Page 1

88

Water & Steam Boilers – Series 2

For Gas, Light Oil, & Gas/Light Oil – Fired Burners

Burner Specification

& Data Sheet

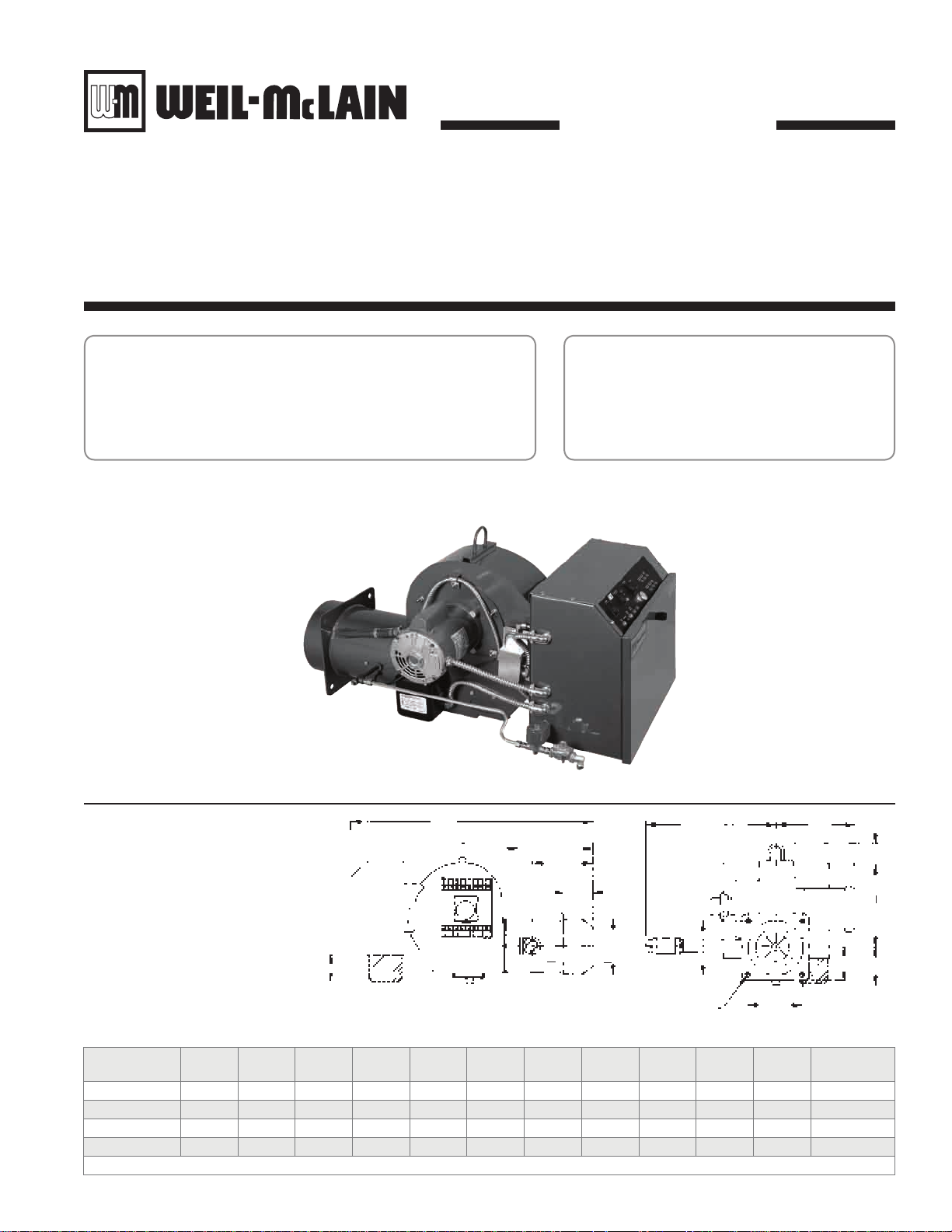

Model WCR Figure 1

A

Power Flame

Gas/Oil Burners

Model WCR

F

S

I

E

C

L

3.13

G

C

L

H

4.00

5/8 Dia., 4 holes

Note : Add .38 to “H” dim for size of opening in boiler front plate.

