Page 1

GOLD CGs

Gas-Fired Water Boiler

Venting Supplement

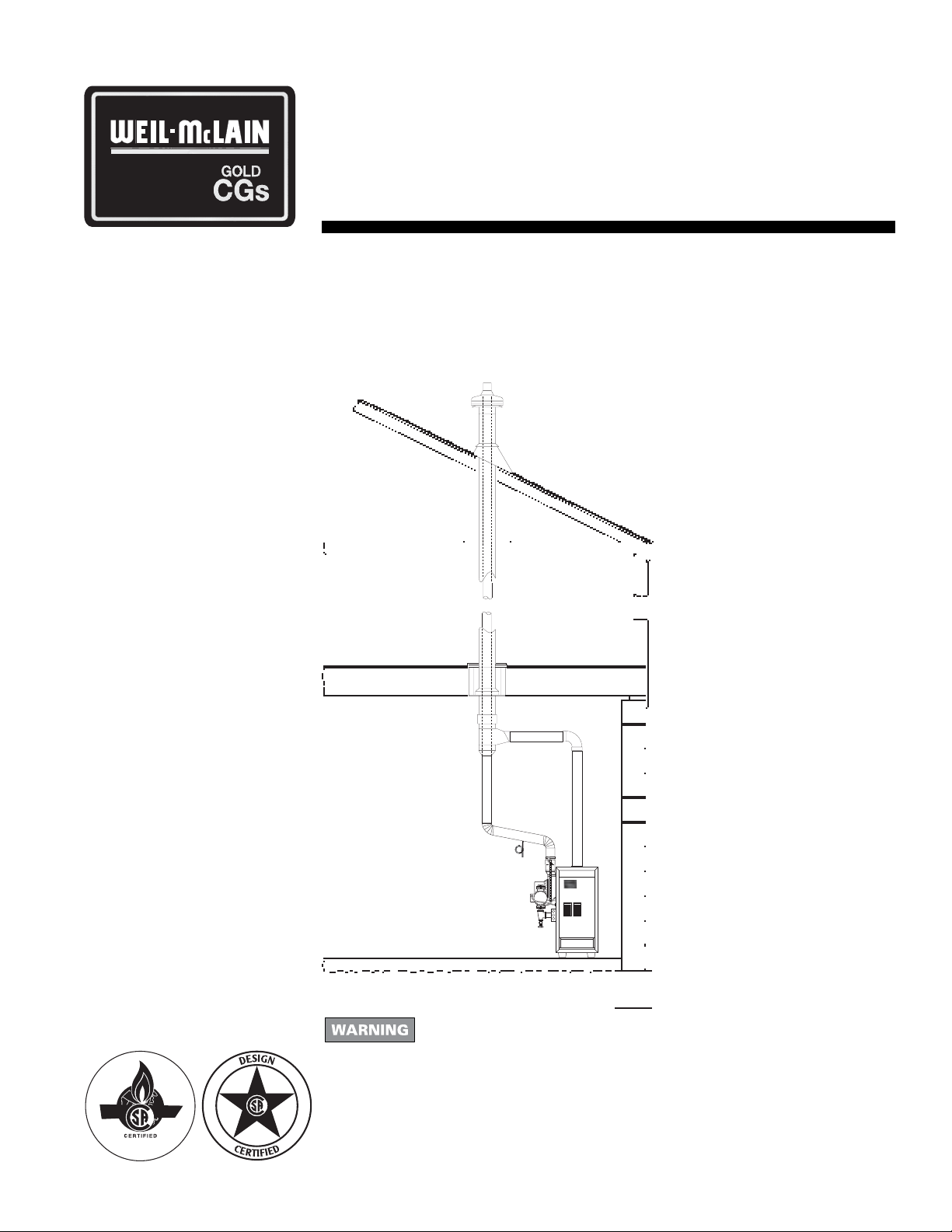

Vertical Direct Venting

For use with Weil-McLain

Roof or Through-Unused-Chimney

Termination Kit

Through-

87300

This Venting Supplement must only be used by a qualified installer/service

technician. Read these instructions completely before beginning the

installation. Failure to follow all instructions in proper order can cause

severe personal injury, death or substantial property damage.

To install a new vent system follow instructions in:

• This Venting Supplement.

• CGs Boiler Manual.

• Vent pipe manufacturer’s instructions supplied with vent material.

Part Number 550-141-873/0502

Page 2

GOLD CGs Gas-FGOLD CGs Gas-F

GOLD CGs Gas-F

GOLD CGs Gas-FGOLD CGs Gas-F

Table of contents

1. Please — read before proceeding.................................3

Hazard definitions .................................................................................... 3

Venting method definitions ..................................................................... 3

To the installer.......................................................................................... 3

2. Determine venting method ..........................................4

Direct exhaust vent methods .................................................................. 4

Direct vent methods................................................................................. 5

ired Wired W

ired W

ired Wired W

ater Boilerater Boiler

ater Boiler

ater Boilerater Boiler

3. Combustion air supply — eliminate contamination .....6

4. Obtain vent system components .................................7

5. Install vent starter .....................................................10

6. Vertical direct vent — vent termination .................... 11

7. Installation guidelines ............................................... 11

8. Verify vent system length..........................................12

9. Installation — assembly .............................................14

2

Part Number 550-141-873/0502

Page 3

VV

ertical Direct Vertical Direct V

V

ertical Direct V

VV

ertical Direct Vertical Direct V

enting — Venting — V

enting — V

enting — Venting — V

enting Supplemententing Supplement

enting Supplement

enting Supplemententing Supplement

1. Please — read before proceeding . . . . .

Hazard definitions

Venting method

definitions

The following terms are used throughout this Venting Supplement to bring

attention to the presence of hazards of various risk levels or to important

information concerning the life of the product.

