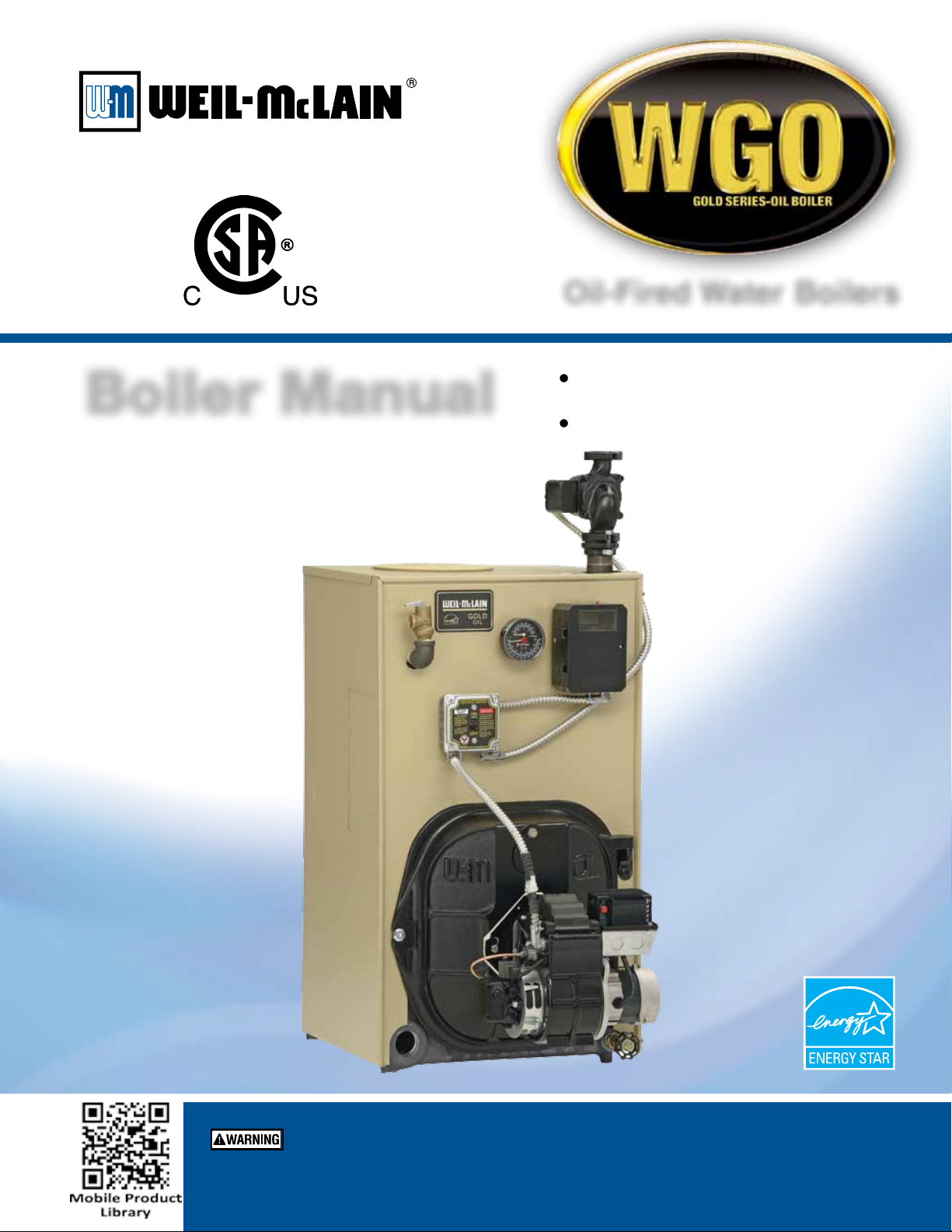

Page 1

Oil-Fired Water Boilers

Boiler Manual

• Installation

• Startup

• Maintenance

• Parts

This manual must only be used by a qualified heating installer/service technician. BEFORE

installing, read all instructions in this manual and all other information shipped with the

boiler. Perform steps in the order given. Failure to comply could result in severe personal

injury, death or substantial property damage.

Part number 550-141-826/1211

Page 2

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

HOMEOWNER and SERVICE TECHNICIAN — read and follow completely.

Using this manual

Homeowner —

Read and follow all information on pages 1 through 7 ONLY.

Service technician —

Read and follow ALL information in the entire manual.

Failure to follow all instructions in proper order can cause severe personal injury, death or

substantial property damage.

When calling or writing about the boiler

Please have boiler model number and series from boiler rating label and CP number(s) from boiler jacket,

burner and controls. On page 28 of this manual is space to list CP number(s).

Packaged and non-packaged boilers

Packaged boilers, available only in sizes 2 through 6, are factory assembled, complete with block, jacket and

controls. Burner is shipped separately.

Non-packaged boilers, available in all sizes, 2 through 9, are shipped with block assembled, with jacket.

Controls, trim and burner shipped separately for field assembly.

Hazard definitions

The following defined terms are used throughout this manual to bring attention to the presence of hazards

of various risk levels or to important information concerning the life of the product.

Indicates presence of hazards that will cause severe personal injury,

death or substantial property damage.

Indicates presence of hazards that can cause severe personal injury,

death or substantial property damage.

Indicates presence of hazards that will or can cause minor personal

injury or property damage.

Indicates special instructions on installation, operation or

maintenance that are important but not related to personal injury

or property damage.

2

Part number 550-141-826/1211

Page 3

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

Contents

HOMEOWNER and SERVICE TECHNICIAN — read and follow completely.

Using this manual . . . . . . . . . . . . . . . . . . . . .2

When calling or writing about the boiler . . . . . . . .2

Packaged and non-packaged boilers. . . . . . . . . .2

Hazard denitions . . . . . . . . . . . . . . . . . . . . .2

Contents . . . . . . . . . . . . . . . . . . . . . . . . . .3

Please read before proceeding . . . . . . . . . . . . . .4

Tips for water systems — . . . . . . . . . . . . . . .4

Routine maintenance schedule. . . . . . . . . . . . . .5

Beginning each heating season . . . . . . . . . . . .5

Daily during heating season . . . . . . . . . . . . . .5

Weekly during heating season . . . . . . . . . . . . .5

End of heating season . . . . . . . . . . . . . . . . .5

Boiler shutdown . . . . . . . . . . . . . . . . . . . .5

Operation. . . . . . . . . . . . . . . . . . . . . . . . . .6

WGO (see Figure 1) . . . . . . . . . . . . . . . . . .6

Troubleshooting . . . . . . . . . . . . . . . . . . . . . .7

Before installing boiler . . . . . . . . . . . . . . . . . .8

Installations must comply with . . . . . . . . . . . . .8

Before selecting boiler location. . . . . . . . . . . . .8

Provide clearances around boiler

(see Figure 2) . . . . . . . . . . . . . . . . . . . . .8

Provide air for combustion and ventilation . . . . . . .9

Foundation . . . . . . . . . . . . . . . . . . . . . . .9

Install boiler — packaged boilers only. . . . . . . . . 10

Place boiler. . . . . . . . . . . . . . . . . . . . . . 10

Perform hydrostatic pressure test . . . . . . . . . . 10

Install boiler — non-packaged boilers only . . . . . . 12

Place boiler. . . . . . . . . . . . . . . . . . . . . . 12

Perform hydrostatic pressure test . . . . . . . . . . 14

Install jacket

(sizes 7 through 9 only) . . . . . . . . . . . . . . . 14

Install boiler controls . . . . . . . . . . . . . . . . .14

Install burner — all boilers . . . . . . . . . . . . . . . 15

Install burner

(also refer to instructions packed with burner) . . . .15

Connect breeching . . . . . . . . . . . . . . . . . . . 16

General chimney requirements. . . . . . . . . . . . 16

Connect water piping . . . . . . . . . . . . . . . . . . 18

General piping information . . . . . . . . . . . . . .18

Install piping . . . . . . . . . . . . . . . . . . . . . 18

DIAPHRAGM expansion tank (Figure 9, page 19) . . 18

CLOSED expansion tank (Figure 10, page 19) . . . 18

To connect WGO boilers to indirect-fired

water heaters. . . . . . . . . . . . . . . . . . . . . 18

Piping MULTIPLE ZONES . . . . . . . . . . . . . .20

Piping for systems requiring

temperatures below 140°F . . . . . . . . . . . . . .21

Use with refrigeration systems . . . . . . . . . . . . 22

Connect wiring. . . . . . . . . . . . . . . . . . . . . . 22

General wiring requirements . . . . . . . . . . . . . 22

Thermostat wiring . . . . . . . . . . . . . . . . . . 22

3-Wire zone valve applications. . . . . . . . . . . . 22

Junction box (furnished) . . . . . . . . . . . . . . .23

Burner wiring . . . . . . . . . . . . . . . . . . . . . 23

High temperature limit . . . . . . . . . . . . . . . . 23

Connect wiring — blocked vent

shutoff switch option . . . . . . . . . . . . . . . . . . 25

Blocked vent shutoff switch . . . . . . . . . . . . . 25

Connect oil piping . . . . . . . . . . . . . . . . . . . . 26

General oil piping requirements . . . . . . . . . . . 26

Oil piping connection at burner. . . . . . . . . . . . 26

Start-up. . . . . . . . . . . . . . . . . . . . . . . . . . 27

Fill the system . . . . . . . . . . . . . . . . . . . . 27

When using antifreeze . . . . . . . . . . . . . . . .27

To place in operation . . . . . . . . . . . . . . . . .27

Check-out procedure . . . . . . . . . . . . . . . . . . 28

Check off steps as completed . . . . . . . . . . . . 28

Installation and service certificate . . . . . . . . . .28

Annual service check list . . . . . . . . . . . . . . . . 29

Controls requiring annual service . . . . . . . . . . 29

Detailed service procedures . . . . . . . . . . . . . . 30

Cleaning boiler flueways . . . . . . . . . . . . . . .30

General description of control operation . . . . . . .30

Handling ceramic ber and berglass materials . . . 31

Close clearance installation . . . . . . . . . . . . . . 32

Close clearance installation . . . . . . . . . . . . . 32

Burner adjustments for packaged

and non-packaged boilers . . . . . . . . . . . . . .32

Replacement parts . . . . . . . . . . . . . . . . . . . 34

Dimensions . . . . . . . . . . . . . . . . . . . . . . . 40

Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Part number 550-141-826/1211

3

Page 4

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

HOMEOWNER and SERVICE TECHNICIAN — read and follow completely.

Please read before proceeding

Homeowner —

• For homeowner or person responsible for

simple start-up and routine maintenance of

the system

• Instructions on page 1 through page 7 must

be followed to assure proper operation of your

boiler. See page 7 for lists common problems

and possible corrections. In addition, it is your

responsibility to:

• Have boiler and burner installed by a quali-

fied installer.

• Have boiler and burner serviced annually

by a qualified service technician.

• Review and understand start-up and rou-

tine maintenance procedures with qualified service technician.

• Perform routine maintenance as described

on page 5.

Service technician —

• For a qualified service technician who has the

necessary equipment to check the boiler and

system performance, and is responsible for

start-up and service of boiler and system.

• All instructions in this manual must be followed to assure proper operation of this boiler.

• Annually service boiler and burner to assure

proper operation. See page 29 for service

record.

• Review and explain start-up and routine maintenance procedures with homeowner.

Follow instructions below to prevent severe personal

injury, death or substantial property damage:

• To avoid electric shock, disconnect electrical supply to burner

service switch and additional external switches before performing service.

• To avoid severe burns, allow boiler to cool before performing

service.

• Do not block flow of combustion or ventilation air to boiler.

• Boiler must be connected to a flue with sufficient draft at all times

to assure proper operation.

• Do not use this boiler if any part has been under water. Electrical

and mechanical failures may cause electric shock and fire risks.

