Weil-McLain 1194, 1294, 1094, 1394, 1494 Series Manual

...

94

Series 3

Water & steam boilers

for use with Gas, Light Oil, & Gas/Light Oil – Fired Burners

Boiler Manual

• Installation

• Startup

• Maintenance

• Parts

For additional

information, refer to . .

Burner specifi cation

and data sheets

(for burners pre-tested with

model 94 boilers)

This manual must only be used by a qualifi ed

heating installer/service technician. Read

all instructions before installing. Follow

all instructions in proper order. Failure

to comply could result in severe personal

injury, death or substantial property damage.

INSTALLER Consider piping and installation when determining

boiler location.

Any claims for damage or shortage in shipment must be

fi led immediately against the transportation company

by the consignee.

USER . . . . This manual is for use only by your qualifi ed heating

installer/service technician. Boiler and burner must be

installed by a qualifi ed service technician. We recommend regular service by a qualifi ed service technician,

at least annually.

Part No. 550-110-275/1018

Weil-McLain 94 Series 3 Water and steam boilers — for Gas, Light Oil, & Gas/Light Oil-Fired Burners

Read before proceeding

Read before proceeding:

Read all instructions before installing. Fail-

ure to follow all instructions in proper order

can cause severe personal injury, death or

substantial property damage.

Do not use petroleum-based cleaning or

sealing components in boiler system. Severe

damage to system components can result,

causing substantial property damage.

Propane boilers only — Your propane

supplier mixes an odorant with the propane

to make its presence detectable. In some

instances, the odorant can fade and the gas

may no longer have an odor.

■ Propane gas can accumulate at floor

level. Smell near the floor for the gas

odorant or any unusual odor. If you

suspect a leak, do not attempt to light

the burner.

■ Use caution when attempting to light a

propane burner (or pilot burner). This

should be done by a qualified service

technician, particularly if flame outages (or pilot outages) are common.

Hazard Definitions

The terms defined below are used throughout this manual

to bring attention to the presence of hazards of various

risk levels, or to important information concerning the

life of the product.

Indicates presence of hazards that will

cause severe personal injury, death or

substantial property damage if ignored.

Indicates presence of hazards that can

cause severe

substantial property damage if ignored.

Indicates presence of hazards that will or

can cause minor personal injury, death or

substantial property damage if ignored.

Indicates special instructions on installa-

tion, operation or maintenance that are important but not related to personal injury.

personal injury, death or

■ Periodically check the odorant level of

your gas.

■ Inspect boiler and system at least yearly

to make sure all gas piping is leak-tight.

■ Consult your propane supplier regarding installation of a gas leak detector.

There are some products on the market

intended for this purpose. Your supplier may be able to suggest an appropriate device.

Controls:

One limit control is supplied with the

boiler. A second limit control must be

supplied by the installer (field installed)

to comply with current ASME Boiler and

Pressure Vessel Code, Section IV.

IMPORTANT

When calling or writing about the boiler, please provide:

• Boiler model number

• Series

• CP number

This information is located on the boiler label/nameplate.

2 Part No. 550-110-275/1018

Boiler manual: • Installation • Start-Up • Maintenance • Parts

Contents

Before installing boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Set boiler in place . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Assembling the block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Perform hydrostatic pressure test . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Control tapping locations — water boilers . . . . . . . . . . . . . . . . . . . . . . 12

Control tapping locations — steam boilers . . . . . . . . . . . . . . . . . . . . . . 13

Connect water boiler piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Connect steam boiler piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Complete block assembly & install jacket . . . . . . . . . . . . . . . . . . . . . . . 20

Pipe tankless heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Install water boiler controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Install steam boiler controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Connect breeching and venting systems . . . . . . . . . . . . . . . . . . . . . . . 31

Install fuel piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Make final adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Handling ceramic fiber and fiberglass materials . . . . . . . . . . . . . . . . . . . 36

Maintenance and troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3Part No. 550-110-275/1018

Weil-McLain 94 Series 3 Water and steam boilers — for Gas, Light Oil, & Gas/Light Oil-Fired Burners

Before installing boiler

Installation must comply with —

1. State, provincial and local plumbing, heating and electrical codes.

2. Regulations of servicing utilities.

3. ASME Section IV, Low Pressure Boiler and Pressure Vessel Code.

4. National Fuel Gas Code, ANSI/NFPA 54, when applicable.

5. National codes where applicable.

Before selecting boiler location

1. Check for nearby connections to:

a. Fuel supply.

b. Electrical power.

c. System water or steam piping.

d. Venting systems — see page 31.

e. Combustion and ventilation air supply — see page 5.

2. Check area around boiler. Remove any combustible materials, gasoline

and other flammable vapors and liquids.

Failure to keep boiler area clear and free of combustible

materials, gasoline and other flammable liquids and vapors

can result in severe personal injury, death and substantial

property damage.

Provide clearance around boiler

1. Provide minimum clearances to combustible materials:

• Boiler top — 24 inches.

• Boiler front — 48 inches.

•

Boiler flue — 9 inches.

• Boiler rear — 9 inches.

• Boiler sides — 6 inches.

• Single-wall vent pipe – 18 inches.

• Double-wall vent pipe – refer to vent pipe manufacturer's recom-

mendations for vent pipe clearances.

2. Boiler may be installed on combustible flooring.

3. See page 42 for boiler dimensions.

Flue pipe/breeching clearances take precedence over jacket

clearances. Follow local codes requirements for clearances.

Increase clearances if necessary.

4. Provide minimum clearances for servicing:

• Right side — for cleaning and for tankless heater insertion/re-

moval — 44 inches.

•

Rear — for breeching — 50 inches.

• Allow sufficient space on remaining sides for cleaning, servicing

and burner installation. See burner literature for length and recommended service clearances.

Lay a foundation, if needed

1. Floor construction and condition must be suitable for weight of boiler

when filled with water. See page 42 for approximate boiler operating

weight.

2. A level concrete or brick foundation, constructed per Figure 1 and

Figure 2 is required when:

a. A floor could possibly become flooded.

b. Non-level conditions exist.

c. Boiler must be raised for burner clearance.