Burner

Model Number

WCR1 34.13 5.56 14.50 4.63 12.25 20.00 3.25 7.25 7.38 12.63 7.25 175-200

WCR2 39.13 6.13 14.00 5.25 14.00 20.00 4.00 8.75 8.50 13.38 8.50 220-300

WCR3 44.00 7.00 15.25 6.00 16.00 22.38 5.00 10.13 11.50 15.50 10.00 360-400

WCR4 50.00 7.31 17.69 7.00 18.50 28.00 6.00 12.13 14.25 19.13 12.00 500-550

A B(R) C(R) D E F* G H I S X

* Required for installation of standard control components

X

X

Part No. 550-142-029/0508

C(R)

C

L

B(R)

D

Approximate

Weight

Page 2

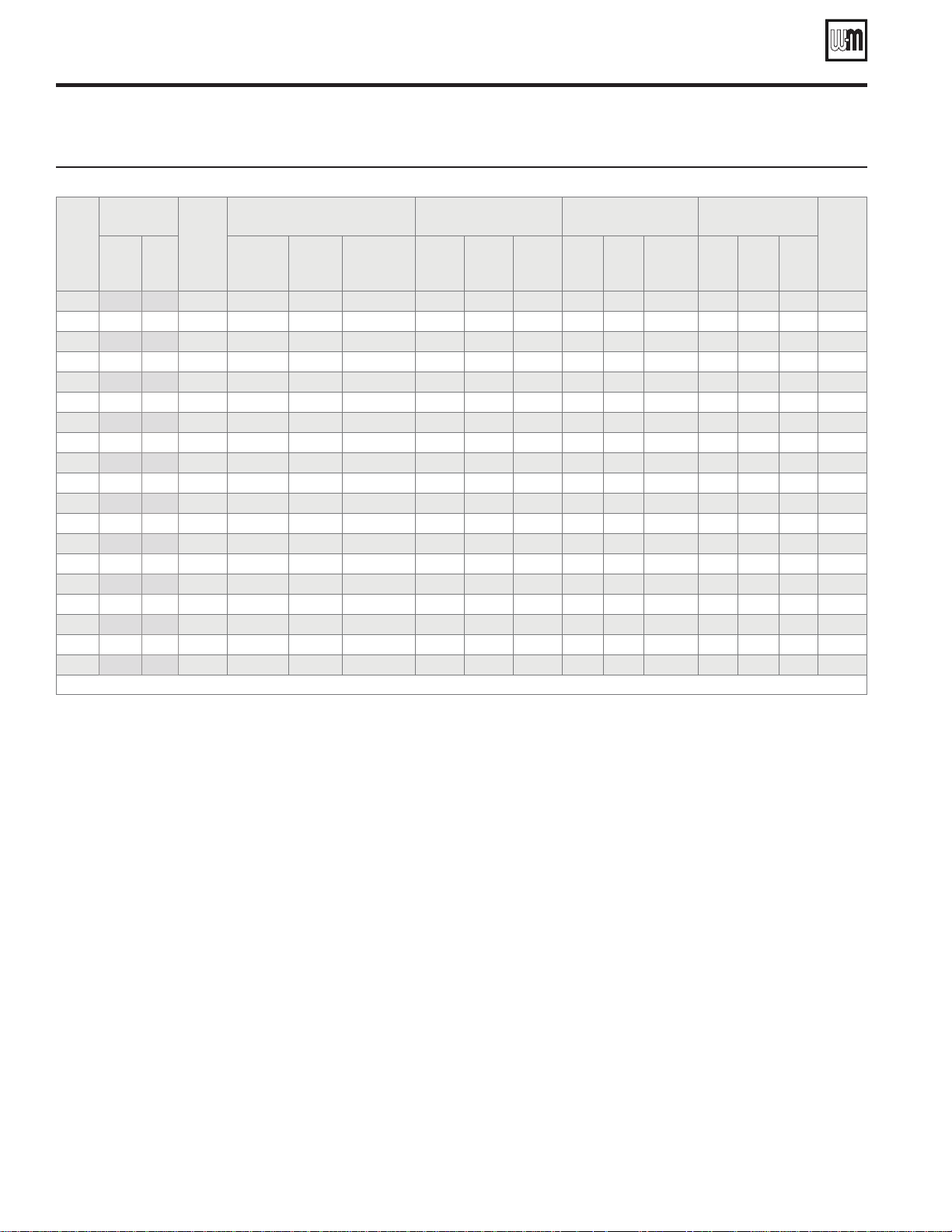

Weil-McLain 88 Water and Steam Boilers — Series 2 — For Gas, Light Oil, & Gas/Light Oil-Fired Burners

Burner specifications and settings

Burner dataTable 1

Boiler

Model

Number

488R

488

588

688

788

888

988R

988

1088R

1088

1188

1288

1388

1488

1588

1688R

1688

1788

1888

Burner Input

No. 2 Oil

Gph

6.9 996

7.0 1,010

9.4 1,356

11.8 1,701

14.2 2,046

16.6 2,382

17.2 2,482

18.8 2,737

20.0 2,887

21.5 3,082

23.5 3,428

26.0 3,773

28.5 4,119

31.0 4,464

33.0 4,809

34.5 4,979

35.5 5,155

38.0 5,494

40.5 5,845

Positive

Pressure

In Firebox

Gas

In. W.C.