Immediately call a qualified service technician to inspect chimney

or vent, boiler and burner. Have the boiler flueways cleaned and

have the following replaced:

• all electrical and mechanical controls

• electrical wiring

• oil burner and controls

• insulation and chamber lining

Tips for water systems —

• Check boiler and system piping for leaks. Continual makeup water

will reduce boiler life. Minerals can build up in sections, reducing heat transfer and causing cast iron to overheat, resulting in

section failure.

Failure to maintain recommended pH and repair leaks

can cause section iron corrosion, leading to section

failure and leaks. Do not use petroleum-based sealing

or stop-leak compounds in boiler systems. Damage to

system components can result, causing property damage.

Follow instructions below to prevent

severe personal injury, death or substantial property damage:

• Do not use crankcase drainings or any oil

containing gasoline. See burner manual for

proper fuel oil.

• Do not attempt to start burner when excess

oil has accumulated in combustion chamber,

when unit is full of vapor, or when combustion

chamber is very hot.

• Do not start burner unless collector hood, flue

cap, jacket cap, breeching and burner mounting door are secured in place.

• Never burn garbage or paper in the boiler.

Never leave combustible material around

boiler.

• DO NOT TAMPER WITH UNIT OR CONTROLS. Always follow specific instructions

when starting up boiler or performing routine

maintenance or service.

4

• Boiler water pH 7.0 to 8.5 is recommended. For pH conditions

outside 7.0 to 8.5 range or unusually hard water areas (above 7

grains hardness), consult local water treatment company.

• When using antifreeze:

Use antifreeze especially made for hydronic systems. Inhibited

propylene glycol is recommended.

Do not use automotive, ethylene glycol, undiluted or

petroleum-based antifreeze. Severe personal injury, death

or substantial property damage can result.

50% solution provides protection to about –30°F.

Local codes may require back-flow preventer or actual discon-

nect from city water supply.

Determine quantity according to system water content. Boiler

water content is listed on back cover of Boiler Manual.

Percent of solution will affect sizing of heat distribution units,

circulator and expansion tank.

Follow antifreeze manufacturer’s instructions.

Do not add cold water to hot boiler. Thermal shock can cause

sections to crack.

Part number 550-141-826/1211

Page 5

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

HOMEOWNER and SERVICE TECHNICIAN — read and follow completely.

Routine maintenance schedule

Beginning

each heating season

Daily

during heating season

Weekly

during heating season

Call a qualified service technician to perform annual service.

Check that boiler area is free from combustible materials, gasoline

and other flammable vapors and liquids.

Check for and remove any obstructions to flow of combustion or

ventilation air to boiler.

Check that breeching is attached between boiler and chimney. If

breeching is loose or damaged, immediately turn off switch on

boiler and call service technician to repair.

Check for oil leaks in oil piping and around burner. If found, im-

mediately call qualified service technician to correct situation.

Check for water leaks in boiler and piping; also check for leaks

around tankless heater plate, if installed. If found, immediately call

service technician to repair.

End

of heating season

Boiler

shutdown

If tankless heater is installed, boiler will continue to operate. Check

for the following:

• All daily and weekly instructions listed on this page must be followed.

• Burner motor may have to be oiled. Some motors are permanently

lubricated and do not need additional oil. Check for oiling instructions on burner or motor.

Do not drain boiler unless exposure to freezing temperatures will

occur.

Always keep manual fuel supply shut off if burner is shut down for

an extended period of time.

• Turn off switch at boiler and any external switch to boiler.

• Close fuel valves.

• Turn off water feed valve.

• Cover burner to protect from dust and dampness.

Part number 550-141-826/1211

5

Page 6

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

Operation

HOMEOWNER and SERVICE TECHNICIAN — read and follow completely.

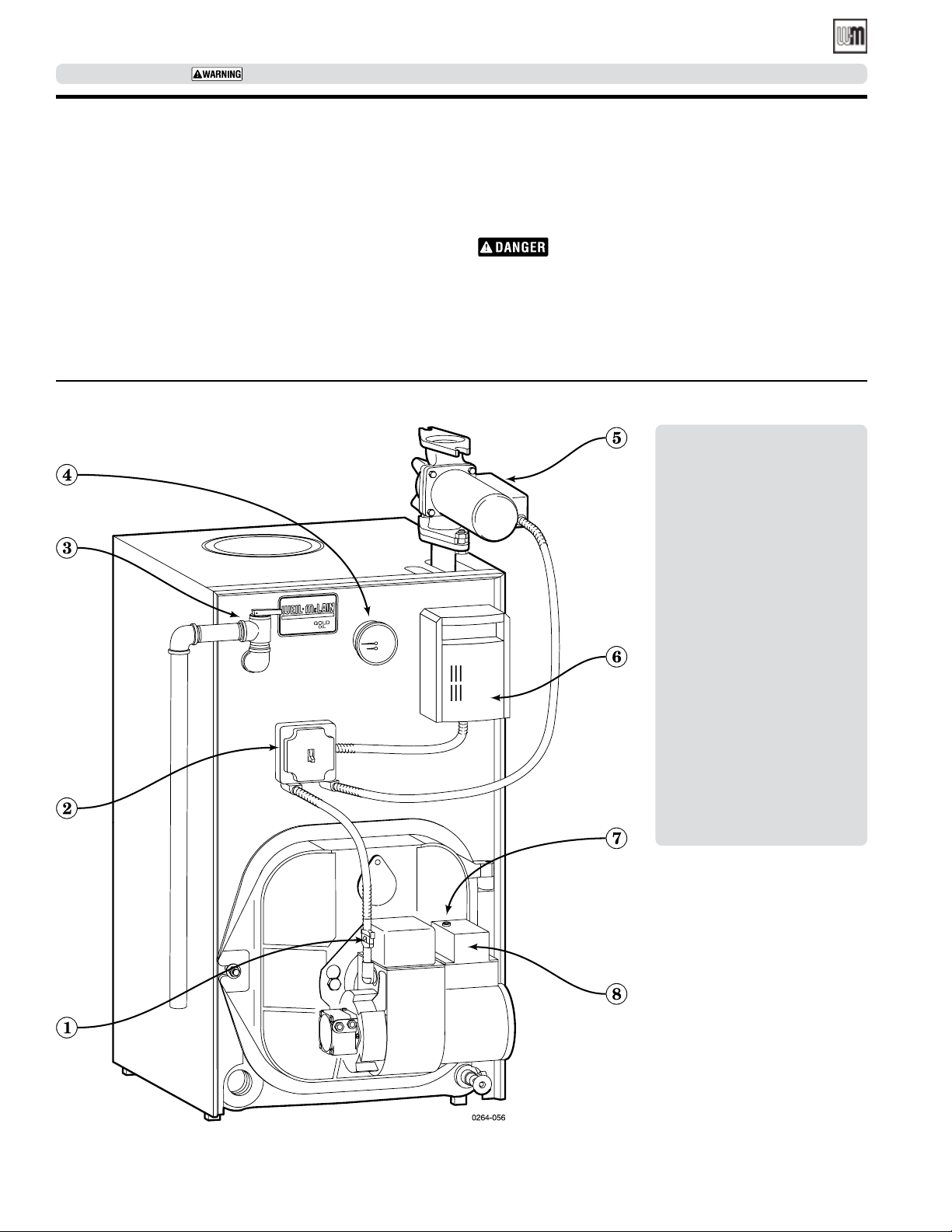

WGO (see Figure 1)

1. If burner does not fire, check for:

• Service switch on boiler or additional switches turned off.

• Fuses or breaker switch tripped.

• Thermostat set below room temperature.

• Fuel valves turned off.

• Not enough oil in tank to supply burner.

Figure 1 WGO Boilers

2. Correct problems found in step #1. If burner does not fire,

press reset button on burner primary control only once.

Repeated presses will deposit oil in combustion chamber.

Burner must never be fired when oil is in combus-

tion chamber. Immediately call qualified service

technician.

3. If burner still does not fire, call qualified service technician.

1 Burner disconnect plug

2 Service switch on boiler

3 Water relief valve

4 Temperature-pressure gauge

5 Circulator

6 Limit control / low water

cut-off

7 Reset button on burner

primary control

8 Burner primary control

6

Part number 550-141-826/1211

Page 7

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

HOMEOWNER and SERVICE TECHNICIAN — read and follow completely.

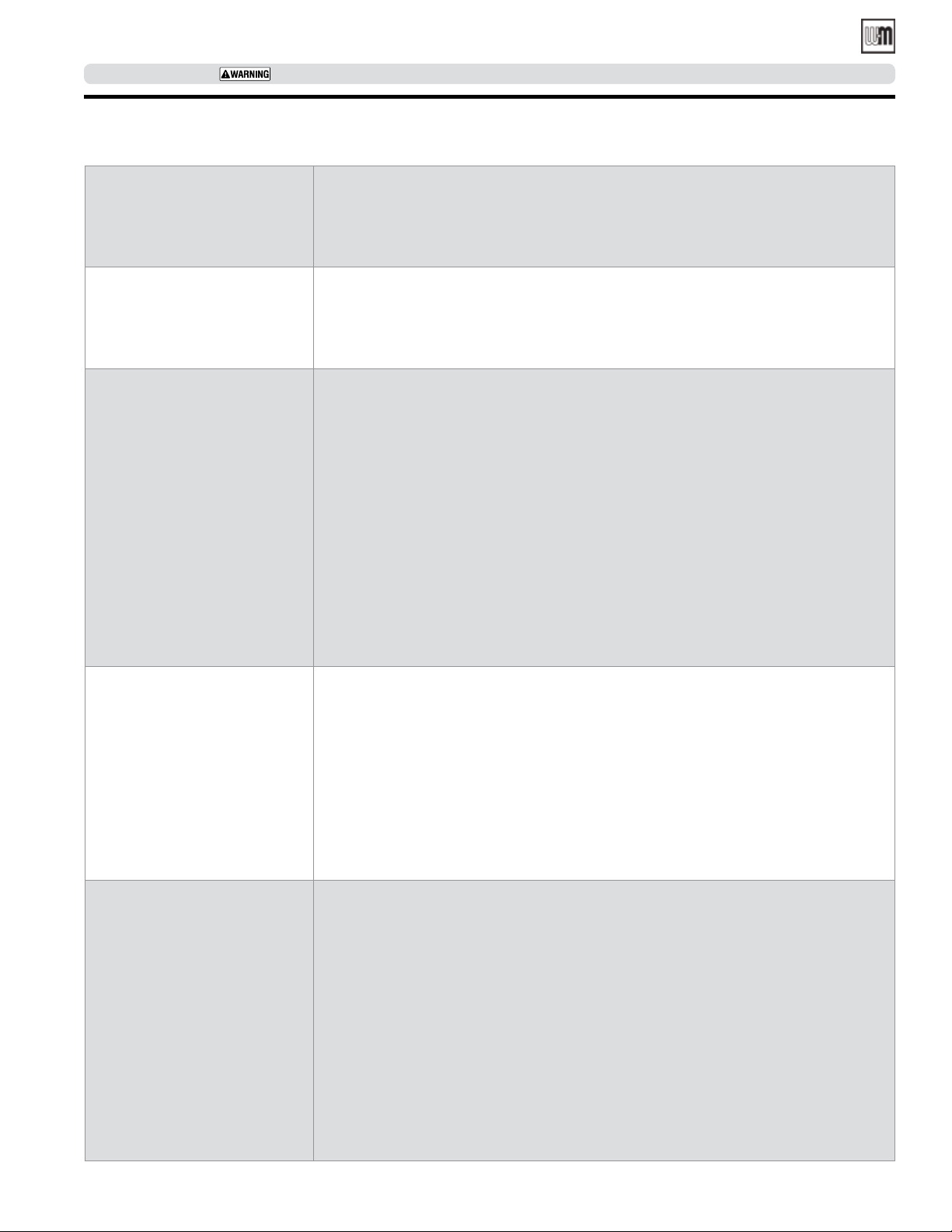

Troubleshooting

Homeowners — The problems and corrections below represent common situations that can occur. There may be

others not listed below. It is important always to contact a qualified service technician if you have any questions

about the operation of your boiler or system.

