boiler and replace with

a cover plate. Allow water to drain from coil. Do not plug the

tankless coil.

Plugging tankless coil inlet and outlet will result in severe

personal injury, death or substantial property damage.

Studies have indicated that dangerous bacteria,

including

the potable water distribution system if certain

minimum water temperatures are not maintained.

Contact your local health department for more

information.

legionella pneumophila, can form in

Hot Water Can Scald!

• Water heated to temperature for clothes washing,

dish washing and other sanitizing needs can scald

and cause permanent injury.

Water heater operating restrictions

1. Read the operating limits under “Operating restrictions,” page 3.

Magnesium anode — The water heater is equipped with

a magnesium sacrificial anode. The anode may erode over

time, and should be inspected at least once annually, only

by a qualified service technician. For installations with

a likelihood of poor water conditions, the anode should

be inspected at least every six months. Failure to comply

could result in loss of protection by the anode, causing

possible severe personal injury, death or substantial

property damage due to water heater leakage.

The domestic water chloride concentration must not ex-

ceed 200 ppm. High chloride concentrations can rapidly

disintegrate the water heater’s protective anode.

Boiler water restrictions

1. Read the WARNINGS under “Boiler water restrictions,” page 3.

• Children, elderly, and infirm or physically handicapped persons are more likely to be permanently

injured by hot water. Never leave them unattended

in bathtub or shower. Never allow small children to

use a hot water tap or draw their own bath.

• If anyone using hot water in the building fits

the above description, or if state laws or local

codes require certain water temperatures at

hot water taps, you must take special precautions:

• Use lowest possible temperature setting.

• Install some type of tempering device, such

as an automatic mixing valve, at hot water

tap or water heater. Automatic mixing valve

must be selected and installed according

to valve manufacturer’s recommendations

and instructions.

• Water passing out of drain valves may be extremely

hot. To avoid injury:

• Make sure all connections are tight.

• Direct water flow away from any person.

Protection must be taken against excessive temperature and pressure! — Installation of a temperature & pressure (T&P) relief valve (provided

with water heater) and a thermostatic mixing valve

(provided by installer) is required.

Part number GL-E223-ADOC 0311

5

Page 6

AQUA PLUS indirect-fired water heaters — Product Manual

Domestic water piping

Piping overview

THERMAL EXPANSION TANK — If a

backflow preventer, check valve, or pressure reducing valve is piped on cold water

inlet of water heater, you must install an

expansion tank on cold water supply line

to prevent normal thermal expansion

from repeatedly forcing open T&P relief

valve.

The T&P relief valve is not intended for

constant duty, such as relief of pressure

due to repeated normal system expansion. Refer to expansion tank manufacturer’s instructions for proper sizing.

Failure to comply could result in severe

personal injur y, death or substantial

property damage.

General applications

1. Figure 2 — This piping configuration can be used in

most cases, except where local codes require special

components or piping not illustrated.

2. Some codes may require the items listed as optional,

such as a vacuum breaker on the inlet line, or recirculation piping.

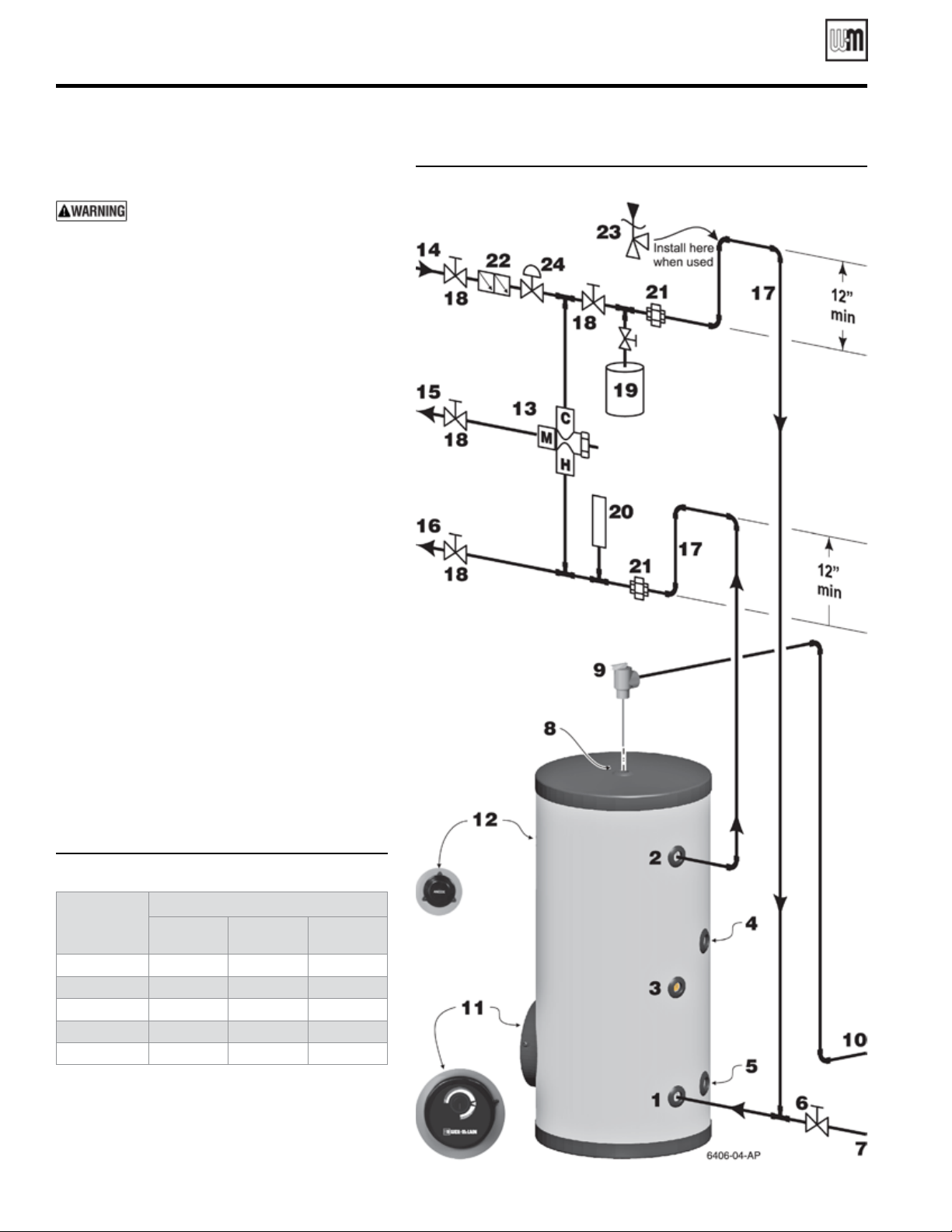

Figure 2 DHW piping

Massachusetts applications

1. For Massachusetts code applications, or as

required elsewhere by local codes, install the following options.

a. Thermal siphon on DHW inlet and outlet.

b. Vacuum breaker on domestic water inlet line.

c. Recirculation — Massachusetts code applica-

tions require recirculation piping or heat-traced

piping if the distance from the water heater to

the furthest fixture exceeds 100 feet. See page 8

for details.

Figure 3 Piping connection sizes

Model

AQUA PLUS

35

45

55

85

105

Connections

DHW

in/out

¾ 1 ¾

¾ 1 ¾

¾ 1 ¾

1 1 ¾

1 1 ¾

(inches NPT)

Boiler water

in/out

Recirculation

tapping

6

Part number GL-E223-ADOC 0311

Page 7

AQUA PLUS indirect-fired water heaters — Product Manual

Domestic water piping

(continued)

LEGEND for Figure 2, page 6

Domestic water supplied to fixtures that could pose

an injury hazard due to high temperature, such as

showers and faucets, should be equipped with a

temperature regulating device, such as an anti-scald

mixing valve

.

When the supply pressure is higher than 70 PSIG,

install a

pressure reducing valve on cold water

supply line to prevent water loss through T&P relief

valve. A thermal expansion tank is also required.

This symbol, where used in this manual, indicates the

item is required by Massachusetts code.

This symbol indicates the item is optional, unless

required by applicable codes.

1

Domestic cold water inlet connection — see Figure3,page6 for size

2 Domestic hot water outlet connection — see Fig-

ure3,page6 for size

3 Domest ic recirculation connec tion — see Fig-

ure3,page6 for size

4 Boiler water inlet to coil — see Figure3,page6 for size

5 Boiler water outlet from coil — see Figure3,page6 for

size

6 Drain valve — provided by installer

• Install a drain valve on the DHW inlet to the water heater

as shown.

7

Piping from drain valve

• Pipe from drain to floor drain, if available.

8

T&P valve connection

9 T&P relief valve — supplied with water heater

• Use only the T&P valve supplied with the water heater.

See Replacement parts for part number.

• Install the T&P relief valve in the top center tapping, as

shown.

10

T&P relief valve discharge piping —

• must be made of material serviceable for temperatures

of 250°F or greater.

• must be directed so that hot water flows away from all

persons.

• must be directed to a suitable place for disposal.

• must be installed so as to allow complete draining of the

T&P relief valve and discharge line.

• must NOT be excessively long — using more than 2 elbows or 15 feet of piping can reduce discharge capacity.

• must NOT be directly connected to a drain — terminate

discharge piping within 6” from floor — refer to local

codes.

• must NOT be plugged, reduced or restricted.

• must NOT be subjected to freezing.

Do not install any valve between T&P relief valve and

tank connection, or on T&P relief valve discharge

piping. Do not plug T&P relief valve or its discharge

piping. Improper placement and piping of T&P relief valve can cause severe personal injury, death or

substantial property damage.

Temperature adjustment knob

11

12Anode access

• The anode is specially made for this water heater. Use

only the anode available from Weil-McLain, as listed in

Replacement parts.

