Weil-McLain 800057000-Brn-PO Rie F5, 800059000-Brn-PO Rie F5, 800058000-Brn-PO Rie F5 User Manual

Installation & Operating Manual

Single stage operation oil burners

RETROFIT APPLICATIONS ONLY

If this burner is being installed in a packaged unit (ie. burner comes with a boiler or furnace), follow

the installation and set-up instructions supplied with the heating unit, as settings may differ from

those shown in this manual.

- The following pages contain information, descriptions and diagrams for the proper installation

and wiring of the burner. Please read carefully before attempting final installation.

- This manual is to remain with the final installation designation. It is the installer’s responsibility to ensure that the burner installation and operation instructions mentioned in this manual are followed and

operated within local code authority limits.

RIELLO 40

CODE MODEL TYPE

C8512519 800057000-Brn-PO Rie F5 1.00GPH Vnt-C

C8512520 800058000-Brn-PO Rie F5 1.20GPH Vnt-C

C8512521 800059000-Brn-PO Rie F5 1.40GPH Vnt-C

C6501071(0)

GB

INSTALLLATION PRECAUTIONS

AIR FOR COMBUSTION

Do not install burner in room with insufficient air for combustion. Be sure there is an adequate air supply for

combustion if the boiler/furnace room is enclosed. It may be necessary to create a window to permit sufficient air to enter the boiler/furnace room. The installer must follow local ordinances in this regard.

CANADA It is suggested that the installer follow CSA standard B139.

USA It is suggested that the installer follow NFPA manual #31.

CHIMNEY

Be sure chimney is sufficient to handle the exhaust gases. It is recommended that only the burner be connected to the chimney. Be sure that it is clean and clear of obstructions.

OIL FILTER

An external oil filter is REQUIRED, even though there is an internal strainer in the pump. The filter should be

replaced at least once a year, and the filter container should be thoroughly cleaned prior to installing a new

filter cartridge.

DRAFT

Follow the instructions furnished with the heating appliance. The pressure in the combustion area should be

kept as close to zero as possible. The burner will operate with a slight draft or pressure in the chamber.

ELECTRICAL CONNECTIONS

CANADA All electrical connections should be done in accordance with the C.E.C. Part 1, and all local codes.

The system should be grounded.

USA All electrical connections should be done in accordance with the National Electrical Code, and all

local ordinances. The system should be grounded.

CONTROL BURNER OPERATION

Check out the burner and explain its operation to the homeowner. Be sure to leave the Owner’s Instruction

sheet with the homeowner.

FIRE EXTINGUISHER

If required by local codes, install an approved fire extinguisher.

ELECTRICAL CONNECTIONS

In most localities, a number 14 wire should be used inside a metal conduit. The system should be grounded.

A service switch should be placed close to the burner on a fireproof wall in an easily accessible location.

3223

GB

TABLE OF CONTENTS

PACKAGE CONTENTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SERIAL NUMBER IDENTIFICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Mounting flange dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INITIAL SET-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

OIL BURNER COMPONENT IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Burner components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ASSEMBLY OF AIR TUBE TO BURNER CHASSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

MOUNTING BURNER TO BOILER OR FURNACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 5

Method 1-Universal Mounting Flange. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Method 2-Semi-flange Collar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Method 3-Pedestal Mount. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

AMULET INSTALLATION INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

INTERNAL FACTORY WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

APPLICATION FIELD WIRING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

NOZZLE PLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

INSERTION / REMOVAL OF DRAWER ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

ELECTRODE SETTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

TURBULATOR SETTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

OIL LINE CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 12

Single line (Gravity feed system) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Two line (Lift system) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

PUMP PURGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Single line (Gravity feed system) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Two line (Lift system) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

SETTING THE AIR ADJUSTMENT PLATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

BURNER ADJUSTMENT TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

BURNER START-UP CYCLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

EXPLODED SPARE PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

SPARE PARTS LIST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 - 16

3223

GB

PACKAGE CONTENTS LIST

Your Riello 40 burner should include the following parts. Please check to make sure all parts are present before beginning the installation.

