Weil-McLain 80, 380, 480, 580, 680 User Manual

...

Water & steam boilers

for use with Gas, Light Oil, &

80

Gas/Light Oil – Fired Burners

Boiler Manual

INSTALLER

USER

This manual must only be used by a qualified heating installer/service

technician. Read all instructions before installing. Follow all instructions

in proper order. Failure to comply could result in severe personal injury,

death or substantial property damage.

• Consider piping and installation when determining boiler location.

• Any claims for damage or shortage in shipment must be filed immediately

against the transportation company by the consignee.

• This manual is for use only by your qualified heating installer/service

technician.

• Boiler and burner must be installed by a qualified service technician.

• We recommend regular service by a qualified service technician, at least

annually.

When calling or writing about the boiler— Please have the boiler model

number from the boiler rating label and the CP number from the boiler

jacket.

Part No. 550-141-935/0602

Weil-McLain 80 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners

Contents

Page

1. Before installing boiler .................................................................................. 3

2. Set boiler in place........................................................................................... 5

3. Assemble block .............................................................................................. 6

4. Perform hydrostatic pressure test ................................................................ 8

5. Complete block assembly ............................................................................. 9

6. Install flue collector...................................................................................... 10

7. Connect water boiler piping ........................................................................ 14

8. Connect steam boiler piping ....................................................................... 16

9. Install jacket .................................................................................................. 20

10. Pipe tankless heaters................................................................................... 27

11. Install water boiler controls......................................................................... 28

12. Install steam boiler controls........................................................................ 29

13. Connect breeching and venting system .................................................... 31

14. Install burner................................................................................................. 32

15. Wiring and fuel piping.................................................................................. 32

16. Make final adjustments ................................................................................ 32

17. Dimensions and ratings............................................................................... 34

18. Parts .............................................................................................................. 36

Handling ceramic fiber and fiberglass materials....................................... 38

Hazard Definitions

The following defined terms are used throughout this manual to bring attention to the presence of hazards of various

risk levels, or to important information concerning the life of the product.

Indicates presence of hazards that will cause severe personal injury, death or substantial property

damage if ignored.

Indicates presence of hazards that can cause severe personal injury, death or substantial property

damage if ignored.

Indicates presence of hazards that will or can cause minor personal injury, death or substantial

property damage if ignored.

Indicates special instructions on installation, operation or maintenance that are important but not

related to personal injury.

Read all instructions before installing.

Failure to follow all instructions in proper

order can cause severe personal injury,

death or substantial property damage.

2 Part No. 550-141-935/0602

Do not use petroleum-based cleaning or

sealing components in boiler system.

Severe damage to system components can

result, causing substantial property

damage.

• Installation • Start-Up • Maintenance • Parts

1

Before installing boiler

Installation must comply with —

• State, provincial and local plumbing, heating and

electrical codes.

• Regulations of servicing utilities.

• National codes where applicable.

Before selecting boiler location

1. Check for nearby connections to:

a. Fuel supply

b. Electrical power

c. System water or steam piping

d. Venting systems - see page 31

e. Combustion and ventilation air supply — see

"Provide combustion and ventilation air supply

openings" on page 4.

2. Check area around boiler. Remove any combustible

materials, gasoline and other flammable vapors and

liquids.

Failure to keep boiler area clear and free

of combustible materials, gasoline and

other flammable liquids and vapors can

result in severe personal injury, death and

substantial property damage.

