OPERATING MANUAL

SPARE PART LIST

W aschbär SE 1 12 / 1 18

HWY1 18 EXT

Weidner Reinigungssysteme

D-74523 Schwäbisch Hall, Steinbeisweg 29

Telefon (0791) 95012-0 Fax (0791) 54 742

e-mail:info@weidner-cleaning.com

Internet: www .weidner-cleaning.com

GeneralRemarks:

1. the "Guidelines for LiquidJets" (RFL) ofthe CentralFederation ofIndustrial Trade Unions

-Technical Committee on Chemistry are to be observed. The brochure "Guidelines

forLiquidJets" is available from the Carl Heymanns- Verlag KG, Luxemburger Straße

449,50939 Cologne, under order No. ZHl/406.

2. The RFL orders that high-pressure cleaning equipment must be tested for operational

safe as often as required, though at least every 12 months by a qualified person

(persons who have adequate knowledge of the pertinent regulations on account of

theirtraining and experience to be able to assess thesafeworkingcondition

oftheequipment). Theresultsofsuch tests are to be puton written record.

3. The owner of the equipment must issue corresponding instructions necessary for a

safe operation and monitor their observance. It is thus necessary that the owner of the

equipment observes the Guidelines for Liquid Jets.

4. If connectedinto the public waternetwork the regulations of the waterworks are to be

observed.

5. When making the electrical connections, pleas pay attention tho the regulations of the

pertinent electric company ( electricity works ).

6. The heating device consists of a bumerwhich must be checked once a year by your

local chimney sweep in accordance with the 1

st

Implementing Order oft the Federal

Pollution Protection Legislation to ensure that the immission limit values are observed.

7. When operatingthe equipmentin rooms, a safe discharge ofthe flue gases must

beensured (flue gas pipe with airflue interruption/ chirnney). Care must also be taken to

ensure that adequate ventilationis provided ( combustion air).

8. Repairs to the high-pressure cleaner may only be carried out by the firm of Weidner or

by a person authorised by such.

9. During repairwork only original Weidner parts may be used in accordance with the

enclosed parts list.

10. 0nly original high-pressure hoses, type DN 8 ST1, operating pressure 210 bar, are to be

used. Please pay particulare attentione to the hoses. Every-pressure hose must comply

with the safety regulations and be marked with the operating pressure, date of

manufacture regulations and be marked with the operating pressure, date of

manufacture and manufacture.

Attention:

High~pressure hoses with a short service life and repaired high-pressure hoses are

extremely dangerous. Burst or leaky high-pressure hoses can lead to injuries, in

particular scaldings through pressurizedhot water.

11. 0nly use chemicals which comply with the detergents act, are biologically degradable

and do not burden the environment. Askfor aDIN specification sheet.

12. We recommend the conclusion of a maintenance contract with the firm of Weidner

agencies to ensure the regular and professional testing of the high-pressure cleaner.

13. Accessories and cleaning agents can be found in our list of accessories. We will be

delighted to help you in the choice accessories and cleaning agents suitable for your

cleaning needs.

14. Befor working on the high-pressure cleaner it must be disconnected from the mains,

remove plug from socket.

Description and function ofthe safety devices

Unloader valve with switch:

The unloader valve limits the operating presur. The desired operating pressure can be infinitely varied with this. If

the max. permissible operating pressure is exceeded or the spray gun closed the unloader valve channels the

water through its bypass line depressurized back to the high-pressure pump.

While the gun is closed the integrated micro-switch will open. About 20 sec. After the mikro-switch opened, the

motor of devices with time delay stop will be cut of.

If thepressure sinks below 10bar , the motor switches on irnmediately again.

*There will be no time delayed stop after the gun closed at devices without time delay stop. The device r uns

without pressure in the bypass. /

Attention:

The unloader valve has to be adjusted that overpressure is not more than 10% over working pressure.

Use and description of the equipment

The Weidner Waschbär SE 112/118 is a fully enclosed mobile hot -water high-pressure cleaning device.

The working pressure is generated by a Triplex pump with 3 ceramic plungers. The pump is flange- mounted

directly on thequill motor. There is apressure regulator with mechanical switch, flow controller and presure relief

valve on the high-pressure side of the pump. When the gun ist closed the pressur e regulator receives a switching

surge which causes the water conveyed by the high-pressure pump to be retumed to the high-pressure pump' s

suction side depressurized. The motor and pump run without a load. Heating is by means of af low heaterwith

heating spiral. The oil feed is controlled by thecontrol chain thermostat, flow controller and microswitch in the

mechanical pressure regulator. Ap-type heating oil switch can be incorporated in this control chain as an

accessory.