Mixing valve — — RECOMMENDED

13

• See Replacement parts for thermostatic mixing valves

available from Weil-McLain.

Domestic cold water supply

14

When the water supply pressure is higher than

70 PSIG, install a pressure-reducing valve on the

cold water supply line to prevent leakage from the

T & P relief valve. A thermal expansion tank is also

required.

Domestic mixed-temperature water supply to

15

system

(when used — requires mixing valve)

16Domestic high-temperature hot water supply to

system

17Heat trap loops (12” minimum) —

18Isolation valves

19Thermal expansion tank —

• REQUIRED if cold water line is equipped with a backflow

preventer or pressure reducing valve — see EXPANSION

TANK WARNING

Shock arrester —

20

on page 6.

Dishwashers, clothes washers, and fast-closing positive

shutoff valves incorporated in the system all contribute to creating water shock. Install a water hammer

arrester to prevent damage to pipes and appliances.

See control manufacturer’s instructions for application and installation.

Unions

21

• Use dielectric unions or couplings to protect hot and cold

water fittings from corrosion when connecting dissimilar

materials such as copper and galvanized iron pipe.

Backflow preventer — — — (required

22

for Commonwealth of Massachusetts)

23Vacuum breaker —

24Pressure reducing valve —

• REQUIRED when the supply pressure is higher than

70 PSIG — A thermal expansion tank is also required.

Part number GL-E223-ADOC 0311

7

Page 8

AQUA PLUS indirect-fired water heaters — Product Manual

Recirculation

Massachusetts code applications require recircu-

lation piping or heat-traced piping if the distance

from the water heater to the furthest fixture exceeds

100 feet.

Maintaining domestic water

temperature in the supply piping

1. Recirculation is used to reduce wait time for water use, to

minimize hot water and energy waste caused during the

waiting period, and to prevent degradation of the system

supply water temperature. ASPE recommends recirculation

when the distance from the water heater to the furthest fixture exceeds 100 feet or the time lag for hot water to reach a

fixture(s) exceeds 30 seconds.

2. Consult local codes and American Society of Plumbing

Engineers (ASPE) Domestic Water Heating Design Manual,

1998, for further information.

Time delay at fixtures

1. Figure 4, page 9 is from the ASPE Domestic Water Heating

Design Manual, 1998. It shows the time required for usable

hot water to arrive at a fixture based on the fixture flow rate

(available from industry and manufacturer’s data) and the

length and diameter of the dead-end branch pipe supplying

the fixture.

2. These branches must be balanced to prevent pipe erosion

and unacceptable time delays at some fixtures.

3. Balancing options include circuit setters, memory stop valves

or factory preset devices (with flow metering provision in

the piping).

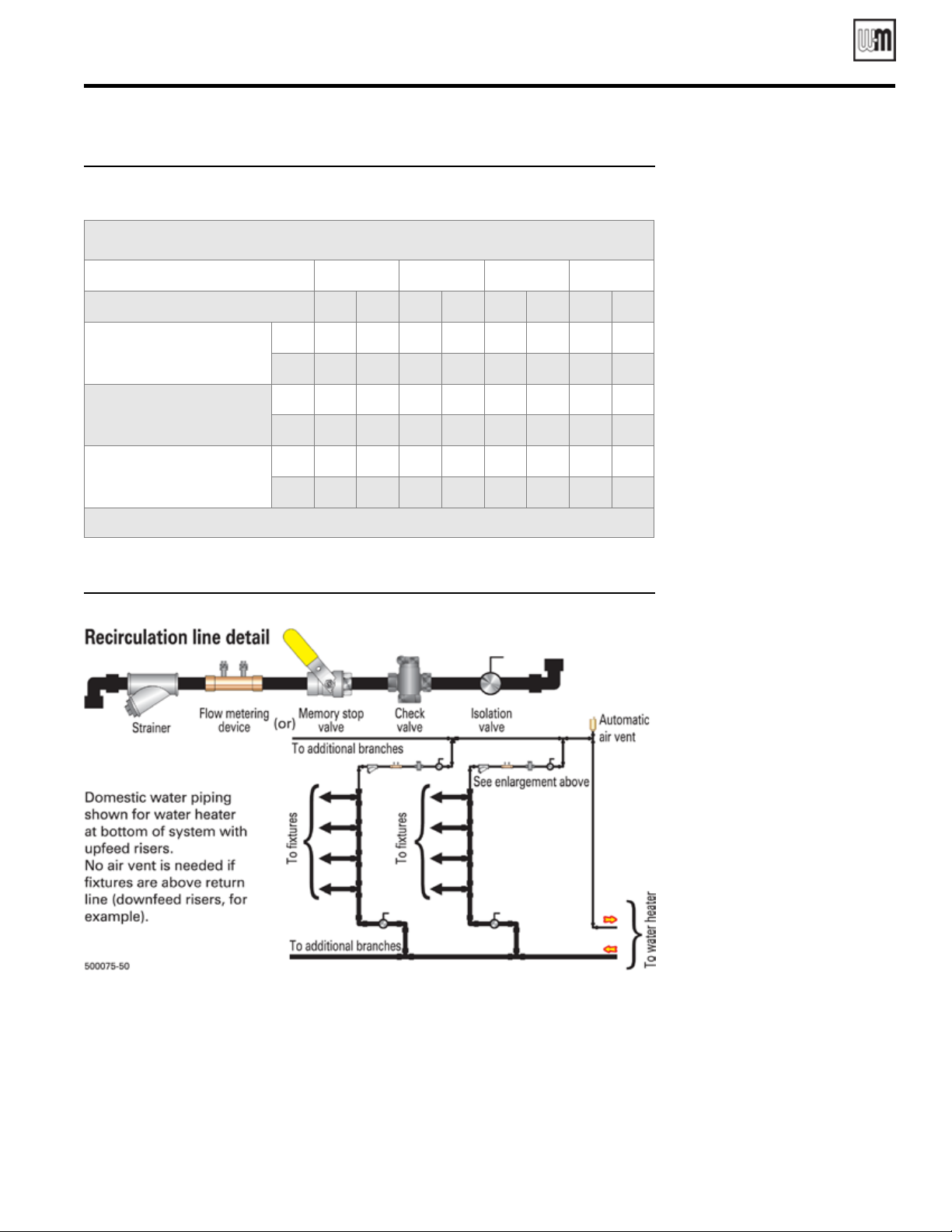

Components required

1. For residential applications, consult circulator manufacturer’s

data for circulator selection and additional components

required.

2. On most commercial systems, install the devices shown in

Figure 5, page 9, and any other devices or piping methods

required by local codes.

a. The check valves are required to prevent fixtures from

taking hot water through the return lines.

b. Shutoff valves are needed to allow cleaning and replacing

balancing devices.

c. Include strainers to remove sediment which could

damage the circulator and / or affect the flow balancing

devices.

3. Size the circulator and piping based on the temperature drop

allowed between the water available at the water heater and

the water delivered at the fixture.

2. The time lag should generally not exceed 30 seconds.

3. For residential and office applications, the owner may prefer

a limit of 10 seconds.

4. You can use Figure 4 as a guide to determining the location

of circulation return lines relative to fixtures.

Balancing

1. When multiple branches are connected to the supply piping, each branch must be connected to the recirculation

system.

a. At each of these connections to the return piping, install

shutoff valves, a flow metering device, check valve and a

strainer as shown in Figure 5, page 9.

b. Check local codes for specific installation require-

ments.

a. The return piping will almost always be smaller than the

supply piping, but should never be smaller than ½” to

prevent problems with the circulator.

4. Make provision for removal of air in all return lines. Where

the returns cannot be vented by topmost fixtures in the

system, install automatic air venting at the top of the return

piping.

Connecting to the water heater

1. Install the domestic water components as shown in Figure 2, page 6.

2. See Figure 6, page 10 for the piping required to the water

heater.

— Continued on page 10 —

8

Part number GL-E223-ADOC 0311

Page 9

AQUA PLUS indirect-fired water heaters — Product Manual

Recirculation

Figure 4 Time lag to obtain hot water at fixture for branch lengths of 10 and 25 feet

(ASPE Domestic Water Heating Design Manual)

Time in seconds required to get hot water at fixture (from ASPE)

Fixture flow rate (GPM) - 0.5 1.5 2.5 4.0

Piping length (feet) - 10 25 10 25 10 25 10 25

Copper pipe ½” 25 63 8 21 5 13 3 8

Steel pipe ½” 63 157 21 52 13 31 8 20

CPVC pipe ½” 64 159 21 53 13 62 8 20

NOTE: Select branch size and length for less than 31 seconds delay.