Indicates presence of hazards that will cause severe

personal injury, death or substantial property damage.

Indicates presence of hazards that can cause severe

personal injury, death or substantial property damage.

Indicates presence of hazards that will or can cause

minor personal injury or property damage.

Indicates special instructions on installation, operation

or maintenance that are important but not related to

personal injury or property damage.

Direct vent — Uses outside combustion air with combustion air connector

piping sealed at all joints and seams. Also known as sealed combustion.

All CGs flue gas vents are pressurized, requiring careful sealing of all joints.

See also

Exhaust: Vertical and Sidewall

Direct exhaust venting — Uses inside combustion air with no combustion

air connector piping. All CGs flue gas vents are pressurized, requiring careful

sealing of all joints. Also known as non-direct venting. See

Supplement — Direct Vent: Sidewall & Direct Exhaust: Vertical and

Sidewall

CGs Venting Supplement — Direct Vent: Sidewall & Direct

for alternate direct vent method.

CGs Venting

venting supplement for application information.

To the installer

Chimney draft vent — Uses the natural draft provided by a vertical vent

or chimney. (This method cannot be used with CGs boilers.)

Chimney draft venting cannot be used for CGs

boilers.

venting materials listed in this Venting Supplement.

Existing vertical vents or chimneys may only be used as

raceways for routing vent or vent/air piping as described

in this supplement or CGs Direct Vent Supplements.

Boiler must be vented and supplied with combustion

air as described in this supplement. Failure to do so will

result in severe personal injury, death or substantial

property damage.

Use only the sealant specified by the vent pipe

manufacturer, applied per their instructions. Vent

piping must be sealed gas-tight to prevent possibility

of flue gas spillage and carbon monoxide emissions,

resulting in severe personal injury or death.

Provide combustion and ventilation air openings as

described in the CGs Boiler Manual and this

supplement. Failure to provide adequate air supply

could result in severe personal injury, death or

substantial property damage.

