Weil-McLain 800062000-Brn-PO Rie BF5, 800061000-Brn-PO Rie BF5, 800060000-Brn-PO Rie BF5 User Manual

Installation & Operating Manual

Single stage operation oil burners

RETROFIT APPLICATIONS ONLY

If this burner is being installed in a packaged unit (ie. burner comes with a boiler or furnace), follow

the installation and set-up instructions supplied with the heating unit, as settings may differ from

those shown in this manual.

- The following pages contain information, descriptions and diagrams for the proper installation

and wiring of the burner. Please read carefully before attempting final installation.

- This manual is to remain with the final installation designation. It is the installer’s responsibility to ensure that the burner installation and operation instructions mentioned in this manual are followed and

operated within local code authority limits.

This burner is not equipped for 2 line operation.

For 2 line operation order: part # C7001025 for BF3, C7001026 for BF5.

RIELLO 40 BF

CODE MODEL TYPE

C8512352 800060000-Brn-PO Rie BF5 1.00GPH Vnt-D

C8512353 800061000-Brn-PO Rie BF5 1.20GPH Vnt-D

C8512354 800062000-Brn-PO Rie BF5 1.40GPH Vnt-D

C6501073(0)

GB

INSTALLLATION PRECAUTIONS

AIR FOR COMBUSTION

Do not install burner in room with insufficient air for combustion. Be sure there is an adequate air supply for

combustion if the boiler room is enclosed. It may be necessary to create a window to permit sufficient air to

enter the boiler room. The installer must follow local ordinances in this regard.

CANADA It is suggested that the installer follow CSA standard B139.

USA It is suggested that the installer follow NFPA manual #31.

CHIMNEY

Be sure chimney is sufficient to handle the exhaust gases. It is recommended that only the burner be connected to the chimney. Be sure that it is clean and clear of obstructions.

OIL FILTER

An external oil filter is REQUIRED, even though there is an internal strainer in the pump. The filter should be

replaced at least once a year, and the filter container should be thoroughly cleaned prior to installing a new

filter cartridge.

DRAFT

Follow the instructions furnished with the heating appliance. The pressure in the combustion area should be

kept as close to zero as possible. The burner will operate with a slight draft or pressure in the chamber.

ELECTRICAL CONNECTIONS

CANADA All electrical connections should be done in accordance with the C.E.C. Part 1, and all local codes.

The system should be grounded.

USA All electrical connections should be done in accordance with the National Electrical Code, and all

local ordinances. The system should be grounded.

CONTROL BURNER OPERATION

Check out the burner and explain its operation to the homeowner. Be sure to leave the Owner’s Instruction

sheet with the homeowner.

FIRE EXTINGUISHER

If required by local codes, install an approved fire extinguisher.

ELECTRICAL CONNECTIONS

In most localities, a number 14 wire should be used inside a metal conduit. The system should be grounded.

A service switch should be placed close to the burner on a fireproof wall in an easily accessible location.

3398

GB

TABLE OF CONTENTS

PACKAGE CONTENTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SERIAL NUMBER IDENTIFICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

TECHNICAL DATA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Burner and mounting flange dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Burner components identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

MOUNTING THE BURNER TO BOILER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ELECTRICAL CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

APPLICATION FIELD WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INSERTION / REMOVAL OF DRAWER ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ELECTRODE SETTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

NOZZLE PLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

TURBULATOR SETTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

OIL LINE CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Single line (Gravity feed system) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

NPTF - NPT pipe adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Two line (Lift system) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

PUMP PURGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Single line (Gravity feed system) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Two line (Lift system) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SETTING THE AIR ADJUSTMENT PLATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

COMBUSTION CHAMBER PRESSURE CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

BURNER SET UP CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

BURNER START-UP CYCLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

TROUBLE SHOOTING CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

A TYPICAL LAYOUT FOR BF BURNER INTAKE AIR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

EXPLODED SPARE PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

SPARE PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

BURNER START-UP LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3398

GB

PACKAGE CONTENTS LIST

Your Riello 40 BF burner should include the following parts. Please check to make sure all parts are present before beginning the installation.