(continued)

¾” 48 119 16 40 10 24 6 15

¾” 91 228 30 76 18 46 11 28

¾” 95 238 32 79 19 48 12 30

Figure 5 Recirculation components

Part number GL-E223-ADOC 0311

9

Page 10

AQUA PLUS indirect-fired water heaters — Product Manual

Recirculation

(continued)

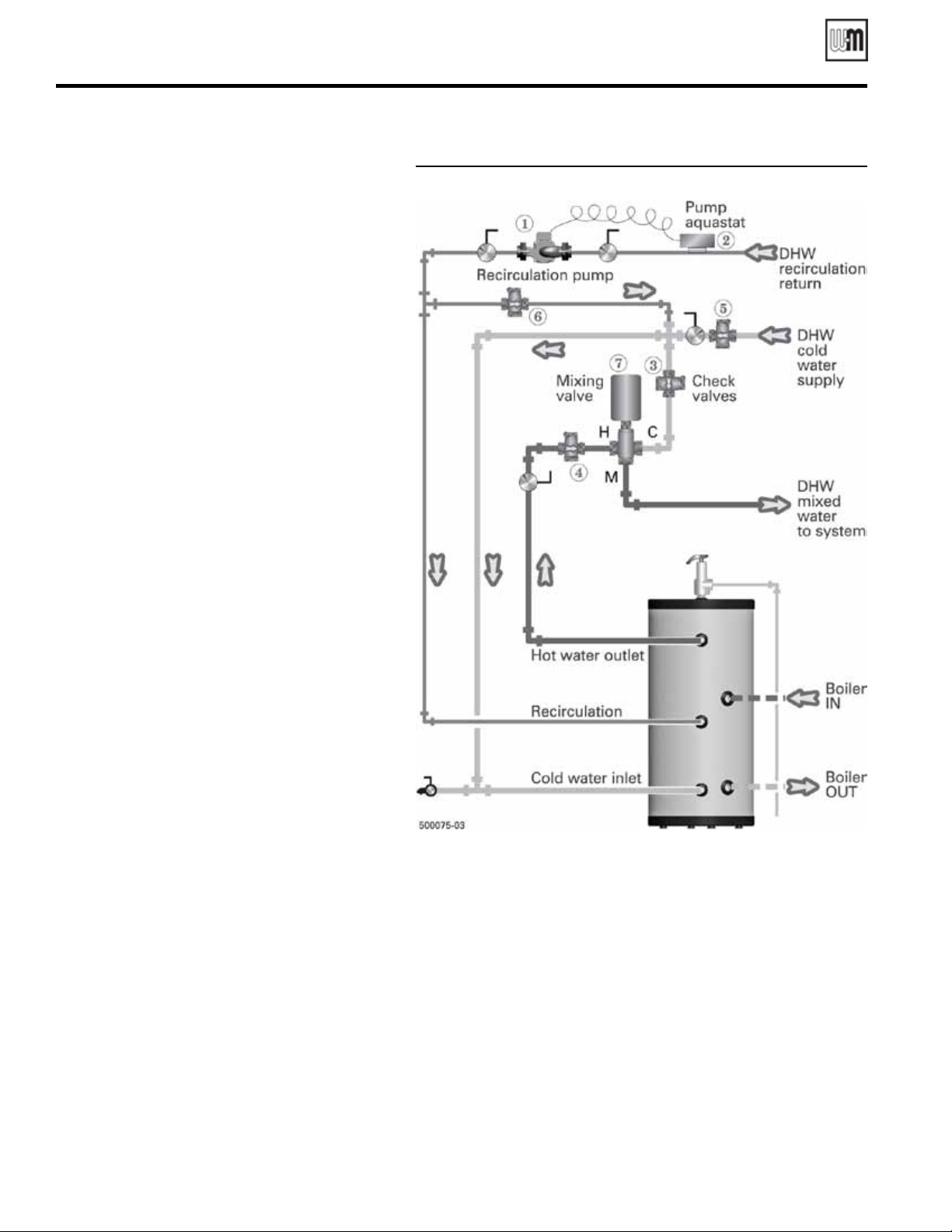

Components

Circulator (Figure 6, item 1)

1. Little flow is required to maintain a temperature

in the piping.

2. Size of circulator depends on minimum flow requirements of the tempering valve.

3. Minimum flow rates of the tempering valve must

be maintained.

Aquastat (Figure 6, item 2)

1. Used to control the on-off position of the circulator. Aquastat is set 5° to 10° lower than mixed water

outlet of the mixing valve (#7).

2. The circulator cannot run continuously as bypass

through the mixing valve will eventually allow the

temperature on the piping to climb to the water

heater temperature during draw periods.

Figure 6 Recirculation piping

Check valves (Figure 6, items 3–6)

1. Assure the flow of water in one direction.

2. Each check valve functions as follows:

a. #3 and #4 prevent bypass in the event of pres-

sure drop.

b. #5 prevents thermal siphoning of hot water to

the cold water supply.

c. #6 prevents flow of cold water to the tempered

water supply. A draw of tempered water will

not result in flow of cold water into the return

loop.

Operation

1. During period of normal use (fixtures on) — Circulator is off. There is no flow through #6, there is

flow through #5 equal to the flow at the fixtures,

there is flow through #3 and/or #4 equal to flow

at fixture.

2. When all fixtures are off — Circulator is off. There is

no flow through #3, #4, #5 or #6. Water temperature

in piping is cooling.

3. When temperature at aquastat #2 falls 10° below

temperature to be maintained — Circulator is on.

There is flow through #6 equal to the minimum

required by the mixing valve, flow through #3 and

#4 equals the flow of the circulator. There is no

flow through #5.

4. Aquastat reaches temperature — Circulator is off.

There is no flow through #3, #4, #5 or #6.

Potential problems

1. Missing check valves #3 or #4 — Extreme pressure drop can cause

reverse flow of water; hot to cold supply or cold to hot supply.

2. Missing check valve #5 — Hot water can migrate from the water heater

back through the cold water supply.

3. Missing check valve #6 — Cold water can be forced back through the

tempered water supply when a fixture is opened.

4. No aquastat #2 — Circulator runs continuously. Small amount of

water will pass through mixing valve. Eventually all hot water is flowing through valve. Recirculated water through cold port, hot water

through hot port.

5. Circulator too small — Mixing valve performance erratic.

10

Part number GL-E223-ADOC 0311

Page 11

AQUA PLUS indirect-fired water heaters — Product Manual

Boiler-side piping

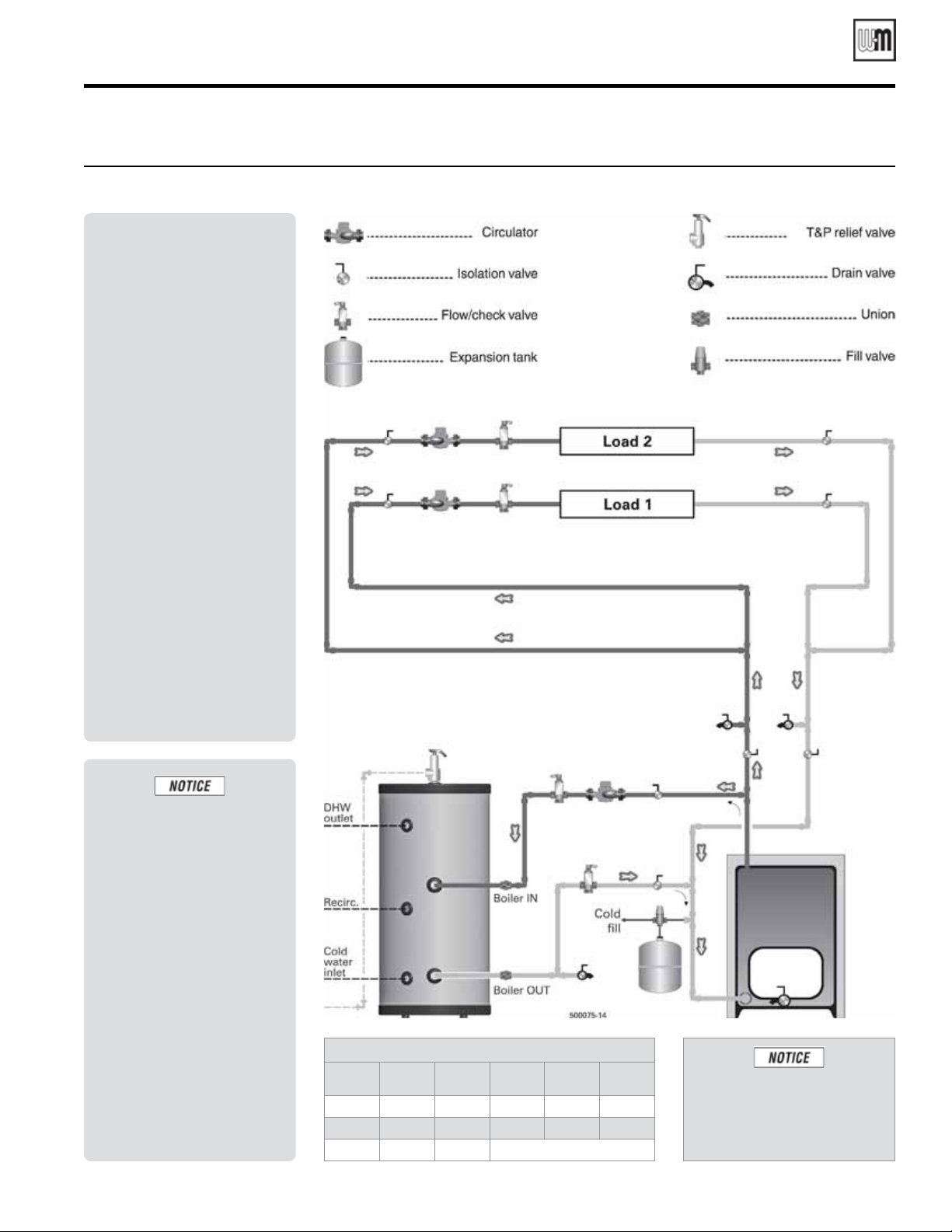

Figure 7 Zoning with circulators — direct-connected system piping

Notes

• Place circulators at beginnings of zones. Placing

them at the ends of zones

could result in heating idle

zones.

• Size manifold piping for

total flow of all zone circulators.

• Locate flow / check valves

as close as possible to water

heater boiler side connections — to reduce heat loss

between cycles.

Wiring

• WMCR zone controller,

optional priority — Figure 18, page 21.

1. This drawing is conceptual

only. It shows representative piping components

and layout. Weil-McLain

does not represent that this

drawing meets any particular mechanical or building codes. The installer is

responsible for inclusion

of all required safety devices, or other miscellaneous piping hardware not

shown on drawing. The

installer is responsible for

proper sizing / selection of

all hardware shown on this

diagram.

2. See boiler manual for specific details on installing

the boiler.