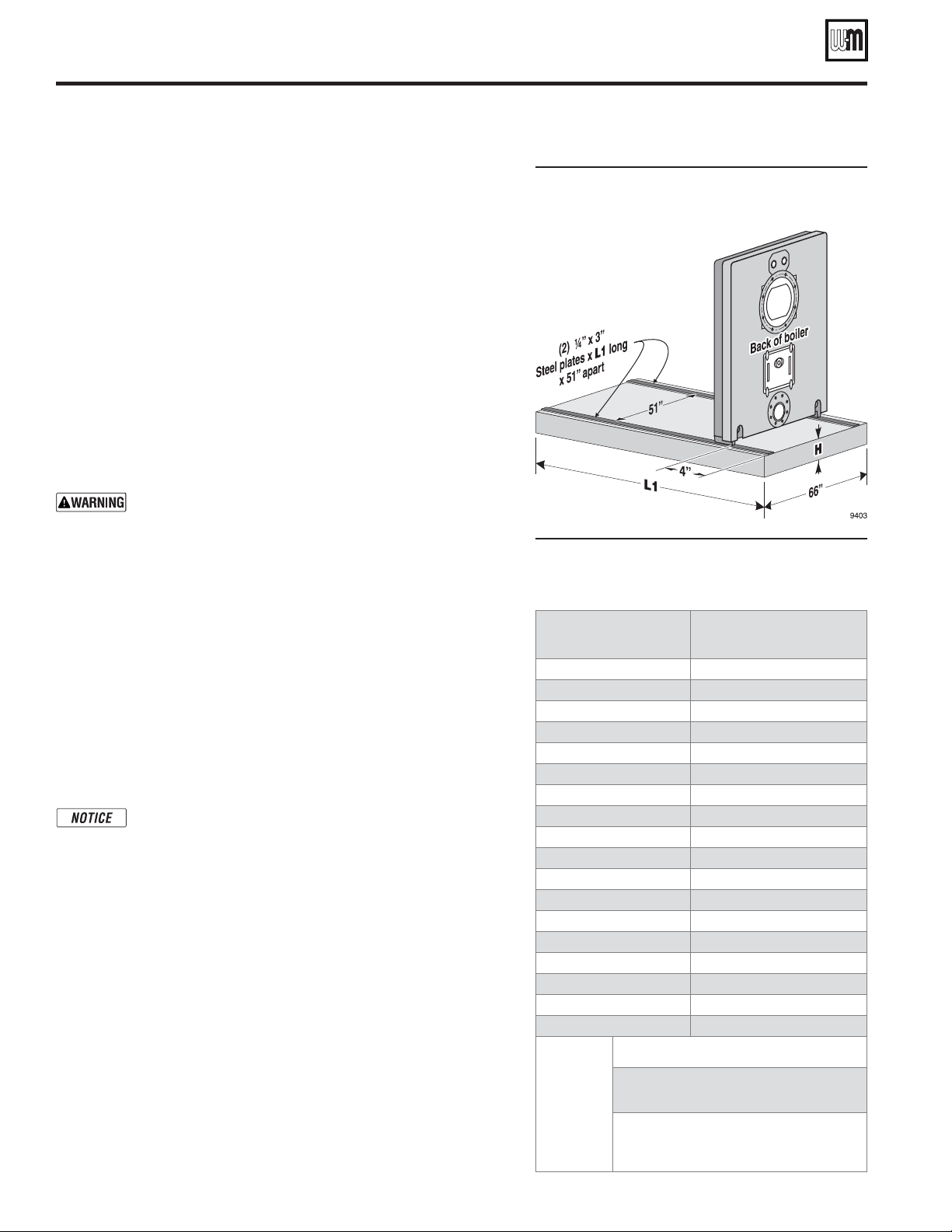

Figure 1 Boiler foundation, when required —

always use steel strips as shown for

proper draw-up and alignment of

sections

Figure 2 Boiler foundation (see Figure 1)

(boiler sections flush with one end of

foundation, 4 inches from the other

end)

Boiler model

number

894

994

1094

1194

1294

1394

1494

1594

1694

1794

1894

1994

2094

2194

2294

2394

2494

2594

Height,

H

(inches)

Gun-type burner: 2 inches min.

Horizontal rotary or air atomizing

burner: 7 inches min.

Consult burner manufacturer for

required clearances if burner is not

supplied by Weil-McLain.

Length,

(inches)

55

61

67

73

79

85

91

97

103

109

115

121

127

133

139

145

151

157

L1

4 Part No. 550-110-275/1018

Boiler manual: • Installation • Start-Up • Maintenance • Parts

Before installing boiler

(continued)

Combustion and ventilation air openings

Adequate combustion and ventilation air must be

provided to assure proper combustion and prevent

possibility of flue gas leakage and carbon monoxide

emissions, causing severe personal injury or death.

Do not install an exhaust fan in boiler room. Incor-

rect burner operation can result.

