Weil-McLain EGH-105, EGH-125 User Manual

EGHEGH

EGH

EGHEGH

Control SupplementControl Supplement

Control Supplement

Control SupplementControl Supplement

EGH-105 to EGH-125 Series 4

Gas-Fired Boiler

Natural gas

CSD-1

control system

‡

‡ For propane boilers, install EGH propane conversion kit in addition to following the

instructions in this Control Supplement.

Part No. 550-110-677/0299

EGH-105 to EGH-125 EGH-105 to EGH-125

EGH-105 to EGH-125 Control Supplement

EGH-105 to EGH-125 EGH-105 to EGH-125

Please read this page first

Hazard definitions

To the installer:

The following terms are used throughout this Control Supplement to bring attention to the

presence of hazards of various risk levels or to important information concerning the life of the

product.

Indicates presence of hazards that will cause severe personal injury, death or

substantial property damage.

Indicates presence of hazards that can cause severe personal injury, death or

substantial property damage.

Indicates presence of hazards that will or can cause minor personal injury or

property damage.

Indicates special instructions on installation, operation or maintenance that

are important but not related to personal injury or property damage.

This Control Supplement must only be used by a qualified installer/service

technician. Read these instructions completely before beginning the

installation. Failure to follow these instructions can cause severe personal

injury, death or substantial property damage.

This Control Supplement is for CSD-1 controls on EGH-105 to EGH-125

boilers only, specifically for:

• Water boilers without tankless heater. (CSD-1 is not available for

water boilers with tankless heater.)

• Steam boilers with or without tankless heater.

This document is only intended as a supplement to the EG, PEG and EGH

(Series 4) Boiler Manual

Follow all instructions in the EGH Manual in addition to the instructions in

this Control Supplement.

(referred to in this Supplement as the EGH Manual).

Contents

The installation must conform to the requirements of the authority having

jurisdiction, or, in the absence of such requirements, to the National Fuel Gas

Code, ANSI Z-223.1/NFPA-54 (latest edition). Where required by the authority

having jurisdiction the installation must conform to the American Society of

Mechanical Engineers (ASME) Safety Code for Controls and Safety Devices

for Automatically-Fired Boilers, Number CSD-1.