Vent system must be constructed only using

Part Number 550-141-873/0502

3

Page 4

GOLD CGs Gas-FGOLD CGs Gas-F

87251

GOLD CGs Gas-F

GOLD CGs Gas-FGOLD CGs Gas-F

ired Wired W

ired W

ired Wired W

ater Boilerater Boiler

ater Boiler

ater Boilerater Boiler

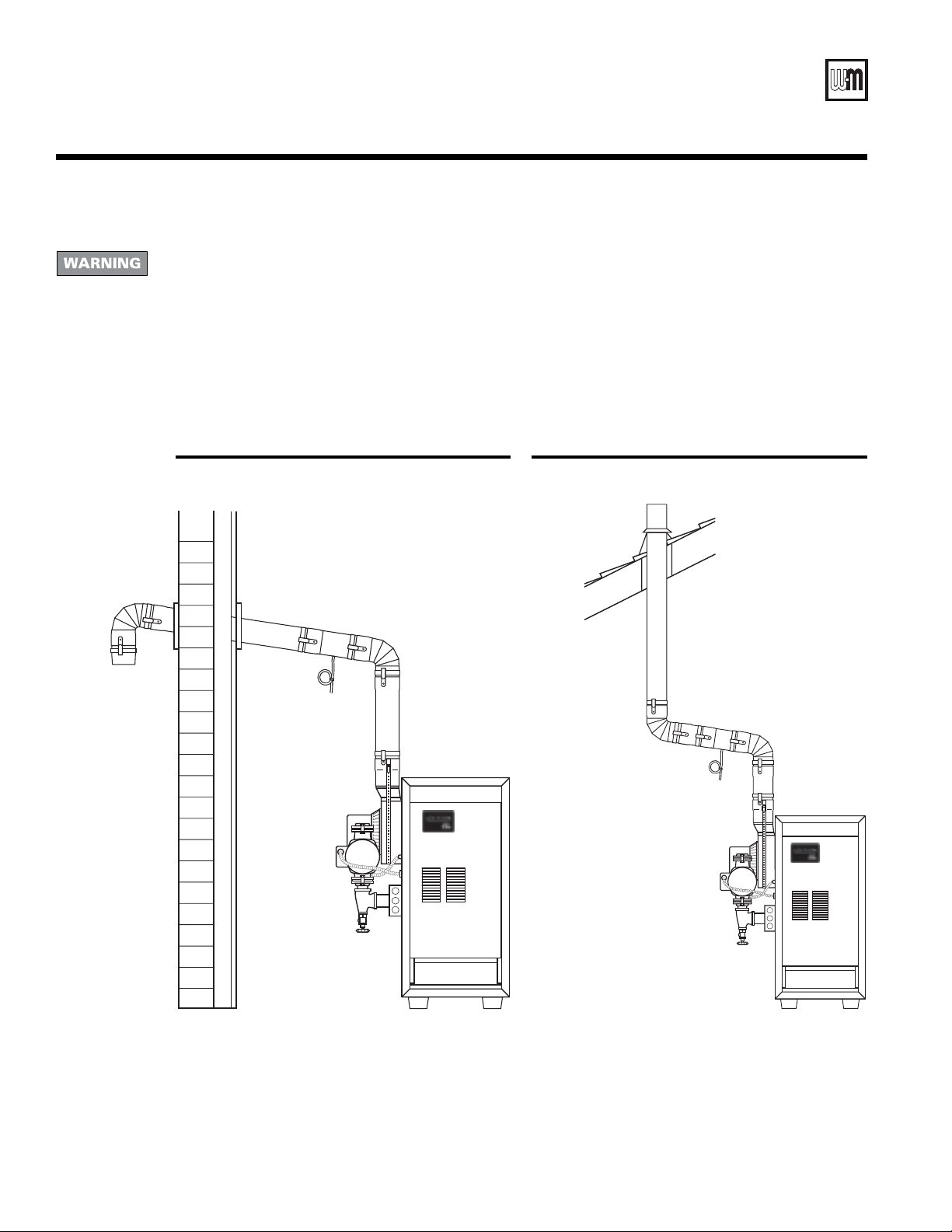

2. Determine venting method

To prevent potential of severe personal injury or death,

check for areas and products listed on page 6 before

installing boiler. If found:

• remove products permanently

—

OR —

• provide outside combustion air (direct vent

installation).

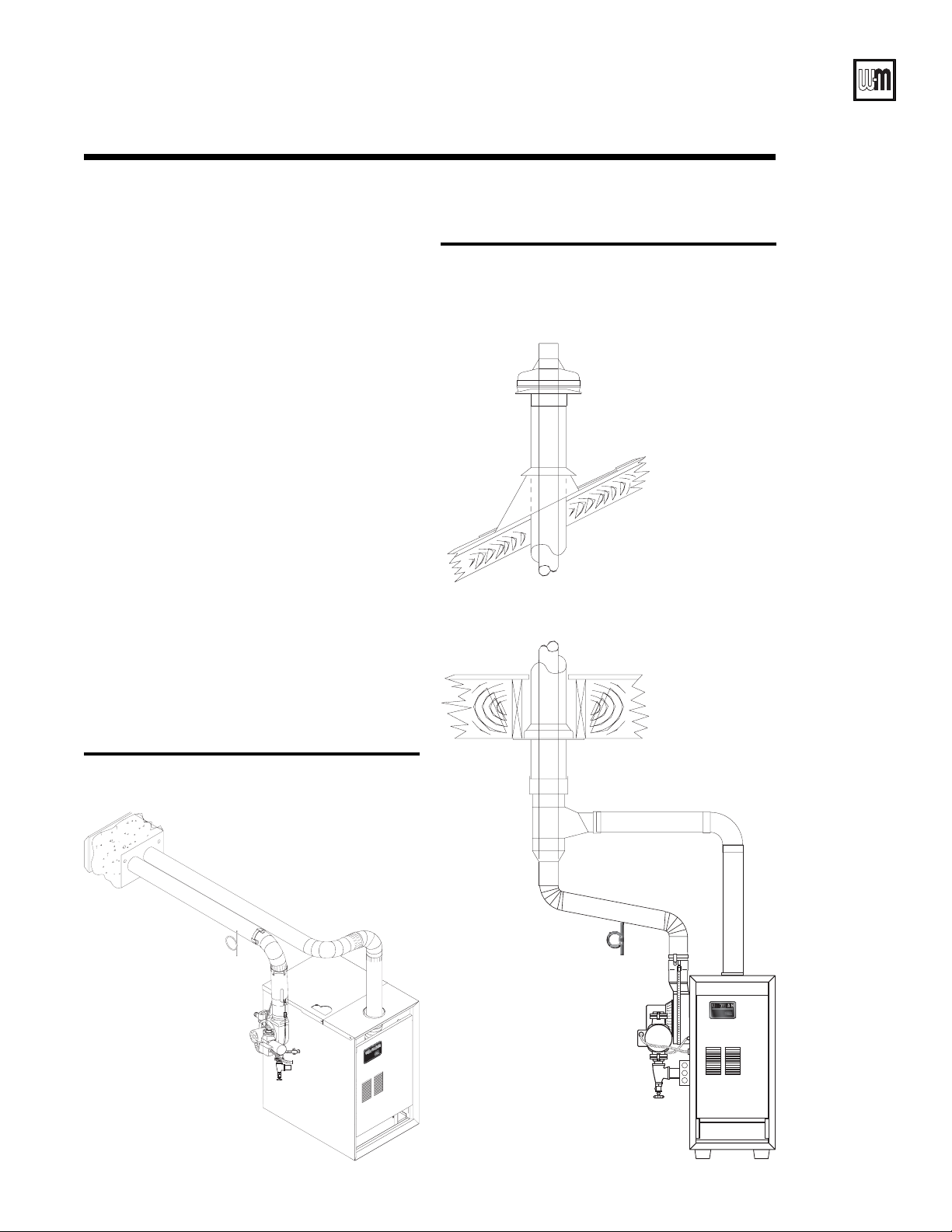

Figure 1 Typical sidewall direct exhaust

vent installation

Direct exhaust ventingDirect exhaust venting

Direct exhaust venting

Direct exhaust ventingDirect exhaust venting

Use only when openings for inside combustion air can

be supplied in accordance with the CGs Boiler manual,

this venting supplement and with all applicable codes.

