Weil-McLain EVG 70, EVG 155, EVG 110 User Manual

CONDENSING GAS BOILER

70/110/155

®

Boiler Manual

• Installation

• Startup

• Maintenance

• Parts

This manual must only be used by a qualifi ed heating installer/service technician. Read all instructions, including this manual and

all other information shipped with the boiler, before installing. Perform steps in the order given. Failure to comply could result in

severe personal injury, death or substantial property damage.

Part number 550-100-191/0917

®

Contents

gas-fired water boiler — 70/110/155 Boiler Manual

The Evergreen® Gas-fi red water boilers . . . . . . . . . . . . 2

Please read before proceeding . . . . . . . . . . . . . . . . 7

Boiler location . . . . . . . . . . . . . . . . . . . . . . . . . 8

Prepare boiler location . . . . . . . . . . . . . . . . . . . . 10

Wall-mounting the boiler. . . . . . . . . . . . . . . . . . . 10

Boiler hydrostatic test . . . . . . . . . . . . . . . . . . . . 13

Converting boiler to propane — EVG 70 . . . . . . . . . . . 15

Converting boiler to propane — EVG 110 . . . . . . . . . . 17

Converting boiler to propane — EVG 155 . . . . . . . . . . 19

Gas piping — sizing gas lines . . . . . . . . . . . . . . . . 21

Venting/air piping — general . . . . . . . . . . . . . . . . 22

Commonwealth of Massachusetts installations . . . . . . 25

Vent termination requirements . . . . . . . . . . . . . . . 26

Boiler room air openings . . . . . . . . . . . . . . . . . . . 27

DIRECT VENT — Sidewall with separate pipes . . . . . . . 28

DIRECT VENT — Sidewall concentric . . . . . . . . . . . . 30

DIRECT VENT — Sidewall with W-M vent/air plate . . . . . 32

DIRECT VENT — Vertical with separate pipes. . . . . . . . 34

DIRECT VENT — Vertical concentric. . . . . . . . . . . . . 36

Concentric termination, typical (sidewall or vertical). . . . 38

Vent and air piping and boiler connections . . . . . . . . . 39

Install water piping . . . . . . . . . . . . . . . . . . . . . 40

Direct Connect System Piping - Single Boiler System . . . 41

Verify the application will work. . . . . . . . . . . . . . . . . . 41

Expansion tank location. . . . . . . . . . . . . . . . . . . . . . 41

Diaphragm- or bladder-type tank. . . . . . . . . . . . . . . . . 41

Closed-type expansion tank . . . . . . . . . . . . . . . . . . . 42

System water piping methods . . . . . . . . . . . . . . . . . . 43

Install relief valve . . . . . . . . . . . . . . . . . . . . . . . . . 43

ZONE VALVE zoning – direct connection . . . . . . . . . . . . . 44

Primary/Secondary System Piping - Single Boiler System See

Advanced Manual for Multiple Boiler Systems . . . . . . . 45

Expansion tank location. . . . . . . . . . . . . . . . . . . . . . 45

Diaphragm- or bladder-type tank. . . . . . . . . . . . . . . . . 45

Closed-type expansion tank . . . . . . . . . . . . . . . . . . . 46

System water piping methods . . . . . . . . . . . . . . . . . . 47

Install relief valve . . . . . . . . . . . . . . . . . . . . . . . . . 48

ZONE VALVE zoning – primary/secondary . . . . . . . . . . . . . . . 49

CIRCULATOR zoning – primary/secondary . . . . . . . . . . . . . . 50

CIRCULATOR zoning – primary/secondary multi. temp. zone . . . . 51

Install condensate line. . . . . . . . . . . . . . . . . . . . . . . . 52

Gas piping . . . . . . . . . . . . . . . . . . . . . . . . . . 53

DO NOT SERVICE THE BOILER

WITHOUT AN Evergreen®

MAINTENANCE KIT AVAILABLE

The maintenance kit includes components that may have

to be replaced when accessing or disassembling parts of the

boiler. Failure to replace damaged components and to use

only the parts specifi cally intended for the boiler can result in

severe personal injury, death or substantial property damage.

See Figure 110, page 127 for part number.

Field wiring . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Wiring diagram — schematic . . . . . . . . . . . . . . . . 62

Wiring diagram — ladder . . . . . . . . . . . . . . . . . . 63

Zoning with the EVG Control . . . . . . . . . . . . . . . . . 64

Evergreen control operation . . . . . . . . . . . . . . . . . 66

EVG control settings menus . . . . . . . . . . . . . . . . . 70

EXPRESS SETUP — Example A . . . . . . . . . . . . . . . 72

EXPRESS SETUP — Example B . . . . . . . . . . . . . . . 74

EXPRESS SETUP — Example C . . . . . . . . . . . . . . . 76

Available control settings and system presets . . . . . . . 78

CONTRACTOR menus . . . . . . . . . . . . . . . . . . . . . 79

BOILER SETTINGS menu, BASIC mode . . . . . . . . . . . . 80

PRIORITY 1, 2, 3 menus, BASIC mode . . . . . . . . . . . . 81

ASSIGN INPUTS menu, BASIC mode . . . . . . . . . . . . . 82

DIAGNOSTIC menu . . . . . . . . . . . . . . . . . . . . . . 84

MAINTENANCE, DATE AND TIME menus . . . . . . . . . . . 89

Startup — fi ll the system . . . . . . . . . . . . . . . . . . 91

Startup — fi nal checks . . . . . . . . . . . . . . . . . . . 93

Check-out/startup verifi cation. . . . . . . . . . . . . . . . 99

Annual startup and general maintenance . . . . . . . . . . 100

Annual startup . . . . . . . . . . . . . . . . . . . . . . . . 101

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . 107

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 115

Cleaning heat exchanger fl ue side, 70. . . . . . . . . . . . 117

Cleaning heat exchanger fl ue side, 110 . . . . . . . . . . . 120

Cleaning heat exchanger fl ue side, 155 . . . . . . . . . . . 123

Replacement parts . . . . . . . . . . . . . . . . . . . . . . 126

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Ratings — Evergreen® boilers . . . . . . . . . . . . . . . 139

Installation and Service Certifi cate . . . . . . . . . . . . . 141

Evergreen® Gas Boiler Data Collection Sheet . . . . . . . 144

Hazard defi nitions

The following defi ned terms are used throughout this manual to bring attention to the presence of hazards of various risk levels

or to important information concerning the life of the product.

Indicates presence of hazards that will cause severe

personal injury, death or substantial property

damage.

Indicates presence of hazards that can cause severe

personal injury, death or substantial property

damage.

2

Indicates presence of hazards that will or can

cause minor personal injury or property damage.

Indicates special instructions on installation,

operation or maintenance that are important

but not related to personal injury or property

damage.

Part number 550-100-191/0917

®

gas-fired water boiler — 70/110/155 Boiler Manual

The Evergreen® Gas-fi red water boilers

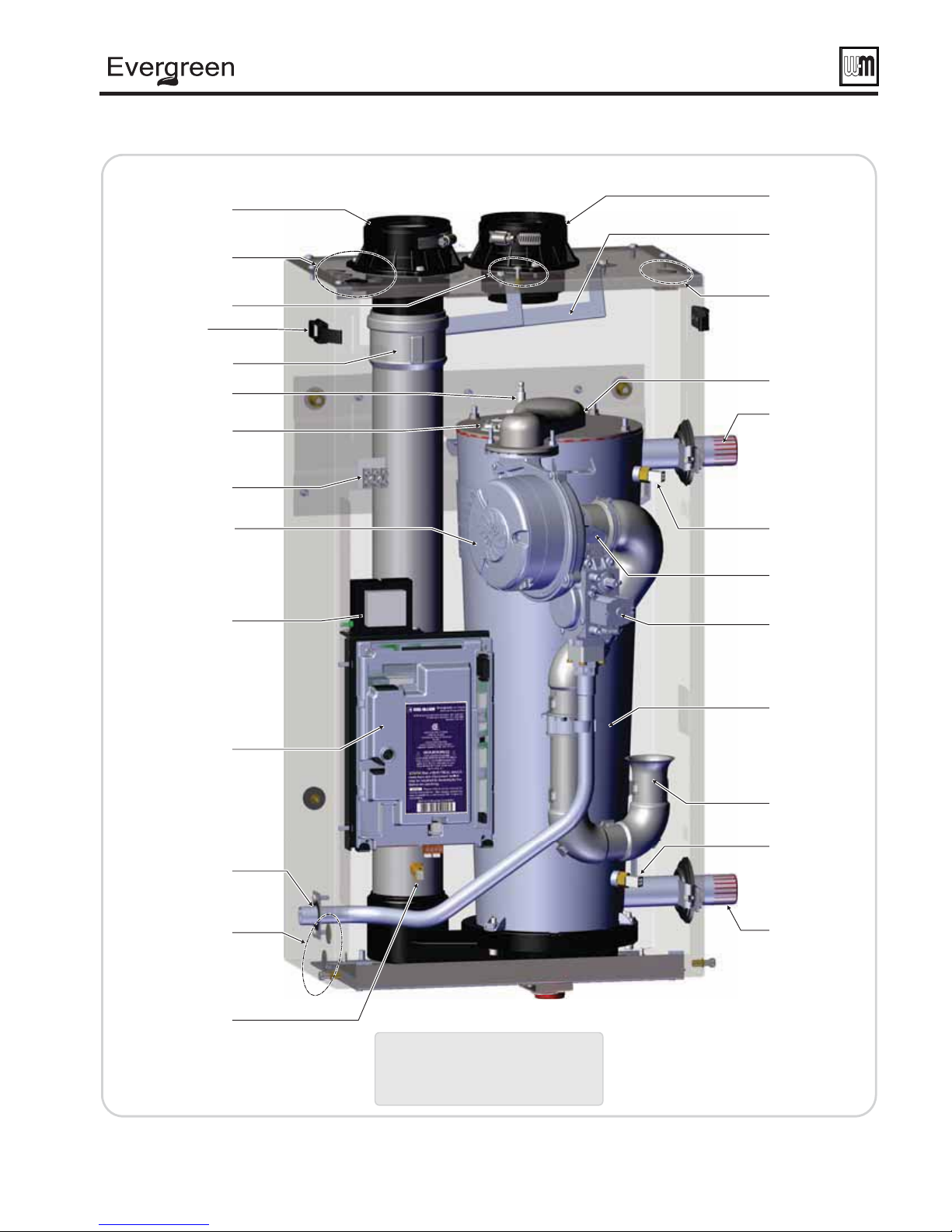

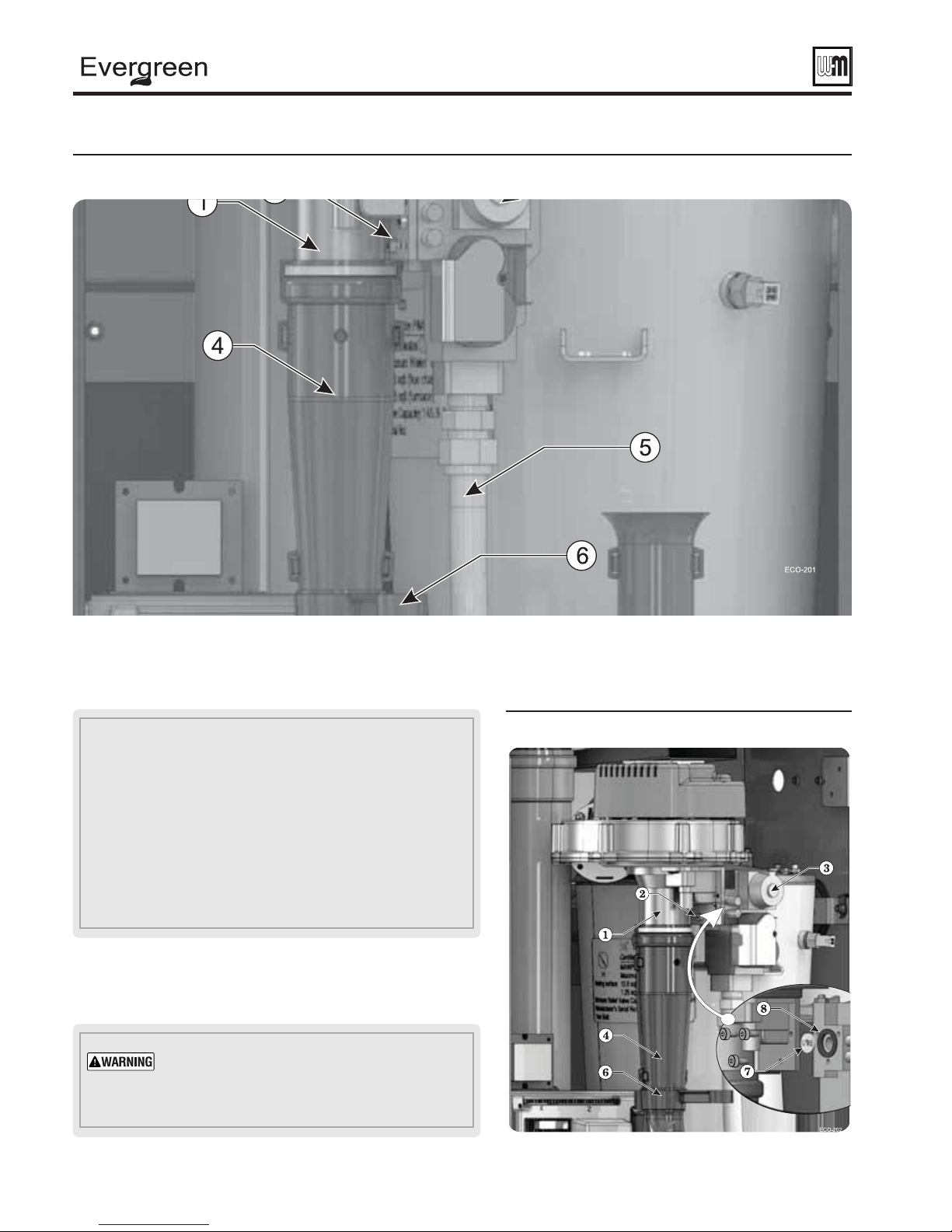

1. Stainless steel fi retube heat exchanger

2. Heat exchanger access cover/burner mounting plate

3. Blower

The advanced blower design and air inlet silencer on Evergreen® boilers

result in very quiet operation.

Air enters the boiler enclosure through the air intake adapter (Item 19),

fl ows through the enclosure, enters the air inlet silencer (Item 5), then enters

the venturi (Item 6) where it mixes with gas before entering the blower. The

blower pulls air through these components and then pushes it through the

cover plate to the burner (Item 12).

4. Gas valve

The automatic gas valve references the pressure in the cabinet and allows gas to

fl ow when the control (Item 16) applies power. A manual gas shut off valve is

shipped loose with the boiler. It allows shutting off the gas supply for servicing

or shut down. See instructions in this manual for manual gas valve installation.

5. Air inlet silencer

The horn-shaped air inlet silencer signifi cantly reduces fan noise, providing

exceptionally quiet operation.

6. Venturi

When air fl ows through the venturi, a negative pressure is created. This causes

gas to fl ow from the gas valve into the venturi, where it is mixed with the air.

The gas/air mixture then continues into the blower.

7. Supply water temperature dual sensor

This dual sensor monitors boiler outlet water temperature. The control adjusts

boiler fi ring rate so the outlet water temperature is correct, based on the

calculated (if outdoor reset used — see page 139 ) or fi xed target temperature.

8. Return water temperature sensor

This sensor monitors return water temperature to the boiler. The control

reduces or increases boiler input, depending on how close the return water

temperature is to the outlet water temperature.

9. Electronic display & buttons

The electronic display is used to confi gure boiler settings and monitor

boiler operation. The buttons allow changing display mode, selecting and

adjusting control settings, and resetting the control after lockout.

10. Flue adapter (fi ts 3" PVC)

11. Flue pipe

12. Burner (not shown)

Made with high-grade stainless steel construction, the burner uses premixed air and gas. The burner and control provide modulating fi ring.

13. Water outlet pipe (system supply)

14. Water inlet pipe (system return)

15. Gas line

This stainless steel fl exible gas line connects the incoming gas line to the

gas valve.

The gas line has a ½” NPT connection for installation.

16. Control module (see discussion upper right)

17. Communication Board

The communication board provides boiler-to-boiler communication and

Building Management System (BMS) interface.

18. Boiler circulator terminal block

19. Air intake adapter (fi ts 3" PVC)

20a. Electrical entrances (line voltage)

The top left side knockouts are designated for line voltage wiring only.

Ensure all wiring entrances are sealed.

20b. Electrical entrances (low voltage)

The bottom left side knockouts are designated for low voltage wiring

only. Ensure all wiring entrances are sealed.

20c. Electrical entrance (multiple boiler communication)

The top right knockout (1) is designated for multiple boiler

communication and BMS wiring. Ensure all wiring entrances are sealed.