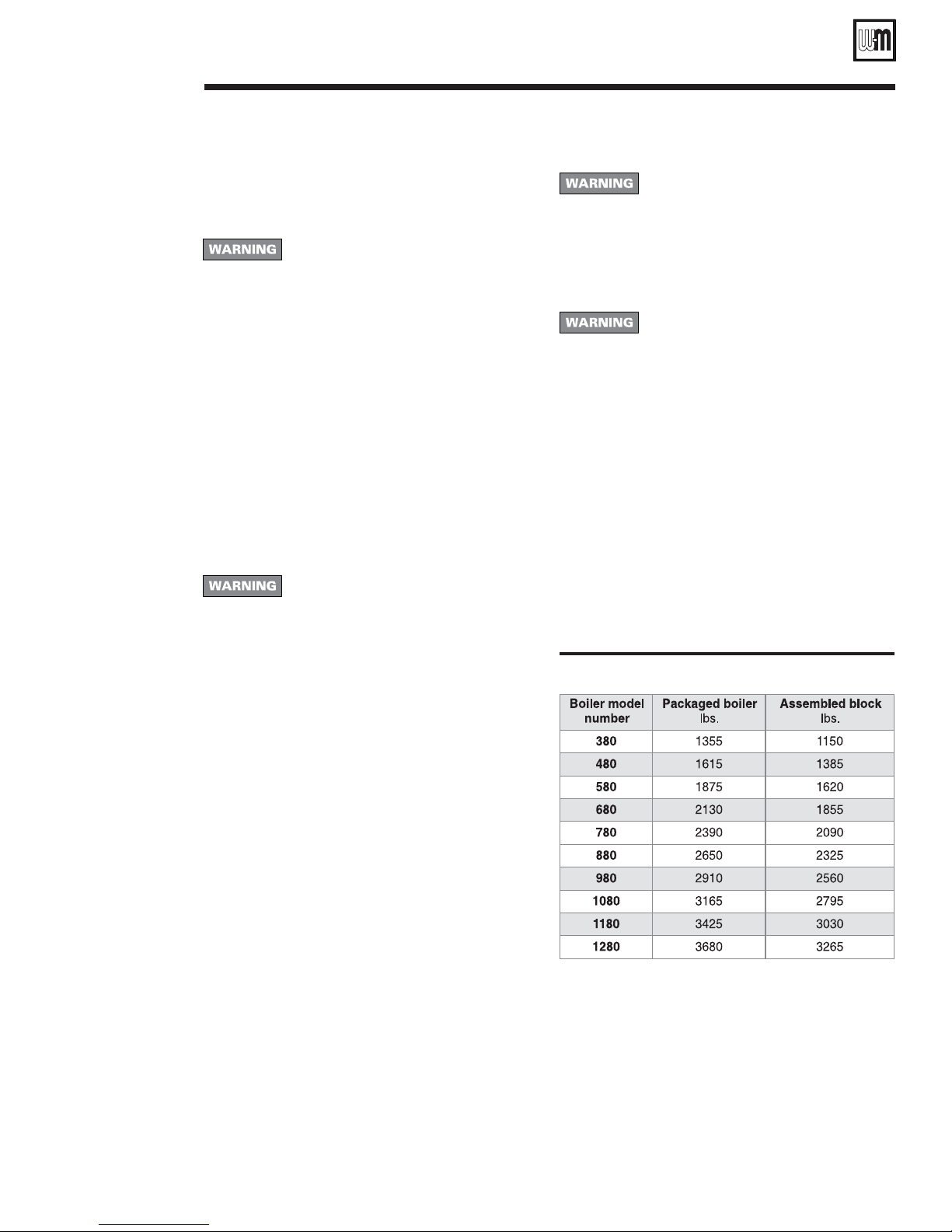

Lay a foundation, if needed:

Floor construction and condition must be suitable for

weight of boiler when filled with water. See page 34 for

approximate boiler operating weight.

A level concrete or brick foundation (constructed per

Table 1 and Figure 1) is required when:

1. A floor could possibly become flooded.

2. Non-level conditions exist.

Table 1 Boiler foundation (see Figure 3)

Figure 1 Boiler foundation

Provide clearance around boiler

• Provide minimum clearances to combustible materials:

1. Singlewall vent pipe – 18 inches.

2. Doublewall vent pipe – refer to vent pipe

manufacturer's recommendations for vent pipe

clearances.

3. Boiler top — 24 inches.

4. Boiler front — 48 inches.

5. Boiler flue — 9 inches.

6. Boiler rear — 9 inches.

7. Boiler sides — 6 inches.

• Boiler may be installed on combustible flooring.

• See pages 34 and 35 for boiler dimensions.

Flue pipe/breeching clearances take

precedence over jacket clearances.

• Left side — for cleaning and tankless heater removal –

34 inches.

• Allow sufficient space on remaining sides for cleaning,

servicing and burner installation. See burner literature

for length and recommended service clearances.

3Part No. 550-141-935/0602

Weil-McLain 80 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners

1

Before installing boiler (continued)

Provide combustion and ventilation air

openings:

Do not install an exhaust fan in boiler

room. Adequate combustion and

ventilation air must be provided to assure

proper combustion and prevent

possibility of flue gas leakage and carbon

monoxide emissions, causing severe

personal injury or death.

Opening sizes must comply with state, provincial or local

codes. In their absence, use the following when boiler is in

a confined room:

• Provide two permanent openings in boiler room — one

within 12 inches of ceiling, one within 12 inches of floor.

Minimum dimension of each opening is 3 inches.

1. When all air is taken from within building, each

opening should be at least one square inch/1,000

Btuh boiler input and freely connect with areas

having adequate infiltration from outside.