You must direct vent the boiler if the boiler area may

contain contaminants as described in this supplement

Two direct exhaust vent options are permitted: sidewall

and vertical, per instructions in

Sidewall

Venting Supplement.

Figure 2 Typical vertical direct exhaust

& Direct Exhaust Venting: Vertical or Sidewall

vent installation

CGs Direct Venting:

.

87250

1. Sidewall direct exhaust venting

— using vent manufacturer’s termination fittings

listed in this supplement. See Figure 1.

See instructions on pages 6, 7, 8, 9 and 10 – 13.

4

2. Vertical direct exhaust venting

— using penetration through roof or using existing

unused chimney or vent as raceway for vent pipe.

See Figure 2.

See instructions in

Direct Exhaust: Vertical or Sidewall

Supplement.

CGs Direct Vent: Sidewall &

Part Number 550-141-873/0502

Venting

Page 5

VV

ertical Direct Vertical Direct V

V

ertical Direct V

VV

ertical Direct Vertical Direct V

Direct vent methodsDirect vent methods

Direct vent methods

Direct vent methodsDirect vent methods

Combustion air is provided by air piping connecting

from the boiler Air intake fitting to the outside.

You must direct vent the boiler (pipe outside air to

boiler air intake fitting) if the boiler area may contain

contaminants as described in this supplement.

Two direct vent options are permitted:

enting — Venting — V

enting — V

enting — Venting — V

1. Sidewall direct vent

enting Supplemententing Supplement

enting Supplement

enting Supplemententing Supplement

Figure 4 Typical vertical direct vent

installation

— using Weil-McLain

Kit

. See instructions in

& Direct Exhaust: Vertical or Sidewall

Supplement. Termination kit is included with CGs

boiler. See Figure 3.

Vent/Air Intake Termination

CGs Direct Vent: Sidewall

2. Vertical direct vent

— using Weil-McLain

Unused-ChimneyTermination Kit

vertical direct venting are covered in this

supplement. See Figure 4.

Figure 3 Typical sidewall direct vent

installation

Through-Roof or Through-

. Instructions for

Venting

Part Number 550-141-873/0502

87203

87205

5

Page 6

GOLD CGs Gas-FGOLD CGs Gas-F

GOLD CGs Gas-F

GOLD CGs Gas-FGOLD CGs Gas-F

ired Wired W

ired W

ired Wired W

3. Combustion air supply —

eliminate contamination

ater Boilerater Boiler

ater Boiler

ater Boilerater Boiler

If the boiler is installed in any area likely to cause

contamination

contaminate the air cannot be removed, you must pipe

combustion air to the boiler air intake

combustion air will damage the boiler, resulting in

possible severe personal injury, death or substantial

property damage. Do not install a CGs boiler in a

laundry room or pool facility

using ducted outside air. These areas will always contain

contaminants.

Please review the following information on potential

combustion air contamination problems.

Refer to Table 1 for products and areas that may cause

contaminated combustion air. These contaminants may

cause damage to the vent piping, and must be eliminated

Table 1 Corrosive contaminants

Products to avoid Areas likely to have contaminants

Spray cans containing chloro/fluorocarbons Dry cleaning/laundry areas and establishments

, or if products which would

. Contaminated

, for example, without

from the boiler combustion air supply. You may do this

by removing the contaminants permanently from the

area or piping air directly to the boiler (direct vent) using

one of the methods referenced in this supplement and

described in the direct vent supplements.

To prevent potential of severe

personal injury or death, check for

areas and products listed below

before installing boiler. If found:

• remove products permanently

— OR —

• provide outside combustion air

(direct vent installation).

Permanent wave solutions Swimming pools

Chlorinated waxes/cleaners Metal fabrication plants

Chlorine-based swimming pool chemicals Beauty shops

Calcium chloride used for thawing Refrigeration repair shops

Sodium chloride used for water softening Photo processing plants

Refrigerant leaks Auto body shops

Paint or varnish removers Plastic manufacturing plants

Hydrochloric acid/muriatic acid Furniture refinishing areas and establishments

Cements and glues New building construction

Antistatic fabric softeners used in clothes

dryers

Chlorine-type bleaches, detergents, and cleaning solvents found in household laundry rooms

Adhesives used to fasten building products and

other similar products

6

Remodeling areas

Garages with workshops

Part Number 550-141-873/0502

Page 7

VV

ertical Direct Vertical Direct V

V

ertical Direct V

VV

ertical Direct Vertical Direct V

enting — Venting — V

enting — V

enting — Venting — V

enting Supplemententing Supplement

enting Supplement

enting Supplemententing Supplement

4. Obtain vent system components

The following special gas vent systems comply with UL-1738 and ULCS636 standards and are certified by CSA as the only systems suitable for

use with CGs boilers:

• Heat-Fab, Inc. Saf-T Vent

• Flex-L International, Inc. StaR-34

• Z-Flex®, Inc. Z-Vent II

•ProTech Systems FasNSeal™

Use only the vent starter of the same manufacturer as the vent components. Do not mix components from different systems. The vent system

could fail, causing flue gas spillage, resulting in severe personal injury or

death.