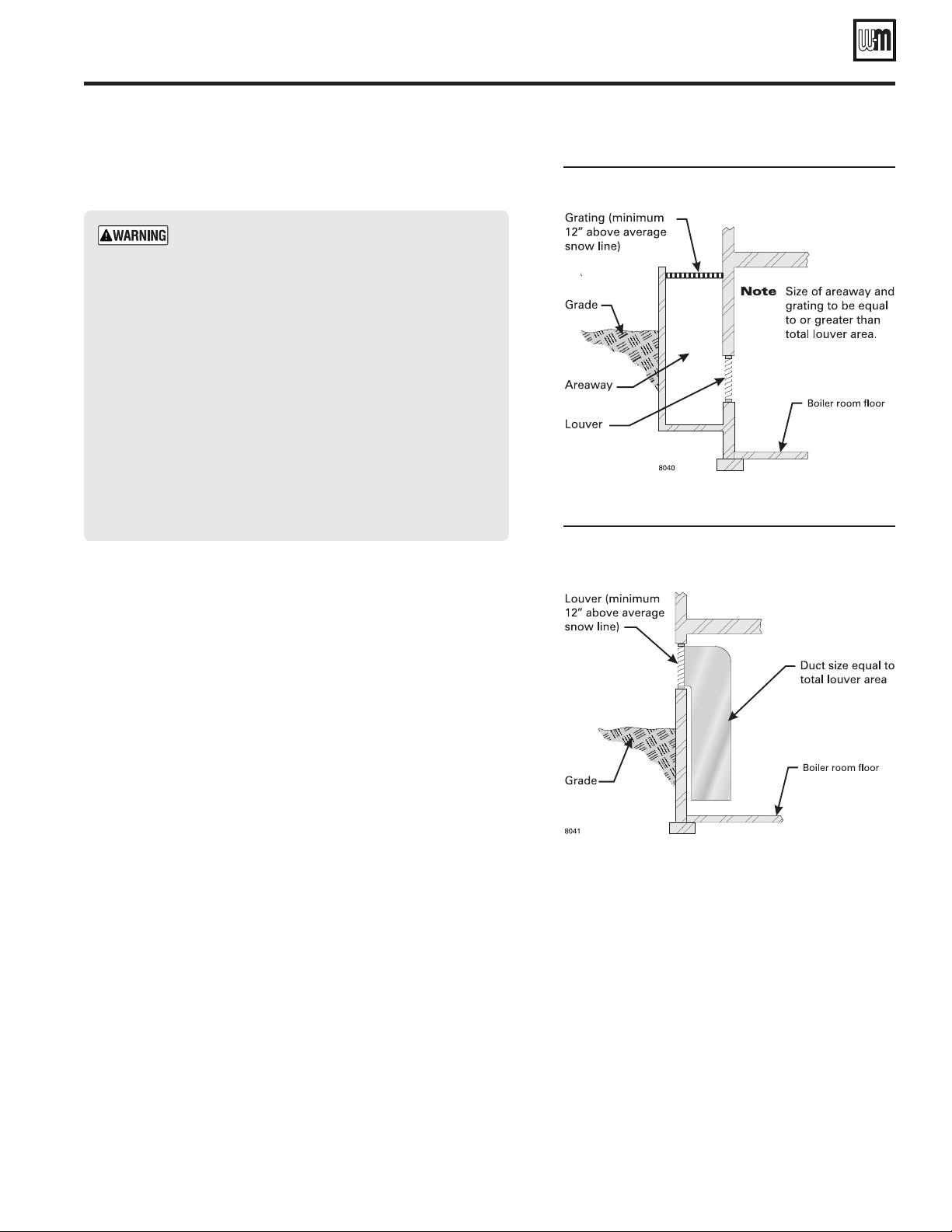

When combustion and ventilation air enters

through side wall openings, ensure that the openings comply with the requirements of Figure 3 and

Figure 4.

Opening sizes must comply with state, provincial or

local codes. In the absence of local requirements, use

the National Fuel Gas Code, ANSI/NFPA 54). The

following information is taken from ANSI/NFPA 54.

For details and information not addressed below,

refer to the standard.

Figure 3 Combustion and ventilation air

openings — Boiler room below grade

Figure 4 Combustion and ventilation air

openings — Boiler room partially or

completely above grade

Combustion air openings to inside

Required volume of interior spaces

ANSI/NFPA 54 allows combustion air to be supplied through openings

to interior spaces if the volume of the connected interior spaces

meets the minimum volume required by the standard.

The minimum volume of interior spaces can be taken as 50 cubic feet

per 1,000 Btuh of all appliances in the spaces, or the minimum volume

can be calculated using the formulas given in ANSI/NFPA 54. Exception: If the air infiltration rate for the spaces is known to be less than

0.40 air changes per hour, the minimum volume must be calculated

as specified in the standard.

Inside air opening sizes and locations

For spaces that provide the minimum volume required by ANSI/

NFPA 54, the air openings must be sized per the following:

Combining spaces on the same story — Each opening shall have

a minimum free area of 1 in2 ⁄1000 Btuh (2200 mm2 /kW) of the total

input rating of all appliances in the space but not less than 100 in2

(0.06 m2). One opening shall commence within 12 inches (300 mm)

of the top, and one opening shall commence within 12 inches (300

mm) of the bottom, of the enclosure. The minimum dimension of air

openings shall be not less than 3 inches (80 mm).

Combining spaces in different stories — The volumes of spaces

in different stories shall be considered as communicating spaces where

such spaces are connected by one or more openings in doors or floors

having a total minimum free area of 2 in2 ⁄1000 Btuh (4400 mm2 /kW)

of total input rating of all appliances.

Combustion air openings to

outside

Outdoor combustion air can be taken through permanent openings (TWO or ONE), as described in the

following. The minimum dimension of air openings

shall not be less than 3 inches (80 mm).

Outside openings: TWO permanent openings

method

Two permanent openings, one commencing within

12 inches (300 mm) of the top and one commencing

within 12 inches (300 mm) of the bottom of the enclosure shall be provided. The openings shall communicate

directly, or by ducts, with the outdoors or spaces that

5Part No. 550-110-275/1018

Weil-McLain 94 Series 3 Water and steam boilers — for Gas, Light Oil, & Gas/Light Oil-Fired Burners

Before installing boiler

freely communicate with the outdoors, as follows:

• Where directly communicating with the outdoors or

where communicating to the outdoors through vertical

ducts, each opening shall have a minimum free area of

2

⁄4000 Btuh (550 mm2/kW) of total input rating of

1 in

all appliances in the enclosure.

• Where communicating with the outdoors through hori-

zontal ducts, each opening shall have a minimum free

area of 1 in

rating of all appliances in the enclosure.

Outside openings: ONE permanent opening method

One permanent opening, commencing within 12 inches

(300 mm) of the top of the enclosure, shall be provided. The

appliance shall have clearances of at least 1 in. (25 mm) from

the sides and back and 6 inches (150 mm) from the front of the

appliance. The opening shall directly communicate with the

outdoors or shall communicate through a vertical or horizontal

duct to the outdoors or spaces that freely communicate with the

outdoors and shall have a minimum free area of the following:

2

(1) 1 in

of all appliances located in the enclosure, and . . .

(2) Not less than the sum of the areas of all vent connectors in

the space.

⁄3000 Btu/hr (700 mm2 per kW) of the total input rating

2

⁄2000Btuh (1100 mm2 /kW) of total input

(continued)

Combustion air — combination indoor

and outdoor openings

ANSI/NFPA 54 allows combustion air to be taken from a combination of openings to outside and to interior spaces. Follow all

requirements of the standard to determine the minimum volume

of interior spaces and to calculate minimum sizes of openings.

Mechanical Combustion Air Supply

Where all combustion air is provided by a mechanical air supply

system, the combustion air shall be supplied from outdoors at

the minimum rate of 0.35 ft3/minute per 1000 Btuh (0.034 m3/

min per kW) for all appliances located within the space.

• Where exhaust fans are installed in the building, additional air shall be provided to replace the exhausted air.

• Each of the appliances served shall be interlocked to the

mechanical air supply system to prevent main burner

operation where the mechanical air supply system is not

in operation.

• Where combustion air is provided by the building’s mechanical ventilation system, the system shall provide the

specified combustion air rate in addition to the required

ventilation air.

Louvers, Grilles, and Screens.

The required size of openings for combustion, ventilation, and

dilution air shall be based on the net free area of each opening.