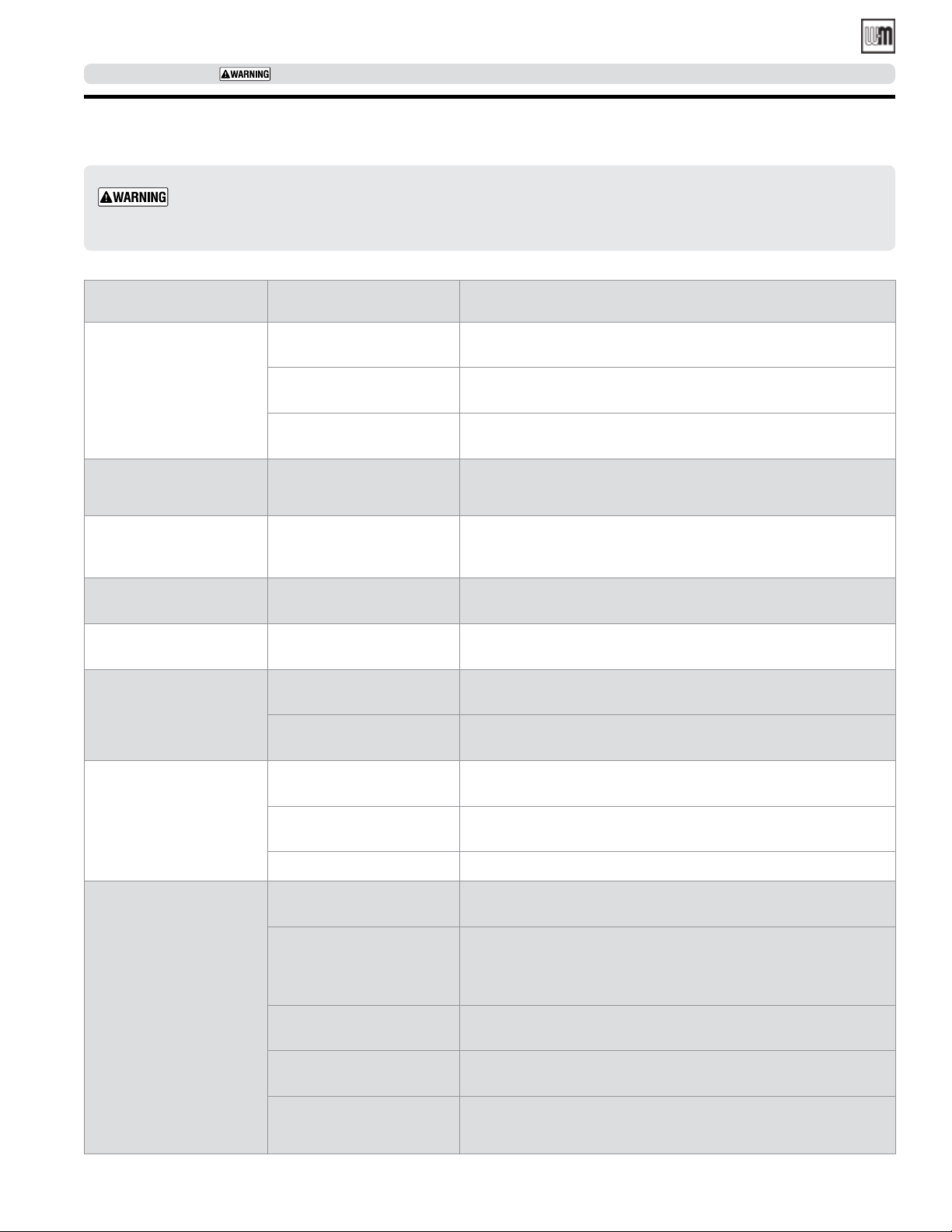

Common Problems Common Causes Possible Corrections

Rapid cycling — burner

turns on and off frequently.

Need to frequently add

makeup water.

Popping or percolating

noise heard in boiler.

Black water condition.

Frequent release of water

through relief valve.

Metal flakes found in

flueway.

Some radiators or

baseboard units do not

heat or are noisy.

Thermostat installed where

Locate thermostat on inner wall away from heat sources or cool drafts.

drafts or heat affect reading.

Heat anticipator in thermostat adjusted incorrectly.

Adjust heat anticipator to match current draw. Refer to boiler wiring

diagram.

Incorrect limit setting. Have qualified service technician increase limit setting to decrease

cycling. Maximum setting 220° F.

Leaks in boiler or piping. Have qualified service technician repair leaks at once to avoid constant

use of makeup water.

Mineral deposits in sections

due to constant use of makeup water, or incorrect pH.

Oxygen corrosion due to

leaks in piping.

Expansion tank sized too

Have qualified service technician de-lime boiler, repair leaks at once

to avoid constant use of makeup water and check pH (between 7.0

and 8.5).

Have qualified service technician repair leaks at once to avoid constant

use of makeup water and check pH (between 7.0 and 8.5).

Have qualified service technician check expansion tank operation.

small or water-logged.

Contaminated combustion

air supply.

Condensation of combustion

Remove sources of hydrocarbons in or near boiler area. (Bleaches,

cleaners, chemicals, sprays, fabric softeners, paint remover, etc.)

Have qualified service technician check boiler operation.

gases.

Air in system. Bleed air from system through air vents in radiators or baseboard units.

Low system pressure. Have qualified service technician check for leaks in boiler or piping

at once.

Domestic water from

tankless heater is hot then

suddenly turns cold.

OR

Domestic water from

tankless heater is always

lukewarm.

Part number 550-141-826/1211

High limit set too low. Have qualified service technician adjust limit to higher setting.

Mineral deposits insulate

Have qualified service technician delime or replace coil.

internal waterways of heater.

Boiler stop-leak compound

has been added to boiler wa-

Have qualified service technician remove and clean coil and drain,

and flush boiler to remove stop-leak.

ter and is insulating outside

of coil.

Incorrect mixing valve setting

Have qualified service technician adjust mixing valve setting.

for tankless heater.

Domestic flow rate too high. Have qualified service technician install flow check valve set to rating

of tankless heater.

Incorrect setting on tankless

heater control.

Have qualified service technician raise tankless control setting. Adjust

differential on tankless control to lower setting.

7

Page 8

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

SERVICE TECHNICIAN ONLY — read and follow completely.

Before installing boiler

Homeowner — STOP! The procedures and information on this and following pages are intended only for a quali-

fied service technician who has the necessary equipment to inspect and adjust boiler and burner. A homeowner

should never attempt these procedures. The service technician must also read pages 1 through 7 before proceeding.

Installations must comply with

• United States

• State and local plumbing, heating and electrical codes.

• National codes where applicable.

• Canada

• Canadian Standards Association, CSA B139, Installation Code for Oil-

Burning Equipment.

• CSA C22.1 Canadian Electrical Code Part One.

• Applicable local or provincial codes.

Before selecting boiler location

Check for nearby connections to:

• System water piping.

• Chimney. See page 16. Boiler can be top or back vented.

• Combustion and ventilation air supply. See page 9.

• Oil supply. See page 26 for oil line routing.

• Electrical power.

• Check area around boiler. Remove any combustible materials, gasoline

and other flammable liquids.

Failure to keep boiler area clear and free of combustible materials, gasoline and other flammable liquids and vapors

can result in severe personal injury, death or substantial property damage.

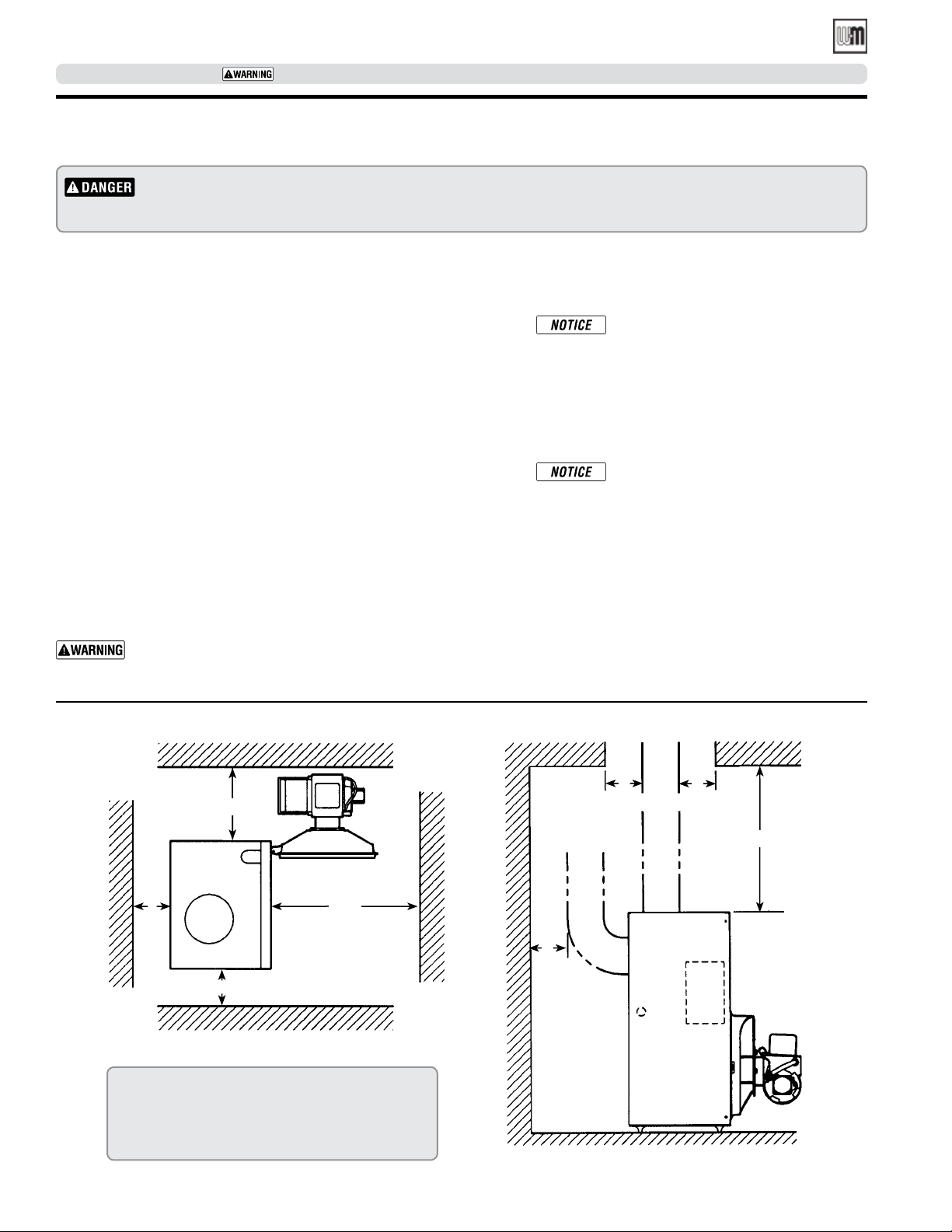

Figure 2 Recommended service clearances

Provide clearances around boiler

(see Figure 2)

Jacket cap must be in place on boiler to

avoid requiring an 9" minimum clearance

from back or top of boiler to combustible

material.

• MINIMUM clearances from vent pipe to

combustible material

• 6 inches — Type “L” double-wall vent*

• 9 inches — Single-wall vent*

Flue pipe clearances must take precedence

over jacket clearances.

• Recommended SERVICE clearances

• 24 inches — Front and top

• 6 inches — Left side, back and right side

• 12 inches — Right side for burner door

swing radius

• Special close clearances (alcove, closet, under counters, etc.) — see Appendix, page 32.

Walls

B

A

A

A

Top View

A Provide 6" minimum clearance for service, provide 12"

minimum clearance for burner door swing.