Quantity Description Code

1 Burner with combustion head mounted C8512519 - C8512520 - C8512521

1 Mounting gasket C6880016

1 Par

1 Parts bag 25

1 Install

1

Parts bag 2569525 Parts bag 2569526

ts bag 2569525

69526

ation manual C6501071

Separate carton - OEM burners shipped with combustion head mounted

Quantity Description

1

1

1

1

1

1

By-pass plug

Female ¼” NPT adapter

Male 3/8” NPT adapter

2.5 mm Allen key

Oil pump connector (supply)

Oil pump connector (return)

Quantity Description

2

2

2

4

2

Semi-flange bolts (long)

Semi-flanges

Mounting flange bolts (short)

Nuts

Chrome nuts

SERIAL NUMBER IDENTIFICATION

Your Riello burner may have been manufactured in more than one location and therefore there are two possible serial

number identification.

The Riello 9 character serial number, example,

06 01 12345, is identified as follows:

06 = Last two digits of the year of manufacture;

01 = Week of manufacture;

12345 = Increment of 1 for each burner produced – specific

to product code – reset to zero each January 1

st

.

The Riello 15 character serial number, example,

06 A 8511111 00025, is identified as follows:

06 = Last two digits of the year of manu-

facture;

A = BI-week of manufacture;

Year of

manufacture

8511111 = Burner product code;

00025 = Increment of 1 for each burner pro-

duced – specific to product code –

st

reset to zero each January 1

.

Year of

manufacture

(06) (A) (8511111) (00025)

BI-week of

manufacture

(06) (01) (12345)