I. ................. Installation .......................................................................... 4

II. ................ Piping connections ............................................................. 6

III. ............... Install boiler controls ......................................................... 6

IV. ............... Optional heaters ................................................................7

V. ................ Gas piping ........................................................................... 8

VI. .............. Wiring ..................................................................................8

VII. ............. Final adjustments ............................................................. 22

VIII. ............ Check-out procedure .......................................................24

IX. .............. Service and maintenance ................................................ 31

X. ............... Replacement parts ........................................................... 32

2

Part Number 550-110-677/0299

CSD-1 control system — Natural gas

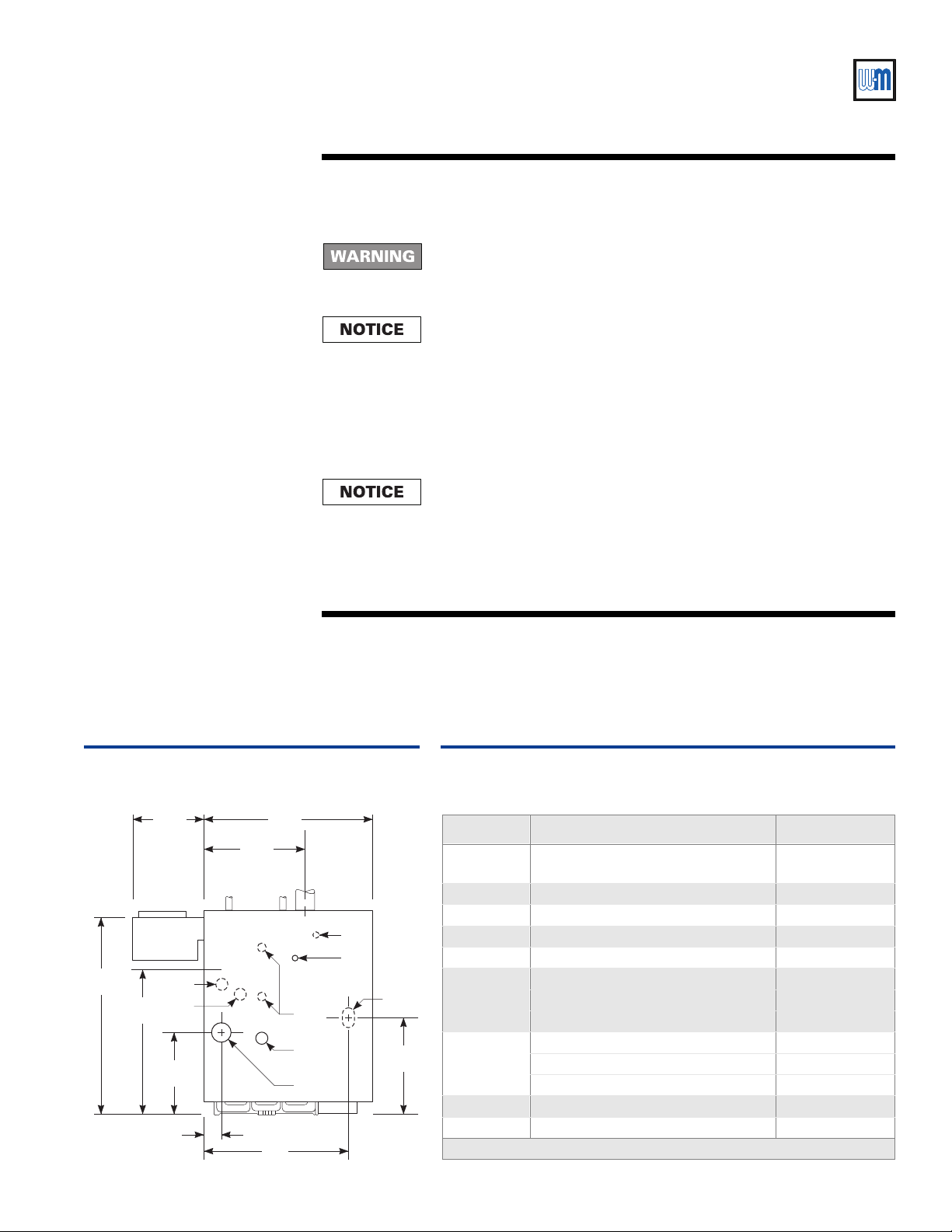

Carton guide

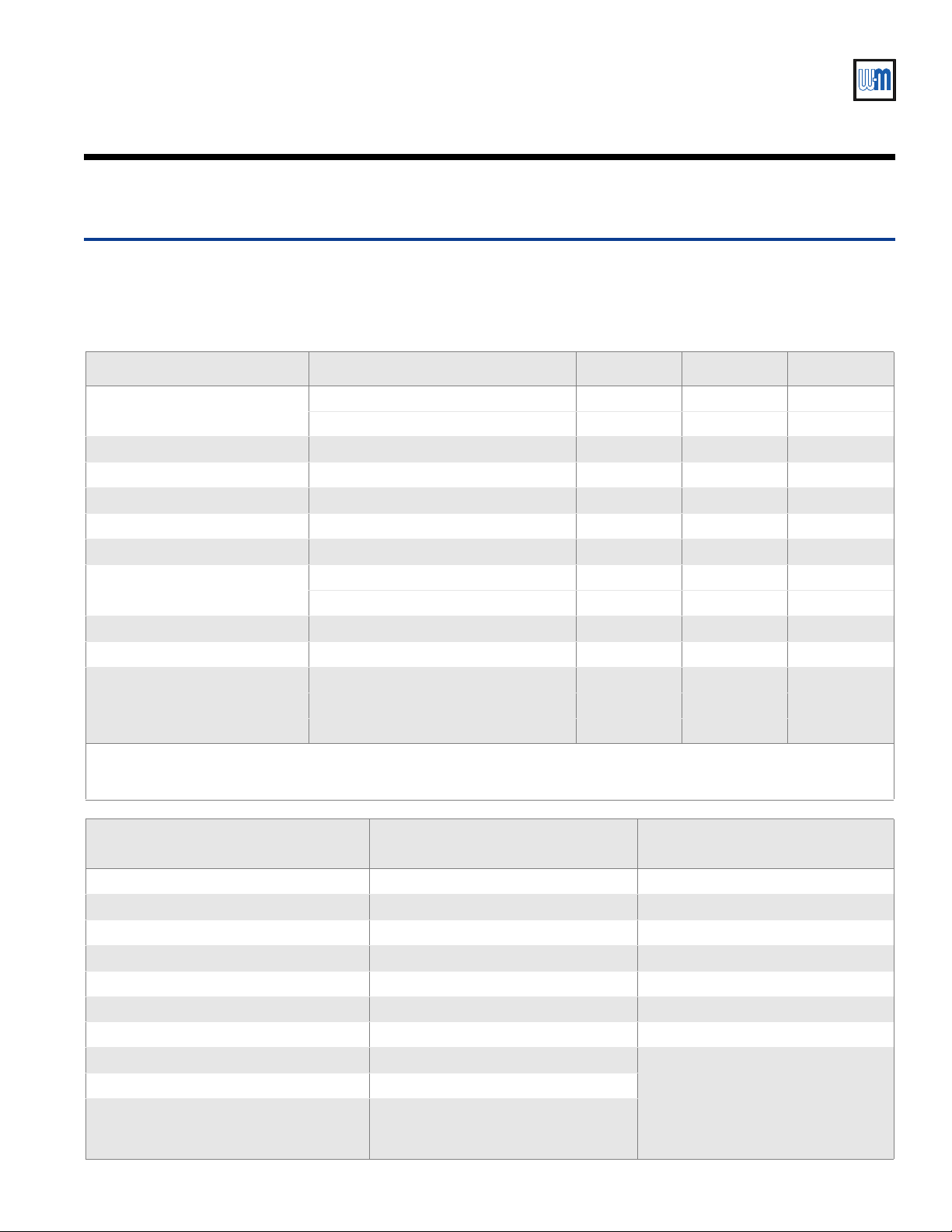

Table 1 Boiler cartons

Verify that the correct cartons are available bef ore beginning assembly. Note that the Base assembly and Trim &

controls cartons for CSD-1 are special. The CSD-1 ignition control panel (in Base assembly carton) consists of ignition

control module, impulse relay and lighted push-button switch mounted and wired on a panel base.

Carton Comments EGH-105 EGH-115 EGH-125

Section assembly (a)

Base assembly (b) CSD-1 381-700-400 381-700-402 381-700-404

Base panels 381-700-250 381-700-255 381-700-260

Jacket 411-800-280 411-800-290 411-800-300

Collector hood 450-014-752 450-014-753 450-014-754

Draft hood 450-206-242 450-206-243 450-206-244

Float low water cutoff (steam)

Vent damper (optional) (c) 381-800-446 381-800-447 381-800-447

T ankless heater (optional) Steam boilers only 386-700-350 386-700-350 386-700-350

T rim & controls (see below)

Note a — CSD-1 water boilers cannot be equipped with a tankless heater.

Note b — Base assembly includes burner tubes, gas train components, pilot assembly and control panel (with ignition control).

Note c — EGH vent dampers meet ASME CSD-1 requirements (paragraph CF-210(c)) because they comply with ANSI Z21.13.

Steam trim and control carton

Gravity return

With tankless opening 321-711-120 321-711-130 321-711-140

Without tankless opening 321-711-125 321-711-135 321-711-145

Gravity return (M&M #67W-1) 381-700-341 381-700-341 381-700-341

Pumped return (M&M #42-A) 511-114-531 511-114-531 511-114-531

Water , CSD-1 — or — 381-700-406 381-700-406 381-700-406

Steam, CSD-1, gravity return — or — 381-700-408 381-700-408 381-700-408

Steam, CSD-1, pumped return 381-700-410 381-700-410 381-700-410

Steam trim and control carton

Pumped return

Water trim carton

Pressure limit control, automatic reset Pressure limit control, automatic reset Aquastat, automatic reset

Pressure limit control, manual reset Pressure limit control, manual reset Aquastat, manual reset

Probe low water cutoff, manual reset Probe low water cutoff, manual reset Probe low water cutoff, manual reset

Transformer/relay Transformer/relay Transformer/relay

Wire harness, steam gravity return Wire harness, steam pumped return Wire harness, water

