Page 1

User’s

Information Manual

TM

Wall Mount

Gas-Fired Water Boilers

70/110/155

If the information in this manual is not followed exactly, a fire or explosion may result,

causing property damage, personal injury or loss of life.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS —

• Donottrytolightanyappliance.

• Donottouchanyelectricalswitch;donotuseanytelephoneinyourbuilding.

• Immediatelycallyourgassupplierfromaneighbor’stelephone.Followthegassupplier’sinstructions.

• Ifyoucannotreachyourgassupplier,calltheredepartment.

Installation & service must be performed by a qualified installer, service technician or the gas supplier.

Part number 550-142-123/0513

Page 2

TM

gas-fired water boiler — User’s information Manual

Please read this page first

To . . . Read and use . . . Page

Learn

precautions

Locate boiler

components

Prevent air

contamination

Maintain

boiler

Start — or —

Shutdown

boiler

Understand

control

display

See Hazard Definitions, below

See illustration at right

Laundry room or pool — make sure

boiler air is piped to boiler per manual.

Read list of air contaminants you must

avoid. Have boiler air re-piped to

another location if you can’t avoid.

Set up a plan for maintaining the

boiler using the schedule included in

this manual.

Schedule an annual start-up by a

qualified service technician before

every heating season.

Follow the Operating instruction

sheet details to start or shutdown your

boiler.

This page shows display screen

modes and menu access information.

This page shows how to access the

USER MENU to set date and time

and reset faults if the boiler enters

LOCKOUT.