B Minimum clearance from vent pipe to combustible mate-

rial: 6" for type “L” double-wall vent, 9" for single-wall

vent.

8

24"

B

Wall

Left side

B

24"

Part number 550-141-826/1211

Ceiling

Floor

Page 9

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

SERVICE TECHNICIAN ONLY — read and follow completely.

Before installing boiler (continued)

Provide air for combustion and

ventilation

Do not install exhaust fan in boiler room.

Adequate combustion and ventilation air:

• Assures proper combustion.

• Reduces risk of severe personal injury or death from

possible flue gas leakage and carbon monoxide

emissions.

Older buildings with single-pane windows, minimal

weather-stripping and no vapor barrier often provide

enough natural infiltration and ventilation without

dedicated openings.

New construction or remodeled buildings are most

often built tighter. Windows and doors are weatherstripped, vapor barriers are used and openings in

walls are caulked. As a result, such tight construction

is unlikely to allow proper natural air infiltration and

ventilation.

Follow state, provincial or local codes when sizing

adequate combustion and ventilation air openings. In

absence of codes, use the following guidelines when

boiler is in a confined room (defined by NFPA 31 as

as less than 7200 cubic feet per 1 GPH input of all appliances in area. A room 8 ft. high x 33.5 ft. x 33.5 ft.

is 7200 cu. ft.).

Permanent Openings

Provide two permanent openings, one within 12 inches

of ceiling, one within 12 inches of floor. Minimum

height or length dimension of each rectangular opening

should be at least 3 inches.

Inside air

When inside air is used, each opening must freely

connect with areas having adequate infiltration from

outside. Each opening should be at least 140 sq. in. per

1 GPH input (1 sq. in. per 1000 Btu input) of all fuelburning appliances plus requirements for any equipment that can pull air from room (including clothes

dryer and fireplace).

Outside air

When outside air is used, connect each opening directly

or by ducts to the outdoors or to crawl or attic space

that freely connects with outdoors. Size per below:

• Through outside wall or vertical ducts — at least

35 sq. in. per 1 GPH input (1 sq. in. per 4000 Btu

input) of all fuel-burning appliances plus requirements for equipment that can pull air from room

(including clothes dryer and fireplace).

• Through horizontal ducts — at least 70 sq. in. per 1

GPH boiler input (1 sq. in. per 2000 Btu input) of all

fuel-burning appliances plus requirements for any

equipment that can pull air from room (including

clothes dryer and fireplace).

Where ducts are used, they should have same crosssectional area as free area of openings to which they

connect. Compensate for louver, grille or screen blockage when calculating free air openings. Refer to their

manufacturer’s instructions for details. If unknown,

use:

• Wood louvers, which provide 20-25% free air.

• Metal louvers or grilles, which provide 60-75%

free air.

Lock louvers in open position or interlock with equipment to prove open before boiler operation.

Foundation

Lay a foundation, if needed. Boiler may be installed

on non-carpeted combustible flooring. Solid concrete

blocks can be used to create a pad.

For residential garage installation, install boiler so

burner is at least 18 inches above floor to avoid contact

with gasoline fumes.

A level concrete or masonry foundation is required

when:

• Floor could possibly become flooded.

• Non-level conditions exist.

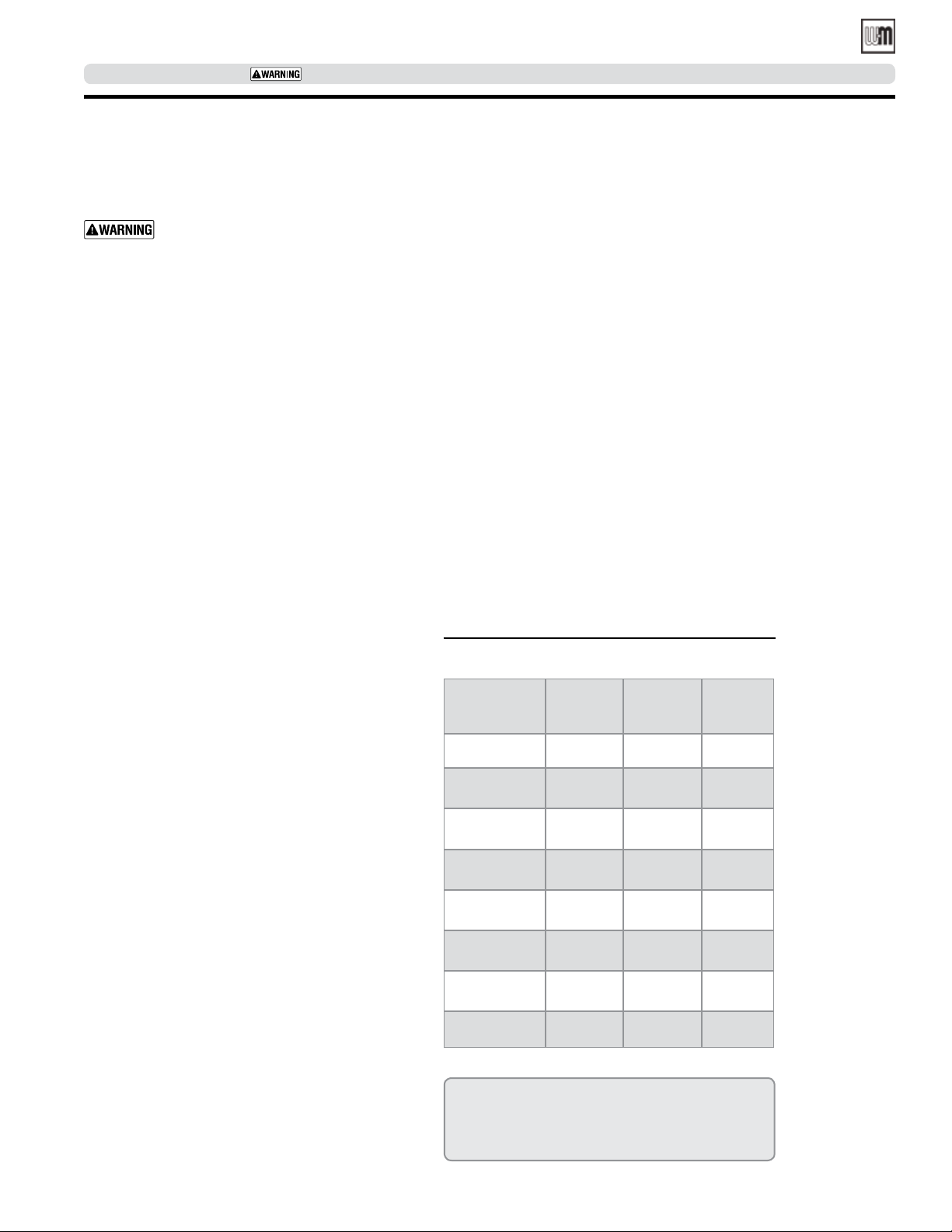

Table 1 Boiler foundation sizes

Boiler

model

WGO-2

WGO-3

WGO-4

WGO-5

WGO-6

WGO-7

WGO-8

WGO-9

Length

inches

14 22 2

17 22 2

17 22 2

20 22 2

23 22 2

26 22 2

29 22 2

32 22 2

Width

inches

Installation instructions:

Packaged boiler — Continued on page 10

Non-packaged boiler — Continued on page 12

Min.

height

inches

Part number 550-141-826/1211

9

Page 10

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

SERVICE TECHNICIAN ONLY — read and follow completely.

Install boiler — packaged boilers only

Place boiler

1. Remove circulator strapped to pallet.

Circulator will be damaged if not removed before boiler is

lifted from pallet.

2. Remove boiler from pallet.

Do not drop boiler or bump jacket on floor or pallet. Damage

to boiler can result.

Smaller sized boilers may be top heavy. Use caution when

handling to avoid minor personal injury or property damage.

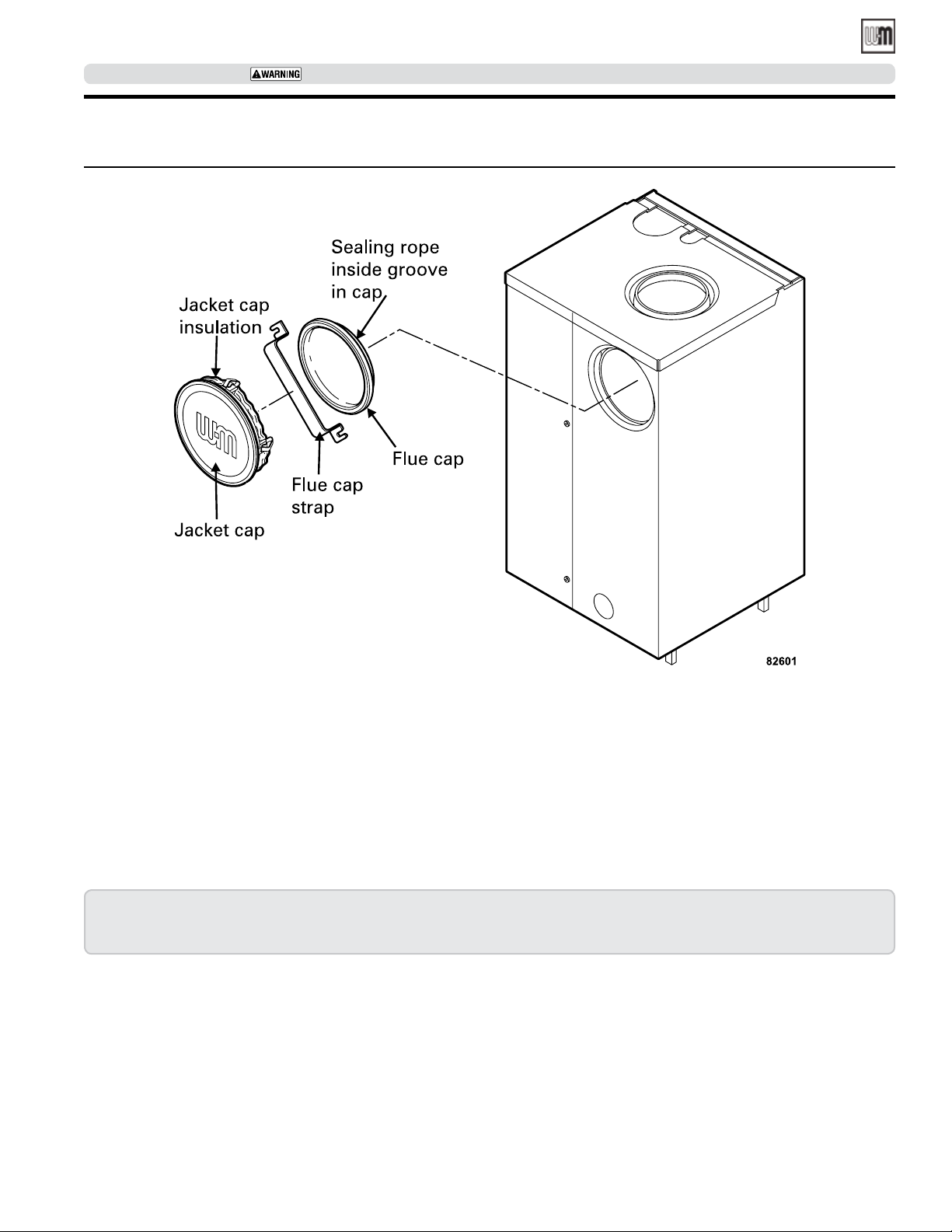

3. Boiler is shipped for back flue outlet. To change to top flue outlet (see

Figure 3, page 11):

a. Remove jacket cap on top of boiler.

b. Loosen two screws holding flue cap strap to collector hood. Remove

strap and flue cap from opening. Re-tighten screws.

c. Check rope placement inside flue cap.

(Read

d. Loosen two screws on back flue outlet. Set flue cap on outlet. Install

e. Snap jacket cap in back outlet opening.

