Weil-McLain 550-141-850-0599 User Manual

GOLDGOLD

GOLD

GOLDGOLD

Water boiler — Series 3

Boiler manual

GVGV

GV

GVGV

• Installation

• Start-Up

• Maintenance

Parts

This manual must only be used by a qualified heating installer/

service technician. Failure to comply could result in severe personal

injury, death or substantial property damage.

Part No. 550-141-850/0699

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

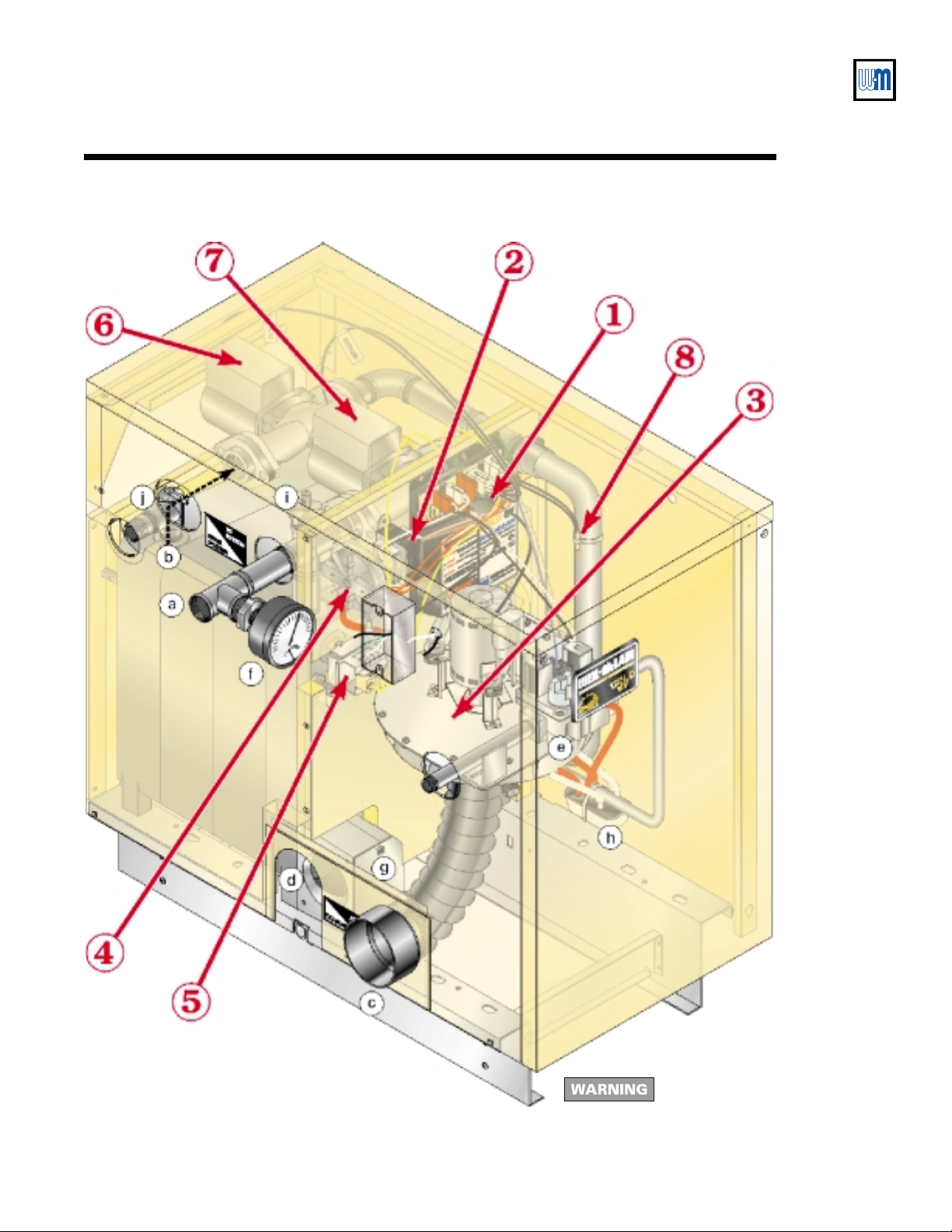

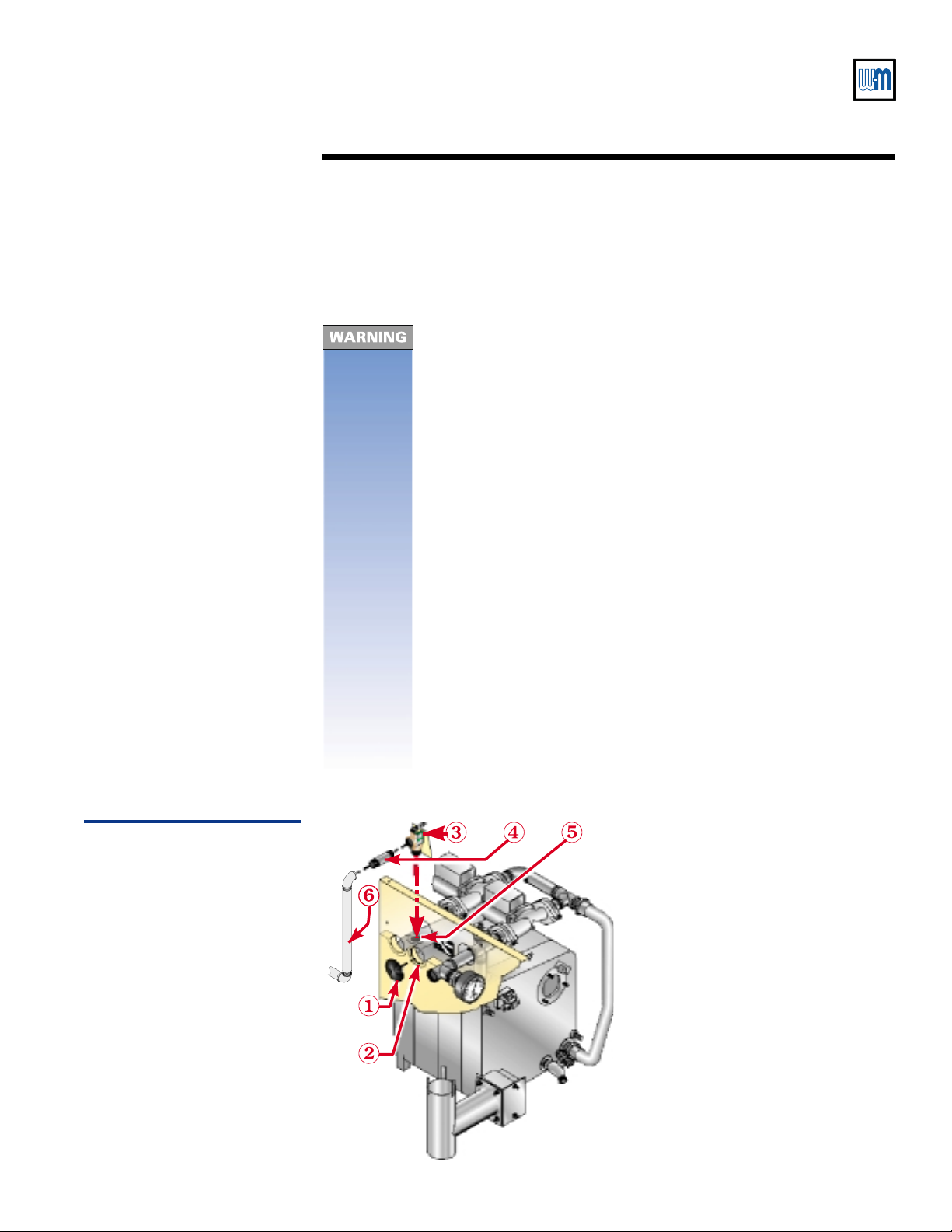

How it works . . .

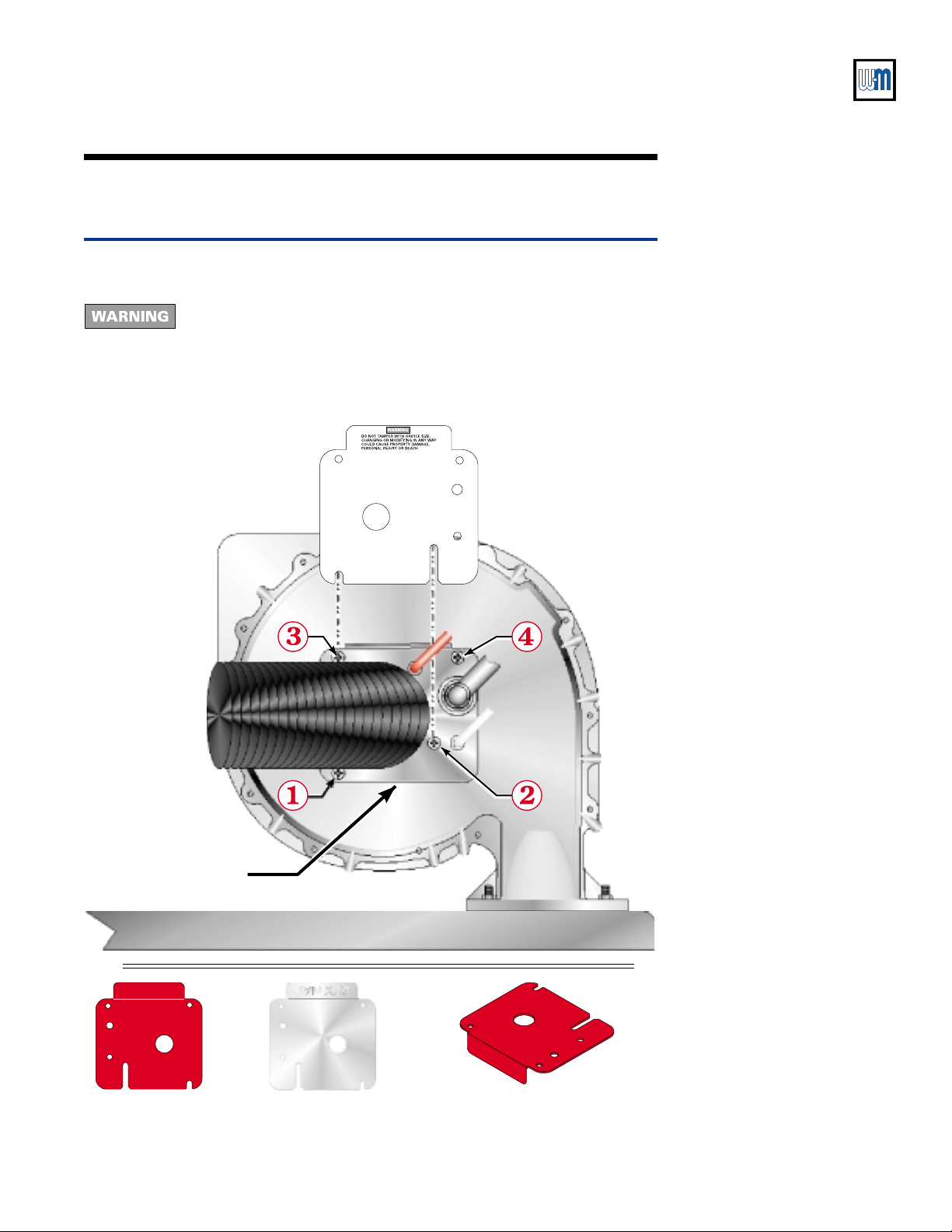

Control module

①

The GCM control module responds to signals from the room thermostat, air pressure switch, inlet

water sensor and boiler limit circuit to operate the circulators, gas valve, igniter and blower. When

a room thermostat calls for heat, the GCM starts the system circulator and blower.

The GCM runs the blower long enough to purge the boiler flue passages, then turns on the igniter

and lets it warm up.

After a 15-second warmup, the GCM opens the gas valve, turns the igniter off, and checks for

flame. The flame must come on within 4 seconds or the GCM will shut down and try the full cycle

again.

When the room thermostat is satisfied, the GCM turns off the boiler components and waits for the

next heat call.

The GCM indicator lights show normal sequence when the lights are on steady. When a problem

occurs, the GCM flashes combinations of lights which indicate the most likely reason for the

problem.

Transformer

②

The control transformer reduces line voltage to 24 volts for the gas valve and limit circuit.

Blower

③

The blower pulls in air and mixes it with gas from the gas valve. The blower forces this mixture into

the burner for combustion inside the boiler chamber.

Air pressure switch

④

The air pressure switch signals the control module, telling the control module whether air is

moving through the blower.

Water temperature limit switch

⑤

The water temperature limit switch turns off the gas valve if the temperature in the boiler goes

above its setting. (The circulators will continue to run as long as there is a call for heat.)

System circulator

⑥

The system circulator circulates water through the external (system) piping. The flow rate of the

circulator is controlled by the GCM, depending on the temperature of the water entering the boiler

sections.

Bypass circulator

⑦

The GCM operates the bypass circulator to mix hot water from the boiler outlet with colder return

water from the system as needed to prevent condensation of flue gases in the boiler.

When the water returning to the boiler is below 130 °F, the GCM regulates the bypass circulator

and system circulator flow rates to raise the return water temperature up to 130 °F before it enters

the boiler sections. By balancing these flow rates, the GCM can protect against condensation even

if return water is as low as 60 °F.

Water temperature sensor

⑧

The water temperature sensor monitors the temperature of the water entering the boiler sections.

The sensor sends this information to the GCM. The GCM determines how much to adjust the

circulator flow rates to provide at least 130 °F entering water.

Part number 550-141-850/06992

Ž Installation • Start-Up • Parts • Maintenance

GOLD GV Water boiler — Series 3

a

supply to system

b

return from system

c

combustio n a ir in le t fittin g

d

flue outlet

e

gas valve (see warning, right)

f

pressure/temperature gauge

g

flueway inspection port cover

h

sensor hose trap

i

manual air vent

j relief valve

85001

Thisboilerusesa

regulated

gasvalve,setforanoutlet

pressure approximately w.c..

set the outlet pressure higher than

NOT

negative-pressure-

–0.20" DO

factory setting.