3

2

4

5

9

10

11

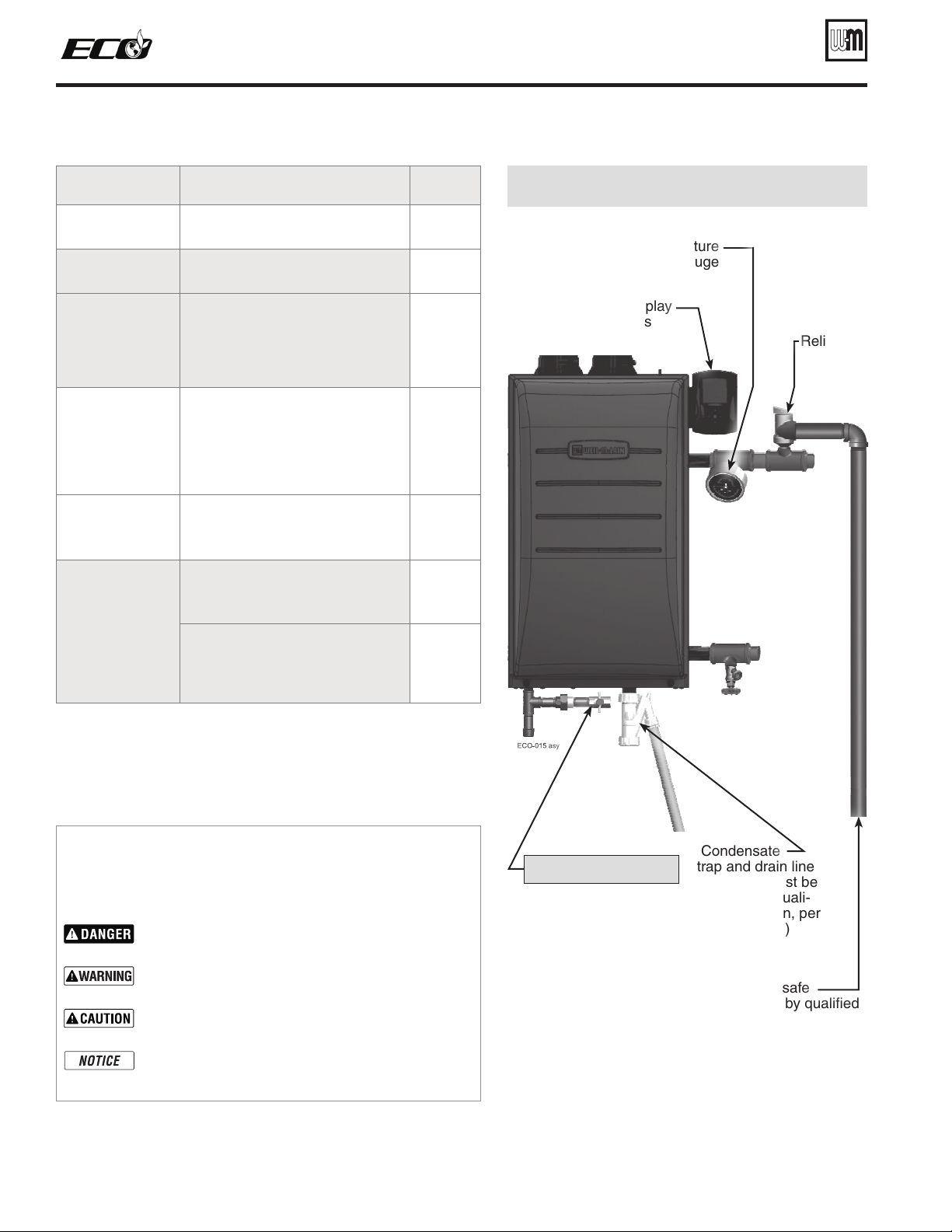

ECO Boiler components

Pressure/temperature

gauge

Control display

and buttons

Relief valve

Piping to system

Piping from system

Hazard definitions

The following defined terms are used throughout this manual to

bring attention to the presence of hazards of various risk levels or

to important information concerning the life of the product.

Indicates presence of hazards that will cause severe

personal injury, death or substantial property damage.

Indicates presence of hazards that can cause severe

personal injury, death or substantial property damage.

Indicates presence of hazards that will or can cause

minor personal injury or property damage.

Indicates special instructions on installation, operation

or maintenance that are important but not related to

personal injury or property damage.

2

Condensate

MANUAL GAS VALVE

Relief valve drain line (must be run to safe

drainage location — must be installed by qualified

technician, per boiler manual)

trap and drain line

(drain line must be

installed by quali-

fied technician, per

boiler manual)

Part number 550-142-123/0513

Page 3

TM

gas-fired water boiler — User’s information Manual

STOP!! — Read before proceeding

Have this boiler serviced/

inspected by a qualified

service technician, at least

annually.

Failure to comply with the above

could result in severe personal

injury, death or substantial property damage.

When calling or writing about the

boiler— Please have the boiler

model number from the boiler

rating label and the CP number

from the boiler cabinet.

Failure to adhere to the guidelines on this page can result in severe personal

injury, death or substantial property damage.

• Should overheating occur or gas supply fail

• Do not use this boiler if any part has been

Boiler service and maintenance —

• To avoidelectric shock, disconnect electrical

supply before performing maintenance.

• Toavoidsevereburns,allow boiler to cool before

performing maintenance.

• You mustmaintain the boiler as outlined in the

manual and have the boiler started up and ser-

viced at least annually by a qualified service technician to ensure boiler/system reliability.

to shut off, DO NOT turn off or disconnect electrical

supply to circulator. Instead, shut off the gas supply at

a location external to the appliance.

under water. Immediately call a qualified service

technician to inspect the boiler and to replace any part

of the control system and any gas control that has been

under water.

Carbon monoxide detector —

• A carbon monoxide detector that is wired on the

same electrical circuit as the boiler is strongly recommended.

Boiler water —

• Do not use petroleum-based cleaning or sealing

compounds in boiler system. Gaskets and seals in the

system may be damaged. This can result in substantial

property damage.

Boiler operation —

• Do not block flow of combustion or ventilation air to

boiler. This boiler is equipped with a control which

will automatically shut down the boiler should air or

vent be blocked. If vent or air blockage is easily accessible and removable, remove it. The boiler should

attempt to restart within an hour. If blockage is not

obvious or cannot be removed, have the boiler and

system checked by a qualified service technician.

Combustion air —

• DO NOT obstruct the combustion air intake or

expose the air intake to corrosive chemicals

(see next page).