If workis interruptedfor longer than 1 minutes the device should be switched offto saveenergy .The device is

suitable to remove dirt from surfaces by means of a freely-expelled water jet. The cleaning device is particularly

suitable forcleaning machines, building facades, stables and floors as well as vehicles such as cars and trucks.

The choice of working pressure depends on the cleaning task. In the case of hard and stubborn dirt the highest

possible pressure should be used for cleaning. The operating pressure depends on the size of t he spray nozzle,

whereby the max. operating pressure is limited by the pressure regulator.

Apart from the working pressure and working distance from the object to be cleaned , thejet shape is also

important for the cleaning effect. A round spray nozzle with an angle of O degrees has the highest mechanical

effect an is, e.g. appropriate for cleaning stables or heavily soiled construction machinery and equipment. Normal

work can be carried out with a 25 degree nozzle. In case oflarge-scale cleaning work, e.g. floors, a 40 degree

nozzle can be used.

Important notices

If you discover transportation damage during unpacking pleas contact your Weidner sales office.

Start-up:

Open the stainless steel cover ( 64), check the oil level in the high-pressure pump and top up as required (see

specifications). /

Electrical connections

The voltage shown on the ratings plate must correspond with the voltage from the source of electr ic power.

The current lead must be fused with 32A on the SE112 ans with 50A on the SE118. A higher fusing is

not allowed.An FI safety switch is to be provided by the customer. .

The electrical connections and mains fusing should ony be installed by a professional.

The device may only be connected to a socket which has been installed in accordance with local laws . Work on

electrical components in the device may only be carried out by a qualied electrican.

Additional safety measures and precautions when working with el

1. Only connect the equipment to regular sources of electric power.

2. Check the cables for darnage before use -never connect damaged cables.

3. Connections must be dry and should not lie on the tl oor .

4. Do not touch the plug with wethands.

5. If an extension cable is used this should be completelyunwound from its drum and should have an adequate

wire cross section, otherwise the cable can overheat (scorch) andcause ashort-circuit;

(Threephase current equipment up to 10 meters long wire cross section 1.5 mm, up to 30 m long 2.5 mm, singlephase device type Waschbär SE 112/118. ..generally at least 2.5 mm wire cross section.)

Water supply

Connect water hose with Geka coupling on high-pressure cleaner at .

Connect water connection piece.

Fully open water tap.

Water feed pressure min. 2 bar,.max. 4 bar:A pressure reducing va1ve must be incorpor atedin the feed

line with higher water mains pressures.

Connection ofthe high.pressure hose

Screw one end of the high-pressure hose onto the pressure output nipple on the device. The other end

ofthe high-pressure hose is screwed to the spray gun.

Cleansant feed and supply

An injector will meter out the cleansant. Connect the cleansant hose to the injektor and place the suction

filter into the cleansant. The quantity of cleansant can be adjusted by turning the hand nut at the cleansant-injektor.

If all the prenamed points are fullfilled, activate the cleansant feed while opening the pressure adjusting nozzle at

the end of the jet pipe. The more the pressure adjusting nozzle is opened the more cleansant will be feed and the

other way around.

The function of the injector takes place only in case of*low pressure*. Feeding takes place only to a max. hose

length of 15 meters. Before using for other purposes consult with the firm of weidner or one of their agencies first.

Protection against freezing

Freeze can destroy equipment which has not been completely emptied of water .The best protection against freeze

is to place the device in a room protected against frost.

Warnings

Do not point the water jet at persons or animals (risk of injuries through pressure and heat as well as irritation of

mucous membranes and acid burn through chemicals ).

Do not point the water jet at the device itself or other electrical components (risk of short-circuits and other

damage ).

The device may not be used in rooms exposed to the risk of explosions.

When using chemicals suitable safety equipment should be worn ( safety goggles, safety overall, safety gloves,

boots etc.).

PIease pay attention to Section " A " of the appendix to VBG 1 35-47, Protection against dangerous chernicals.

Operation

Cold-water operatibn

Appliance switch to "0".

Thermostat to "0" degrees C (off).

