Page 1

SpeedMarking-Laser

User's Manual

Page 2

Page 3

Foreword

5658600000/00/05.07

3

Foreword

Revisions

Version Date Modification

0.0 05/07 First release

Range of delivery

Please check to ensure that your SpeedMarkingLaser is complete. Your SpeedMarking-Laser should

contain the following parts.

• Special packing SpeedMarking-Laser

• SpeedMarking-Laser

• Toner

• Parallel printer cable

• Power cord

• User's Manual

• CD with software and driver

Installation instructions

This manual contains important information for installing and initial start-up procedures for the

SpeedMarking-Laser.

You can find here information about the installation,

setup and remedy of defects of the SpeedMarkingLaser.

For more information, useful tips, or the latest drivers, check our homepage at:

www.weidmueller.com

Follow the Downloads → Printer Drivers → Speed

Marking Laser links.

You can also send us an e-mail at

info@weidmueller.com.

Contact address

Weidmüller Interface GmbH & Co. KG

Postfach 3030

32720 Detmold

Klingenbergstraße 16

32758 Detmold, Germany

Phone +49 (0) 5231 14-0

Fax +49 (0) 5231 14-2083

E-Mail info@weidmueller.com

Internet www.weidmueller.com

Page 4

Contents

4

5658600000/00/05.07

Contents

Foreword ............................................................................................................................3

Revisions.............................................................................................................................3

Range of delivery.................................................................................................................3

Installation instructions.........................................................................................................3

Contact address...................................................................................................................3

Contents.............................................................................................................................4

1. Safety instructions................................................................................................6

2. Printer installation.................................................................................................8

2.1 Printer components.................................................................................................8

2.2 Setting up the printer...............................................................................................9

2.3 Unpacking the printer............................................................................................10

2.4 Insertion of toner cartridge ....................................................................................10

2.5 Connection of printer cable ...................................................................................11

2.6 Connection of mains cable....................................................................................12

2.7 Installation of printer driver....................................................................................12

3. Basic information of the printer......................................................................... 14

3.1 Printer functions....................................................................................................14

3.2 Operating panel.....................................................................................................15

3.3 Operating panel buttons........................................................................................15

3.4 LED displays.........................................................................................................16

3.5 Switch for printing SF markers..............................................................................17

3.6 Printer drivers........................................................................................................17

3.7 Accessories and ordering information...................................................................18

4. Printing jobs........................................................................................................19

4.1 Printing of adhesive backing markers ...................................................................19

4.2 Printing preparation...............................................................................................19

4.3 Printing jobs ..........................................................................................................20

Page 5

Contents

5658600000/00/05.07

5

5. Printer tips and maintenance.............................................................................21

5.1 Improvement of printing ........................................................................................21

5.2 Extend the lifespan of the special-toner cartridge .................................................21

5.3 Maintenance of special-toner cartridge.................................................................21

5.4 Printer maintenance..............................................................................................22

6. Troubleshooting..................................................................................................23

6.1 Fuses....................................................................................................................23

6.2 Overheating shutoff...............................................................................................23

6.3 Remedy for congestion.........................................................................................23

6.4 Problems with the printing quality..........................................................................25

6.5 Checklist for troubleshooting.................................................................................26

7. Guarantees ..........................................................................................................28

7.1 Limited guarantee .................................................................................................28

7.2 Guarantee exclusions ...........................................................................................28

7.3 Restriction of liability .............................................................................................28

7.4 Customer support during and after the guarantee period......................................29

7.5 Packaging instructions..........................................................................................29

7.6 Guarantee for toner...............................................................................................29

8. Printer specifications..........................................................................................30

8.1 Environmental conditions......................................................................................30

8.2 Consumables........................................................................................................31

Page 6

Safety instructions

6

5658600000/00/05.07

1. Safety instructions

Read the following instructions carefully before starting up the SpeedMarking-Laser.

Observe the warnings and notices on the

SpeedMarking-Laser at all times.

• The mains voltage must correspond to

the system voltage given on the SpeedMarking-Laser type plate.

• Connect the device to a properly earthed

and fused socket outlet only. Do not use

a socket outlet already being used by

devices that are turned on and off at

regular intervals, such as photocopiers

or ventilators.

• Do not connect the SpeedMarking-Laser

to either a switched or a timer-controlled

socket outlet.

Do not use the computer system close to

potential electromagnetic disturbance

fields such as loudspeakers or base transceiver stations for mobile telephones.

If you connect the SpeedMarking-Laser to

the power supply via an extension cable,

ensure that the total nominal current of all

of the devices connected to the extension

cable does not exceed the capacity for that

extension cable. In addition, you should

ensure that the total nominal current of all

the devices plugged into the wall-mounted

socket outlet does not exceed the ampere

rating for that socket outlet.

Do not carry out repairs to the device yourself.

• Never use damaged or worn out power

cables.

• Connect the device to the mains only

with cable described in this guide.

• Avoid the usage of multiple cables.

• Connect the network cable directly

(never via an extension cable) to the

power socket.

• Keep the mains cable undamaged and

keep it in its original state. Do not place

any heavy objects on it. Do not pull at it

with force and do not bend it more than

necessary. A disregard of these instructions can lead to electrocution or fire.

• Place the device close to an accessible

power socket in order to be able to pull

the mains plug in case of an emergency.

• Never connect or disconnect the mains

plug to the power socket with wet hands.

There is a risk of electrocution.

Disconnect the SpeedMarking-Laser and

contact a qualified service engineer if any

of the following occurs:

• The power cord or plug are worn or damaged.

• A fluid has penetrated into the SpeedMarking-Laser.

• The SpeedMarking-Laser is allowed to

fall or the enclosure is damaged.