Recommended flow rate and minimum boiler-side pipe size

Heater

model

35

45

55

GPM

Pipe

size

8 1”

8 1”

8 1”

Heater

model

85

105

Requires 1¼”x1” reducers at water heater

GPM

14 1¼” *

14 1¼” *

Pipe

size

GV90+ or Ultra gas boilers:

DO NOT apply the drawings in

this manual. Refer only to the

boiler manual.

Part number GL-E223-ADOC 0311

11

Page 12

AQUA PLUS indirect-fired water heaters — Product Manual

Boiler-side piping

(continued)

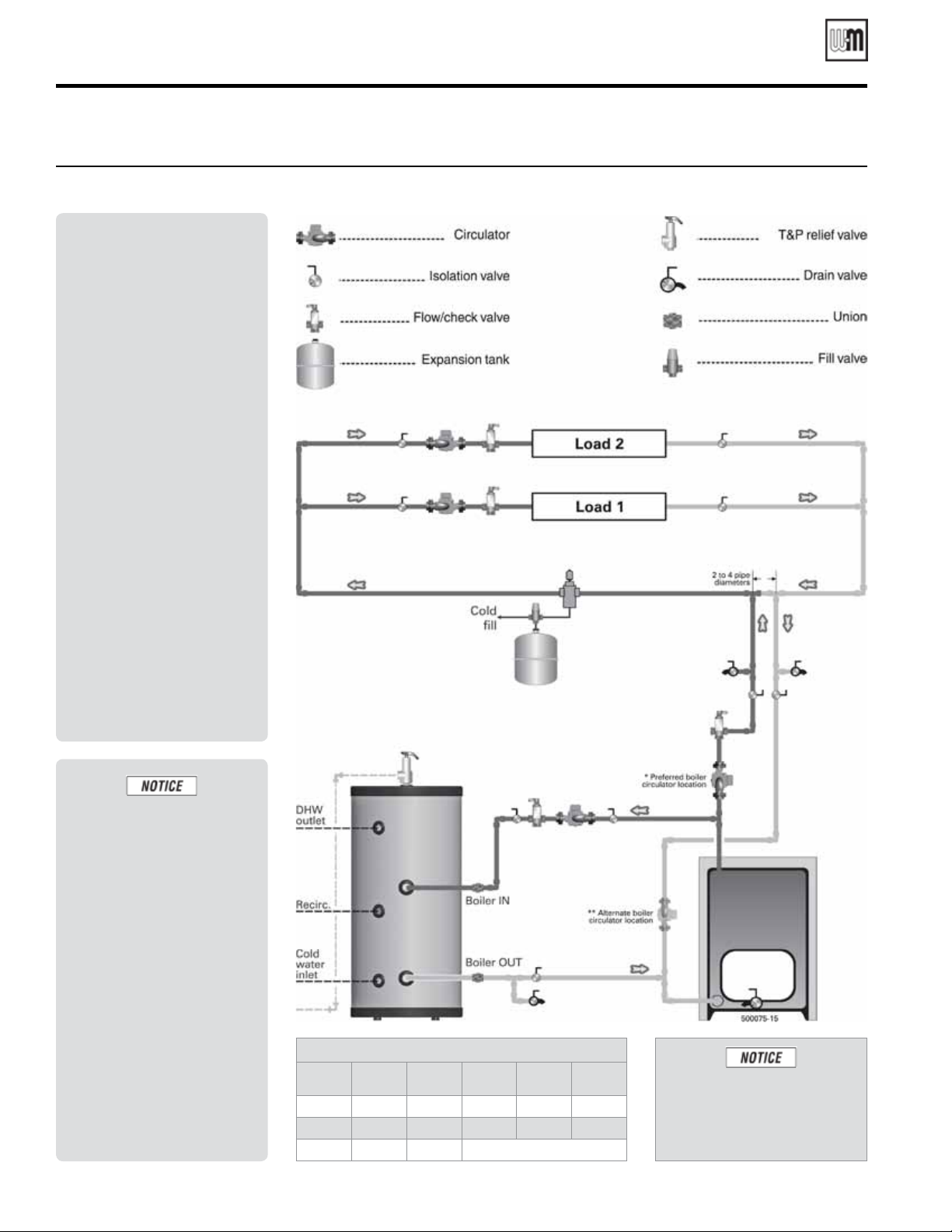

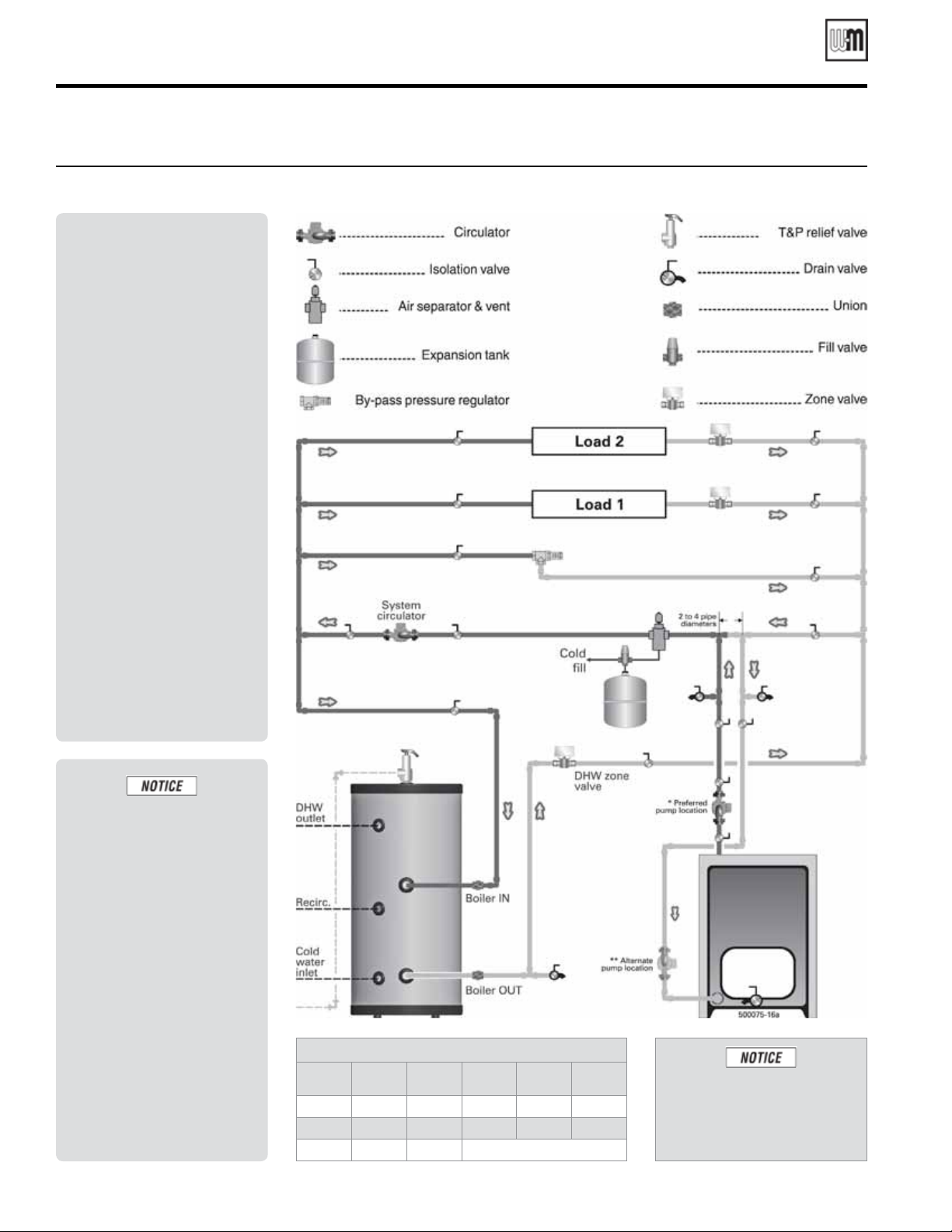

Figure 8 Zoning with circulators — primary/secondary system piping

Notes

• Place circulators at beginnings of zones. Placing

them at the ends of zones

could result in heating idle

zones.

• Size manifold piping for

total flow of all zone circulators.

• Locate flow / check valves

as close as possible to water

heater boiler side connections — to reduce heat loss

between cycles.

Wiring

• WMCR zone controller,

optional priority — Figure 18, page 21.

1. This drawing is conceptual

only. It shows representative piping components

and layout. Weil-McLain

does not represent that this

drawing meets any particular mechanical or building codes. The installer is

responsible for inclusion

of all required safety devices, or other miscellaneous piping hardware not

shown on drawing. The

installer is responsible for

proper sizing / selection of

all hardware shown on this

diagram.

2. See boiler manual for specific details on installing

the boiler.

12

Recommended flow rate and minimum boiler-side pipe size

Heater

model

35

45

55

GPM

Pipe

size

8 1”

8 1”

8 1”

Heater

model

85

105

Requires 1¼”x1” reducers at water heater

GPM

14 1¼” *

14 1¼” *

Pipe

size

GV90+ or Ultra gas boilers:

DO NOT apply the drawings in

this manual. Refer only to the

boiler manual.