2. When all air is taken from outdoors, each opening

should connect directly or by ducts from outdoors

or crawl or attic spaces that freely connect with

outdoors and sized as listed below:

a. through outside wall or vertical ducts - at least

one square inch/4,000 Btuh boiler input.

b. through horizontal ducts - at least one square

inch/2,000 Btuh boiler input.

c. where ducts are used, they should be same cross-

sectional area as free area of openings they are

connected to.

d. compensate for louver, grille or screen blockage

when calculating free air openings. Refer to their

manufacturer's instructions for size. If

unknown, use:

• wood louvers - 20-25% free air.

• metal louvers or grilles - 60-75% free air.

• screens - not less than ¼ inch mesh.

Figure 2 Combustion and ventilation air

openings — Boiler room below grade

Figure 3 Combustion and ventilation air

openings — Boiler room partially or

completely above grade

Lock louvers in open position, or interlock with equipment

to prove open before boiler operation.

When combustion and ventilation air enters through

sidewall openings, ensure openings comply with Figures 2

and 3.

4 Part No. 550-141-935/0602

• Installation • Start-Up • Maintenance • Parts

Set boiler in place2

For packaged boiler:

1. Remove top jacket panels. Set aside until after boiler is

piped.

The boiler contains ceramic fiber and

fiberglass materials. Use care when

handling these materials per instructions

on page 38 of this manual. Failure to

comply could result in severe personal

injury.

2. Remove lag screws (2 in front, 2 in rear) from shipping

rails.

3. Remove boiler from skid. Cables are already attached

to block assembly. See Table 2 for lifting weight.

• Using crane — hook middle of each cable to eye of

crane.

• Using hoist — hook middle of each cable to hoist.

Raise boiler off skid. Use pipe rollers under skid

angles to roll boiler.

4. Place boiler in final position. Center boiler on

foundation, if used.

5. Level boiler. Shim under skid angles, if necessary.

6. Cut off cables.

Cables are not intended for long-term

usage. Cables may corrode inside boiler,

weakening their lifting strength. Failure to

remove cables can result in severe personal

injury, death or substantial property

damage.

7. Proceed to "Perform hydrostatic pressure test," page 8.

Cables are not intended for long-term

usage. Cables may corrode inside boiler,

weakening their lifting strength. Failure to

remove cables can result in severe personal

injury, death or substantial property

damage.

6. Inspect block assembly for disjointed sections. Check

gas-tight seal of flue collector hood and cleanout plates.

Gas tight seal must be maintained to

prevent possible flue gas leakage and

carbon monoxide emissions, resulting in

severe personal injury or death.

a. Check inside section assembly for any light passing

through unsealed areas.

b. Mark all unsealed areas.

c. At unsealed areas, check for:

• damaged gaskets.

• sealing rope not in place.

• loose bolts or nuts.

d. Correct all conditions and repeat step b. If unsealed

areas still exist, contact your Weil-McLain

distributor or sales office before continuing

installation.

7. Proceed to "Perform hydrostatic pressure test," page 8.

Table 2 Lifting weights

For block assembly:

1. Remove lag screws (2 in front, 2 in rear) from shipping

rails.

2. Remove boiler from skid. Cables are already attached

to block assembly. See Table 2 for lifting weight.

• Using crane – attach free end of cables to eye of

crane.

• Using hoist – attach free end of cables to hoist. Raise

boiler off skid. Use pipe rollers under steel skid

angles to roll boiler.

3. Place boiler in final position. Center boiler on

foundation, if used.

4. Level boiler. Shim under skid angles, if necessary.

5. Cut off cables.

5Part No. 550-141-935/0602

Weil-McLain 80 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners

Assemble block3

Sections are top heavy. Unbolted sections

may fall if not supported, resulting in

severe personal injury or death.