Part number 550-142-123/0513

• Leaks in boiler or piping must be repaired

at once to prevent make-up water. Use this

boiler ONLY in a closed-loop system. Con-

tinual fresh make-up water will reduce boiler life.

Mineral buildup in heat exchangers reduces heat

transfer, overheats the materials, and causes failure.

Addition of oxygen carried in by make-up water can

cause internal corrosion.

• Do not add cold water to hot boiler. Thermal

shock can cause heat exchanger to crack.

Freeze protection fluids —

• NEVER use automotive or standard glycol antifreeze.

Use only freeze-protection fluids made for hydronic

systems. Follow all guidelines given by the antifreeze

manufacturer. Thoroughly clean and flush any replacement boiler system that has used glycol before

installing the new boiler.

3

Page 4

TM

gas-fired water boiler — User’s information Manual

Prevent combustion air contamination

Air contamination

Common household and hobby products often contain

fluorine or chlorine compounds. When these chemicals

pass through the boiler, they can form strong acids in

the vent system or boiler. The acid can eat through

the vent or boiler wall, causing serious damage and

presenting a possible threat of flue gas spillage into

the building.

Please read the information on this page.

If the boiler combustion air inlet is

located in any area likely to cause

contamination, or if products which

would contaminate the air cannot be

removed, you must have the combustion air and vent re-piped and

terminated to another location

Contaminated combustion air will dam-

age the boiler, resulting in possible severe

personal injury, death or substantial

property damage.

.

Combustion air contamination:

Ensure that the combustion air will not contain any of

the contaminants in Figure 1

Combustion air supply openings or intake terminations

must NOT be near a swimming pool, for example.

Avoid areas subject to exhaust fumes from laundry facilities.

These areas will always contain contaminants.

Figure 1

Products to avoid

Corrosive contaminants and sources

Spray cans containing chloro/fluorocarbons

Permanent wave solutions

Chlorinated waxes/cleaners

Chlorine-based swimming pool chemicals

Calcium chloride used for thawing

Sodium chloride used for water softening

Refrigerant leaks

.

Do not operate the ECO boiler if its

combustion air inlet is located in

a laundry room or pool facility

, for

example. These areas will always contain

hazardous contaminants.