4. Check level. Shim legs, if needed.

5. Check for secure placement of insulation on target wall, chamber floor

and burner door.

6. Visually check:

a. Flue collector hood seal.

b. Burner mounting door seal.

under step #6 below).

strap by engaging slots in screws. Tighten screws. Make sure cap is

securely installed.

Jacket cap must be in place on boiler to avoid requiring an 18”

minimum clearance from back or top of boiler to combustible

material.

Obtain gas-tight seal to prevent possible flue gas leakage

and carbon monoxide emissions, which can lead to severe

personal injury or death.

Perform hydrostatic pressure test

1. Remove relief valve installed in boiler.

2. Install air vent in “N” tapping on top boiler.

3. Plug supply and return tappings.

4. Drain valve is already factory-installed.

5. Fill boiler. Vent all air. Pressure test boiler at 1½

times working pressure.

Do not leave boiler unattended. Cold

water fill can expand and damage cast

iron, resulting in severe personal injury,

death or substantial property damage.

6. Check for maintained gauge pressure for more

than 10 minutes. Visually check for leaks if gauge

pressure drops.

7. Drain boiler. Repair leaks if found.

Do not use petroleum-based sealing

compounds to repair leaks. Damage to

system components can result, causing

property damage.

8. Retest boiler after repairing leaks.

9. Remove air vent and plugs. Reinstall relief valve.

10

Part number 550-141-826/1211

Page 11

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

SERVICE TECHNICIAN ONLY — read and follow completely.

Install boiler — packaged boilers only (continued)

Figure 3 Change from back flue outlet to top flue outlet (optional)

Part number 550-141-826/1211

Instructions for packaged boilers continued on page 15.

11

Page 12

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

SERVICE TECHNICIAN ONLY — read and follow completely.

Install boiler — non-packaged boilers only

Fiberglass wool and ceramic fiber ma-

terials are possible cancer hazards. See

warning on page 31.

Place boiler

Non-Packaged WGO-2 through 6 —

position on site

Smaller sized boilers may be top heavy.

Use caution when handling to avoid minor personal injury or property damage.

Boiler is shipped for back flue outlet. To change to top

flue outlet (see Figure 3):

1. Loosen two screws holding flue cap strap to collector hood. Remove strap and flue cap from opening.

Re-tighten screws.

2. Check rope placement inside flue cap.

(Read

3. Loosen two screws on back flue outlet. Set flue cap

on outlet. Install strap by engaging slots in screws.

Tighten screws. Make sure cap is securely installed.

under Step #3 on page 13.)

Non-Packaged WGO-7, 8 & 9 — split the assembled

block for easier handling (see Figure 4, page 13)

1. Open burner mounting door and, using utility knife, slit floor insulation at joint to be separated.

2. Remove 5½" draw rod and the longest draw rod from each side. Pull

block apart. Save draw rods, nuts, washers and sealing rings for reassembly.

3. Move divided block to location.

4. Clean port openings with clean rag.

Do not use petroleum-based compounds to clean openings.

Damage to system components can result, causing property

damage.

5. Place rings in port openings. If ring slips out of groove, stretch ring

gently for several seconds, then place in groove.

6. Position sections so aligning lugs fit into sockets of next section. Make

sure sealing rope is in good condition and in position.

7. Oil threads on draw rods. Install washer and nut on end to be tightened.

Use nut only on other end.

8. With wrench at washer/nut end, uniformly tighten nuts starting with

5½" rod at large port, 5½" rod at small port, bottom long rod and

finally top long rod.

9. Torque on both 5½" rods and bottom long rod should be 50-60 ft. lbs;

long top rod should be 20-25 ft. lbs. Do not back-off nuts.

10. Metal-to-metal contact should be made around port openings. If gap

does exist, it should be less than .020". Check with feeler gauge.

11. If gap around port openings exceeds .020", check for dirt on port

openings, sockets or misaligned lugs. If corrections are made and gap

still exists, contact your Weil-McLain distributor or sales office before

continuing installation.

12

Part number 550-141-826/1211

Page 13

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

SERVICE TECHNICIAN ONLY — read and follow completely.

Install boiler — non-packaged boilers only (continued)

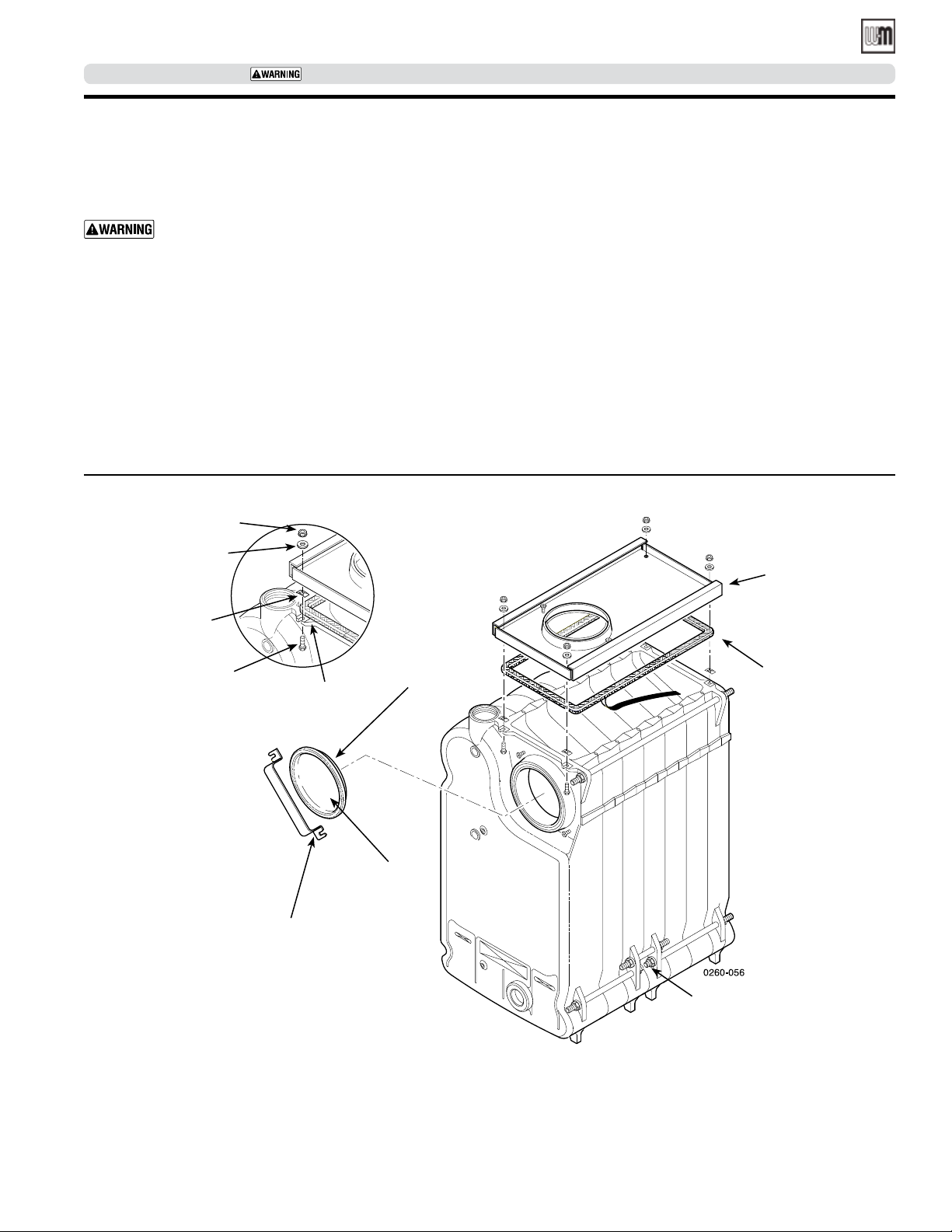

Non-Packaged WGO-7, 8 & 9 — install flue

collector hood

Obtain gas-tight seal to prevent possible flue gas

1. Thread tinnerman clip on screw so that clip fits snugly in

notch of hold-down lug. Screw must not turn.

2. Remove paper on sealing rope. Starting at back section near

flue collar, position sealing rope around top of block with

adhesive side to sections. Do not stretch rope. Make sure rope

ends meet. Trim excess rope.

3. Position flue collector hood on top of boiler sections and

over screws and clips as shown in Figure 4.

Figure 4 Change from back flue outlet to top flue outlet (optional)

Tinnerman

(see Figure 4)

leakage and carbon monoxide emissions, leading

to severe personal injury or death.

Nut

Washer

clip

Screw

Hold-down

lug

Sealing

rope in

groove

inside cap

4. Install washers and nuts. Tighten nuts until collector hood

makes contact with tinnerman clip.

5. Flue Cap

• Back flue outlet boiler — Position flue cap and strap over

opening in flue collector hood. Make sure rope in cap is

in place and in good condition. Tighten strap to hood

with screws provided.

• Top flue outlet boiler — Position flue cap and strap over

opening in back section. Make sure rope in cap is in place

and in good condition. Tighten strap to boiler with screws

provided in section. Install remaining screws in holes in

flue collector hood.

6. Check level. Shim legs, if needed.

Flue

collector

hood

Sealing

rope with

adhesive

tape

Part number 550-141-826/1211

Flue

cap

Flue cap

strap

Separate

block here

for easier

handling

13

Page 14

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

SERVICE TECHNICIAN ONLY — read and follow completely.

Install boiler — non-packaged boilers only (continued)

Perform hydrostatic pressure test

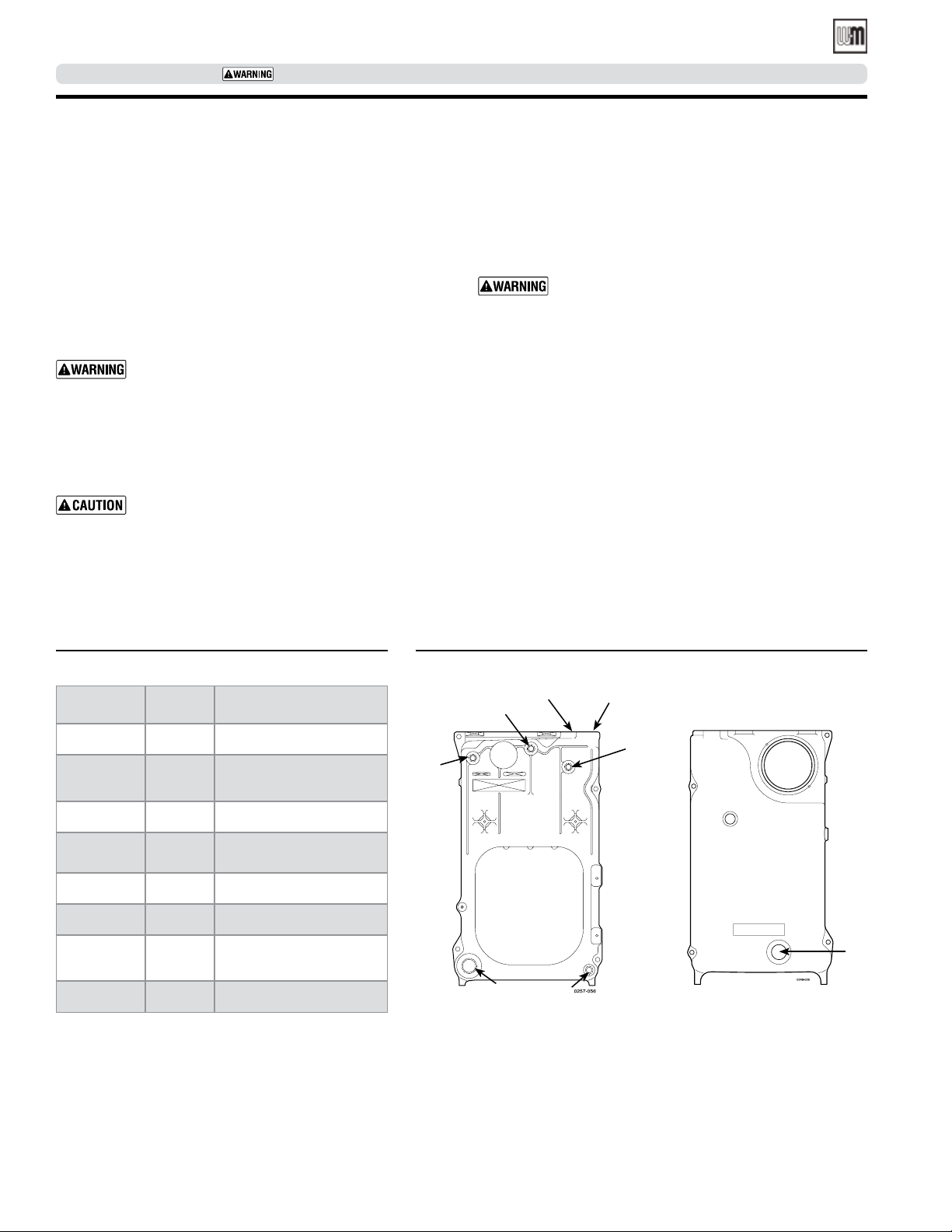

1. See Figure 5 and Control Tapping table to install:

a. Boiler drain.

b. Water pressure gauge (test only). Be sure gauge can

handle test pressure.

c. Air vent in upper “N” tapping.

d. Plugs in remaining tappings.