Where the free area through a design of louver or grille or screen

is known, it shall be used in calculating the size opening required

to provide the free area specified.

Where the louver and grille design and free area are not known,

it shall be assumed that wood louvers will have 25 percent free

area, and metal louvers and grilles will have 75 percent free area.

Non-motorized louvers and grilles shall be fixed in the open

position.

Minimum screen mesh size

Screens shall not be smaller than ¼ inch mesh.

Motorized louvers

Motorized louvers shall be interlocked with the appliance so they

Engineered Installations

Engineered combustion air installations shall provide an adequate supply of combustion, ventilation, and dilution air and

shall be approved by the authority having jurisdiction.

6 Part No. 550-110-275/1018

are proven in the full open position prior to main burner ignition

and during main burner operation. Means shall be proved to

prevent the main burner from igniting should the louver fail to

open during burner startup, and to shut down the main burner

if the louvers close during burner operation.

Boiler manual: • Installation • Start-Up • Maintenance • Parts

Set boiler in place

Ensure the equipment and cables used for lifting are

designed to handle the load. See Figure 5 for approximate

weights of model 94 section assemblies. Failure to comply

can result in severe personal injury, death or substantial

property damage.

The boiler contains ceramic fiber and fiberglass materials.

Use care when handling these materials per instructions

on "Handling ceramic fiber and fiberglass materials,"

page 36 of this manual. Failure to comply could result

in severe personal injury.

For packaged boiler or assembled block

assembly:

1. Packaged boilers only — Remove top jacket panels. Set aside until

after boiler is piped.

2. Remove lag screws from shipping rails.

3. Remove boiler from skid. Cables are already attached to block assembly. See Figure 5 for lifting weight.

• Using crane – attach free end of cables to eye of crane.

• Using hoist – attach free end of cables to hoist. Raise boiler

off skid. Use pipe rollers under steel skid angles to roll boiler.

4. Place ¼" x 3" steel plates on floor or foundation, spaced 51 inches

apart, as shown in Figure 1, page 4.

5. Place boiler in final position. Place boiler on foundation (if used)

as shown in Figure 1, page 4.

6. Level boiler. Shim under legs if necessary.

7. Cut off cables.

Cables are not intended for long-term usage. Cables may

corrode inside boiler, weakening their lifting strength.

Failure to remove cables can result in severe personal

injury, death or substantial property damage.

8. Inspect block assembly for disjointed sections.

a. Check inside section assembly for any light passing through

unsealed areas.

b. Mark all unsealed areas.

c. At unsealed areas, check for:

• Damaged gaskets.

• Sealing rope not in place.

• Loose bolts or nuts.

d. Correct all conditions and repeat step b. If unsealed areas still

exist, contact your Weil-McLain distributor or sales office

before continuing installation.

9. Check gas-tight seal of flue collector hood and cleanout plates.

Do not raise or move assembled sections

using a jack or forklift. This could cause

the sections to shift, resulting in leaks.

Figure 5

Section assembly lifting weights

Boiler

model

number

894 8600

994 9500

1094 10300

1194 11200

1294 12000

1394 12800

1494 13700

1594 14500

1694 15400

1794 16200

1894 17100

1994 17900

2094 18700

2194 19800

2294 20600

2394 21500

Approximate

lifting

weight

(pounds)

Minimum

sling length —

(from crane hook to

boiler lifting lugs)

3' 6"

3' 6"

4' 0"

4' 6"

5' 0"

5' 0"

5' 0"

5' 0"

5' 0"

5' 0"

5' 0"

5' 6"

5' 6"

7' 6"

7' 6"

7' 6"

Gas tight seal must be maintained to prevent possible flue

gas leakage and carbon monoxide emissions, resulting

in severe personal injury or death.

10. Proceed to "Perform hydrostatic pressure test," page 11.

2494 22400

2594 23200

8' 0"

8' 0"

7Part No. 550-110-275/1018

Weil-McLain 94 Series 3 Water and steam boilers — for Gas, Light Oil, & Gas/Light Oil-Fired Burners

Assembling the block

Sections are top heavy. Unbolted sections may fall if not

supported, resulting in severe personal injury or death.

Prepare the back section first

1. Place ¼" x 3" steel plates on the floor or foundation, spaced 51 inches

apart, as shown in Figure 1, page 4.

2. Apply

1

⁄8" continuous bead of sealing rope adhesive in sealing rope

grooves around section perimeter and around flueways — see Figure 6.

Do not get any adhesive on the machined port surfaces.

Place sealing rope in grooves

1. Place 5⁄8" coated and uncoated sealing rope in the rope grooves as shown

in Figure 6.

2. See WARNING below — place coated rope and uncoated rope as

described.

3. Around curves, grasp rope at 1" intervals and push together.

stretch the rope

.