3Part number 550-141-850/0699

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

Please read before proceeding

Hazard definitions

Installer

The following defined terms are used throughout this manual to bring

attention to the presence of hazards of various risk levels or to important

information concerning the life of the product.

Indicates presence of hazards that will cause severe

personal injury, death or substantial property damage.

Indicates presence of hazards that can cause severe

personal injury, death or substantial property damage.

Indicates presence of hazards that will or can cause

minor personal injury or property damage.

Indicates special instructions on installation, operation

or maintenance that are important but not related to

personal injury or property damage.

Read all instructions before installing. Follow all

instructions in proper order to prevent personal injury

or death.

• Also refer to GV Series 3 Venting supplements.

• Consider piping and installation when determining boiler location.

• Any claims for damage or shortage in shipment must be filed

immediately against the transportation company by the consignee.

User

• This manual is for use only by your qualified heating installer/

service technician

• Please refer to the User’s information manual for your reference.

• We recommend regular service by a qualifed service technician,

at least annually

.

.

Table of contents See pages 6 and 7 for Table of contents.

Part number 550-141-850/06994

• Installation • Start-Up • Parts • Maintenance

Please read before proceeding

Failure to adhere to the guidelines on this page can result in severe personal

injury, death or substantial property damage.

When servicing boiler —

• To avoid electric shock, disconnect electrical supply before

performing maintenance.

• To avoid severe burns, allow boiler to cool before performing

maintenance.

Boiler operation —

• Do not block flow of combustion or ventilation air to boiler.

• Should overheating occur or gas supply fail to shut off, do not

turn off or disconnect electrical supply to pump. Instead, shut off the

gas supply

• Do not use this boiler if any part has been under water.

Immediately call a qualified service technician to inspect the boiler and to

replace any part of the control system and any gas control, which has

been under water.

at a location external to the appliance.

Boiler water —

• DO NOT use petroleum-based cleaning or sealing compounds in

boiler system. Water seal deterioration will occur, causing leakage between

sections. This can result in substantial property damage.

• DO NOT use "homemade cures" or "boiler patent medicines".

Serious damage to boiler, personnel and/or property may result.

• Continual fresh makeup water will reduce boiler life. Mineral

build-up in sections reduces heat transfer, overheats cast iron, and causes

section failure. Addition of oxygen and other gases can cause internal

corrosion. Leaks in boiler or piping must be repaired at once to prevent

makeup water.

• Do not add cold water to hot boiler. Thermal shock can cause

sections to crack.

5Part number 550-141-850/0699

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

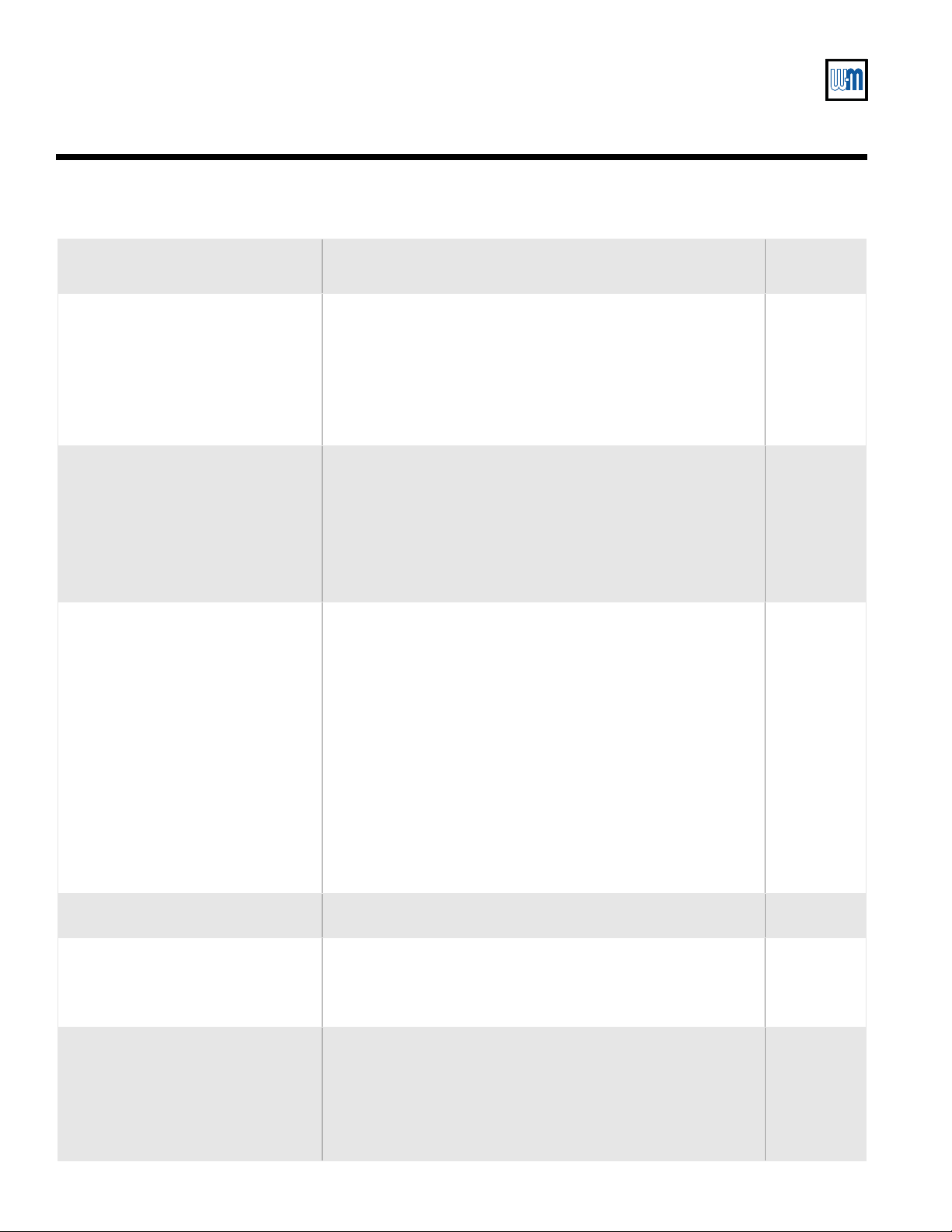

Contents

Contents Summary Pages

I. Prepare boiler location • Verify code compliance.

Check for high altitude requirements.

Provide required clearances and accessibility.

Plan vent and combustion air provisions.

Check existing common v ents to be sure the y will work when

old boiler is removed from system.

II. Prepare boiler Leave boiler on its skid until preparation complete.

Install vent starter tee.

Inspect/replace if necessary the gas/air orifice.

Install high altitude kit (over 5,500 feet).

Place boiler in position.

Hydrostatically test boiler.

III. Water piping Select system type from navigation table on page 26, cover-

ing baseboard systems, radiator systems, radiant heating

systems, heat pump systems, snow melt systems and water

chiller systems.

Review boiler connections pages 28 – 29, including instal-

lation of air separator and expansion tank.

Review general system information, page 30.

Obtain any system components needed but not on hand at

the job site.

Install relief valve and discharge piping.

Connect system piping.

Install low water cutoff and additional limit control, if

required.

8 – 15

16 – 25

26 – 36

IV. Venting and combustion air Refer to Vent supplements included with boiler 37

V. Gas piping Connecting gas supply, including need for pipe supports.

Natural gas boilers — gas line sizing (for 0.3" w.c. drop).

Propane boilers — refer to gas supplier.

VI. Field wiring Code compliances.

Wiring must be N.E.C. Class 1.

Thermostat connections.

Junction box installation.

Field wiring diagram.

Part number 550-141-850/06996

38 – 39

40 – 41

• Installation • Start-Up • Parts • Maintenance

Contents

Contents Summary Pages

VII.Start-up • Determine water treatment needs, if any.

Obtain correct antifreeze if freeze protection required.

Check for gas leaks (ha ve propane odorant verified by supplier).

Fill system and purge air.

Read Operating instructions, section IX, then start boiler.

Check all piping and verify leak-free.

Check gas valve outlet pressure (altitudes over 5,500 feet).

VIII.Check-out procedure Complete checklist and fill out certificate. 48 – 49

IX. Operation GCM (control module) indicator lights and sequence of opera-

tion.

Ladder wiring diagram (page 52).

Schematic wiring diagram (page 53).

Lighting instruction sheet — boiler with Robertshaw 7200DERN

gas valve (page 54).

Lighting instruction sheet — boiler with White-Rodgers 36E gas

valve (page 55).

X. Service and maintenance Service/maintenance schedule table (page 57).

Detailed instructions for annual start-up and service.

Special procedures for condensate drain line check v alve (page

63, if needed) and cleaning boiler heating surfaces (page 64).

42 – 47

50 – 55

56 – 65

XI.Troubleshooting Troubleshooting procedures (page 67).

Checking air pressure switch (page 68).

Servicing tips and precautions — Igniter, gas valve and blower

housing (page 69).

Servicing tips and precautions plus indicator lights and lockout

modes of GCM (control module) (page 70).

Common problems and solutions (pages 72 and 73).

Troubleshooting based on GCM indicator lights (pages 74 – 81).

XII. Replacement parts Accessory bag assembly shipped with boiler (page 83).

Section assembly parts (page 84).

Jacket assembly parts (page 86).

Blower assembly parts (page 88).

Trim assembly parts (page 90).

Interior panel parts (page 92).

XIII.Dimensions and ratings Dimensional drawing and boiler rating table. 94 – 95

66 – 81

82 – 93

7Part number 550-141-850/0699

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

Ia

Prepare boiler location — overview

Overview of this section

❏ Verify the boiler installation will meet all applicable codes.

❏ If the boiler installation is at high altitude (over 5,500 feet) make sure to

obtain and install the high altitude kit. Obtain the high altitude kit and

review the instructions included. Note the venting restrictions and input

reductions at altitudes over 5,500 feet.

❏ Check the boiler space to be sure minimum clearances and accessibility

are available.

❏ Obtain special venting materials and make sure vent will comply with

instructions.

❏ Direct vent installation (outside air piped to boiler) is optional in most

cases. But, if air contamination is likely, you will have to pipe air to the

boiler

. Note list of contaminants on page 13.

❏ If the GV boiler is replacing a boiler being removed from a combined vent

system

manual to verify vent performance.

that will still serve other appliances, follow the procedure in this

Part number 550-141-850/06998

• Installation • Start-Up • Parts • Maintenance

Prepare boiler location — codes & altitudeIb

Installations must

follow these codes:

High altitude

installations

• Local, state, provincial, and national codes, laws, regulations and ordinances.

• National Fuel Gas Code, ANSI Z223.1- latest edition.

• Standard for Controls and Safety Devices for Automatically Fired Boilers, ANSI/ASME CSD-1,

when required.

• National Electrical Code.

• For Canada only: CAN/CGA B149.1 or B149.2 Installation Code and C.S.A. C22.1 Canadian

Electrical Code Part 1 and any local codes.

The GV boiler gas manifold and controls met safe lighting and other performance criteria when

boiler underwent tests specified in ANSI Z21.13 — latest edition.

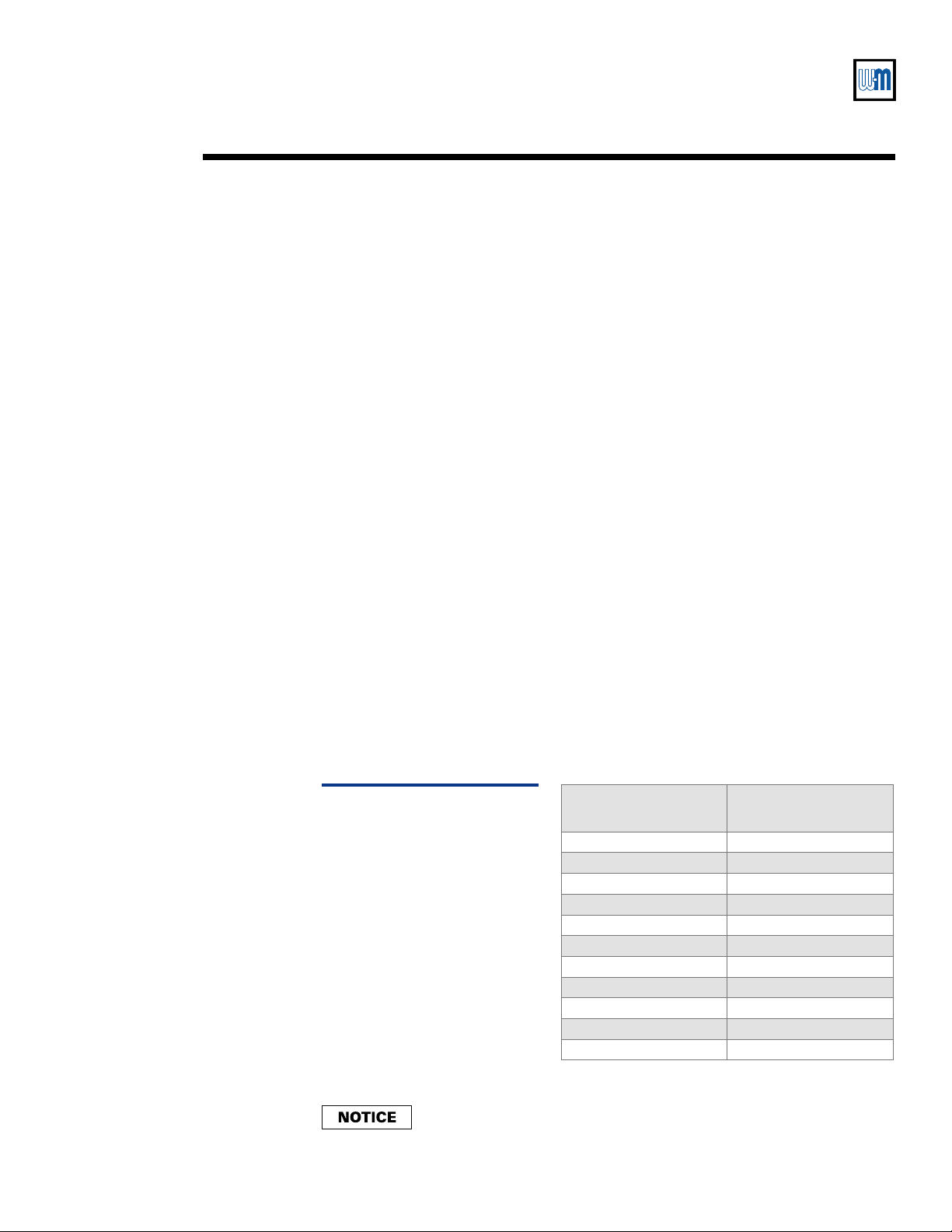

GV boiler controls automatically reduce input with increasing altitude. See Table 1 for estimated

input at altitude as a percentage of sea level input. Multiply the boiler sea level input by this

percentage to obtain the estimated high altitude input. Note that the length of the venting system

will also have a minor impact on input. Refer to the vent supplement for further information.