®

1. The

2. Verify that the vent termination will comply with the requirements

3. You will need to obtain stainless vent pipe and fittings, using only the

4. Use suitable 3" material for combustion air connector piping, such as:

Through-Roof or Through-Unused-Chimney Termination Kit

provides special parts required to route 3-inch stainless vent pipe

through 5-inch B-vent. The space between the vents provides the

passage for combustion air. See page 9 for parts included with the kit.

listed on page 11. Then verify that the vent and air piping will not

exceed the length limits given in section 8 of this supplement before

locating boiler or floor/roof penetrations.

vent systems listed in the CGi, CGs & GV Vent Component

Supplement. Also obtain B-vent pipe and fittings for the vertical run

and floor/roof penetrations (See Table 3).

• Dryer vent

• Galvanized steel

• PVC (3" I.D.)

Part Number 550-141-873/0502

7

Page 8

GOLD CGs Gas-FGOLD CGs Gas-F

GOLD CGs Gas-F

GOLD CGs Gas-FGOLD CGs Gas-F

ired Wired W

ired W

ired Wired W

ater Boilerater Boiler

ater Boiler

ater Boilerater Boiler

4. Obtain vent system components (continued)

Figure 5 Typical installation,

showing component

identification

Termination coupling

Elastomer

flashing*

5”Type “B”

storm ring

5”Type “B”

adjustable

flashing

Vent pipe

5”Type “B” rain cap with

hole in top for vent pipe

For minimum height

followType “B” gas

vent manufacturer’s

instruction

5”Type “B” stack

Fire stop

Fire stop

Single wall stack

reducer tee*

Cap with hole

for vent pipe

Elastomer

flashing*

3” vent pipe:

Heat-Fab Saf-T Vent

®

Z-Flex Z-Vent II

Flex-L International StaR-34

ProTech Systems FasNSeal™

* furnished in kit

®

Condensate drain line

Vent starter must be

by same manufacturer

as the vent pipe.

5” type “B” support

5” type “B” draft hood connector

Air intake pipe – 3” pvc,

standard 3” galvanized

or aluminum single

wall pipe, or 3” flexible

dryer vent

CGs boiler

87303

8

Part Number 550-141-873/0502

Page 9

VV

ertical Direct Vertical Direct V

V

ertical Direct V

VV

ertical Direct Vertical Direct V

Figure 6 Parts provided in kit Table 2 Parts provided in kit

enting — Venting — V

enting — V

enting — Venting — V

enting Supplemententing Supplement

enting Supplement

enting Supplemententing Supplement

Item Description Qty

1 Tee —

galvanized 5" x 5" x 3"

2 Vent clamp 5

3 Bottom cap —

3

1

2

4

6

8

Table 3 Parts below are required for installation and are provided by installer (not included in kit)

7

5

87302

galvanized with 4 ½" hole

4 Vent support 1

5 Elastomer grippers 11

6 Screws — sheet metal

type A, #10 x 1¼"

7 Screws — sheet metal

type A, #10 x ½"

8 Elastomer flashing 2

1

1

11

3

Description Quantity

Rain cap, galvanized, 5" 1

Adjustable flashing, type B, 5" 1

Fire stop for each floor or attic penetration 1

Storm ring, type B, 5" 1

Support, type B, 5" 1

Draft hood connector, type B, 5" 1

Adequate B-Vent with clamp rings for combustion air run (less than 30 feet) -Adequate 3" vent material for vent run and elbows from one of the following (See Note):

• Heat-Fab, Inc. — Saf-T Vent

• Flex-L International, Inc. — StaR-34 • Z-Flex

Adequate sealant specified by vent pipe manufacturer’s instructions -Adequate 3" PVC, galvanized or dryer vent (for combustion air supply piping between tee and boiler) --

Note: Do not mix types of vent material. CSA certification will be void.

Part Number 550-141-873/0502

®

• ProTech Systems — FasNSeal™

®

, Inc. — Z-Vent II

--

9

Page 10

GOLD CGs Gas-FGOLD CGs Gas-F

GOLD CGs Gas-F

GOLD CGs Gas-FGOLD CGs Gas-F

ired Wired W

ired W

ired Wired W

ater Boilerater Boiler

ater Boiler

ater Boilerater Boiler

5. Install vent starter

1. Select a vent pipe manufacturer and obtain all vent

components needed, based on boiler location and

venting method.

2. You must use the vent starter made by the vent pipe

manufacturer. See separate CGi, CGs & GV Vent

Component Supplement

, for part numbers of each

component, listed by vent manufacturer.

Use only the vent starter of the same

manufacturer as the vent components. Do not mix components from

different systems. The vent system

could fail, causing flue gas spillage,

resulting in severe personal injury or

death.

Band clamp

Band clamp

strap

screw

FasNSeal™

starter

Band clamp

screw

Figure 7

FasNSeal™ vent starter

3. Follow all applicable national, state, local or

provincial codes when venting the CGs boiler.