2. Fill boiler. Vent all air. Pressure test boiler at 1 times working pressure. For boilers split and reassembled, test between

75 and 85 psig.

Do not leave boiler unattended. Cold water fill

could expand and damage cast iron, resulting in

severe personal injury, death or substantial property damage.

3. Check for maintained gauge pressure for more than 10 minutes. Visually check for leaks if gauge pressure drops.

4. Drain boiler. Repair leaks if found.

Do not use petroleum-based compounds to repair

leaks. Damage to system components can result,

causing property damage.

5. Re-test boiler after repairing leaks.

6. Remove pressure gauge, air vent and plugs from tappings

used for controls.

7. Visually check:

a. Sealing rope placement.

b. Metal-to-metal contact around port openings.

c. Flue collector hood seal.

d. Burner mounting door seal.

Obtain gas-tight seal to prevent possible flue gas

leakage and carbon monoxide emissions, which

can lead to severe personal injury or death.

Install jacket

(sizes 7 through 9 only)

Before installing jacket, remove burner mounting door. See jacket

instructions for details.

Install boiler controls

See Control Tapping Table and Figure 5 and Figure 6, page 15

to install controls.

1. Install limit control. If not furnished, use high limit with

maximum 220°F setting.

2. Affix CP number label(s) on jacket front panel.

Table 2 Control tappings

Location Size Function

B1 1½" Return piping

B2 1½"

C 1½" Supply piping

E3 ¼"

H ¾" Drain valve

L ¾" High limit control

N ½"

R1 ¾" Relief valve

Alternate return piping for

A/B WGO

Pressure-temperature

gauge

Air vent or expansion

tank piping

Figure 5 Control tapping locations

R1

N

E3

B1

Front section

H

C

L

B2

Back section

14

Part number 550-141-826/1211

Page 15

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

SERVICE TECHNICIAN ONLY — read and follow completely.

Install burner — all boilers

Install burner

(also refer to instructions packed with

burner)

Use only burners specified for use on

Weil-McLain GOLD oil boilers. DO

NOT use burners specified for use on

Weil-McLain Model 68 boilers. Contact

individual burner manufacturers for

proper burner selections.

Figure 6 Water boiler controls

Circulator

Relief

valve

For P-WGO and A-WGO boiler:

1. Secure universal mounting flange and gasket to burner mounting door.

Use three bolts provided.

2. Secure burner on flange with three bolts.

3. Position burner so end of air tube is level to 1½° tilt downward. Open

door to verify burner position. End of air tube should be flush to ¼"

recessed from inside wall of burner door refractory. Check for secure

placement of insulation on target wall, chamber floor and burner

mounting door. Securely close door with nut.

Water

pressure-temperature

gauge

Limit control / low water cut-off

Drain valve

Part number 550-141-826/1211

15

Page 16

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

SERVICE TECHNICIAN ONLY — read and follow completely.

Connect breeching

General chimney requirements

• Designed for natural draft firing. Connect boiler to vertical chimney.

• Insufficient draft can cause flue gas leakage and carbon monoxide

emissions, which will lead to severe personal injury or death.

• Use vent material approved by local codes for oil-fired burners. In their

absence, refer to:

• NFPA 31, Installation of Oil-Burning Equipment.

• NFPA 211, Standard for Chimneys, Fireplaces, Vents and Solid Fuel

Burning Appliances.

• In Canada, refer to CSA B139, Installation Code for Oil-Burning

Equipment.

• NFPA 211 requires chimney to be lined before connected to boiler.

• Inspect existing chimney before installing new boiler. Failure to do any

of the following will result in severe personal injury or death:

• Clean chimney, including removal of blockage.

• Repair or replace damaged pipe or liner.

• Repair mortar and joints.

• To prevent downdrafts, extend chimney at least 3 feet above highest

point where it passes through roof and 2 feet higher than any portion

of building within 10 feet. Increase chimney cross-sectional area and

height at least 4% per 1,000 feet above sea level.

• Minimum clearances from vent pipe to combustible material:

• 6 inches — Type “L” double-wall vent

• 9 inches — Single-wall vent

• Minimum chimney sizes should be used.

Table 3 Minimum chimney sizes

Boiler

model

number

WGO-2

WGO-3

WGO-4

WGO-5

WGO-7

WGO-8

WGO-9

Note 1 6¾" x 6¾" inside liner

Note 2 6½" x 10½" inside liner

Minimum

breeching

diameter

(note 3)

5"

6"

6"

7"

7"

Minimum

I=B=R

chimney size

Rect. Round

8" x 8"

(note 1) 6" 15'

8" x 8"

(note 1) 7" 15'WGO-6

8" x 12"

(note 2)

Minimum

chimney

height

7" 20'

Oversized chimneys, outside masonry chimneys and/or

derated inputs can result in condensation in chimney.

Connect breeching:

Long horizontal breechings, excessive number of tees and

elbows or other obstructions restricting combustion gas flow

can result in possibility of condensation, flue gas leakage

and carbon monoxide emissions, which can lead to severe

personal injury or death.

1. Install 2 flue pipe brackets.

2. Connect full-sized breeching when possible. See Minimum Chimney

Size Table.

• Back outlet — see Figure 7, page 17.

• Top outlet — see Figure 8, page 17.

3. Connection must be made above bottom of chimney to avoid blockage.

Breeching must not enter chimney far enough to cause obstruction.

Use thimble or slip joint where breeching enters chimney to allow

removal for cleaning.

Note 3 Flue collar on boiler is 7" diameter

4. When burner and boiler are properly installed, draft

overfire will be approximately -0.01" to -0.02" W.C.

Install barometric control in breeching, per control

manufacturer’s instructions, when excess draft

needs to be relieved or to comply with applicable

codes and regulations. Use draft gauge to adjust

proper opening.

5. An induced draft fan for the chimney may be

necessary if:

• Excessive resistance to flow of combustion gases

can be expected.

• Cross-sectional area of chimney is smaller than

minimum recommended.

• Chimney height is less than recommended.

Seal all vent joints. Interlock burner with

fan operation.

16

Part number 550-141-826/1211

Page 17

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

SERVICE TECHNICIAN ONLY — read and follow completely.

Connect breeching (continued)

Figure 7 Back outlet breeching connection

Typical location for

barometric control

(Also see control

manufacturer’s

instructions)

Figure 8 Top outlet breeching connection

Flue pipe

bracket

(One on each

side of pipe)

Typical location for barometric

control

(Also see control manufacturer’s

instructions)

Flue pipe bracket

(One on each side of pipe)

Part number 550-141-826/1211

17

Page 18

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

SERVICE TECHNICIAN ONLY — read and follow completely.

Connect water piping

General piping information

• All packaged WGO boilers are shipped with an installed

combination temperature limit control/low water cut-off.

• If installation is to comply with ASME or Canadian

requirements, an additional high temperature limit is

needed. Install control in supply piping between boiler

and isolation valve. Set control to a minimum of 20°F

above set point of combination control. Maximum allowable set point is 220°F. Wire control as shown on

wiring diagram.

• Use backflow check valve in cold water supply as required

by local codes.

Install piping

• See Figure 9 or Figure 10, page 19, and Table 4, page 18

for near-boiler piping and single-zone piping. See page 20

to complete multiple-zone piping or page 21 to complete

piping for systems operating below 140°F.

• For multiple-boiler piping, refer to Weil-McLain’s “Primary/Secondary Piping Guide” and “M-WGO Multiple

Boiler Manual.”

• Install relief valve vertically in “R1” tapping on front

of boiler. See Figure 9 or Figure 10 and also refer to tag

attached to relief valve for manufacturer’s instructions.

Pipe relief valve discharge line near floor close

to floor drain to eliminate potential of severe

burns. Do not pipe to any area where freezing

could occur. Do not plug, valve or place any

obstruction in discharge line.

CLOSED expansion tank

(Figure 10, page 19)

• Ensure expansion tank size will handle boiler and

system water volume and temperature.

Undersized expansion tanks cause system

water to be lost from relief valve and

makeup water added through fill valve.

Eventual section failure can result.

• Connect tank from “N” tapping shown in Figure

9 to expansion tank. Use ½" N.P.T. piping. Pitch

any horizontal piping up towards tank 1 inch per

5 feet of piping.

To connect WGO boilers to

indirect-fired water heaters

Install and wire per water heater manual provided with

water heater.

Table 4 Water piping sizes

Boiler model

number

WGO-2 1" 1"

To system From system

DIAPHRAGM expansion tank

(Figure 9, page 19)

• Make sure expansion tank size will handle boiler and

system water volume and temperature. Tank must be

located near boiler before inlet to circulator. See tank

manufacturer’s instructions for details.

• Undersized expansion tanks cause system water to be lost

from relief valve and makeup water added through fill

valve. Eventual section failure can result.

• Install automatic air vent in “N” tapping as shown in

Figure 9.

WGO-3 1¼" 1¼"

WGO-4 1¼" 1¼"

WGO-5 1½" 1½"

WGO-6 1½" 1½"

WGO-7 1½" 1½"

WGO-8 2" 2"

WGO-9 2" 2"

* All piping sizes based on 20°F

temperature rise through boiler.

18

Part number 550-141-826/1211

Page 19

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

SERVICE TECHNICIAN ONLY — read and follow completely.

Connect water piping (continued)

Figure 9 Piping with DIAPHRAGM expansion tank

Circulator

Automatic

air vent

From

Isolation

valve

Cold water

fill

To diaphragm

expansion tank

and fittings

Circulator

(Alternate circulator location)

system

Isolation

valve

To system

“C” tapping

“N” tapping

Relief

valve

“B1” tapping

Figure 10 Piping with CLOSED expansion tank

Circulator

From

system

Isolation

valve

(Alternate circulator location)

Circulator

“B1” tapping

Closed type expansion tank

Cold water fill

Isolation valve

To system

“C” tapping

“N” tapping

Relief

valve

Part number 550-141-826/1211

19

Page 20

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

SERVICE TECHNICIAN ONLY — read and follow completely.

Connect water piping (continued)

Piping MULTIPLE ZONES

1. Follow instructions on page 18 and page 19 to

install piping near boiler.

2. See Figure 11 or Figure 12 to complete installation

3. Zoning with circulators:

a. Size each circulator to individual circuit re-

quirements.

b. Remove circulator (when furnished as standard

equipment).

c. Install balancing valves to adjust flow to distrib-

ute heat to all zones.

d. Separate relay is required for each circulator.