Part number GL-E223-ADOC 0311

Page 13

AQUA PLUS indirect-fired water heaters — Product Manual

Boiler-side piping

(continued)

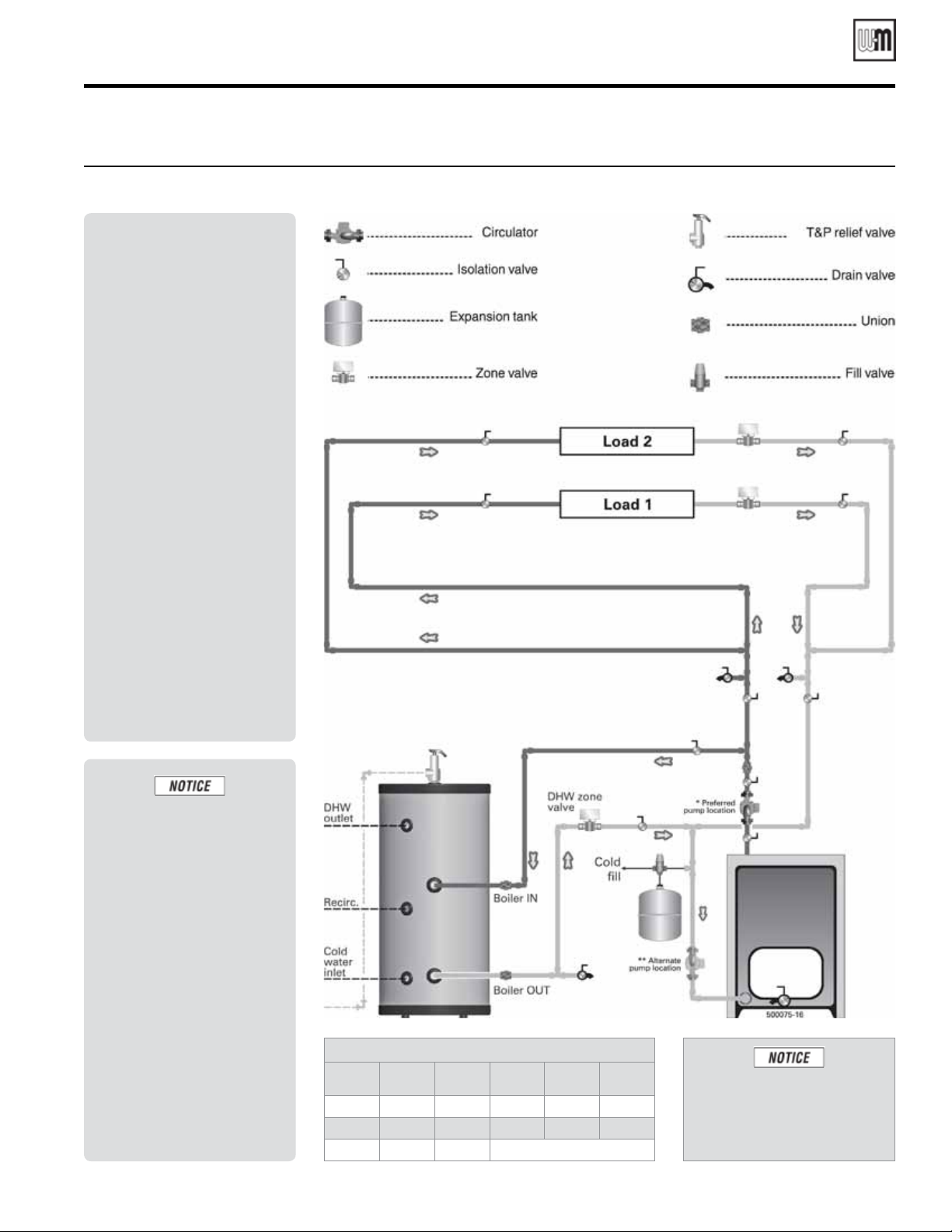

Figure 9 Zoning with zone valves — direct-connected system piping

Notes

• Place circulators at beginnings of zones. Placing

them at the ends of zones

could result in heating idle

zones.

• Size manifold piping for

total flow of all zone circulators.

• Locate flow / check valves

as close as possible to water

heater boiler side connections — to reduce heat loss

between cycles.

Wiring

• WMZV zone controller,

optional priority — Figure 19, page 22.

1. This drawing is conceptual

only. It shows representative piping components

and layout. Weil-McLain

does not represent that this

drawing meets any particular mechanical or building codes. The installer is

responsible for inclusion

of all required safety devices, or other miscellaneous piping hardware not

shown on drawing. The

installer is responsible for

proper sizing / selection of

all hardware shown on this

diagram.

2. See boiler manual for specific details on installing

the boiler.

Part number GL-E223-ADOC 0311

Recommended flow rate and minimum boiler-side pipe size

Heater

model

35

45

55

GPM

Pipe

size

8 1”

8 1”

8 1”

Heater

model

85

105

Requires 1¼”x1” reducers at water heater

GPM

14 1¼” *

14 1¼” *

Pipe

size

GV90+ or Ultra gas boilers:

DO NOT apply the drawings in

this manual. Refer only to the

boiler manual.

13

Page 14

AQUA PLUS indirect-fired water heaters — Product Manual

Boiler-side piping

(continued)

Figure 10 Zoning with zone valves — primary/secondary system piping

Notes

• Place circulators at beginnings of zones. Placing

them at the ends of zones

could result in heating idle

zones.

• Size primary piping for

total flow of all zone circulators.

• Locate flow / check valves

as close as possible to water

heater boiler side connections — to reduce heat loss

between cycles.

Wiring

• WMZV zone controller,

optional priority — Figure 19, page 22.

1. This drawing is conceptual

only. It shows representative piping components

and layout. Weil-McLain

does not represent that this

drawing meets any particular mechanical or building codes. The installer is

responsible for inclusion

of all required safety devices, or other miscellaneous piping hardware not

shown on drawing. The

installer is responsible for

proper sizing / selection of

all hardware shown on this

diagram.

2. See Boiler Manual for specific details on installing

the boiler.

14

Recommended flow rate and minimum boiler-side pipe size

Heater

model

35

45

55

GPM

Pipe

size

8 1”

8 1”

8 1”

Heater

model

85

105

Requires 1¼”x1” reducers at water heater

GPM

14 1¼” *

14 1¼” *

Pipe

size

GV90+ or Ultra gas boilers:

DO NOT apply the drawings in

this manual. Refer only to the

boiler manual.

Part number GL-E223-ADOC 0311

Page 15

AQUA PLUS indirect-fired water heaters — Product Manual

Boiler-side piping

Figure 11 Dedicated single-boiler piping

Notes

• Place circulators at beginnings of zones. Placing

them at the ends of zones

could result in heating idle

zones.

• Size manifold piping for

total flow of all zone circulators.

• Locate flow / check valves

as close as possible to water

heater boiler side connections — to reduce heat loss

between cycles.

Wiring

• Connect water heater thermostat wires to boiler’s

T-T terminals or heat demand connection.

(continued)

1. This drawing is conceptual

only. It shows representative piping components

and layout. Weil-McLain

does not represent that this

drawing meets any particular mechanical or building codes. The installer is

responsible for inclusion

of all required safety devices, or other miscellaneous piping hardware not

shown on drawing. The

installer is responsible for

proper sizing / selection of

all hardware shown on this

diagram.

2. See boiler manual for specific details on installing

the boiler.

Part number GL-E223-ADOC 0311

Recommended flow rate and minimum boiler-side pipe size

Heater

model

35

45

55

GPM

Pipe

size

8 1”

8 1”

8 1”

Heater

model

85

105

Requires 1¼”x1” reducers at water heater

GPM

14 1¼” *

14 1¼” *

Pipe

size

GV90+ or Ultra gas boilers:

DO NOT apply the drawings in

this manual. Refer only to the

boiler manual.

15

Page 16

AQUA PLUS indirect-fired water heaters — Product Manual

Boiler-side piping

Figure 12 Multiple water heaters — domestic water piping

Failure to install automatic

mixing valve where recommended can result in severe

personal injury or death.

(continued)

1. This drawing is conceptual

only. It shows representative piping components

and layout. Weil-McLain

does not represent that this

drawing meets any particular mechanical or building codes. The installer is

responsible for inclusion

of all required safety devices, or other miscellaneous piping hardware not

shown on drawing. The

installer is responsible for

proper sizing / selection of

all hardware shown on this

diagram.

2. Wire water heater thermostats in series when connecting to boiler controller

or boiler T-T terminals.

3. Install automatic mixing

valve at either the system

hot water connection or

at each water heater.

4. See page 8 through page 10

for additional recirculation information and piping details.

Figure 13 Alternate methods of revers-return piping and Easy-Fit® Manifold detail

16

Part number GL-E223-ADOC 0311

Page 17

AQUA PLUS indirect-fired water heaters — Product Manual

Boiler-side piping

Figure 14 Multiple water heaters and dedicated multiple boilers — boiler water piping

Notes

• See legend and details in

Figure 12, page 16.

(continued)

1. This drawing is conceptual

only. It shows representative piping components

and layout. Weil-McLain

does not represent that this

drawing meets any particular mechanical or building codes. The installer is

responsible for inclusion

of all required safety devices, or other miscellaneous piping hardware not

shown on drawing. The

installer is responsible for

proper sizing / selection of

all hardware shown on this

diagram.

2. See boiler manual for specific details on installing

the boiler.

Part number GL-E223-ADOC 0311

GV90+ or Ultra gas boilers:

DO NOT apply the drawings in this manual. Refer only to the boiler manual.

17

Page 18

AQUA PLUS indirect-fired water heaters — Product Manual

Connecting to a low-pressure steam boiler

Special considerations

When designing steam and domestic hot water systems, there are some

key issues that must be taken into consideration during the initial design phase. By designing the system properly from the start, you can

avoid problems and have a hot water loop in a steam boiler system.

• The domestic water demand should preferably not exceed 1/3

of the steam boiler capacity. Larger demand may cause difficulty

obtaining steam as needed.

• Keep the loop temperature below the flash point. Flashing can result

in noise and circulator damage or shortened life.

• Be sure the loop is completely closed, with no automatic or manual

air vents, or anything that could allow air to enter the system when

the pump shuts off.

• Pipe supply from one side of the boiler, return to the opposite

side as shown.

• Supply from a tapping that is high enough to prevent introducing

sediment into the piping and circulator yet still below the water

line. Avoid the mud leg of the boiler.