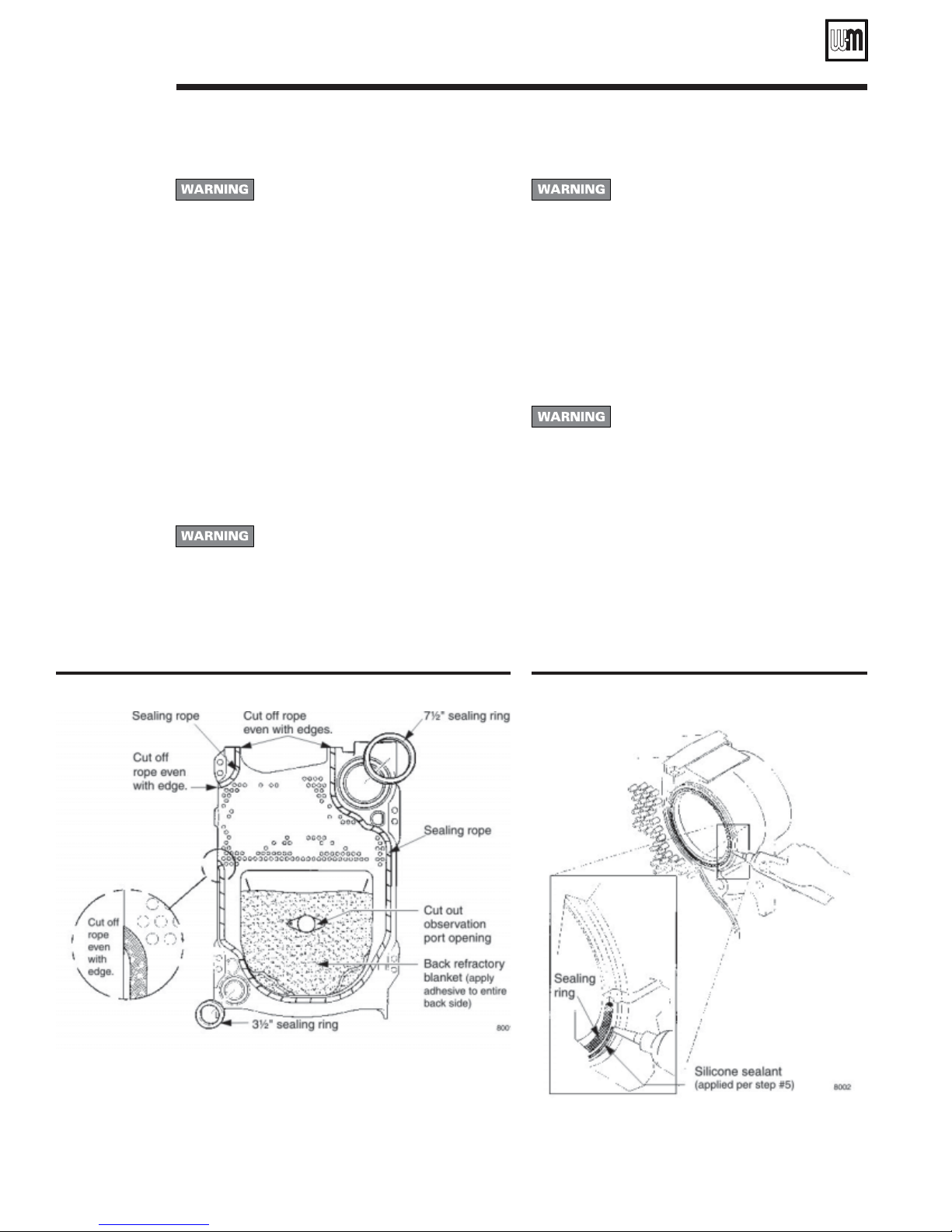

Install back refractory blanket

1. Lay back section on floor with ports face up.

2. Apply adhesive to blanket.

3. Press blanket against back target wall as shown in

Figure 4.

4. Using knife, cut hole through blanket to expose

observation port opening.

Prepare back section

1. Apply 1/8" continuous bead of sealing rope adhesive in

sealing rope grooves. See Figure 4.

adhesive on machined port surfaces.

2. Place ½" sealing rope in groove. Around curves, grasp

at 1" intervals and push together. Do not stretch.

Do not pre-cut rope. Gas tight seal must

be maintained to prevent possibility of

flue gas leakage and carbon monoxide

emissions, causing severe personal injury

or death.

3. Remove any grit from port machined surfaces with

clean rag.

Do not get any

Do not use petroleum-based cleaning or

sealing compounds in boiler system.

Severe damage to system components can

result, causing substantial property

damage.

4. Place 7½" and 3½" sealing rings in appropriate port

openings. See Figure 4. If sealing ring slips out of groove,

stretch ring gently for several seconds, then reposition

in groove.

5. Apply continuous bead of silicone sealant no larger than

1

/16" around entire outside edge of outer machined

surface of port. Refer to Figure 5.

silicone sealant on, next to or under sealing ring.

Silicone sealant applied as specified above

prevents unburned oil vapors from

coming in contact with sealing ring. Vapor

contact can damage rings, resulting in

severe damage to boiler and substantial

property damage.

6. Position section upright on foundation (if used) and

screw 3" pipe at least 22" long into 3" return tapping.