Mbh

0.80 WCR1-G-12 WCR1-OS WCR1-GO-12 RM7897A R7184P RM7897C OO FALFS OO/FALFS

0.80 WCR1-G-12 WCR1-OS WCR1-GO-12 RM7897A R7184P RM7897C OO FALFS OO/FALFS

0.58 WCR1-G-12 WCR1-OS WCR1-GO-12 RM7897A R7184P RM7897C OO FALFS OO/FALFS

0.46 WCR2-G-15 WCR2-OAS WCR2-GO-15 RM7897A R7184P RM7897C LHO LHO LHO/LHO

0.47 WCR2-G-15 WCR2-OAS WCR2-GO-15 RM7897A R7184P RM7897C LHO LHO LHO/LHO

0.49 WCR2-G-20A WCR2-OBS WCR2-GO-20A RM7897A R7184P RM7897C LHO LHO LHO/LHO

0.50 WCR2-G-20B WCR2-OBS WCR2-GO-20B RM7897A R7184P RM7897C LHO LHO LHO/LHO 1 1 1 240/60/1

0.50 WCR2-G-20B WCR2-OBS WCR2-GO-20B RM7897C R7184P RM7897C LHO LHO LHO/LHO 1 1Z\x 1Z\x 240/60/1

0.52 WCR2-G-20B WCR2-OBS WCR2-GO-20B RM7897C RM7897A RM7897C LHO LHO LHO/LHO 1 1Z\x 1Z\x 240/60/1

0.73 WCR3-G-20 WCR3-O WCR3-GO-20 RM7897C RM7897A RM7897C LHO LHO LHO/LHO 1Z\x 2 2 240/60/1

0.53 WCR3-G-20 WCR3-O WCR3-GO-20 RM7897C RM7897A RM7897C LHO LHO LHO/LHO 1Z\x 2 2 3-Phase*

0.48 WCR3-G-20 WCR3-O WCR3-GO-20 RM7897C RM7897A RM7897C LHO LHO LHO/LHO 1Z\x 2 2 3-Phase*

0.56 WCR3-G-25 WCR3-O WCR3-GO-25 RM7897C RM7840L RM7840L LHO LHO LHO/LHO 1Z\x 2 2 3-Phase*

0.58 WCR3-G-25B WCR3-OB WCR3-GO-25B RM7840L RM7840L RM7840L LHO LHO LHO/LHO 3 3 3 3-Phase*

0.59 WCR3-G-25B WCR3-OB WCR3-GO-25B RM7840L RM7840L RM7840L LHO LHO LHO/LHO 3 3 3 3-Phase*

0.80 WCR3-G-25B WCR3-OB WCR3-GO-25B RM7840L RM7840L RM7840L LHO LHO LHO/LHO 3 3 3 3-Phase*

0.80 WCR3-G-25B WCR3-OB WCR3-GO-25B RM7840L RM7840L RM7840L LHO LHO LHO/LHO 3 3 3 3-Phase*

0.62 WCR4-G-25 WCR4-OA WCR4-GO-25 RM7840L RM7840L RM7840L LHO LHO LHO/LHO 3 5 5 3-Phase*

0.69 WCR4-G-25 WCR4-OA WCR4-GO-25 RM7840L RM7840L RM7840L LHO LHO LHO/LHO 3 5 5 3-Phase*

Gas Light

Standard

Burner Model Designation

Gas/Light Oil

Oil

* 208/60/3, 240/60/3, 480/60/3 burner motor voltage must be specified.

Standard

Combustion Control

Gas Light

Oil

Gas/Light

Oil

Standard

Control System

Gas Light

Oil

Gas/Light

Oil

Burner Motor

3450 Rpm

Gas Light

Oil

Z\x Z\x Z\x

Z\x Z\x Z\x

Z\x Z\x Z\x

Z\x C\v C\v

Z\x C\v C\v

C\v

1 1 240/60/1

Gas/

Light

Oil

Standard

Motor

Voltage

120/60/1

120/60/1

120/60/1

120/60/1

120/60/1

Notes for Table 1 and Table 2

Burner capacities listed for elevations up to 2,000 feet. For higher eleva-1.