• The SpeedMarking-Laser does not operate normally or the standard of performance varies noticeably.

Keep any moisture or dust off the device.

Otherwise, there is the danger of fire or

electrocution.

Page 7

Safety instructions

5658600000/00/05.07

7

• Do not spill any fluids into the SpeedMarking-Laser.

• Place the device onto a solid, flat surface. Otherwise, it could fall down and

lead to possible danger to personnel.

• For installation in limited space, make

sure that there is sufficient ventilation for

the device.

• Do not block or cover openings of the

SpeedMarking-Laser.

• Do not insert any objects into these

openings.

This device is not to be operated without supervision.

The internally-emitting radiation is kept inside the printer by the protective housing

and the external cover. The laser beam

cannot emit from the device during operation.

The printer cannot be used or maintained if

the protective cover is taken off the laser or

scanner unit. The reflective beam is invisible and can damage the eyes.

Warning signs (BGV A 8 (VBG 125) & DIN 4844)

WARNING

Mind your hands.

Do not reach inside.

WARNING

Hot surface.

Do not touch.

Page 8

Printer installation

8

5658600000/00/05.07

2. Printer installation

This chapter is for the setup and installation of the

new SpeedMarking-Laser.

Follow after unpacking the printer the listed steps in

the checklist in its exact order. Each step is described in detail with easily understandable specifications.

2.1 Printer components

A B

C

Figure 1 Front side

A Cover

B Operating panel

C Output

A B

Figure 2 Rear side

A Parallel interface

B On/Off switch and mains connection

A

Figure 3 Rear side

A Input

Page 9

Printer installation

5658600000/00/05.07

9

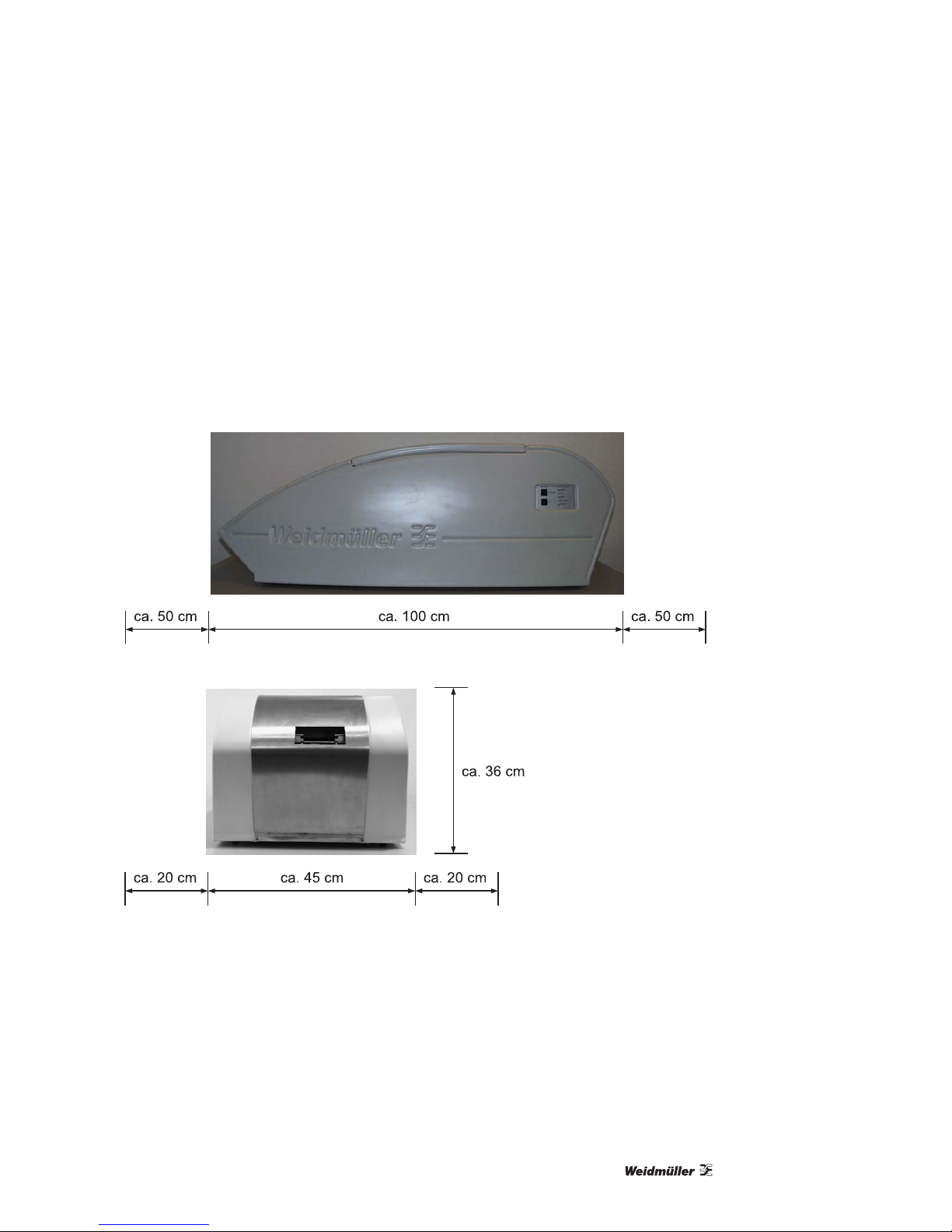

2.2 Setting up the printer

• Place the device onto a solid, flat surface.

• Provide sufficient ventilation.

• The ambient conditions should be stable, e.g. the temperature and humidity fluctuations should be limited

(Temperature: 20 °C – 35 °C; Humidity: 55% – 75%).

• Avoid direct sunlight on the printer.

