Weil-McLain EG User Manual

EGEG

EG

EGEG

Gas-fired Boilers — Series 4

Boiler ManualBoiler Manual

Boiler Manual

Boiler ManualBoiler Manual

, ,

,

, ,

PEGPEG

PEG

PEGPEG

, ,

,

, ,

EGHEGH

EGH

EGHEGH

• Installation

• Operation

EG

• Service

• Boiler Parts

For additional information,

refer to . . .

Control Supplement

and Gas Control Parts

for Natural or Propane gas

with optional tankless heater

application

EGH

Read all instructions before installing

Installer Leave all instructions with boiler for future reference.

Any claims for damage or shortage in shipment must be filed

immediately against the transportation company by the consignee.

Owner Installation and service should be performed by qualified service

technician.

Part No. 550-110-639/0703

1

EG, PEG, EGH GAS-FIRED BOILERS — SERIES 4 — BOILER MANUAL

Contents

Installation .............................................................................................3

Piping Connections................................................................................9

Install Boiler Controls..........................................................................12

Optional Heaters .................................................................................13

Gas Piping............................................................................................14

Wiring ...................................................................................................15

Final Adjustments................................................................................16

Check Out Procedure ..........................................................................18

Service..................................................................................................19

Replacement Parts...............................................................................22

Data ......................................................................................................26

Ratings .................................................................................................27

Hazard definitions

The following defined terms are used throughout this manual to bring attention to the presence of hazards of various

risk levels, or to important information concerning the life of the product.

Indicates presence of hazards that will cause severe personal injury, death or substantial property

damage.

Indicates presence of hazards that can cause severe personal injury, death or substantial property

damage.

Indicates presence of hazards that will or can cause minor personal injury or property damage.

Indicates special instructions on installation, operation or maintenance that are important but not

related to personal injury or property damage.

The boiler contains ceramic fiber and fiberglass materials. Use care when handling these materials per

instructions on page 19 of this manual. Failure to comply c ould result in severe personal injury .

Do not use petroleum-based cleaning or sealing compounds in boiler system. Severe damage to system

components can result, causing substantial property damage.

Read all instructions before installing. Failure to follow all instructions in proper order can cause severe

personal injury, death or substantial pro perty damage.

When calling or writing about the boiler— Please have the boiler model number from the boiler rating

label and the CP number from the boile r jacket. You may list the CP number in the space pr ovided on

the Installation and service certificate found on page 18.

Important

EG and EGH boilers for tankless or storage heater application are available only on special order as factory-installed

optional equipment. T ankless heat er cannot be added to standard block assembl y . Block assemb ly must be ordered

with heater openings. Standard boilers cannot be adapted for heater use.

2

Part Number 550-110-639/0703

1

EG, PEG, EGH GAS-FIRED BOILERS — SERIES 4 — BOILER MANUAL

Installation

Codes

Installations must comply with all local codes, laws,

regulations and ordinances. Also National Fuel Gas Code

ANSI Z223.1-latest edition. When required, installations

must conform to Standard for Controls and Safety

Devices for Automatically Fired Boilers, ANSI/ASME

CSD-1. Safe lighting and other performance criteria were

met with the gas manifold and control assembly provided

on boiler when boiler underwent tests specified in ANSI

Z21.13-latest edition.

Canadian installations must comply with CAN/CSA

B149.1 or .2 Installation Codes. The equipment shall be

installed in accordance with those installation regulations

in force in the local area where the installation is to be

made. These shall be carefully followed in all cases.

Authorities having jurisdiction shall be consulted before

installations are made.

Combustion air and ventilation

openings

Combustion air and ventilation openings must comply

with Section 5.3, Air fo r Combustion and Ventilation, of

National Fuel Gas Code ANSI-Z223.1-latest edition, or

applicable building codes. Canadian installations must

comply with CAN/CSA B149.1 or .2 Installation Codes.

Provide adequate combustion and

ventilation air to:

• Assure proper combustion

• Reduce risk or severe personal injury

or death from flue gas spillage and

carbon monoxide emissions.

Do not install an exhaust fan in the boiler

room.

Boiler installation must assure sufficient openings in

building and boiler room to provide adequate combustion

air and ventilation. Consider construction tightness of

building when deciding whether additional outside

openings may be needed.

Older buildings with single-pane windows, minimal

weatherstripping and no vapor barrier often provide

enough natural infiltration and ventilation without

dedicated openings.

New construction or remodeled buildings are most often

built tighter. Windows and doors are weatherstripped,

vapor barriers are used and openings in walls are caulked.

As a result, such tight construction is unlikely to allow

proper natural air infiltration and ventilation.

Air from inside building (boiler in interior room):

• Tightly constructed buildings must be provided with

openings to outside for combustion and ventilation

air. These o penings must be sized to handle all fuel

burning appliances, exhaust and ventilation fans and

fireplaces.

• When openings to boiler room are taken to interior

spaces, provide two permanent openings: a

combustion air opening within 12 inches of floor

and a ventilation opening within 12 inches of ceiling.

