Weil-McLain 382-200-305 User Manual

GV BOILERGV BOILER

GV BOILER

GV BOILERGV BOILER

Intermediate or Back Section Repair Kit

Part Number 382-200-305

Replacement InstructionsReplacement Instructions

Replacement Instructions

Replacement InstructionsReplacement Instructions

The following terms are used in these instructions to bring attention to presence of hazards of various risk levels, or to important

information concerning the life of the product.

WARNING

Indicates presence of hazard which

can cause severe personal injury ,

death or substantial property damage.

CAUTION

Indicates presence of hazard which will

or can cause minor personal injury or

property damage.

WARNING

Contents of Kit:

2” square cut seals

Silicone sealant

Nuts and washers for draw rods

Instructions

Instructions for blower removal/replacement

1. Remove jacket top and front panels. Lay aside boiler

insulation.

2. Close isolation valves between boiler and system.

Drain boiler.

3. Remove:

All wiring connectors from control tray .

Control tray (if applicable).

External system gas and water piping from boiler.

Thermostat wiring.

External vent piping.

External combustion air piping, if used.

V ent condensate drain hose.

Blower assembly and burner . See “Blow er Assembly

or Burner Replacement Instructions, ” part number

550-141-608, packed with kit.

High limit control bulb from well.

Relief valve and external piping (back section only).

External air vent piping.

Remaining outside and interior jacket panels.

Block temperature limit switch.

Circulator(s).

4. Tilt block assembly onto back section to rest on 2

short pieces of 2 x 4’s.

CAUTION

5. DO NOT remove drain valv e and all other remaining

piping on front section.

6. Remove base rail assembly and tie rods from block

assembly.

Failure to follo w items below can cause severe personal injury, death or substantial property damage:

These instructions are for use by a qualified installer/service technician. F ollow all instructions in proper order.

Shut off main gas valve and disconnect electricity to boiler .

Wait until boiler is cooled down before proceeding with replacement.

Section block is heavy - care must be

taken in moving to avoid personal

injury.

7. Remove section(s) to be changed.

8. Remove silicone sealant from mating sections.

9. Clean new section and mating sections of any oil

and dirt or silicone sealant will not adhere properly.

10. Clean square cut sealing surfaces on new and

mating sections.