tions, consult local Weil-McLain distributor/agent or sales office.

Light oil ratings based on No. 2 fuel oil with heating value of 140,000 2.

Btu per gallon.

Gas ratings based on natural gas with heating value of 1,000 Btu per 3.

cubic foot and specific gravity of 0.60. Gas burners for other gases are

available. Consult local Weil-McLain distributor/agent or sales office.

Boiler-burner unit to be adjusted to achieve +0.10 inches W.C. pressure 4.

at the flue collar, resulting in positive pressure in firebox as listed.

Minimum gas pressures listed are subject to variations due to job condi-5.

tions. Gas burners for other gas pressures are available. Consult local

Weil-McLain distributor/agent or sales office.

Tee pressures shown are for initial start-up. Final pressure should be 6.

determined after checking actual gas flow and combustion readings.

120/60/1 control circuit is used for all burners.7.

Control circuit transformer is available as an option.8.

Motor relay or contactor will be furnished for all units, except 488R 9.

and 488.

Airflow safety switch is standard for all gas and combination gas/light 10.

oil units.

Burners will be completely assembled and wired (except gas train) and 11.

factory test-fired.

Burners listed by Underwriters Laboratories, Inc., state of Connecti-12.

cut, Fire Marshal state of Massachusetts, city of New York MEA, and

others.

2 Part No. 550-142-029/0508

Special controls can be provided to meet other code requirements 13.

not listed. Consult your local Weil-McLain distributor/agent or sales

office.

Electric gas pilot will be furnished as standard equipment on all gas and 14.

combination gas/light oil units.

Direct spark ignition is standard for light oil units. Direct spark ignition 15.

is available as an option for combination gas/light oil units. Consult

your local Weil-McLain distributor/agent or sales office.

Gas Control Systems:16.

OO On-off operation, low fire start, high fire run. Single-position

air, adjustable opening gas valve.

LHO On-off operation, low fire start, high fire run. 488-1388:

two-position air controlled by damper arm on motorized gas

valve, fixed damper pre-purge. 1488-1888: two-position air

controlled by separate motor, open damper pre-purge.