4. Connect vent starter to blower housing outlet as

shown in the

Figures 7 through 10, below.

a. Do not mix components from different vent

manufacturers.

b. Maintain minimum 2" clearance from

combustible materials to vent pipe.

c. Seal with sealant specified by vent pipe

manufacturer, using ³⁄₈" bead (not required for

FasNSeal™).

d. Tighten strap at band clamp screw until strap is

snug around blower housing.

Tighten

position

Feed

Band clamp

strap

position

Z-Vent II

starter

Band clamp

screw

³⁄₈ " Bead

of sealant

Band clamp

strap

Blower

housing

outlet

87211

Saf-T Vent

starter

Band clamp

screw

³⁄₈ " Bead of

sealant

Blower

housing

outlet

87208

Z-Vent II vent starter

®

Figure 9

Saf-T Vent® vent starter

StaR-34 vent starter

Figure 8

Figure 10

Band clamp

strap

Blower

housing

outlet

87210

StaR-34

starter

Band clamp

screw

3/8" Bead

of sealant

Blower

housing

outlet

87209

10

Part Number 550-141-873/0502

Page 11

VV

ertical Direct Vertical Direct V

V

ertical Direct V

VV

ertical Direct Vertical Direct V

enting — Venting — V

enting — V

enting — Venting — V

enting Supplemententing Supplement

enting Supplement

enting Supplemententing Supplement

6. Vertical direct vent — vent termination

Follow instructions on this page

when determining vent location to

avoid possibility of severe personal

injury, death or substantial property

damage.

1. Locate the boiler and vent penetration through the

roof so all requirements on this page will be met.

Also follow vent manufacturer’s instructions.

2. Gases will form white plume in winter. Plume could

obstruct window view of nearby windows in multistory buildings.

3. Prevailing winds could cause freezing of condensate

and water/ice buildup on vent termination, building,

plants or roof. Ice buildup on vent termination can

cause boiler shutdown and building freezeup.

4. Locate or guard vent termination to prevent

condensate from damaging exterior surfaces.

5. Locate the vent termination well away from trees,

shrubs, and decorative items.

6. Locate or guard vent to prevent accidental contact

by people or pets.

7. Do not terminate vent in window well, stairwell,

alcove, courtyard, or other recessed areas.

8. Do not wrap or insulate vent pipe or fittings.

9. Do not connect:

• Any other appliance to vent pipe.

• Multiple boilers to a common vent pipe.

10. Canadian installations — See B149.1 or B149.2

Installation Code. Terminate vent no less than 6 feet

from another combustion air inlet, 3 feet from any

other building opening, and 3 feet from any gas

service regulator.

11. The vent must terminate:

• more than 1 foot below or to side of all doors

or windows.

• more than 1 foot above grade or anticipated

snow line.

• 3 feet above any forced air intake within 10

feet.

12. Vent must also terminate:

• at least 6 feet away from adjacent walls.

• no closer than 5 feet below roof overhang.

• at least 4 feet horizontally (and in no case above

or below unless a 4 foot horizontal distance is

maintained) from electric meters, gas meters,

regulators, relief valves, and other equipment.

13. Site conditions may dictate greater clearances.

Do not terminate the vent adjacent

to a wall or below any building

extension such as eaves, parapets,

balconies or decks. Failure to

comply could result in severe

personal injury, death or substantial

property damage.

14. Multiple boilers may be vented with vent

terminations at the same height. Space

terminations to provide a minimum of 1 foot

between pipes for U.S. installations. For Canadian

installations, provide clearances required by

B149.1 or B149.2 Installation Code.

7. Installation guidelines

1. Codes — Install vent and combustion air piping in

compliance with all applicable national, state, local

or provincial codes.

2. Do not connect:

• Any other appliance to combustion air or vent

piping.

• Any other appliance into or through chimney

when using existing chimney as raceway.

• Multiple boilers into common vent.

3. Vent length limits — Position boiler as close as

possible to vertical vent/air run. Do not exceed vent

length limits given in Section 8 of this supplement.

B-vent limit is 30 feet. Vent or air max. lengths are:

• CGs-3 & CGs-4: Max 55 equivalent feet

• CGs-5 & CGs-6: Max 45 equivalent feet

Part Number 550-141-873/0502

4. Materials and construction —

• Seal all B-vent combustion air joints with

• Construct vent joints per vent manufacturer’s

• Use only one of the approved vent systems listed

5. Install boiler per CGs Boiler Manual.

approved silicone sealant (Dow Corning 700™

or 732™, General Electric 108 or 800, or sealant

specified by vent pipe manufacturer. B-vent

sections must be straight — no elbows

instructions, including use of their specified

sealant. Vent pipe routed inside B-vent must

also be fitted with vent clamps with elastomer

grippers, installed per section 9 of this

supplement.

in Table 2. Do not mix types of vent material.

CSA certification will be void.

.

11

Page 12

GOLD CGs Gas-FGOLD CGs Gas-F

GOLD CGs Gas-F

GOLD CGs Gas-FGOLD CGs Gas-F

ired Wired W

ired W

ired Wired W

ater Boilerater Boiler

ater Boiler

ater Boilerater Boiler

8. Verify vent system length

The vent or air piping must be no longer than the

maximum value given in

tables that the maximum length of connector piping

(vent or air piping between boiler and B-vent tee

connection) depends on the number of elbows and the

length of the B-vent section. The reason for this is that

each 90-degree vent or air pipe elbow cause the same

pressure drop as 7 feet of straight pipe.