Each opening must provide a minimum free area of

one square inch per 1,000 Btuh input of all appliances

in room plus requirements for any exhaust fans in

room. The interior space supplying combustion and

ventilation air must have adequate infiltration from

outside.

Air directly from outside to boiler room:

• Tightly constructed buildings must be provided with

combustion air and ventilation openings to boiler

room which are adequate to handle the boiler needs

plus the needs of all other fuel-burning appliances,

fireplaces and exhaust or ventilation fans.

• Combustion and ventilation openings connecting

directly or by ducting to outside, or to attic or crawl

spaces that freely connect with outside, must be sized

as follows:

1. Outside wall or vertical ducting - one square

inch per 4,000 Btuh input of all appliances in

room plus requirements for any exhaust fans

or other appliances in room.

2. Horizontal ducting - one square inch per 2,000

Btuh of all appliances in room plus

requirements for any exhaust fans or other

appliances in room.

3. All ducting must be same size as permanent

openings. Minimum area dimensions of

ducting must be no less than 9 square inches.

4. Other size ducting must comply with local

codes.

Part Number 550-110-639/0703

3

1

EG, PEG, EGH GAS-FIRED BOILERS — SERIES 4 — BOILER MANUAL

Installation

(continued)

Chimney or vent requirements

(also refer to Breaching erection, Page 8)

V enting must be installed acc ording to Pa rt 7, Venting of

Equipment, of National Fuel Gas Code ANSI Z223.1latest edition and applicable building codes. Canadian

installations must comply with CAN/CSA B149.1 or .2

Installation Codes.

Minimum chimney or vent sizes are on page 27 of these

instructions. A chimney or vent without a listed cap

should extend at least 3 feet above the highest point where

it passes through a roof of a building and at least 2 feet

higher than any portion of a building within a horizontal

distance of 10 feet. A chimney or vent must not extend

less than those distances stated above.

A lined chimney is preferred and must be used when

required by federal, provincial, territorial, state, or local

building codes. Vitreous tile linings with joints that

prevent retention of moisture and linings made of

noncorrosive materials are best. Advice for flue

connections and chimney linings can be obtained from

local gas utility. T ype “B” double wall metal vent pipe or

single wall vent pipe may be used as a liner.

Cold masonry chimneys, also known as outside

chimneys, typically have one or more walls exposed to

outside air .

When any atmospheric gas-fired boiler with automatic

vent damper is vented thr ough this type of chimney, the

potential exists for condensation to occur . Condensation

can damage a masonry chimney.

Weil-McLain recommends the following to prevent

possible damage:

1. Line chimney with corrosion-resistant metal liner

such as AL29-4C® single wall stainless steel or B-vent.

Size liner per National Fuel Gas Code ANSI Z223.1-latest

edition.

2. Provide drain trap to remove any condensate.

Inspect existing chimney or vent before

installing boiler. Failure to clean or replace

perforated pipe or tile lining will cause

severe injury or death.

Do not alter boiler draft hood or place any

obstruction or non-approved damper in

the breeching of vent system. CSA

certification becomes void. Flue gas spillage

and carbon monoxide emissions will occur

causing severe personal injury or death.

When removing boiler from common venting

system

Failure to follow all instructions listed below can cause flue gas

spillage and carbon monoxide emissions, resulting in severe

personal injury, death or substantial property damage.

At the time of removal of an existing boiler, the following steps shall be

followed with each appliance remaining connected to the common venting

system placed in operation, while the other appliances remaining connected

to the common venting system are not in operation.

a. Seal any unused openings in the common venting system.

b. Visually inspect the venting system for proper size and horizontal pitch and

determine there is no blockage or restriction, leakage, corrosion and other

deficiencies which could cause an unsafe condition.

c. Insofar as is practical, close all building doors and windows and all doors

between the space in which the appliances remaining connected to the

common venting system are located and other spaces of the building. Turn

on clothes dryers and any appliance not connected to the common venting

system. Turn on any exhaust fans, such as range hoods and bathroom exhausts,

so they will operate at maximum speed. Do not operate a summer exhaust

fan. Close fireplace dampers.

d. Place in operation the appliance being inspected. Follow the lighting

instructions. Adjust thermostat so applianc e will operate continuously.

e. Test for spillage at the draft hood relief opening after 5 minutes of main

burner operation. Use the flame of a match or candle, or smoke from a

cigarette, cigar or pipe.

f. After it has been determined that each appliance remaining connected to

the common venting system properly vents when tested as outlined above,

return doors, windows, exhaust fans, fireplace dampers, and any other gasburning appliance to their previous conditions of use.

g. Any improper operation of the common venting system should be corrected

so the installation conforms with the National Fuel Gas Code, ANSI Z223.1latest edition. When resizing any portion of the common venting system,

the common venting system should be resized to approach the minimum

size as determined using the appropriate tables in Part 11 in the National

Fuel Gas Code, ANSI Z223.1-latest edition.