21. Boiler drain valve (not shown)

Shipped loose for fi eld piping. Pipe drain valve on reducing tee at the lowest

point of return piping to boiler. See instructions, page 14 in this manual.

22. Condensate trap nozzle

The outlet at the bottom of the condensate collection dish. This is where

condensate is discharged from the boiler. The condensate trap assembly

attaches here.

Part number 550-100-191/0917

Evergreen® control overview

• The Evergreen® control can operate a single boiler or coordinate

with other Evergreen® boilers in a multiple boiler system.

• Control inputs and outputs allow operation of multiple heating

circuits (space heating and DHW, for example).

• Up to three priority levels can be set, providing automatic switchover on demand.

• This manual provides quick set-up information for single boiler

installations.

• The Advanced Manual, also supplied with the boiler, provides

instructions for setting up multiple-boiler systems and for using

advanced options for single boilers.

Evergreen® control operation

• The control responds to signals from the room thermostats, DHW

aquastats (if used), boiler sensors (boiler return, boiler supply, fl ue

temperature), outdoor temperature and system sensors, if used.

• The control automatically adjusts blower speed (and gas fl ow

rate) to match boiler output to space heating and/or DHW

heating demand.

• The default control settings provide for three space heating zones.

The control can be easily set up for operation with a DHW zone,

with or without domestic priority.

Evergreen® control WIZARD

• The control setup Wizard is available from the BOILER

SETTINGS menu that appears during initial startup.

• The Wizard leads through a step-by-step setup procedure

designed for the application chosen.

• Context-sensitive help is available to explain the purpose of key

setup items.

23. Flue gas condensate drain trap assembly and bracket

The condensate trap assembly and bracket are fi eld-installed, condensate

drain trap is connected to the condensate trap nozzle as shown in this

manual.

24. Jacket door

The jacket door is sealed to the boiler assembly around its entire perimeter.

25. Front door latches

Two (2) latches secure the door in place.

26. Door retention screw

27. Ignition electrode/fl ame sensor

The burner fl ame is ignited by applying a high voltage to the ignition

electrode. This causes a spark (from electrode to ground). After ignition,

the electrode measures fl ame signal.

28. Flame inspection window

The quartz glass window provides a view of the burner surface, the fl ame,

and the ignition electrode.

29. Flue gas dual sensor

This dual sensor monitors the fl ue gas exit temperature. The Evergre en®

control will shut down the boiler if fl ue gas temperature gets too hot.

This protects the fl ue pipe and the heat exchanger from overheating.

30. Gas valve reference hose (EVG-70 only)

This rubber line connects the gas valve diaphragm reference chamber to

the venturi intake to insure the valve senses the correct reference pressure.

31. Transformer

The 120V/24V transformer provides 24V to low voltage control circuitry.

Do NOT splice wiring into transformer.

32. Air baffl e

The air baffle protects internal boiler components by diverting any

incoming moisture or debris away from critical components. It must be

temporarily removed while servicing the heat exchanger.

33. Floor stand assembly

The provided stand allows for the Evergreen® boiler to be either wall

hung or fl oor standing.

3

C

D

B

J

O

U

C

D

B

®

gas-fired water boiler — 70/110/155 Boiler Manual

The EVG-70 Gas-fi red water boilers

B

D

&7(

*OUFSJPS

OUFS

TPNFDPNQPOFOUTPNJUUFEGPSDMBSJUZ

TPNFDPNQPOFOUTPNJUUFEGPSDMBSJUZ

C

&WFSHSFFO

#PUUPN

&WFSHSFFO

5PQ

&WFSHSFFO

&WFSHS

'SPOU

S

O

(9*

4

B

D

C

Part number 550-100-191/0917

C

D

B

®

gas-fired water boiler — 70/110/155 Boiler Manual

The EVG-110 Gas-fi red water boilers

B

D

C

&7(

*OUFSJPS

TPNFDPNQPOFOUTPNJUUFEGPSDMBSJUZ

(9*

Part number 550-100-191/0917

5

C

D

B

®

gas-fired water boiler — 70/110/155 Boiler Manual

The EVG-155 Gas-fi red water boilers

B

D

6

C

&7(

*OUFSJPS

TPNFDPNQPOFOUTPNJUUFEGPSDMBSJUZ

(9*

Part number 550-100-191/0917

®

gas-fired water boiler — 70/110/155 Boiler Manual

Please read before proceeding

Installer— Read all instructions, including this

manual and all other information shipped with the

boiler, before installing. Perform steps in the order given.

User — This manual is for use only by a qualifi ed

User — Have this boiler serviced/inspected by a

Failure to comply with the above could result in severe

heating installer/service technician. Refer to User’s

Information Manual for your reference.

qualifi ed service technician, at least annually.

personal injury, death or substantial property damage.

If any part of a boiler, burner or its controls has

been sprayed with or submerged under water,

either partially or fully, DO NOT attempt to

operate the boiler until the boiler has been either

replaced or completely repaired, inspected, and

you are sure that the boiler and all components

are in good condition and fully reliable.

Otherwise, by operating this boiler, you will

cause a fi re or explosion hazard, and an electrical

shock hazard, leading to serious injury, death, or

substantial property damage. See the instructions

at right.

Failure to adhere to the guidelines below can result in severe personal injury, death or substantial property damage.

EXPANSION TANK

• Relieve pressure from the system

before isolating the expansion tank.

When servicing boiler —

• To avoid electric shock, disconnect all

electrical supplies to the boiler before

performing maintenance.

• To avoid severe burns, allow boiler to cool

before performing maintenance.

• This boiler contains ceramic fiber

and fiberglass materials. Refer to the

WARNING and instructions on page 101 .

Boiler operation —

• Do not block fl ow of combustion or

ventilation air to boiler.

• Should overheating occur or gas supply

fail to shut off, do not turn off or

disconnect electrical supply to circulator.

Instead, shut off the gas supply at a

location external to the appliance.

Combustion air —

• DO NOT install combustion air intake

where there is a risk of combustion air

contamination.

Carbon monoxide detector —

• A carbon monoxide detector that is

wired on the same electrical circuit as

the boiler is strongly recommended.

SURGE PROTECTOR —

• Provide surge protection in the boiler

power supply. This will reduce the

possibility of damage to the boiler

control.

Boiler water —

• The Evergreen® heat exchanger is made

of stainless steel, and requires that

system water chemistry be within the

limits in this manual. Use the Sentinel

X100 inhibitor supplied with boiler.

ADDITIONAL CHEMICAL TREATMENT

MAY BE NECESSARY

details.

• Thoroughly fl ush the system (BEFORE

connecting boiler) to remove sediment.

The high-effi ciency heat exchanger can

be damaged by build-up or corrosion

due to sediment.

• Do not use petroleum-based cleaning

or sealing compounds in boiler system.

Gaskets and seals in the system may be

damaged. This can result in substantial

property damage.

• Continual fresh make-up water will

reduce boiler life. Mineral buildup in

eat exchanger reduces heat transfer,

overheats the stainless steel heat

exchanger, and causes failure. Addition

of oxygen carried in by make-up water

can cause internal corrosion. Leaks in

Write in the CP number in the space provided on the

Installation certifi cate on page 141 if not already shown.

When calling or writing about the boiler— Please

Consider piping and installation when determining

have the boiler model number from the boiler rating

label and the CP number from the boiler jacket.

boiler location.

Any claims for damage or shortage in shipment

must be fi led immediately against the transportation

company by the consignee.

Saltwater Damage — The exposure of boiler components to

saltwater can have both immediate and long-term effects. While

the immediate effects of saltwater damage are similar to those of

freshwater (shorting out of electrical components, washing out of

critical lubricants, etc.), the salt and other contaminants left behind can

lead to longer term issues after the water is gone due to the conductive

and corrosive nature of the salt residue. Therefore, Weil-McLain

equipment contaminated with saltwater or polluted water will

no longer be covered under warranty and should be replaced.

Electrical Damage — If any electrical component or wiring

came into contact with water, or was suspected to have come into

contact with water, replace the boiler with a new Weil-McLain boiler.

boiler or piping must be repaired at once

to prevent make-up water. Use this boiler

ONLY in a closed-loop system.

• Do not add cold water to a hot boiler.

Thermal shock can cause the heat

exchanger to crack.

Freeze protection fl uids —

• NEVER use automotive or standard

glycol antifreeze. Use only freezeprotection fluids made for hydronic

systems. Follow all guidelines given by

. See page 91 for

the antifreeze manufacturer. Thoroughly

clean and fl ush any replacement boiler

system that has used glycol before

installing the new boiler. Use only the

products listed by Weil-McLain for use

with this boiler. See page 92 for details.

Frozen Water Damage

Hazard

Residences or buildings that are unattended

in severely cold weather, boiler system

components failures, power outages,

or other electrical system failures could

result in frozen plumbing and water

damage in a matter of hours. For your

protection, take preventative actions such

as having a security system installed that

operates during power outages, senses

low temperature, and initiates an effective

action. Consult with your boiler contractor

or a home security agency.

Commonwealth of

Massachusetts

When the boiler is installed within the Commonwealth of Massachusetts:

• This product must be installed by a licensed plumber or gas fi tter.

• If antifreeze is used, a reduced pressure back-fl ow preventer device shall be used.

• Sidewall vent air installations — see instruction on page 25 .

Part number 550-100-191/0917

7

®

gas-fired water boiler — 70/110/155 Boiler Manual

Boiler location

Installations must comply with:

• Local, state, provincial, and national codes, laws,

regulations and ordinances.

• National Fuel Gas Code, ANSI Z223.1/NFPA 54 - latest

edition.

• National Electrical Code ANSI/NFPA 70 – latest edition.

Electrical installation and grounding must be in

accordance with CSA C22.1, Part 1, Canadian Electrical

Code, and/or local codes.

• For Canada only: CAN/CSA B149.1, Natural Gas and

Propane Installation Code, and any local codes.

• Where required by the authority having jurisdiction, the

installation must conform to the Standard for Controls

and Safety Devices for Automatically Fired Boilers,

ANSI/ASME CSD-1.

The Evergreen® boiler gas manifold

and controls met safe lighting and other

performance criteria when boiler underwent

tests specifi ed in ANSI Z21.13 — latest

edition.

Before locating the boiler, check:

®

1. The Evergreen

mounted.

2. Wall construction — If the boiler is wall-mounted,

make sure the wall construction is suitable to carry

the weight of the boiler and components. See page 10

for instructions.

3. The boiler is suitable for INDOOR installation

4. Check for nearby connection to:

• System water piping • Venting connections

• Gas supply piping • Electrical power

• Condensate drain

5. Check area around boiler. Remove any combustible

materials, gasoline and other fl ammable liquids.

Failure to keep boiler area clear and free of

6. The Evergreen

control system components are protected from dripping

or spraying water or rain during operation or service.

7. If new boiler will replace existing boiler, check for and

correct system problems, such as:

• Sediment or corrosion in system piping — clean and

fl ush piping BEFORE connecting the new boiler.

See page 91 .

• System leaks causing oxygen corrosion or heat ex-

changer cracks from hard water deposits.

• Incorrectly-sized expansion tank.

• Lack of freeze protection in boiler water causing

system and boiler to freeze and leak.

boiler

can be fl oor-standing or wall

only.

combustible materials, gasoline and other

fl ammable liquids and vapors can result in

severe personal injury, death or substantial

property damage.

®

boiler must be installed so that gas

Residential garage installation

Precautions

1. Take the following special precautions when installing the boiler in

a residential garage. If the boiler is located in a residential garage:

• Mount the boiler with its burner and igniter are at least

18 inches above the fl oor. Follow the National Fuel Gas Code,

ANSI Z223.1 for U. S. installations, or Natural Gas and Propane Installation Code, CSA B149.1 and B149.2 for Canadian

installations.

• Locate or protect the boiler so it cannot be damaged by a

moving vehicle.

• Ensure that the installation complies with all applicable codes.

• Prevent boiler water and condensate from freezing.

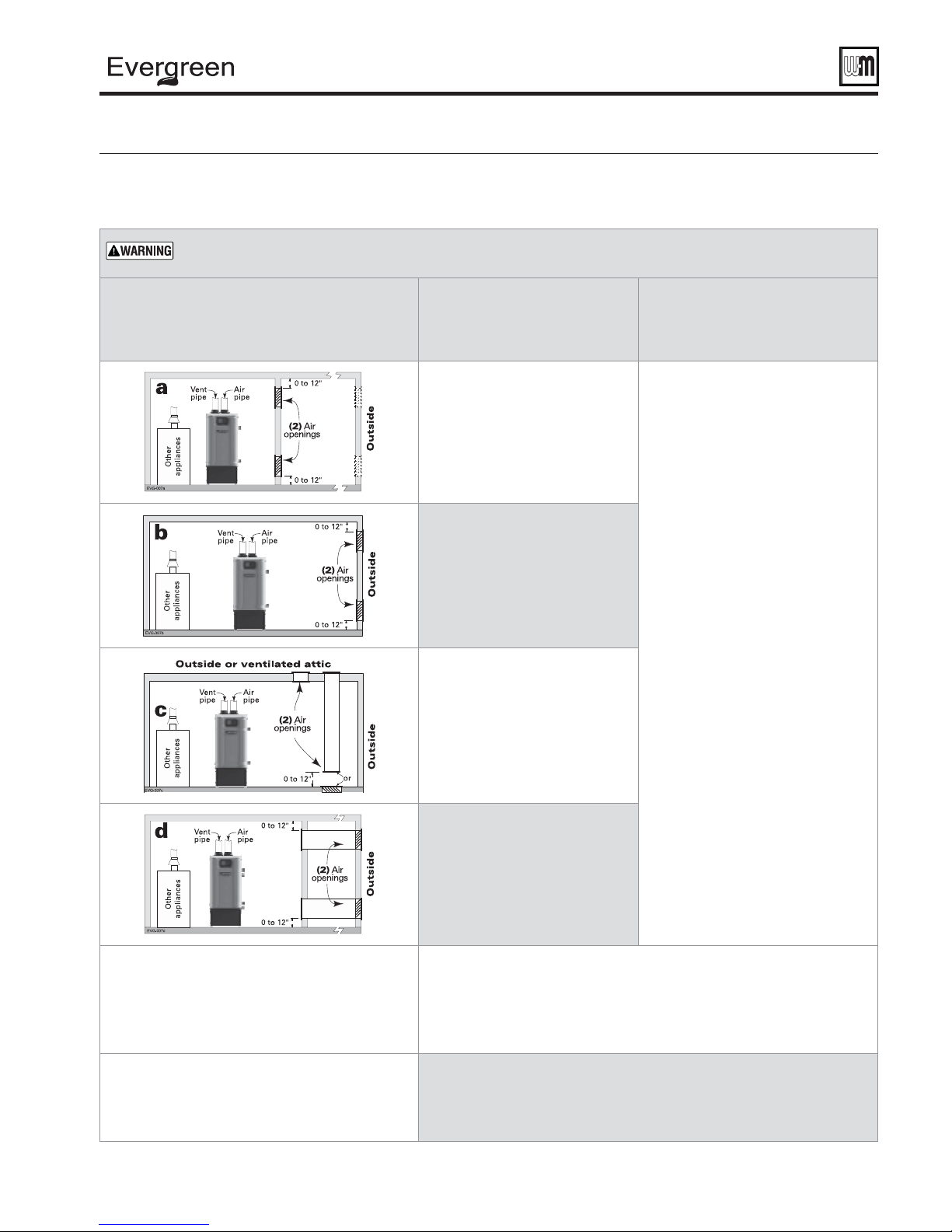

Provide air openings to room

Evergreen® boiler alone in boiler room

1. No air ventilation openings into boiler room are needed if

clearances around boiler are at least equal to the SERVICE

clearances shown in Figure 1, page 9 .

2. For spaces that DO NOT supply the minimum service clearances,

provide two openings as shown in Figure 1, page 9 . Each opening

must provide 1 square inch free area per 1,000 Btuh of boiler input.

The space must be provided with combustion/

ventilation air openings correctly sized for all

appliances located in the same space as the Evergreen®

boiler.

Reinstall boiler jacket door after servicing. The boiler

Failure to comply with the above warnings could

jacket door must be securely fastened to the boiler to

prevent boiler from drawing air from inside the boiler

room. This is particularly important if the boiler is

located in the same room as other appliances.

result in severe personal injury, death or substantial

property damage.

Evergreen® boiler in same space with other gas or

oil-fi red appliances

1. Follow the sizing requirements shown in Figure 25, page 27 .

Vent and air piping

1. The EVG boiler requires a special vent system, designed for

pressurized venting. The boilers are rated ANSI Z21.13 Category

IV (pressurized vent, likely to condense in the vent). See

instructions beginning on page 22 .

2. You must also install air piping from outside to the boiler air

intake adapter. The resultant installation is categorized as direct

vent (sealed combustion). Note prevention of combustion air

contamination on

3. Vent and air must terminate near one another unless otherwise

specifi ed in this manual. Vent and air piping may be routed

vertically through the roof or out a side wall, following the options

given in this manual. You may use any of the vent/air piping

methods covered in this manual. Do not attempt to install the

EVG boiler using any other means.