4. Zoning with zone valves:

a. Install balancing valves to adjust flow to distrib-

ute heat to all zones.

b. Separate transformer is required to power zone

valves. Refer to “Weil-McLain Zone Valve Wiring Guide” for details.

Figure 11 Multiple zoning with CIRCULATORS

Zone 2

Zone 1

1

2

1

5

1

2

3

1

5

Legend

1 Isolation valve

2 Flow control valve

3 Circulator

4 Zone valve

5 Drain valve

Figure 12 Multiple zoning with ZONE VALVES

Zone 2

Zone 1

1

5

1

1

1

4

5

20

Part number 550-141-826/1211

Page 21

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

SERVICE TECHNICIAN ONLY — read and follow completely.

Connect water piping (continued)

Piping for systems requiring

temperatures below 140°F

In most systems, this type of piping is not required. If

system water temperature requirements are less than

140°F, such as radiant panels or converted gravity systems, use piping as shown in Figure 13 or Figure 14. If

system piping is plastic without an oxygen barrier, a

heat exchanger must be used.

Figure 13 Piping with CIRCULATORS

Legend

1 Isolation valve

2 Flow control valve

3 Circulator

4 System temperature

gauge

5 Zone valve

6 Drain valve

7 System temperature

valves

Adjust valves so that:

- the temperature at

gauge 8 is at least 140°F

- the temperature at

gauge 9 is at least 160°F

8 Blend temperature

gauge

9 Boiler temperature

gauge

Figure 14 Piping with ZONE VALVES

Part number 550-141-826/1211

21

Page 22

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

SERVICE TECHNICIAN ONLY — read and follow completely.

Connect water piping

(continued)

Use with refrigeration systems

• Install boiler so that chilled medium is piped in

parallel with heating boiler. Use appropriate valves

to prevent chilled medium from entering boiler.

Consult I=B=R Installation and Piping Guides.

• If boiler is connected to heating coils located in

air handling units where they can be exposed to

refrigerated air, use flow control valves or other

automatic means to prevent gravity circulation

during cooling cycle.

Figure 15 Use with refrigeration system

1

Supply

1

Circ.

Chiller

Strainer

Exp. tank

Circ.

Connect wiring

General wiring requirements

Electric shock hazard. Can cause severe personal injury or

death if power source, including service switch on boiler, is

not disconnected before installing or servicing.

• Installations must follow these codes:

• National Electrical Code, ANSI/NFPA 70, latest edition and

any additional national, state or local codes.

• In Canada, CSA C22.1 Canadian Electrical Code Part 1 and any

local codes.

• Wiring must be N.E.C. Class 1. If original wire as supplied with boiler

must be replaced, type 105°C wire or equivalent must be used. Supply

wiring to boiler and additional control wiring must be 14 ga. or heavier.

• Provide electrical ground at boiler as required by codes.

Thermostat wiring

• Install thermostat on inside wall away from influences of drafts, hot

or cold water pipes, lighting fixtures, television, sun rays or fireplaces.

• Follow instructions with thermostat. If it has a heat anticipator, set

heat anticipator in thermostat to match power requirements of equipment connected to it. Boiler wiring diagrams give setting for standard

equipment.

Exp. tank

1 Isolation valve 2 Balancing valve

1

1

2

Zone Valve Wiring

DO NOT connect directly from 3-wire zone valves

to the T-T terminals on the boiler

zone valves, install an isolation relay. Connect the zone

valve end switch wires to the isolation relay coil. Connect

the isolation relay contact across the boiler T-T terminals. Failure to comply can result in damage to boiler

components or cause unreliable operation, resulting in

possible severe property damage.

4- wire zone valves may be connected directly to the boiler control.

. When using 3-wire

22

Part number 550-141-826/1211

Page 23

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

SERVICE TECHNICIAN ONLY — read and follow completely.

Connect wiring (continued)

Junction box (furnished)

• Junction box houses electrical connections for all

boiler components.

• “P” boilers have harnesses furnished.

• “A” boilers are furnished with burner and limit

harnesses.

• All field-provided high voltage wiring must be

sheathed in flexible metal conduit.

• Connect incoming line voltage “HOT” wire to

service switch, and neutral wire to white wire.

Field-install equipment ground wire to green wire

with wire nut.

• Service switch (15 amp) is provided with boiler. “A”

boilers — install switch as shown.

• Some local codes may require an emergency shutoff switch installed at a location away from boiler.

Follow local codes.

Burner wiring

• Burner harness incorporates a disconnect plug,

providing a convenient way to disconnect wiring

when burner mounting door is opened.

• All “P” boilers have a power disconnect plug installed on burner.

• On “A” boilers, mount the plug (provided in water

trim carton) on the burner housing as shown in

Figure 16. For Carlin burners, screw burner plug

into threaded conduit coupling, then mount this

assembly to the burner housing using the chase

nipple. Route wires through housing and make

connections in burner junction box as shown in

boiler wiring diagram.

High temperature limit

• To comply with ASME, UL 726 or Canadian requirements, an additional

high temperature limit is needed.

• Install the secondary control in the supply piping between boiler and

isolation valve.

• Set the control to a minimum of 20˚F above the set point of the combination control.

• The maximum allowable set point is 220˚F.

• Wire the control as shown on page 24.

Figure 16 Boiler wiring for forced hot water

Limit control

wiring harness

Service

switch

on

boiler

Burner

wiring

harness

Circulator

wiring

harness

(not

furnished

on “A”

boilers)

Part number 550-141-826/1211

Burner

disconnect plug

23

Page 24

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

SERVICE TECHNICIAN ONLY — read and follow completely.

Connect wiring (continued)

Figure 17 Wiring diagram

24

Part number 550-141-826/1211

Page 25

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

SERVICE TECHNICIAN ONLY — read and follow completely.

Connect wiring —

blocked vent shutoff switch option

Blocked vent shutoff switch

In Canada, blocked vent shutoff switch kit

(see parts list page 34) must be installed.

See Figure 18. The wiring diagram in

Figure 19 shows boiler wiring only up

to the burner disconnect. For additional

information, refer to manufacturer’s

instructions.

Electric shock hazard. Turn off electrical

power supply at service entrance panel

before making any electrical connections

to avoid possible electric shock hazard.

Failure to do so can cause severe personal

injury or death.

After installing BVSS switch, proceed as follows:

1. Disconnect power.

2. Install Spill Switch (BVSS) Wiring Harness (P/N 591-391-942) as follows:

a. Remove cover from BVSS Box.

b. Install straight fitting end of the harness on the BVSS Box. Install

elbow (90º) end fitting on the Boiler Junction Box (see Figure 18).

c. Install both the fork ends to the screw terminals on the BVSS Switch

as per the wiring diagram, (see Figure 19).

d. Replace BVSS box cover.

e. Locate Combination Control, remove cover, and disconnect red

wire from “B1” terminal.

f. If red wire from Step “e” has uninsulated female end, replace it

with insulated female end as supplied in kit.

g. Connect female end of Spill Switch BVSS Harness (blue wire) to

“B1” terminal.

h. Connect male end of Spill Switch BVSS Harness to the red wire

removed in Step “e”.

i. Replace Combination Control Cover.

3. Turn on power and verify safe operation of the appliance.

4. Restore boiler to normal operation.

Figure 18 Blocked vent shutoff switch installation Figure 19 BVSS wiring diagram

120 vac

field wiring

Low voltage

field wiring

120 vac

factory wiring

Low voltage

factory wiring

Part number 550-141-826/1211

25

Page 26

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

SERVICE TECHNICIAN ONLY — read and follow completely.

Connect oil piping

General oil piping requirements

• Location and installation of oil tanks, oil piping

and burners must follow:

• NFPA 31, Standard for the Installation of Oil-

Burning Equipment.

• In Canada, CSA B139, Installation of Oil-

Burning Equipment.

• Local codes and regulations.

• Information provided with burner and fuel

pump.

• If any part of fuel oil tank is above level of burner,

installation of an anti-siphon device is highly recommended to be used to prevent flow of oil in case

of oil line break.

• Support oil lines as required by codes.

• Make tank connections with swing joints or copper

tubing to prevent breaking in case the tank settles.

Make swing joints so they will tighten as tank settles.

Non-hardening pipe joint compounds should be

used on all threads.

Figure 20 Recommended oil piping connection to burner

Do not use Teflon tape as an oil pipe

sealant. It can cause valves to fail, creating

hazards. Do not use compression fittings.

• Underground pipe must be run in a casing to prevent oil leaking into ground or under floor. Check

local codes for information.

Oil piping connection at burner

See Figure 20 for recommended connection at burner,

allowing burner mounting door to swing open completely for servicing.

26

See local codes for

appropriate arrangement and

piping of filter control valves,

etc., back to oil tank

Flare fitting

Part number 550-141-826/1211

Page 27

GOLD

WGO

Start-up

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

SERVICE TECHNICIAN ONLY — read and follow completely.

Fill the system

1. Close manual and automatic air vents and boiler

drain cock.

2. Fill to correct system pressure. Correct pressure will

vary with each installation. Normal cold water fill

pressure for residential systems is 12 psig. Boiler

water pH 7.0 to 8.5 is recommended.

Failure to maintain recommended pH

level can cause section failure and leaks.

3. Open automatic air vent one turn.

4. Open other vents.

a. Starting on the lowest floor, open air vents one

at a time until water squirts out. Close vent.

b. Repeat with remaining vents.

5. Refill to correct pressure.

When using antifreeze

Do not use automotive, ethylene glycol,

undiluted or petroleum-based antifreeze.

Severe personal injury, death or substantial property damage can result.

• Use antifreeze especially made for hydronic systems.

Inhibited propylene glycol is recommended.

• 50% solution provides protection to about -30°F.

Do not exceed 50% mixture.

• Local codes may require back-flow preventer or

actual disconnect from city water supply.

• Determine quantity according to system water content. Boiler water content is listed on back cover of

manual. Percent of solution will affect sizing of heat

distribution units, circulator and expansion tank.

• Follow antifreeze manufacturer’s instructions.

• Do not add cold water to hot boiler. Thermal shock

can cause sections to crack.

To place in operation

1. Verify boiler is filled with water.

2. Open burner mounting door and verify rear target wall, floor and burner door insulations are in

proper position.

3. Verify burner mounting door is closed tightly and

burner wiring harness is connected to junction box.

4. Factory burner adjustment and settings may not be

suitable for specific job conditions. See Appendix,

page 32.

Make final burner adjustments using

combustion test equipment to assure

proper operation. Do not fire boiler

without water. Sections will overheat,

damaging boiler and resulting in substantial property damage.

5. Vent air from system. Repeat steps 4 and 5 under

“Fill the system.” Air in system can interfere with

water circulation and cause improper heat distribution.

6. Check boiler and system piping for leaks. See “Tips

for water systems” on page 4.

7. Inspect breeching and venting for proper operation.

Part number 550-141-826/1211

27

Page 28

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

SERVICE TECHNICIAN ONLY — read and follow completely.

Check-out procedure

Check off steps as completed

Boiler and heat distribution units filled with water?

Automatic air vent, if used, opened one full turn?

Air purged from system? Piping checked for leaks?

Air purged from oil piping? Piping checked for leaks?

Flue cap in place and tightened? Burner door closed, sealed

and nut tight? Burner plugged in and service switch on?

Obtain gas-tight seal to prevent possible flue gas

leakage and carbon monoxide emissions, leading

to severe personal injury or death.

Proper draft and burner flame? Final adjustment made with

combustion test equipment?

Test limit control: While burner is operating, move indica-

tor on limit control below actual boiler water temperature.

Burner should go off while circulator continues to operate.

Raise setting on limit control above water temperature and

burner should re-ignite.

operation as outlined by the manufacturer. Burner should be

operating and should go off when controls are tested. When

controls are restored, burner should re-ignite.

Limit control set to system temperature requirements (max.