Crimp spade wire terminations Crimp spade wire terminations Crimp spade wire terminations

ASME Relief valve ASME Relief valve ASME Relief valve

Pressure gauge Pressure gauge

Gauge glass and valves Gauge glass and valves

Brass cross, brass nipple, bushings (3) and

siphons (3) for mounting pressure controls

and gauge

Part Number 550-110-677/0299

Brass cross, brass nipple, bushings (3)

and siphons (3) for mounting pressure

controls and gauge

Pressure/temperature gauge

3

EGH-105 to EGH-125 EGH-105 to EGH-125

EGH-105 to EGH-125 Control Supplement

EGH-105 to EGH-125 EGH-105 to EGH-125

InstallationI

Place the boiler

Install gas train

Refer to the EGH Manual. Read Section I and follow all of its guidelines. Complete the

following steps of Section I of the EGH Manual:

• Placing the boiler

• Installation of optional water heaters, steam boilers only (including pages 13–14)

• Hydrostatic pressure test

• Installation of flue collector hood

• Installation of (burner) drawer assembly and front access panel and back base channel

• Jacket installation

• Draft hood installation

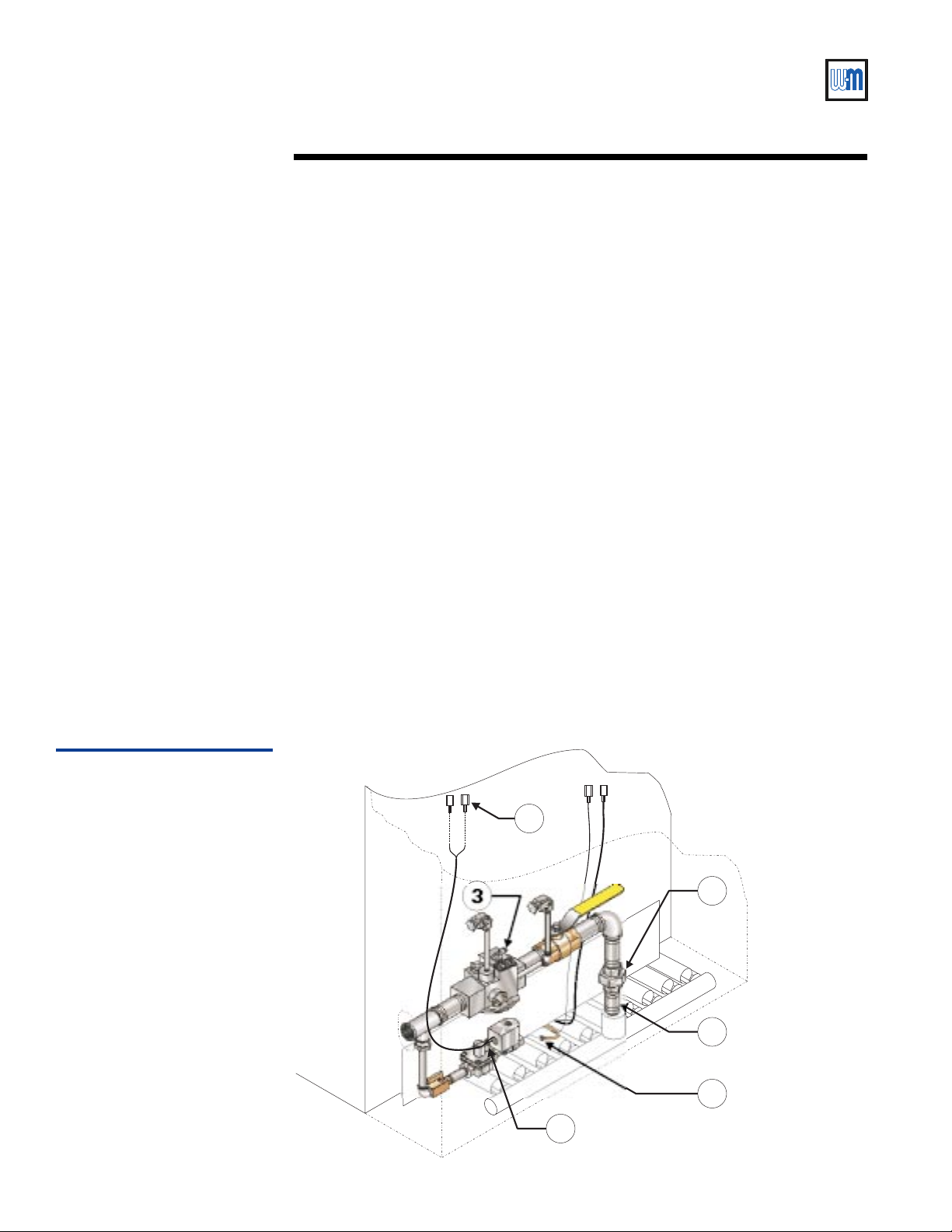

Connect gas train assembly to burner manifold:

• Apply pipe dope to 1" nipple for insertion into burner manifold coupling (Figure 1,

item 1). Insert and tighten nipple.

• Pipe lower half of ground joint union to the 1” nipple (Figure 1, item 2).

• Knock out the jacket gas valve opening on the desired side of the boiler (may be routed

through either right or left side).

• Place gas train in position (either routed to the left, as shown, or to the right) and tighten

the ground joint union loosely. Position the gas train assembly and tighten the union.

• Connect vent lines (routed to outside per code requirements) to ¼" tubing vent

connections on main gas valve and pilot gas pressure regulator (Figure 3, item 3).

• Connect pilot gas tubing (1/8" aluminum) to adapter in pilot gas valve outlet

(Figure 1, item 4).

• Crimp connect two ¼" spade terminals (provided) to ends of pilot gas valve wires

(Figure 1, item 5).

Install vent/breeching

Figure 1

Gas train assembly

Install vent system and breeching per EGH Manual Section I. If optional vent damper is used,

install vent damper (using Section I of this Supplement) before installing breeching.