Insert appliance plug into socket.

Turn on water supply .

Pull spray gun trigger and set appliance switch to position 1 "pump on".

The device starts.

The pump at first empties the device of air. After a while water comes out of the spray gun. Hold the spray gun

open unntil a steady jet of water is ejected. Now close the spray gun and switch off device.

Screw the lance with nozzle piece (34) onto the spray gun.

The device is now ready for operation.

Attention:

The water jet emitted causes a repulsion power in he spray gun. In the case of an angular lance with a spray

nozzle size 05 the repulsion power amounts to43 N (Newton).

Keep a tight hold on the lance and spray gun.

Cleansant additive

The dilution of the cleansant and the adjustment of the concentration at the metering valve depends on the

cleansant and the field of application.

Cleansant from integrated cleansant tank -turn the switch into the direction "tank".

Cleangant from seperate drum -turn the gwitch into the direction "2" .

If the cleangant tank/ drum is empty the metering valve should be closed (pos since otherwise air will be sucked in

and the working pressure will drop completely. On completion of work with cleansant the device should be

thoroughly rinsed with clear water .

Stopping

Close gun.

Set selector switch to "0".

Close water tap.

Open gun to allow remaining air to escape.

Close gun and secure trigger .

Remove plug from socket

Store hoses without bending ,

Care and maintenance

The care and maintenance of the device are the concern of the oper ator.

This must be carried out carefully so as to maintain the operational safety and efficiency of the device.

Attention:

The most important components of the high-pressure clianer suche as the high-pressure hoses, spray gun, pum p

and safety devices are to be checked for proper function before every use.

Maintenance plan:

Weekly oil level: is the oil cloudly or has it dropped to below the MIN mark ? Change or top up oil.

Oi lchange every 5O working hours at the latest, thoug at the latest every 6 months.

Check heating oil filter for dirt and lean as required.

Scheck filling of lime stabilizer, always keep the stabilizer bottle fun.

Fault and remedies

Fault Possible cause Remedy

device does not start no electricity check cables, plugs

socket and fuse

thermoprobe motor deterrnine and remedy

triggered cause of overload

pilot fuse defect replace pilot fuse

find out cause if there

is a burn throuh again

pump under pressure trigger spray gun

water leak packing worn or plunger pipe defect replace

pump does not reach pressure or water supply inadequate open wat er tap

is loud, pressure fluctations check float valve

clean water inlet sieve

reduce height of suction

suction valve clogged rins pump with clear water

soiled or wom valves, packing worn clean or replace

unloader valve leaky or soiled

nozzle washed out or replace

wrong nozzle size

oil leak on crankshaft shaft seal faulty replace seal, scheck shaft

incrased noise with no loss baring worn out replace bearing,

of pressure change

interval to long

pump oil milky white condensation water forrnation reduce oil change

interval

unloader valve tops at short gun or hp-hose leaky seal, replace

intervals with gun closed jack valve or unloader valve worn out replace jach valve

hight pressure gauge defection when unloader valve incorrectly set or foul adjust unloader valve,

gun closed replace

Water volu me to small wrong no zzle size

use nozzle acc. to rating, plates

nozzle dirty clean or replace

unloader valve too low set sorrectly

unloader valve faulty replace

Chemicals are not sucked in chemical tank emty fill

Chemical line blocked clean

Chemical line faulty replace

injector blocked clean

injector faulty replace

pressure adjustment nozzle too far open

closed

hp-hose too long use a hose w. nominal diameter

20

Pos. No. Bezeichnung Description

2 3851502700 1 Passfeder parallel key

5 3851502745 8 Schraube screw

8 EPACA43344 halb Lagerdeckel quill

10 EPACA43343 2 O-Ring Lagerdeckel o-ring quill

11 EPACA43222 halb Simmering simmering

15 EPACA014480 2 Lager camp

20 EPACA043345 3 Pleuel, kompl. piston rod

25 EPACA044923 1 Kurbelwelle crankshaft

30 EPACA044949 1 Hauptschalter für Bodenbefestigunng main switch for soil attachment

32 EPACA043211 1

Verschluß

(Öleinfüllstutzen

)