Canadian installations must comply with CAN/CSA B149.1 or .2 Installation

Code.

Select the boiler location

• Consider all connections to boiler before selecting a location.

• Boiler must be installed so gas control system components are protected

from dipping or spraying water or rain during operation or service.

• Non-combustible floor ONL Y. See “Boiler foundation ”, P age 5.

T o a void personal injury , death or prope rty damage, keep boiler

area clear and free from combustible materials, gasoline and

other flammable vapors and liquids.

Where two or more gas appliances vent into a common

chimney or vent, equivalent area should be at least equal

to the area of the vent outlet on the largest appliance plus

50 percent of the area of the vent outlet on the additional

appliance.

4

Part Number 550-110-639/0703

1

EG, PEG, EGH GAS-FIRED BOILERS — SERIES 4 — BOILER MANUAL

Installation

(continued)

Installation clearances

Suggested minimum clearances for servicing

• 24 inches for cleaning and servicing, left side.

• 18 inches for access to controls and components, front.

• 46 inches from top for cleaning flueways.

• 6 inches on remaining sides.

Required minimum clearances to combustible material in

alcove installations

T op 46" R. Side 4" Front: Alcove

Rear 6" L. Side 4"

EGH 105-125: Provide service clearances listed above and minimum 24"

between jacket and any combustible wall(s) and ceiling.

Install in space large in comparison to size of boiler.

• Single wall vent pipe must be at least 6 inches from combustible material.

• Type "B" double wall metal vent pipe - refer to vent manufacturer's

recommendation for clearances to combustible material.

• Hot water pipes must be at least ½" from combustible material.

Residential garage installation

Install boiler so burners are at least 18 inches abov e the floor .