No modifications to the boiler should be necessary for installations up to 5,500 feet above sea

level. For higher elevations, the air pressure switch must be changed to a special high altitude

switch. Refer to the high altitude kit instructions, manual Section IId. Note that the gas valve

outlet pressure must be checked (and adjusted if necessary) in accordance with manual Section

VIIf.

Table 1

Estimated GV input at altitude

At altitudes above 5,500 feet, GV boilers can be sidewall vented only when

using direct vent (ducted combustion air). GV boilers can be vertically vented

in any of the configurations shown in the vent supplements. Refer to vent

supplements for more detail.

Altitude

(feet)

1,000 97

2,000 93

3,000 90

4,000 87

5,000 83

5,500 82

6,000 80

7,000 77

8,000 74

9,000 72

10,000 69

% Sea level input

9Part number 550-141-850/0699

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

Ic

Prepare boiler location — clearances

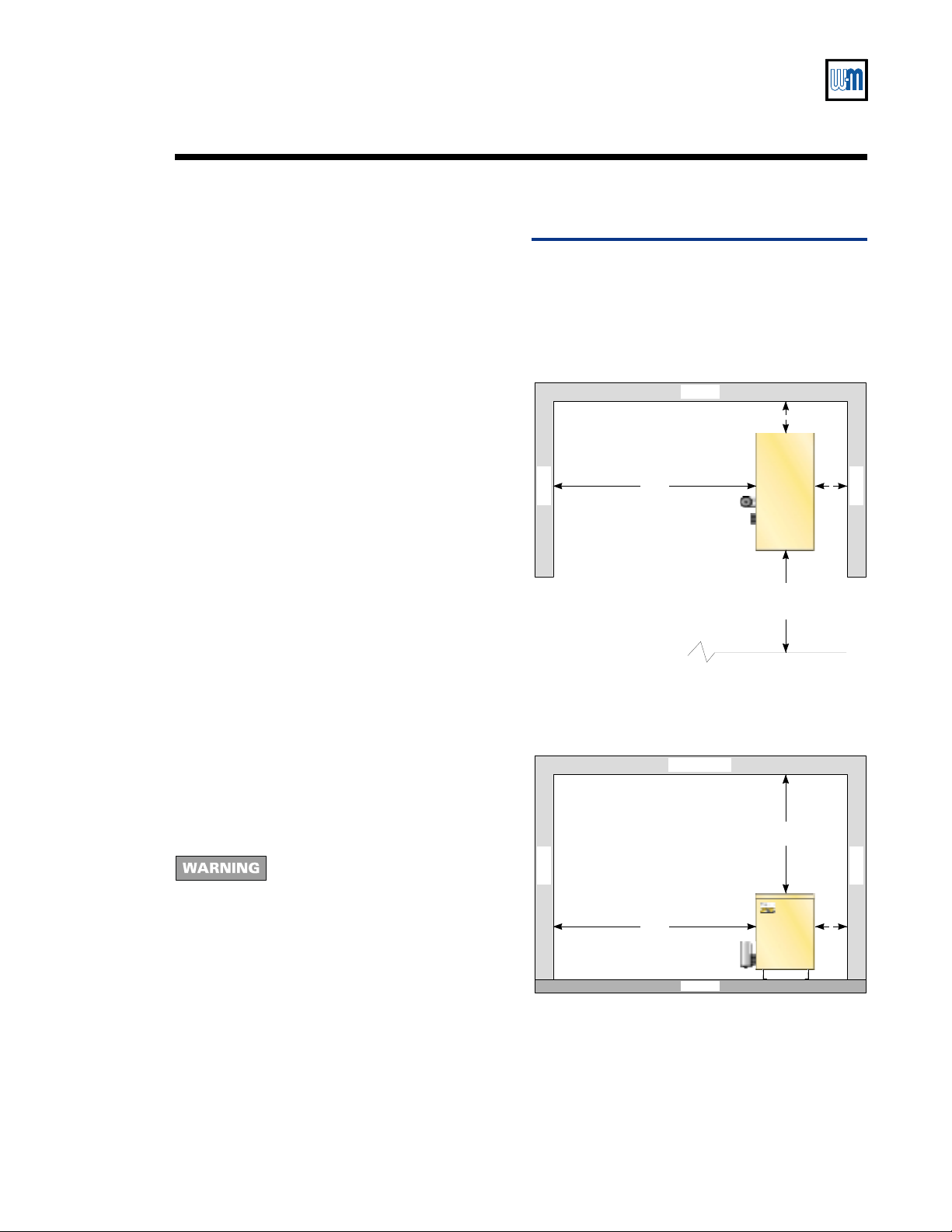

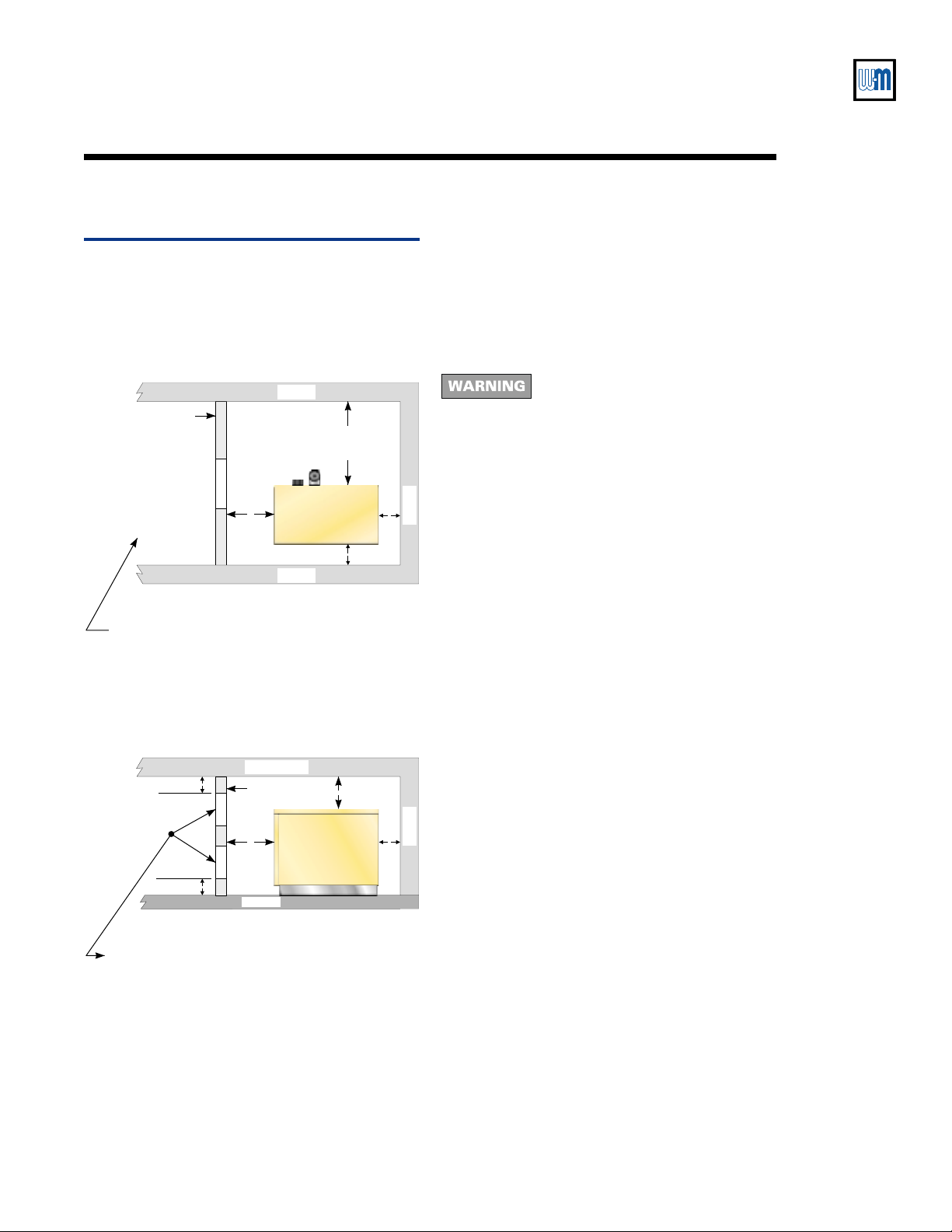

Clearance options:

Large space

The boiler space must be at least as big as shown in

Figure 1 to qualify as a

• Air openings to a large space can be per manual

Ie.

Section

• The space will probably be large enough for most

service and maintenance to be done in place.

Small space

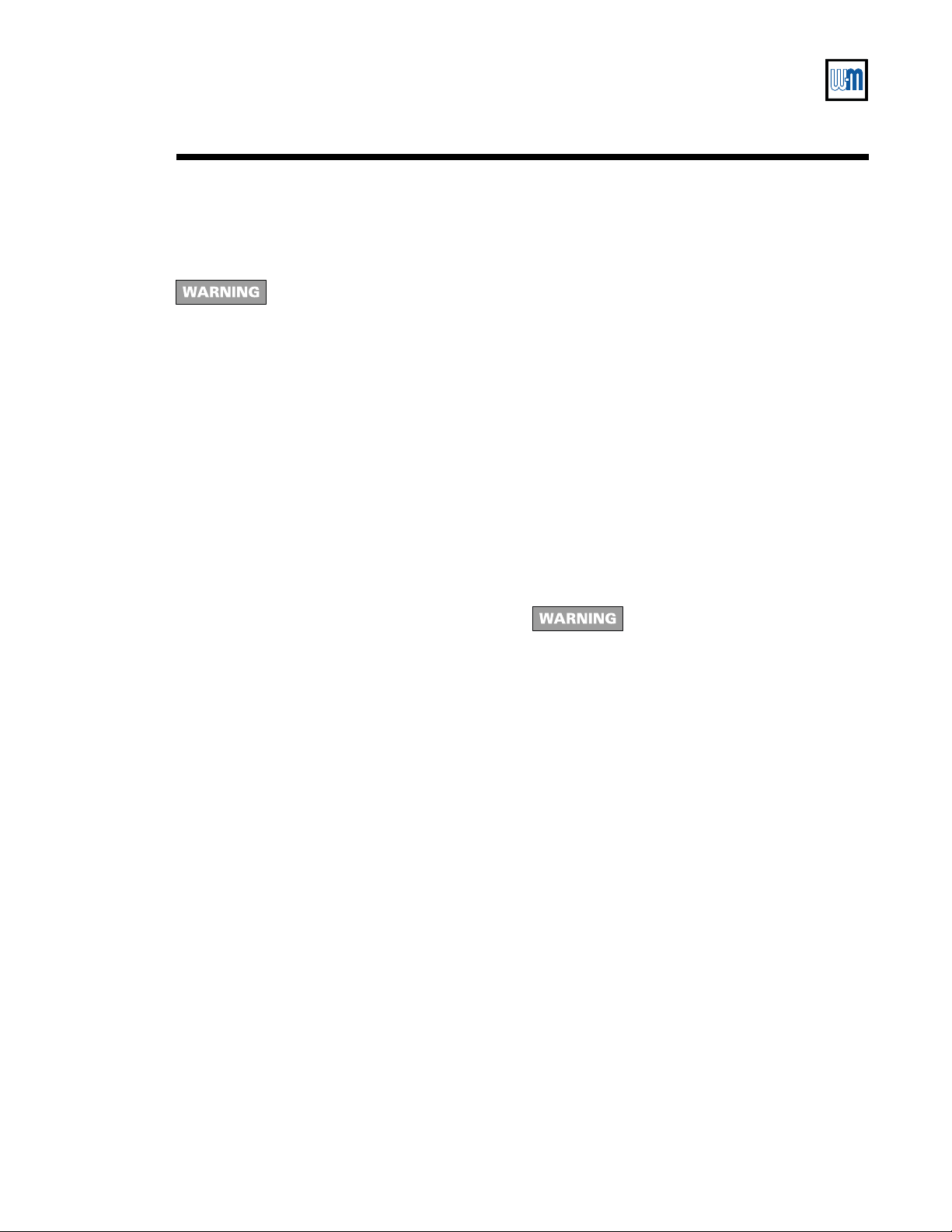

You can install the boiler in a space smaller than Figure 1,

but no smaller than shown in Figure 2 — this is called a

small space installation.

• Air openings to a small space must provide at least 1

square inch free area for every 1,000 Btuh of boiler

input (at least 75 sq. in. for GV-3, 105 sq. in. for GV-

4, 140 sq. in. for GV-5 or 175 sq. in. for GV-6). The air

opening free area must be at least this size even if the

boiler uses outside air.

• Air openings have to be within 6 inches of the floor

and 6 inches of the ceiling of the space to prevent

overheating of boiler internal components.