4. Be sure to locate the boiler such that the vent and air piping can be

routed through the building and properly terminated. The vent/air

piping lengths, routing and termination method must all comply

with the methods and limits in instructions beginning on

page 22 when considering vent/air termination.

page 22 .

8

Part number 550-100-191/0917

®

gas-fired water boiler — 70/110/155 Boiler Manual

Boiler location (continued)

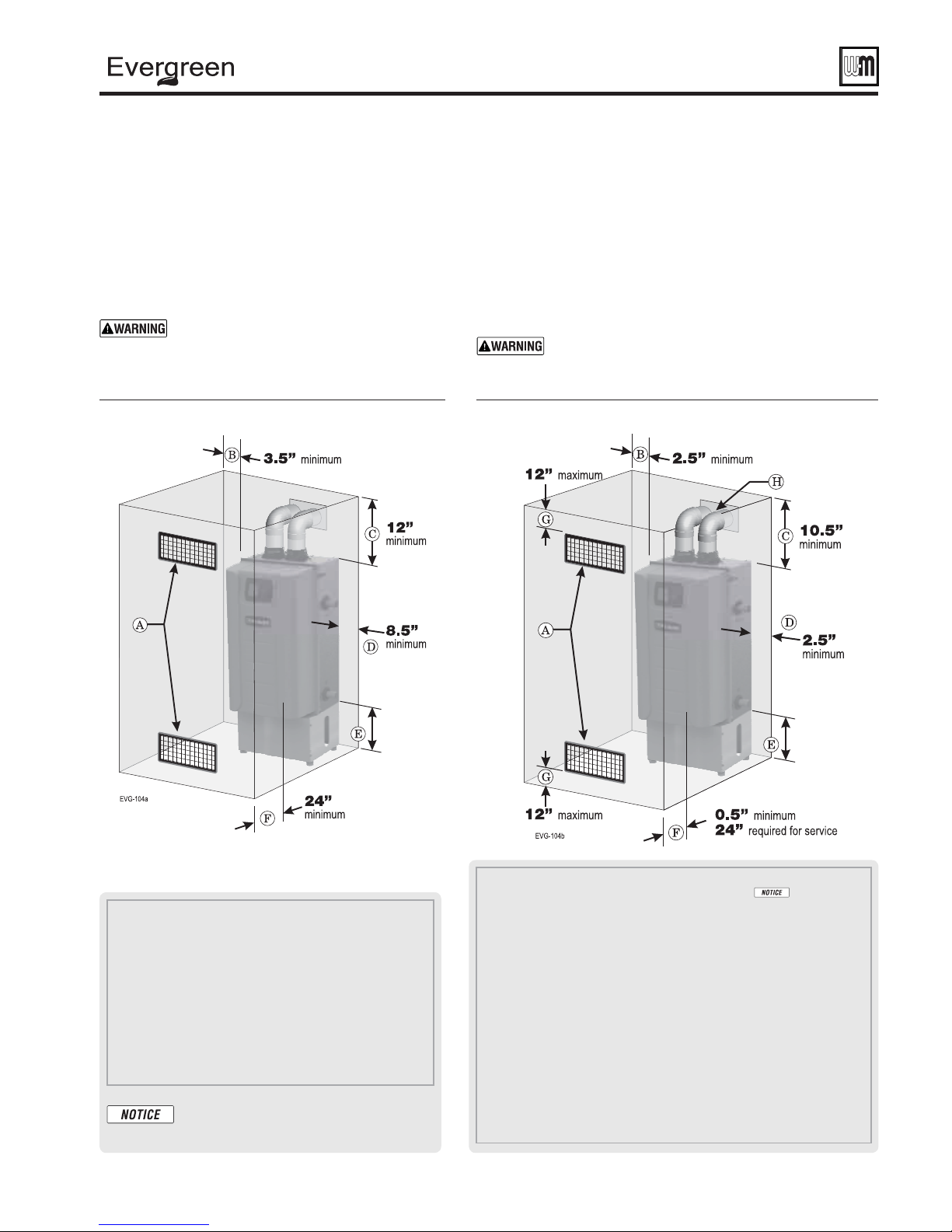

Provide clearances for service

access — RECOMMENDED

1. See Figure 1 for recommended service clearances.

2. If you do not provide minimum service clearances

shown, it might not be possible to service the boiler

without removing it from the space.

3. Clearance D, Figure 1 allows for the installation of

piping as shown in Figure 8, page 12 plus a close nipple

and elbow.

Closet or small-enclosure installations

which do not provide at least these

recommended clearances require the

specially-sized and placed air openings

shown in Figure 2

Figure 1 RECOMMENDED service clearances

(

all dimensions are in inches)

.

Provide clearances from combustible

materials — REQUIRED

1. See Figure 2 for REQUIRED minimum clearances. ALL

installation must provide at least these minimums.

2. Hot water pipes — at least ½ inches from combustible materials.

3. Vent pipe — at least

4. Clearance D, Figure 2 allows for the installation of a reducer

bushing (155 only) and elbow. Other piping may require

additional clearance.

5. See Figure 1 for service clearance minimums.

Closet or small-enclosure installations which do

not provide at least the recommended service

clearances shown in

sized and placed air openings shown in Figure 2

Figure 2 REQUIRED minimum clearances

(

all dimensions are in inches)

3/16 inches from combustible materials.

Figure 1 require the specially-

.

A Provide combustion air/ventilation openings per

Figure 25, page 27 or as otherwise directed in this manual or

by applicable codes. NOTE: If the installation does not provide

the minimum clearances in this illustration, then the enclosure

must have air openings located and sized per Figure 2 .

B Left side service clearance = 3.5 inches minimum.

C Service clearance above top of boiler = 12 inches minimum.

D Right side service clearance = 8.5 inches minimum.

E Service clearance below the boiler = 12 inches minimum for

wall hung installation, 0 inches minimum for fl oor standing

installation.

F Service clearance in front of the boiler = 24 inches minimum.

ADDITIONAL service clearance may be

needed, depending on how piping is routed

to the boiler.

Part number 550-100-191/0917

A Provide combustion air/ventilation openings per Figure 25, page 27 or as

otherwise directed in this manual or by applicable codes.

installation does not provide the minimum clearances in Figure 1 , then the

enclosure MUST HAVE air openings located per Figure 2 , above. Each of these air

openings must have free area of at least 1 square inch per 1,000 MBH of boiler

input.

B Left side clearance to combustibles =2.5 inches minimum.

C Top of boiler clearance to combustibles = 10.5 inches minimum.

D Right side clearance to combustibles = 2.5 inches minimum.

E Bottom of boiler clearance to combustibles = 7 inches minimum (must be

18 inches above fl oor for garage installations) for wall hung installation, 0 inches

minimum for fl oor standing installation.

F Clearance in front of the boiler = 0.5 inches, but 24 inches minimum required

for service.

G Air openings must be located in the FRONT of the enclosure, as shown. They must

be no more than 12 inches from the fl oor or ceiling, as shown.

H Vent pipe must be minimum 3/16 inch from combustibles. Opening in

combustible wall, fl oor, ceiling or roof must be 3/8 inches larger than fl ue pipe

diameter, fi tted with corrosion resistant steel thimble, or larger if required by

codes or as specifi ed by vent pipe manufacturer.

If the

9

®

gas-fired water boiler — 70/110/155 Boiler Manual

Prepare boiler location

Flooring and foundation

Flooring

1. The boiler is approved for installation on combustible fl ooring,

but must never be installed on carpeting.

Do not install boiler on carpeting even if foundation is

used. Fire can result, causing severe personal injury, death

or substantial property damage.

Foundation

1. Provide a solid foundation pad, at least 2 inches above the fl oor, if

any of the following is true:

• fl oor can become fl ooded.

• the fl oor is dirt, sand, gravel or other loose material.

• the boiler mounting area is severely uneven or sloped.

2. The minimum foundation size is:

• Evergreen

3. Foundation may be of wood, brick or concrete (minimum 2 inches

thick) construction.

If fl ooding is possible, elevate boiler suffi ciently to prevent water

from reaching boiler.

Remove boiler from crate

Do not drop boiler or bump jacket on fl oor or pallet.

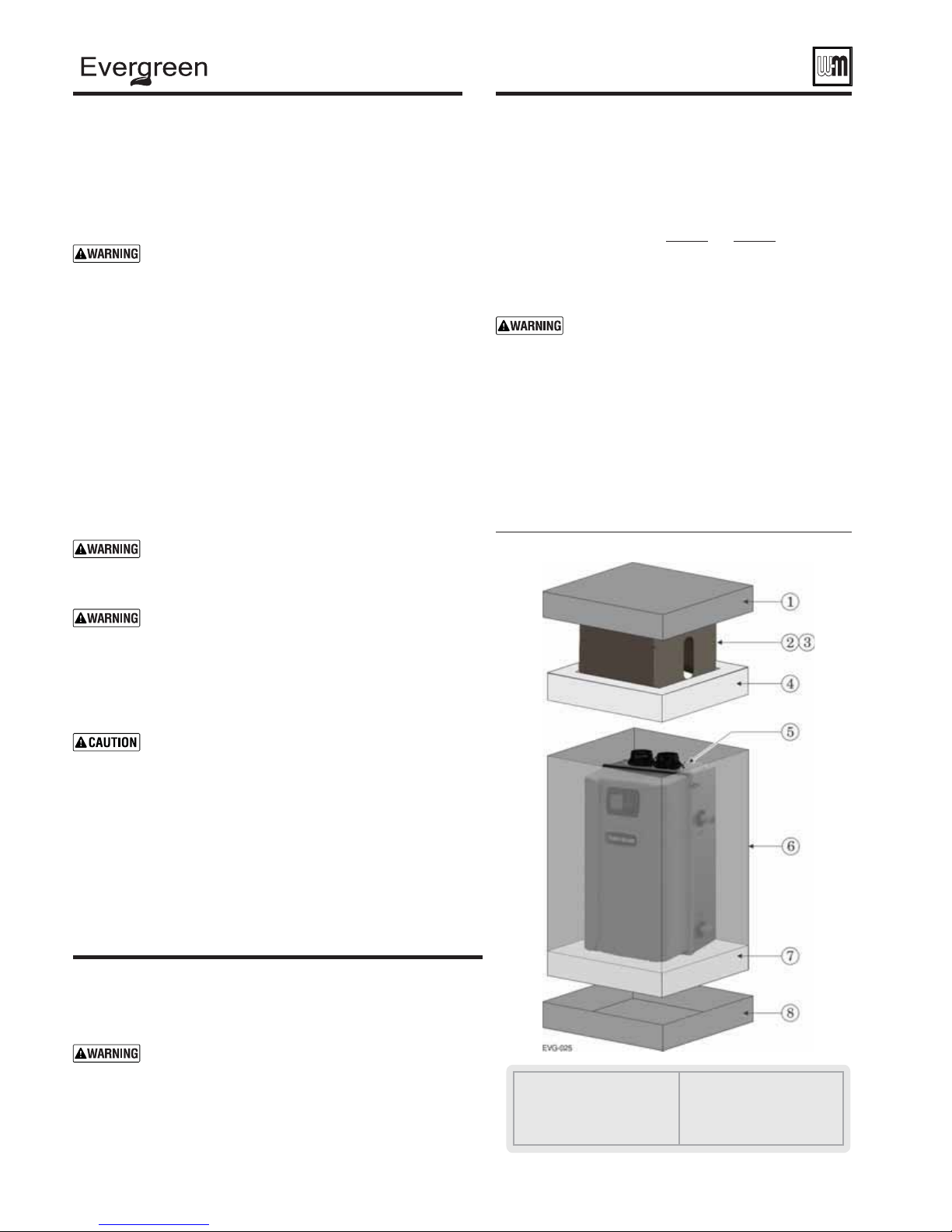

1. The Evergreen

after removing the shipping container.

2. Remove items 1, 2, 3 and 6 in Figure 3 . Remove trim kit and parts

from item 2.

3.

Leave the boiler resting on the styrofoam protective base

(item 6) and bottom cardboard cap (item 7), until ready to place

on the wall. If removing the boiler from the shipping base, rest the

boiler on its back, NOT on its bottom.

®

: 18 inches wide x 18 inches deep

The boiler is heavy. Use caution not to drop the boiler

or cause bodily injury while lifting and handling. Verify

that the boiler is securely attached to prevent possibility

of boiler falling after installation.

After the boiler is removed from the shipping carton,

DO NOT allow the boiler to sit on its bottom. This would

cause pressure on protruding plastic, resulting in interior

damage. Either lay the boiler on its back or leave on the

styrofoam protective shipping base.

Damage to boiler can result.

Cold weather handling — If boiler has been stored in a

very cold location (below 0°F) before installation, handle

with care until the plastic components come to room

temperature.

®

boiler is generally easier to handle and maneuver

Wall-mounting the boiler

(continued)

The operating weights for Evergreen® boilers are:

EVG 70 112 125

EVG 110 107 120

1. Stud spacing: Bracket holes are spaced for studs on

16-inch centers. For other stud spacing, provide secure,

solid mounting surface on which to attach the boiler

wall-mounting bracket. The mounting surface must not

extend above the top of the boiler jacket.

2. Wood stud wall: Install bracket with lag screws (3/8" x

3") included in kit, only into the studs.

3. Metal stud wall: Secure bracket and spacer board to studs

with 3/16-inch toggle bolts and 3/16-inch fl at washers

(not included with kit).

Figure 3 Boiler shipping container

EVG 155 129 143

Failure to comply with above and the procedure

given below could result in severe personal

injury, death or substantial property damage.

Without

Stand

lbs.

With

Stand

lbs.

Wall-mounting the boiler

Wall-mounting requirements

DO NOT attempt to attach the wall mount bracket using

anchors or any means other than directly securing to the

wall studs (or equivalent wood structure if studs are not

on 16-inch centers).

The wall must be vertically plumbed and capable of

carrying the weight of the boiler and any attached

piping components.

10

1 Cardboard cap, top

2 Floor stand assembly

3 Trim box (

4 Styrofoam protective cap

nestled inside Floor

stand assembly)

5 Boiler

6 Cardboard sleeve

7 Styrofoam protective base

8 Cardboard cap, bottom

Part number 550-100-191/0917

®

gas-fired water boiler — 70/110/155 Boiler Manual

Wall-mounting the boiler (continued)

Verify that the studs are suitable for carrying a wall-

mounted load. Some metal studs are not designed for

this purpose.

4. If the mounting wall has exposed studs, installer must provide a

backer board to mount boiler. Boiler cannot be leveled without a

backing surface.

5. Mount the boiler on the wall following these instructions. The

boiler mounting studs must engage with the wall-mount bracket.

Make sure the bracket is not just resting on the edge of the mounting

stud or washer. Perform all procedures given in the Boiler Manual

on previous pages before mounting the boiler.

Install the wall-mount bracket (by installer)

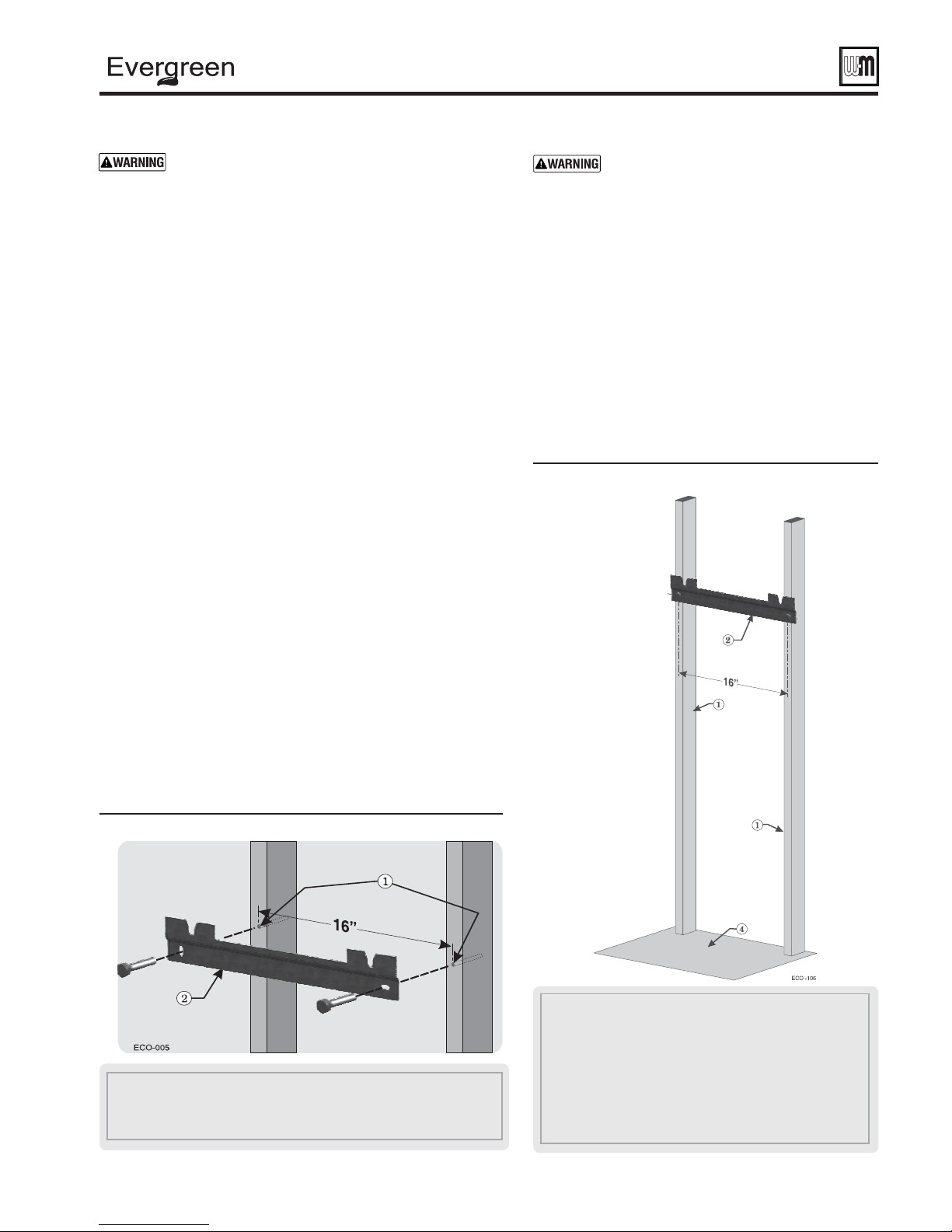

1. See Figure 4 .

2. Locate the studs — must be on 16-inch centers. See previous

page instructions if studs are not on 16-inch centers.

