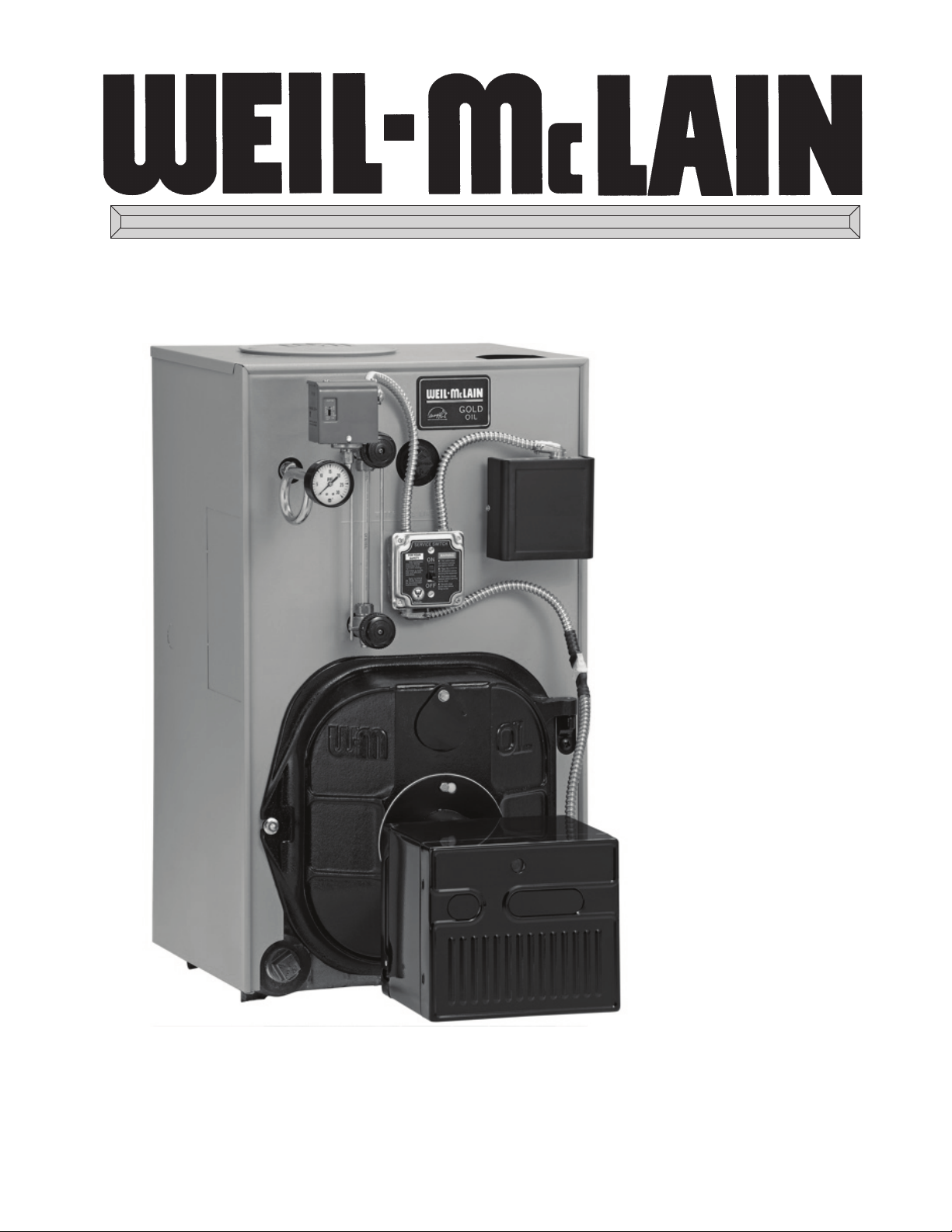

Weil-McLain 550-141-830-1202 User Manual

SGO Series 3 Oil-Fired Steam Boiler

Maintenance

and Service

Guide

For future reference, leave this manual

with other boiler instructions

in the envelope provided with the boiler.

Part No. 550-141-830/1202

Read This Page First

Hazard Definitions

Following terms are used to bring attention to the presence of hazards of various risk levels, or

to important information concerning product life.

Indicates presence of hazards that will cause severe personal injury, death or

substantial property damage if ignored.

Indicates presence of hazards that can cause severe personal injury, death or

substantial property damage if ignored.

Indicates presence of hazards that will or can cause minor personal injury or

property damage if ignored.

Indicates special instructions on installation, operation, or maintenance that

are important but not related to personal injury hazards.

Symbol Definitions

These symbols indicate information for and procedures to be followed by:

Homeowner or person responsible for simple start-up and routine

maintenance of boiler and system. Pages 2 through 6 must be followed

to assure proper operation of your boiler. Page 7 lists common problems

and possible corrections. In addition, it is your responsibility to:

●

Have boiler and burner installed by a qualified installer.

●

Have boiler and burner serviced annually by a qualified service

technician.