• Provide at least screwdriver clearance to jacket front

panel screws for removal of front panel for inspection

and minor service.

• The boiler cannot be serviced in place. Pipe the

boiler with unions and isolation valves so it can be

slid out of the space and serviced in an adjacent area.

The space has to be equipped with a door so boiler

can be accessed, unpiped and removed.

• No other appliance or air handler can be installed in

the same space or share its air supply.

large space.

Install the boiler so control system

components are protected from

dripping or spraying water or

rain

during operation. Allowing

these components to become wet

could cause a boiler failure, resulting

in severe personal injury, death or

substantial property damage.

Figure 1

Large space — minimum clearances between

boiler and walls or obstructions as below; see

Section Ie for minimum combustion/ventilation

air opening sizing.

TOP VIEW

Wal l

36"

Wal l

min

Wall or obstruction

FRONT VIEW

Ceiling

Wal l

36"

min

Floor

min

Boiler

front

36"

min

36"

min

Boiler

front

6"

6"

min

Wal l

85006a

Wal l

6"

min

Part number 550-141-850/069910

• Installation • Start-Up • Parts • Maintenance

Figure 2

Small space — installation with less clearance

than Figure 1 – BUT – no less than below; air

openings for combustion/ventilation must be

as shown below even for direct vent system.

TOP VIEW

Wal l

Access

DOOR

with fresh air

openings

4"

min

Wal l

Area adjacent to access door must be accessible

and must allow for removal of the GV boiler for service.

No other appliance or air mover (exhaust fan, etc.)

may be mounted in the same space.

10"

min

Boiler

top

Front

1" min

1"

min

Flooring and foundation

Flooring

The GV boiler is approved for installation on combustible

flooring, but must never be installed on carpeting.

Do not install boiler on carpeting even

if foundation is used. Fire can result,

causing severe personal injury, death

or substantial property damage.

Foundation

Provide a solid brick or minimum 2-inch thick concrete

Wal l

foundation pad if any of the following is true:

• floor can become flooded.

• the boiler mounting area is not level.

• high profile condensate pump is used.

(Foundation thickness will depend on height

of condensate pump inlet.) Refer to separate

Weil-McLain supplement for details.

The minimum foundation size is 16" wide by:

• 30¾" long for GV-3 or GV-4.

• 37¾" long for GV-5 or GV-6.

SIDE VIEW

Ceiling

6" max

6" max

(2) Fresh air openings —

Each with at least 1 sq. inch per 1,000 Btuh

of boiler input

Access door

4"

min

Floor

85006b

1"

min

Boiler

side

Front

1"

min

Residential garage installation

Precautions

Wal l

Take the following special precautions when installing

the boiler in a residential garage. If the boiler is located in

a residential garage, per ANSI Z223.1, paragraph 5.1.9:

• Mount the boiler a minimum of 18 inches

above the floor

of the garage to assure the

burner and ignition devices will be no less than

18 inches above the floor.

• Locate or protect the boiler so it cannot be

damaged by a moving vehicle.

11Part number 550-141-850/0699

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

Id

Prepare boiler location — vent system

Removing from existing vent

Failure to follow all instructions

following can result in flue gas

spillage and carbon monoxide

emissions, causing severe personal

injury or death.

When removing a boiler

from an existing common vent system:

At the time of removal of an existing boiler, the following

steps shall be followed with each appliance remaining

connected to the common venting system placed in

operation, while the other appliances remaining connected

to the common venting system are not in operation.

a. Seal any unused openings in the common

venting system.

b. Visually inspect the venting system for proper

size and horizontal pitch and determine there is no

blockage or restriction, leakage, corrosion and other

deficiencies which could cause an unsafe condition.

c. Test vent system — Insofar as is practical, close

all building doors and windows and all doors between

the space in which the appliances remaining

connected to the common venting system are located

and other spaces of the building. Turn on clothes

dryers and any appliance not connected to the

common venting system. Turn on any exhaust fans,

such as range hoods and bathroom exhausts, so they

will operate at maximum speed. Do not operate a

summer exhaust fan. Close fireplace dampers.

d. Place in operation the appliance being inspected.

Follow the lighting instructions. Adjust thermostat

so appliance will operate continuously.

e. Test for spillage at draft hood relief opening after

5 minutes of main burner operation. Use the flame

of a match or candle, or smoke from a cigarette,

cigar, or pipe.

f. After it has been determined that each appliance

remaining connected to the common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, fireplace dampers, and

any other gas-burning appliance to their previous

conditions of use.

Any improper operation of common venting system

should be corrected so the installation conforms with

the National Fuel Gas Code, ANSI Z223.1 — latest edition.

Correct by resizing to approach the minimum size as

determined using the appropriate tables in Part 11 of

that code. Canadian installations must comply with CAN/

CGA B149.1 or B149.2 Installation Code.

GV special vent system

Vent system

The GV boiler requires a special vent system, designed

for pressurized venting with likelihood of condensation

in the vent. This is referred to as ANSI Z21 Class IV,

Condensing

You may use any of the vent systems covered by the GV

venting supplements included in the instruction manual

envelope. The GV vent starter tee is a special item designed

only for the GV boiler, available from each vendor. Do

not attempt to connect the vent to the GV boiler with any

other means.

Vent termination and

combustion air supply

The GV boiler may be vented through the roof or through

a side wall. Follow the appropriate vent supplement for

the vent system chosen. The maximum vent length

depends on boiler size. Refer to the vent supplement to

verify vent length will be acceptable.

Combustion air for the GV boiler may be from inside or

ducted directly to the boiler from outside. For outside air

(direct vent installation), two options are available for

the flue/air termination. The air supply must ALWAYS

terminate at the same location as the flue, using either:

1. Vertical direct vent installation. Obtain the Through-

roof or through-unused chimney kit and

supplement. Find additional information in the vent

supplement for the venting material chosen.

2. Sidewall vent/air termination. This requires the Weil-

McLain GV vent/air intake termination kit. Refer

to the instructions packed with the kit and the vent

supplement for the venting material chosen.

Installations above 5,500 feet altitude must be

direct vent if sidewall vented.

.

DO NOT mix components from

different systems. The vent system

could fail, causing leakage of flue

products into the living space, causing

severe personal injury or death.

Part number 550-141-850/069912

• Installation • Start-Up • Parts • Maintenance

Ie

Prepare boiler location — contamination

Air contamination

Please review the following information on potential

combustion air contamination problems.

If the boiler is installed in any area likely to cause contamination, or if products which

would contaminate the air cannot be removed, you must pipe combustion air to the boiler

air intake. Contaminated combustion air will damage the boiler, resulting in possible severe

personal injury, death or substantial property damage. Do not install GV boiler in a

room or pool facility, for example

contain contaminants.

Table 2 Corrosive contaminants

Products to avoid Areas likely to have contaminants

Spray cans containing chloro/fluorocarbons Dry cleaning/laundry areas and establishments

Permanent wave solutions Swimming pools

Refer to Table 2 for products and areas which may cause

contaminated combustion air.

, without using ducted outside air. These areas will always

laundry

Chlorinated waxes/cleaners Metal fabrication plants

Chlorine-based swimming pool chemicals Beauty shops

Calcium chloride used for thawing Refrigeration repair shops

Sodium chloride used for water softening Photo processing plants

Refrigerant leaks Auto body shops

Paint or varnish removers Plastic manufacturing plants

Hydrochloric acid/muriatic acid Furniture refinishing areas and establishments

Cements and glues New building construction

Antistatic fabric softeners used in clothes dryers Remodeling areas

Chlorine-type bleaches, detergents, and cleaning

solvents found in household laundry rooms

Garages with workshops

Adhesives used to fasten building products and

other similar products

13Part number 550-141-850/0699

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

If

Prepare boiler location — air openings

GV combustion air options

Using inside air — non-direct vent

The GV boiler can use inside air if no contaminants are

present in the boiler space.

Using outside air — direct vent

Combustion air can be ducted directly from outside to

the GV boiler air intake fitting. The installation is defined

as direct vent (also referred to as sealed combustion).

Sizing air openings

Air openings to the GV boiler space are always required,

regardless whether combustion air is taken from inside or

outside. These air openings provide for ventilation (as

well as combustion air) to prevent overheating of the

boiler controls and boiler space. Air is also needed for

other appliances located in the same space.

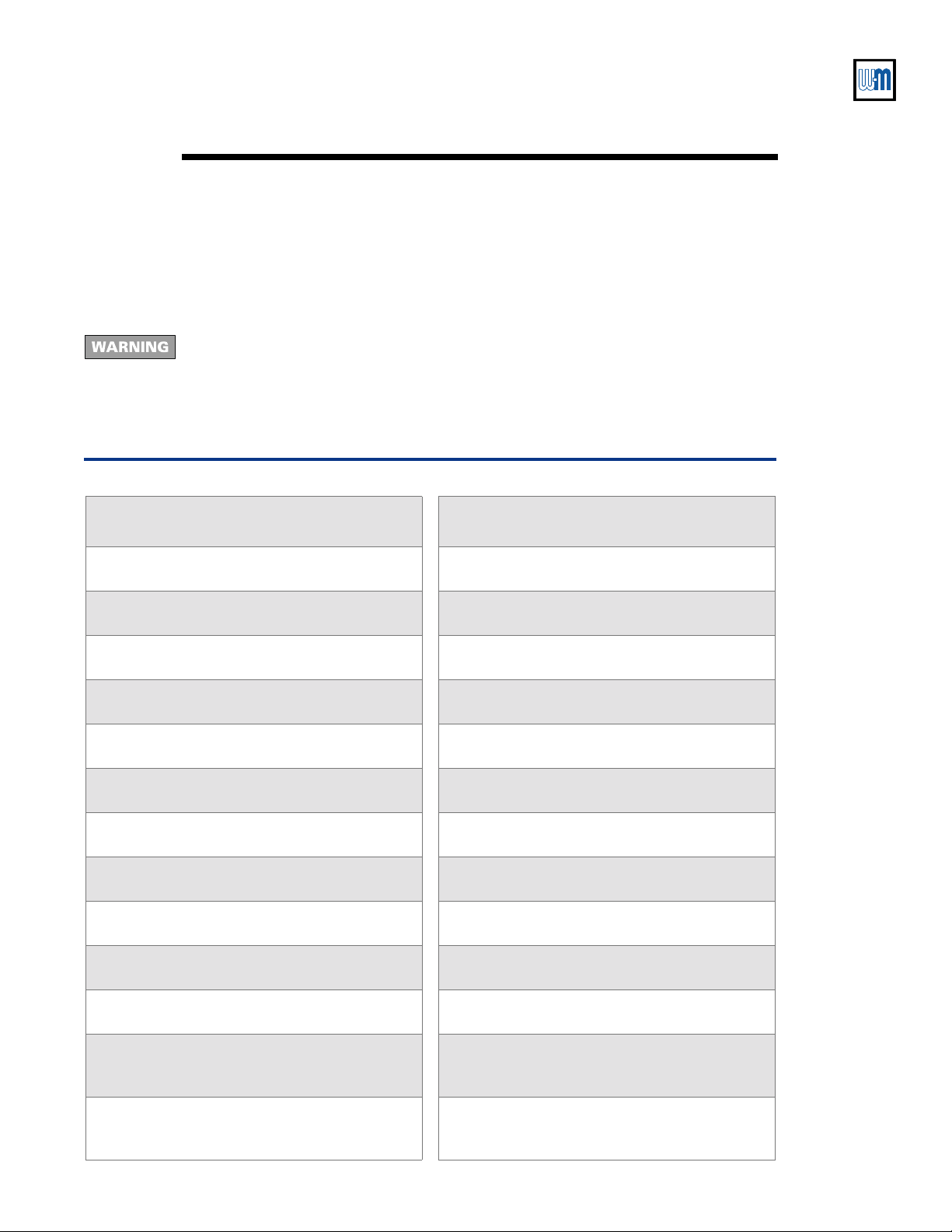

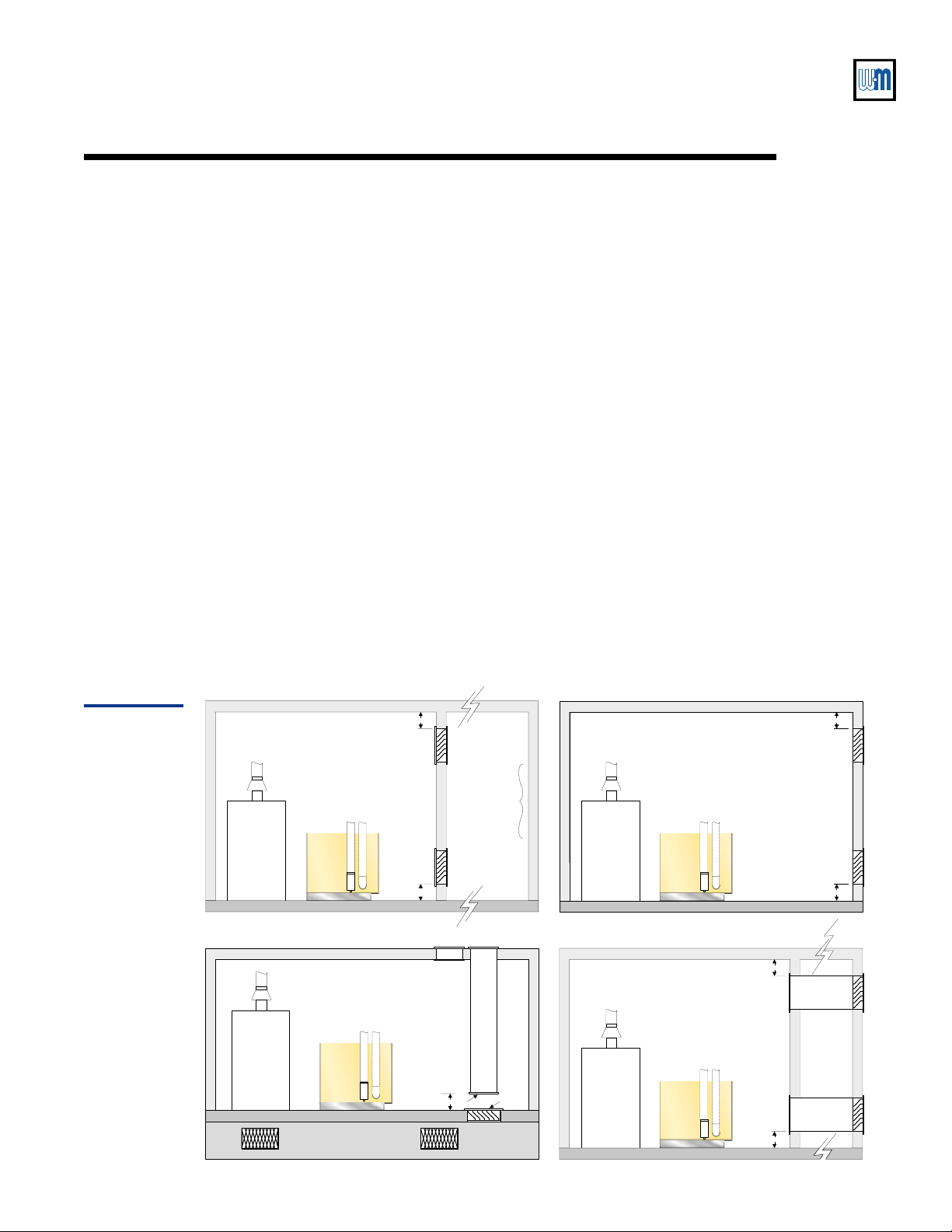

Use Figure 3, cases a through d, depending on how the

air is supplied and whether the space contains only the

GV or other appliances as well. The air opening sizing of

Figure 3 is based on ANSI Z223.1, National Fuel Gas

Code, intended for natural draft appliances. The GV boiler

is not natural draft, so its requirements differ.