Do not

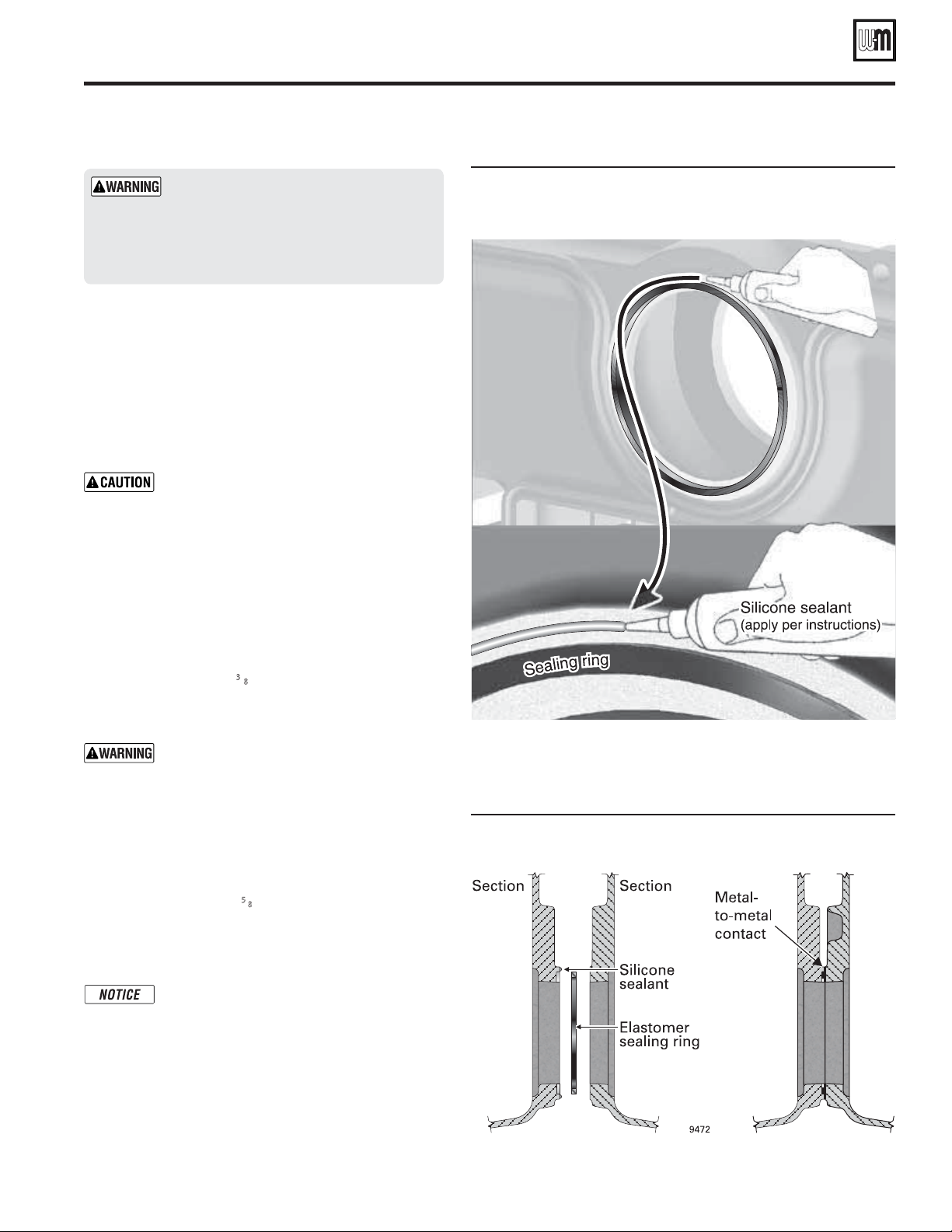

Figure 6 Sealing rope installation

The boiler is supplied with TWO types of section sealing

rope — uncoated and coated with a narrow uncoated strip.

Use the uncoated rope only on the flueways as shown in

Figure 6.

Use the coated rope around the perimeter and around the

upper nipple port as shown in Figure 6. The uncoated side

of the rope must be pressed into the adhesive as shown in

order to obtain a proper adhesion.

DO NOT pre-cut rope for sections. Cut rope as each section

is placed.

A gas-tight seal must be maintained to prevent possibility

of flue gas leakage and carbon monoxide emissions, causing

severe personal injury or death.

Do not use petroleum-based cleaning or sealing com-

pounds in boiler system. Severe damage to system components can result, causing substantial property damage.

Install nipple port sealing rings

1. Remove any grit from port machined surfaces with clean rag.

2. Place 9" and 6" sealing rings in appropriate port openings as shown in

Figure 6, page 8. If sealing ring slips out of groove, stretch ring gently

for several seconds, then reposition in groove.

3. Apply a continuous bead of silicone sealant no larger than

entire outside edge of the outer machined surface of the port. See Figure 7. Do not apply silicone sealant on, next to or under sealing ring.

1

⁄16" around

8 Part No. 550-110-275/1018

Boiler manual: • Installation • Start-Up • Maintenance • Parts

Assembling the block

Silicone sealant applied as specified above

prevents unburned oil vapors from coming

in contact with sealing ring. Vapor contact can damage rings, resulting in severe

damage to boiler and substantial property

damage.

Raise the rear section upright

1. Hoist the back section upright.

2. Move rear section into position on the steel rails. The

section should be 4 inches from the end of the foundation (if used) as shown in Figure 1, page 4.

3. Block under the flueway outlet to hold the rear section

upright in plumb position.

The back section must be plumb before in-

stalling other sections to ensure the block will

assemble correctly.

4. The blocking under the flueway can be removed later,

after several intermediate sections have been attached

and the assembly is stable.

5. Install intermediate sections and front section as described on the following.

(continued)

Figure 7 Applying silicone sealant around outsides of sealing

rings (shown on 94 intermediate section upper nipple

port)

Install intermediate sections

1. Remove and discard 3⁄8" diameter shipping tie rods.

2. Remove grit from port machined surfaces with clean

rag. Also remove grit from tapped holes in all sections.

Do not use petroleum-based cleaning or

sealing compounds in boiler system. Severe

damage to system components can result,

causing substantial property damage.

3. Position intermediate section so aligning lugs fit into

sockets of next section. See Figure 8.

4. Draw sections together until metal-to-metal contact is

made around machined port openings (see Figure 8):

a. Oil threads on (4)

and nut on end to be tightened. Use nut only on

other end.

b. Uniformly draw sections together, starting at

washer/nut end.

Important — Leave an equal amount of thread

on each end of the draw rod. This is needed

to allow securing the jacket support brackets

in place. The draw rods must not extend past

the face of the front or back section, or they

will interfere with the jacket.

c. Draw rods should be torqued to a range of 100 to

120 ft-lbs. Do not back off draw rods.

d. Metal-to-metal contact will be achieved around port

openings. See Figure 8. If gap occurs, it should be no

greater than .032". Check with feeler gauge.

5

⁄8" x 11" draw rods. Install washer

Figure 8 Sealing ring installation and port alignment, typical

Weil-McLain cast iron section nipple port

9Part No. 550-110-275/1018

Weil-McLain 94 Series 3 Water and steam boilers — for Gas, Light Oil, & Gas/Light Oil-Fired Burners

Assembling the block

e. If, for any reason, the gap around machined port open-

ing exceeds .032", check for rope extending from rope

(continued)

6. Check each section for proper sealing rope position before

proceeding to next section.

grooves, dirt on port openings or sockets, or misaligned

lugs. If corrections are made and gap still exists, contact

your Weil-McLain distributor or sales office before continuing installation.

Failure to position sealing rope properly can

cause boiler to not seal gas-tight. Gas tight seal

prevents possible flue gas leakage and carbon

monoxide emissions, resulting in severe personal

After erecting first intermediate section, check

injury or death.

both sections for plumb. Repeat the check as each

additional section is installed. Failure to plumb sections can cause misaligned piping and breeching,

7. Install remaining intermediate sections and front section

using the same procedure.

possibly resulting in property damage.

5. Repeat steps 1-5 for all remaining sections. NOTE — use

x 10" draw rods between intermediates. When used, install TI

(tankless intermediate) and SI (supply intermediate) sections

in the positions shown in Figure 9, page 10.