7. Place a block under pipe to hold section upright.

Do not apply

Figure 4 Sealing rope installation Figure 5 Silicone sealant

6 Part No. 550-141-935/0602

• Installation • Start-Up • Maintenance • Parts

Assemble block (continued)3

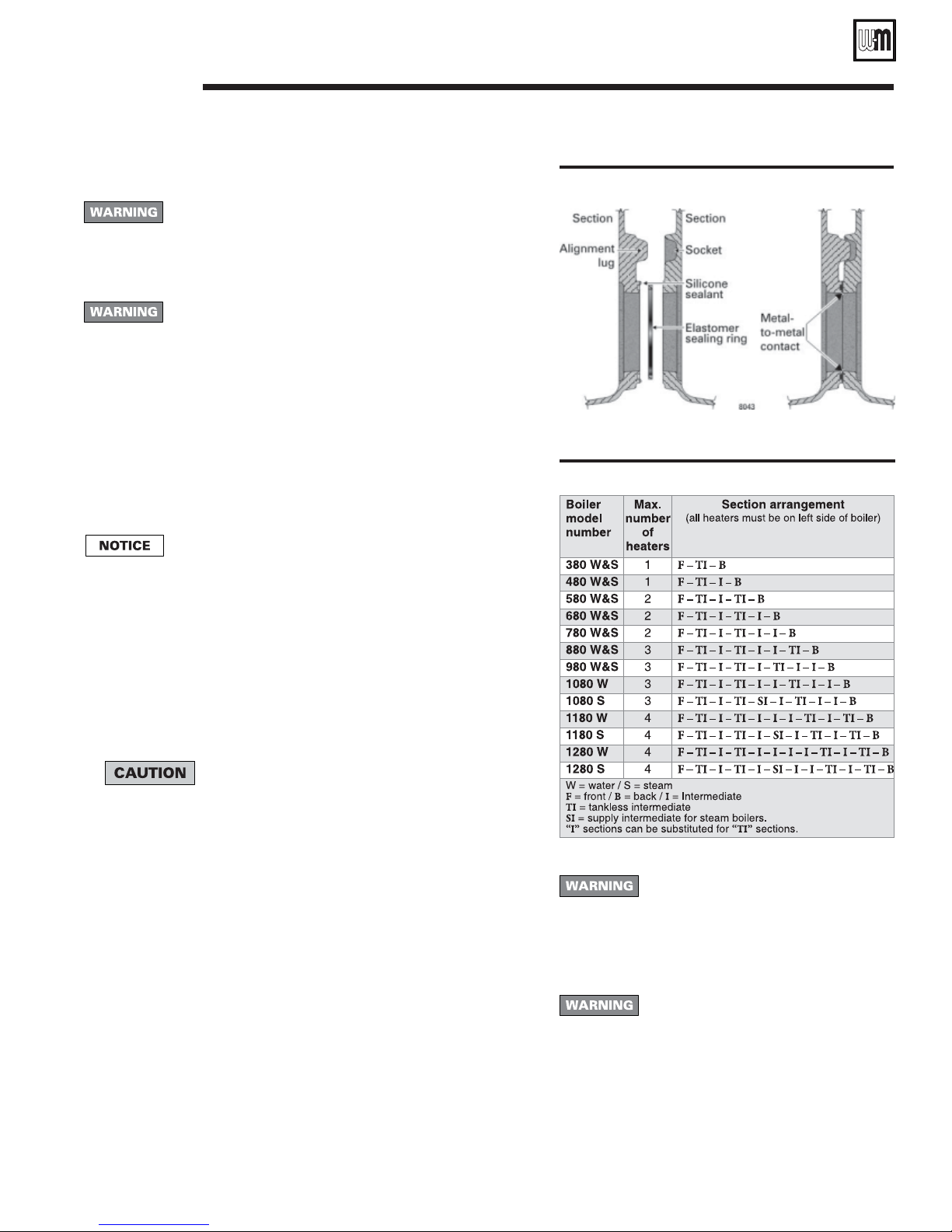

Install intermediate sections

Sections are top heavy. Unbolted sections may fall if not

supported, resulting in severe personal injury or death.

1. Remove and discard

2. Remove grit from port machined surfaces with clean rag.

3. Position intermediate section so aligning lugs fit into sockets of next section.

See Figure 6.

4. Install TI (tankless intermediate) and SI (supply intermediate) sections

(when used) in order shown in Table 3.

5. Draw sections together until metal-to-metal contact is made around

machined port openings (see Figure 6):

a. Oil threads on 4 draw rods. Install washer and nut on end to be tightened.

Use nut only on other end.

b. Uniformly draw sections together, starting at washer/nut end.

c. Draw rods should be torqued to a range of 90 to 100 ft. - lbs. Do not

back off draw rods.

d. Metal-to-metal contact will be achieved around port openings. See Figure

6. If gap occurs, it should be no greater than .032". Check with feeler

gauge.

e. If, for any reason, gap around machined port opening exceeds .032",

check for rope extending from rope grooves, dirt on port openings or

sockets, or misaligned lugs. If corrections are made and gap still exists,

contact your Weil-McLain distributor or sales office before continuing

installation.

6.

7. Repeat steps 1-5 from “Prepare back section,” page 6.

3

/8" diameter shipping tie rods.