5

3

2

1

4

3

677-09

4

Part Number 550-110-677/0299

CSD-1 control system — Natural gas

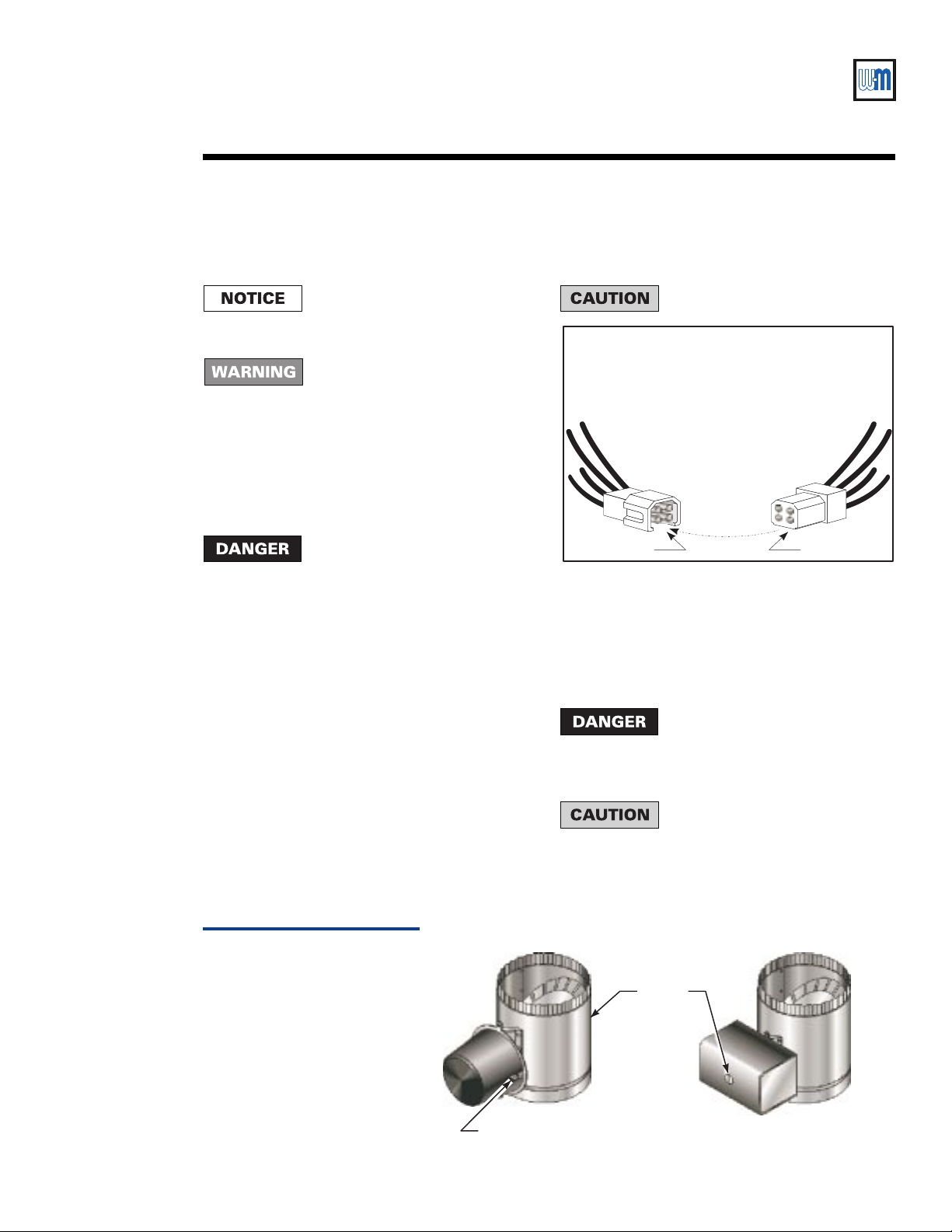

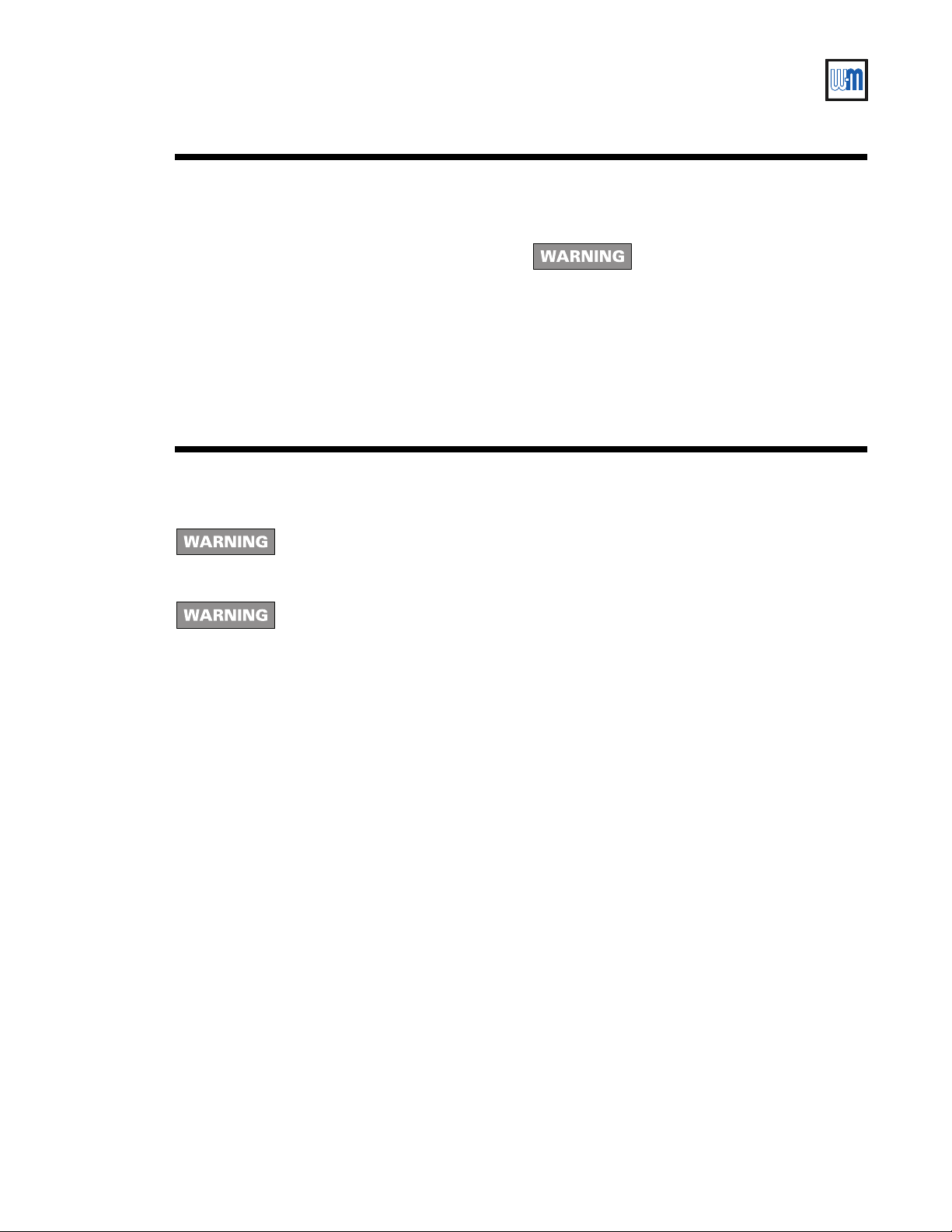

Install optional vent damper (if supplied)

If not installing a vent damper, proceed to next section

(Piping connections).

Once a vent damper has been

operated on an EGH boiler, the boiler

will no longer operate without a

damper installed.

Only dampers listed in the

Replacement parts list in this

Supplement are certified for use with

EGH Series 4 boilers. Any other

damper installed could cause severe

personal injury or death.

Minimum clearances — Provide a minimum of 6" between

the damper and any combustible material. (Provide a

minimum of 46" between EGH jacket top and a

combustible ceiling.)

Damper must be installed directly on

top of draft hood so that it serves

only that boiler. DO NOT modify

draft hood or damper, or make

another connection between draft

hood and damper or boiler. This will

void AGA/CGA certification and will

not be covered by Weil-McLain

warranty. Any changes will cause

severe personal injury, death or

substantial property damage.

Install damper directly on top of draft hood, with arrow

pointing straight up. Install so the damper blade indicator

is visible to the user. See Figure 2.

Screws or rivets used to secure the damper to the vent

pipe and the draft hood must not interfere with rotation

of the damper blade.

Install damper harness between damper actuator and

knockout in right top of boiler jacket. Knock out opening

in jacket top and install strain relief bushings in jacket

and actuator wiring openings. Insert wires and secure

strain relief clamps. See Figure 6, 8, or 10 as applies.

Keep wiring harnesses clear of all hot

surfaces.

WARNING

LINE UP KEYWAY WHEN