Paint or varnish removers

Hydrochloric acid/muriatic acid

Cements and glues

Antistatic fabric softeners used in clothes dryers

Chlorine-type bleaches, detergents, and cleaning solvents found in

household laundry rooms

Adhesives used to fasten building products and other similar products

Excessive dust and dirt

Areas likely to have contaminants

Dry cleaning/laundry areas and establishments

Swimming pools

Metal fabrication plants

Beauty shops

Refrigeration repair shops

Photo processing plants

Auto body shops

Plastic manufacturing plants

Furniture refinishing areas and establishments

New building construction

4

Part number 550-142-123/0513

Page 5

TM

gas-fired water boiler — User’s information Manual

Annual startup and general maintenance

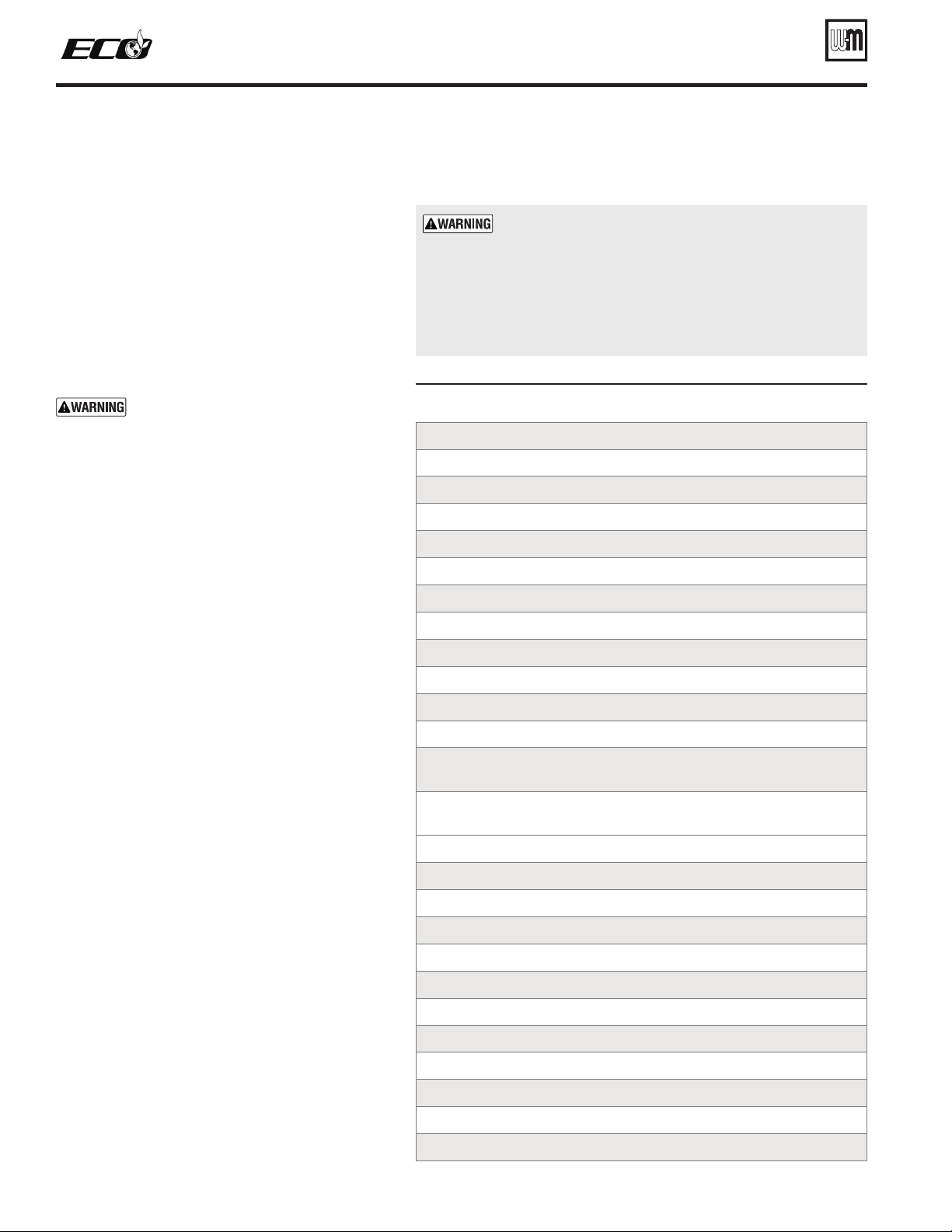

Figure 2 Service and maintenance schedules

OWNER MAINTENANCE (see the following pages for instructions)

Contact your boiler service technician to inspect, service and start

BEGINNING OF SEASON

up your boiler. You must have an annual start-up performed by

a qualified service technician to ensure reliable operation of the

boiler and system.

• Check boiler area.

DAILY

MONTHLY

EVERY 6 MONTHS

• Check air openings.

• Check pressure/temperature gauge.

• Verify boiler jacket door is securely closed.

• Check vent piping.

• Check air piping.

• Check relief valve.

• Check condensate drain system.

• Check automatic air vents (if used).

• Check display date and time.

• Check boiler piping (gas and water).

• Operate relief valve.

Follow the service and maintenance procedures given throughout this manual and in component literature

shipped with the boiler. Failure to perform the service and maintenance could result in damage to the boiler or

system. Failure to follow the directions in this manual and component literature could result in severe personal

injury, death or substantial property damage.

Part number 550-142-123/0513

5

Page 6

TM

gas-fired water boiler — User’s information Manual

User maintenance procedures

The boiler should be inspected and started annually, at the beginning of the heat-

Boiler must

be serviced and

maintained

ing season, only by a qualified service technician. In addition, the maintenance

and care of the boiler designated on page 5 and explained on the following pages

must be performed to assure maximum boiler efficiency and reliability. Failure

to service and maintain the boiler and system could result in equipment failure,

causing possible severe personal injury, death or substantial property damage.