Do not use petroleum-based cleaning or sealing compounds

in boiler system. Severe damage to system components can

result, causing substantial property damage.

Important — Leave an equal amount of thread on each end

of the draw rod. This is needed to allow securing the jacket

support brackets in place (see pages 20 and 21).

After erecting first intermediate section, check both

sections for plumb. Failure to plumb sections can cause

misaligned piping and breeching, possibly resulting in

property damage.

Figure 6 Sealing ring installation and port alignment

Table 3 Section arrangement

Install bottom refractory blanket on combustion

chamber floor inside section block

1. Unroll blanket only to depth of back section and first intermediate section.

2. Spread adhesive on bottom side of blanket.

3. Press blanket into center bottom of sections.

4. Unroll and install blanket per steps 2 and 3 as each intermediate and front

section are installed.

5. At front section, cut off blanket 2 ½" from burner opening. Discard unused

blanket.

Prepare remaining sections

1. Follow “Prepare intermediate section” for remaining intermediate and front

sections:

a. Remove any grit from threads inside tapped holes with clean rag.

Do not use petroleum-based cleaning or

sealing compounds in boiler system.

Severe damage to system components can

result, causing substantial property

damage.

b. Check each section for proper sealing rope position

before proceeding to next section.

Failure to position sealing rope properly

can cause boiler to not seal gas-tight. Gas

tight seal prevents possible flue gas leakage

and carbon monoxide emissions,

resulting in severe personal injury or

death.

If using tankless heater (TI) sections

1. Install tankless heaters and gaskets or heater cover plates

and gaskets. Use

3

/8" x 3/4" studs, washers and nuts.

7Part No. 550-141-935/0602

Weil-McLain 80 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners

4

Perform hydrostatic pressure test

Prepare boiler and test:

1. See pages 28 and 29 for tapping locations. Install:

a. Boiler drain (not furnished).

b. Water pressure gauge — for test only. Be sure gauge can handle test pressure — see step 3.

c. Air vent in upper tapping (K).

2. Plug remaining tappings.

Do not pressure test with any control installed. Damage to control can occur due

to overpressure.

3. Fill boiler. Vent all air. Pressure test at least 10 minutes at a pressure not less than the following:

Steam boiler:

Between 45 and 55 psig.

Wa t e r boiler:

1½ times maximum allowable working pressure (MAWP) stamped on the boiler nameplate,

located on boiler jacket front panel.

Do not exceed above test pressures by more than 10 psig.

Do not leave boiler unattended. Cold water fill could expand and cause excessive

pressure, resulting in severe personal injury, death or substantial property damage.

4. Check for maintained gauge pressure and leaks. Repair if found.

Leaks must be repaired at once. Failure to do so can damage boiler, resulting in

substantial property damage.

Do not use petroleum-based cleaning or sealing compounds in boiler system. Severe

damage to system components can result, causing substantial property damage.

5. Drain boiler and remove air vent, boiler drain and gauge. Remove plugs from tappings that will

be used for controls and accessories.

8 Part No. 550-141-935/0602

• Installation • Start-Up • Maintenance • Parts

Complete block assembly5

Install burner mounting plate on front section

1. Install four ½" x 4¾" studs to secure burner mounting plate to section:

a. Thread and lock together two nuts on rounded end of stud. Thread flat end of stud into one

of four holes located around opening.

b. Remove nuts.

c. Repeat steps a and b for remaining studs.

2. Install burner mounting plate:

a. Apply

b. Position ½" sealing rope in groove. Overlap ends at least one inch.

c. Install burner mounting plate. Use ½" washers and nuts.

Install observation port assemblies on front and back sections:

1

/8" continuous bead of sealing rope adhesive in groove around opening in section.

1. Install front observation port assembly:

1

a. Apply

b. Position

c. Secure assembly to section. Use

/8" continuous bead of sealing rope adhesive in groove on observation port.

3

/8" sealing rope in groove.

5

/

" - 18 x ¾" slotted head screws.

16

2. Repeat above steps for back observation port assembly.

Install cleanout plates

Cleanout plates must be installed gas-tight to prevent possibility of flue gas leakage

and carbon monoxide emissions, resulting in severe personal injury or death.

1. See Figure 7. Position two ¼" x 1¾" carriage bolts in cleanout opening. Secure with washers and

nuts.

2. Place blanket insulation piece against cleanout plate.

3. Mount cleanout plate over opening. Secure with nuts and washers.

4. Repeat steps 1 through 3 for remaining cleanout plates.

The boiler contains ceramic fiber and

fiberglass materials. Use care when

handling these materials per

instructions on page 38 of this

manual. Failure to comply could

result in severe personal injury.