• The environment of the printer should be free of any chemicals.

The following dimensions show the space required for setting up the printer.

Figure 4 Space in front of and behind the printer

Figure 5 Space on both sides of the printer

Make sure that there is enough space in order:

• to open the upper cover

• to load material into the entry

• to empty the storage tray

• to be able to access the on/off switch

• to connect the mains and printer connection

• to use the operating panel

Page 10

Printer installation

10

5658600000/00/05.07

2.3 Unpacking the printer

Store all packaging material.

In case of repairs you should return the

printer in its original packaging to avoid any

possible damage in transit.

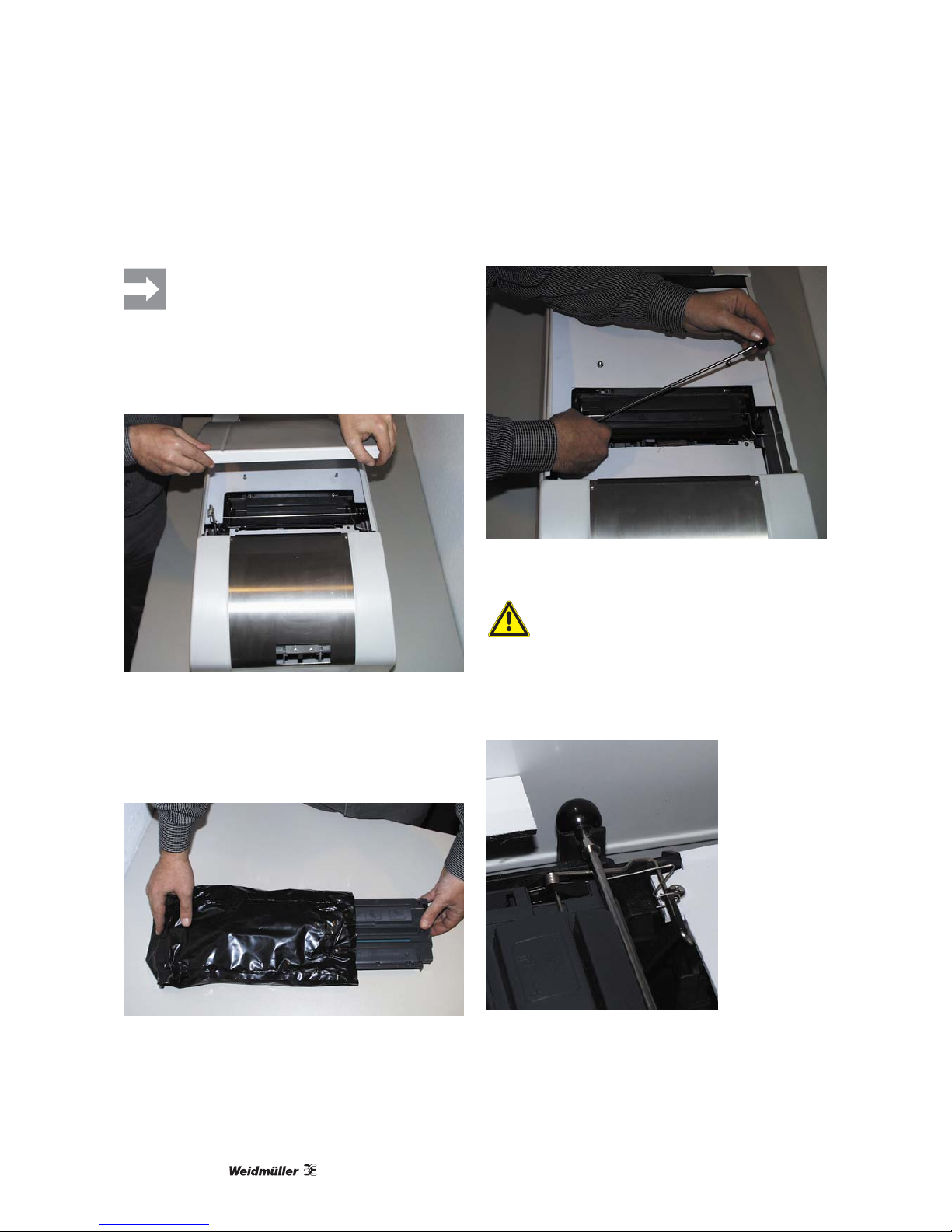

2.4 Insertion of toner cartridge

Figure 6 Opening the upper cover

1 Open the upper cover

2 Remove the transport retainer that is situated be-

low the cover of the SpeedMarking-Laser.

3 Take the toner cartridge out of its packaging.

Figure 7 Removal of toner cartridge out of pack-

aging

4 Remove the alignment rod for the roller.

Figure 8 Remove alignment rod for the roller

Caution

To avoid any damages, the toner cartridge

should be exposed to the sunlight only for

a few minutes.

5 Follow for steps 5-6 the instructions on the roller.

Figure 9 Roller

6 Do not position the toner cartridge upside down

and do not shake it.

Page 11

Printer installation

5658600000/00/05.07

11

7 The transparent plastic-sealing strip is at the right

side of the toner cartridge.

Pull the strip (30 - 35 cm) completely out of the

toner cartridge and dispose of it.

Avoid any contact with the black toner on

the strip.

If any toner gets on your clothing, wipe it of

f

by means of a dry cloth. Wash it subsequently with cold water.

8 Insert the toner cartridge into the printer. Observe

that the arrow on the toner cartridge is pointing in

the same direction as the arrow on the printer.

Insert the alignment rod for the roller in its designated holding fixture. Close the upper cover.

Figure 10 Insertion of toner cartridge

Never print without the cover of the

SpeedMarking-Laser. The possible light

exposure of the toner results in strong soiling of the device. The MultiCard strips will

be printed completely black.