catch

33 EPACA014177 1 O-Ring Verschluß o-ring catch

37 EPACA043987 1 Ölschauglas

38 EPACA044428 1 Flachdichtung gasket

40 EPACA092520 4 Schraube screw

48 EPACA025625 1 Ölablaßschraube oil drain plug

49 EPACA023170 1 O-Ring, Ablaßschraube o-ring,

50 EPACA043339 1 Gehäusedeckel discharge screw

51 EPACA043340 1 O-Ring, Gehäusedeckel o-ring, fram cover

53 EPACA043338 1 Kurbelgehäuse crank case

56 EPACA043355 1 Ölwanne oil pan

64 EPACA043351 3 Bolzen pin

65 EPACA43365 3 Plungerstange plunger seaweeds

70 EPACA043228 3 Simmerring Buna-N simmering

75 3851502778 3 Stauscheibe pilot disk

88 EPACA045697 3 Scheibe disk

90 EPACA043367 3 Keramikplunger creamics plunger

96 EPACA043235 3 Stützring, Plungerhalter back-up ring

97 EPACA017399 3 O-Ring, Plungerhalter o-ring, plunger owner

98 EPACA045891 3 Scheibe disk

99 EPACA104360 3 Plungerhalter plunger owner

100 EPACA0456812 3 Dichtungshalter kmpl. seal owner

101 EPACA043302 3 Ölfilz oil felt

106 EPACA043305 3 ND-Dichtung ND-seal

120 EPACA045679 3 Dichtungsgehäuse seal housing

121 EPACA014200 3 O-Ring, Dichtungsgehäuse.Buna-N o-ring, seal housing

121A EPACA011719 3 O-Ring, Dichtungsgehäuse, Viton o-ring, seal housing

125 EPACA046667 3 HD-Dichtung, Buna-N HD-seal

125A 3851502811 3 HD-Dichtung, Viton HD-seal

139 EPACA022179 1 Stopfen, Einlaß 1/2" plug inlet

162 EPACA043357 6 Stützring back up ring

163 EPACA043358 6 O-Ring, Ventilsitz Buna-N o-ring, valve seat

163A EPACA044938 6 O-Ring, Ventilsitz Viton o-ring, valve seat

164 EPACA030821 6 Ventilsitz valve seat

166 EPACA030821 6 Ventil valve

167 3851502832 6 Ventilfeder vale spring

168 EPACA044565 6 Federhalter Ventil penholder valve

172 EPACA017615 6 O-Ring Ventilst. Buna-N o-ring valve Buna-N

172A EPACA015855 6 O-Ring Viton o-ring Viton

174 EPACA043849 6 Ventilstopfen valve pot

185 EPACA044837 1 Pumpenkopf pumping head

186 EPACA012503 2 Federring lock washer

188 EPACA087931 2 Schraube M10x35 screw M10x35

250 803118672 1 Wellenschutzkappe waving protective cap

299 EPACA810027 1 Pumpenkopf komplett pump head cmpl.

350 EPACA030696 1

Werkzeug

(Ventilsitz)

tool (valve seat)

351 EPACA035104 1

Werkzeug

(Dichtungsgehäuse)

tool (seal housing)