CONNECTING PLUGS.

FORCING A MISMATCH

CAN CAUSE A

HAZARDOUS CONDITION.

Keyway Key

Read and apply the harness plug warning label (above)

so that it is visible after installation.

Remove dummy plug from damper connector in boiler

wiring harness. Plug damper harness receptacle into

damper harness plug. See Figure 6, 8, or 10 as applies.

By-passing (jumpering) damper will

cause flue products such as carbon

monoxide to escape into the house.

This will cause severe personal injury

or death.

After boiler has operated once, if

either end of harness is disconnected,

the system will shut down. The boiler

will not operate until the harness is

reconnected.

677-10

Vent damper assemblies

Part Number 550-110-677/0299

Figure 2

Effikal damper

Hold-open switch (Effikal only) —

Install damper so that switch is

visible and accessible to user.

Damper

blade

indicator

Johnson Controls damper

677-05

5

EGH-105 to EGH-125 EGH-105 to EGH-125

Tapping Application W-M Part No.

D Boiler drain connection —

E ASME relief valve (per EGH manual) —

G Pipe to air vent or compression tank —

H Honeyw ell L4006E-1000 M/R limit 510-312-041

L Pressure/temperature gauge 510-218-097

S Temperature limit control, auto reset 510-312-209

V Gas supply connection (right or left) —

Not shown

McDonnell & Miller PS852M-24 M/R

probe LWCO (Mount in supply or

return piping, above top of boiler)

511-114-530

Plug all tappings not used.

EGH-105 to EGH-125 Control Supplement

EGH-105 to EGH-125 EGH-105 to EGH-125

Piping connectionsII

Connect steam (water) piping to the boiler per EGH Manual Section II.

Water boilers — make provision for mounting probe low water cutoff in the supply or return

piping, above the top of the boiler. The low water cutoff must be between the boiler and any

isolation valve(s).