The following information provides detailed instructions for completing the

maintenance items listed in the maintenance schedule, page 5. In addition to

this maintenance, the boiler must be serviced and started up at the beginning of

each heating season by a qualified service technician.

DAILY

Maintenance

Check boiler area

To prevent potential of se-

vere personal injury, death or

substantial property damage,

eliminate all materials discussed below from the boiler

vicinity. If contaminants are

found:

Remove products immediately

from the area. If they have been

there for an extended period,

call a qualified service technician to inspect the boiler and

vent system for possible damage from acid corrosion.

If products cannot be removed,

immediately call a qualified

service technician to address

the problem.

1. Combustible/flammable materials — Do

not store combustible materials, gasoline

or any other flammable vapors or liquids

near the boiler. Remove immediately if

found.

2. Air contaminants — Products containing

chlorine or fluorine, if allowed to contaminate the boiler intake air, will cause

acidic condensate in the vent and boiler.

This will cause significant damage to the

vent and/or boiler if allowed to continue.

3. Read the list of potential materials listed

on page 4 of this manual. If any of these

products are in the room from which

the boiler takes its combustion air, they

must be removed immediately or the

boiler combustion air must be supplied

from outside.

4. See WARNING above.

Check air openings

1. Verify that combustion and ventilation

air openings to the boiler room and/or

building are open and unobstructed.

2. Verify that boiler vent discharge and air

intake are clean and free of obstructions.

Remove any debris on the air intake or

flue exhaust openings.

Check boiler pressure/

temperature gauge

1. Make sure the pressure reading on the

boiler pressure/temperature gauge does

not exceed 24 psig. Higher pressure may

indicate a problem with the expansion

tank.

2. Contact a qualified service technician if

problem persists.

Verify that boiler jacket

door is securely closed

1. Visually inspect boiler jacket door to be

sure it is sealed all around its perimeter.

Verify that the two door screws are tight.

The boiler jacket door must be

securely fastened to the boiler

to prevent boiler from drawing

air from inside the boiler room.

Screws should be hand tight.

This is particularly important if

the boiler is located in the same

room as other appliances.

Failure to keep the door se-

curely fastened could result in

severe personal injury or death.

Contact your installer or tech-

nician immediately if the front

door does not close correctly or

if the door gaskets are damaged.

6

Part number 550-142-123/0513

Page 7

85036

A

B

TM

gas-fired water boiler — User’s information Manual

User maintenance procedures (continued)

MONTHLY

Maintenance

Check vent & air piping

1. Visually inspect the flue gas vent piping

and air piping for any signs of blockage,

leakage or deterioration of the piping.

Notify your qualified service technician

at once if you find any problem.

Failure to inspect the vent/air

system as noted above and have

them repaired by a qualified

service technician can result

in vent system failure, causing

severe personal injury or death.

Check the relief valve

1. Inspect the boiler relief valve and the

relief valve discharge pipe for signs of

weeping or leakage.

2. If the relief valve often weeps, the expansion tank may not be working properly.

Immediately contact your qualified service technician to inspect the boiler and

system.

Check the condensate

drain system

1. Visually inspect the condensate drain

tubing and the end of the tube. Make

sure the tube is in good condition and

that condensate can run freely.

2. Inspect the boiler condensate trap, located under the boiler (see Figure 3). Make

sure the ball float in the trap is in place

and appears to be free to move. Make sure

the trap has water in it.

3. Contact a boiler service technician if you

observe any problems.

Figure 3 Boiler condensate trap

Ball float

Contact a boiler service techni-

cian immediately if you find

the trap dry (no water inside).

Figure 4

Automatic air vent

Check automatic air vents

(if used — automatic air vents

must be used with diaghragm-type

expansion tanks only)

1. See Figure 4.

2. Remove the cap from any automatic air

vent in the system and check operation

by depressing valve “B” slightly with the

tip of a screwdriver.

Scald hazard — Water from

air vent may be very hot. Avoid

contact to prevent possible

severe personal injury.

3. If the air vent valve appears to be work-

Part number 550-142-123/0513

ing freely and not leaking, replace cap “A”,

twisting all the way on.