• Use an all bronze circulator.

• Avoid wet rotor circulators. Select a circulator with a large

volute, such as a typical 3-piece circulator.

• This will reduce clogging and will resist the corrosion potential

from the steam condensate.

• Make sure the circulator is properly sized. If the circulator runs too

far out on its curve, cavitation potential increases significantly.

• Use (2) flow / check valves as shown to reduce the potential for

gravity circulation.

• DO NOT use spring-loaded check valves in place of the

flow / check valves shown in Figure 16, page 19.

Installation and start-up of water heaters

connected to steam boilers

1. See Figure 16, page 19, for suggested piping schematic.

2. Pipe the domestic water connections to the water heater per “Domestic water piping,” page 6.

Boiler connections for the water heater must be below

the water line. DO NOT use the gauge glass tapping or a

low water cut-off tapping if a LWCO is installed there.

For steam piping, refer to the steam boiler manual.

DO NOT install an air vent anywhere in the piping. The

piping must be air tight.

3. Wire the water heater and circulator to the boiler per suggested

wiring in Figure 15. The water heater must be wired and ready to

operate before proceeding. Note that the L4006A aquastat is located

in the boiler and sets a boiler operating temperature when there is

no call for steam heating.

To fill the boiler and water heater:

1. Follow the procedure given in Figure 16, page 19 to fill the water

heater piping.

2. Follow the boiler manual instructions to fill the steam boiler.

Figure 15 Typical wiring for connection to low-

pressure steam boiler

Install the Honeywell L4006A aquastat in the boiler, below the water line. Set for a temperature of 180 to 190°F

to control boiler temperature when there is no call for

steam heating.

Valve 7, the memory stop valve, must

be supplied, piped and adjusted as instructed. This valve allows cooler return

water to mix with the hot water from

the steam boiler. The valve is set to yield

approximately 180°F water entering the

circulator. Higher temperature water

could cause cavitation in the circulator,

damaging the impeller and shortening

circulator life.

DO NOT connect the piping to the boil-

er’s mud leg. This would probably cause

excessive sediment to enter the water

heater piping, damaging the circulator.

The strainer in the circulator suction line

must be serviced regularly. NOTE that

noise from the circulator is a likely sign

that the strainer is restricting circulator

flow, causing cavitation.

18

Part number GL-E223-ADOC 0311

Page 19

AQUA PLUS indirect-fired water heaters — Product Manual

Connecting to a low-pressure steam boiler

(continued)

Figure 16 Low pressure steam boiler application — Domestic water heating using water pumped from steam boiler

Notes

• Locate flow / check valve as

close as possible to water

heater boiler side connections — to reduce heat loss

between cycles.

Use memory stop valve 7 to

blend some of the water returning to the boiler with the

hot water coming from the

boiler. This will reduce the

possibility of flashing (cavitation) in the circulator. Slowly

open valve 7 until temperature

gauge 8 reads 200°F.

Set the memory stop on valve 7

after adjusting. Attach a tag to

the valve warning no to close

or change valve position.

NOTE —

level should drop below either the water heater boiler

water supply or return line,

the filling procedure will

have to be repeated.

1. This drawing is conceptual

2. See boiler manual for spe-

If the boiler water

only. It shows representative piping components

and layout. Weil-McLain

does not represent that this

drawing meets any particular mechanical or building codes. The installer is

responsible for inclusion

of all required safety devices, or other miscellaneous piping hardware not

shown on drawing. The

installer is responsible for

proper sizing / selection of

all hardware shown on this

diagram.

cific details on installing

the boiler.

Filling the piping

1. Parts of the boiler water piping to the

water heater may be higher than the water line, depending on the height of the

water heater boiler supply connection.

The piping must be air tight to prevent air

from pocketing at the top of the piping,

stopping flow.

2. The boiler MUST be filled and ready to

operate before proceeding. Follow the

boiler manual to fill the boiler.

3. Follow the procedure below to fill the

boiler-to-water heater piping. See Figure 16.

Step 1 Close isolation valves 5 and 6 to isolate

the boiler.

Step 2 Close valve 3 and open valve 4. Con-

nect a cold water supply hose to

valve 3. Connect a hose from valve 4

to a drainable location.

Step 3 Close valve 10. Open valve 7.

Step 4 Open valve 3. Water will flow through

valve 7 and out through valve 4 to

drain. Let water run until all air has

been removed from the line. Close

valve 4. Then close valve 3.

Step 5 Close valve 7. Then open valve 10.

Step 6 Open valve 3. Water will flow through

the circulator line, the water heater

coil and the return piping, then out

through valve 4 to drain. Let water run

until all air has been removed from the

line. Close valve 4. Then close valve 3.

Remove hoses.

Step 7 Follow the instructions in “Water

heater filling and start-up,” page 23,

to fill the domestic water side of the

water heater.

Step 8 Open valve 7 about ¼ turn for an

initial setting.

Step 9 Open isolation valves 5and 6. Make

sure the boiler water level is correct

per the boiler manual.

Step 10 Start the boiler per instructions given

in the boiler manual. Allow boiler to

begin steaming.

Step 11 Start the DHW circulator. Watch the

temperature at gauge 8. Adjust valve 7

until gauge 8 reads about 180°F with

system at steady operation.

Step 12 Continue checking under var ying

DHW demand conditions to ensure

system will operate as required.

Part number GL-E223-ADOC 0311

19

Page 20

AQUA PLUS indirect-fired water heaters — Product Manual

Boiler-side wiring and controls

Electrical shock hazard — Can cause severe personal

injury, death or substantial property damage. Disconnect

power before installing and / or servicing.

Wiring requirements

1. All wiring must be a minimum of 18 gauge and installed in accordance

with:

• U.S.A. — National Electrical Code and any other national, state or

local code requirements having jurisdiction.

• Canada — CSA C22.1 Canadian Electrical Code Part 1 and any

other national, provincial and local code requirements having

jurisdiction.

2. If original wire as supplied with appliance must be replaced, Type 90°

C or its equivalent must be used.

3. Refer to control component instructions packed with boiler for application information.

4. An optional service switch may be installed in water heater electrical circuit. This switch would only shut off the water heater, not the

home heating system. Do not shut off water heater if there is a chance

of freezing.

5. All electrical contacts are shown with no power applied — off-theshelf condition.

Use domestic priority

1. When possible, set controls to provide domestic

priority — that is, on a call for domestic water

the control switches from space heating to DHW

only.

2. Domestic priority ensures the fastest possible response to the DHW call for heat.

3. The smaller the water heater, the greater the need

for rapid response.

Figure 17 Inspection hatch assembly (hatch

cover shown transparent)

Circulators

1. Size priority relay for total amp draw of all circulators.

Zone Valves

1. Size transformer for maximum load of all zone valves.

Wiring to the water heater

1. Field connections to the water heater thermostat are for 24 VAC only,

connecting to the two-pole terminal block shown in Figure 17.

Wiring options

1. This manual shows wiring only for use of Weil-McLain WMCR Circulator Zone Controller or Weil-McLain WMZV Zone Valve Zone

Controller.

2. Other wiring methods may be acceptable and are left to the installer.

1 Temperature adjustment knob

2 Inspection plate (handhole)

3 Factory wires from thermostat to field wiring terminal

block

4 Field wiring terminal block

5 M8 hex nut

6 Inspection plate bracket

20

Part number GL-E223-ADOC 0311

Page 21

AQUA PLUS indirect-fired water heaters — Product Manual

Wiring — zoning with circulators

Figure 18 Typical wiring — zoning with circulators — DHW priority with Weil-McLain WMCR Circulator Zone Controller

Notes

• Also refer to the WMCR

manual and Weil-McLain

Boiler Zone Wiring Guide

for further details.

• Refer to Wiring requirements on page 20.

System piping

• Figure 7, page 11

• Figure 8, page 12

1. This drawing is conceptual

only. It shows representative components and wiring. Weil-McLain does not

represent that this drawing

meets any particular mechanical or building codes.

The installer is responsible for inclusion of all

required safety devices, or

other miscellaneous piping hardware not shown

on drawing. The installer

is responsible for proper

si zing / selec t ion of all

hardware shown on this

diagram.

2. Follow component manufacturer’s instructions for

installation of all items

shown.

3. See boiler manual for specific details on installing

the boiler.

GV90+ or Ultra gas boilers:

DO NOT apply the drawings in this manual. Refer only to the boiler manual.

Part number GL-E223-ADOC 0311

21

Page 22

AQUA PLUS indirect-fired water heaters — Product Manual

Wiring — zoning with zone valves

Figure 19 Typical wiring — zoning with zone valves — DHW priority with Weil-McLain WMZV Zone Valve Zone Controller

Notes

• Also refer to the WMZV

manual and Weil-McLain

Boiler Zone Wiring Guide

for further details.

• Refer to Wiring requirements on page 20.

System piping

• Figure 9, page 13

• Figure 10, page 14

Install all zone valves per valve

manufacturer’s instructions.

1. This drawing is conceptual

only. It shows representative components and wiring. Weil-McLain does not

represent that this drawing

meets any particular mechanical or building codes.

The installer is responsible for inclusion of all

required safety devices, or

other miscellaneous piping hardware not shown

on drawing. The installer

is responsible for proper

si zing / selec t ion of all

hardware shown on this

diagram.

2. Follow component manufacturer’s instructions for

installation of all items

shown.

3. See boiler manual for specific details on installing

the boiler.

GV90+ or Ultra gas boilers:

DO NOT apply the drawings in this manual. Refer only to the boiler manual.

22

Part number GL-E223-ADOC 0311

Page 23

AQUA PLUS indirect-fired water heaters — Product Manual

Water heater filling and start-up

The installation and water chemistry must meet the

requirements below. Failure to comply could result in

damage to the water heater, causing possible severe

personal injury, death or substantial property damage.