3. Place the wall-mount bracket (Figure 4, item 2) on the wall, using

a level to align correctly.

4. Place the wall-mount bracket so the mounting slots are centered

over the studs.

5. Level the bracket and trace the outline of the screw slots with a

pencil.

6. Remove the mounting bracket and drill holes 1/4" diameter by 3

inches deep, centered on the screw slot outlines. (For metal stud

walls, using 3/16" toggle bolts, drill required clearance holes.)

7. Position the wall-mount bracket on the wall. Insert and loosely

tighten the two lag screws (or toggle bolts for metal studs).

8. Level the wall-mounting bracket. Then tighten lag screws securely.

For drywall or plaster lathe installations, avoid tightening so

much that the bracket digs into the wall surface.

The boiler is heavy, and requires two

people to lift and place. Wear non-slip

leather gloves to prevent possibility of cuts

from sheet metal edges.

The jacket door can be left in place when

handling the boiler, but the boiler must

ONLY be lifted by the bottom and rear of

the sheet metal housing — NOT by any pipe

or plastic part.

3. Obtain assistance to lift the boiler into

position.

4. Lift the boiler high enough that its mounting studs

( Figure 6, page 12 , item 3) will be above the wallmount bracket (item 2).

5. Let the rear of the boiler slide against the lag screw

heads as you lower the boiler into place. The V-groove

will help guide the studs into the slot.

Figure 5 Place boiler on wall-mount bracket

Place boiler on bracket

1. See Figure 5 . The wall-mount bracket must be installed before

mounting the boiler.

2. Measure 22 1/2 inches below the bottom edge of the wall-mount

bracket (item 2). Strike a line or place a piece of masking tape

with its top edge even with the 22 1/2-inch mark. (This line, or

tape, will indicate whether the boiler has been properly seated

onto the wall-mount bracket.)

Figure 4 Wall-mount bracket and studs

1 Studs — Pre-drill through the wall into the studs ¼ inch diameter x 3 inches deep for

3/8-inch lag screws— Studs must be on 16-inch centers. If studs are any other spacing,

provide a secure, solid mounting surface on which to attach the boiler wall-mounting bracket.

2 Wall-mount bracket

1 Studs — Pre-drill through the wall into the studs ¼ inch diameter x 3

inches deep — Studs must be on 16-inch centers. If studs are any other

spacing, provide a secure, solid mounting surface on which to attach

the boiler wall-mounting bracket.

2 Wall-mount bracket — secure wall mount bracket to wall as instructed

on previous page.

3 Boiler mounting studs (Figure 6 back of boiler) — The V-groove on the

wall-mount bracket will help guide the studs into the slots. The studs

are attached to the back of the boiler.

4 Floor surface

Part number 550-100-191/0917

11

(continued)

ge

®

gas-fired water boiler — 70/110/155 Boiler Manual

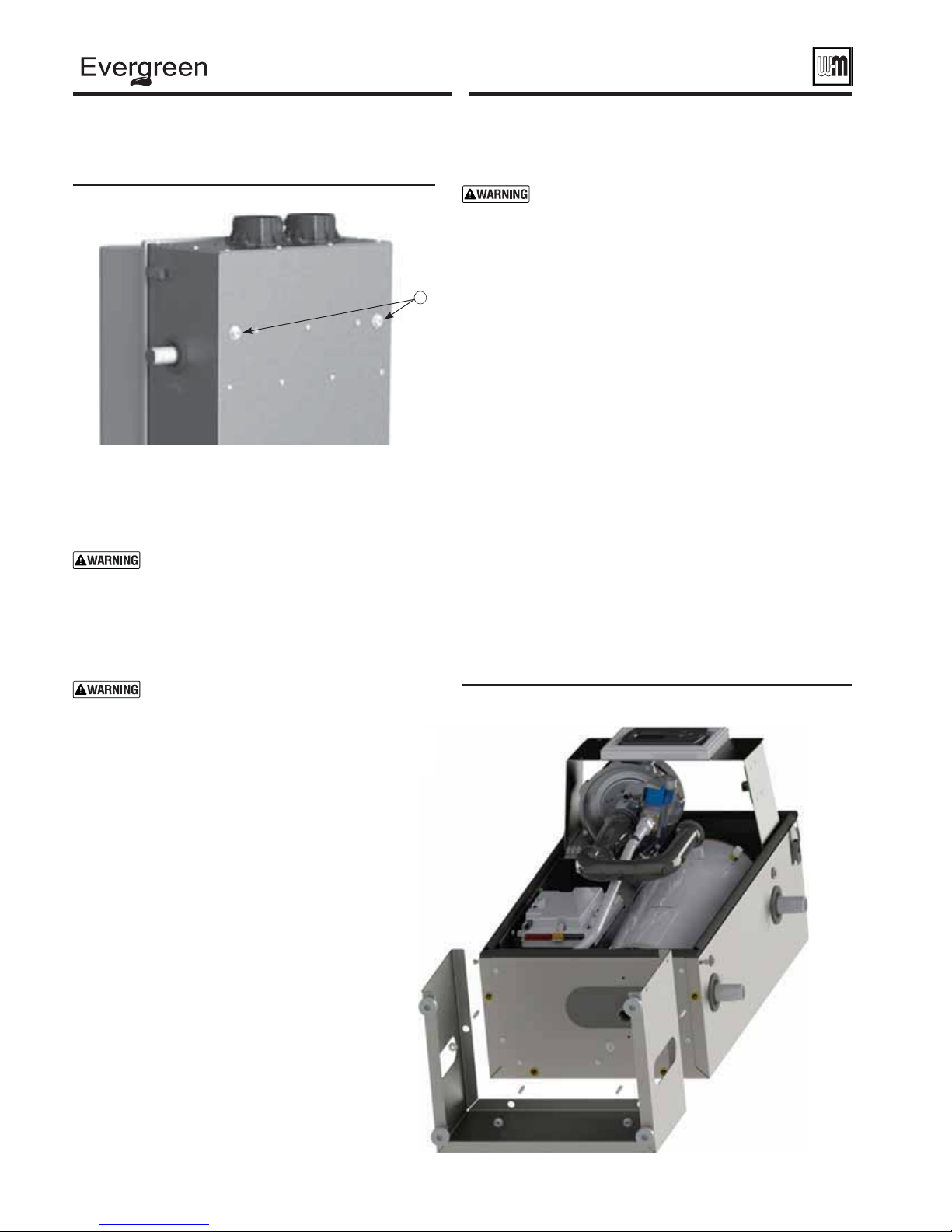

Floor Stand AssemblyWall-mounting the boiler

Floor Standing

Figure 6 Boiler mounting studs

3

6. When the brackets are engaged correctly, the bottom of

the boiler enclosure will be at or near the pencil line, or

tape, you applied in step 2.

7. Adjust the studs properly until engaged with the bracket

and the boiler slips into the correct position.

When mounting the boiler, use the method

described on step 2, page 11 to ensure the

mounting studs are properly engaged. If not,

the boiler could fall. Failure to comply could

result in severe personal injury, death or

substantial property damage.

8. Ensure boiler is level front-to-back.

Ensure boiler is NOT pitched upward

with the front of the boiler higher than

the back of the boiler. This can prevent

condensate from draining properly. Failure

to comply could result in severe personal

re

al

injury, death or substantial property damage.

The boiler is heavy, and requires two people to

lift and place upright. Use caution not to drop

the boiler or cause bodily injury while lifting

and handling. Wear non-slip gloves to prevent

possibility of cuts from sheet metal edges.

After the boiler is removed from the shipping

carton, DO NOT allow the boiler to sit on its

bottom, before stand is installed. Doing so may

result in damage to the condensate dish.

1. Carefully remove boiler from styrofoam protective base and set

on back. Remove door from front of boiler by loosening screw

on top of boiler and unfastening latches on side of cabinet.

2. Remove four (4) 5/16” studs from fl oor stand hardware trim

bag. Install studs by hand in rivet nuts on bottom of Evergreen

boiler. See Figure 7 .

3. Remove front access panel from stand assembly using 5/16”

driver.

4. Align holes in top of stand with studs on bottom of boiler.

Slide stand over studs. Remove 5/16” nuts from trim bag.

Install nuts on studs using ½” socket or wrench. Make sure

to align sides of stand with cabinet before tightening down

nuts. Do not overtighten.

5. Install the condensate trap assembly following instructions

on page 52

6. After confi rming nuts are tightened, obtain assistance and lift

the boiler into upright position.

7. Set boiler in place and level by adjusting leveling legs with

fl at head screwdriver.

Figure 7 Floor stand assembly (front access panel

removed)

.

®

12

(9*

Part number 550-100-191/0917

®

gas-fired water boiler — 70/110/155 Boiler Manual

Boiler hydrostatic test

DO NOT install a relief valve with a pressure

higher than 30 PSIG

allowable relief valve setting for the boiler. Failure

to comply could prevent the relief valve from

operating as needed, resulting in possibility of

severe personal injury, death or substantial property

damage.

Use two wrenches when tightening any pipe

connection to the boiler

boiler pipes from turning could damage pipes or

heat exchanger, resulting in possible severe personal

injury, death or substantial property damage.

. This is the maximum

. Failure to prevent the

Hydrostatic pressure test

Pressure test the boiler before permanently attaching water or

gas piping or electrical supply.

Install pipe fi ttings for relief valve and

P/T gauge

1. Install the reducer bushings (155 only), reducing tees, and

close nipples, shipped loose with the boiler, located and

oriented as shown in Figure 8, page 14 .

Boilers installed in locations with less than the

RECOMMENDED service clearances will need to

adjust piping layout to meet space requirements.

2. Apply pipe dope to all fi ttings sparingly.

DO NOT install the relief valve until after

the hydrostatic test. Temporarily install a ¾"

pipe plug in the relief valve location as directed in

these instructions. The plug must be removed after

the test.

TEMPORARILY insert a ¾" NPT pipe plug in the relief valve

2.

tapping. After the hydrostatic test, this plug must be removed

and the relief valve must be installed.

Fill and pressure test

1. See Figure 9, page 14 for use with the following instructions.

2. CLOSE the boiler drain valve (item 11). Connect a hose to

fresh water supply and to the drain valve.

3. Place a bucket under the ends of the isolation valves (item 9

and 10) to catch water drippings.

4. CLOSE isolation valve item 10, then crack open the valve

slightly. Leave isolation valve item 9 open.

5. Slowly open the boiler drain valve (item 11) and fresh water

supply to fi ll boiler with water. The boiler and piping will fi ll

quickly because of the low water content.

6. When water begins to fl ow from bottom isolation valve (item

10), close the valve.

7. Continue fi lling until water fl ows from top isolation valve (item

9), then close the valve.

8. When pressure on the pressure/temperature gauge (item 4)

reaches at least 45 PSIG, but no higher than 55 PSIG, CLOSE

the boiler drain valve (item 11).

9. Hold at test pressure for 10 minutes.

Do not leave boiler unattended. A cold water fi ll

could expand and cause excessive pressure, resulting

in severe personal injury, death or substantial

property damage.

10. Make sure constant gauge pressure has been maintained

throughout test. Check for leaks. Repair if found.

Leaks must be repaired at once. Failure to

do so can damage boiler, resulting in substantial

property damage.

Connect the relief valve ONLY on the

BOILER SUPPLY OUTLET, NOT the boiler

return. Connect the relief valve only as shown in

this manual. Ensure relief valve is located above

heat exchanger.

Failure to comply with the above could prevent

the relief valve from operating as needed, resulting

in possibility of severe personal injury, death or

substantial property damage.

3. Install the pressure/temperature gauge to the reducing tee as

shown in Figure 8, page 14 .

Install fi ttings and valves required for

hydrostatic testing

1. The following piping components (supplied by installer) are

required for the test confi guration:

a. Two shut-off valves (1" NPT on 70/110,

1¼" NPT on 155).

b. Two close nipples (1" NPT on 70/110,

1¼" NPT on 155).

c. ¾" NPT pipe plug.

Part number 550-100-191/0917

Do not use petroleum-based cleaning or sealing

compounds in boiler system. Gaskets and seals

in the system may be damaged. This can result in

substantial property damage.

Drain and remove fi ttings

1. Disconnect fi ll water hose from water source.

2. Drain boiler through drain valve

Use caution when releasing pressure from the boiler.

Rapid water fl ow could cause injury.

3. Remove hose after draining.

4. Remove nipples and valves unless they will remain for use in

the system piping.

5. Remove plug and install relief valve as specifi ed in the following

WARNING.

Remove plug from relief valve tee. Install the

relief valve in the ¾" tee. See page 43 or page 48

to install relief valve discharge piping. Failure to

install the boiler relief valve could result in severe

personal injury, death or substantial property

damage.

(item 11).

13

®

9

gas-fired water boiler — 70/110/155 Boiler Manual

Boiler hydrostatic test (continued)

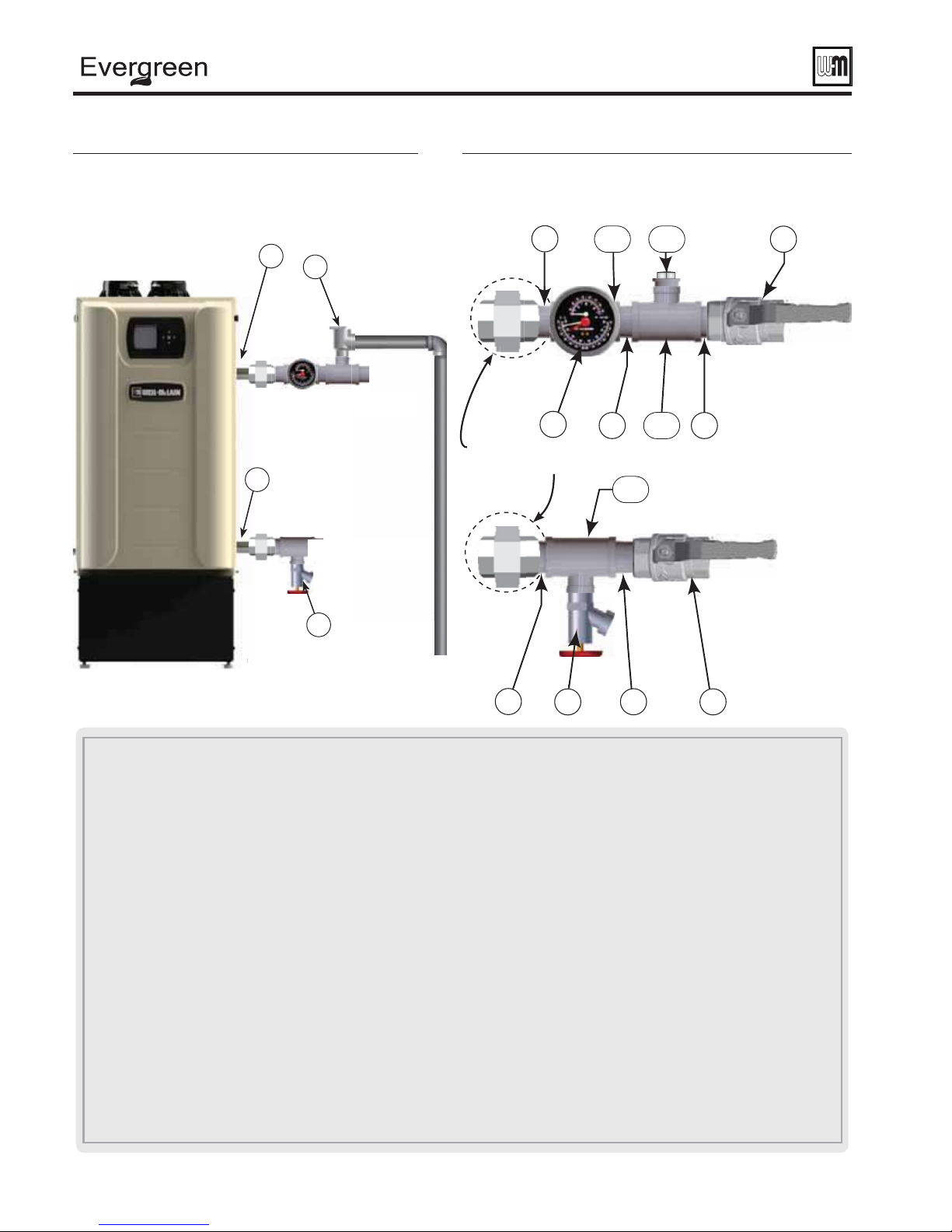

Figure 8 Install pipe fi ttings for relief valve and

pressure/temperature gauge —

NOT mount relief valve until AFTER

hydrostatic testing

(see legend below)

1

3

Piping to system

DO

2

Piping from system

Figure 9 Install piping components required for

(155 only)

Recommended but

not included

hydrostatic test (

B

see legend below)

B

C

C

11

(9*

(155 only)

1 Boiler supply (outlet) connection, (male, 1" NPT )

2 Boiler return (inlet) connection, (male, 1" NPT )

3 Boiler relief valve, shipped loose with boiler — DO NOT mount relief valve until AFTER hydrostatic testing.

3a TEMPORARILY ONLY — Insert a ¾" NPT plug in the relief valve tapping of the reducing tee. This MUST BE REMOVED after

the test and the relief valve mounted here.