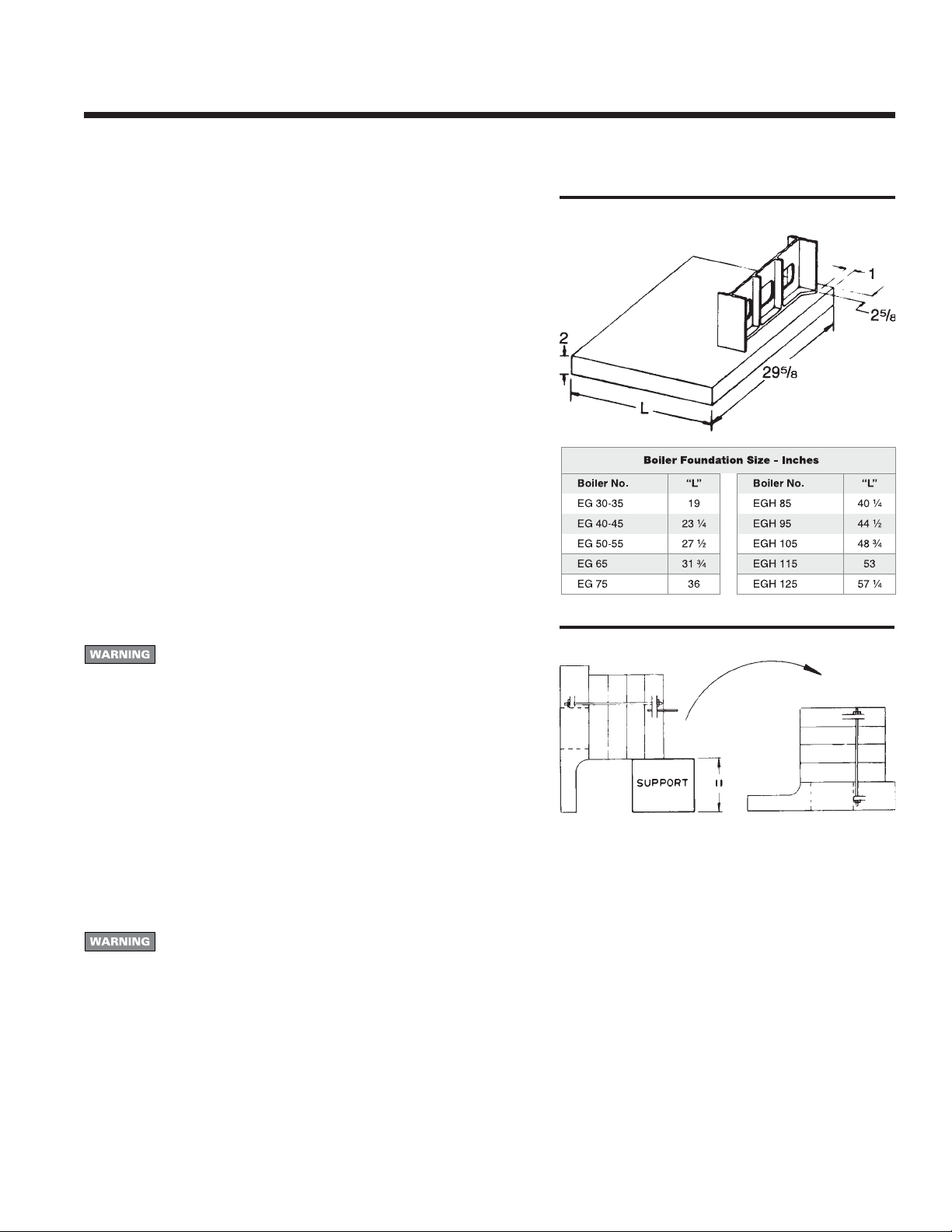

Figure 1 Boiler foundation

Boiler foundation

Never install boiler on combustible flooring or carpeting, even if

a concrete or aerated foundation is used. Severe personal injury,

death or substantial property damage can result.

1. See Figure 1. A level concrete or solid brick pad is required if:

a) There is a possibility of the floor becoming flooded.

b) Non-level conditions exist.

2. An aerated boiler foundation is recommended if any of the following

conditions exist:

a) Electrical wiring or telephone cables buried in the concrete floor of the boiler

room.

b) Concrete floor is "green."

c) There is a history of the floor becoming flooded.

d) Water is channeled under the concrete.

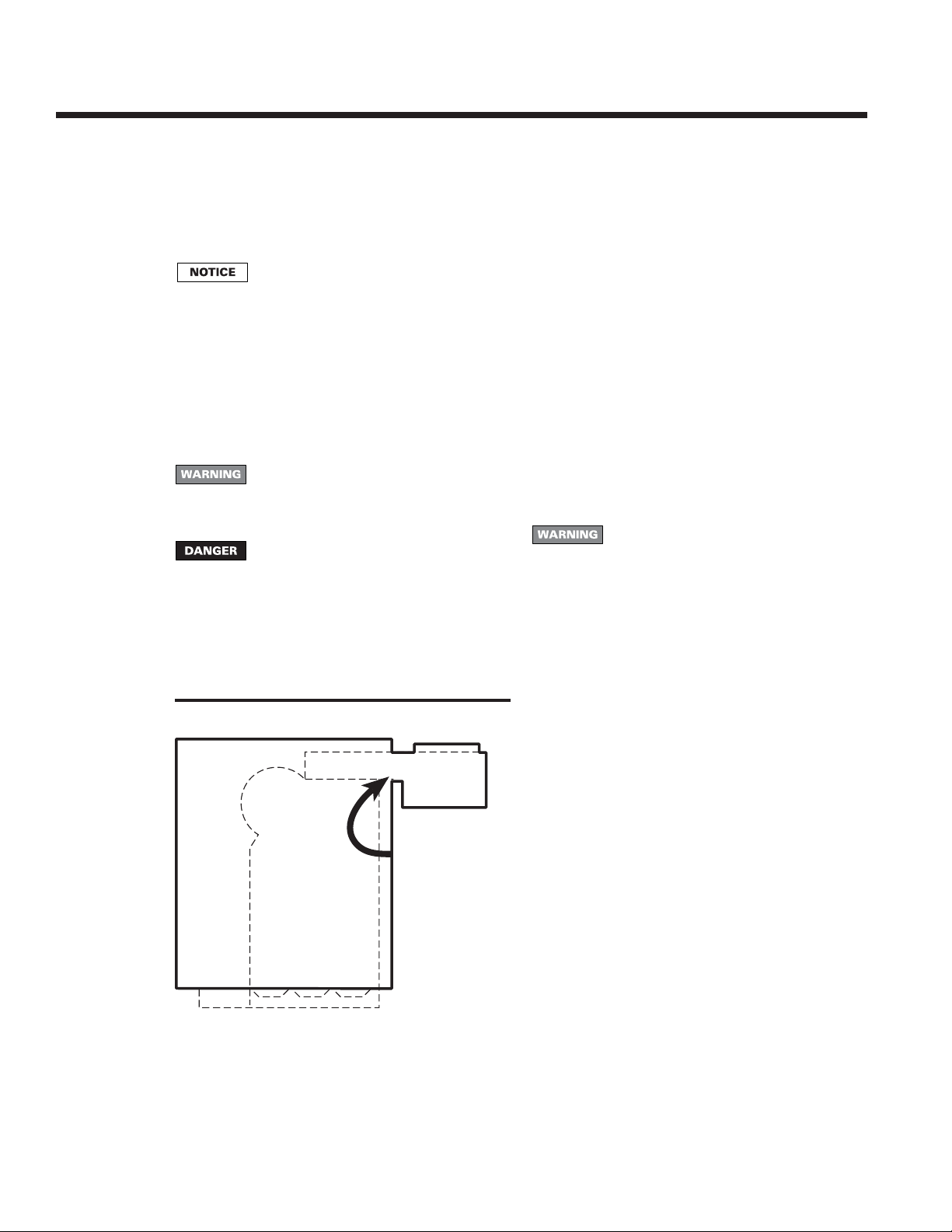

Placing the boiler

Block assembly is extremely heavy. Handle with caution to avoid

personal injury.