LHL Low-high-low-off firing conditions. 488-1388: two-position

air controlled by damper arm on motorized gas valve, fixed

damper pre-purge. 1488-1888: two-position air controlled by

separate motor, open damper pre-purge.

MOD On-off operation, with proven low fire start and full modulating

firing conditions with combustion air control. Proportional

motor drives fuel metering valve and combustion air damper

according to the firing conditions. Fixed damper pre-purge on

488-1388, open damper pre-purge on 1488-1888.

Page 3

Burner Specification & Data sheet — Power Flame Gas/Oil Burners — Model WCR

Burner specifications and settings

Gas train components and flame safeguardsTable 2

Boiler

Model

Number

488R

488

588

688

788

888

988R

988

1088R

1088

1188

1288

1388

1488

1588

1688R

1688

1788

1888

Gas Pressure

Pressure

Drop Thru

Gas Train

Inches

W.C.

2.20 2.10 4.10 14.00

2.20 2.10 4.30 14.00

1.80 2.60 4.40 14.00

2.70 1.70 4.40 14.00

2.50 2.30 4.80 14.00

3.90 1.20 5.10 14.00

4.60 1.60 6.20 14.00

4.50 1.90 6.40 14.00

4.90 2.00 6.90 14.00

4.00 2.30 6.30 14.00

3.30 2.10 5.40 14.00

4.10 2.50 6.50 14.00

3.50 2.70 6.20 27.70

4.70 3.60 8.20 27.70

5.30 3.90 9.20 27.70

5.80 4.10 10.50 27.70

6.20 4.40 10.50 27.70

6.50 2.80 9.30 27.70

7.10 3.20 10.30 27.70

Required At Gas

Manifold

Pressure

Control Inlet

Inches W.C.*

Inches

W.C.*

Min Max Top Bottom

* Gas pressure shown are for standard gas train arrangement ** Primary manufacturer. For alternate nozzles, contact Power-Flame

Initial Low Fire

Damper Setting

Inches

Gph @

100

Psig

M\, M\,

M\, M\,

1 1

C\, C\,

C\, C\,

C\, C\,

C\, C\,

C\, C\,

C\, C\,

C\, C\,

C\, C\,

C\, C\,

C\, C\,

Z\v Z\v

Z\v Z\v

Z\v Z\v

Z\v Z\v

Z\v Z\v

Z\v Z\v

*** 70° spray angle standard, 60° or 80° approved and available upon request

4.50 No Delavan Solid 80° 300 295 — 100-150 B2TA-8850-4 37

4.50 No Delavan Solid 80° 300 300 — 100-150 B2TA-8850-4 37

5.50 No Delavan Solid 80° 300 300 — 100-150 B2TA-8850-4 37

7.00 No Delavan Solid 80° 300 300 183 100-150 B2TA-8851-4 43

8.50 No Delavan Solid 70° 300 300 195 100-150 B2TA-8851-4 43

9.50 No Delavan Solid 70°*** 300 300 210 100-150 B2GA-8852 43

10.00 No Monarch PLP 60° 300 300 110 80-100 B2GA-8852 47

11.00 No Delavan Solid 70°*** 300 280 135 80-100 B2GA-8852 47

12.00 No Monarch PLP 60° 300 290 140 80-100 B2GA-8852 47

16.00 Yes Del. Variflo BPS 80° 300 225 150 100-150 22R322D 105

(fixed)

14.00 Yes Del. Variflo BPS 80° 300 295 140 50-108 22R322D 105

(fixed)

16.00 Yes Del. Variflo BPS 80° 300 290 133 50-110 22R322D 105

18.00 Yes Del. Variflo BPS 80° 300 244 166 60-108 22R322D 105

20.00 Yes Del. Variflo BPS 80° 300 280 180 100-150 22R623D 105

22.00 Yes Del. Variflo BPS 60° 300 290 165 100-150 22R623D 105

22.00 Yes Del. Variflo BPS 60° 300 295 175 100-150 22R623D 135

22.00 Yes Del. Variflo BPS 60° 300 295 155 100-150 22R623D 135

24.00 Yes Hago BPS 60° 300 300 165 100-150 22R623D 135

26.00 Yes Hago BPS 60°

Bypass

Oil

System

Oil Nozzle

(One Per Unit)