2.5 Connection of printer cable

The SpeedMarking-Laser possesses a parallel connection. Use this connection, if

• a connection should be established to a computer

or laptop.

• your parallel cable has a standard length (up to

3 m).

A

Figure 11 Connection

A Parallel connection for the printer cable

The printer cable is included in the range of

supply.

Page 12

Printer installation

12

5658600000/00/05.07

2.6 Connection of mains cable

Figure 12 Connection of mains cable

WARNING

Make sure that the power is not switched

on.

1 Switch off the printer by pressing the On/Off but-

ton on the rear side.

2 Insert the mains cable firmly into the printer.

3 Connect one end of the mains cable to an

earthed multiple socket. Make sure that the

mains connection is sufficiently secured.

You can find more information in chapter 8

"Printer specifications".

4 Switch on the printer.

2.7 Installation of printer driver

Before printing, you should install the

printer software.

Before you can use the printer with its

software applications, you have to install

the printer driver.

Windows printer system

Install one of these printer drivers, if the operating

system on your computer is Windows NT4, Windows

95/98, Windows ME, Win 2000/XP.

The SpeedMarking-Laser is compatible to the following printer types:

• HP III

• HP LaserJet 6P

• HP LaserJet 6P/6MP (recommended)

Install from the delivered CD the printer driver HP

LaserJet 6P/6MP-Standard

1 Place the CD into your CD-ROM drive. The CD

starts automatically.

2 In the following menu, choose "printer driver" →

"SMARK“ → and your installed operating system.

3 If the CD does not start automatically, choose

from the CD the file “setup.exe”

or

the following path:

(CD-ROM:\ D:\Driver\SMARK\English\[Choose

the corresponding operating system]).

Page 13

Printer installation

5658600000/00/05.07

13

Installation of the Windows printer drivers

For Windows 2000/XP

1 Save the printer driver locally on the hard disk.

2 Add a new printer.

Windows 2000:

1 “Start“ → “Settings“ → “Printer“ → “New printer“.

2 Follow the installation assistant of the printer.

3 Select “Local printer“ → “Use existing connec-

tion“ (LPT1:).

4 Press the button "data carrier" and choose by

pressing "search" the file "hp6pmp.inf" from the

previous locally-stored driver files.

5 Choose the printer HP LaserJet 6P/6MP-

Standard and finish the installation.

Windows XP:

1 „Start“ → ”Settings“ → ”Printer & Fax machine“ →

“Add printer“.

2 Follow the installation assistant of the printer.

3 Select “Local printer“ → “Use existing connec-

tion“ (LPT1:).

4 Press the button "data carrier" and choose by

pressing "search" the file "hp6pmp.inf" from the

previous locally-stored driver files.

5 Choose the printer HP LaserJet 6P/6MP-

Standard and finish the installation.

For Windows ME

1 Follow the installation assistant of the printer.

2 Select “Local printer” (LPT1:).

3 Press the button "disk" and choose by pressing

"search" the file "OEM95.inf" from the previous

locally-stored driver files.

4 Choose the printer HP LaserJet 6P/6MP-

Standard and finish the installation.

For Windows 95/98

The installation program for the printer driver starts

automatically from the CD.

1 Follow the instructions of the program and install

the printer driver locally on the hard disk.

For Windows NT 4

1 Follow the installation assistant of the printer.

2 Select “Local printer“ (LPT1:).

3 Press the button "search" and choose by press-

ing "search" the file "hp6pmp.inf" from the previous locally-stored driver files.

4 Choose the printer HP LaserJet 6P/6MP-

Standard and finish the installation.

Page 14

Basic information of the printer

14

5658600000/00/05.07

3. Basic information of the printer

3.1 Printer functions

Technical data

Application: Printing of the product portfolio MultiCard

Speed: Maximum 3-4 cards per minute

Operating time: Approx. 2-3 hours per day

Printing quality: 600 x 600 points dpi for texts and graphics

Feed: Manual loading

Conditioning: Heat radiator with approx. 1200 Watt

Fusing: Heat radiator with approx. 1200 Watt

Interface: Centronics parallel (others optionally possible)

Connection: AC 230 V / 16A

Operating conditions: Office conditions

Ambient temperature: 20 °C – 35° C

Humidity: 55% – 75%

Dimensions (W x L x H): 1000 x 430 x 380 mm

Table 1 Technical data

The SpeedMarking-Laser offers the user the

following:

• Saving of time: 3 - 4 MultiCards per minute

• Easy to use

• High marking quality

• Markers immediately ready for use

• Works fast, independent of the amount of data

• Extreme flexibility through fast and demand-

oriented production

• Printing of the product portfolio MultiCard

You can find more information in chapter

4.1 "Printing of adhesive backing markers".

• Reduced storage costs because only neutral

markers are needed

• Suitable for graphics

Page 15

Basic information of the printer

5658600000/00/05.07

15

3.2 Operating panel

A

B

C

D

E

F

Figure 13 Operating panel

A Button Job Cancel

B Button Test

C LED Error (red)

D LED Data (green)

E LED Ready (green)

F LED MultiCard (yellow)

3.3 Operating panel buttons

The printer possesses the buttons: Job Cancel (A)

and Test (B).

Job Cancel

Press the button Job Cancel to abort an ongoing

printing job. During deletion of the printer storage,

the LEDs on the operating panel will light up one after the other. The LEDs will then switch into the

ready mode. This can take some time depending on

the size of the printing job.

If the button Job Cancel has been pressed

by mistake, then the job has to be printed

again.

If the button Job Cancel is pressed during

no-load operation, the upper LEDs of the

operating panel will light one after the

other.