300* EPACA033623 1

Dichtungssatz STG,

enthält Nr.97; 101; 106; 121; 125

gasket kit

C:\\HWY_HWYSE112/118EXT

Reinigungssysteme

...die sauberste Lösung

HWY 118EXT_Blechteile

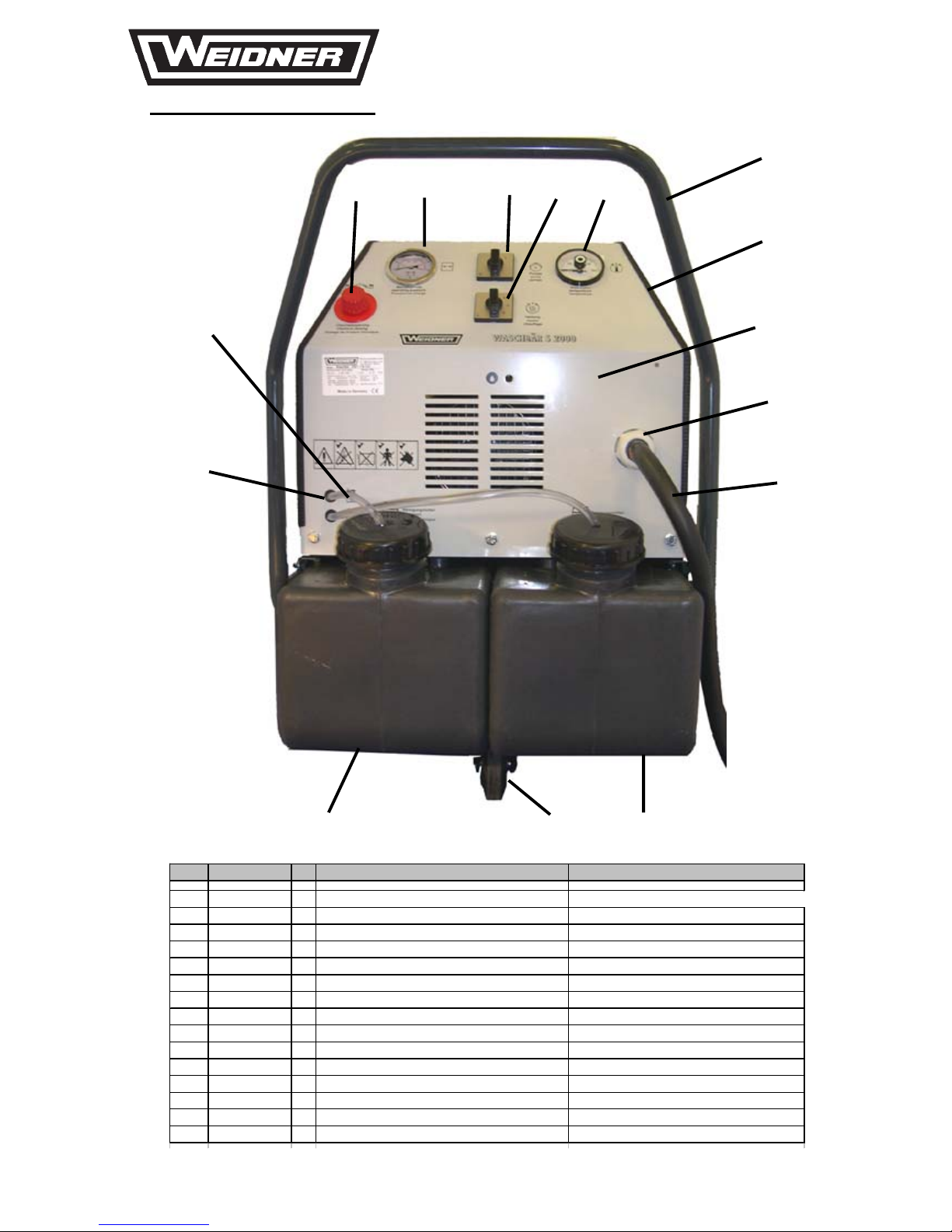

Pos. No. Bezeichnung Description

1 ETA200035 Schi ebebügel W a sc hbär ab 0 6/1999 handle, Ve rsion aft er 06/1999

2 ETD130000 Ma nom eters chl auch, 410 lg. 250 bar h.p. hos e f. pressure gauge

3 3882800060 Brennkam m er VA Wasc hbär SE com bust i on cam ber

4 ETB220102 Stec kdeck el P V C Cover

5 359000 01060 Sich erhei ts therm ost at 9 5°C m i t Tauchhül se safety t herm ostat with di ppi ng case

6 EP A CA 003 00 Hoc hdruck pumpe CAT 300 in spezial ausf. HP pum p CA T 300 sp ecial edit i on

7 ETA200600 Laufrad,schwarz , luft berei ft 260x 85 air wheel,bl ack

8 ETA201500 2 Starlockkappe für 20mm A chs e loc k di sc for wheel

9 3651427520 Hauptschalter für Bo denbefest igun ng mai nswitc h

1

9

2

3 4

5

8

7 6

C:\\HWY_HWYSE112/118EXT

Reinigungssysteme

...die sauberste Lösung

Pos. No. Bezeichnung Description

1418 38 82800 060 Brennkammer V A Wasc hb är SE combus tion cham b er

1423 36 56040600 Ei ns chraubhei zk örpe r 403K 600/44/ 3 B G 1 6000W heatin g uni t 6000W

HWY 118EXT_Rückwand

1

2

C:\\HWY_HWYSE112/118EXT

Reinigungssysteme

...die sauberste Lösung

Pos. No. Bezeichnung Description

1 3882 800 040 Rückwand Wasc hbär SE mont agefertig rear panel

2 3882 800060 Brennkam mer VA Wasch bär SE combus tion cham ber

3 3708 500 518 Hochdrucks chlau ch 600m m 2S T 10,e s A G

R

hp hose 600m m 2S T 10, es A GR 3/ 8"