5

If using tankless heater (TI) sections

⁄8"

• Install tankless heaters and gaskets or heater cover plates

and gaskets.

3

• Use

⁄8" x 3⁄4"studs, washers and nuts.

Figure 9 Section arrangement (location of TI and SI sections, numbered from REAR to FRONT of block assembly)

Boiler

W = water

S = steam

# of coils ——

894 W or S 5 5, 7 3, 5, 7 — — — — — —

994 W or S 6 6, 8 2, 4, 6 2, 4, 6, 8 — — — — —

1094 W or S 4 2, 4 2, 4, 7 2, 4, 7, 9 — — — — —

1194 W or S 4 2, 4 2, 4, 8 2, 4, 8, 10 — — — — —

1294 W or S 4 2, 4 2, 4, 9 2, 4, 9, 11 2, 4, 7, 9, 11 — — — —

1394 W or S 5 3, 5 3, 5, 10 3, 5, 10, 12 3, 5, 8, 10, 12 — — — —

1494 W or S 6 4, 6 2, 4, 6 4, 6, 11, 13 2, 4, 6, 11, 13 2, 4, 6, 9, 11, 13 — — —

1594 W or S 6 4, 6 2, 4, 6 4, 6, 12, 14 2, 4, 6, 12, 14 2, 4, 6, 10, 12, 14 — — —

1694 W or S 6 4, 6 2, 4, 6 4, 6, 13, 15 2, 4, 6, 13, 15 2, 4, 6, 9, 11, 13 2, 4, 6, 9, 11, 13, 15 — —

1794 W or S 7 5, 7 3, 5, 7 5, 7, 14, 16 3, 5, 7, 14, 16 3, 5, 7, 10, 12, 14 3, 5, 7, 10, 12, 14, 16 — —

1894 W or S 8 6, 8 2, 4, 6 2, 4, 6, 8 2, 4, 6, 8, 15 2, 4, 6, 8, 15, 17 2, 4, 6, 8, 11, 13, 15 2, 4, 6, 8, 11, 13, 15, 17 —

1994 W or S 6 4, 6 2, 4, 6 4, 6, 9, 11 2, 4, 6, 9, 11 2, 4, 6, 9, 11, 16 2, 4, 6, 9, 11, 16, 18 2, 4, 6, 9, 11, 14, 16, 18 —

2094 W or S 6 4, 6 2, 4, 6 4, 6, 10, 12 2, 4, 6, 10, 12 2, 4, 6, 10, 12, 17 2, 4, 6, 10, 12, 17, 19 2, 4, 6, 10, 12, 15, 17, 19 —

If the boiler was ordered with tankless coils, the heaters must be located on the right hand side of the boiler. It is important to position the TI

sections (where used) in the exact location in the boiler section assembly as shown above so the heater knockout openings in the jacket side

panels will accommodate the heaters. If the TI sections and internal water heaters are not positioned in the boiler section assembly as shown

above, the installer must cut openings in the jacket side panels to accommodate the heaters.

>

12 3 4 5 6 7 8

2194 W 6 4, 6 2, 4, 6 2, 4, 6, 9 2, 4, 6, 9, 11 2, 4, 6, 9, 11, 13 2, 4, 6, 9, 11, 13, 16 — 18, 20

2294 W 6 4, 6 2, 4, 6 2, 4, 6, 10 2, 4, 6, 10, 12 2, 4, 6, 10, 12, 14 2, 4, 6, 10, 12, 14, 17 — 19, 21

2394 W 6 4, 6 2, 4, 6 2, 4, 6, 9 2, 4, 6, 9, 11 2, 4, 6, 9, 11, 13 2, 4, 6, 9, 11, 13, 15 2, 4, 6, 9, 11, 13, 15, 18 20, 22

2494 W 8 6, 8 2, 4, 6 2, 4, 6, 8 2, 4, 6, 8, 12 2, 4, 6, 8, 12, 14 2, 4, 6, 8, 12, 14, 16 2, 4, 6, 8, 12, 14, 16, 19 21, 23

2594 W 8 6, 8 2, 4, 6 2, 4, 6, 8 2, 4, 6, 8, 11 2, 4, 6, 8, 11, 13 2, 4, 6, 8, 11, 13, 15 2, 4, 6, 8, 11, 13, 15, 17 22, 24

2194 S 2 2, 9 2, 9, 11 2, 9, 11, 13 2, 9, 11, 13, 20 — — — 4, 6, 16, 18

2294 S 2 2, 10 2, 10, 12 2, 10, 12, 14 2, 10, 12, 14, 21 — — — 4, 6, 17, 19

2394 S 2 2, 9 2, 9, 11 2, 9, 11, 13 2, 9, 11, 13, 15 2, 9, 11, 13, 15, 22 — — 4, 6, 18, 20

2494 S 8 2, 8 2, 8, 12 2, 8, 12, 14 2, 8, 12, 14, 16 2, 8, 12, 14, 16, 23 — — 4, 6, 19, 21

2594 S 8 2, 8 2, 8, 11 2, 8, 11, 13 2, 8, 11, 13, 15 2, 8, 11, 13, 15, 17 2, 8, 11, 13, 15, 17, 24 — 4, 6, 20, 22

[numbering from REAR to FRONT, beginning with rear section as section number 1]

Placement of special intermediate sections (TI and SI)

TI sections

with tankless coil openings

SI sections

with supply

tappings

10 Part No. 550-110-275/1018

Boiler manual: • Installation • Start-Up • Maintenance • Parts

Perform hydrostatic pressure test

Install boiler connections

894 – 1294 W

1. Secure supply elbow and gasket to front section and supply

outlet cover plate and gasket to back section.

• Use

• Thread flat end of stud into section.

2. Secure 6" NPT return opening counter flange and gasket to

back section using ¾" x 2" cap screws and washers.

1394 – 2094 W

1. Secure supply elbow and gasket to front section.

2. Use

3. Thread flat end of stud into section.

4. Secure supply outlet cover plate and gasket to back section.

5. Use

6. Secure 8" pipe with standard 8" flange (not furnished) and

gasket (furnished) to back section. Use ¾" x 2" cap screws

and washers (furnished).

2194 — 2594 W

1. Secure outlet cover plate with 3 holes (¾" tapping on top)

and gasket to front section.

2. Secure outlet cover plate with 2 holes and gasket to back

section.