Boiler water restrictions

• Thoroughly flush the boiler system (without water heater connected) to remove sediment.

• The water heater heat exchanger can be damaged by build-up or

corrosion due to sediment.

• Boiler water (including additives) must be practically non-toxic,

having toxicity rating or class of 1, as listed in Clinical Toxicology

of Commercial Products.

• If antifreeze is used in boiler system:

• Local codes may require a backflow preventer on cold water

supply line.

• Use antifreeze specifically intended for hydronic heating sys-

tems. Inhibited propylene glycol is recommended.

• Follow boiler manual instructions for antifreeze usage.

• Do not use automotive, ethylene glycol or petroleum-based

antifreeze. Do not use any undiluted antifreeze.

Maximum boiler-side flow rate

• Select the boiler-side circulator carefully. The flow rate through the

boiler side of the water heater must not exceed the values below.

Higher flow rates could result in an input above the rating of the

T&P valve.

Models AQUA PLUS-32, 42 and 52 — do not exceed 12 GPM.

•

• Models AQUA PLUS-80 and 105 — do not exceed 16 GPM.

Start-up checklist

Verify that T&P relief valve is properly installed

and piped as directed in this manual and per local

code requirements.

Verify that the DHW tank and boiler-side piping

are complete and are filled with water and pressurized.

Verify that all air has been bled from both domestic

and boiler water systems.

Verify that cold and hot water lines are correctly

connected to domestic water system.

Verify that supply and return piping from boiler is

correctly connected to water heater.

Check all fittings and piping for leaks.

Verify that all wiring is installed correctly.

Set water heater thermostat according to system

requirements. See “Water heater temperature adjustment,” page 24.

Start boiler according to the Boiler Manual.

Verify that the boiler and water heater are operating

correctly, per “Water heater temperature adjustment,” page 24.

Filling the domestic water tank

1. Fill the domestic water tank with fresh water that meets the chemistry

requirements above.

2. Do not exceed a fill pressure of 70 PSIG.

When the water supply pressure is higher than 70 PSIG, make

sure that a pressure-reducing valve is installed on the cold

water supply line to prevent leakage from the T&P relief valve.

A thermal expansion tank is also required.

3. Vent the piping as necessary to remove any trapped air.

Start-up and operation

1. Follow the “Start-up checklist,” page 23 to prepare for start-up.

Part number GL-E223-ADOC 0311

Review the following sections with the homeowner

or system operator:

• Water Heater Start-Up

• Adjusting Water Heater Temperature

• Water Heater Maintenance

23

Page 24

AQUA PLUS indirect-fired water heaters — Product Manual

Water heater temperature adjustment

General notes

• Household water usage patterns will affect water temperature at

any faucet or shower.

• Occasionally check temperature at each point of use, then

adjust thermostat accordingly.

• Always recheck temperature after adjusting thermostat.

• When hot water is used in repeated small quantities, a “stacking”

effect can develop in hot water tank. The upper layer of water in

tank can be much hotter than lower layers.

• Lowering the thermostat setting or installing automatic mixing

valves as indicated in these instructions will reduce water temperature levels. Consult your installer or service technician.

At no time should boiler limit control be set above 200°F.

This can cause severe personal injury, death or substantial

property damage if ignored.

Studies have indicated that dangerous bacteria, includ-

ing legionella pneumophila, can form in the potable

water distribution system if certain minimum water

temperatures are not maintained. Contact your local

health department for more information.

Hot Water Can Scald!

Setting the thermostat

1. The water heater thermostat is factory set to its lowest temperature.

This may or may not be suitable for your needs.

2. Turn thermostat knob

ture.

3. Turn thermostat knob

perature.

4. When decreasing temperature setting, the stored hot water must

be drawn off before checking temperature at faucet.

5. Check water temperature at a hot water faucet immediately after

first heating cycle. Further temperature adjustment may be necessary as water heating system is used. Recheck water temperature

at faucet after adjustment.

6. When adjusting thermostat, be sure boiler limit control is set a

minimum 20°F higher.

Figure 20 Water heater temperature adjustment knob (on

lower front of water heater)

clockwise to increase water tempera-

counter-clockwise to reduce water tem-

• Water heated to temperature for clothes washing,

dish washing and other sanitizing needs can scald

and cause permanent injury.

• Children, elderly, and infirm or physically handicapped persons are more likely to be permanently

injured by hot water. Never leave them unattended

in bathtub or shower. Never allow small children to

use a hot water tap or draw their own bath.

• If anyone using hot water in the building fits

the above description, or if state laws or local

codes require certain water temperatures at

hot water taps, you must take special precautions:

• Use lowest possible temperature setting.

• Install some type of tempering device, such

as an automatic mixing valve, at hot water

tap or water heater. Automatic mixing valve

must be selected and installed according

to valve manufacturer’s recommendations

and instructions.

• Water passing out of drain valves may be extremely

hot. To avoid injury:

• Make sure all connections are tight.

• Direct water flow away from any person.

24

Protection must be taken against excessive temperature and pressure! — Installation of a temperature & pressure (T&P) relief valve (provided

with water heater) and a thermostatic mixing valve

(provided by installer) is required.

Part number GL-E223-ADOC 0311

Page 25

AQUA PLUS indirect-fired water heaters — Product Manual

Water heater maintenance

Boiler water — read and comply with all requirements under

“Boiler water restrictions,” page 3.

Water from opened drain valves, unions and other connec-

tions may be extremely hot. To avoid severe personal injury,

death or substantial property damage:

• Tighten all drain hose connections.

• Direct hot water away from all persons.

ATTENTION USER!

Have the water heater serviced at least once an-

by a qualified service technician.

nually

Follow the

monthly.

Read “Water heater temperature adjustment,” page 24.

Failure to comply with the above can result in severe

personal injury, death or substantial property damage.

maintenance procedures below at least

MONTHLY maintenance by user

• At least MONTHLY, visually check valves, pipes and fittings for

leaks.

• Check hot water supply at several outlets. Make sure water

temperature is not too hot.

• Call qualified service technician to repair leaks or address

problems.

MONTHLY maintenance by user

• At least MONTHLY, visually check valves, pipes and fittings for leaks.

• Check hot water supply at several outlets. Make sure water temperature

is not too hot.

• Call qualified service technician to repair leaks or address problems.

ANNUAL start-up by qualified service

technician

Obtain an Inspection and service kit (see “Replacement parts,”

page 39) before attempting to perform the annual start-up.

This kit contains items that will usually have to be replaced.

Check water supply temperature at several outlets to ensure

the water temperature is acceptable for intended use and

that all temperature control devices are functioning properly.

Read page 3 and verify that all requirements are met by the

installation.

Figure 21 T&P valve operation

Before operating the T&P relief

valve, make sure no one is in front of

or around the T&P relief valve discharge piping. Hot discharge water

can cause severe personal injury or

substantial property damage.

Plugging T&P relief valve or dis-

charge piping can cause excessive

pressure in the water heater, resulting in severe personal injury, death

or substantial property damage.

Perform the following procedures:

Perform any procedures required by local codes.

Verify system pressure both on domestic water and

boiler water sides.

Manually operate T&P relief valve at least once

a year (see Figure 21). This will release some hot

water. Move operating lever to open position for

a few seconds and then move it back, allowing it

to snap closed. After T&P relief valve is operated,

if it continues to release water, close cold water

inlet to water heater immediately. Follow draining

instructions, and replace the T&P relief valve. If

T&P relief valve weeps periodically, it may be due

to thermal expansion. Install an expansion tank if

not already installed.

Follow instructions on circulator to oil it, if oil-

lubricated.

Follow instructions in “Inspect anode and water

heater interior,” page 26.

Check valves, pipes and fittings for leaks.

Check function of all controls and valves (see con-

trol manufacturer’s instructions).

Review homeowner’s maintenance responsibilities

Part number GL-E223-ADOC 0311

25

Page 26

AQUA PLUS indirect-fired water heaters — Product Manual

Water heater maintenance

and their frequencies, including any not listed in the following

paragraphs.

The purpose of the magnesium anode is to reduce

the damaging effects of aggressive water on the water heater. Aggressive water will cause the anode to

erode.

The anode must be inspected at least annually to de-

termine whether a new anode should be installed.

Severe or rapid deterioration of the anode indicates

very aggressive water. If this occurs, have the water

tested to verify whether it is within the limits given

under “Operating restrictions,” page 3.

Failure to inspect the anode regularly and replace if

necessary could result in damage to the water heater,

causing possible severe personal injury, death or

substantial property damage.

(continued)

Figure 22 Inspection hatch assembly (hatch cover

shown transparent)

Inspect anode and water heater interior

1. Close domestic water isolation valves.

2. Drain the water heater completely and allow it to cool off.

3. Remove the inspection hatch cover (Figure 24, page 39, item 8).

a. The temperature control bulb will have to be pulled out of the

immersion well, located in the inspection plate.

4. After the water heater has drained and cooled, remove the inspection plate (Figure 22, page 26, item 2).

There will be some water remaining in the bottom of the

water heater. This can be siphoned off or removed with

a wet/dry vacuum.

a. Partially unscrew the M8 hex nut (Figure 22, page 26, item 5)

while holding the bracket (Figure 22, page 26, item 6). DO

NOT completely remove the nut.

b. Hold and turn the bracket 90 degrees, being careful not to drop

the inspection plate inside the tank.

c. Remove the inspection plate.

5. Use a work light or flash light to inspect the interior of the tank.

6. Use a plastic scraper if needed to remove any accumulation on the

coil. DO NOT use abrasives or metallic objects.

7. Remove as much sediment as possible through the inspection

opening.

8. Rinse the bottom and remove remainder with a wet/dry shop

vacuum.