Figure 7 Cleanout plate assembly

9Part No. 550-141-935/0602

Weil-McLain 80 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners

Install flue collector6

Flue collector assembly

1. Figure 10, page 11, shows flue collector components

and locations. Figure 11, page 13, shows collector hoods

for all models. Follow all instructions in this manual to

ensure correct installation of the flue collector.

2. Model 80 boilers are available with either rear flue or

top flue. Verify that you have the correct components

for your application. You can convert a Model 80 from

rear to top or top to rear flue using a flue conversion

kit, available from your Weil-McLain distributor.

The flue outlet for top flue models must

be located as shown in this manual.

Install collector hold-down bolts

1. Figure 10, lower left — Install a collector hold-down

bolt assembly at each section joint, and on both sides

of the boiler section assembly. Set aside the flanged nuts

for securing the collector assembly when it is ready.

2. Each hold-down bolt assembly consists of a

carriage bolt, flat washer, regular hex nut and a flanged

nut as shown.

5

/16" x 2"

Prepare flue collector hood assembly

Make sure gaskets are intact, not torn or

otherwise damaged. These conditions can

cause possible flue gas leakage and carbon

monoxide emissions, resulting in severe

personal injury or death.

The boiler contains ceramic fiber and

fiberglass materials. Use care when

handling these materials per instructions

on page 38 of this manual. Failure to

comply could result in severe personal

injury.

1. Stand flue collector hood front module (item

as in Figure 8, left side.

Figure 8 Collector hood preparation

4) on end

2. Wipe all flanged surfaces with clean rag.

3. Lay flue collector hood gasket (item

4. Place flue collector end cap (item

bolt holes. Secure with seven

and flanged nuts.

inch-pounds torque.

right column.)

5. For 880 - 1280:

a. Stand remaining hood module on end, as in

Figure 8, right side.

b. Wipe all flanged surfaces with clean rag.

c. Lay gasket on flange.

d. Carefully place open end of first module on top of

gasket, aligning flanged surfaces.

e. Secure with seven

flanged nuts.

pounds torque.

6. Attach flat-stitched sealing rope to hood assembly. See

Figure 9:

a. Lay hood on floor with flanged side up.

b. Wipe flanged surface with clean rag to remove dirt

and oil.

c. Apply double-faced tape to flanged surface.

d. Apply rope to tape beginning on one side of open

end of hood, leaving ¼" extending past edge. Bend

rope around corners.

rope.

e. Continue around entire flange. At other open end,

leave ¼" rope extending past edge of flange. Cut off

excess rope.

Tighten to between 30 and 35

(See WARNING on page 12, top

5

/16" x 5/8" flanged bolts and

Tighten to between 30 and 35 inch-

(See WARNING on page 12.)

DO NOT cut or stretch

Do not pre-cut rope. All collector hood

joints must be sealed gas-tight to prevent

possible flue gas leakage and carbon

monoxide emissions, resulting in severe

personal injury or death.

Double-faced tape serves only to hold

sealing rope in place during installation.

It will disintegrate over time. If collector

hood and sealing rope are removed for any

reason, install new tape and new gasket.

2) on flange.

1) on gasket. Align

5

/16" x 5/8" flanged bolts

10 Part No. 550-141-935/0602

Figure 9 Flue collector sealing rope installation

• Installation • Start-Up • Maintenance • Parts

6

Figure 10 Flue collector components, typical (Model 880 collector configurations shown)

Install flue collector (continued)

11Part No. 550-141-935/0602

Weil-McLain 80 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners

Install flue collector (continued)6

Before installing flue collector

1. See Figure 10, page 11, for general assembly of flue

collector components.

2. See Figure 11, page 13 for the placement of flue collector

hoods on each model.

3. Prepare mounting holes in boiler rear section.

a. The boiler rear section has tapped holes for mounting

rear flue collector component.

b. Remove any grit from threads inside tapped holes with

clean rag.

Rear flue boilers only:

1. See Figure 10, page 11 and Figure 11, page 13.

2. Place collector hood transition on rear section:

a. Wipe item 10, Figure 10, collector hood transition

flange surfaces with a clean rag.

b. Apply a few pieces of double-faced tape on the

collector hood transition flange.

c. Place the

Figure 10) on the collector hood transition flange.

Align holes in gasket with holes in flange. Press gasket

firmly in place.

d. Position collector hood transition on back of boiler

rear section, aligning collector hood transition flange

holes with tapped holes in boiler rear section.

e. Insert a 5/16" x 5/8" flanged bolt through the bottom

center hole and finger tighten to hold transition in

place.

f. Install six remaining bolts securing collector hood

transition to rear section.