BI-week of

manufacture

BI-week of

manufacture

Increment

Increment

3223

1

GB

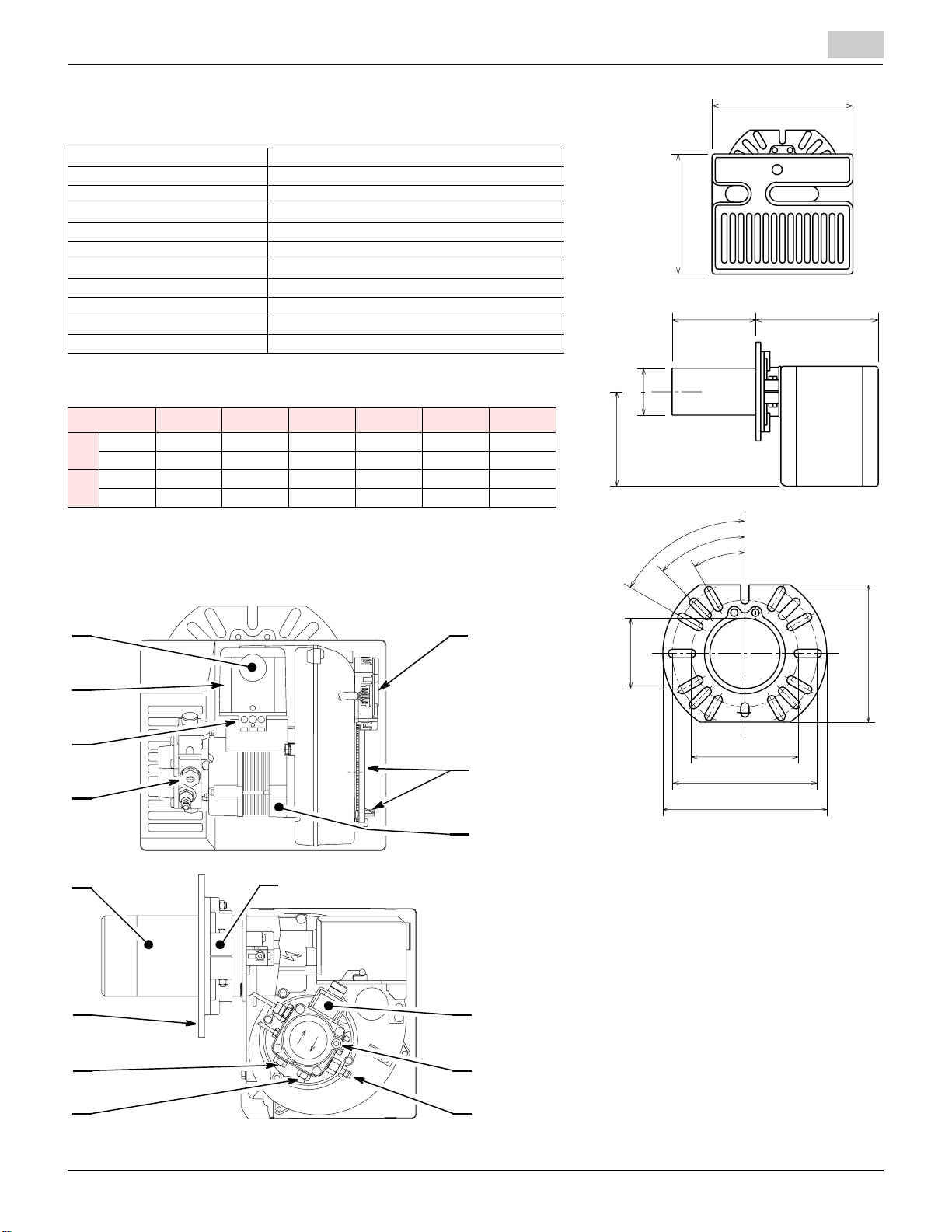

TECHNICAL DATA

SPECIFICATIONS

Fuel No heavier than # 2 fuel oil

F3 Firing rate - Effective Output 0.50 to 0.95 US GPH - 70,000 to 133,000 BTU/h

F5 Firing rate - Effective Output 0.75 to 1.65 US GPH - 105,000 to 231,000 BTU/h

Voltage (single phase) 120V 60Hz (+ 10% - 15%)

F3 Absorbed electrical power 155 Watts

F5 Absorbed electrical power 175 Watts

Motor (rated) 3250 rpm Run Current 2.2 AMP

Capacitor 12.5 Microfarads

Pump pressure 130 to 200 psig

Primary control RIELLO 530 SE/C

Ignition transformer 8kV 16mA

BURNER DIMENSIONS

Model A B C D E F

Inches 8 15/32 9 59/64 6 15/32 3 1/2 6 8 29/32

F3

mm 215 252 164 89 152 226

Inches 9 11/64 10 11/16 7 3/32 3 1/2 6 9 13/32

F5

mm 233 272 180 89 152 239

E1: 10-inch long (254mm) tubes are also available.

B

A

EF

E1

D

C

D7352

°

0

6

°

5

4

°

30

BURNER COMPONENTS IDENTIFICATION

1

2

3

4

8

10

11

9

D7304

7

6

5

12

13

1415

”

32

/

31

101 mm

3

5 1/2”-140mm

7 1/2” - 190 mm

8 15/32” - 215 mm

BURNER COMPONENTS

1 Lockout indicator lamp and reset button

2 Primary control

3 Primary control sub-base

4 Pump pressure regulator

5 Motor

6 Air adjustment and shutter

7 Electronic air shutter assembly

8 Combustion head

9 Semi flange 2 pieces

10 Mounting flange with gasket

11 Supply fuel line port

12 Pump valve (coil)

13 Vacuum gauge port

14 Pressure gauge and bleeder port

15 Return fuel line port

D7351

” - 180 mm

32

3/

7

3223

2

GB

INITIAL SET-UP

A) Remove burner and air tube from cartons. Check parts list (inside cover) to ensure all parts are present.

B) Remove burner cover by loosing the three screws securing it. Remove control box and air tube cover.

C) Remove drawer assembly from air tube, insert nozzle and set Turbulator adjustment for specific input required, then

set aside.

D) Mount air tube to burner chassis.