Test

• Press the button Test to restart the printing after

the printer has been stopped or data is still stored

in the printer storage (the Data LED and Ready

LED light up).

• Press the button Test in order to delete error mes-

sages of the printer (Error LED lights up).

A

B

Figure 14 Operating panel buttons

A Cancel job

B Test

Page 16

Basic information of the printer

16

5658600000/00/05.07

3.4 LED displays

The LED displays indicate status and error messages. The LEDs can be in the following mode.

Off On Flashing

Messages of the upper status field

The following status messages of the operating

panel indicate different requirements of the printer

for the preparation of a printing job or during printing.

If the error LED lights up, then there is an error at

the printer.

You can find more about error messages

in chapter 6 "Troubleshooting".

Errors Data Ready MultiCard Description

The printer is ready for printing.

The printer is receiving or processing data.

Data that has not been printed is in the printer storage.

Press the button Test in order the print the data or the

button Cancel job to delete a job.

If all LEDs light up one after the other, the printer is per-

forming a warming-up, processes a self-test or cancels a

printing job.

Table 2 LED displays

Page 17

Basic information of the printer

5658600000/00/05.07

17

3.5 Switch for printing SF markers

Figure 15 SF switch

1 Open the cover of the SpeedMarking-Laser.

The switch for printing SF markers is situated here.

If SF marker should be printed, the switch must be

set to "SF 1-6".

If long or high markers are used (e.g. SF

5/21) and the print-out in the last row is not

printed properly, than set the switch also to

"SF 1-6".

3.6 Printer drivers

The SpeedMarking-Laser is compatible to the following printer types:

• HP III

• HP LaserJet 6P

• HP LaserJet 6P/6MP (recommended)

More information for installation of the

printer driver is available in chapter 2.7

"Installation of printer driver".

Page 18

Basic information of the printer

18

5658600000/00/05.07

3.7 Accessories and ordering information

Optional Description and utilization Part numbers

Special-toner cartridge Spare cartridge 1770070000

Cable and interface accessories Connection of printer

Software CD CD including drivers and printing software 1954040000

Loader Automatic feeding of MultiCard 1782880000

Table 3 Accessories and ordering information

Page 19

Printing jobs

5658600000/00/05.07

19

4. Printing jobs

This chapter is about printing options and printing

jobs that have to be performed regularly.

4.1 Printing of adhesive backing

markers

The Weidmüller adhesive-backing device

markers ESG, SM and CC are recognizable by their brown paper material. Their

suitability for printing in the SpeedMarkingLaser is only limited.

Please make sure that each used type of

marker has been tested and approved by

the user, by checking for any issues with

the adhesive part of the marker. In case

adhesive may leak from the marker, do not

use it.

CAUTION

Observe the following for the automatic labelling of the adhesive-backing markers.

The impairment of the interaction area as

well as the soiling of the roller can lead to

blotchy printing of the markers and to

damaging the device.

It is necessary to clean the Corona unit if

printing 5 MultiCards or more.

• The adhesive backing of the markers leave adhe-

sive remnants on the Corona unit of the printer.

• A roller contaminated by glue residues of the spe-

cial-toner cartridge cannot be cleaned and must

therefore be changed.

The cleaning of the Corona unit is described under "Cleaning of the SpeedMarking-Laser" in chapter 5.4 "Printer maintenance".

4.2 Printing preparation

Selection of media

Only markers of the Weidmüller MultiCard line with a

height of 9 mm or less can be printed with the

SpeedMarking-Laser.

You can find more information in chapter

4.1 "Printing of adhesive backing markers".

For usage of SF MultiCard strips, please

observe the chapter 3.5 "Switch for printing

SF markers".

CAUTION

It is only allowed to feed entire MultCard

strips into the printer.

Damaged or incomplete MultiCard strips

can damage the device.

As a rule, soiled or smudgy MultiCard

strips should not be used.

Each MultiCard can only be used once.

Page 20

Printing jobs

20

5658600000/00/05.07

4.3 Printing jobs

4.3.1 Stopping a printing job

A printing job can be stopped by the software application, printer queue or by pressing the button Job

Cancel.

If the printer has not started a printing job, try to stop

it first using the software application.

If the printing job is in the printing queue or in the

printing spooler, try to delete the printing job there.

If the printing job is printing, press the button Job

Cancel. The printer finishes the MultiCard strips that

are already in the printer storage and deletes the

rest of the printing job.

If the status LEDs light up one after the other after

the printing job has been cancelled, the computer

sends the printing job nevertheless to the printer.

Delete the printing job from the printer queue or wait

until the printer has finished sending the data.

The printer switches into the ready mode (ready

LED lights up).

A

Figure 16 Job Cancel button

A Job Cancel

Tips for cancelling a job

If you press the button Job Cancel, only

the current printing job in the printer will be

cancelled.

If multiple printing jobs are in the printer

storage, the button Job Cancel has to be

pressed for each printing job.

4.3.2 Printing with manual feeding

The SpeedMarking-Laser is equipped with a manual

feed. This is done as follows.

1 The MultiCard markers will be fed with the project

marking surface into the entry (see also Figure

17 “Manual feeding”).

2 The marker is inserted until it firmly touches the

stop at the end.

Figure 17 Manual feeding

When a marker has been drawn in, the

next MultiCard can be inserted.

Page 21

Printer tips and maintenance

5658600000/00/05.07

21

5. Printer tips and maintenance

This chapter includes suggestions how high quality

and low consumption can be reached at the same

time. Moreover, special maintenance jobs for toner

cartridge and printer are described here.

5.1 Improvement of printing

In this chapter, the described settings concerning

the printing quality can be modified via the software

program of the Windows printer drivers.