220°F)?

For multiple zones, flow adjusted to distribute heat in all

zones?

Thermostat heat anticipator setting (if available) set properly?

Refer to “Connect wiring,” page 22.

Boiler cycled with thermostat? Raise to highest setting and

verify boiler goes through normal start-up cycle. Lower to

lowest setting and verify boiler goes off.

Observed several operating cycles for proper operation?

Set room thermostat(s) to desired room temperature?

Completed Installation and Service Certificate below?

Reviewed pages 1–7 with owner or maintenance person and

instructed person to keep for future reference?

Test additional field-installed controls: If boiler has a low

water cutoff, additional high limit or other controls, test

Installation and service certificate

Date Installed: ____________________________

Boiler Model Number: _______ Series: ____________

CP Number(s): ___________________________

Measured Btu or GPH Input: ________________

Installer: ________________________________________________________________________________________________

(Company) (Address) (Phone)

_________________________________________

Returned all instructions provided with boiler to its envelope

and placed with boiler for future reference?

Installation instructions have been followed.

Check-out procedure has been performed.

Above information is certified to be correct.

Information received and left with owner/maintenance

person.

(Installer’s Signature)

28

Part number 550-141-826/1211

Page 29

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

SERVICE TECHNICIAN ONLY — read and follow completely.

Annual service check list

Annual Service Call

Checklist

(follow in order listed below)

Check that boiler area is free from

combustible materials, gasoline and

1

other flammable vapors and liquids.

Check for and remove any obstruction

to combustion and ventilation air flow

2

to boiler.

Check breeching and chimney or vent

for obstructions, damage, etc. Repair

3

or replace as necessary.

Clean boiler flueways. See Figure 21, page 30.

4

Dates Comments

Perform service on relief valve and

5

circulator. See page 30.

Check boiler and piping for leaks and

repair if found. Check for leaks at

tankless heater plate. Tighten nuts only

6

if leaks are found (for WGO torque to

20-25 ft.lbs.).

Inspect and adjust burner. See burner

manual and:

• change nozzle.

• check ignition electrode settings.

• clean blower housing and wheel.

7

• make sure blower wheel turns

freely.

• oil burner motor if required.

• clean air inlet.

• clean or change fuel filter and

strainer.

Make sure boiler is filled with water.

8

Start unit and verify combustion settings with combustion test equipment.

9

See page 28.

Verify operation of all controls on

10

boiler. See page 28.

Any parts of the boiler furnished by Weil-McLain must be replaced by parts listed in Weil-McLain Boiler and Repair Parts Book.

Controls requiring annual service

Water Relief Valve

Check operation of water relief valve.

Follow instructions on label fastened to

relief valve.

Part number 550-141-826/1211

Scald potential. Do not check

operation of relief valve unless discharge piping has

been installed according to

Boiler Manual. If piping is

not in place, a qualified service technician must properly install piping.

Circulator

Follow oil-lubricating instructions on circulator. Over-oiling will damage circulator.

Water-lubricated circulators do not need

oiling.

29

Page 30

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

SERVICE TECHNICIAN ONLY — read and follow completely.

Detailed service procedures

Cleaning boiler flueways

Make sure all electrical connections to boiler are turned

off and wait until boiler is warm, not hot, before cleaning. Failure to do so will result in severe personal injury,

death or substantial property damage.

1. Top flue boilers -remove breeching and jacket top panel.

Rear flue boilers - remove jacket top panel.

2. Remove flue collector hood, saving hardware for reassembly.

3. Shut off oil valves. Arrange drip pans under the areas of oil piping

that will be disconnected. Disconnect oil line at burner so that you

can swing open the door completely.

4. Line combustion chamber floor with newspaper to catch any soot

that will be loosened in the cleaning process.

5. Starting at the top of the boiler, use a wire flue brush to thoroughly

clean between all pins at all angles. Be careful not to damage side

walls of rear refractory.

6. Move to the bottom of the flueways and clean up between the

sections to reach pins left uncleaned in step #5.

7. Once the flueways are cleaned, carefully remove the paper from

the floor of the combustion chamber.

8. Verify sealing rope around flue area is intact. Visually check condition and

position of insulation in combustion chamber floor, and the refractories

at the rear of boiler and in the burner mounting door. Replace any parts

as necessary.

9. Close burner mounting door and tighten nut securely. Place flue

collector hood on top of boiler. Secure with hardware from step #2.

Figure 21 Thoroughly clean flueways between all pins

at all angles. Start on top of boiler, finish from

the bottom.

Maintain a gas-tight seal to avoid possible flue gas leak-

age and carbon monoxide emissions, which can lead to

severe personal injury or death.

10. Check breeching for sooting and clean if necessary. Install jacket

top panel and breeching.

11. Reconnect oil line and all electrical connections.

General description of control operation

Automatic air vent

Air is released when cap is unscrewed one turn. If air vent leaks, remove small cap on top of vent, push in stem of valve and then release

to clean valve seat. Screw cap completely on, then unscrew one turn.

Temperature limit control

If high boiler water temperature occurs, control shuts down burner, but

allows circulator to run as long as there is a call for heat. Limit should

be set higher than temperature needed for the system.

Maximum limit setting is 220°F.

Water relief valve

Provides discharge if boiler pressure exceeds 30 psig.

Circulator

Circulator provides forced water circulation through boiler

and piping system.

Pressure-temperature gauge

Provides reading of boiler pressure and temperature. Maximum boiler pressure is 50 psig, maximum water temperature is 220°F. Temperature will vary according to system

and daily heating demands. The range will be from room

temperature up to limit control setting.

30

Part number 550-141-826/1211

Page 31

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

SERVICE TECHNICIAN ONLY — read and follow completely.

Handling ceramic fiber and fiberglass materials

REMOVAL OF COMBUSTION CHAMBER

LINING OR BASE PANELS

The combustion chamber lining or base

insulation panels in this product contain

ceramic fiber materials. Ceramic fibers

can be converted to cristobalite in very

high temperature applications. The International Agency for Research on Cancer

(IARC) has concluded, “Crystalline silica

inhaled in the form of quartz or cristobalite

from occupational sources is carcinogenic

to humans (Group 1).”:

Precautionary measures

Avoid breathing fiberglass dust and contact with

skin or eyes.

• Use NIOSH certified dust respirator (N95).

This type of respirator is based on the

OSHA requirements for fiberglass wool at

the time this document was written. Other

types of respirators may be needed depending on the job site conditions. Current

NIOSH recommendations can be found on

the NIOSH web site at http://www.cdc.gov/

niosh/homepage.html. NIOSH approved respirators, manufacturers, and phone numbers

are also listed on this web site.

• Wear long-sleeved, loose fitting clothing,

gloves, and eye protection.

Apply enough water to the combustion chamber

lining or base insulation to prevent airborne dust.

Remove combustion chamber lining or base in-

sulation from the boiler and place it in a plastic

bag for disposal.

Wash potentially contaminated clothes separately

from other clothing. Rinse clothes washer thoroughly.

REMOVAL OF FIBERGLASS WOOL

or

INSTALLATION OF FIBERGLASS WOOL

OR BASE PANELS:

This product contains fiberglass jacket

insulation and ceramic fiber materials in

combustion chamber lining or base panels

in gas fired products. Airborne fibers from

these materials have been listed by the State

of California as a possible cause of cancer

through inhalation.

Precautionary measures

Avoid breathing fiberglass dust and contact with

skin or eyes.

• Use NIOSH certified dust respirator

(N95). This type of respirator is based

on the OSHA requirements for fiberglass

wool at the time this document was written. Other types of respirators may be

needed depending on the job site conditions. Current NIOSH recommendations

can be found on the NIOSH web site at

http://www.cdc.gov/niosh/homepage.html.

NIOSH approved respirators, manufacturers, and phone numbers are also listed on

this web site.

• Wear long-sleeved, loose fitting clothing,

gloves, and eye protection.

Operations such as sawing, blowing, tear out, and

spraying may generate airborne fiber concentration requiring additional protection.

Wash potentially contaminated clothes separately

from other clothing. Rinse clothes washer thoroughly.

NIOSH stated First Aid

Eye: Irrigate immediately

Breathing: Fresh air

Part number 550-141-826/1211

NIOSH stated First Aid

Eye: Irrigate immediately

Breathing: Fresh air

31

Page 32

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

SERVICE TECHNICIAN ONLY — read and follow completely.

Close clearance installation

To provide close clearances as described on pages 26 and 27:

Obtain the Close Clearance Kit, Weil-McLain Part No. 386-500-050. Install the kit as described below. Failure to use

kit or install as described can result in a fire hazard, causing severe personal injury, death or substantial property

damage.

Close clearance installation

Substitute these instructions for corresponding material in

manual. All other procedures and practices must remain the same.

Recommended service and minimum clearances shown on

page 8 should be used where possible. Where closer clearances

are required:

• Top of boiler — If less than 24" available, provide removable

surface to allow for cleaning boiler flueways.

• Right or left side — Minimum 2 inches.

• Front — Minimum 2 inches from burner.

• Double-wall flue pipe to combustible surface — as listed in

Table 5, page 33 and Figure 24 through Figure 26, page 33.

Jacket cap must be in place on boiler to avoid requir-

ing an 9" minimum clearance from back or top of

boiler to combustible material. Flue pipe clearances

must take precedence over jacket clearances.

1. Install boiler using clearances described at left.

2. Install barometric control 18-20 inches from boiler in

breeching.

Figure 22 Manual reset temperature switch location

3. Attach manual reset temperature switch near upper surface

of enclosed area. See Figure 22.

4. Wire switch in series with thermostat. See Figure 23.

5. Provide two combustion/ventilation openings when installing in confined space. Size opening 140 sq. in. (1000 Btu)

per 1 GPH input. Locate openings near top and bottom of

enclosed space.

Burner adjustments for packaged and

non-packaged boilers

Final burner adjustments must be made using com-

bustion test equipment to assure proper operation.

Do not fire boiler without water or sections will

overheat.

1. Refer to burner manual for start-up.

2. Allow boiler to heat to design condition.

3. Using combustion test equipment, adjust burner for:

a. CO2 between 11% and 12% and 0 smoke.

b. -0.01” to -0.02” W.C. draft in combustion chamber.

Figure 23 Manual reset temperature switch wiring

Manual reset

temperature

switch

Area above boiler

32

1 to 5

inches

Bracket

Combustible surface

#6 X ½" Phillips

Sheet metal

screw

#10 X ½" Phillips

sheet metal screw

Manual reset

temperature switch

44156

Thermostat

Part number 550-141-826/1211

Page 33

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 — Boiler Manual

SERVICE TECHNICIAN ONLY — read and follow completely.

Close clearance installation (continued)

Figure 24 Flue pipe clearances Figure 25 Back vent clearances

Combustible surface

A

Protection

Type “L” double-wall

vent piping

Type “L”

double-wall

vent pipe

6"

6"

Table 5 Protection required for clearances

less than 6 inches from doublewall

vent pipe*

Dimension A

When desired minimum

clearance from

Type “L” double-wall

vent pipe to combustible

surface is:

3"

2"

3"

Use the following

protection**:

½” thick insulation board

***

over one-inch glass fiber

or mineral wool batts+

24 gauge sheet metal with

one-inch ventilated air

space

½” thick insulation board

***

with one-inch ventilated air

space

24" For servicing

or min. 2" For close

clearances

Combustible

surface

2"

Note: 2" min. on sides

Figure 26 Top vent clearances

A

A

Combustible

surface

A

A

Combustible

surface

24" For

servicing

or min. 2"

For close

clearances

* All clearances measured from outer surface of

equipment to combustible surface, not to the

protection used.

** Apply to combustible surface unless otherwise

noted. Cover all surfaces as specified in Table and

Figure 24. Thicknesses are minimum.

*** Factory-fabricated board made of non-

combustible materials, normally fibers, having

thermal conductivity in range of one (Btu-inch)/