3. Use

4. Secure 10" supply outlets and gaskets on top of "SI" sections.

• Supply outlet should have 1¼" tapping facing front.

• Use

5. Secure 10" flanged return adapter and gasket to back section

using ¾" x 2" hex head cap screws and washers.

894 S

1. Secure supply elbow and outlet gasket to front section and

supply outlet cover plate and gasket to back section.

• Use

2. Secure 6" return opening counter flange and gasket to back

section. Use ¾" x 2" cap screws and washers.

994 — 2094 S

1. Secure supply elbows and outlet gaskets to front and back

sections.

• Use

• Thread flat end of stud into section.

2. Secure 6" NPT return opening counter flange and gasket to

back section. Use ¾" x 2" cap screws and washers.

2194 — 2594 S

1. Secure outlet cover plates and gaskets to front and back

sections.

• The ¾" tappings in plates should be at top.

• Use

5

⁄8" x 3" studs, nuts, and washers.

5

⁄8" x 3" studs, nuts, and washers.

5

⁄8" x 1¾" bolts.

5

⁄8" x 1¾" bolts.

5

⁄8" x 3" studs, nuts, and washers.

5

⁄8" x 1¾" bolts.

5

⁄8" x 3" studs, nuts and washers.

5

⁄8" x 1¾" bolts.

2. Secure 10" supply outlets and gaskets on top of "SI" sections.

• Supply outlet installed close to boiler front should have

1¼" tapping facing front.

• Use

5

⁄8" x 3" studs, nuts, and washers.

3. Secure 6" NPT return opening counter flange and gasket to

back section using ¾" x 2" hex head cap screws and washers.

Prepare boiler and test:

1. See Figure 10 (water boilers) or Figure 11 (steam boilers) for

tapping locations.

2. Install water pressure gauge —

can handle test pressure — see step 8 for required test pressure. Gauge range should be at least 1.5 times the test pressure. Install the pressure test gauge in the tapping specified

in Figure 10 (water boilers) or Figure 11 (steam boilers).

3. Install an air vent in an upper tapping.

4. On front section: Install 3" close nipples and caps in washout

tappings.

5. On rear section: Install drain valve (furnished by installer)

in one of the washout tappings. (Verify drain valve size per

Figure 15, page 15.) Install 2" x 2

other washout tapping.

6. Plug or use blind flanges on remaining tappings.

Do not pressure test with any control installed.

Damage to control can occur due to overpressure.

7. Fill the boiler with water. Vent all air.

8. Pressure test at least 10 minutes at a pressure not less than

the following:

a.

Steam boiler: Between 45 and 55 psig.

b.

Water boiler: 1½ times maximum allowable working

pressure

(MAWP) stamped on the boiler nameplate,

located on boiler jacket front panel.

Do not exceed above test pressures by more than

10 psig.

Do not leave boiler unattended. Cold water fill

could expand and cause excessive pressure, resulting in severe personal injury, death or substantial

property damage.

9. Check for maintained gauge pressure and leaks. Repair if

found.

Leaks must be repaired at once. Failure to do so

can damage boiler, resulting in substantial property

damage.

Do not use petroleum-based cleaning or sealing

compounds in boiler system. Severe damage to

system components can result, causing substantial

property damage.

10. Drain boiler and remove air vent, boiler drain and gauge.

11. Remove plugs from tappings that will be used for controls

and accessories.

for test only. Be sure gauge

1

⁄2" nipple and cap in the

11Part No. 550-110-275/1018

Weil-McLain 94 Series 3 Water and steam boilers — for Gas, Light Oil, & Gas/Light Oil-Fired Burners

Control tapping locations — water boilers

Figure 10 Model 94 water boiler control tappings

Item # Function Size

(Inches

NPT)

PRESSURE TEST GAUGE — REMOVE AFTER

J1

HYDROSTATIC TEST

J1 Temperature control or limit

J2 & J5

M3 Probe-type low water cutoff

M1 + M2

M3 + M4

P1 or R1 Temperature control or limit

S1 P/T gauge or temperature gauge

T1 or T2

U1 & U2

V1 Temperature control or limit

PLUG these tappings — not used on water boilers

Float-type low water cutoff or LWCO/feeder

combination

Temperature control or limit — or —

Air vent piping to compression tank

Pressure relief valve(s):

894–2094: Install relief valve in one tapping and plug

the other tapping

2194–2594: Install a relief valve in each tapping

(2 relief valves required on these boilers)

1¼

½

½

½

1

1

3

¾

2

4

W1 or W2

X1 or X2

Y1 & Y2

Z1 or Z2

Z3 or Z4

—

Temperature control or limit — or —

P/T gauge or temperature gauge

Temperature control or limit — or —

Air vent piping to compression tank

PLUG this tapping — unless needed for a control

Cleanout tappings — Front section — Install 2" NPT

close nipple and 2" NPT cap in each cleanout tapping

Cleanout or drain tappings — Rear section —

Install drain valve in one tapping; install 2" NPT x 2½"

length nipple and 2" NPT cap in the other

Low limit control (when using tankless heaters) —

locate in control tapping on one of the tankless heaters

Controls and fi ttings must not

obstruct cleanout openings or

prevent required access to the

boiler or components.

1¼

¾

3

⁄8

2

2

—

12 Part No. 550-110-275/1018

Boiler manual: • Installation • Start-Up • Maintenance • Parts

Control tapping locations — steam boilers

Figure 11 Model 94 steam boiler control tappings

Item # Function Size

PRESSURE TEST GAUGE — REMOVE AFTER

J1

HYDROSTATIC TEST

J1 + J5

M3

M1 + M2

M3 + M4

P1 Skim tapping

P2 Steam pressure relief valve

R1 Skim tapping

R2 Steam pressure relief valve

S1

S2 Pressure controls (limit, operating, etc.)

T1 or T2 Pressure controls (limit, operating, etc.)

T3 or T4

U1 or U2

V1 or V2

W1 or W2

W3 or W4 Pressure controls (limit, operating, etc.)

X1 & X2

X3 & X4

Y1 & Y2 Try cocks

Z1 or Z2

Z3 or Z4

Gauge glass

J2

PLUG this tapping — not used

PLUG this tapping — not used

Float-type low water cutoff, LWCO/pump control or

LWCO/feeder combination

Steam pressure gauge — or —

Pressure controls (limit, operating, etc.)

Steam pressure gauge — or —

Pressure controls (limit, operating, etc.)

Steam pressure relief valve — Install relief valve in

one tapping and plug the other

Steam pressure relief valve — or —

Skim tapping

Steam pressure gauge — or —

Pressure controls (limit, operating, etc.)