Brand** Type

Spray

Angle

Pump

Capacity

Psig

300 300 175 100-150 22R623D 135

(continued)

Oil Pressures

Psig

Approximate Return

High Fire

Pump

Pressure

High Fire Low Fire

Psig

Fuel Unit Data Burner-

Motor Driven

3450 Rpm

Type

Gear

Gph

Standard Gas Control Components And Sizes In Inches

Boiler Model

Number

488R-488 1Z\v Optional Optional 1Z\v Optional Optional 1Z\v 1Z\v Optional

588 1Z\v Optional Optional 1Z\v Optional Optional 1Z\v 1Z\v Optional

688 1Z\v Optional Optional 1Z\v 1Z\v Optional * 1Z\v Optional

788 1Z\x Optional Optional 1Z\x 1Z\x Optional * 1Z\x Optional

888 2 Optional Optional 1Z\x 1Z\x Optional * 1Z\x Optional

988R 2 Optional 2 — 1Z\x Optional 1Z\x 1Z\x Optional

988-1088R 2 Standard 2 — 2 Optional 1Z\x 1Z\x Standard

1088 2 Standard 2 — 2 Optional 2 2 Standard

1188-1588 2 Standard 2 — 2 Optional 2 2 Standard

1688R-1888 2 Standard 2 — — 2 2 2 Standard

Manual Hand

Valve

Low Gas

Pressure

Switch

Light Oil Control Systems:17.

FALFS On-off operation, fixed air, reduced fuel low fire start, high fire run. Single-

position air, two-position oil.

OO On-off operation, low fire start, high fire run. Single-position air, single-position

oil.

LHO On-off operation, low fire start, high fire run. Two-position air, two-position oil.

Fixed damper pre-purge on 488-1288, open damper pre-purge on 1388-1888.

LHL Low-high-low-off firing conditions. Two-position air, two-position oil. Fixed

damper pre-purge on 488-1288. Open damper pre-purge on 1388-1888.

MOD On-off operation, with proven low fire start and full modulating firing condi-

tions. Proportional motor drives fuel metering valve and combustion air damper

according to the firing conditions. Fixed damper pre-purge on 488-1088R, open

damper pre-purge on 1088-1888.

Gas

Pressure

Regulator

* Combination operating gas valve and regulator also serves as safety gas valve.

Combination

Gas Valve And

Regulator

Motorized

Operating

Gas Valve

Motorized Operating

Gas Valve

(With Proof Of Closure)

Gas/Light Oil Control Systems:18.

OO/FALFS Combines gas and light oil characteristics

OO/OO Combines gas and light oil characteristics

LHO/LHO Combines gas and light oil characteristics

LHL/LHL Combines gas and light oil characteristics

MOD/MOD Combines gas and light oil characteristics

Safety

Gas Valve

Manual

Checking

Gas Valve

High

Gas Pressure

Switch

listed above.

listed above.

listed above. Open damper pre-purge on

1388-1888.

listed above. Open damper pre-purge on

1388-1888.

listed above. Open damper pre-purge on

1388-1888.