3. Place collector hood assembly on sections:

a. Carefully set collector hood assembly on top of section

assembly. Align slotted holes in collector hood flanges

with the hold-down bolts in the sections.

b. Place the collector hood assembly so its rear flange is

against the collector hood transition flange gasket.

c. Thread flanged nuts onto hold-down bolts and

tighten only.

d. Insert five 5/16" x 5/8" flanged bolts through holes in

collector hood transition and collector hood assembly

rear flange. Thread on nuts and

4. Tighten flue collector bolts and nuts:

a. Gradually tighten all bolts and nuts on flue collector

assembly and boiler.

inch-pounds torque. See WARNING, upper right.

b. Alternate locations as you tighten the fasteners to

ensure all parts are evenly drawn down, with no gaps

or distortion of parts.

5. Install damper and flue caps:

a. Wipe item 5, Figure 10, flue damper flange surface

with a clean rag.

b. Apply a few pieces of double-faced tape to the flue

damper flange. Position flue collar gasket on damper

and press firmly in place. Align all holes before

securing.

c. Position flue damper assembly against collector hood

transition. Insert a #10 x ½" screw through the top

center hole. Lightly tighten to hold flue damper in

position.

d. Insert remaining #10 screws into flue damper flange

and lightly tighten. Alternate from screw to screw and

tighten all screws evenly and securely.

e. Install flue caps on flue collector top opening(s) using

steps 5a through 5d.

collector hood transition gasket (item 8,

Finger-tighten only.

finger-

finger-tighten only.

Tighten to between 30 and 35

DO NOT overtighten bolts in flue collector hood assembly.

Gasket material could extrude, causing possible flue gas leakage

and carbon monoxide emissions, resulting in severe personal

injury or death.

Top flue boilers only:

1. See Figure 10, page 11 and Figure 11, page 13.

2. Place rear flue cap on rear section:

a. Wipe item 9, Figure 10, rear flue cap gasket surface with a clean rag.

b. Apply a few pieces of double-faced tape on the rear flue cap gasket surface.

c. Place the

holes in gasket with holes in rear flue cap. Press firmly in place.

d. Position rear flue cap on back of boiler rear section, aligning rear flue cap

holes with tapped holes in boiler rear section.

e. Insert a 5/16" x 5/8" flanged bolt through the bottom center hole and finger

tighten to hold rear flue cap in place.

f. Install six remaining bolts securing rear flue cap to rear section.

tighten only.

rectangular gasket (item 8, Figure 10) on the flue cap, aligning

3. Place collector hood assembly on sections:

a. Carefully set collector hood assembly on top of section assembly. Align

slotted holes in collector hood flanges with the hold-down bolts in the

sections.

b. Place the collector hood assembly so its rear flange is against the rear flue

cap gasket.

b. Thread flanged nuts onto hold-down bolts and

c. Insert five 5/16" x 5/8" flanged bolts through holes in rear flue cap and

collector hood assembly rear flange. Thread on nuts and finger-tighten only.

finger-tighten only.

4. Tighten flue collector bolts and nuts:

a. Gradually tighten all bolts and nuts on flue collector assembly and boiler.

Tighten to between 30 and 35 inch-pounds torque. See WARNING, above.

b. Alternate locations as you tighten the fasteners to ensure all parts are evenly

drawn down, with no gaps or distortion of parts.

5. Install damper and flue caps (see Figure 11, page 13):

a. Wipe item 5, Figure 10, flue damper flange surface and flue collector

assembly surfaces with a clean rag.

b. Position round gasket (item 7, Figure 10) on flue collector assembly

flue location shown in Figure 11, page 13

c. Place flue damper assembly on gasket. (See NOTICE, below.) Insert #10 x

½" screws through the holes. Alternate from screw to screw and tighten all

screws evenly and securely.

. Align bolt holes.

Model 380 top flue applications — always mount the damper

assembly with the damper adjustment plate pointed toward

the rear of the boiler as shown in Figure 11. Otherwise, the

jacket top panels may be difficult to install.

e. Install flue cap on remaining top opening (if any) using steps a through c,

above.

After installing flue collector, ALL BOILERS

1. Check for gas-tight seal of all flue collector hood components.

All collector hood joints must be sealed gas-tight to prevent

possible flue gas leakage and carbon monoxide emissions,

resulting in severe personal injury or death.

a. Open flue damper. Visually inspect inside section assembly and flue collector

assembly for any light passing through unsealed areas.

b. Mark all unsealed areas.

c. Check unsealed areas for cause — damaged gaskets, sealing rope not in

place, or loose bolts or nuts.

d. Correct all conditions and repeat inspection procedure.

e. If unsealed areas cannot be eliminated, discontinue the boiler installation.

Contact your Weil-McLain distributor or sales office for assistance.

Finger-

in the

12 Part No. 550-141-935/0602

Loading...

Loading...