4 Pressure/temperature gauge, shipped loose with boiler

5a Reducing tee, NPT, 1 " x 1 " x ¼" on 70/110, & 1 ¼" x 1 ¼" x ¼" on 155, shipped loose with boiler

5b Reducing tee, NPT, 1 " x 1 " x ¾" on 70/110, & 1 ¼" x 1 ¼" x ¾" on 155, shipped loose with boiler

6 Nipple, NPT 1" x close on 70/110, & 1 ¼" x close on 155, shipped loose with boiler

7 Bushing, NPT, 1 ¼" x 1", shipped loose with boiler (155 only)

8 Nipple, NPT 1" x close on 70/110, & 1 ¼" x close on 155, by installer

9 Isolation valve on supply connection, by installer (1" NPT on 70/110, 1¼" NPT on 155)

(9*D

10 Isolation valve on return connection, by installer (1" NPT on 70/110, 1¼" NPT on 155)

11 ¾" NPT boiler drain valve, shipped loose with boiler — after hydrostatic testing, move drain valve to lowest point on the return piping if not

already there.

14

Part number 550-100-191/0917

®

gas-fired water boiler — 70/110/155 Boiler Manual

Converting boiler to propane — EVG 70

Prepa re boiler for propane —

EVG 70 only (if required)

Propane operation

ALL Evergreen

for propane operation

Converting an existing natural gas-fi red

boiler for propane

installed, you must turn off gas supply, turn off

power and allow boiler to cool before proceeding.

You must also completely test the boiler after

conversion to verify performance and start up

the boiler following instructions beginning on

page 91 of this manual.

Failure to comply could result in severe personal

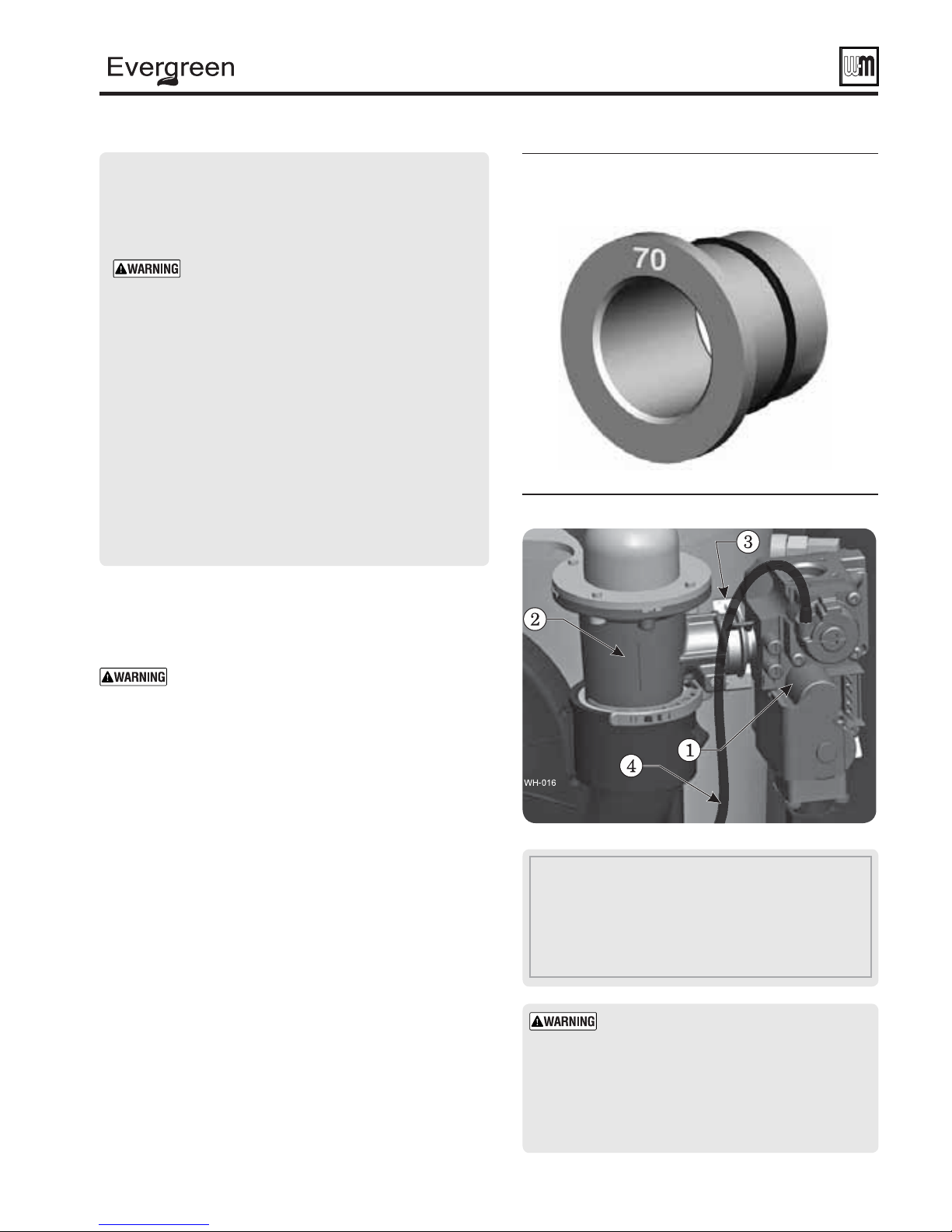

Verify 70 propane gas orifice size —

See Figure 10 . Verify when installing that the

orifi ce size marking is correct. Orifi ces will be

stamped as in illustration or with “3.75” for

model 70.

injury, death or substantial property damage.

®

boilers must be converted

.

— For a boiler already

Figure 10 Propane gas orifi ce identifi cation

EVG 70 (may be stamped 3.75)

Figure 11 Gas valve and venturi

Installing propane orifi ce —

EVG 70 only

If boiler is already installed — You must turn off

electrical supply to the boiler and close the external

manual gas shut-off valve to isolate the boiler during

conversion. Allow the boiler to cool if it has been

operating.

Following conversion of an installed boiler, follow

all instructions in this manual to start up the boiler

and verify operation of the boiler and all system

components.

1. Locate the propane orifi ce from the propane conversion kit bag.

2. Verify that the stamping on the orifi ce is correct for the model

size (see Figure 10 ).

3. If the jacket door is not already removed, remove it.

4. Locate the gas valve and venturi (see Figure 11 ).

5. Pull the gas valve retention ring (item 3, Figure 11 ) off of the

gas valve/venturi joint.

6. Carefully pull the gas valve to the right until it is free of the

venturi. Leave the pressure reference hose (item 4, Figure 11 )

connected at both ends.

1 Gas valve

2 Venturi

3 Gas valve retention ring

4 Pressure reference hose — LEAVE CONNECTED AT BOTH

ENDS

Support the gas valve after disconnecting

it. DO NOT allow it to hang from the gas

valve fl ex line. When re-attaching the gas

valve, ensure the gas valve-to-venturi O-ring

(item 5, Figure 12, page 16 ) is in place and

in good condition. Inspect the gas valve fl ex

line to ensure it is undamaged and in good

condition.

Part number 550-100-191/0917

15

®

gas-fired water boiler — 70/110/155 Boiler Manual

Converting boiler to propane — EVG 70

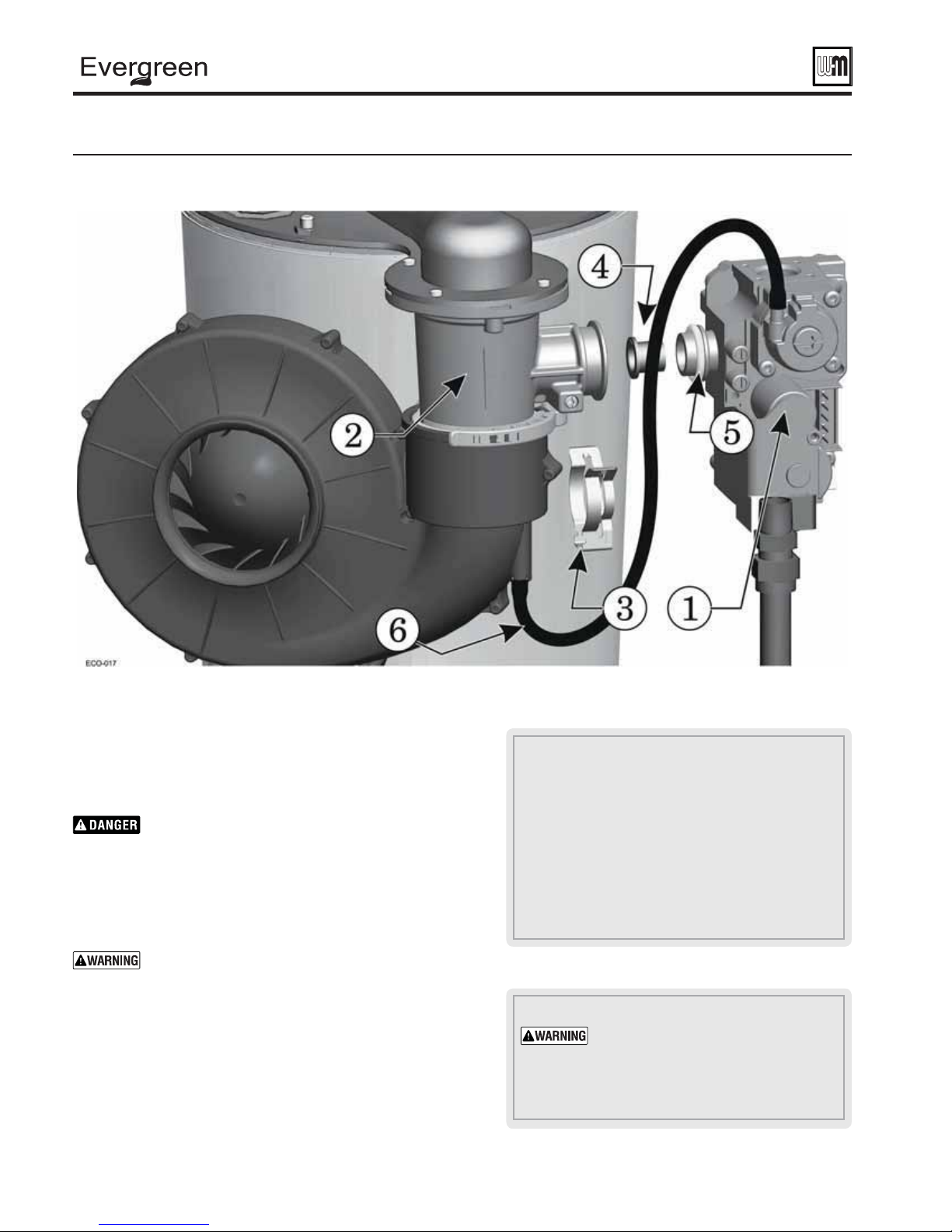

Figure 12 Installing the propane gas orifi ce (some details omitted for clarity)

(continued)

7. See Figure 12 . Insert the propane gas orifi ce (item 4) into the gas

valve outlet as shown.

8. Press the orifi ce into the gas valve outlet until the bushing fl ange

butts against the gas valve outlet.

Inspect the O-rings on the propane gas orifi ce an on the

gas valve outlet (item 5, Figure 12 ). The O-rings must

be in good condition and must be installed. Failure to

comply will cause a gas leak, resulting in severe personal

injury or death.

9. Reposition gas valve into the venturi and reinstall the gas valve

retention ring (item 3, Figure 12 ).

DO NOT ATTEMPT TO MEASURE VALVE OUTLET

PRESSURE.

fl uid contamination. Failure to comply could result in

severe personal injury, death or substantial property

damage.

10. After installation is complete, attach the propane conversion label

(in conversion kit bag) next to the boiler rating plate.

11. Perform complete start-up sequence (beginning on page 91 ),

including check for gas leaks and checking for proper operation.

12. Reinstall jacket door.

16

The valve could be damaged by manometer

LEGEND for Figure 12

1 Gas valve

2 Venturi

3 Gas valve retention ring

4 Propane orifi ce with o-ring

5 Gas valve o-ring

6 Pressure reference hose — LEAVE CONNECTED AT BOTH

ENDS

The jacket door must be in place

during operation.

the boiler with the jacket door removed

except for inspection and testing as

directed in this manual.

DO NOT operate

Part number 550-100-191/0917

®

gas-fired water boiler — 70/110/155 Boiler Manual

Converting boiler to propane — EVG 110

Prepa re boiler for propane —

EVG 110 only (if required)

Propane operation

ALL Evergreen

for propane operation

Converting an existing natural gas-fi red

boiler for propane

installed, you must turn off gas supply, turn

off power and allow boiler to cool before

proceeding. You must also completely test the

boiler after conversion to verify performance

and start up the boiler following instructions

beginning on page 91 of this manual.

Verify 110 propane gas orifice size —

See Figure 13 . Verify when installing that the

orifi ce size marking is correct. Orifi ces will be

stamped as in illustration or “3.7” for model

110.

®

boilers must be converted

.

— For a boiler already

Figure 13 Propane gas orifi ce identifi cation

EVG 110 (may be stamped 3.7

Figure 14 EVG 110 Gas valve and venturi

only

)

Failure to comply could result in severe personal

injury, death or substantial property damage.

Installing propane orifi ce —

EVG 110 only

If the boiler is already installed — You must turn

off electrical supply to the boiler and close the external

manual gas shut-off valve to isolate the boiler during

conversion. Allow the boiler to cool if it has been

operating.

Following conversion of an installed boiler, follow

all instructions in this manual to start up the boiler

and verify operation of the boiler and all system

components.

1. Locate the propane orifi ce from the propane conversion kit bag.

2. Verify that the stamping on the orifi ce is correct for the model

size (see Figure 13 ).

3. If the jacket door is not already removed, remove it.

4. Locate the gas valve and venturi (see Figure 14 ).

5. Release the gas line from the silencer bracket clip (item 5, page

18) and rotate it out of the way.

6. Use a T25-mm torx bit to remove the two (2) bolts (item 3)

that secure the gas valve to the venturi.

1 Gas valve

2 Venturi

3 Gas valve screws to venturi

Support the gas valve after disconnecting

it. DO NOT allow it to hang from the gas

valve fl ex line. When re-attaching the gas

valve, ensure the gas valve propane orifi ce

is properly seated in rubber boot (item 6,

Figure 15, page 18 ) and is in place and in good

condition. Inspect the gas valve fl ex line to

ensure it is undamaged and in good condition.