Single air opening option

A single air opening within 12 inches of the ceiling may be

used where the GV boiler is installed in a large space

(clearances per Figure 1) with other appliances.

The other appliances must all be installed with at least 1

inch clearance from the sides and back, and 6 inches from

the front. The GV boiler must have minimum clearances

as shown in Figure 1.

The single air opening may be connected from outside to

the appliance space by any of the methods of Figure 3.

The free area of the opening must also be at least equal to

the combined area of all appliance vent connectors OR

sized per the following, whichever result is larger:

GV direct vent — large shared space —

single air opening

Size the single air opening for 1 square inch of free opening

for each 3,000 Btuh of all appliances other than the GV.

No additional air opening is needed for the GV.

GV inside air — large shared space —

single air opening

Size the air opening for 1 square inch of free opening for

each 3,000 Btuh of all appliances, including the GV.

Air openings must be sized to handle

all appliances and air movers

(exhaust fans, etc.) using the air

supply.

Louver allowance

The free area of openings means the area after reduction

for any installed louvers or grilles. Be sure to consider

this reduction when sizing the air openings.

GV with other appliances

If the GV boiler is installed in a large space (clearances per

Figure 1) providing air for a water heater or other gas

appliance, size the air openings as follows:

GV direct vent — large shared space

Provide two openings per Figure 3, based only on the size

of the other appliances and air movers. No additional air

opening area is required for the GV boiler.

GV inside air — large shared space

If the GV combustion air comes from the inside space,

size two air openings for the total of all appliances and air

movers, including the GV boiler. Use the formula from

the appropriate case in Figure 3.

GV without other appliances

If the GV boiler is installed in a space by itself, with no

other appliance or air mover using air from the space,

and with clearances around the boiler no less than those

shown in Figure 1 for large space installations:

GV direct vent — large space — alone

Air is needed only for ventilation. Size the air openings

for any of the cases of Figure 3 for a free area of at least:

1 square inch per 8,000 Btuh of GV input

for each of the two openings. (If a single opening within

12 inches of the ceiling is used, size the opening for 1

square inch of free area for each 3,000 Btuh of GV input.)

GV inside air — large space — alone

Size the air openings for any of the cases of Figure 3 for a

free area of at least:

1 square inch per 4,000 Btuh of GV input

for each of the two openings. (If a single opening within

12 inches of the ceiling is used, size the opening for 1

square inch of free area for each 3,000 Btuh of GV input.)

Part number 550-141-850/069914

• Installation • Start-Up • Parts • Maintenance

Air

Air

Air

Air

opening

Add air openings

to outside if

building is tight

construction.

Air

opening

Air

opening

Air

opening

Air (direct vent)

(optional)

Air (direct vent)

(optional)

Air (direct vent)

(optional)

0 to 12"

0 to 12"

12"

0 to 12"

0 to 12"

Flue

Flue

Flue

Other

appliances

Other

appliances

Other

appliances

Other

appliances

GV

GV

Air

Air (direct vent)

(optional)

Flue

GV

GV

Outside

Outside or ventilated attic

Air

opening

Air

opening

0 to 12"

0 to 12"

Outside

Ventilated

crawl space

— or —

a

d

b

c

Each opening free area =

1 sq. inch per 4,000 Btuh

Each opening free area =

1 sq. inch per 2,000 Btuh

Each opening free area =

1 sq. inch per 1,000 Btuh

Each opening free area =

1 sq. inch per 4,000 Btuh

85005

GV in small space (less than Fig. 1) — alone

For all vent/air situations, whether air is taken from inside or outside, provide

two openings, each with minimum free area of:

1 square inch per 1,000 Btuh of GV input.

The openings must be within 6 inches of the ceiling and 6 inches of the floor

as shown in Figure 2 for small space installations.

Special considerations

Tight construction

ANSI Z223.1 defines unusually tight construction where:

a. Walls and ceilings exposed to the outside atmosphere have a continuous

water vapor retarder with a rating of 1 perm or less with openings gasketed,

and . . .

b. Weatherstripping has been added on openable windows and doors, and

. . .

c. Caulking or sealants are applied to areas such as joints around windows

and door frames, between sole plates and floors, between wall-ceiling

joints, between wall panels, at penetrations for plumbing, electrical, and

gas lines, and in other openings.

For buildings with such construction, provide air openings into the building

from outside, sized per the appropriate case in Figure 3 if appliances are to

use inside air for combustion and ventilation.

Exhaust fans and air movers

The appliance space must never be under a negative

pressure, even if the appliance(s) are installed as direct

vent. Always provide air openings sized not only to the

dimensions required for the firing rate of all appliances,

but also to handle the air movement rate of the exhaust

fans or air movers using air from the building or space.

Motorized air dampers

If the air openings are fitted with motorized dampers,

electrically interlock the damper to:

• Prevent the boiler from firing if the damper is not

fully open.

• Shut the boiler down should the damper close during

boiler operation.

To accomplish this interlock, wire an isolated contact

(proving the damper open) in series with the thermostat

input to the boiler. The boiler will not start if this contact

is open, and will shut down should it open during

operation.

Figure 3

Air openings:

GV in space

with other

appliances

a —

Air from inside

building

b —

Air directly

from outside

c —

Air through

vertical ducts

(or inlet air

from ventilated

crawl space)

d —

Air through

horizontal

ducts

15Part number 550-141-850/0699

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

IIa

Overview of this

section

Prepare boiler — vent starter tee & drainIIb

Prepare boiler — overview

❏ Leave the boiler on its skid until installation site is ready and boiler prep is

complete per this section.

❏ Install vent starter tee and condensate drain line.

❏ Inspect gas/air orifice plate to verify model size and gas markings agree

with boiler and application. Install propane gas/air orifice for propane

installations.

❏ Install high altitude kit for altitudes more than 5500 feet above sea level.

❏ Place boiler in position and install jacket rear panel.

❏ Plug openings and hydrostatically test boiler. Remove plugs.

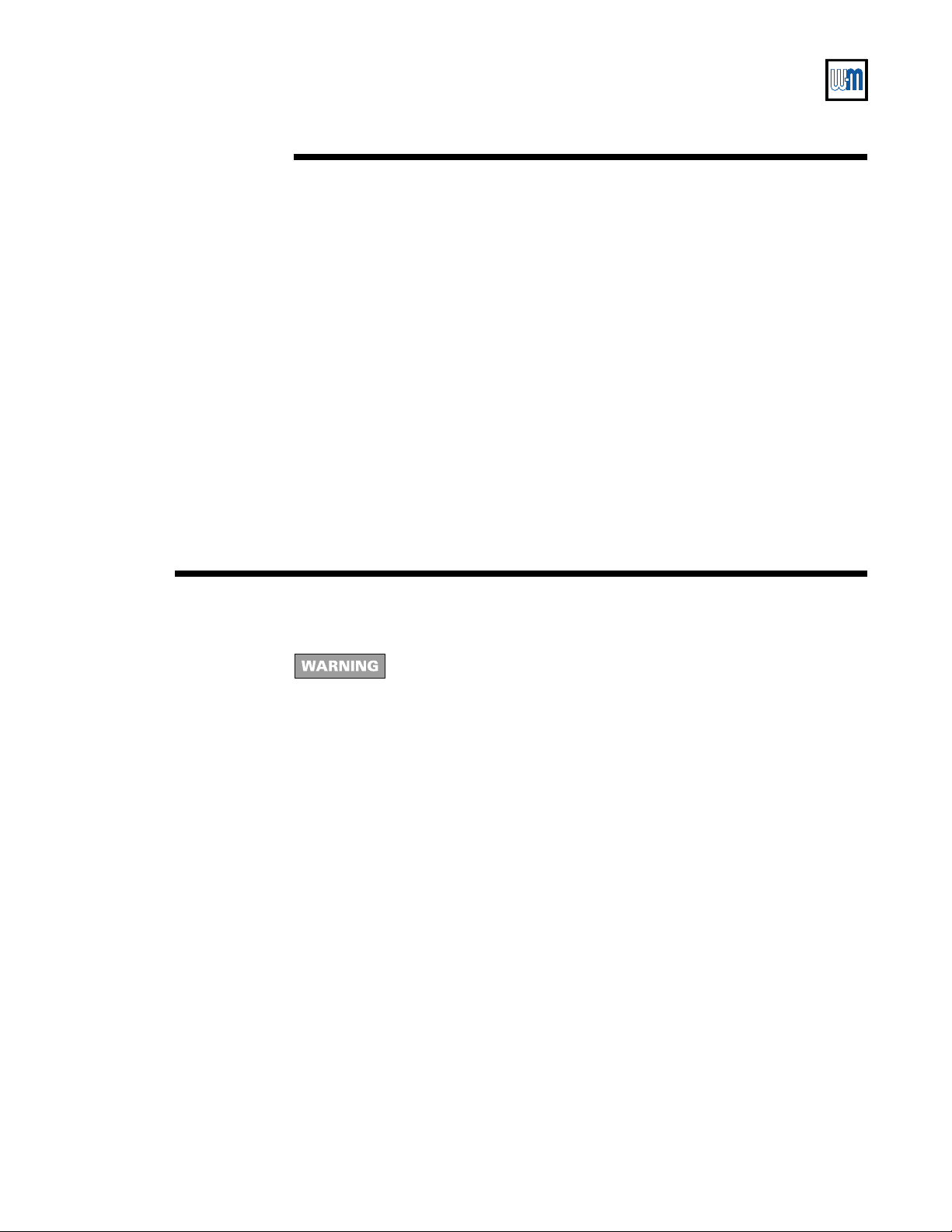

Install vent starter

tee and condensate

drain hose

Use only the vent starter tee of the same manufacturer as the

vent components

systems. The vent system could fail, causing flue gas spillage, resulting in

severe personal injury or death.

Install vent starter tee as shown in Figure 4.

1. Remove jacket access panel (item 1). You can rotate the plate out of the way, leaving the air

hose connected to the air intake fitting, or loosen the hose clamp (item 2) and pull the air hose

off of the fitting as shown in Figure 4.

2. Remove the hex nuts (item 5) from the vent starter tee studs at the boiler vent connection.

3. Remove the vent starter tee gasket (item 4) from the studs.

4. Clean the surface of the boiler flue connection to assure a good seal. Use emery cloth if

necessary to remove any accumulated rust.

5. Place the vent starter tee gasket (item 4) over the studs.

6. Slide the holes in the vent starter tee flange (item 3) over the studs.

7. Apply the (4) hex nuts (item 5), align the vent starter tee (item 3) and tighten the nuts

uniformly.

Install condensate trap hose as shown in Figure 4.

1. Loosen and slide a spring hose clamp (item 8) over each end of the condensate drain hose

(item 6).

2. Loosen the clamp and slide one end of the hose over the CPVC drain elbow (item 7). Slide

clamp into position and release.

3. Attach and clamp the other end of the hose to the drain connection on the bottom of the vent

starter tee (item 3).

to be used. Do not mix components from different

Replace jacket access panel (item 1), reconnecting the air hose to the air intake fitting if necessary.

Part number 550-141-850/069916

• Installation • Start-Up • Parts • Maintenance

IIb

Figure 4 Install vent starter tee and

Prepare boiler — vent starter tee & drain (cont.)

condensate drain hose before

placing boiler.

Screw hole

and notch, located

in base rail under

vent outlet

Base rail

Insert CPVC elbow

into bracket. Then

attach bracket to

base rail with screw

as shown at left.

10-32 x 3/8"

85002

Vent starter tee — not included

with boiler. See information

below.

The vent starter tee is NOT supplied with the boiler. Obtain this

part as a separate purchase from your Weil-McLain wholesaler.

The vent starter tee shown is for Saf-TVent®. Use only the vent tee

made for the vent system you are using. DO NOT mix different

brands of vent system components. The vent system could fail to

operate properly, causing leakage of flue products into the living

space, resulting in severe personal injury or death.

17Part number 550-141-850/0699

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

IIc

Check for correct

orifice plate and

replace if necessary

Prepare boiler — orifice plate

The correct orifice plate must be used. Failure to do so will result in severe

personal injury, death or substantial property damage.