The printing must always be done with the best quality and the highest resolution.

You can find more general information

concerning these settings and adjustments

on the help screens of the software.

5.2 Extend the lifespan of the

special-toner cartridge

If light areas appear on the printout, then toner is

missing. You can improve the printing quality temporarily by re-distributing the toner in the cartridge.

1 Finish the current print job before changing the

toner cartridge.

2 Open the cover of the SpeedMarking-Laser.

3 Take the toner cartridge out of the SpeedMark-

ing-Laser.

4 Sway (never shake) the toner cartridge back and

forth multiple times in order to distribute the toner

again. Do not position the toner cartridge upside

down.

5 Insert the toner cartridge again into the Speed-

Marking-Laser.

6 Close the cover.

If the printout remains pale, change the

toner cartridge.

If any toner gets on your clothing, wipe it of

f

by means of a dry cloth. Wash it subsequently with cold water.

5.3 Maintenance of specialtoner cartridge

5.3.1 Lifespan of special-toner cartridges

The lifespan of a special-toner cartridge depends on

the amount of toner being used for printing jobs. If

mainly text is printed, the special-toner cartridge

lasts for 1500 MultiCard strips with a coverage of

5%.

It is taken for granted that "Highest quality" and a

printing density of "3" (standard setting) is set.

5.3.2 Storage of special-toner cartridge

Take the special-toner cartridge out of the packaging

just before installation. The period of storage of an

unopened special-toner cartridge is approximately

2.5 years. In contrast, the period of storage of an

opened special-toner cartridge is 6 months.

CAUTION

To avoid any damages, the toner cartridge

should only be exposed to the sunlight for

a few minutes.

Page 22

Printer tips and maintenance

22

5658600000/00/05.07

5.4 Printer maintenance

Cleaning of the SpeedMarking-Laser

To maintain high printing quality, clean the SpeedMarking-Laser each time after changing the special

toner cartridge. The cleaning also has to be done if

there are problems with the printing quality. In this

regard, observe the following instructions:

Keep the SpeedMarking-Laser free of dust or any

dirt particles.

Clean the outside of the housing with a slightly moist

cloth.

CAUTION

Do not use any ammonia-containing cleaning agents on or in the vicinity of the

SpeedMarking-Laser.

• Over time, small dust particles and toner residues

accumulate in the Speed-Marking-Laser. This can

lead to white strips on the printout. After cleaning,

you will get a normal printing result.

WARNING

Switch off the SpeedMarking-Laser and

pull the mains cable before you start cleaning the SpeedMarking-Laser.

1 Open the cover of the SpeedMarking-Laser.

2 Take the toner cartridge out of the SpeedMark-

ing-Laser.

CAUTION

To avoid any damages, the toner cartridge

should be exposed to the sunlight only for

a few minutes.

3 With a dry and lint-free cloth, remove any dust,

dirt, toner and possible adhesive elements out of

the printing area.

Figure 18 Print area

4 Insert the toner cartridge again into the Speed-

Marking-Laser.

5 Insert the alignment rod for the roller in its desig-

nated holding fixture.

6 Close the cover, insert the mains cable and

switch the printer on again.

Page 23

Troubleshooting

5658600000/00/05.07

23

6. Troubleshooting

This chapter is about troubleshooting if the following

problems with the printer occur:

6.1 Fuses

A

B

Figure 19 Fuses

A Upper fuse:

5 x 20 mm 10 A / Slow → Control printer

B Lower fuse:

5 x 20 mm 10 A / Slow → Power circuit of the

pre-heating and of the fixation unit

The lower fuse is for the power circuit of the preheating and for the fixation unit. If this fuse fails, neither of the heaters will work.

The upper fuse is for the control of the printer. If the

control is not working, the printer cannot be switched

on.

This device is subject to special conditions regarding

its connection to the mains supply (EU Member

States).

The supply impedance at the point of connection to

the public electricity supply must not exceed (0.14 +

i 0.09) Ohm.

In all other cases, consult the power supply company before connecting the device to the public supply system.

6.2 Overheating shutoff

During long operation, the device may be shutoff to

save it from overheating.

The error LED is lit. If pressing the button Test does

not lead to an intake of a MultiCard, leave the device

on for 10 - 15 minutes for cooling down and press

the button Test again. The stored printing jobs will

be processed.

6.3 Remedy for jamming

Occasionally, jamming of MultiCards can occur during a printout.

Jamming can occur in the following areas:

• Input area

• Toner cartridge area

• Output area

Normally, jamming occurs in the following cases:

• A MultiCard strip has not been loaded or transported properly.

• The cover was opened during printing.

• In the input area was a deficient or an incomplete

MultiCard strip.

Remove the accumulated MultiCard and

follow the instructions on the following

pages. If it is not clear where the problem

was, look at first in the area of the toner

cartridge.

Page 24

Troubleshooting

24

5658600000/00/05.07

6.3.1 Congestion in the input area

1 Turn the SpeedMarking-Laser off.

2 Open the cover and remove the toner cartridge.

CAUTION

To avoid any damages, the toner cartridge

should be exposed to the sunlight only for

a few minutes.

3 Remove the accumulated material from the input

area. To do this you may have to move the green

transport belt. Care must be taken to avoid moving the belt out of its guides.

4 Check whether the input area is completely

cleaned.

5 Insert the toner cartridge again.

6 Insert the alignment rod for the roller in its desig-

nated holding fixture.

7 Close the cover.

8 Turn the SpeedMarking-Laser on again.

The SpeedMarking-Laser should now be operational

again.

If the error LED does not go out, there is

the possibility of accumulated material in

the SpeedMarking-Laser.