4 ETD130000 Manom eters chl auch, 410 l g . 250 bar h.p. hos e f. pressure gauge

5 3882 800030 Arm at urbl ech Was chbär S E m ontageferti g front panel

6 E TE504 300 E l ek trom ot or 3,0 KW 40 0V , 50Hz, 1420 Elec trom ot or 3,0 KW, 400V , 50Hz , 1420

7 E TA200 035 S c hi e bebügel Wasc hbä r ab 06/ 1999 9 handle, V e rs i on aft er 06/1999

8 3914 900010 Rohrschel le , 22 m m , A l um i n ium , clam p, al u mi n ium

9 EPA CA00300 Hochdruc kpum p e CA T 300 in spezialaus f. HP pu m p CAT 300 sp ecia l e di tion

10 ETA200600 Laufrad,s chwarz , l uftb erei ft 26 0x 8 5 air wheel, bl ack

11 ETA201500 2 St arl ock kappe für 20mm A chs e loc k disc for wheel

12 35900001060 Sicherhei t st herm o s tat 95°C m i t Tauch hül s e S afet y t herm ost at 95 °C with dipp i ng c ase

13 ETB220102 Ste ck d eckel PV C Cover

1

2 3 4 5

13

12

11 10 8

9

7

6

HWY 118EXT_Seitenansicht

C:\\HWY_HWYSE112/118EXT

Reinigungssysteme

...die sauberste Lösung

Pos. No. Bezeichnung Description

1 4561 664 xx 8 Kabeltü llen dopps. 9 X 11 X 16 Cable sleeve

2 E TG111055 PV C-S c h l auc h 5 x 2, Länge angeb. PVC hose order leng ht y o u need

3 E TG204500 Dosie rventil für Reini gung s m i t tel dosi ng valve for 2 det ergent

4 ETD260200 1 Druckma nom e ter 0-250 bar, 63mm pressure gauge 0 -250 bar

5 3652 827 502 Ei n-Aus schalter 1 pol i g f. Frontbefestigu ng swit ch off/on 0 / 1

6 3652 827602 Gruppens chal t er 1pol i g f. Fro nt befes tig ung swi t ch 0/ 1/2/ 3 for Heati n g

7 ETE186200 Temperat urregl er 0 -95°C m it Tauch hül se t em pe rature regula tor with dipping cas e

8 E TA200 035 S c hi e bebügel Wasc hbä r ab 06/ 1999 9 handle , V ersion aft er 06/1999

9 E TA190 100 1 Kant ensc hutz ,k l . Länge angeben protect i on profil e order le nght y ou need

10 3882800030 Armaturblech Was chbär S E m ontageferti g front pane l

11 3654899108 Kabel verschra ubung M 32 aus P ol y a mi d cable gla nd M 32

12 3655005100 Gummi kabel H07RN-F 5G1 0 rubber wire 5 G 10mm ²

13 ETB110601 Chemiet ank ant hrazit-grau dtergent tank anth raz i t - grey

14 3759900019 Lenkrol l e 10 0 x 30, 4 Loch Fl a nsch jockey whe el 4 h ol e fixing

15 ETB110701 Heizöl tank anthraz i t -gra u fuel tank ant h raz i t - grey

15 14 13

8

9

10

11

12

3 4 5 6 7

2

1

HWY 118EXT_Frontansicht

C:\\HWY_HWYSE112/118EXT

Reinigungssysteme

...die sauberste Lösung

HWY 118EXT_Schwimmerventil

Pos. No. Bezeichnung Desc ription

1305 39 09900 153 1 PVC Kunststoffschwi m mer 65 x 130 pvc ball 65 x 130

1304 39 09900103 1 Schwim m erventi l 3/ 8" 12m m , 170 mm floatvalve 3/ 8" 12mm ,1 70 m m

1

2

C:\\HWY_HWYSE112/118EXT

Reinigungssysteme

...die sauberste Lösung

Pos. No. Bezeichnung Description

1 ETE504300 Elekt romoto r 3,0 K W 400V, 50Hz, 1420 E l e ct rom o tor 3, 0 KW, 4 00V, 50 Hz, 1420

2 56 80301 580 1 Sc hlauc h tüll e, 3/8" AG x 13 m m brass n i pple 3/ 8" x 13 m m