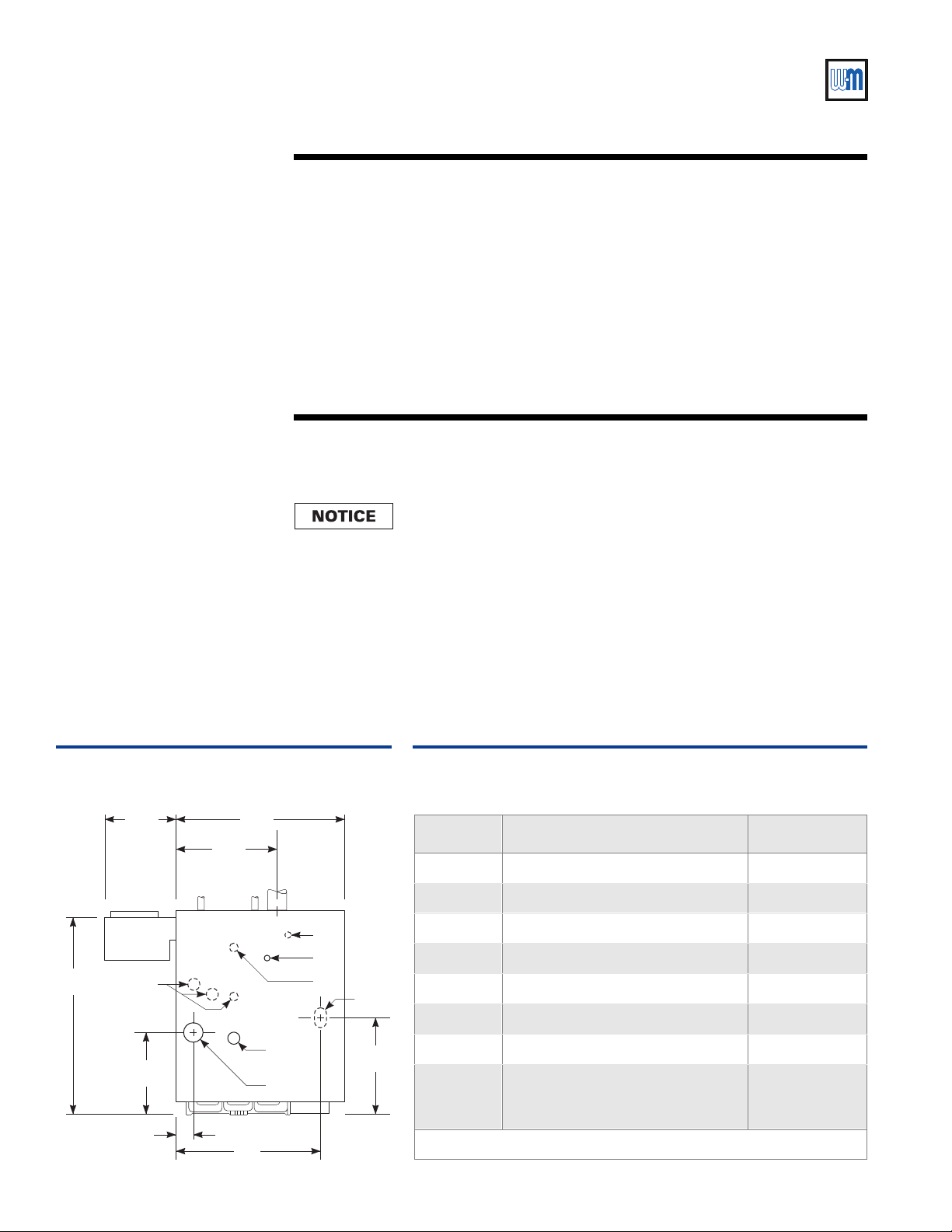

Install boiler controls — water boilersIII

The controls may be mounted on either end of the boiler. Mount all controls

on the same end. The junction box (electrical entrance) must also be mounted

on the same end as the controls.

Install the probe low water cutoff in the supply or return piping, above the

top of the boiler. The low water cutoff must be mounted between the boiler

and any isolation valve(s) installed in the piping.

Install water trim components as required by ASME CSD-1, latest edition. See Figure 3 and

Table 2 for controls required and tapping usage. See Figure 6 for finished assembly.

Plug all unused tappings.

All piping and control connections must also comply with the EGH Manual.

Figure 3

Water boiler connections

5

11¾" 27 / "

16 / "

32¾"

Not

used

EG

8

3

16

Supply

L

S

H

V

Table 2

Water boiler connections

6

13½"

11

16

2/"

D

Return

24"

5

16/"

677-08

8

Part Number 550-110-677/0299

CSD-1 control system — Natural gas

Install boiler controls — steam boilersIII

All water level controls must mount on the left end of the boiler. Failure to do

so could result in nuisance shutdowns and possible lockout on the manual

reset control due to water level variations from end to end. Substantial

property damage could result from freezing due to loss of heat.

All controls must mount on left end of the boiler. The correct tappings are

available only on the left end section.

Install steam trim components as required by CSD-1, latest edition. See Figure 4 and Table 3.

See also Figure 8 or Figure 10 for finished assembly.

• CSD-1 requires two low water cutoffs (one manual reset) and two limit controls (one

manual reset) as shown in the illustration.

• For float type (automatic reset only) low water cutoffs other than those shown in this

Supplement, refer to EGH Manual for mounting and piping instructions.

Install a blowdown valve on any float type low water cutoff as described in

the EGH Manual, Section III.

Figure 4

Steam boiler connections

11¾" 27 / "

3

16 / "

EG

32¾"

23 / "

(Water line)

13

16

2/"

13½"

11

16

C

T

16

24"

Plug all unused tappings.

All piping and control connections must also comply with the EGH Manual.

Optional heaters — steam boilers onlyIV

Install optional tankless heater, if used, (steam boiler only) per EGH Manual Section IV.

Table 3

Steam boiler connections

5

8

H

D

Return

Supply

risers

L

S

V

5

16/"

677-07

Tapping Application W-M Part No.

T

C Not used — plug tapping —

D Drain connection (per EGH manual) —

E ASME relief valve (per EGH manual) —

G Not used - plug tapping —

H

8

L

S Skim tapping (per EGH manual) 510-312-209

V Gas supply connection (right or left) —

McDonnell & Miller PS852M-24 M/R

probe LWCO

Float LWCO, automatic reset — —

Gravity return — McD-M 67W-1 511-114-494

Pumped return — McD-M 42-A 511-114-531

Pressure gauge 510-218-045

Pressure limit, automatic reset 510-312-135

Honeywell L404C-1147 M/R limit 510-312-060

Plug all tappings not used.

511-114-530

Part Number 550-110-677/0299

7

EGH-105 to EGH-125 EGH-105 to EGH-125

EGH-105 to EGH-125 Control Supplement

EGH-105 to EGH-125 EGH-105 to EGH-125

Gas pipingV

Size and connect gas supply piping per EGH Manual,

Section V.

The gas supply can enter from either the right or left

side of the jacket. Be sure the gas train is directed to the

correct side.