4. Loosen cap “A” one turn to allow vent to

operate.

5. Have vent replaced if it does not operate

correctly.

Check display date and

time

1. Observe the date and time shown below

the Weil-McLain logo on the control

display.

2. If the date or time is incorrect, follow the

instructions in Figure 7, page 11 to access

the USER MENU and change the date

and/or time settings.

3. Keeping the date and time current makes

sure the control can record problems

accurately.

7

Page 8

TM

gas-fired water boiler — User’s information Manual

User maintenance procedures (continued)

EVERY

6 MONTHS

Maintenance

Check boiler piping

1. Check all gas lines and smell for gas

odors. Perform gas leak inspection per

steps 1 through 7, Operating Instructions,

page 9. If gas odor or leak is detected,

immediately shut down boiler following

procedures on page 9. Call a qualified

service technician.

2. Visually inspect for water leaks around

all piping, circulators, relief valves and

other fittings.

3. Immediately call a qualified service technician to repair any leaks.

Have leaks fixed at once by a

qualified service technician.

Continual fresh makeup water

will reduce boiler life. Minerals

can build up in the heat exchanger, reducing heat transfer

and causing overheating. Heat

exchanger failure can occur.

Do not use petroleum-

based cleaning or sealing

compounds

Severe damage to boiler and

system components can occur,

resulting in possible severe

personal injury, death or substantial property damage.

in boiler system.

Operate boiler relief valve

1. Before proceeding, verify that the relief

valve outlet has been piped to a safe place

of discharge, avoiding any possibility of

scalding from hot water.

3. Lift the relief valve top lever slightly, allowing water to relieve through the valve

and discharge piping.

4. If water flows freely, release the lever and

allow the valve to seat. Watch the end of

the relief valve discharge pipe to ensure

that the valve does not weep after the line

has had time to drain. If the valve weeps,

lift the seat again to attempt to clean the

valve seat. If the valve continues to weep

afterwards, contact your qualified service

technician to inspect the valve and system.

5. If water does not flow from the valve

when you lift the lever completely, the

valve or discharge line may be blocked.

Immediately shutdown the boiler, following the lighting instructions on the

inside jacket top. Call your qualified

service technician to inspect the boiler

and system.

To avoid water damage or scald-

ing due to valve operation, a

metal discharge line must be

connected to relief valve outlet and run to a safe place of

disposal. This discharge line

must be installed by a qualifed

heating installer or service

technician in accordance with

the instructions in the ECO

Boiler Manual

line must be terminated so

as to eliminate possibility of

severe burns should the valve

discharge.

. The discharge

2. Read the boiler pressure/temperature

gauge to make sure the system is pressurized.

8

Part number 550-142-123/0513

Page 9

TM

gas-fired water boiler — User’s information Manual

OPERATING INSTRUCTIONS

Figure 5 Operating instructions (see page 2 for location of manual gas valve)

Part number 550-142-123/0513

9

Page 10

TM

gas-fired water boiler — User’s information Manual

The ECO control display

Figure 6 ECO boiler control display states

10

Part number 550-142-123/0513

Page 11

TM

gas-fired water boiler — User’s information Manual

The ECO control display

(continued)

Figure 7 ECO boiler control display USER Menu — (set date and time, reset faults).

Date and time

1. Set month, date, year, hour and minutes.

2. Keeping the date and time current makes sure the

control can record problems accurately.

Figure 8 ECO boiler control display LOCKOUT SCREEN — screen turns red when boiler locks out —

highlight and select MANUAL RESET to reset boiler as shown below.

Resetting faults:

1. During a fault, the status will change to LOCKOUT and the

Time & Date line will alternate with the fault name. The line

MANUAL RESET will appear on the Homeowner screen.

2. Select MANUAL RESET to reset fault condition.

3. The MANUAL RESET screen will indicate whether the fault

was a manual or automatic reset, the fault name, and the time

and date it occurred.

4. Call for service if fault continues.

Part number 550-142-123/0513

11

Page 12

TM

gas-fired water boiler — User’s information Manual

12

Part number 550-142-123/0513

Loading...

Loading...