Quantity Description Code

1 Burner with combustion head mounted

1 Mounting gasket C6880016

1 Parts bag C7001060 - C7001038

1 Installation manual C6501073

Parts bag C7001060 - C7001038

Quantity Description

1

1

2

3

SERIAL NUMBER IDENTIFICATION

NPT - NPTF pipe adapter

3/8” straight connector

Anti-shorts bushings

Wire nuts

The Riello 15 character serial number, example,

06 A 8511111 00025, is identified as follows:

06 = Last two digits of the year of manu-

facture;

A = BI-week of manufacture;

8511111 = Burner product code;

00025 = Increment of 1 for each burner pro-

duced – specific to product code –

reset to zero each January 1

st

.

(06) (A) (8511111) (00025)

Year of

manufacture

BI-week of

manufacture

Burner

product code

Increment

3398

1

GB

TECHNICAL DATA

SPECIFICATIONS

Fuel No. 2 Fuel Oil

BF3 Firing rate - Effective Output

BF5 Firing rate - Effective Output

Voltage (single phase) 120V 60Hz (+ 10% - 15%)

BF3 Absorbed electrical power

BF5 Absorbed electrical power

Motor (rated) 3250 rpm Run Current 2.2 AMP

Capacitor 12.5 Microfarads 260V

Pump pressure 100 to 200 PSI

Primary control RIELLO 530 SE/C

Ignition transformer 8kV 16mA

0.50 to 0.95 US GPH - 70,000 to 133,000 BTU/h

0.75 to 1.65 US GPH - 105,000 to 231,000 BTU/h

192 Watts

204 Watts

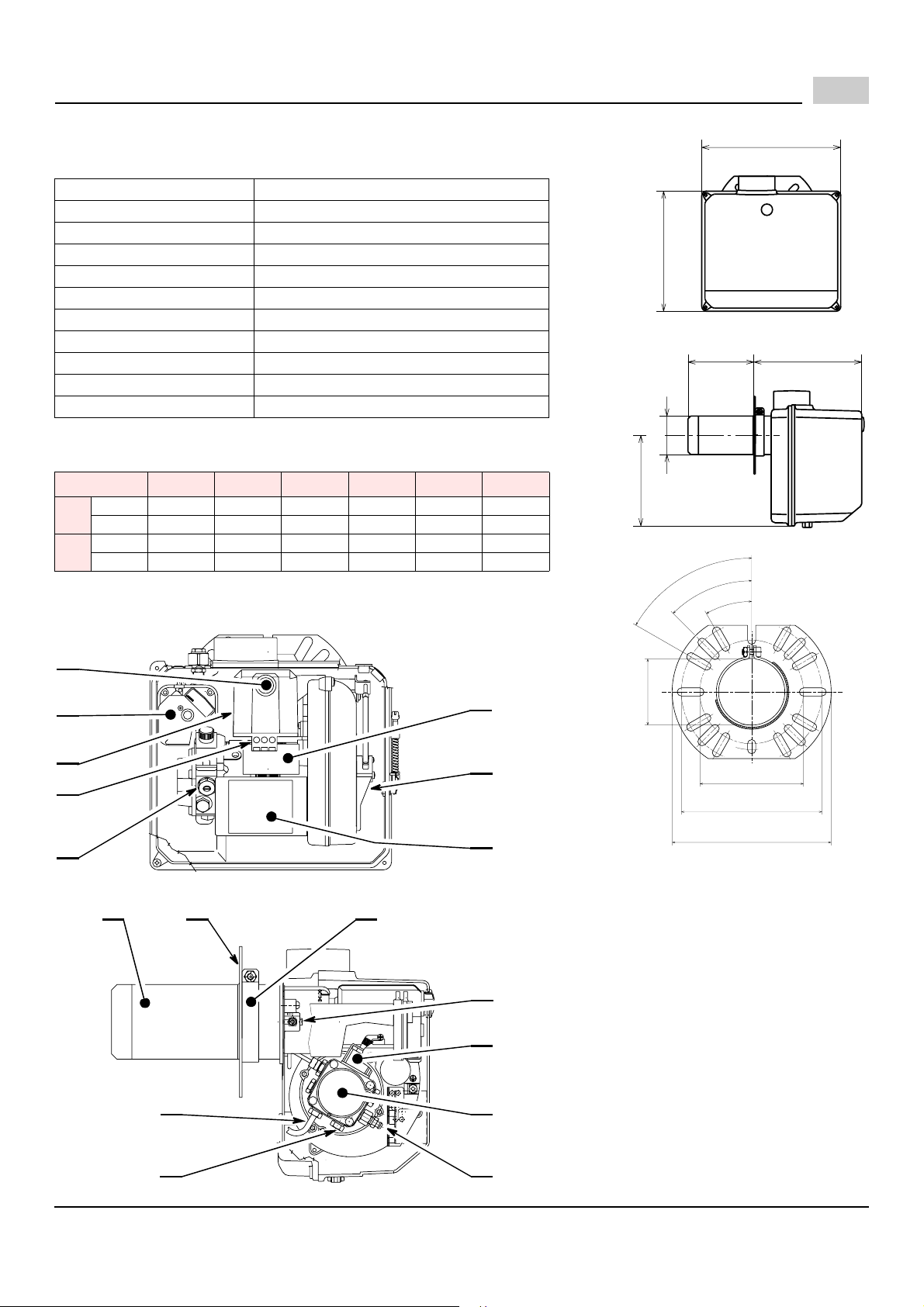

BURNER AND MOUNTING FLANGE DIMENSIONS

Model A B C D E F

Inches 9 13/16 11 1/4 7 1/2 3 1/2 4 5/8 8 21/32

BF3

mm 249 286 193 89 117 220

Inches 9 13/16 11 1/2 7 1/2 3 1/2 6 5/16 6 13/16

BF5

mm 249 292 193 89 160 173

BURNER COMPONENTS IDENTIFICATION

B

A

EF

D

C

D7515

°

0

6

°

5

4

°

0

3

1

17

2

3

4

D8174

8 9 10

03

15

7

6

5

11

12

16

1314

”