PLUG these tappings — not used

PLUG these tappings — not used

Cleanout tappings — Front section — Install 2" NPT

close nipple and 2" NPT cap in each cleanout tapping

Cleanout or drain tappings — Rear section —

Install drain valve in one tapping; install 2" NPT x 2½"

length nipple and 2" NPT cap in the other

Low limit temperature control (when using tankless

—

heaters) — locate in control tapping on one of the tankless

heaters

(Inches

NPT)

½

½

½

1

1

3

3

4

4

¾

¾

1¼

1¼

2

4

¾

¾

1¼

1¼

3

⁄8

2

2

—

Controls and fi ttings must not

obstruct cleanout openings or

prevent required access to the

boiler or components.

13Part No. 550-110-275/1018

Weil-McLain 94 Series 3 Water and steam boilers — for Gas, Light Oil, & Gas/Light Oil-Fired Burners

Connect water boiler piping

General water piping information

1. System water supply and return piping should be installed and

piping connections attached to boiler before erecting jacket or

installing controls.

2. Do not pipe in through supply and out through return. This creates

reverse water flow through boiler that must not be used.

3. When installing in a system in which return water temperature can

drop below 140°F, apply the by-pass piping with by-pass pump as

shown in Figure 16, page 15.

4. When three-way valves are used for temperature modulation,

install slow-opening valves to minimize the potential of boiler

thermal shock.

Install piping

Install piping as shown in Figure 12, page 14 and Figure 16, page 15

(if applicable) for single boilers. For multiple boilers, see Figure 17, page 15.

Improperly piped systems or undersized piping can

contribute to erratic boiler operation and possible boiler

or system damage.

1. Connect supply and return piping:

a. Size according to tables below.

• For

• For

known flow rates or higher flow rate (less than 20°F

temperature rise) through boiler, see Figure 13.

unknown flow rates, size piping per Figure 15, page 15,

using 20°F temperature rise through boiler.

Figure 12 Water boiler piping, typical

Flow at higher rates than shown in the tables in this

manual for given pipe sizes can damage the boiler, causing substantial property damage.

b. Locate circulator in supply piping.

c. For return piping, use full diameter pipe for 10 times that

diameter before making any reduction. For example, a 4-inch

return should not be reduced any closer to boiler return tapping than 40 inches.

d. Install system blow-off (drain) valve in lowest part of return

piping close to boiler. ASME minimum size requirements are

given in Figure 15, page 15.

2. Install expansion tank:

a.

Closed type – connect to 1

1

⁄4" tapping T1, T2 or X2 (see

Figure 10, page 12). Use 1" NPT piping. Any horizontal piping must pitch up toward tank at least 1 inch per each 5 feet

of piping.

b.

Diaphragm type – Refer to tank manufacturer's literature for

location. Install automatic air vent in 1

1

⁄4" tapping T1, T2 or

X2 (see Figure 10, page 12).

c. Connect cold water fill to expansion tank piping. Figure 12

shows typical piping when using a closed type tank. Connect

to the same location as the expansion tank connects to the

system when using a diaphragm type tank.

d. Also shown are recommended valves and water meter, when

used. Water meter will detect added make-up water, indicating

leaks in system.

Figure 13 Recommended minimum pipe sizes for

known flow rates

Water flow

rate, GPM

up to 77

78 – 132

133 – 208

209 – 300

301 – 520

521 – 820

Note 1 High temperature rise through boiler is per missible when boiler

Supply pipe sizeAReturn pipe size

3" 3"

4" 4"

5" 5"

6" 6"

8" 8"

10" 10"

piping connections are sized per this table.

Intermittent flow at high velocities may damage any

boiler.

(note 1)

B

14 Part No. 550-110-275/1018

Boiler manual: • Installation • Start-Up • Maintenance • Parts

Connect water boiler piping

Figure 14 Recommended minimum pipe sizes when flow rate is

994 – 1294

1394 – 2094

2194 – 2594

Note 1 Pipe sizes are based on a 20°F temperature rise through the boiler. For

Figure 15 ASME drain valve size

not known (see Figure 12, page 14)

Boiler

model

894

applications with higher flow rates (lower temperature rise), determine

the flow rate and use Figure 13, page 14 to size the piping. DO NOT

use flow rates in excess of 520 GPM through 894–2094 or 820 GPM

through 2194–2594.

Boiler

model

894 – 994

1094 – 2194

2294 – 2594

Supply pipe size

A

5" 5"

6" 6"

8" 8"

10" 10"

Minimum drain/blow-off

(note 1)

Return pipe size

B

valve size

1¼"

1½"

2"

(continued)

Figure 16 By-pass piping for return water less

than 140°F

By-pass circulator sizing:

1. Size system circulator as required. Determine GPM

and head requirements.

2. Provide a by-pass circulator for EACH boiler. The flow

rate for each by-pass circulator will be:

Flow = ¼ x (System circulator GPM) ÷ (# of boilers)

3. All circulators must run at the same time.

4. Example: For a 1,000,000 Btuh single boiler, with

system temperature drop of 20°F:

• System GPM = 1,000,000 ÷ 20 ÷ 500 = 100 GPM

• By-pass GPM = ¼ x 100 GPM = 25 GPM

• Determine by-pass circuit head loss for pipe size

and fittings used.

5. In most applications, a standard booster pump should

be adequate.

Piping multiple boilers

1. See Figure 16. (Expansion tanks, relief valves and other accessories

are required, but omitted from the illustration for simplicity.)

2. The boiler piping circuits are referred to as the secondary circuits

in the following.

3. The legend for Figure 16 and boiler pump sizing recommendations follow:

A Size boiler pump GPM based on the following:

a. Temp rise = High limit temp – Return water temp

b. GPM =

c. Calculate only secondary (boiler) piping circuit resistance. Al-

low for head loss through the boiler equal to three 90 degree

elbows of secondary pipe size.

d. Operate each boiler and its pump with a Weil-McLain boiler

control panel.

e. Size secondary (boiler) circuit piping using the flow rate ranges

given in Figure 15.

B Primary pump GPM and head calculation should not include

secondary boiler circuits. Primary pump can operate continuously

during heating season.

C Connection to primary circuit — Space 12" maximum or as close

as practical.

D Check valve.

E Hand valve.

Boiler Gross Output, Btuh

Temperature rise x 500

Figure 17 Multiple water boiler piping

15Part No. 550-110-275/1018

Loading...

Loading...