Where the EGH block assembly is taken apart for handling:

1. Put a support under center of block. Support must be within 1/2 inch of

block bottom.

2. Remove short center draw rods.

3. Tip half blocks on end as shown in Figure 2. Save elastomer sealing rings and

cope seal between sections.

Figure 2

4. After moving half-blocks into desired location, clean

port surfaces with clean, dry rag. Do not use oil. Place

sealing rings in recessed ports. Place cope seal in section

grooves.

5. Re-assemble block in reverse order. When drawing

sections together , use 45 ( ± 5) ft-lbs tor que.

Installation of optional indirect

water heater

For a boiler ordered with internal type indirect water heater ,

remove heater opening cover plate (water boilers - round

plate on left side; steam boilers - rectangular plate on front).

Install heater(s) as shown on pages 13. Do not over tighten

studs and nuts - damage to the gasket can occur ..

Part Number 550-110-639/0703

5

1

EG, PEG, EGH GAS-FIRED BOILERS — SERIES 4 — BOILER MANUAL

Installation

Figure 3

(continued)

Hydrostatic pressure test

Pressure test before attaching gas piping or electrical supply .

1. Plug any necessary boiler tappings or openings.

2. Do not use gauge supplied with boiler for pressure testing. Install gauge with

appropriate range.

3. Fill boiler with water . V ent all air . Test steam boilers between 45 - 55 psi and

water boilers at 1-1/2 times working pressure.

Do not leave boiler unattended. A cold water fill could expand

and cause excessive pressure, resulting in severe personal injury,

death or substantial property damage.

4. Check for maintained gauge pressure and leaks. Repair if found.

Leaks must be repaired at once. Failure to do so can cause boiler

damage, resulting in substantial property damage.

Do not use petroleum-based sealing compounds in boiler system.

Severe damage to boiler will result, causing substantial property

damage.