Part number 550-100-191/0917

17

®

gas-fired water boiler — 70/110/155 Boiler Manual

Converting boiler to propane — EVG 110

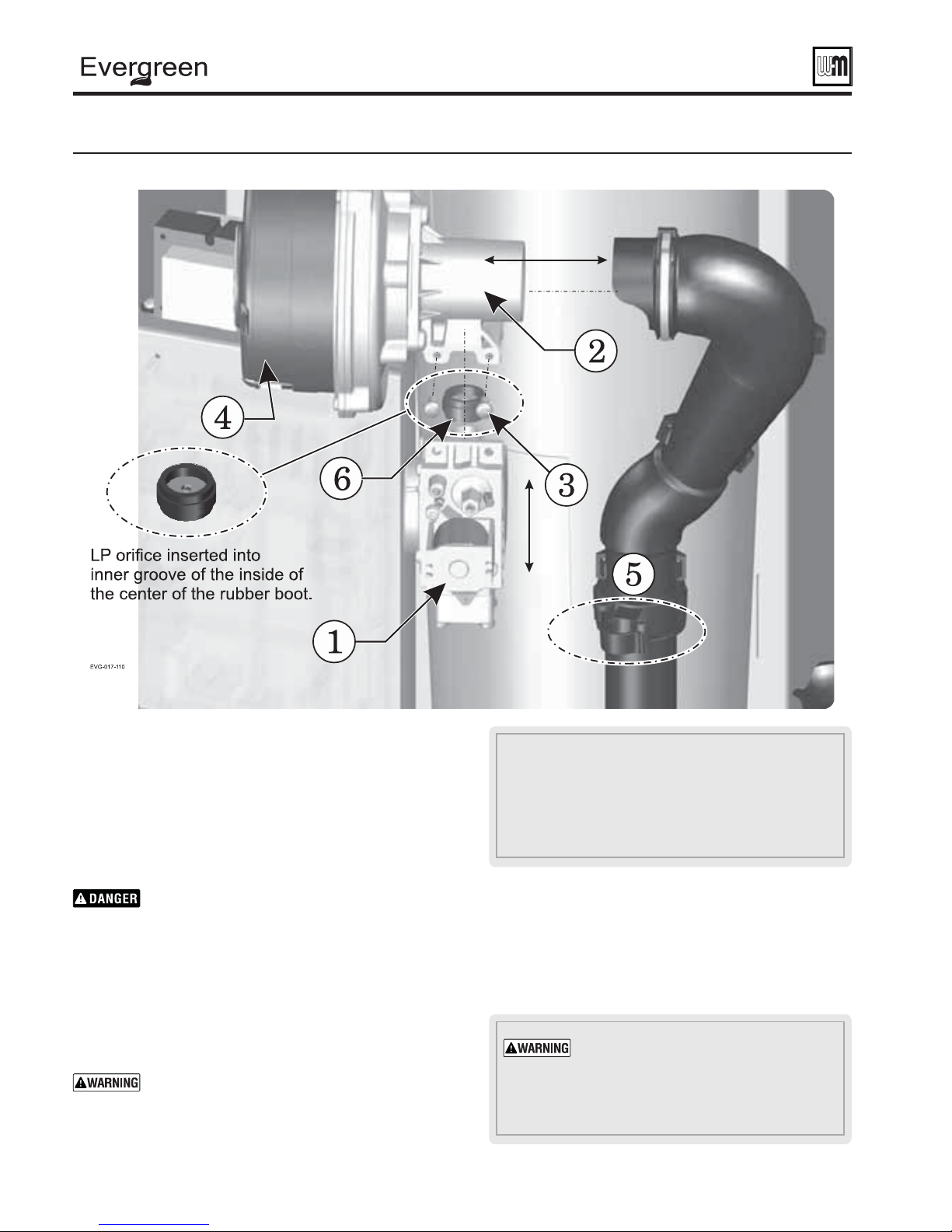

Figure 15 EVG-110 -Installing the propane gas orifi ce (some details omitted for clarity)

(continued)

7. See Figure 15 , Carefully pull the gas valve down until it is free

of the venturi. Securely support the gas valve — DO NOT

leave it dangling.

8. Remove the rubber boot from the gas valve or venturi.

9. Insert the propane gas orifi ce into the rubber boot. Orifi ce

must be seated into the inner groove inside the center of the

rubber boot.

10. Install the rubber boot (item 6) guaranteeing that it is fi rmly

seated on the gas valve opening.

When re-attaching the gas valve, ensure the gas

valve rubber boot (item 6, Figure 15 ) is in place

and in good condition.

Failure to comply will cause a gas leak, resulting

in severe personal injury or death.

11. Reposition gas valve onto the venturi and reinstall the gas

valve retention bolts (item 3). Make sure the rubber boot is

fully seated on both the gas valve and venturi.

12. Swing the silencer bracket clip (item 5) back into position

and snap on to the gas line.

DO NOT ATTEMPT TO MEASURE VALVE

OUTLET PRESSURE.

damaged by manometer fluid contamination.

Failure to comply could result in severe personal

injury, death or substantial property damage.

18

The valve could be

LEGEND for Figure 15

1 Gas valve

2 Venturi

3 Bolts (2) for attaching gas valve to venturi

4 Blower

5 Air silencer bracket clip

6 Propane orifi ce with boot

13. After installation is complete, attach the propane conversion

label (in conversion kit bag) next to the boiler rating plate.

14. Perform complete start-up sequence (beginning on

page 91 ), including check for gas leaks and checking for

proper operation.

15. Reinstall jacket door.

The jacket door must be in place during

operation.

with the jacket door removed except for

inspection and testing as directed in this

manual.

DO NOT operate the boiler

Part number 550-100-191/0917

®

gas-fired water boiler — 70/110/155 Boiler Manual

Converting boiler to propane — EVG 155

Prepa re boiler for propane —

EVG 155 only (if required)

Propane operation

ALL Evergreen

for propane operation

Failure to comply could result in severe personal

Converting an existing natural gas-fired

boiler for propane

installed, you must turn off gas supply, turn off

power and allow boiler to cool before proceeding.

You must also completely test the boiler after

conversion to verify performance and start up the

boiler following instructions beginning on page 91

of this manual.

Verify propane gas orifice size — See

Figure 16 . Verify when installing that the orifi ce

size marking is correct. Orifi ce will be stamped as

in illustration.

injury, death or substantial property damage.

®

boilers must be converted

.

— For a boiler already

Installing propane orifi ce —

EVG 155 only

If boiler is already installed — You must turn off

electrical supply to the boiler and close the external

manual gas shut-off valve to isolate the boiler during

conversion. Allow the boiler to cool if it has been

operating.

Following conversion of an installed boiler, follow

all instructions in this manual to start up the boiler

and verify operation of the boiler and all system

components.

1. Locate the propane orifi ce from the propane conversion kit bag.

2. Verify that the stamping on the orifi ce is correct for the model

size (see Figure 16 ).

3. If the jacket door is not already removed, remove it.

4. See Figure 17, page 20 and Figure 18, page 20 for the following.

5. Locate the gas valve and venturi (items 1 and 3).

6. Release the gas line to silencer bracket (item 6) from the gas line

and rotate it forward out of the way.

7. Use a 5mm hex wrench to remove the three (3) Allen screws

(item 2) that secure the gas valve to the venturi.

8. See Figure 18, page 20 . Carefully pull the gas valve to the right

until it is free of the venturi. Securely support the gas valve —

DO NOT leave it dangling.

Figure 16 Propane gas orifi ce identifi cation

EVG 155

Support the gas valve after

disconnecting from the venturi. DO

NOT allow it to hang from the gas

valve fl ex line.

valve, ensure the gas valve grommet (item

8, Figure 18, page 20 ) is in place and in

good condition. Inspect the gas valve fl ex

line to ensure it is undamaged and in good

condition.

9. Insert the propane gas orifi ce (item 7) into the gas valve

opening as shown in Figure 18, page 20 .

10. Make sure that the rubber grommet (item 8) is fi rmly

seated in the gas valve opening.

When re-attaching the gas valve, ensure the

gas valve grommet (item 8, Figure 18, page 20 )

is in place and in good condition. Failure to

comply will cause a gas leak, resulting in severe

personal injury or death.

11. Reposition gas valve onto the venturi and reinstall the

gas valve retention screws (item 2).

12. Swing the gas line to silencer bracket (item 6) back into

position and snap onto the gas line.

DO NOT ATTEMPT TO MEASURE VALVE

OUTLET PRESSURE.

damaged by manometer fl uid contamination.

Failure to comply could result in severe

personal injury, death or substantial property

damage.

13. After installation is complete, attach the propane

conversion label (in conversion kit bag) next to the

boiler rating plate.

14. Perform complete start-up sequence (beginning on

page 91 ), including check for gas leaks and checking

for proper operation.

15. Reinstall jacket door.

When re-attaching the gas

The valve could be

Part number 550-100-191/0917

19

®

gas-fired water boiler — 70/110/155 Boiler Manual

Converting boiler to propane — EVG 155 (continued)

Figure 17 Installing the propane gas orifi ce (some details omitted for clarity)

LEGEND for Figure 17 and Figure 18

1 Venturi (leave venturi attached to blower)

2 (3) hex-head screws, 5 mm hex (remove and retain)

3 Gas valve

4 Air silencer (leave connected to venturi)

5 Flexible gas line

6 Gas line to silencer bracket (rotate forward before disconnecting gas valve

from venturi

7 Propane orifi ce (in propane conversion kit envelope)

8 Rubber grommet (must be installed in valve for all applications) — make

sure grommet is properly seated in valve before inserting the propane

orifi ce

The jacket door must be in place during

operation.

DO NOT operate the boiler with the

jacket door removed except for inspection and

testing as directed in this manual.

Figure 18 Gas valve and venturi

20

Part number 550-100-191/0917

®

gas-fired water boiler — 70/110/155 Boiler Manual

Gas piping — sizing gas lines

Boiler gas connection is ½" NPT. Size gas lines large

enough to provide gas to all connected appliances.

Natural Gas:

Pipe sizing for natural gas

1. Size gas piping from meter outlet to entrance of boiler in

accordance with Figure 19 and Figure 20 .

2. Use total input of all connected appliances. Divide total input

in Btuh by 1,000 to obtain cubic feet per hour of natural gas.

a. Pipe lengths in Figure 19 are equivalent length of straight

pipe. Convert pipe fi ttings to equivalent lengths using data

from Figure 20 .

b. Figure 19 is only for natural gas with specifi c gravity 0.60,

with a pressure drop through the gas piping as listed in the

table.

c. For additional gas pipe sizing information, refer to ANSI

Z223.1 NFPA 54 - latest edition (or Natural Gas and Propane

Installation CAN/CSA B149.1 or B149.2 for Canadian

installations).

Natural gas s upply pressure

1. Pressure required at gas valve inlet pressure port:

a. Maximum: 13" (330 mm) w.c. with no fl ow (lockup).

b. Minimum gas pressure, with gas fl owing (verify during

boiler startup, while boiler is at high fi re):

EVG 70: 3½" (89 mm) w.c.

EVG 110: 3½" (89 mm) w.c.

EVG 155: 3½" (89 mm) w.c.

c. Nominal gas pressure: 7.0" (178 mm) w.c.

2. Install 100% lockup gas pressure regulator in supply line if inlet

pressure can exceed 13" w.c. at any time. Adjust lockup regulator

for 13" w.c. maximum.

Propane Gas:

You must follow the instructions, beginning on

page 15 , to operate the boiler on propane. Failure to

comply could result in severe personal injury, death or

substantial property damage.

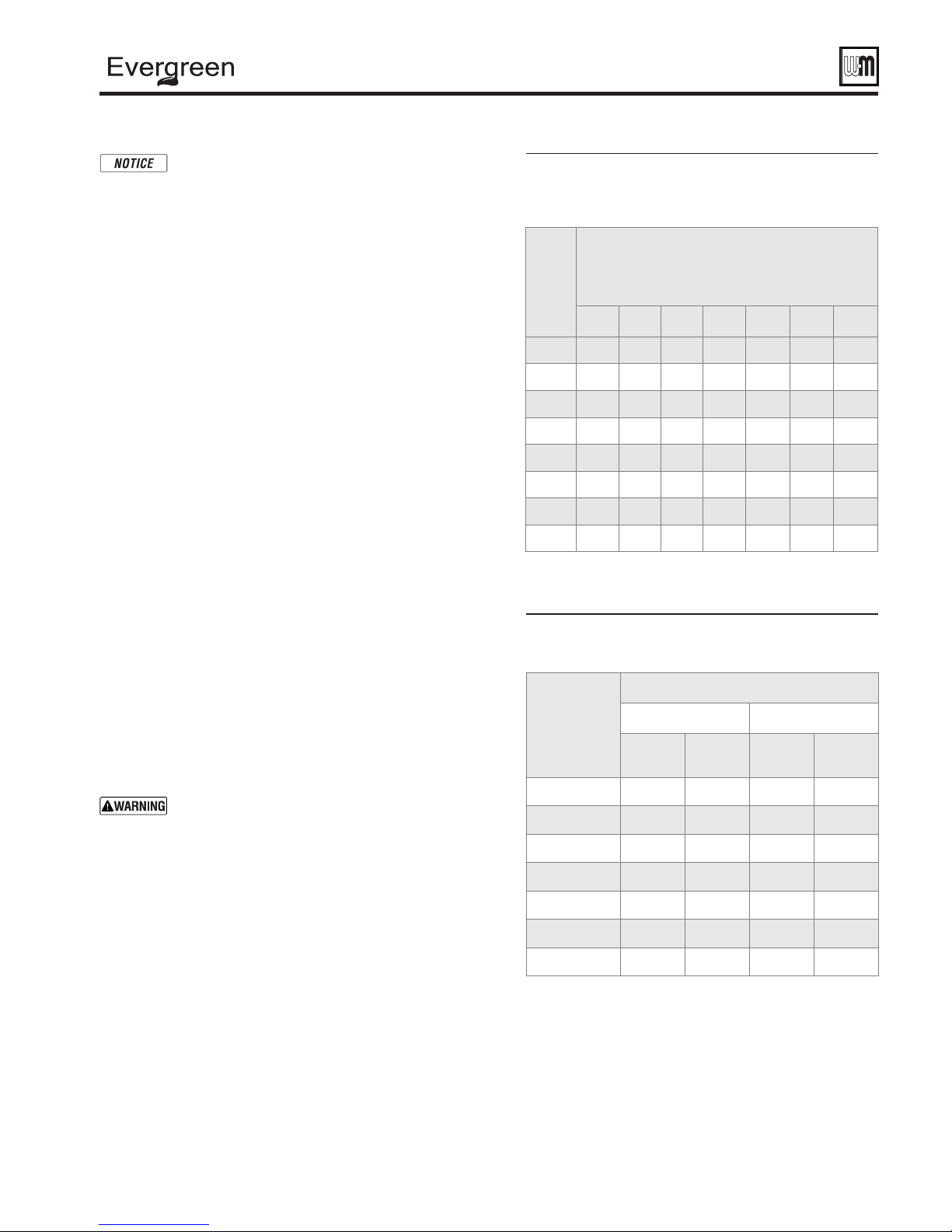

Figure 19 Pipe capacity for 0.60 specifi c gravity

natural gas; pipe length is in equivalent

feet.

Gas

Cubic feet per hour, natural gas, 0.60 specifi c gravity

pipe

total

length,

feet

10 132 278 520 1050 1600 3050 4800

20 92 190 350 730 1100 2100 3300

30 73 152 285 590 890 1650 2700

40 NA 130 245 500 760 1450 2300

50 NA 115 215 440 670 1270 2000

75 NA 105 175 360 545 1020 1650

100 NA 96 150 305 460 870 1400

150 NA 90 120 250 380 710 1130

Gas pressure 13" (330 mm) w.c. or less

Pressure drop 0.3 inches (7.6 mm) w.c

½" ¾" 1" 1¼" 1½" 2" 2½"

Capacity

.

Figure 20 Equivalent lengths of straight pipe for

typical gas line fi ttings.

Equivalent length, feet

Pipe size

inches

½

¾

1

90° Elbow Tee

short

radius

3.6 2.2 1.7 4.2

4.4 2.3 2.4 5.3

5.2 2.7 3.2 6.6

long

radius

line

fl ow

branch

fl ow

Pipe sizing for propane gas

1. Contact gas supplier to size pipes, tanks and 100% lockup gas

pressure regulator.

Propane supply pressure

1. Adjust propane supply regulator provided by gas supplier for

13" (330 mm) w.c. maximum pressure.

2. Pressure required at gas valve inlet pressure port:

a. Maximum: 13" (330 mm) w.c. with no fl ow (lockup).

b. Minimum gas pressure, with gas fl owing (verify during

boiler startup, while boiler is at high fi re):

EVG 70: 3½" (89 mm) w.c.

EVG 110: 3½" (89 mm) w.c.

EVG 155: 3½" (89 mm) w.c.

c. Nominal gas pressure: 11.0" (279 mm) w.c.

Part number 550-100-191/0917

1¼

1½

2

2½

6.6 3.2 4.6 8.7

7.4 3.4 5.6 9.9

8.5 3.6 7.7 12.0

9.3 4.0 9.3 13.0

21

®

gas-fired water boiler — 70/110/155 Boiler Manual

Venting/air piping — general

Any improper operation of the common venting system should be

corrected so the installation conforms with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54- latest edition, and/or the Natural Gas

and Propane Installation Code, CAN/CSA B149.1. When resizing any

portion of the common venting system, the common venting system

should be resized to approach the minimum size as determined using the

appropriate tables in Chapter 13 of the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 - latest edition, and/or the Natural Gas and Propane

Installation Code, CAN/CSA B149.1.