●

Review and understand start-up and routine maintenance

procedures with qualified service technician.

●

Perform routine maintenance as described on page 4.

Qualified service technician who has the necessary equipment to

check the boiler and system performance, and is responsible for

start-up and service of boiler and system. Pages 2 and 3 and 8 through

11 must be followed to assure proper operation of this boiler.

In addition, it is the responsibility of this person to:

Annually service boiler and burner to assure proper operation. See page 8

●

for service record.

Review and explain start-up and routine maintenance procedures with

●

homeowner.

2

Part No. 550-141-830/1202

For Your Safety

Follow instructions below to

prevent severe personal injury, death or substantial property damage:

●

Do not use crankcase drainings or any oil

containing gasoline. See burner manual for

proper fuel oil.

●

Do not attempt to start burner when excess

oil has accumulated in combustion chamber,

when unit is full of vapor, or when combus

tion chamber is very hot.

●

Do not start burner unless collector hood, flue

cap, jacket cap, breeching and burner mount ing door are secured in place.

●

Never burn garbage or paper in the boiler.

●

Never leave combustible material around

boiler.

DO NOT TAMPER WITH UNIT OR CONTROLS.

●

Always follow specific instructions when

starting up boiler or performing routine

maintenance or service.

Follow instructions below to

prevent severe personal injury, death or substantial property damage:

●

To avoid electric shock, turn off electrical

supply at switch on boiler and additional

external switches before performing service.

●

To avoid severe burns, allow boiler to cool

before performing service.

●

Do not block flow of combustion or ventilation

air to boiler.

●

Boiler must be connected to a flue with

sufficient draft at all times to assure proper

operation.

●

Do not use this boiler if any part has been

under water. Electrical and mechanical

failures may cause electric shock and fire

risks. Immediately call a qualified service

technician to inspect chimney or vent,

boiler and burner. Have the boiler flueways

cleaned and have the following replaced:

— all electrical and mechanical controls

— electrical wiring

— oil burner and controls

— insulation and chamber lining

Tips for steam systems:

Check boiler and system piping for leaks.

●

Continual makeup water will reduce boiler life.

Minerals can build up in sections, reducing

heat transfer and causing cast iron to overheat,

resulting in section failure.

Failure to maintain recom-

mended pH and to repair leaks can cause

section iron corrosion, leading to section

failure and leaks. Do not use petroleum-

based sealing or stop-leak compounds in

boiler systems. Damage to system components

can result.

Boiler water pH 7.0 to 8.5 is recommended.

●

For pH conditions outside 7.0 to 8.5 range or

unusually hard water areas (above 7 grains

hardness), consult local water treatment

company.

●

Do not add cold water to hot boiler. Thermal

shock can cause sections to crack.

Clean newly installed steam boiler to remove

●

oil, grease, and other foreign material. Failure

to properly clean can result in violent water

level fluctuations, water passing into steam

mains, or high maintenance costs on strainers,

traps and and vents. A qualified service techni-

cian should skim the boiler by following

instructions on page 10 of this manual.

Part No. 550-141-830/1202

3

Routine Maintenance Schedule

The schedule below is specifically designed for the homeowner.

Please read pages 2 and 3 before proceeding.

Beginning each heating season:

Call a qualified service technician to perform

annual service.

Daily during heating season:

Check that boiler area is free from combusti ble materials, gasoline and other flammable

vapors and liquids.

Weekly during heating season:

Check for and remove any obstructions to flow

of combustion or ventilation air to boiler.

Check that breeching is attached between

boiler and chimney. If breeching is loose or

damaged, immediately turn off switch on front

of boiler and call qualified service technician

to repair.

Check for oil leaks in oil piping and around

burner. If found, immediately call qualified

service technician to correct situation.

Check for water leaks in boiler and piping;

also check for leaks around tankless heater

plate. If found, immediately call qualified

service technician to repair.

Float-type low water cutoff, when used:

Refer to control manufacturer's instructions.

Periodically during heating season:

Probe-type low water cutoff, when used:

Refer to control manufacturer's instructions

for testing.

End of heating season:

If tankless heater is installed, boiler will

continue to operate. Check for the following:

- All daily, weekly and monthly instructions

listed on this page must be followed.

- Burner motor may have to be oiled. Some

motors are permanently lubricated and do

not need additional oil. Check for oiling

instructions on burner or motor.

Boiler shutdown:

Do not drain boiler unless exposure to

●

freezing temperatures will occur.

Do not use antifreeze in steam systems.

●

Always keep manual fuel supply shut off if

●

burner is shut down for an extended period of

time.

a. Turn off switch at boiler and any external

switch to boiler.

b. Close fuel valves.

c. Turn off water feed valve.

d. Cover burner to protect from dust and

dampness.

Scald potential. Do not blow

down low water cutoff unless blowdown

piping has been installed according to Boiler

Manual. If piping is not in place, call qualified

service technician to install.

4

Part No. 550-141-830/1202

Loading...

Loading...