5. Drain boiler and repair leaks if found.

6. Retest boiler after repairing leaks.

7. Remove plugs from any tappings that will be used for controls and accessories.

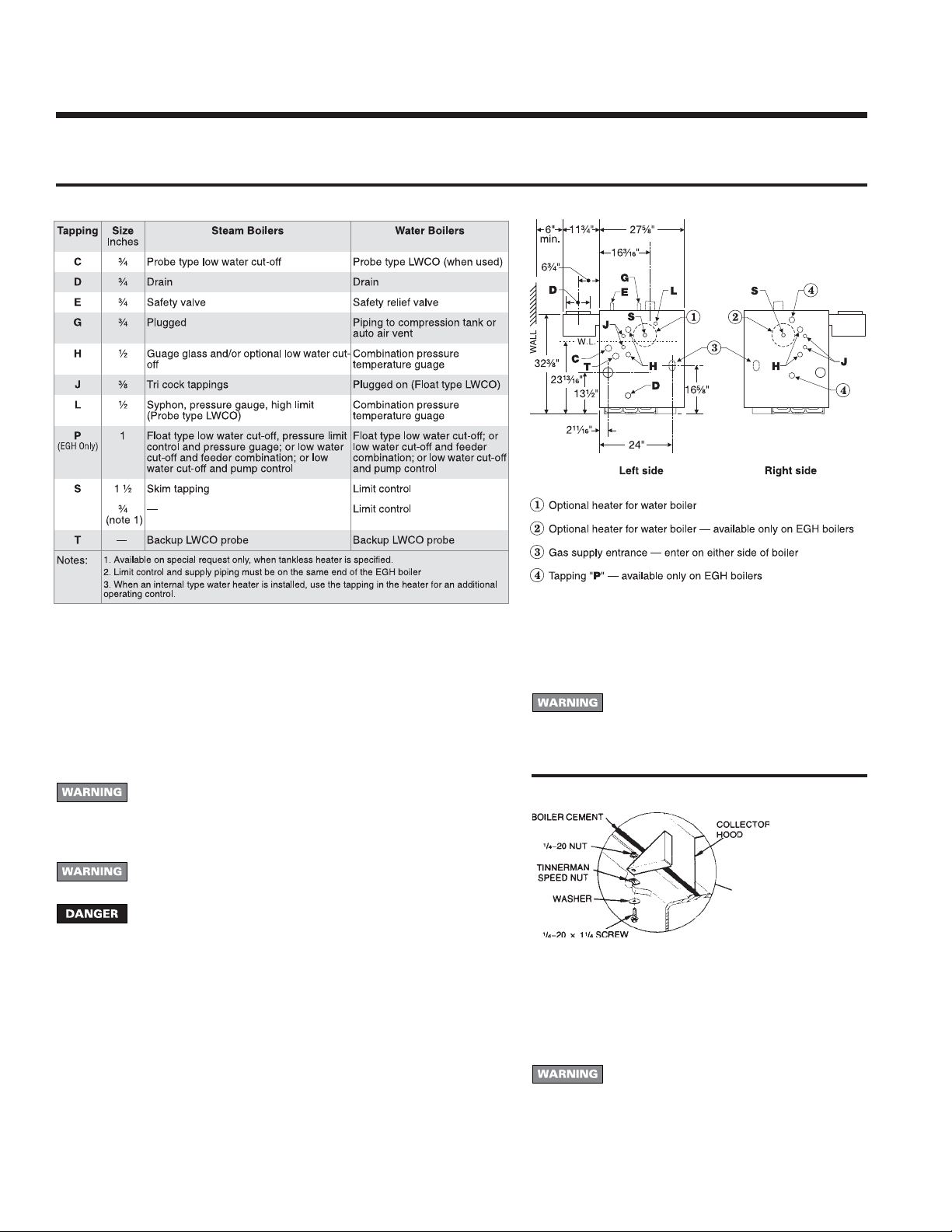

Refer to control tapping table and Figure 3.

8. On initial start-up check for leaks in the system piping. If found, repair at

once.

Installation of flue collector hood

(Factory installed on PEG boilers)

Set flue collector hood on boiler as shown in Figure 4.

Use boiler cement furnished to provide gas-tight seal.

Failure to maintain gas-tight seal can cause

flue gas spillage and carbon monoxide

emissions, resulting in severe personal

injury or death.

Figure 4 Flue collector hood

Installation of front and back base

panels (Factory installed on PEG boilers)

See Figure 5 for installation. Fasten front (6 1/8 inch) and

back 7 5/16 inch) base panels to sections. Seal with boiler

cement along top of insulation panels.

Failure to maintain gas-tight seal can cause

flue gas spillage and carbon monoxide

emissions, resulting in severe personal

injury or death.