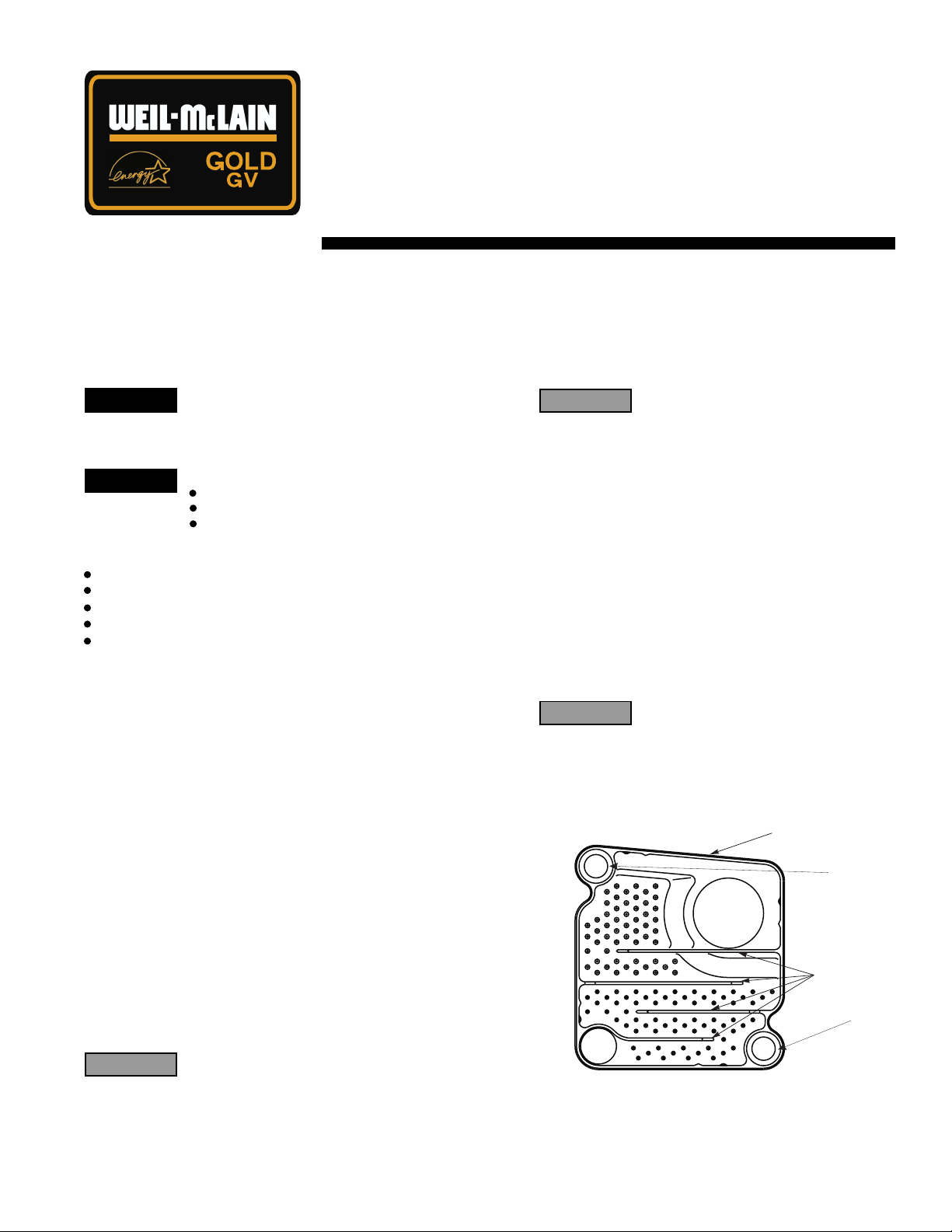

CAUTION

11. Apply bead of silicone sealant around perimeter of

intermediate or back section except on inside of

waterway holes (see Figure 1).

12. Insert new square cut seals.

13. Align new section and lay it on top of existing section.

Repeat steps 10-12 as necessary.

Do not use any cleaner containing

petroleum-based distillate (oil). Square

cut seal failure will occur .

Silicone

Sealant

Do Not

Apply

Silicone

Sealant

Here

Do Not

Apply

Silicone

Sealant

Here

Figure 1

Part number 550-141-588/0501

Intermediate or Back Section Part Number 382-200-305 — Replacement Instructions

Installation — assembly

21. Fill boiler as described in Boiler Manual.

14. Insert draw rods. Mak e sure all sections are aligned

when drawing together , tighten tie rod nuts ev enly

(35

+ 5 ft. lbs. torque).

15. Re-install base rail assembly to bottom of block

assembly . Use a level to assure rails are parallel.

16. Install circulator(s), assuring proper alignment of

pump(s) to both circulator flanges. See Boiler Manual.

17. Pressure test block assembly and water tubing for

leaks as described in Boiler Manual. Repair , if found.

18. Replace blower assemb ly and burner. See “Blo wer

Assembly or Burner Replacement Instructions,” part

number 550-141-608, packed with kit.

19. Tilt block assembly back onto base rails.

20. Re-install:

Block temperature limit switch.

Jacket left and interior panels.

Relief valve and piping.

External air vent piping.

High limit control bulb to well.

External vent piping.

External combustion air piping, if used.

V ent condensate drain hose.

External system gas and water piping to boiler.

Control tray (if applicable).

All wiring connectors to control tray

Thermostat wiring.

22. T u rn on electric and gas to boiler. Check boiler normal

sequence of operation and follow checkout procedure

in Boiler Manual.

23. Check for flue gas leakage around new section using

mirror. Leaks will cause f og on mirror. Repair any leaks

with silicone sealant and recheck.

24. Replace insulation and jacket right, back, front and top

panels.

Weil-McLain

500 Blaine Street

Michigan City, IN 46360-2388

http://www.weil-mclain.com

Part number 550-141-588/0501

Loading...

Loading...