16

/

9

90 mm

3

5 9/16”-141 mm

7 9/16” - 192 mm

8 1/2” - 216 mm

D7516

BURNER COMPONENTS

1 Lockout indicator lamp and reset button

2 Primary control

3 Primary control sub-base

4 Pump pressure regulator

5 Post purge timer

6 Air adjustment

7 Capacitor

8 Combustion head

9 Mounting gasket

10 Universal mounting flange

11 Turbolator adjustment screw

12 Coil

13 Bleeder and pressure gauge port

14 Return fuel line port

15 Inlet fuel line port

16 Pump

17 Air pressure switch

3398

2

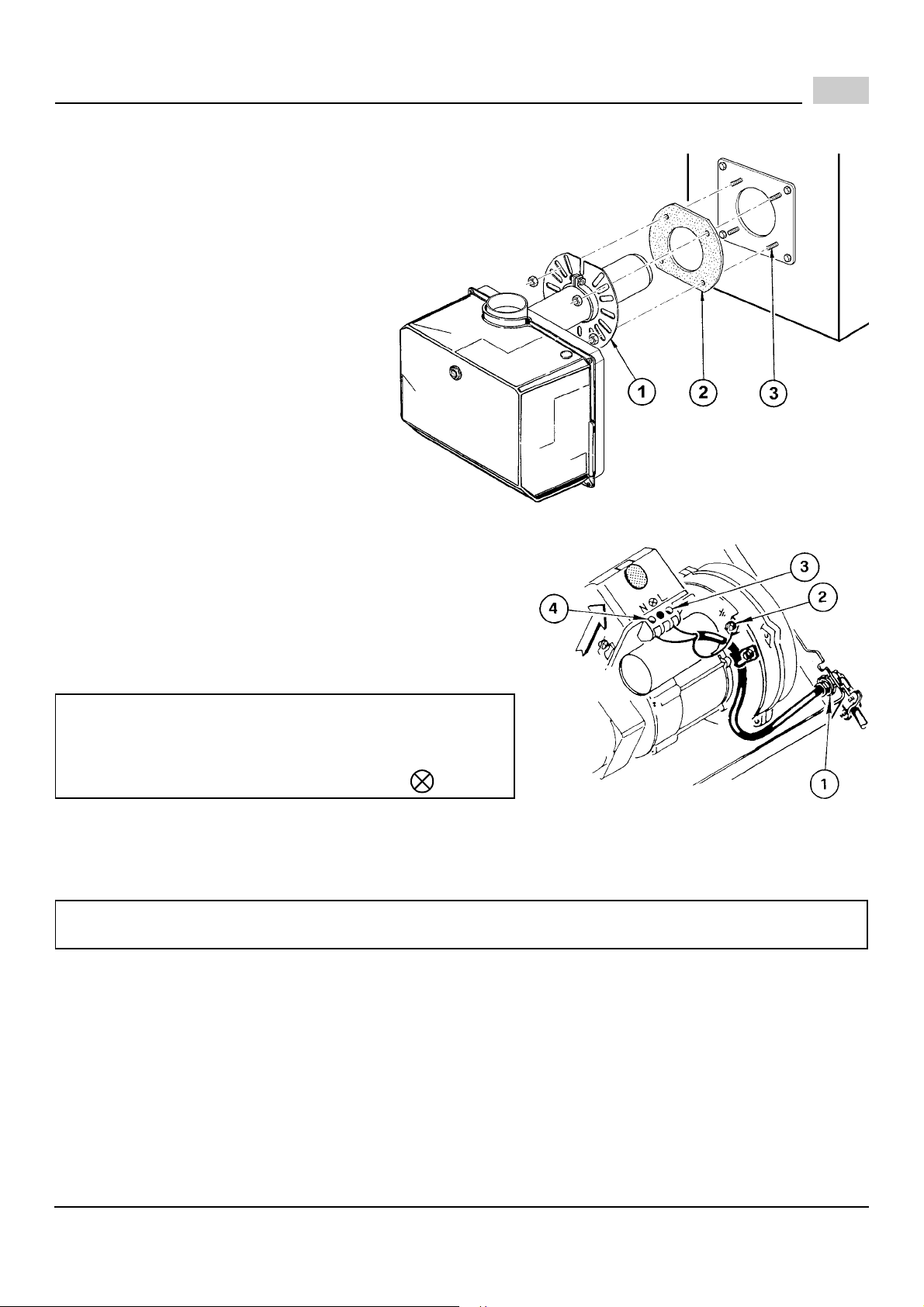

MOUNTING THE BURNER TO THE BOILER

- Position the MOUNTING GASKET (2) between the flat surface of the UNIVERSAL

MOUNTING FLANGE (1) installed on the

burner and the appliance.

- Line up the holes in the UNIVERSAL

MOUNTING FLANGE with the STUDS

(3) on the appliance mounting plate and

securely bolt the UNIVERSAL MOUNTING FLANGE to the plate.

GB

To remove the burner from the boiler, reverse the procedure.

ELECTRICAL CONNECTIONS

It is advisable to leave the control box off the sub-base while completing the electrical connection to the burner.

1) Wire access hole (Use BX electrical connector)

2) Earth ground conductor terminal (Green wire)

3) Hot conductor terminal (Black wire)

4) Neutral conductor terminal (White wire)

WARNING:

The hot (black) wire must be connected to the L terminal and the

neutral (white) wire must be connected to the N terminal or the

primary safety control will be damaged.

Do not connect wither wire to the terminal marked

.

E9328

D7954

Using the appropriate diagram below, make electrical connections to burner.

All wiring must be done in accordance with existing electrical codes, both national and local.

When all electrical connections have been made, the control box may be put back in place on the sub-base.

WARNING: DO NOT activate burner until proper oil line connections have been made, or failure of the

pump shaft seal may occur.

3398

3

Loading...

Loading...