Tables 4 and 5. Note in the

Vent/air piping length verification

procedure:

Step 1 — Determine dimensions of vent/air pipe

needed for planned location

Measure or calculate the vent/air pipe lengths required

for the planned location of the boiler and floor/roof

penetrations. See Figure 11 for a typical layout.

• How long will the vertical B-vent section have to be?

Round up to the nearest 5 feet (for example, if B-vent

length needs to be 12 feet, round this amount up to the

nearest 5 feet — use 15 feet for your B-vent length).

(This is dimension L in Figure 11.)

• How many elbows will be needed in the vent connector

piping (from boiler to B-vent tee)?

• How many feet of vent piping will be needed for the

connector runs?

(This would be the sum of dimensions C & D in Fig. 11.)

• How many elbows will be needed in the air connector

piping (from boiler to B-vent tee)?

• How many feet of air piping will be needed for the

connector runs?

(This would be the sum of dimensions A & B in Fig. 11.)

Step 4 — Replan boiler location & piping if piping

length of vent or air is too long

See if boiler can be moved closer to vertical vent/air

piping.

See if you can reduce the number of elbows required

vent piping must have 2 elbows minimum in order to

provide horizontal piping to install condensate drain

tee.

Example verification (

Step 1 — Vent/air piping required per plan

As an example, consider an installation of a CGs-5

boiler, where the boiler and vent/air locations would

require:

• Boiler model = CGs-5.

• B-vent length (L) = 20 feet.

• Vent connector piping requires 2 elbows.

• Vent connector piping length (D + C) = 16 feet.

• Air connector piping requires 1 elbow.

• Air connector piping length (B + A) = 17 feet.

Step 2 — Verify vent piping

• Enter Table 5 at the row for B-vent length of 20

feet.

• Move to the 2-elbow column.

• Read a maximum connector pipe length of 18 feet.

Conclusion — Vent piping is within limits because

vent connector piping would only be 16 feet (less than

the maximum of 18 feet).

Figure 11Figure 11

Figure 11):

Figure 11Figure 11

12

Step 2 — Verify that vent connector piping is within

allowable limits

Use Table 4 or 5, depending on boiler model to be used.

Find the row with the B-vent length the installation

requires. Move across to the column with the number

of vent elbows needed for the installation. This number

is the maximum allowable vent connector piping length.

Step 3 — Verify that air connector piping is within

allowable limits

Use Table 4 or 5, depending on boiler model to be used.

Find the row with the B-vent length the installation

requires. Move across to the column with the number

of air pipe elbows needed for the installation. This

number is the maximum allowable air pipe connector

piping length.

Step 3 — Verify air piping

• Enter Table 5 at the row for B-vent length of 20

feet.

• Move to the 1-elbow column.

• Read a maximum connector pipe length of 25 feet.

Conclusion — Air piping is within limits because air

connector piping would only be 17 feet (less than the

maximum of 25 feet).

Step 4 — Replanning

No replanning needed. Vent and air piping lengths are

within limits.

Part Number 550-141-873/0502

Page 13

VV

ertical Direct Vertical Direct V

V

ertical Direct V

VV

ertical Direct Vertical Direct V

enting — Venting — V

enting — V

enting — Venting — V

Maximum connector pipe length, vent or air:

• Combustion air connector pipe

• Vent connector pipe

CGs-3 and CGs-4

enting Supplemententing Supplement

enting Supplement

enting Supplemententing Supplement

Figure 11 Typical vent/air pipingTable 4 CGs-3 and CGs-4

“B-Vent”

length

(feet)

L

5 504336292215 8

10 45 38 31 24 17 10 3

15 40 33 26 19 12 5 --

20 35 28 21 14 7 -- --

25 30 23 16 9 2 -- --

30 25 18 11 4 -- -- --

Note: Combustion air connector pipe length = A + B

Vent connector pipe length = C + D

Total number of elbows

1 2 3 4 5 6 7

Max. length from boiler to “B-Vent”

Table 5 CGs-5 and CGs-6

Maximum connector pipe length, vent or air:

• Combustion air connector pipe

• Vent connector pipe

CGs-5 and CGs-6

L

L = B-vent length

A + B

C + D

A

= Combustion air

connector piping length

= Vent connector piping length

Elbow

“B-Vent”

length

(feet)

L

540332619125--

10 35 28 21 14 7 -- --

15 30 23 16 9 2 -- --

20 25 18 11 4 -- -- --

25 20 13 6 -- -- -- --

30 15 8 1 -- -- -- --

Note: Combustion air connector pipe length = A + B

Vent connector pipe length = C + D

Part Number 550-141-873/0502

Total number of elbows

1 2 3 4 5 6 7

Max. length from boiler to “B-Vent”

D

Vent piping

Condensate

drain line

Elbows

87304

C

B

Combustion air piping

13

Page 14

GOLD CGs Gas-FGOLD CGs Gas-F

GOLD CGs Gas-F

GOLD CGs Gas-FGOLD CGs Gas-F

ired Wired W

ired W

ired Wired W

ater Boilerater Boiler

ater Boiler

ater Boilerater Boiler

9. Installation — assembly

Step 1

Step 2

Assemble B-vent piping

1. Install 5" type B support, B-vent combustion air run,

flashing, fire stops and storm collar per

manufacturer’s instructions. Apply approved sealant

to each B-vent joint. See Figure 12.