6.3.2 Congestion in toner area

1 Turn off the SpeedMarking-Laser.

2 Open the cover and remove the toner cartridge.

CAUTION

To avoid any damages, the toner cartridge

should only be exposed to the sunlight for

a few minutes.

3 Remove the accumulated material from the input

area. To do this you may have to move the green

transport belt. Care must be taken to avoid moving the belt out of its guides.

4 Check whether the toner area is completely

cleaned.

5 Check whether the Corona unit runs smoothly.

6 Insert the toner cartridge again.

7 Insert the alignment rod for the roller in its desig-

nated holding fixture.

8 Close the cover.

9 Turn the SpeedMarking-Laser on again.

The SpeedMarking-Laser should now be operational

again.

If the error LED does not go out, there is

the possibility of accumulated material in

the SpeedMarking-Laser.

Page 25

Troubleshooting

5658600000/00/05.07

25

6.3.3 Congestion in the output area

1 Turn off the SpeedMarking-Laser.

2 Open the cover and remove the toner cartridge.

CAUTION

To avoid any damages, the toner cartridge

should be exposed to the sunlight only for

a few minutes.

3 Remove the accumulated material from the input

area. To do this you may have to move the green

transport belt. Care must be taken to avoid moving the belt out of it’s guides.

4 Check whether the output area is completely

cleaned.

5 Check whether the Corona unit runs smoothly.

6 Insert the toner cartridge again.

7 Insert the alignment rod for the roller in its desig-

nated holding fixture.

8 Close the cover.

9 Turn the SpeedMarking-Laser on again.

The SpeedMarking-Laser should now be operational

again.

If the error LED does not go out, there is

the possibility of accumulated material in

the SpeedMarking-Laser.

6.4 Problems with the printing

quality

6.4.1 Checklist for printing quality

General problems with the printing quality can be resolved by observing the following checklist.

1 Re-distribute the toner inside the toner cartridge.

Sway (never shake) the toner cartridge back and

forth multiple times. Do not position the toner cartridge upside down.

2 Clean the inner part of the SpeedMarking-Laser.

Remove with a dry and lint-free cloth any dust,

dirt, toner and possible adhesive elements out of

the printing area.

3 Check the condition of the markers.

CAUTION

Damaged or incomplete MultiCard strips

can damage the device.

A

s a rule, soiled or smudgy MultiCard strips

should not be used.

Each MultiCard can only be used once.

4 Change the special toner and check the printing

quality again.

5 Check the storage conditions of the printing me-

dia (Temperature: 20 °C – 35 °C; Humidity: 55%

– 75%).

An insufficient saturation of the material can lead

to an unsatisfactory printout, pale print and missing sharp contours.

The storage conditions of the printing media are described under "Storage of printing media" in chapter 8.2.2 "Specification

for the printing media".

Page 26

Troubleshooting

26

5658600000/00/05.07

6.5 Checklist for troubleshooting

If the SpeedMarking-Laser is not printing, follow the

checklist in its specified order.

Make sure that the ready LED lights up.

If no LED lights up:

• Check the connection of the mains cable.

• Check the on/off switch.

• Check the power source.

• Check the fuses.

You can find more information in chapter

6.1 "Fuses".

6.5.1 Troubleshooting for error messages

If the error LED lights up, there is an error at the

SpeedMarking-Laser.

Find the corresponding LED display and follow the

solution suggestions to remedy the error.

Repairable errors

• The upper cover is open. Close the upper cover.

• The toner cartridge is missing or has not been in-

stalled properly. Check the toner cartridge and

place it carefully into its right position.

• Accumulated material is in the SpeedMarking-

Laser.

Refer chapter 6.3 "Remedy for ".

Data error

If the error LED and the data LED light up simultaneously, a data error has occurred at the SpeedMarking-Laser.

• To find out the reason for the data error, press the

buttons Test and Job Cancel and keep these

pressed. A second LED display indicates the particular error.

EA error

The connection cable between the printer and computer is possibly loose or of low quality.

• Make sure that the cable is fixed strongly and that

you use a high-quality cable.

Errors, when the printing can be continued

A temporary error occurred during printing.

• Press the key Test. The page will automatically be

printed again.

Temporary error

The printer has a temporary error.

• Turn the SpeedMarking-Laser off and on again. If

the error occurs again, contact the customer support. Phone number +49 (0) 52 31 14 12 52.

Page 27

Troubleshooting

5658600000/00/05.07

27

6.5.2 General troubleshooting

Empty, deficient or incomplete pages and disruption of the printing operation

Pages have been printed but are blank.

• The sealing band of the special-toner cartridge has

not possibly been removed.

Pages have been printed, but the printing is deficient, pages have only been partially printed or the

printing is overlapping.

• Make sure that the software application uses the

right printer driver.

• The data file sent to the printer is incorrect. Try to

print another file in order to see whether this one is

printed correctly.

• Exchange the printer cable with one that you know

is functioning. This tells you whether the printer

cable is faulty.

Font problems

The printing job contains the wrong font types or the

printing job has been formatted wrongly.

• Make sure that the software application uses the

right printer driver.

• The printer does not possess this font type. The

font type has to be downloaded via the software

application.

• It is possible that font is not available on the printer

and has been replaced by the software application

with another font.

You can find information about the selection of font types in the User’s Manual.

Page 28

Guarantees

28

5658600000/00/05.07

7. Guarantees

This chapter offers information about guarantees

that are valid for the SpeedMarking-Laser and the

special-toner cartridge.

7.1 Limited guarantee

Weidmüller offers a six month guarantee on the

SpeedMarking-Laser after purchase by the user.

During the guarantee period, Weidmüller is committed to repair the damaged SpeedMarking-Laser as

they see fit.