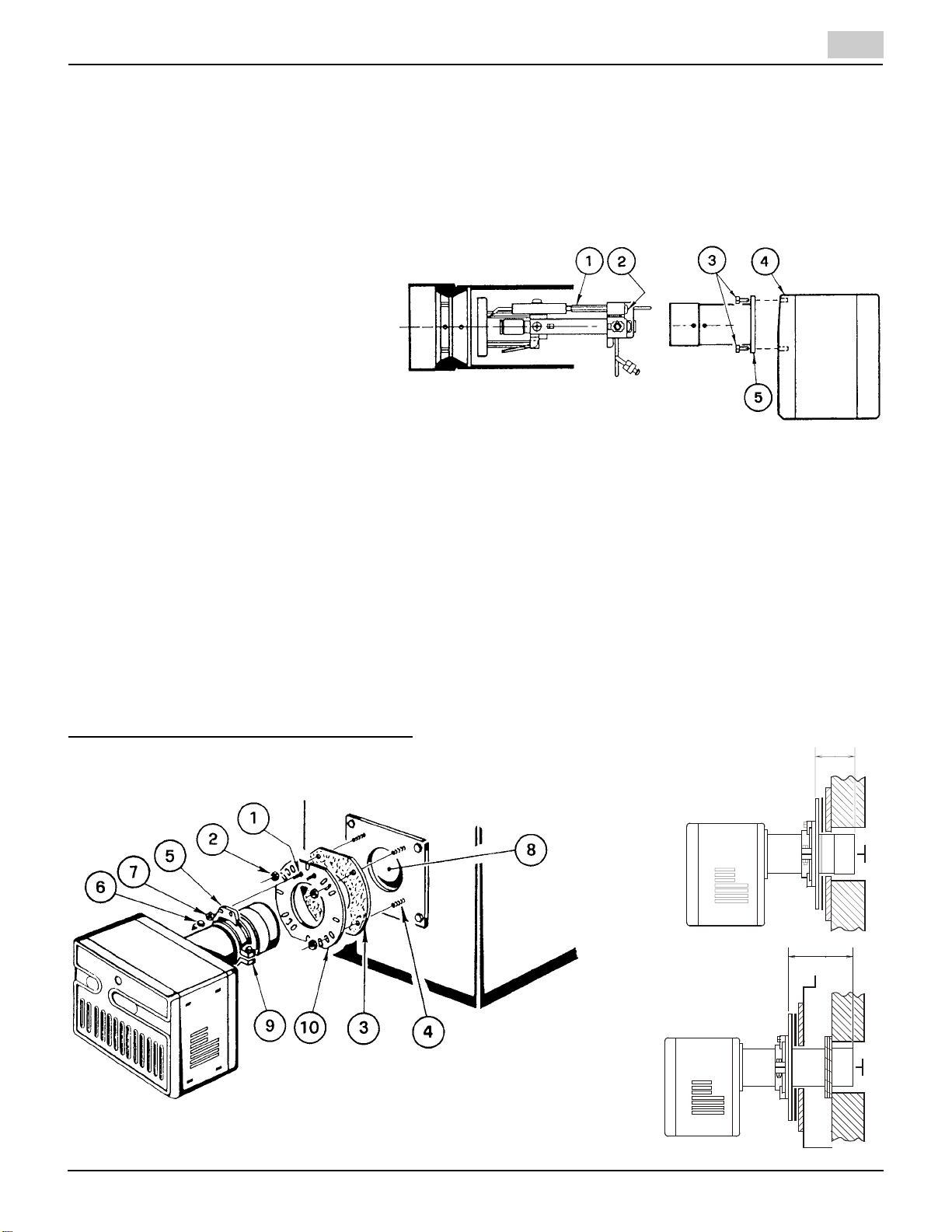

ASSEMBLY OF AIR TUBE TO

BURNER CHASSIS

The air tube and drawer assembly are

shipped in a carton separate from the burner

chassis. Choose the proper air tube length to

obtain the tube insertion for the specific installation.

A) Remove the AIR TUBE and BURNER

CHASSIS from their respective cartons.

B) Remove the DRAWER ASSEMBLY (1)

from inside the AIR TUBE by loosening

the screw (2). Carefully pull the DRAWER ASSEMBLY out of the AIR TUBE, install the required nozzle (see page 8)

and set aside.

C) Remove the two BOLTS (3) from FRONT PLATE (4) of the BURNER CHASSIS. Align the two holes on the AIR

TUBE HOLDING PATE (5) with the two holes on the BURNER CHASSIS FRONT PLATE with the BOLTS (3) removed. Replace the BOLTS and fingers tighten only. Re-install DRAWER ASSEMBLY into AIR TUBE. Tighten

SCREW (2) securely.

D) Tighten the two bolts (3) securely.

MOUNTING THE BURNER TO THE BOILER OR FURNACE

There are three possible methods to mount the burner, depending on the individual application. These are:

1) Universal flange bolted to Boiler/Furnace unit.

2) Semi-flange collar bolted to Boiler/Furnace unit.

3) Universal flange mounted to optional Pedestal mount, where flange mounting direct to appliance is not possible.

Pedestal kit must be ordered separately.

S7462

METHOD 1 – UNIVERSAL MOUNTING FLANGE

S7461

DRY BASE

A

BOILER

B

D6013

A

COMBUSTION

CHAMBER

B

D6014

3223

3

Loading...

Loading...