Do not install the Evergreen® boiler into a common vent

with any other appliance. This will cause fl ue gas spillage or

appliance malfunction, resulting in possible severe personal

injury, death or substantial property damage.

Existing common vent systems may be too large for the

appliances remaining connected after the existing boiler is

removed.

Failure to follow all instructions can result in fl ue gas spillage

and carbon monoxide emissions, causing severe personal

injury or death.

When removing a boiler from an existing

common vent system

The Evergreen® boiler cannot be common vented with any other

appliance

. When an existing boiler is replaced with an Evergreen® boiler,

the Evergreen® boiler CANNOT use the existing common vent. The boiler

requires its own vent and air piping, as specifi ed in this manual. This may

cause a problem for the appliances that remain on the old common vent,

because the vent may be too large. The following test is intended to check

for proper operation of the appliances remaining on the old common vent

system.

Vent system verifi cation

Perform the test sequence below for each appliance remaining on the

original common vent system. Operate each appliance individually, with

other appliances turned off. This procedure will test whether the common

vent system can properly vent each appliance.

Existing vent test procedure

(The following is intended to test whether the appliances remaining

on an existing vent system will operate satisfactorily.)

1. Seal any unused openings in the common venting system.

2. Visually inspect the venting system for proper size and horizontal pitch

and determine there is no blockage or restriction, leakage, corrosion or

other defi ciencies which could cause an unsafe condition.

3. Test vent system — Insofar as is practical, close all building doors and

windows and all doors between the space in which the appliances

remaining connected to the common venting system are located and

other spaces of the building. Turn on clothes dryers and any appliance

not connected to the common venting system. Turn on any exhaust

fans, such as range hoods and bathroom exhausts, so they will operate

at maximum speed. Do not operate a summer exhaust fan. Close

fi replace dampers.

4. Place in operation the appliance being inspected. Follow the lighting

instructions. Adjust thermostat so appliance will operate continuously.

5. Test for spillage at draft hood relief opening after 5 minutes of main

burner operation. Use the fl ame of a match or candle, or smoke from

a cigarette, cigar, or pipe.

6. After it has been determined that each appliance remaining connected

to the common venting system properly vents when tested as outlined

herein, return doors, windows, exhaust fans, fi replace dampers, and

any other gas-burning appliance to their previous conditions of use.

You must pipe combustion air to the

boiler air intake

Install air inlet piping for the Evergreen

.

®

boiler as described in this manual.

The air termination fitting must

be installed with the clearances and

geometry relative to the vent outlet

depicted in this manual to ensure that

fl ue products do not enter the air intake.

Ensure that the combustion air will

not contain any of the contaminants

in Figure 16. Do not pipe combustion

air near a swimming pool, for example.

Avoid areas subject to exhaust fumes

from laundry facilities. These areas will

always contain contaminants.

Contaminated combustion air will

damage the boiler, resulting in possible

severe personal injury, death or

substantial property damage.

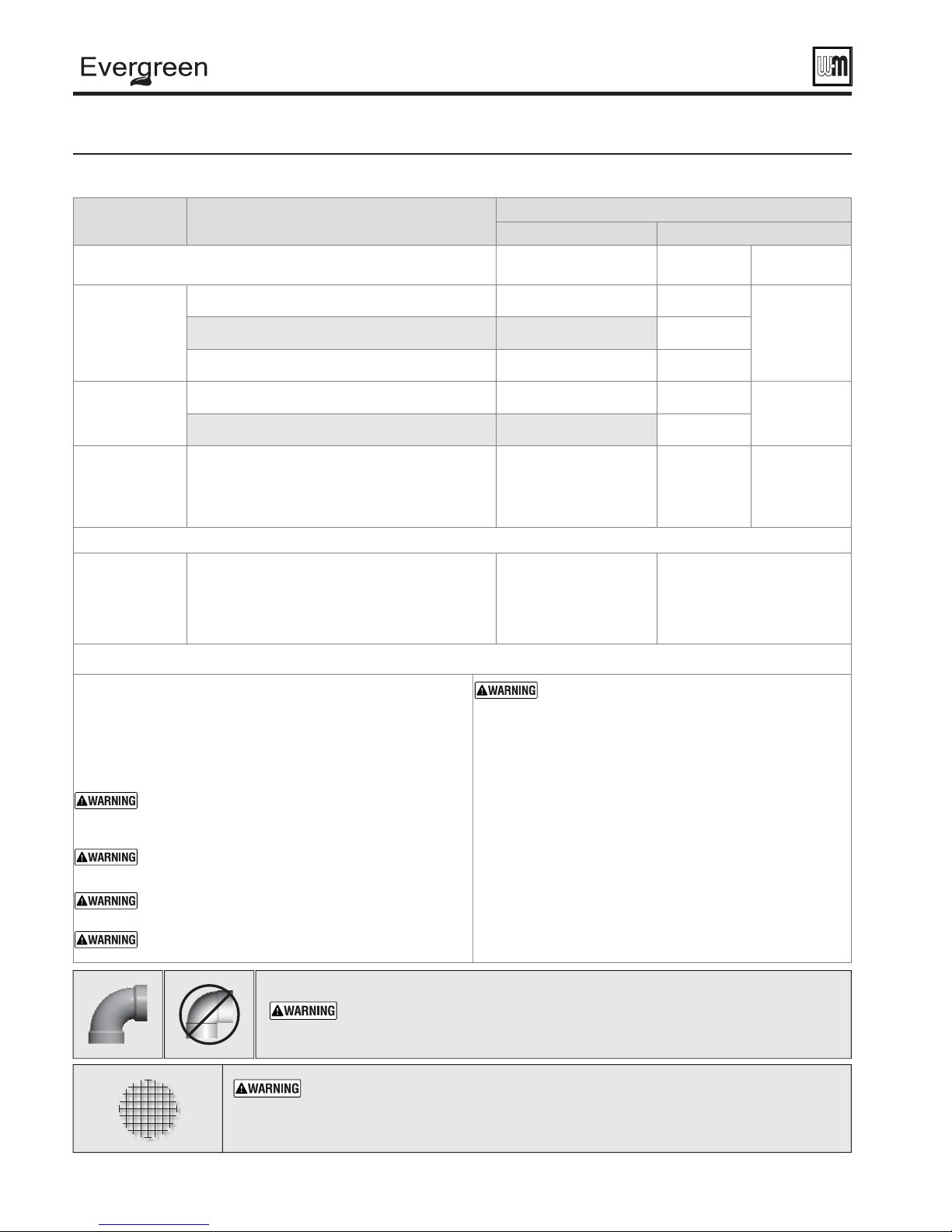

Figure 21 Corrosive contaminants and sources

Products to avoid

Spray cans containing chloro/fl uorocarbons

Permanent wave solutions

Chlorinated waxes/cleaners

Chlorine-based swimming pool chemicals

Calcium chloride used for thawing

Sodium chloride used for water softening

Refrigerant leaks

Paint or varnish removers

Hydrochloric acid/muriatic acid

Cements and glues

Antistatic fabric softeners used in clothes dryers

Chlorine-type bleaches, detergents, and cleaning

solvents found in household laundry rooms

Adhesives used to fasten building products and other

similar products

Excessive dust and dirt

Areas likely to have contaminants

Dry cleaning/laundry areas and establishments

Swimming pools

Metal fabrication plants

Beauty shops

Refrigeration repair shops

Photo processing plants

Auto body shops

Plastic manufacturing plants

Furniture refi nishing areas and establishments

New building construction

Remodeling areas

Garages with workshops

22

Part number 550-100-191/0917

®

gas-fired water boiler — 70/110/155 Boiler Manual

Venting & air — general (continued)