Natural gas:

For natural gas installations, inspect the silver gas/air orifice plate marking. It must be

the same as the boiler size. If the orifice plate is stamped with another size, obtain the correct plate

from your wholesaler. The boiler size is stamped where the “X” is shown in the plate stamping,

Figure 5b.

Propane:Propane:

Propane:

Propane:Propane:

For propane installations, replace the silver gas/air orifice plate with the red/white

, per following instructions. Ensure the red/white plate boiler size is correct for the GV

plate

boiler being installed. The boiler size is stamped where the “X” is shown in the plate stamping,

Figure 5b.

Also fill out the propane label in the conversion kit and attach to the left side of the jacket, above

the gas inlet opening, as shown in Figure 5a.

Plate installation

Access the bottom of the blower housing as shown in Figure 5a.

To inspect the plate only, read the marking on the plate edge. It must read the same as the

boiler size and fuel.

Figure 5a

Check for correct orifice plate

and replace if necessary.

Leave boiler on its back, on

the skid, until inspection/

replacement is completed.

To replace the plate, using a manual screwdriver or nut driver, see Figure 5b:

1. Loosen screws 1 and 2 two full turns.

2. Remove screws 3 and 4.

3. Pull the gas/air orifice plate forward to remove it.

4. Slide in the new plate as shown in Figure 5b. The red side of a propane plate must go

next to the blower housing

5. Replace screws 3 and 4. Tighten all four screws securely and uniformly. DO NOT overtighten.

DO NOT exceed 40 inch-pounds torque.

6. Bend down plate label tab at score mark as shown in lower right corner of Figure 5b.

as shown.

Remove jacket front panel to access the bottom

side of theblowerhousing.

Complete the propane conversion label included

with the conversion kit. Install label on jacket left

side, as shown.

85004a

Leave the boiler on its back, on the skid as

shown, until you have checked the gas/air orifice

plate and replaceitif necessary.

Part number 550-141-850/069918

• Installation • Start-Up • Parts • Maintenance

Bottom side of boiler front section

Figure 5b Checking and replacing gas/air orifice plate. For propane

installations, replace silver plate with red/white propane plate.

DO NOT use electric or

pneumatic screwdrivers

remove or tighten the gas/air boss

screws. Hand-tighten only, using

manual screwdriver. Should the

torque exceed 40 inch-pounds, the

threaded holes could strip out, causing

to

an inadequate seal of the orifice plate.

Failure to properly seal the plate to

the housing could result in a gas leak,

causing severe personal injury, death

or substantial property damage.

White side (propane plate)

Warning label side (natural gas)

(Install with this side

toward air inlet hose)

Gas/air manifold

Bottom side of boiler front section

GVX PROP

GVX PROP

GVX PROP

Propane — red side Natural — plain side

Install plate with red side (propane) or plain side

(natural) .againstthe blower housing

GVX PROP

GVX PROP

GVX PROP

Orifice plate after bending along

score mark. This makes the plate

identification readable after

installation.

85004b

19Part number 550-141-850/0699

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

IId

Prepare boiler — high altitude kit

When requiredWhen required

When required

Obtain high altitude

Install high altitude

air pressure switch

When requiredWhen required

kit

For installations at altitude more than 5,500 feet

above sea level

switch is required. In addition, the gas valve outlet

pressure setting must be checked, and adjusted if

necessary, per the instructions in manual Section VIIf,

altitude over 5,500 feet.

Obtain the GV high altitude kit from your local WeilMcLain distributor. This kit includes the high altitude air

pressure switch and a special tool needed for accessing

the adjusting screw on some gas valves. The kit also

includes tubing fittings as described in manual.

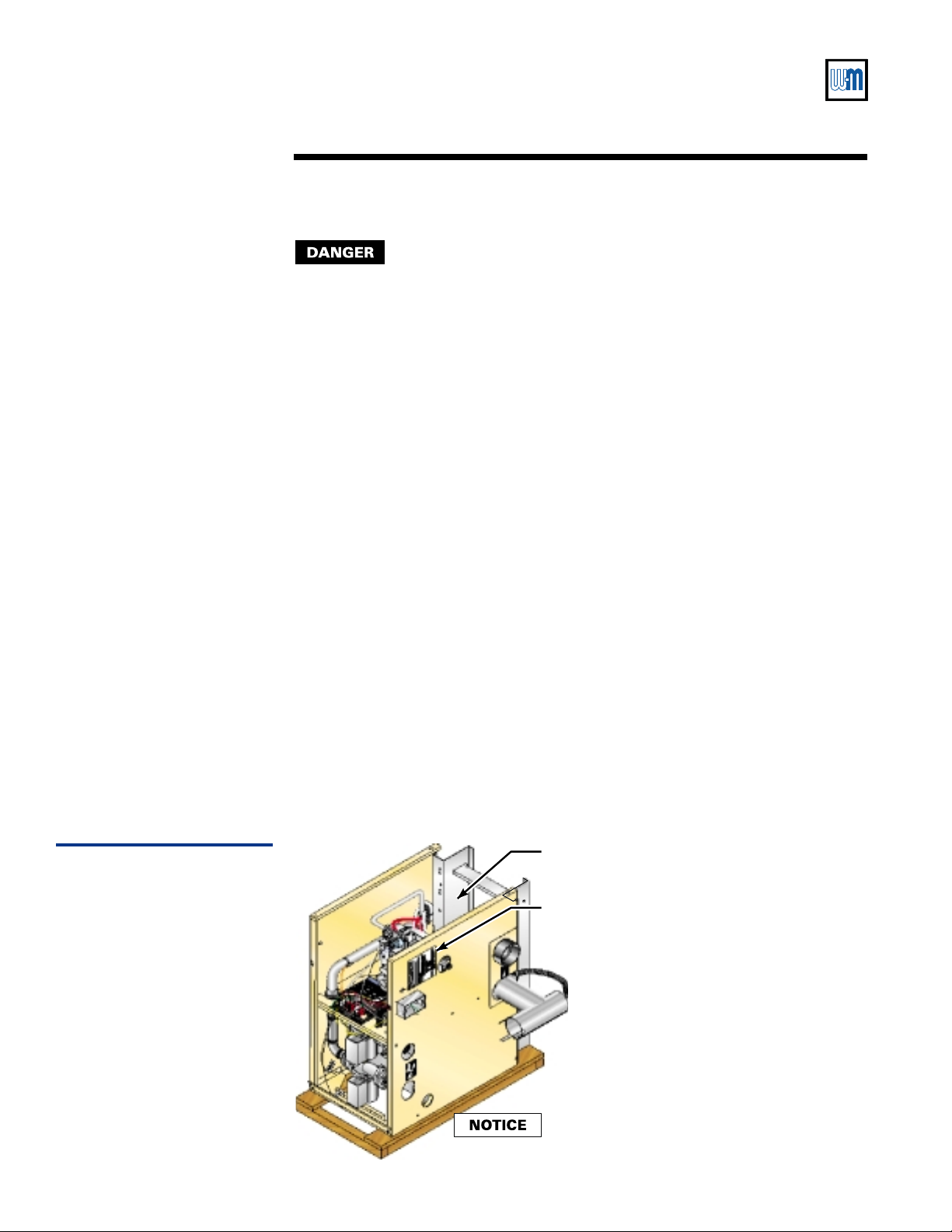

1. See Figure 5c (switch shown with wires removed).

2. Remove the two (RED) control wires from the air

pressure switch spade terminals.

, a special high altitude air pressure

Check gas valve

outlet pressure

3. Remove the factory-installed air pressure switch

(loosen top screw and remove bottom screw holding

switch to jacket interior panel).

4. Install the high altitude air pressure switch in the same

location.

5. Carefully replace the hoses on the new switch, with

the red hose on the hose barb closest to the interior

panel, as shown in Figure 5c. The white hose goes

on the outer hose barb.

6. Replace the two (RED) control wires on the new

pressure switch spade terminals.

After following the start-up procedures of manual Section

VII, follow the procedures of Section VIIf to measure gas

valve outlet pressure and adjust if necessary.

Failure to check gas valve

outlet pressure

necessary, could result in severe

personal injury, death or substantial

property damage. Carefully follow

the guidelines given in this manual.

and adjust, if

Part number 550-141-850/069920

• Installation • Start-Up • Parts • Maintenance

— altitudes above 5,500 feet ONLY

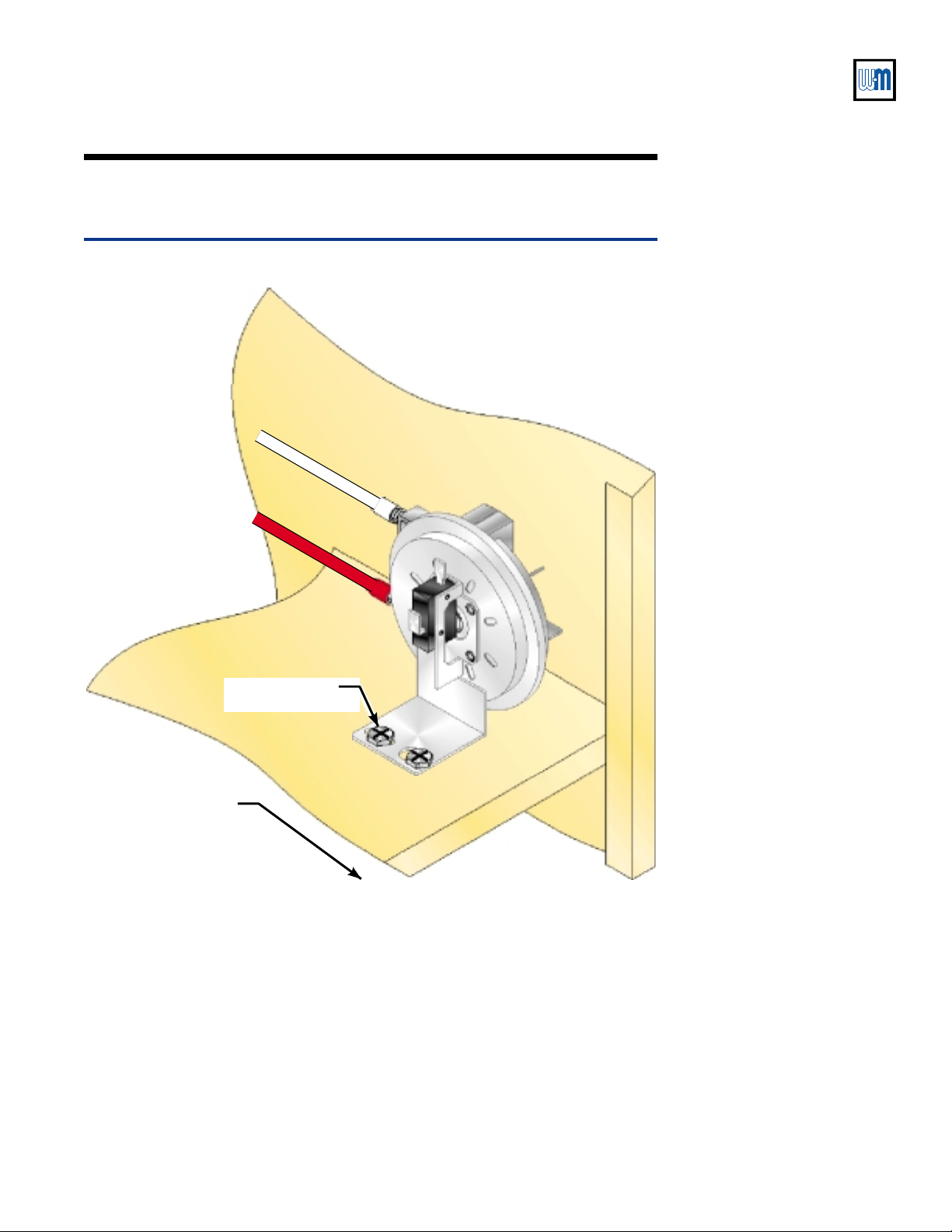

Figure 5c Air pressure switch mounting and sensor hoses

Jacket left

side panel

White

hose

Red

hose

Interior panel

Boiler top

(2) 10-32 x 3/8"