3Part No. 550-142-029/0508

Page 4

Weil-McLain 88 Water and Steam Boilers — Series 2 — For Gas, Light Oil, & Gas/Light Oil-Fired Burners

Burner specifications and settings

Flame safeguardsTable 3

Flame Safeguards Provided with Listed Control Systems by Code

GAS BURNERS

Boiler

Model

Number

488R-588

688-988R

988-1388

1488-1888

Boiler

Model

Number

488R

488-588

688-1088R

1088-1288

1388-1888

OO LHO LHL MOD OO LHO LHL MOD OO LHO LHL MOD OO LHO LHL MOD

RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7897C RM7897C RM7897C RM7840L

— RM7897A RM7897A RM7897A — RM7897A RM7897A RM7897A — RM7897A RM7897A RM7897A — RM7897C RM7897C RM7840L

— RM7897C RM7897C RM7840L — RM7897C RM7897C RM7840L — RM7897C RM7897C RM7840L — RM7897C RM7897C RM7840L

— RM7840L RM7840L RM7840L — RM7840L RM7840L RM7840L — RM7840L RM7840L RM7840L — RM7840L RM7840L RM7840L

FALFS LHO LHL MOD FALFS LHO LHL MOD FALFS LHO LHL MOD FALFS LHO LHL MOD

R7184P R7184P R7184P R7184P R7184P R7184P R7184P R7184P RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7840L

R7184P R7184P R7184P R7184P R7184P R7184P R7184P R7184P RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7840L

— R7184P R7184P R7184P — R7184P R7184P R7184P — RM7897A RM7897A RM7897A — RM7897A RM7897A RM7840L

— RM7897A RM7897A RM7840L — RM7897A RM7897A RM7840L — RM7897A RM7897A RM7840L — RM7897A RM7897A RM7840L

— RM7840L RM7840L RM7840L — RM7840L RM7840L RM7840L — RM7840L RM7840L RM7840L — RM7840L RM7840L RM7840L

UL FM CSD-1 IRI

LIGHT OIL BURNERS

UL FM CSD-1 IRI

COMBINATION GAS/OIL BURNERS

(continued)

Boiler

Model

Number

488R-588

688-988R

988-1288

1388-1888

OO/FALFS LHO LHL MOD OO/FALFS LHO LHL MOD OO/FALFS LHO LHL MOD OO/FALFS LHO LHL MOD

RM7897C RM7897C RM7897C RM7897C RM7897C RM7897C RM7897C RM7897C RM7897C RM7897C RM7897C RM7897C RM7897C RM7897C RM7897C RM7840L

— RM7897C RM7897C RM7897C — RM7897C RM7897C RM7897C — RM7897C RM7897C RM7897C — RM7897C RM7897C RM7840L

— RM7897C RM7897C RM7840L — RM7897C RM7897C RM7840L — RM7897C RM7897C RM7840L — RM7897C RM7897C RM7840L

— RM7840L RM7840L RM7840L — RM7840L RM7840L RM7840L — RM7840L RM7840L RM7840L — RM7840L RM7840L RM7840L

UL FM CSD-1 IRI

Notes for Table 3

Combustion Controls:1.

R7184P Uses cadmium cell for flame detector to monitor oil burner flame, also furnishes intermittent ignition.

RM7897A, RM7897C Uses ultraviolet electronic flame detector to monitor gas or oil burner flame and provides pre-purge programming. “A” models

RM7840L, E110/EPD170 Monitors the oil or gas burner flame, provides pre-purge and post-purge programming, provides switching necessary to allow

RM7800L, E110/EP160 Monitors the oil or gas burner flame with digital readout control system, provides pre-purge and post-purge programming,

provide intermittent pilot; “C” models provide interrupted pilot and RUN/TEST switch. RM7897 provides same as above with

post-purge.

firing rate motor to be driven to both low fire and high fire positions, prevents start-up if pre-ignition interlocks are open and

has low fire start proving circuit. In the event pre-ignition interlock circuit or running interlock circuit does not “prove”, system

will lock out on safety. Ultraviolet sensitive electronic flame detector is standard with infrared detector available.

provides switching necessary to allow firing rate motor to be driven to both low fire and high fire position, prevents start-up

if pre-ignition interlocks are open and has low fire start proving circuit. In the event pre-ignition interlock circuit or running

interlock circuit does not “prove”, system will lock out on safety. Ultraviolet sensitive electronic flame detector is standard with

infrared detector available.

4 Part No. 550-142-029/0508

Loading...

Loading...