3 37 80000030 2 1/2" S chl auch (Länge angeb en) 1/2" ho s e (order l enght y ou need)

4 ETE180500 Wass e rm an gel schalter f. Waschbär S E l ow water swic h

5 56 84901 208 1 WE-15 x 3/ 8 Wi nkel verschraubung, h.p. fit ting

6 ETD500100 Unloaderventil VB 9 m. Druck schalter unloaderventil VB 9 w. swit ch

7 56849 01 060 1 GE 12-PLR-R3/8 G erade E ins chraubvers. hp fitting

8 ETD161600 1 12 x 3/8" WE RST S onder - Winke l versc h raubung hp fit ting

9 56 80301500 Schlaucht ü ll e 1/2" A G x 6 mm l ow pr. F i t t i ng 1/2" A G x 6 mm

10 5680301350 T-S tück 1/2" Mes s. AG x IG x IG T-pc 1/2"

11 ETA350040 4 Gummi-Metall puffer, 40 x 30 mm 2xM 8 AG rubber el e m e nt

12 ETD345010 1 V erl änge rung, 60m m, 1/2" AG x 1/ 2 " IG M ext e ntion brass 1/2" x 60 m m

13 5680301630 1 1/ 2" V ersc hrau bung,k eg. 1/2" A g.x A G . M ess . union 1/2" m x m brass

14 5680301410 Winkel 90° 1/2" IG x A G M essing ellbow 90° 1/2" m a. x fe.

15 3708500518 Hochdrucksch l auch 600 m m 2S T 10, es A G R 3/8" hp hose 600m m 2S T 10, es A G R 3 / 8 "

16 3686904003 Muffenschi eber 1/2" sl eeve valve

17 5680301490 3 Schl aucht ü l l e ,1/ 2"AG . x 13mm brass ni ppl e 1/2" x 13 mm

18 3882800040 Rückwand Waschbär S E mon tageferti g rear panel

HWY 118EXT_Pumpenaggregat

1 2 3 4 5

6

7

8

9

18

17

16

15 14 13 12 11 10

C:\\HWY_HWYSE112/118EXT

Reinigungssysteme

...die sauberste Lösung

1

2 3 4 5

6

7

8

9

10

11

12

13

14

15

16

17

18

1920

21

HWY 118EXT_Schaltkasten

Pos. No. Bezeichnung Description

1 3652458110 Miniat urrelais MY 4 24VAC miniat ur relais

2 3652473404 S chütz 12A 1S + 1Ö 24V 50/ 60Hz contac t or 12 A

3 3651427520 Haupts chal ter für Bode nbefes ti gun ng m ai nswi t ch

4 E TE116200 1 Zeitrelais rückfallverzögernd Typ 51183 elect ronic ti m er relais delayed

5 3659151425 1 Verdrahtungskanal LK 4 40/25 PV C ins t all at i on t ube

6 3652291002 12 Durchgangsk lem m e terminal bl oc k

7 3652299000 S chut zleiter Kl em m e ground terminal bl ock

8 3652251201 S chutzlei terk l em me US LK G16N earth terminal

9 3652251110 Reihenk l em me UKN16BU terminal block

10 3652251100 Reihenklemme UK N5B U terminal block

11 3652251200 Schut z l ei t erk lem m e USLK G4 earth terminal

12 E TE600000 1 Transformator RST 100 400V / 24 AC transformer

13 3652299100 3 S i cherungshalter fuse holder

14 3652051951 Glasrohrsicherung 5x20 3,15A t r fuse 5 x 20 3, 15 A tr

15 E TE153500 1 Gl as rohrs icherung 5 x 20 1,0 A t r fuse

16 E TE153500 1 Gl as rohrs icherung 5 x 20 1,0 A t r fuse

17 E TE151300 Glasrohrsicherung 5 X 20 0,5A träge fuse 0, 5A

18 3651773209 Motorschutzs chalt er 6-10A circuit break er

19 3651251300 Dreiphasensc hine 1065mm S Z PS B 4N power rail 3 ~

20 3651851010 Leitungssc hut zs chalt er B10 1polig fus e automat B10

21 3651268220 1 K l emm kasten power panal

Loading...

Loading...