Phillips/hex screws

85052

21Part number 550-141-850/0699

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

IIe

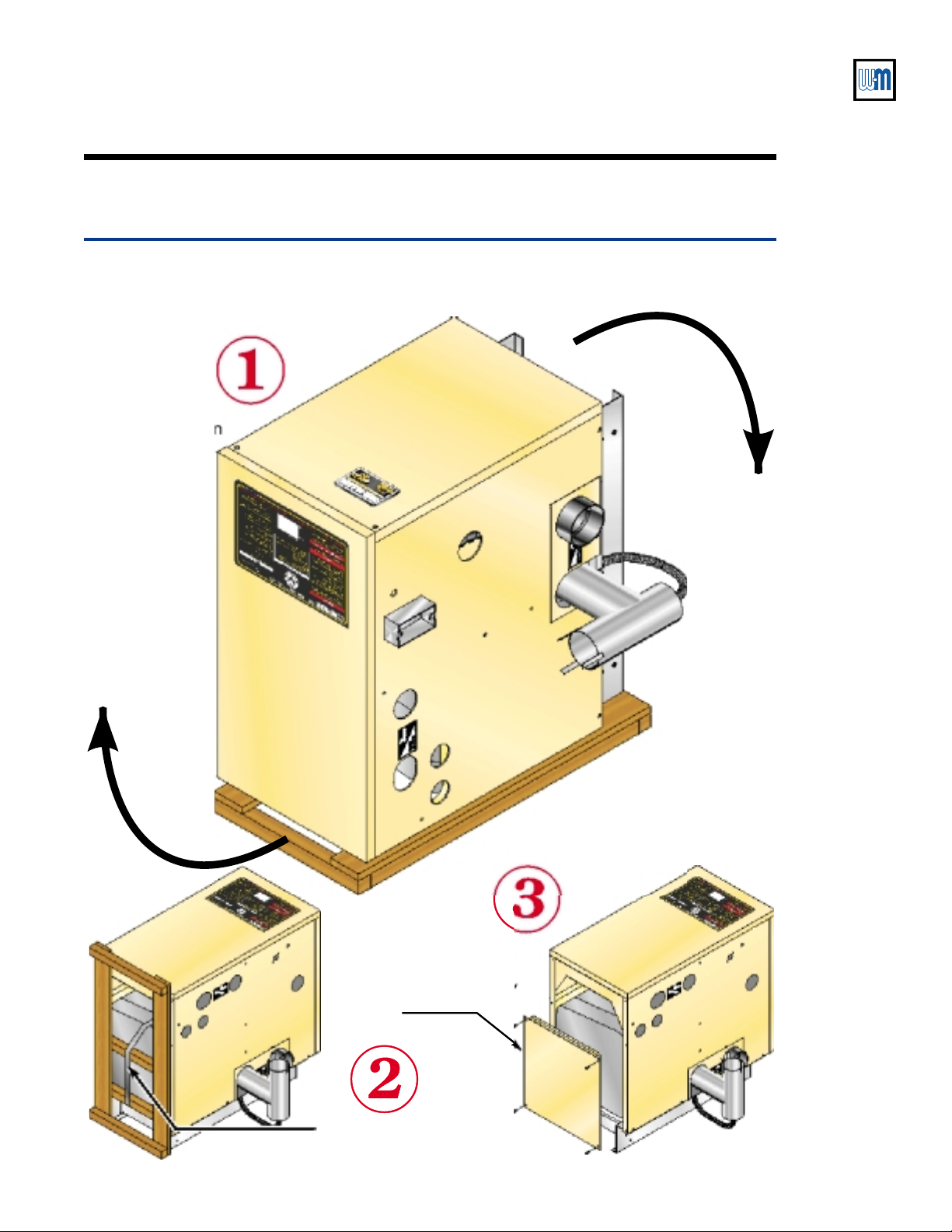

Prepare boiler — place in position

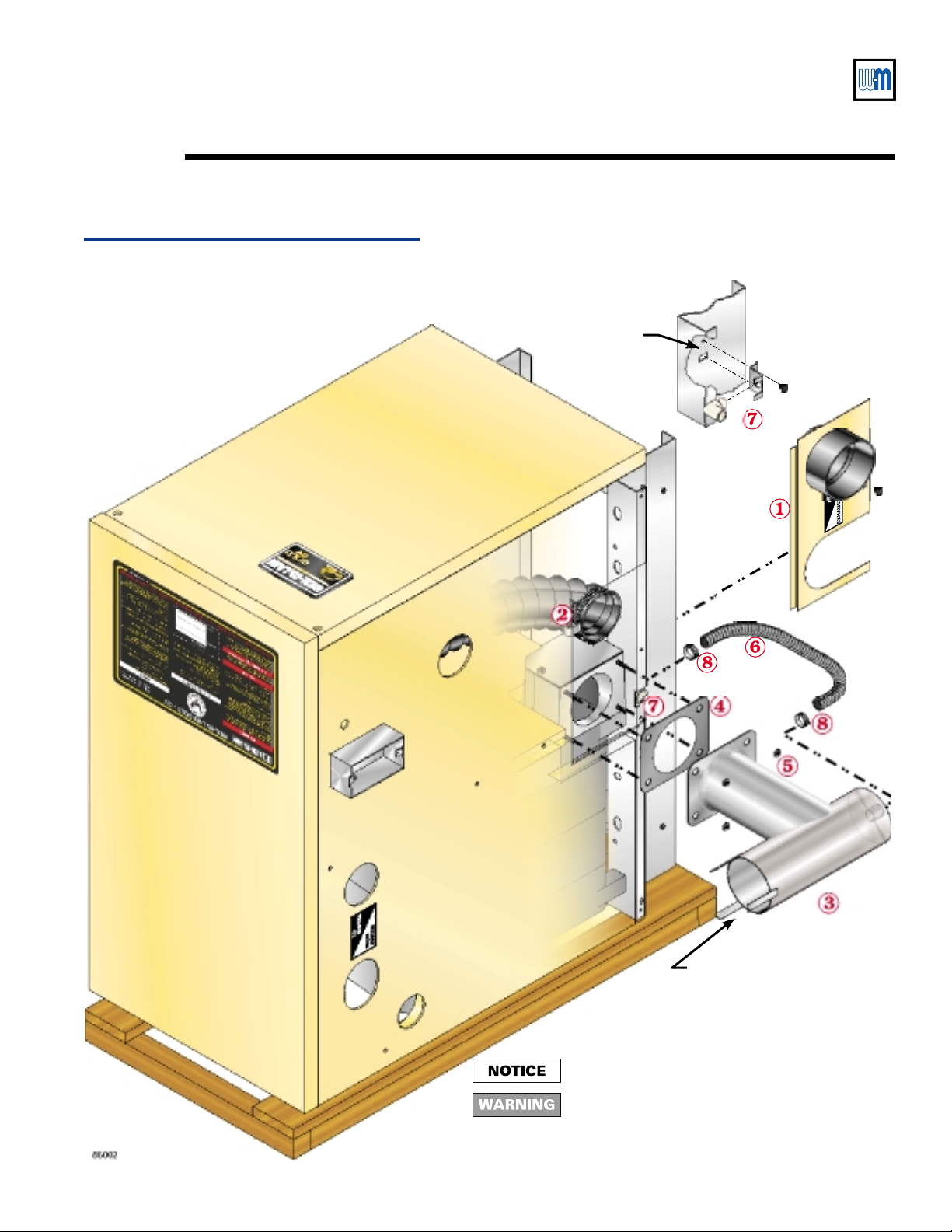

Position boiler

After installing vent starter tee, inspecting (replacing if

necessary) the gas/air orifice and installing the high

altitude kit (if required), move the boiler near its position.

Figure 6 shows the boiler with the front and top panels

replaced. These panels may be left off if desired until the

installation has been completed.

Refer to Figure 6 for placement sequence:

Wearing heavy gloves, carefully rotate the boiler

➀➀

➀

➀➀

over onto its base rail legs.

Clip the shipping strap securing the skid to the

➁➁

➁

➁➁

boiler block assembly. Remove the skid and strap.

Attach the jacket rear panel as shown using (4)

➂➂

➂

➂➂

#10 x ¾" screws provided in the accessory bag.

Boiler is heavy and contains some

sheet metal parts which may have

sharp edges. Wear gloves when

handling and take proper precautions

when moving. Failure to do so will

result in severe personal injury, death

or substantial property damage.

Part number 550-141-850/069922

• Installation • Start-Up • Parts • Maintenance

Figure 6 Rotating boiler into position, removing skid and installing jacket rear panel

Carefully rotate

boiler onto base

rail legs as shown

ROTATE

ROTATE

Install jacket

rear panel

with (4) screws,

#10 x 3/8"

Clip shipping

strap

85003

23Part number 550-141-850/0699

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

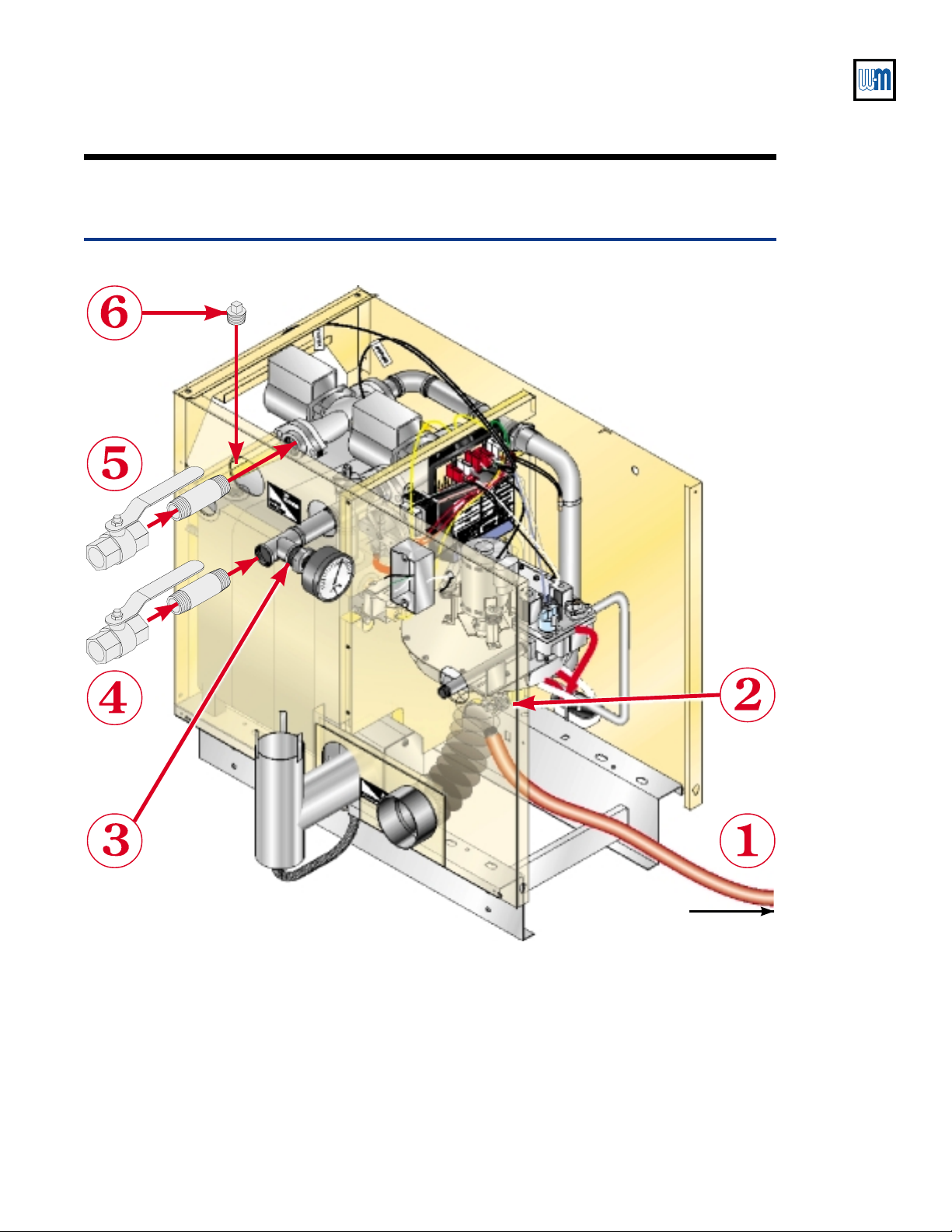

IIf

Prepare boiler — pressure test

Perform hydrostatic pressure

test

Pressure test boiler before attaching water or gas piping

(except as noted below) or electrical supply.

Prepare boiler for test (Fig. 7)

Connect a hose from water supply to fill and drain

➀➀

➀

➀➀

boiler for hydrostatic test. Hose is not included with

boiler.

Connect hose to boiler drain valve. Make sure hose

➁➁

➁

➁➁

can also be used to drain boiler after test.

Remove 1" nipple, 1" tee, bushing and pressure/

➂➂

➂

➂➂

temperature gauge from accessory bag. Pipe to boiler

supply connection as shown. Use pipe dope sparingly.

Connect a nipple and shutoff valve to system supply

➃➃

➃

➃➃

connection on the 1" tee. This valve will be used to

bleed air during the fill. Valve and nipple are not

included with boiler.

Connect a nipple and shutoff valve to system return

➄➄

➄

➄➄

connection at circulator flange. This valve will be used

to bleed air during the fill. Valve and nipple are not

included with boiler.

Install a ¾" pipe plug in the relief valve opening, top

➅➅

➅

➅➅

of the rear boiler section, as shown. Plug is not

included with boiler.

5. Slowly reopen drain valve (item 2) until test pressure

of not more than 45 psi is reached on the pressure

gauge.

6. Test at no more than 45 psi for no more than 10

minutes.

Do not leave boiler unattended.

A cold water fill could expand and

cause excessive pressure, resulting in

severe personal injury, death or

substantial property damage.

7. Make sure constant gauge pressure has been

maintained throughout test. Check for leaks. Repair

if found.

Leaks must be repaired at once.

Failure to do so can damage boiler,

resulting in substantial property

damage.

Do not use petroleum-based

cleaning or sealing compounds in

boiler system. Severe damage to

boiler will occur, resulting in

substantial property damage.

Drain and remove fittings

Fill and pressure test

1. Connect fill water supply through drain valve (item

2).

2. Fill boiler with water (be sure bleed valves at 4 and 5

are open).

3. When water flows from bleed valves, shut off water

at drain valve.

4. Close bleed valves.

1. Disconnect fill water hose from water source.

2. Drain boiler at drain valve or out hose, whichever

provides best access to drain. Close drain valve and

remove hose after draining.

3. Remove nipples and valves at 4 and 5 unless they

will remain for use in the system piping.