2. Install type B draft hood connector to bottom of

combustion air run. Seal with approved sealant.

Prepare & insert vertical vent

1. From top or bottom of combustion air run, install

vent piping

• Top of vent piping must extend 3" above

top of rain cap. See Figure 5, page 8.

• Bottom of vent piping must extend 18"

below draft hood connector.

2. At each vent joint:

a. Follow vent pipe manufacturer’s instructions to

assemble and seal joints. Sealant recommended

by vent pipe manufacturer must be used as

indicated in their instructions.

b. Apply 2 self-adhesive elastomer grippers to vent

clamp. Grippers must be positioned on clamp

as shown in Figure 13. Bend out 2 ears on vent

clamp.

.

Figure 12 Sealing B-vent joints

87305

Figure 13 Apply elastomer strips to vent clamps

87306

Figure 14 Install vent clamps on vent piping

14

c. Fasten clamp around vent pipe with 2 – 1¹⁄₄"

screws in top and bottom holes, about every 5

feet. See Figure 14. Tighten screws until clamp

does not turn or slide around vent piping.

87307

Part Number 550-141-873/0502

Page 15

VV

Draft hood

connector

Vent

support

87308

5” x 5” x 3”

Te e

Elastomer

flashing

Draft hood

connector

Bottom cap

87309

ertical Direct Vertical Direct V

V

ertical Direct V

VV

ertical Direct Vertical Direct V

enting — Venting — V

enting — V

enting — Venting — V

enting Supplemententing Supplement

enting Supplement

enting Supplemententing Supplement

Step 3

Step 4

Install vent support

1. Apply 1 elastomer gripper to vent support.

2. Intall vent support around vent piping just below

draft hood connector as shown in Figure 15. Fasten

support around vent piping with 1 – 1 ¹⁄₄" screw.

3. Tighten screw until support does not turn or slide

around vent piping.

Install 5" x 5" x 3" tee

1. Slide tee over vent piping and attach uncrimped end

to bottom of draft hood connector:

a. Drill 3 holes in tee for ¹⁄₄" sheet metal screws.

Do not allow drill to

penetrate vent pipe. Drill

holes carefully in tee and use

1

only

/

" screws to fasten tee

4

to draft hood connector.

Failure to do so can damage

vent pipe, causing severe

personal injury or substantial

property damage.

b. Seal all seams and screws with approved sealant.

Figure 15 Install vent support

Figure 16 Install tee

2. Secure bottom cap to tee with duct tape. Slide

elastomer flashing up around vent pipe and tuck

lip into cap’s bottom opening. Seal with approved

sealant.

Follow vent pipe manufacturer's instructions to

assemble and seal joints. Sealant recommended by vent

pipe manufacturer must be used as indicated in their

instructions. Vent and combustion air connector piping

must be sealed gas-tight to prevent possibility of flue

gas spillage and carbon monoxide emissions, resulting

in severe personal injury or death.

Part Number 550-141-873/0502

15

Page 16

GOLD CGs Gas-FGOLD CGs Gas-F

Vent pipe

Elastomer

flashing

Rain cap

87310

GOLD CGs Gas-F

GOLD CGs Gas-FGOLD CGs Gas-F

ired Wired W

ired W

ired Wired W

ater Boilerater Boiler

ater Boiler

ater Boilerater Boiler

9. Installation — assembly continued

Step 5 Install rain cap

1. On roof, cut 4 ¹⁄₂" hole in top of rain cap and

install cap over protruding vent pipe. Slide

elastomer flashing down around vent pipe

and tuck lip into cap’s top opening.

2. Connect termination coupling to vent pipe

using vent pipe manufacturer’s specified

sealant.

Step 6

Finish installation

1. Complete vent piping to boiler, making sure to follow vent pipe manufacturer’s instructions and Weil-McLain

vent manufacturers special gas vent system vent and combustion air venting supplements.

2. Use any of the following to install combustion air connector piping from tee to boiler, making sure to seal all

joints and seams:

a. 3" Flexible dryer vent — A piece of 3" galvanized is required at each end to adapt. Seal all pipe joints and

seams between pipe and dryer vent with approved sealant.

b. Galvanized or aluminum single wall pipe — Seal all joints and seams using approved sealant.

c. 3" PVC — Seal all joints using PVC cement.

Figure 17 Install rain cap

16

3. Condensate drain line — A condensate drain fitting is always required for through-roof vents. Follow vent

manufacturer’s instructions to install condensate drain line.

Use only silicone tubing rated for at least 400°F for the first 18" of condensate drain line, then

other non-metallic tubing may be used. Using any other material could cause flue gas leakage,

potentially resulting in severe personal injury, death or substantial property damage.

4. Multiple boilers may be vented with vent terminations at the same height. Space terminations to provide a

minimum of 1 fott between pipes for U.S. installations. For Canadian installations, provide clearances required

by B149.1 or B149.2 Installation Code.

Part Number 550-141-873/0502

Loading...

Loading...