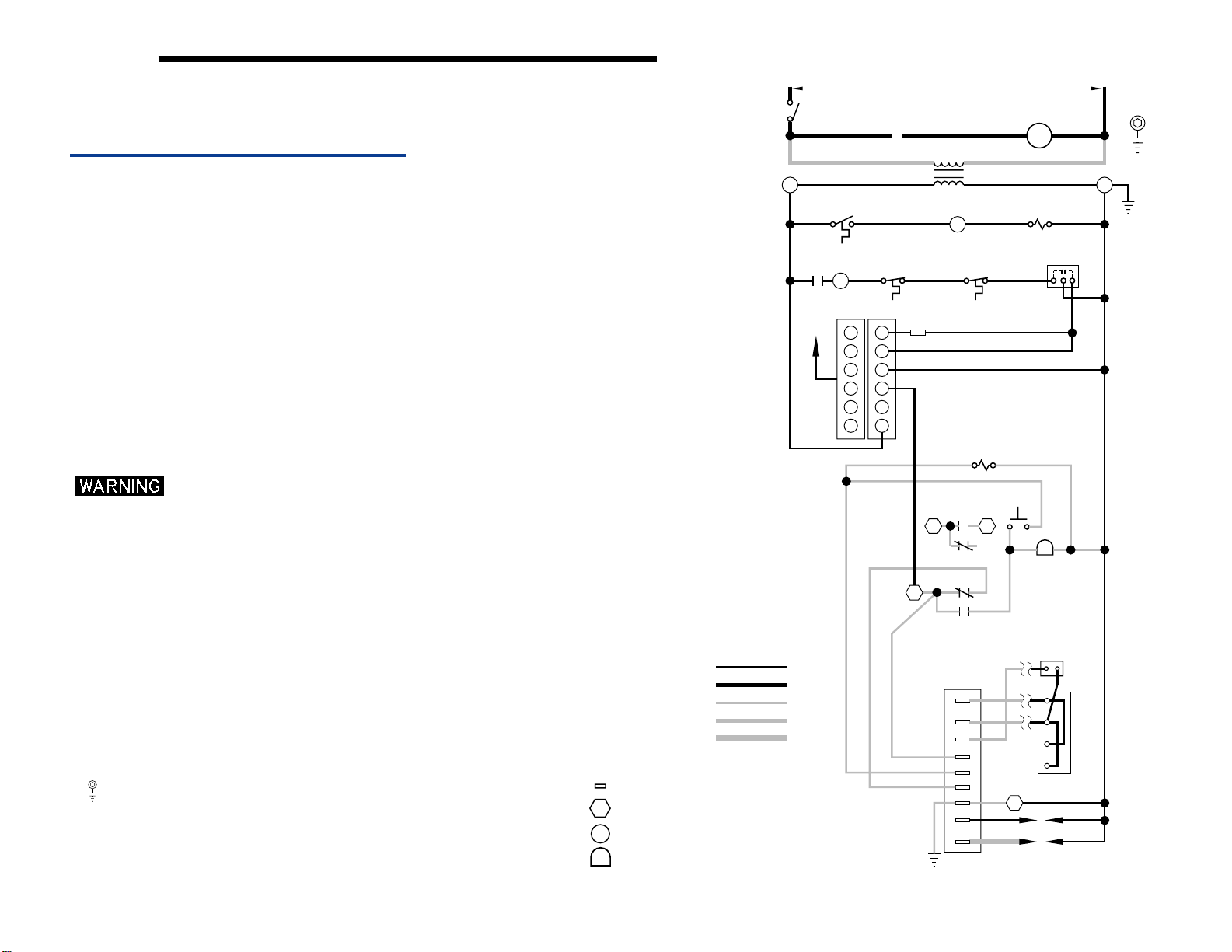

WiringVI

For your safety, turn off electrical

power supply before making any

electrical connections to avoid

possible shock hazard.

A strain relief bushing and adapter

must be used at each point where

wiring passes through the boiler

jacket or control cases to protect

wiring insulation.

Assembly illustrations and wiring

diagrams

This Supplement contains three wiring diagrams and

associated assembly illustrations. Refer to the

following, as applicable:

• Water boilers —Figures 5 and 6

• Steam boilers, gravity return — Figures 7 and 8

• Steam boilers, pumped return — Figures 9 and 10

General

Refer to EGH Manual, Section VI for further

information.

All wiring must be installed in accordance with the

requirements of the National Electrical Code and any

additional national, state or local code requirements

having jurisdiction. All line voltage wiring external to

boiler jacket must be N.E.C. class 1.

Provide a separate electrical circuit with a fused

disconnect switch (15 amp recommended) to supply

the boiler. Wiring to the boiler must be No. 14 gauge or

heavier, installed in conduit.

The boiler must be electrically grounded in accordance

with the National Electrical Code, ANSI/NFPA No. 70,

latest edition.

Support gas line securely. Do not

support weight of gas line off of boiler

gas train.

Purge air from gas piping and perform gas line and gas

connection leak test per Section V of the EGH Manual.

Use 105 °C thermoplastic wire, or equivalent, if any

original wire must be replaced (except for pilot spark

and sense wires).

Wiring procedure

1. Mount all controls as directed in Section III of this

Supplement. Refer to the assembly illustration for

the type of boiler installed (Figure 6, 8 or 10).

2. Mount the junction box supplied with the boiler on

the inside left (or right) side of the jacket as shown

in the assembly illustration (using screws and nuts

provided). Mount the junction box on the same

end of the boiler as the controls will be

mounted

3. Attach the transformer/relay to the junction box.

4. Mount the CSD-1 control panel on the jacket

interior panel as shown in the appropriate

assembly illustration (Figure 6, 8 or 10), using

screws and nuts provided.

5. Crimp connect ¹⁄₄" spade terminals (provided) to

the pilot gas valve wires if not already done in

Section I of this Supplement.

6. If optional vent damper is installed, make sure

damper harness has been routed through a strain

relief bushing in the jacket and damper actuator as

directed in Section I of this Supplement. Secure

damper harness conduit to top of jacket with

clamps provided.

7. The main gas valve wires are pre-attached to the

CSD-1 control panel. The spark and sense wires

from the pilot are factory installed to the pilot.

Connect these wires as shown in the wiring

diagram.

8. Use the wiring harness provided with the boiler to

complete wiring of the remaining components

according to the appropriate wiring diagram and

assembly illustration.

.

8

Part Number 550-110-677/0299

CSD-1 control system — Natural gas

Wiring — sequence of operationVI

General

The following sequence of operation applies to all wiring diagrams in this Supplement — both

water and steam.

Call for heat

On a call for heat (from thermostat or operating control):

1. Limit control and water level control contacts are assumed closed.

2. Vent damper (if provided) will open.

3. Ignition control checks for signal at pilot. (No signal should be present.)

If no signal is sensed

a. Pilot solenoid opens.

b. Pilot ignition spark begins.

c. Pilot ignites.

d. Pilot proves.

If a signal is sensed

4. Once pilot is proved the ignition control activates main gas valve. Main burners will ignite

and boiler will continue to fire until terminated by limit action or no call for heat.

(normal condition):

(abnormal condition) by the ignition control, the control will lockout.

On failure to establish pilot flame signal within 15 seconds, the ignition control

will turn off the pilot gas valve. It will wait 5 minutes, then retry for ignition.

If the second ignition attempt fails, the ignition control will lockout and

illuminate the red lockout light.