9. Remove the magnesium anode cover and anode (Figure 24, page 39,

items 10 and 1).

10. Inspect the anode and replace if needed with part list in (Figure 24, page 39). See WARNING above.

1 Temperature adjustment knob

2 Inspection plate (handhole)

3 Factory wires from thermostat to field wiring terminal block

4 Field wiring terminal block

5 M8 hex nut

6 Inspection plate bracket

11. Replace the inspection plate gasket if necessary. Then

re-install the inspection plate. Align the gasket carefully.

DO NOT over-tighten the bolt. This could damage or

extrude the gasket, or distort the plate.

12. Re-install the access cover hatch and tighten the four M8

Phillips-head screws. Do not over-tighten the screws.

13. Refill the water heater and restore to operation.

14. Verify operation of boiler and water heater.

Drain the water heater if

necessary during shutdown

periods

1. Drain the water heater if it will be shut off and exposed

to freezing temperatures. Freezing water will expand

and may damage water heater.

a. If boiler water contains sufficient antifreeze, then

only the domestic water needs to be drained.

b. If boiler water does not contain sufficient antifreeze,

then the boiler water and the domestic water must

be drained.

26

Part number GL-E223-ADOC 0311

Page 27

AQUA PLUS indirect-fired water heaters — Product Manual

Troubleshooting

Troubleshooting procedures

Follow the troubleshooting guidelines step by step. Always double-check your results.

Skipping or not completing steps can lead to wrong conclusions, repeated callbacks to the

jobsite and unhappy customers.

Preparation for troubleshooting

Tools needed

Electrical meter to measure voltage and continuity.

Pressure gauge (such as Watts #276H300 test gauge).

Temperature gauge.

Stopwatch.

Bucket —

1 gallon or larger, with volume markings.

Suggested parts to have on hand.

Tank thermostat (Aquastat) — see Replacement parts for part number.

Inspection and service kit — see Replacement parts for part number.

Information needed before the service call

Know the water heater model number.

Know the boiler manufacturer and model number.

Have the boiler manual and wiring and piping schematics readily available.

Get the latest revisions from www.Weil-McLain.com.

Review all manuals before leaving for the jobsite.

Part number GL-E223-ADOC 0311

27

Page 28

AQUA PLUS indirect-fired water heaters — Product Manual

Troubleshooting

Figure 23 Typical problems and causes and page location for details

Problem Check possible causes Page

Insufficient

hot water

Excessive

domestic water

temperature

Boiler relief valve

lifting or weeping

(continued)

1 Undersized water heater?

2 Boiler system improperly sized?

3 Check component parts.

4 Check boiler operating tempera-

tures.

1 Reduce stacking

• Lower boiler operating temperature.

1 Undersized expansion tank?

2 Faulty boiler expansion tank?

3 Faulty boiler relief valve?

5 Check location of flow control

devices.

6 Check for air in the system.

7 Clean the boiler water system.

8 Check tank thermostat setting.

2 Install a thermostatic mixing valve.

3 Install a recirculation loop.

4 Faulty boiler fill valve?

29

32

33

Temperature/

pressure relief

valve lifting

or weeping

Water on the

floor near the

tank

Top of tank or

insulation wet

Water quality

problems

1 Undersized or missing domestic

water side expansion tank?

2 Faulty domestic water side expan-

sion tank?

3 Faulty T & P relief valve?

1 Check for leaks from sources other

than the water heater.

1 Check for leaks from sources other

than the water heater.

1 Water smells like “rotten eggs.”

2 Milky water.

4 High domestic water supply pres-

sure?

5 Possible water hammering or pres-

sure spikes?

6 Check boiler operating tempera-

ture.

2 T & P relief valve lifting and dis-

charging?

3 Loose piping connections?

2 Loose piping connections?

3 Discolored water from the hot

water faucet.

34

35

35

37

28

Part number GL-E223-ADOC 0311

Page 29

AQUA PLUS indirect-fired water heaters — Product Manual

Troubleshooting

(continued)

1 Undersized water heater?

• There are many methods of sizing various applications, i.e. ASHRAE sizing tables or ASPE domestic water

heating design manual.

• Confirm the water demand required for the application.

• Confirm the flow rates of the fixtures.

• For example, was the tank sized for shower heads at 2.0 gpm, while the actual heads are 5.0 gpm?

• Use a bucket and a stopwatch to determine fixture flow rates.

• Evaluate the hot water usage pattern for a day.

• Is the peak demand unusually high for the application?

• Has the demand for domestic hot water changed since the system was installed?

• A bathroom remodeling project with a newly installed whirlpool tub will substantially change the

domestic water demand.

Insufficient hot water

2 Boiler system improperly sized?

• Can the boiler provide the required output to meet the domestic water load? Determine the boiler domestic

water capacity, GPH, by the following:

Boiler DHW capacity, GPH =

[Temp. rise °F = Required DHW temp. °F – Incoming temp. °F]

[8.33 = Density of water (lbs/gal) x 1 Btu / lb-°F]

• Example — A single family home with a 3.0 GPM shower fixture and a 150,000 Btuh output boiler capacity.

• The shower demand of 3.0 GPM equals 180 GPH (60 times the GPM).

• Is the boiler capacity enough to deliver this hot water flow at 115°F for an extended period? Determine

the boiler capacity:

Boiler DHW capacity, GPH =

(115°F – 50°F) x 8.33

• The boiler is capable of delivering 277 GPH (or 4.6 GPM) continuously, which is enough for this

application.

• Measure the BTU input to the boiler by clocking the gas meter or finding the oil flow rate based on nozzle

size and pump pressure.

• Does the hot water system need to be wired for domestic priority? For systems in which either the storage or

BTU’s available are marginal it is recommended to wire the domestic water heater in a priority manner.

• Is the boiler piping to the water heater properly sized to allow the required flow rate for maximum BTU

transfer? The temperature differential of the boiler supply and return water should be 20°F to 30°F.

Boiler output Btuh

Temp. rise °F x 8.33

150,000 Btuh

= 277 GPH

Part number GL-E223-ADOC 0311

29

Page 30

AQUA PLUS indirect-fired water heaters — Product Manual

Troubleshooting

(continued)

Insufficient hot water (continued)

• Is the circulator between the boiler and the water heater properly sized to provide enough flow for maximum BTU transfer? Check the table below:

Pipe size Flow, GPM MBH Pipe size Flow, GPM MBH

¾” 1 to 4 50 to 100 1 ½” 14 to 22 200 to 450

1” 4 to 8 100 to 180 2” 22 to 45 300 to 650

1 ¼” 8 to 14 160 to 300

3 Check component parts.

• Is the domestic water thermostat functioning properly?

• Check the water heater thermostat (requires an electrical meter).

1. Disconnect the field wiring to the water heater thermostat terminals.

2. Turn the thermostat knob to the highest setting — clockwise — to initiate a call for heat.

3. Check for continuity across the water heater thermostat terminals. On a call for heat, these contacts

should closed.

4. Continue checking for continuity while turning the thermostat knob to the lowest setting — counter

clockwise — to satisfy the call for heat. The contacts should open, breaking the continuity.

5. If any of these steps fail, replace the thermostat.

• Is the thermostat setting too low?

• If the thermostat setting is too low, the boiler may not have the opportunity to deliver the maximum

BTU’s required to completely heat the entire volume of water stored in the tank.

• During a call for heat by the water heater, does the boiler circulator begin pumping, does the zone valve open,

does the boiler fire? Check every component in the system to ensure they are properly functioning.

30

Part number GL-E223-ADOC 0311

Page 31

AQUA PLUS indirect-fired water heaters — Product Manual

Troubleshooting

(continued)

Insufficient hot water (continued)

4 Check boiler operating temperatures.

• If possible, increase the boiler operating temperature to 180°F or 200°F.

• Maintain a minimal temperature in the boiler during non-heating seasons.

• A boiler typically has a higher standby loss than the indirect water heater.

• After a long standby period, the colder boiler may absorb the stored energy within the water heater

during the initial call for heat.

5 Check location of flow control devices.

• Lab tests have shown that during long standby periods the boiler piping can act as a thermal siphon and

draw stored heat from the domestic water.

• Locate flow control devices (zone valve, spring check valves...) or heat trap loops in the boiler piping

close to the water heater.

• Insulate all boiler piping to and from the water heater.

6 Check for air in the system; check water heater air vent.

• An air-bound water heater or boiler will not circulate system water properly, resulting in a lack of heat

transfer.

7 Clean the boiler water system.

• A dirty boiler system can cause deposits to form on the water heater coil. This insulates the coil, reducing

the heat transfer.

• Clean the boiler system per the boiler manufacturer’s instructions.

• Install a strainer in the boiler piping on older installations or for systems likely to carry sediment.

Part number GL-E223-ADOC 0311

31

Page 32

AQUA PLUS indirect-fired water heaters — Product Manual

Troubleshooting

(continued)

Excessive domestic water temperature

1 Reduce stacking.

• Excessive water temperature is usually the result of stacking within the water heater.

• Stacking is the occurrence of various water temperatures layering within the water heater with the

hottest water in the uppermost layer.

• This layering or stacking effect typically occurs during small draws of hot water (typically less than

25% of the storage capacity) that are long enough to create a call for heat on the thermostat, but are

short enough not to deplete the stored energy within the tank.

• Excessive stacking can occur when frequent short-to-moderate draws are taken in quick succession.

• During this condition, the temperature of the domestic water can approach the temperature of the

boiler water.

• REMEMBER — All water heaters (direct or indirect) will stack.

• To reduce stacking within the tank:

• Reduce the boiler operating temperature to 160°F - 170°F. This will limit the maximum domestic

outlet water temperature during high stacking water usage.

2 Install a thermostatic mixing valve.

• Installing a thermostatic mixing valve will provide uniform delivery temperature with minimal regard

to water usage.