6

Part Number 550-110-639/0703

1

EG, PEG, EGH GAS-FIRED BOILERS — SERIES 4 — BOILER MANUAL

Installation

Figure 5 Front and back base panels

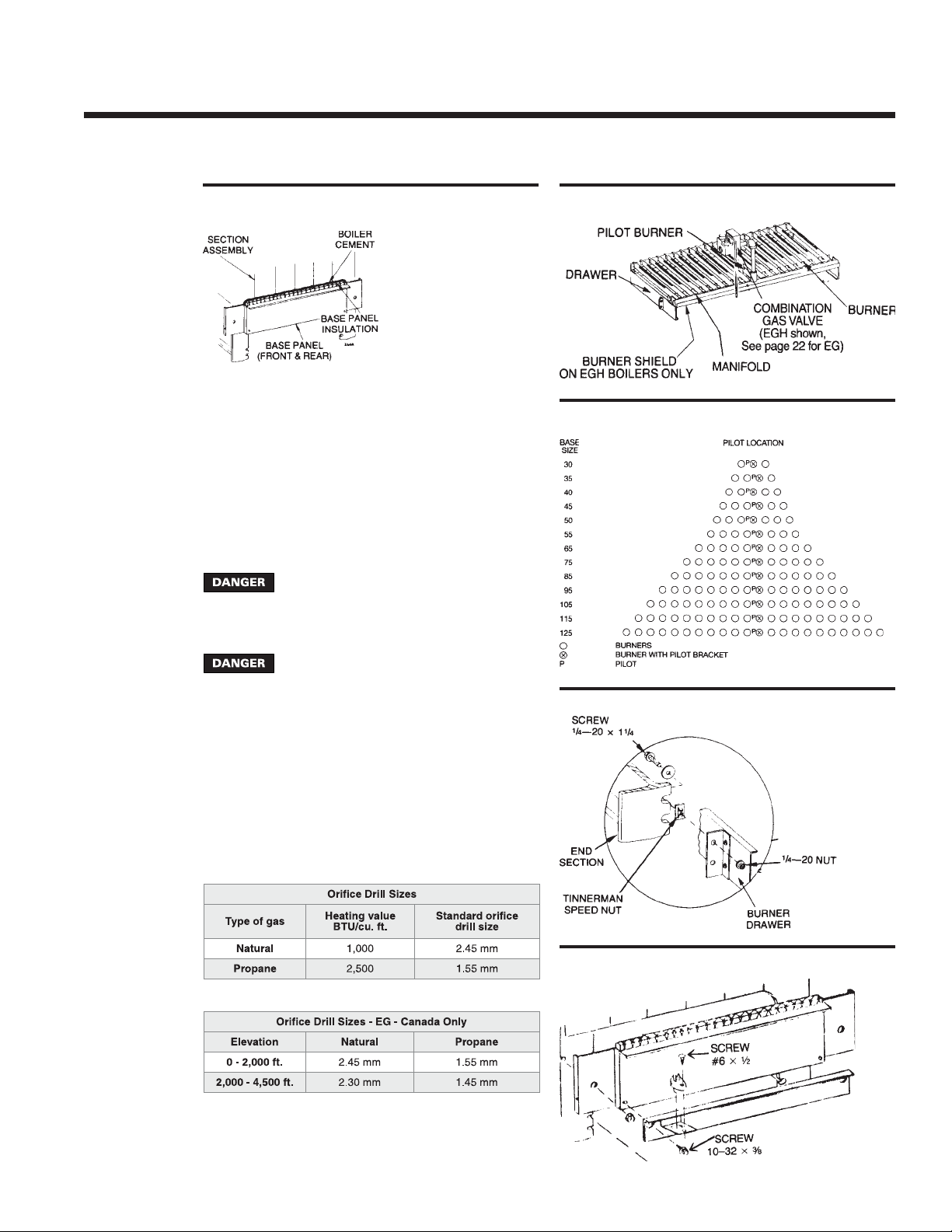

Installation of drawer assembly

and front access panel and back

base channel

steps 2 and 3)

1. The drawer assembly consists of the burner drawer ,

main burners, gas manifold, pilot burner, etc. See

Figures 6, 7 and 8 for installation.

2. Check for proper orifice sizing fro m chart below.

(continued)

Figure 6 Burner drawer assembly

Figure 7 Pilot burner location

(Factory installed on PEG boilers - follow

Proper orifices must be used. Failure to do

so will cause severe personal injury, death

or substantial property damage.

3. Level and straighten burners.

Burners must be properly seated in slots in

back burner support with openings facing

up. Gas orifices must inject down center of

burner. Failure to properly seat burners

will result in severe personal injury, death

or substantial property damage.

4. Install front access panel and back base channel. See

Figure 9.

5. Install rollout thermal fuse element with wire

terminals facing up on front access panel of EG 30-75

boilers only as shown in Figure 9. Wire per Control

Supplement.

Figure 8 Burner drawer installation

Figure 9 Access panel

Part Number 550-110-639/0703

7

1

EG, PEG, EGH GAS-FIRED BOILERS — SERIES 4 — BOILER MANUAL

Installation

Jacket installation (Factory installed on PEG

boilers)

1. Remove the proper knockout discs from panels as

shown in tapping table, page 6.

2. Follow Jacket Instructions in jacket carton.

Draft hood installation

Attach draft hood to flue collector hood using #10 x 1/2"

sheet metal screws provided. Use boiler cement furnished

to provide gas tight seal.

(continued)

Tankless and storage heater knockouts

must be removed for EG and EGH boilers

with optional tankless heaters prior to

jacket installation.

Failure to maintain gas-tight seal can cause

flue gas spillage and carbon monoxide

emissions, resulting in severe personal

injury or death.

Do not alter boiler draft hood or place any

obstruction or non-approved damper in

the breeching or vent system. A.G.A. and

C.S.A. certifications will become void. Flue

gas spillage and carbon monoxide

emissions will occur causing severe

personal injury or death.

Spill switch installation

On EG 30-75 boilers only, fasten spill switch to draft

hood as shown on page 22, Drawing Ref. Letter “K”.

Connect wires as shown in Control Supplement.

Damper installation

If damper will be installed, see Control Supplement for

information.

Breeching erection

Connect from draft hood or damper outlet to chimney

or vent with same size breeching. Where possible, vertical

venting to the outside from draft hood or damper outlet

will offer best performance. Where horizontal breeching

is used, slope upward at least 1/4 inch per lineal foot

toward chimney or vent and support with hangers to

prevent sagging.

A vertical height of 3 feet to 5 feet of

breeching before any elbow or horizontal

breeching is recommended to reduce

chances of flue gas spillage at draft hood

on EGH-95 thru -125 boilers (not

restricted on any EG or EGH-85). Long

horizontal breechings, excessive numbers

of elbows or tees, or other obstructions

which restrict the flow of combustion gases

should be avoided.

Figure 10 Draft hood

Breeching must not be connected to any portion of a

mechanical draft system operating under positive

pressure.

Seal across back of

block assembly with

boiler cement between

cast iron and sheet

metal edge of draft hood

8

Part Number 550-110-639/0703

2

EG, PEG, EGH GAS-FIRED BOILERS — SERIES 4 — BOILER MANUAL

Piping connections

Pipe before installing controls. Connect return piping

after jacket is attached. Connect supply piping before or

after jacket is attached.

Failure to properly pipe the boiler may

result in improper operation and damage

to the boiler or building.