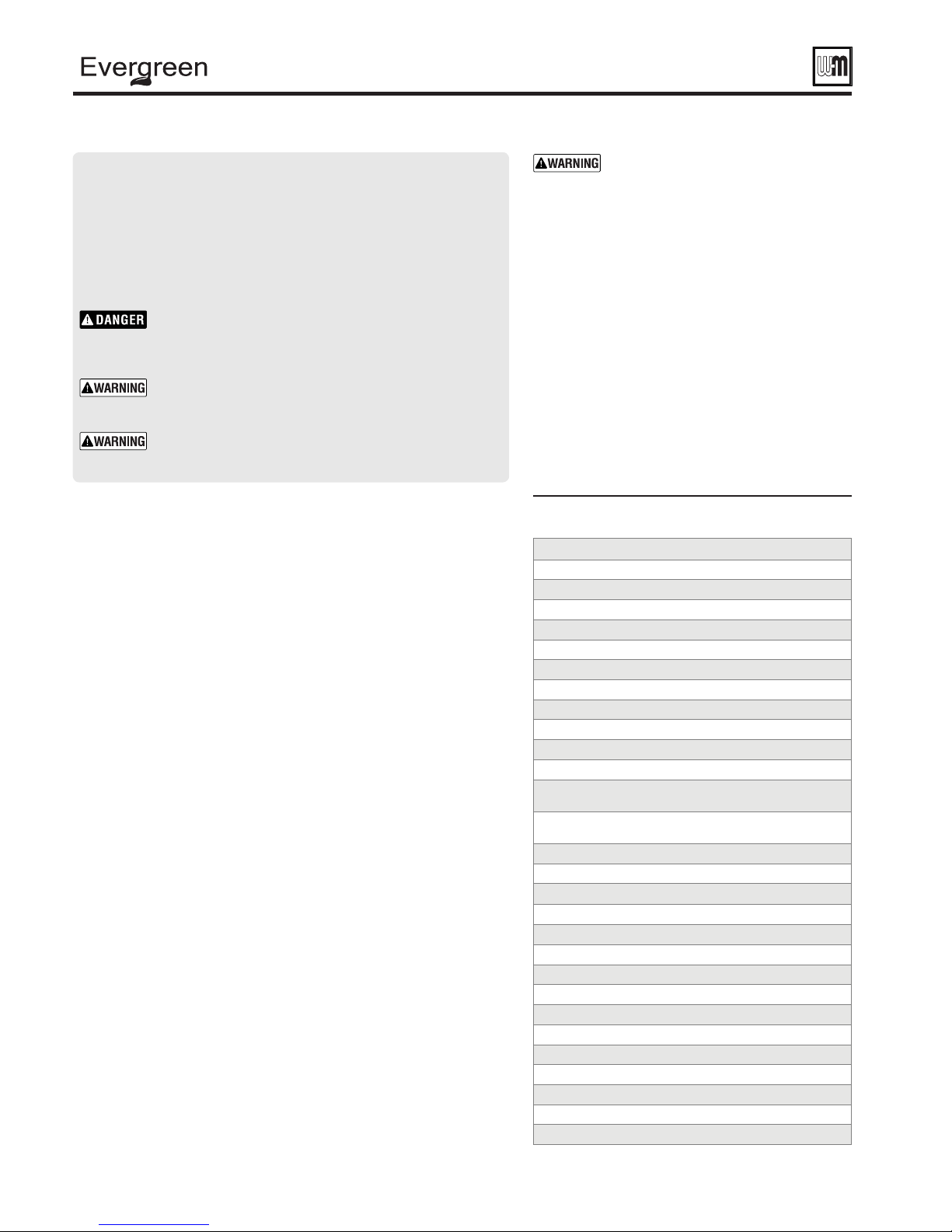

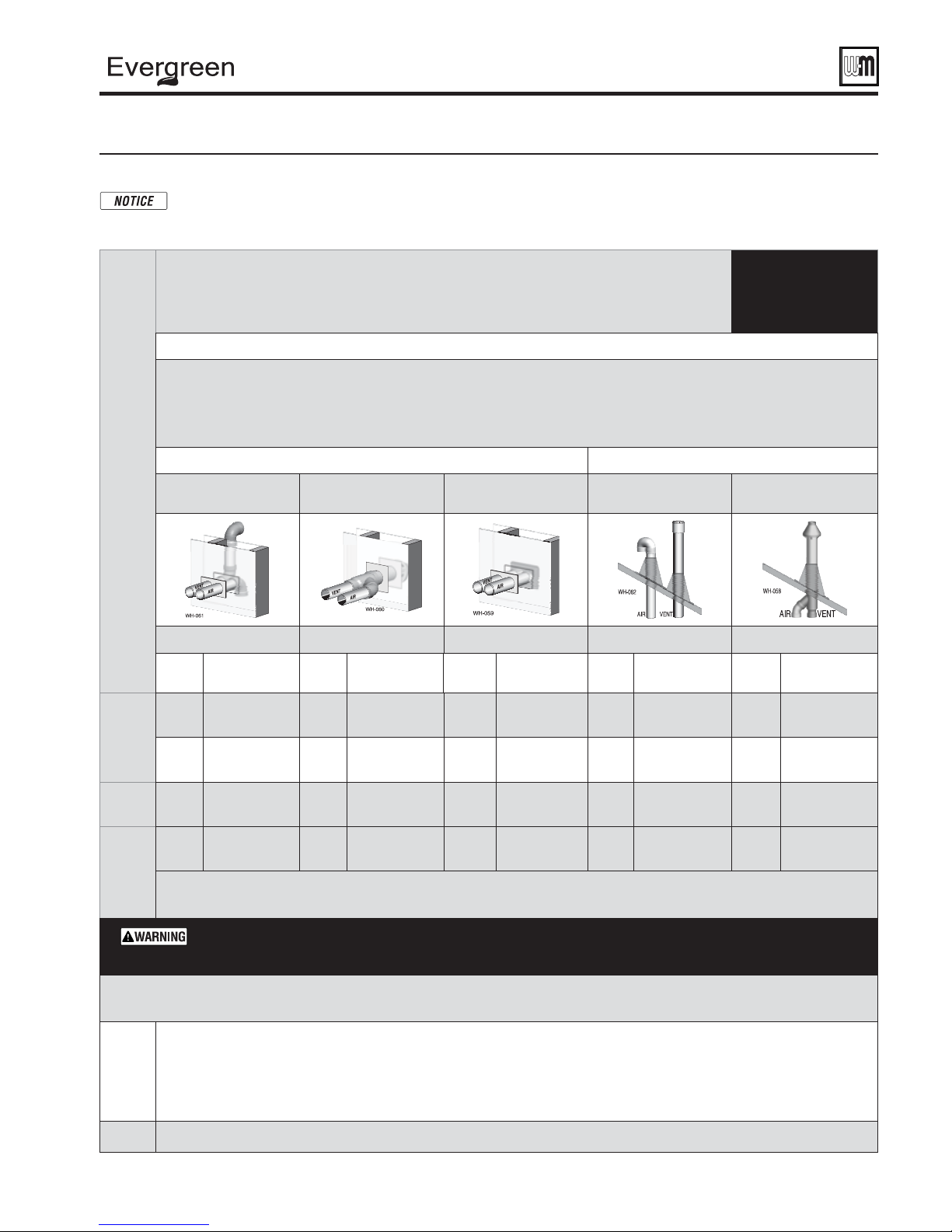

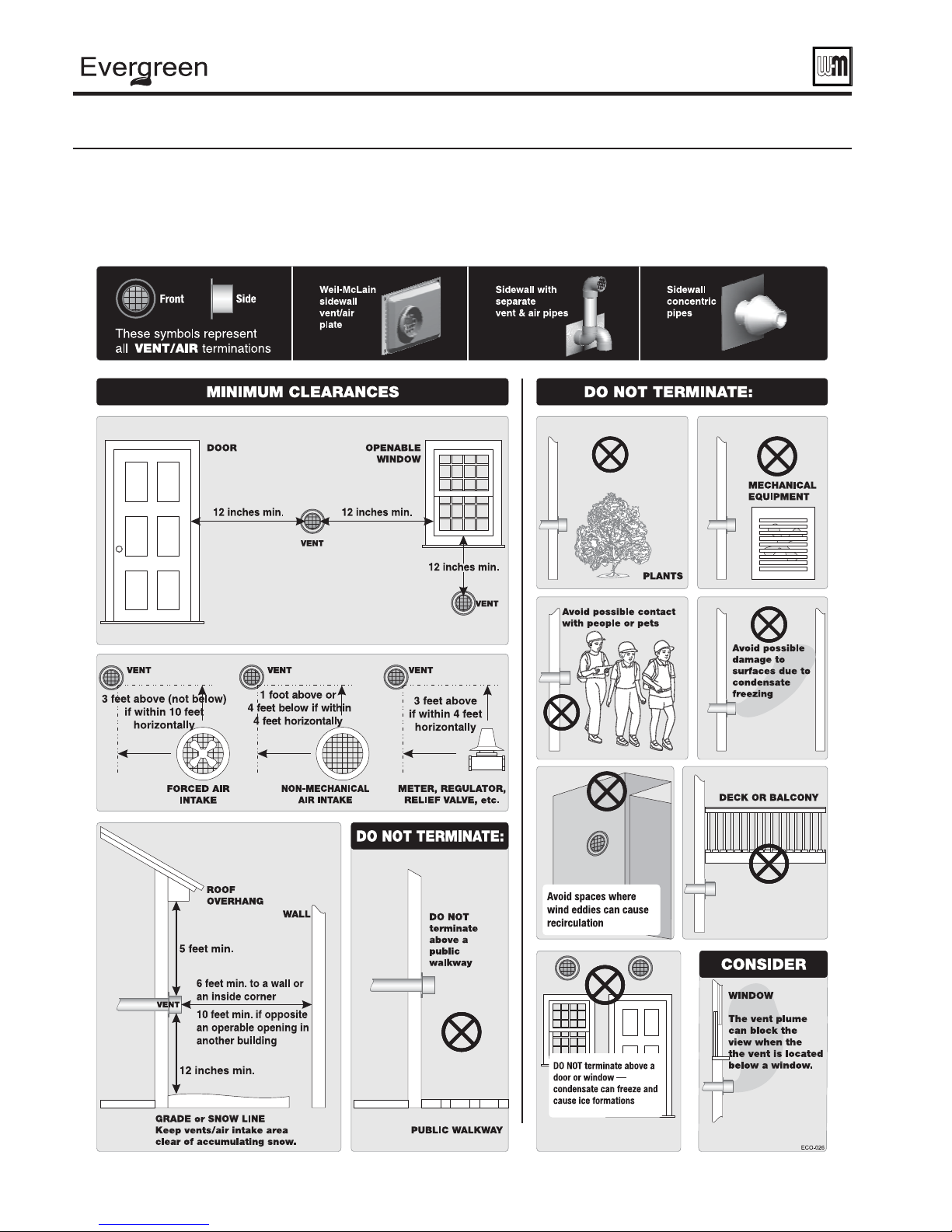

Figure 22 Evergreen

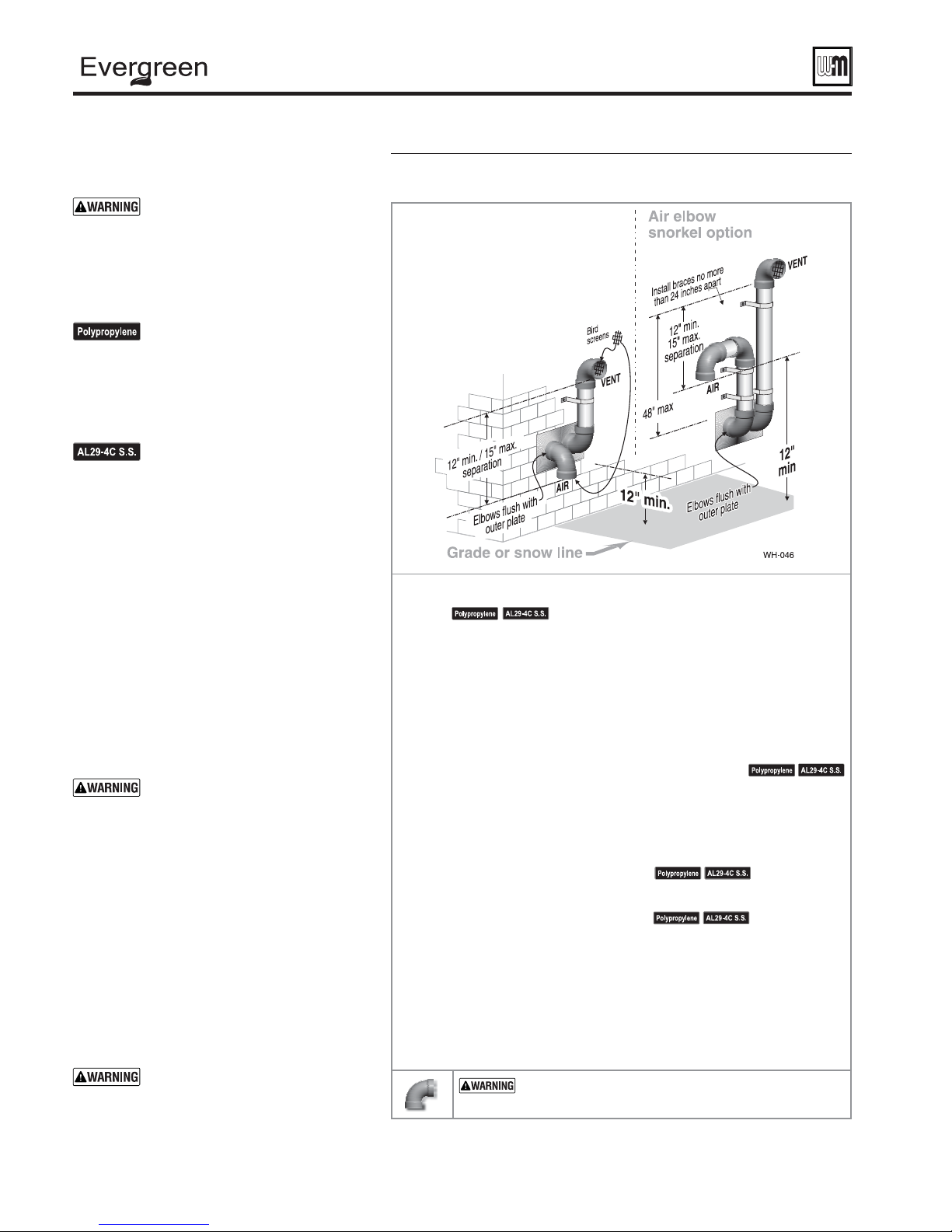

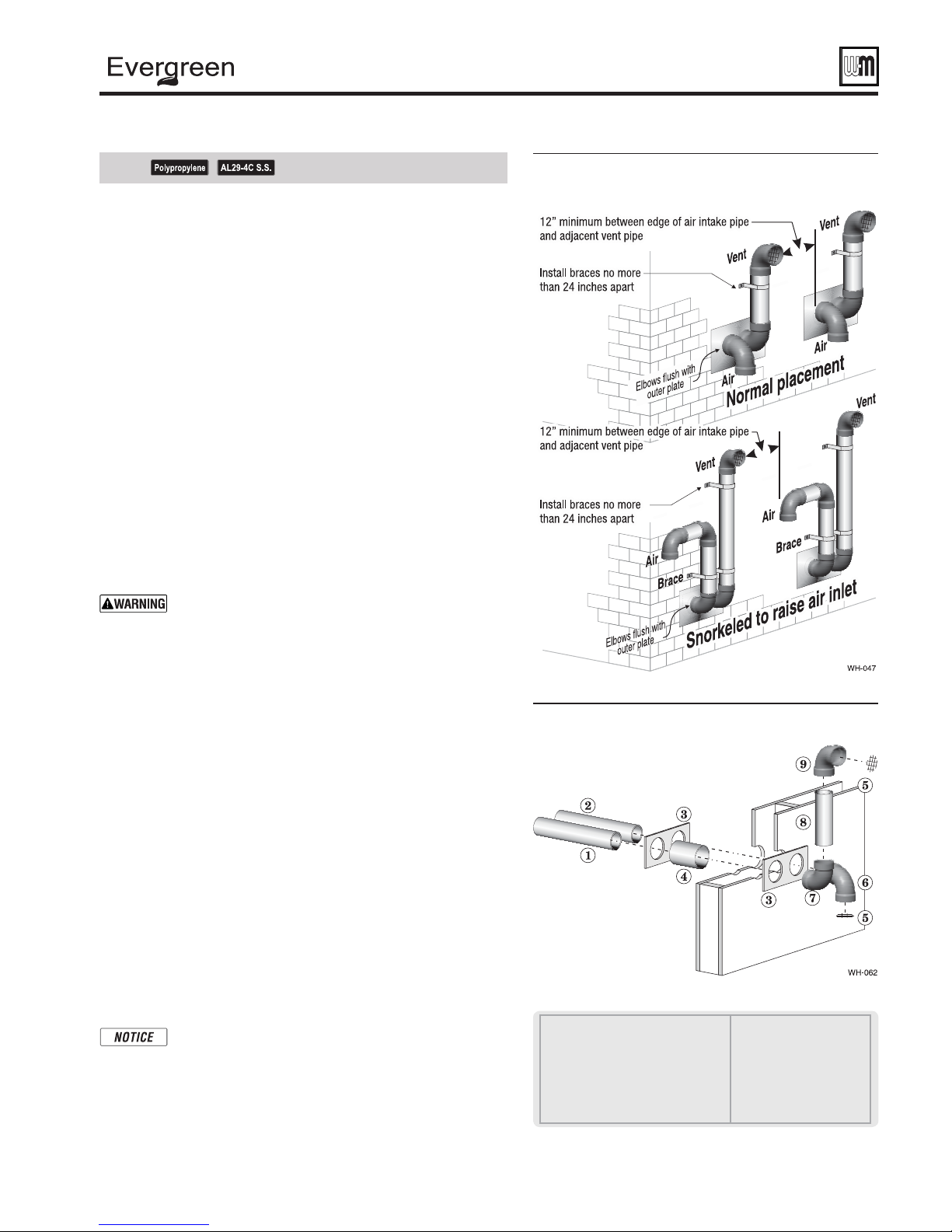

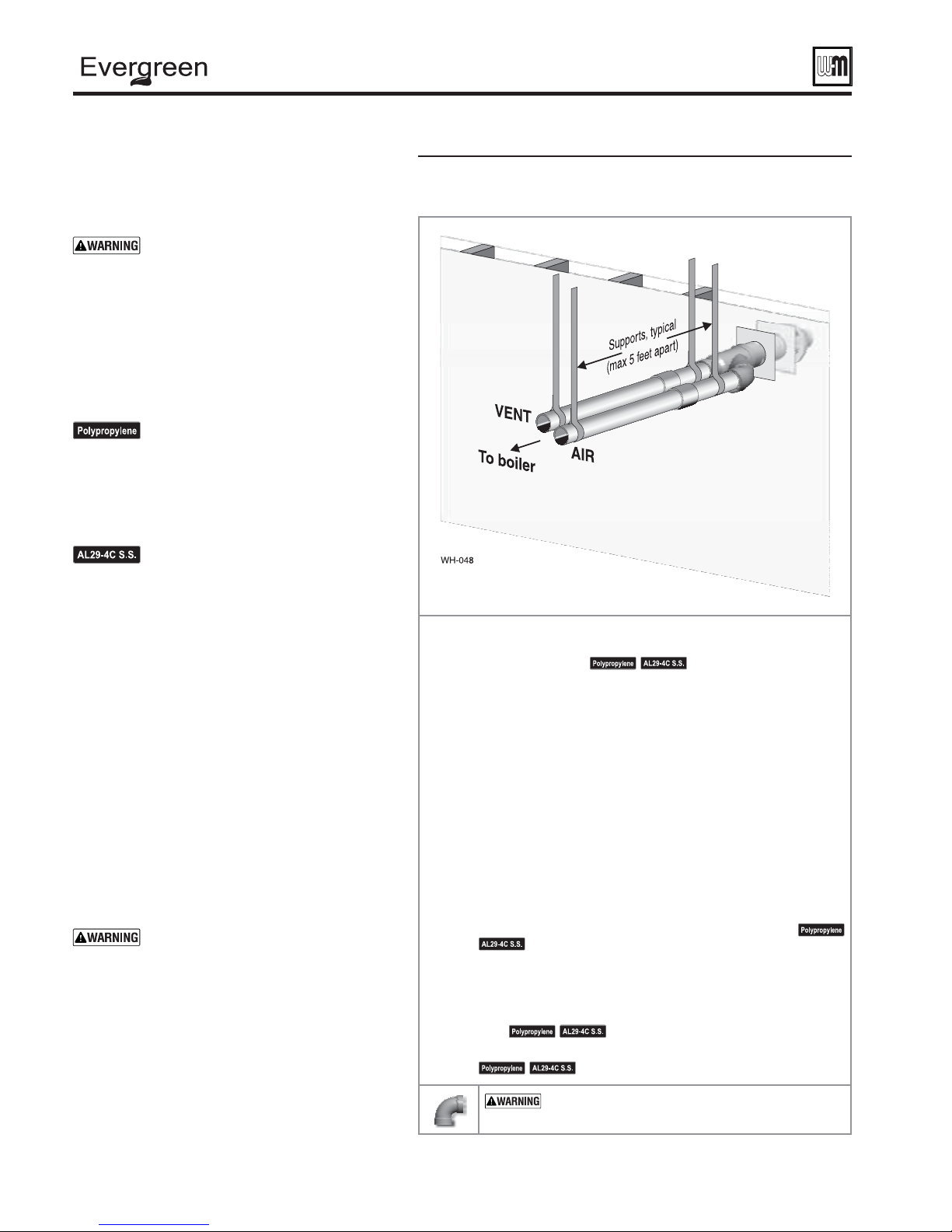

The table below lists the acceptable vent/air pipe terminations described in this manual. Follow all instructions provided to install the

vent/air system.

For these applications, use ONLY the manufacturers’ parts listed and follow all instructions provided by the pipe manufacturer.

Maximum vent and air pipe length = 100 feet for all applications

(All applications include allowance for the termination fi ttings plus one elbow in air piping and one elbow in vent piping).

See Figure23,page24 for material speci cations | See Figure110,page127 for part/kit numbers

If using 2" pipe, provide 3"x 2" tapered reducers at boiler connections and at Weil-McLain vent/air cap or at concentric terminations.

Boilers will derate as vent/air pipe length increases — see rating data on Figure123,page139 for derate amounts.

Model

®

Separate pipes

[Note 1]

Evergreen

®

venting and air piping — DIRECT VENT ONLY — OPTIONS and PIPING LIMITS

NOT SHOWN below, but also approved, are the polypropylene piping and terminations listed in Figure 23, page 24 .

USE SWEEP

(Minimum length for all applications is 2 feet)

ELBOWS

ONLY

Vent and air pipe sizes:

Maximum vent lengths apply for either 2" or 3" vent and air pipe.

SIDEWALL termination VERTICAL termination

PVC or PP Concentric

[Note 1]

3” Weil-McLain PVC

vent/air cap [Note 1]

Separate pipes

[Note 1]

PVC or PP Concentric

[Note 1]

See page 28 See page 30 See page 32 See page 32 See page 36

Size,

inches

2

70

3

110

155

Equivalent feet for elbows (USE SWEEP ELBOWS ONLY) —

• 7 feet per for each additional 90° sweep elbow or 45° elbow —

Note 1:

3

3

** Model 155 may be concentric sidewall vented using Centrotherm polypropylene pipe (Eco Systems InnoFlue® Single-wall) ONLY

if using Centrotherm stainless steel concentric termination kit, part number ICWS3513.

Material abbreviations: PP = polypropylene, SS = AL29-4C stainless steel

If using polypropylene or stainless pipe, provide adapters to for 3” boiler connections and for terminations, if required

IPEX 3” PVC concentric vent kits can be used with standard PVC pipe, fi ttings and cement (ANSI/ASTM D1785) except if ULC S636

compliance is required. For ULC S636 compliance, all pipe, fi ttings and cement must be IPEX System 636. If using IPEX kits, use only

IPEX product code 196006 for 3” venting.

Contact Weil-McLain for ordering information and availability of Weil-McLain venting kits.

Materials

Fig. 23, page 24

PVC/PVC-DWV

CPVC, PP, SS

PVC/PVC-DWV

CPVC, PP, SS

PVC/PVC-DWV

CPVC, PP, SS

PVC/PVC-DWV

CPVC, PP, SS

All elbows in vent and air piping must be sweep elbows ONLY. DO NOT use short-radius elbows. When

transitioning to 3" to 2", use tapered reducer with 3" PVC nipple (L 6"). Do not use 3" to 2" bushing.

Bushings will not seal in boiler adapters.

Size,

inches

2

3

3

3

Materials

Fig. 23, page 24

PVC/PVC-DWV

CPVC, PP, SS

PVC/PVC-DWV

CPVC, PP, SS

PVC Concentric

only

PVC/PVC-DWV

CPVC, SS, PP**

Size,

inches

2

3

––3

3

deduct from max. equivalent length of piping (does not apply to termination fi ttings).

If piping contains more than 1 elbow in air or vent piping, other than termination fi ttings.

Materials

Fig. 23, page 24

PVC/PVC-DWV

CPVC, PP, SS

PVC/PVC-DWV

CPVC, PP, SS

PVC/PVC-DWV

CPVC, PP, SS

Size,

inches

2

3

3

Materials

Fig. 23, page 24

PVC/PVC-DWV

CPVC, PP, SS

PVC/PVC-DWV

CPVC, PP, SS

PVC/PVC-DWV

CPVC, PP, SS

PVC/PVC-DWV

CPVC, PP, SS

Size,

inches

2

3

3

3

Materials

Fig. 23, page 24

PVC/PVC-DWV

CPVC, PP, SS

PVC/PVC-DWV

CPVC, PP, SS

PVC/PVC-DWV

CPVC, PP, SS

PVC/PVC-DWV

CPVC, SS,

Note 2: Use only Weil-McLain approved termination kits listed in Figure 110, page 127