4. Remove plug (item 6) from relief valve tapping.

Part number 550-141-850/069924

• Installation • Start-Up • Parts • Maintenance

Figure 7 Piping connections for hydrostatic test

85007

To fill/drain

25Part number 550-141-850/0699

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

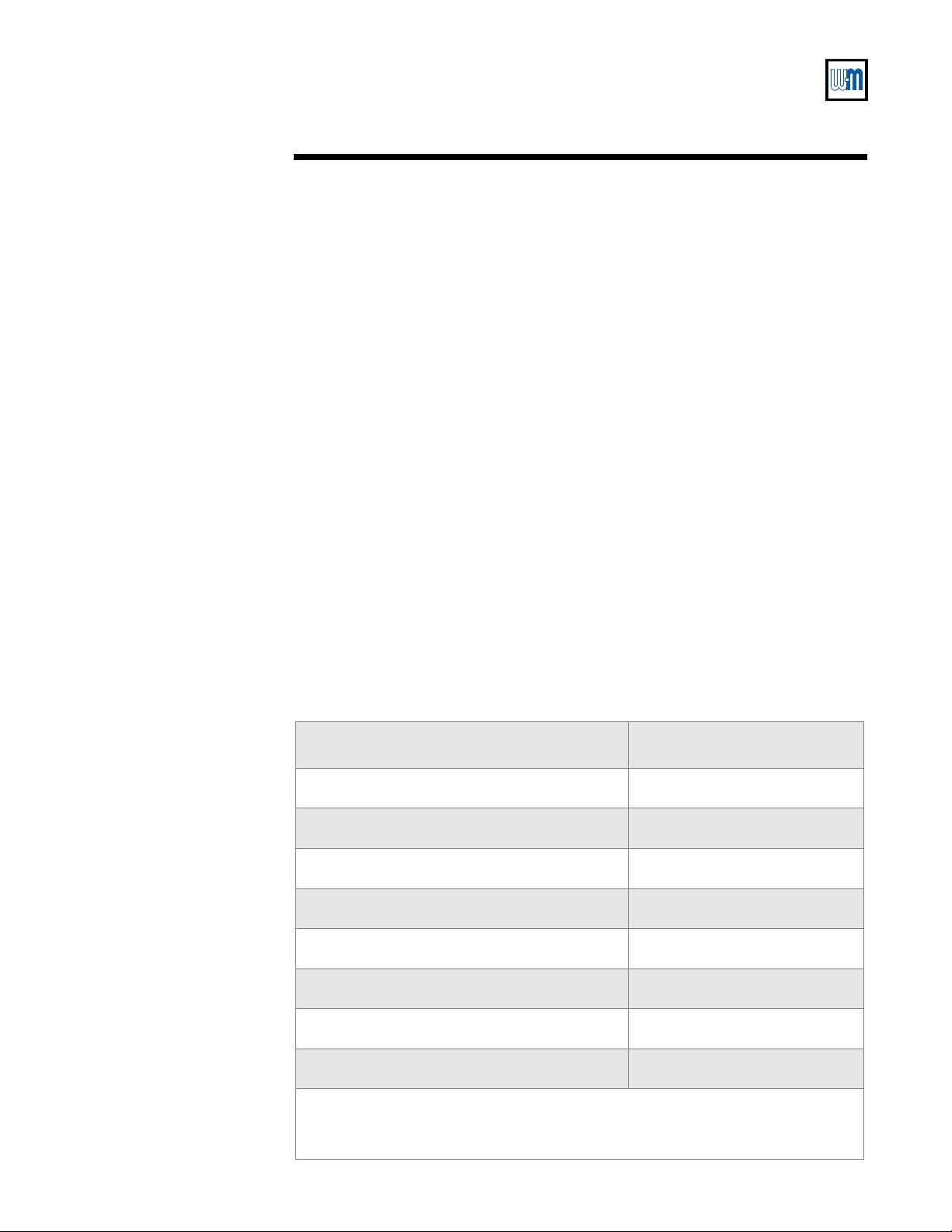

For heating system with . . . See pages 27 – 30 and . . .

Baseboard, finned tube or cast iron

31

Radiators, cast iron

32

Radiant floor, wall or ceiling —

single zone

(note 1)

33

Radiant floor, wall or ceiling —

multiple zones

34

Heat pump (note 1)

33

Snow melt plus space heating

35

Control valve (note 2)

34

Water chiller

36

Note 1: Install a temperature limit control in the supply piping to protect the system.

Note 2: Apply these piping designs for outdoor reset or any system requiring automatic

supply temperature regulation.

GOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

Water piping — overviewIIIa

Overview of this

section

❏ Select suggested piping from the following table, based on the type of

system in which you are installing the GV boiler.

❏ Review boiler connections, pages 28 – 29 — information on supply and

return connections at boiler and key system components (air separator

and expansion tank).

❏ Review page 30, information applying to all systems.

❏ Obtain any system components needed but not on hand or available at

jobsite.

❏ Install boiler relief valve and pipe discharge to a safe location per guidelines

in this section.

❏ Install system piping and boiler connections.

❏ Install additional limit control (if required for code compliance) and low

water cutoff

if required.

Part number 550-141-850/069926

• Installation • Start-Up • Parts • Maintenance

IIIb

Install relief valve

Water piping — relief valve

Refer to Figure 8 for location of the relief valve on the boiler.

Install the relief with the spindle vertical in the ¾" tapping on top left of the back section, as

shown.

To avoid water damage or scalding due to valve operation, a metal discharge

line must be connected to relief valve outlet and run to a safe place of

disposal

should the valve discharge.

Discharge line must be as short as possible and be the same size as the

valve discharge connection throughout its entire length.

Discharge line must pitch downward from the valve and terminate at least

6" above the floor drain where any discharge will be clearly visible.

The discharge line shall terminate plain, not threaded, and must be

rigid metallic pipe of material suitable for temperatures of 375 °F or greater.

Do not pipe the discharge to any place where freezing could occur.

No shutoff valve shall be installed between the relief valve and boiler, or in

the discharge line. Do not plug or place any obstruction in the discharge line.

. Terminate the discharge line to eliminate possibility of severe burns

Figure 8

Install and pipe relief valve

Failure to comply with the above guidelines could result in failure of the

relief valve to operate, resulting in possibility of severe personal injury, death

or substantial property damage.

Test the operation of the valve after filling and pressurizing system by

lifting the lever. Make sure the valve discharges freely. If the valve fails to

operate correctly, replace it with a new relief valve.

1 Jacket plug for unused relief valve jacket

opening.

2 Jackets are provided with two relief valve

openings because each jacket size is used

for two boiler sizes. Cover the unused

opening with the plug provided.

3 Boiler relief valve (from accessory bag)

4 ¾" x 3" nipple, provided in accessory bag

5 ¾" relief valve tapping in back section

6 Connect minimum ¾" discharge piping

to relief valve.

See WARNING above.

85008

27Part number 550-141-850/0699

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

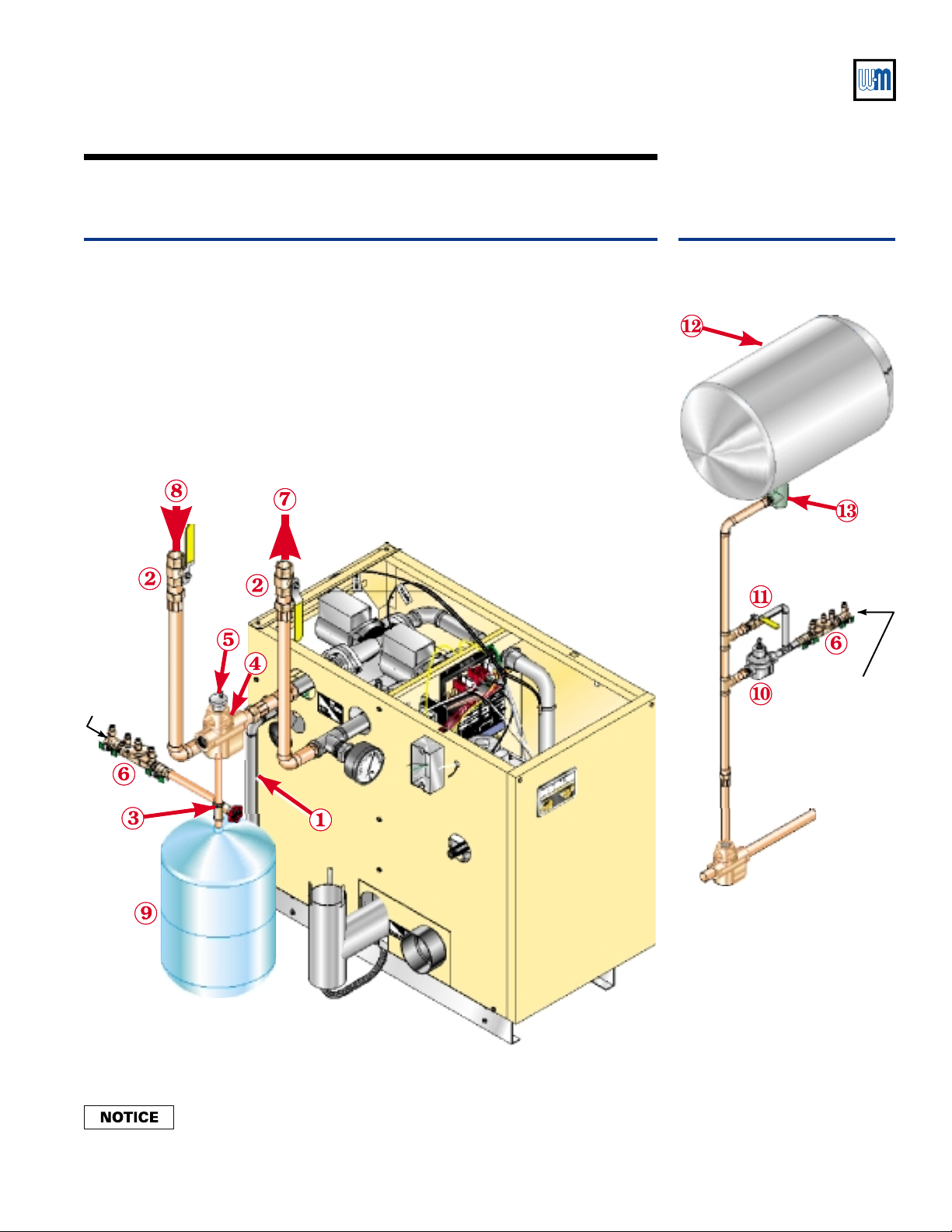

IIIc

Water piping — boiler connections

Supply & return connections

Always connect supply and return connections to the

boiler as shown in Figure 9. (Note in the following and in

the suggested piping drawings in this manual that the

expansion tank and air separator location will depend on

the system piping.)

Air separator

Install an air separator in the piping as shown. For

single-zone systems, install the air separator in the return

piping as shown in Figure 9. This allows mounting the

automatic air vent and expansion tank off of the separator.

Expansion tank

Figures 9 and 10 show typical installation of the

expansion tank when the boiler is connected to a zonevalve zoned baseboard system (see Figure 10). Always

locate the air separator and expansion tank as shown in

the suggested piping drawings, Figures 10 through 16.

Ensure that the expansion tank size will handle boiler and

system water volume and temperature. See tank

manufacturer’s instructions and ratings for details.

Additional tanks may be added to the system if needed to

handle the expansion. These tanks may be installed by

connecting to tees in the system piping.

Undersized expansion tanks

cause system water to be lost from

the relief valve and makeup water to

be added through the fill valve.

Eventual section failure can result.

Always locate the cold water fill

connection

Never locate this elsewhere in the

system.

Diaphragm- or bladder-type tank:

Refer to Figure 9 for suggested piping when using a

diaphragm- or bladder-type expansion tank.

at the expansion tank.

Install an automatic air vent on top of the air separator,

per separator manufacturer’s instructions.

Closed-type expansion tank:

Figure 10 shows suggested piping when using a closedtype expansion tank, in which the air is directly in contact

with tank water.

Connect piping (½" or ¾") from the air separator top

outlet to the tank fitting. Slope any horizontal piping a

minimum of 1 inch per 5 feet of horizontal pipe.

Always use a tank fitting, such as the B&G Tanktrol or

Ta co Taco-Trol (shown). The fitting reduces gravity flow

of water in the piping to the tank, avoids air bubbling

through the tank water, and provides the proper fill height

in the tank.

Operating pressure of system, after

temperature expansion above cold fill

pressure, should not exceed 24 PSIG

to avoid weeping of relief valve.

Correct all leaks in the system or

tank piping. Leaks allow air to escape

from the system and will cause waterlogging of the tank. This will result in

water loss through the boiler relief

valve due to over-pressurization.

NEVER use an automatic air vent in

a system equipped with a closed-type

expansion tank. The air removed

from the system will cause waterlogging of the expansion tank.

Closed-type expansion tank —

Follow tank manufacturer’s

instructions for filling the tank.

Typical tank sizing provides for

approximately 12 PSIG when the

tank is filled to the normal level and

system water is cold. Note that boiler

relief valve is set for 30 PSIG.

Operating pressure of system, after

temperature expansion above cold fill

pressure, should not exceed 24 PSIG

to avoid weeping of relief valve.

Diaphragm- or bladder-type

expansion tank

pressure

pressure. Always check pressure and

charge tank with tank removed from

system to be sure reading is accurate.

Boiler relief valve is set for 30 PSIG.

with the tank air charge

— Control fill

Backflow preventer

Where required by codes, install a backflow preventer

in the cold water fill line, as shown in suggested piping

diagrams on following pages. Install a check valve if a

backflow preventer is not installed.

Part number 550-141-850/069928

• Installation • Start-Up • Parts • Maintenance

Figure 9 Piping to single-zone system using diaphragm- or bladder-type

expansion tank. Boiler connections are 1" NPT (supply from 1" tee,

return to 1" system circulator flange).

1 Relief valve discharge piping — see page 27

2 Boiler isolation valves

3 Fill valve

4 Air separator

5 Automatic air vent

6 Backflow preventer or check valve

7 System supply piping

8 System return piping

9 Diaphragm-type expansion tank —

always locate as shown in the suggested

piping drawings, Figures 10 through 16

Figure 10 Piping closed-

type expansion

tank

To cold fill

To cold fill

Locate the air separator as shown in the suggested piping

diagram, Figures 11 through 16 on the following pages.

Pipe diaphragm- or bladder-type expansion tanks to the

bottom of the separator.

85011

10 Pressure reducing valve

11 Quick-fill bypass valve

12 Closed-type expansion tank —

always locate as shown in the

suggested piping drawings,

Figures 10 through 16

85010

13 Tank fitting

Pipe closed-type (air in contact with water) tanks to the

top of the air separator. Always connect the fill line to the

expansion tank location, as shown above and in the

suggested piping.

29Part number 550-141-850/0699

Loading...

Loading...