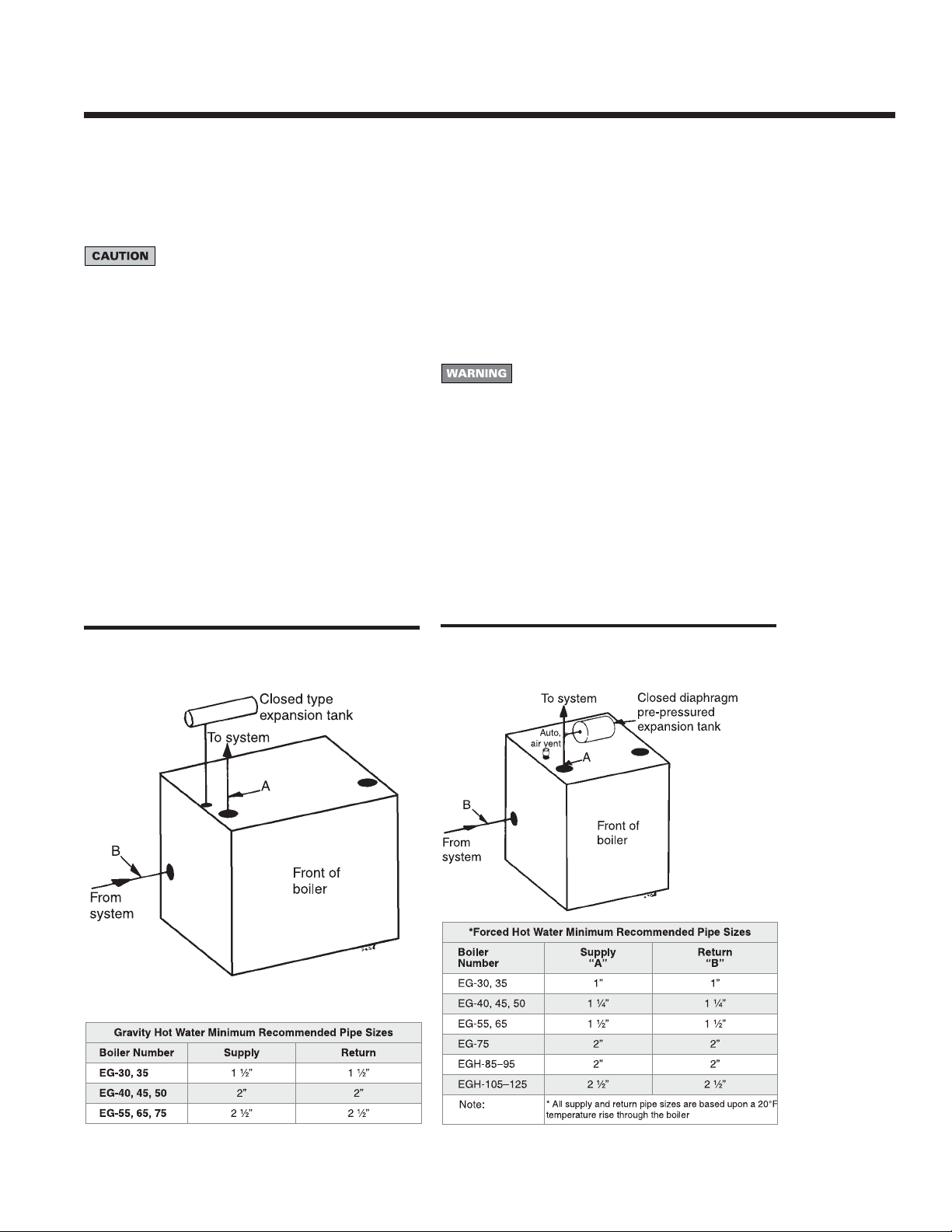

Forced hot water boilers and

gravity hot water boilers (EG Only)

1. T o protect:

• radiant panels, plaster, etc. from high temperature water

supplied from boile r, or

• boiler from condensation caused by low temperature

water returned from system.

2. To protect boiler from condensation formed by low

water temperature returned from large water content

converted gravity systems, etc., see Figure 4, page 6.

Refer to tables and Figures 11a and 11b.

1. Circulator must be selected and sized according to

the design requirements of the system. Size expansion

tank to handle the volume of water in the system.

2. Small expansion tanks cause system water to be lost

from relief valve. Make-up water is then added

Figure 11a Recommended piping connections

forced hot water boilers with closed

type expansion tanks

through fill valve. Eventual section failure can result.

Expansion tank installation:

a) Closed type expansion tank - connect from the 3/4"

N.P.T. tapping on left end section to expansion tank

using 3/4" N.P.T. piping. Any horizontal piping must

pitch upward toward tank at least 1 inch per 5 feet of

piping.

b) Diaphragm type expansion tank - may be located

anywhere in the system, preferably near the boiler . Install

automatic air vent as shown in Figure 11b.

3. Install water relief valve vertically in “E” tapping.

Relief valve discharge piping must be piped

near floor close to floor drain to eliminate

potential of severe burns. Do not pipe to

any area where freezing could occur. Do

not plug, valve or place any obstruction in

discharge line.

4. Connect system return piping to left end for EG -

right or left for EGH. Supply and return must be on

same end of EGH boiler, for proper flow and

disposition of water throughout the sections.

5. Installer must provide drain cock(s).

6. Connect cold water fill supply piping close t o boiler.

7. Plug all unused tappings.

Figure 11b Recommended piping connections

forced hot water boilers with

diaphragm type expansion tanks

Part Number 550-110-639/0703

9

Loading...

Loading...