This will activate the alarm contact of the impulse relay, providing an isolated

contact closure across terminals A1 and A2 of the CSD-1 control panel

terminal strip. The contact rating is 15 amps at 250VAC.

To reset the boiler, push the red reset button on the CSD-1 control panel.

Lockout modes

In addition to lockout on flame-sense failure, the boiler may also experience lockout due to

shutdown of a manual reset control.

The boiler is equipped with a manual reset limit control and a manual reset

low water cutoff. Should the limit control lockout, it can only be reset by

pressing the reset button on the control. The manual reset probe low water

cutoff can be reset after lockout by pressing the reset button on the control or

by interrupting power momentarily.

Part Number 550-110-677/0299

Steam boilers — Do not substitute another manual reset low water cutoff for

the one specified and supplied with the boiler. Other controls may not operate

as intended and could cause serious operating problems or failures.

Troubleshooting

Refer to Section VIII, Check-out procedure — troubleshooting, of this Supplement and to

component manufacturer’s literature supplied in the boiler manual envelope for further

information on operating conditions.

9

10

LADDER WIRING DIAGRAM

Wiring — water boilersVI

SERVICE

SWITCH

1K2

120 V.A.C .

CIRCULAT OR

EQUIPMENT

GROUND

(NOTE 7)

Figure 5

Water boiler wiring —

ladder and schematic diagrams

ELECTRICAL SHOCK HAZARD, CAN CAUSE SEVERE

INJURY OR DEATH. DISCONNECT POWER

BEFORE INSTALLING AND/OR SERVICING.

NOTES:

1. ALL WIRING MUST BE INSTALLED IN ACCORDANCE WITH:

A. U.S.A. - NATIONAL ELECTRICAL CODE AND ANY OTHER NATIONAL, STATE OR LOCAL

CODE REQUIREMENTS.

B. CANADA - C.S.A. C22.1 CANADIAN ELECTRICAL CODE PART 1 AND ANY OTHER

2. ALL CONTACTS SHOWN WITHOUT POWER APPLIED-OFF SHELF CONDITION.

3. IF ORIGINALWIRE AS SUPPLIED WITH THE APPLIANCE MUST BE REPLACED,

TYPE 105 C OR IT’S EQUIVALENT MUST BE USED.

4. REFER TO CONTROL COMPONENT INSTRUCTIONS PACKED WITH BOILER FOR APPLICATION

INFORMATION.

Part Number 550-110-677/0299

5. THERMOSTAT - FOR SINGLE ZONE SYSTEMS, THERMOSTAT ANTICIPATOR SETTING IS 0.40 AMPS.

6. L.W.C.O., HIGH LIMITS, WIRED IN SERIES.

7. DENOTES FIELD INSTALLED CHASSIS GROUND.

8. PILOT LEADWIRES ARE NOT FIELD REPLACEABLE. REPLACE

PILOT ASSEMBLY IF NECESSARY.

9. CIRCULATOR NOT USED WITH GRAVITY HOT WATER.

10. ALARM CONTACT RATINGS: 15 AMP @ 250 VAC.

NATIONAL, PROVINCIAL OR LOCAL CODE REQUIREMENTS.

o

FOR MULTIPLE ZONE SYSTEMS USING ZONE VALVES OR CIRCULATORS, REFER

TO COMPONENT MANUFACTURER’S INSTRUCTIONS FOR APPLICATION WIRING AND

THERMOSTAT ANTICIPATOR SETTING.

EMCS - FOR EMCS CONNECTION IN PLACE OF THERMOSTAT, REFER TO EMCS

INSTALLATION/OPERATING MANUAL.

550-225-026/0199

LOW VOLT AGE FIELD

HIGH VOL TAGE FIELD

LOW VOLTAGE FACTORY

HIGH VOL TAGE FA CT OR Y

IGNITION CABLE

IGNITION CONTROL MODULE TERMINAL.

IGNITION CONTROL PANEL TERMINAL

TRANSFORMER TERMINAL.

IGNITION CONTROL PANEL LAMP

R

R

DAMPER

1K1

CABLE

TO

THERMOSTAT

Y

535

44

66

11

MANUAL

RESET

HIGH LIMIT

3

22

24V (G)

SENSE

SPARK

TRANSFORMER

FUSE

SEE NOTE 10

A

1

1

MV

MV/PV

PV

C

RELAY COIL

PROBE LWCO

PILOT

SOLENOID

VALVE

ROBERTSHAW

GAS VALVE

2

SENSOR

IGNITOR

1K

MANUAL

RESET

R

TH

TR

D+

D

G

HIGH

LIMIT

2K

2K4

A

2

N/A

2K3

2K2

2K1

ALARM

ALARM

24V

Part Number 550-110-677/0299

SCHEMA TIC WIRING DIAGRAM

EQUIPMENT

GROUND

(NOTE 7)

SERVICE

SWITCH

(BY OTHERS)

H

N

Y

W

CIRCULATOR

(NOTE 9)

BK

G

W

Y

BK

Y

BK

JUNCTION BOX

WIRE NUTS (3)

HIGH

LIMIT

BK

G

C

(NOTE 6)

MANUAL

RESET

HIGH LIMIT

BK

THERMOSTAT

OR EMCS

(NOTE 5)

BK

W

G

R

TRANSFORMER

120/24 V .A.C.

PLUG-IN

DPST

RELAY

MANUAL

RESET

PROBE LWCO

BK

CABLE

TO

DAMPER

R

MOMENTARY

SWITCH

R

R

R

IMPULSE

RELAY

R

R

G

G

BK

Y

1

Y

DAMPER

CONNECTOR

R

G

G

BK

G

Y

R

G

A

2

1

TERMINAL

A

2

NOTE 10

R

BLOCK

W

R

TH

PRE-WIRED PANEL

D+

D

TR

ROBERTSHAW

GAS VALVE

W

W

BK

R

R

Y

G

W

W

BK

R

IGNITION CONTROL

MV

MV/PV

PV

ALARM

ALARM

24V

24V (GND)

SENSE

SPARK

O

PILOT

SOLENOID

VALVE

UNIVERSAL SPARK

PILOT

(NOTE 8)

11

EGH-105 to EGH-125 EGH-105 to EGH-125

EGH-105 to EGH-125 Control Supplement

EGH-105 to EGH-125 EGH-105 to EGH-125

CSD-1 control system — Natural gas

Loading...

Loading...