If the SpeedMarking-Laser should be repaired by

Weidmüller, make sure that the SpeedMarkingLaser is not further damaged by the transport packaging or the transport.

If possible, use the original packaging material.

7.2 Guarantee exclusions

Excluded from the guarantee for the SpeedMarkingLaser are errors or damages that can be traced to

the following causes:

• Inappropriate or inadequate maintenance by the

customer.

• Software or interfaces provided by the customer.

• Unauthorized modification or misuse.

• Operation outside the described environmental

conditions.

• Usage of unauthorized printing media.

• Exceeding the indicated throughput.

• Operation of the SpeedMarking-Laser via a me-

chanical relay without an adequate overvoltage

fuse.

• Inappropriate setup and maintenance of the installation location.

• Usage of special-toner cartridges that are not distributed by Weidmüller.

Usage of a toner cartridge that is not distributed by

Weidmüller has no consequences on the guarantee.

If it turns out that the equipment failure, printing

quality, resistance of marker labelling or damage of

the SpeedMarking-Laser is the consequence of usage of a toner cartridge not distributed by Weidmüller, then the repair is not covered by the guarantee.

If the throughput of the SpeedMarking-Laser during

operation is exceeded (when more than 600 MultiCards per day or 12000 MultiCards per month are

printed), this is a misuse of the SpeedMarking-Laser

and the labour and material costs will be charged for

all ensuing repairs.

CAUTION

For usage of a mechanical relay, ensure

that it is equipped with an overvoltage

fuse. The usage of unprotected mechanical relays can lead to damages to the

SpeedMarking-Laser.

The guarantee period starts on the day of delivery or

the day of installation by Weidmüller.

Except for the above mentioned guarantee,

Weidmüller provides no other written, verbal, contractual or legal guarantees.

7.3 Restriction of liability

Weidmüller is not liable for indirect damages or compensation for expenditures

while fulfilling the contract including compensation demands for lost earnings or lost

savings.

Page 29

Guarantees

5658600000/00/05.07

29

7.4 Customer support during

and after the guarantee period

If the SpeedMarking-Laser fails during the guarantee

period, please contact the customer support.

If you send the device to the customer support, pack

it according to the packaging instructions in this

chapter. We recommend insuring the package for

the transport.

Transport damages caused by insufficient

packaging are at the expense of the customer.

If possible, use the original packaging material.

Please observe the packaging instructions.

7.5 Packaging instructions

1 Remove the special-toner cartridge and put it into

the original carton of the SpeedMarking-Laser.

If possible, use the original carton and the packaging material.

2 If possible, add printing examples and MultiCard

strips of the used material.

3 Attach a copy of the completed info formula (next

page) for the customer support.

If you have disposed of the original packaging material of the SpeedMarking-Laser, contact a packaging

or postal service to pack the SpeedMarking-Laser

again.

Transport damages caused by insufficient

packaging are at the expense of the customer.

If possible, use the original packaging material.

Please observe the packaging instructions.

7.6 Guarantee for toner

1 Pack the defect special-toner cartridge into the

original carton.

2 Make sure that the toner packaging is sealed.

Use additional packaging parts in order to stabilize the toner cartridge.

Attach the following information to the packet:

• Your name and your address

• If possible, printing examples of the deficient spe-

cial-toner cartridge

• Attach a copy of the completed info formula (next

page) for the customer support.

The info sheet “Form for customer support“

is at the end of this User’s manual.

Page 30

Printer specifications

30

5658600000/00/05.07

8. Printer specifications

8.1 Environmental conditions

8.1.1 Dimensions

Height 380 mm

Width 430 mm

Length 1000 mm

Weight

(including toner cartridge)

35 kg

8.1.2 Electrical ratings:

Mains voltage: 110 V/AC 230 V/AC

Power input 1300 W 1300 W

Recommended minimum

current capacitance

16 A 16 A

Frequency 50 – 60 Hz 50 – 60 Hz

8.1.3 Environmental conditions

Environmental conditions during operation

Temperature 20 °C to 35 °C

Relative humidity 55% to 75%

Page 31

Printer specifications

5658600000/00/05.07

31

8.2 Consumables

8.2.1 Toner

Article No.: 1760070000

Durability: 2.5 years (original packaging, at 10 °C – 40 °C)

Capacity: 1500 cards with 5% coverage

8.2.2 Specification for the printing media

You can print with the SpeedMarking-Laser entire cards of the Weidmüller MultiCard program, if you follow

the specifications and guidelines of this manual. Printing media that do not fulfil these requirements can

damage the printer and it can result in forfeiting the guarantee.

Storage of printing media

For reaching optimal printing results, we recommend an initial storage phase (of at least 24 hours before

use) under office conditions (Temperature: 20 °C – 35 °C; Humidity: 55% – 75%).

Page 32

Printer specifications

32

5658600000/00/05.07

Page 33

Info - Form for customer support

Date:

Person who sends back the device:

Contact person:

Telephone number:

( )

Additional contact persons: Telephone number:

( )

Address of shipper: Special shipment instructions:

Which product will be sent? Model number: Serial number:

Add relevant printouts to the return consignment of the product.

Accessories not relevant for the repair, e.g. manuals, shouldn´t be sent.

What has to be done?

1. Describe the failure. (What has been the failure? What have you been doing during occurrence of the

failure? Could the failure happen again? etc.)

2. Additional comments:

How is being paid for repairs?

Covered under guarantee Date of purchase/Date of receipt:________________

By order number:

Apart from the guarantee service, a repair request must be supplemented by an order number and/or an

authorized signature. If the standard repare prices are not correct, a minimum order quantity is necessary.

The standard repare prices can be requested at the service station.

Authorized signature: ____________________ Telephone number:

____________________

The invoice should be sent to the following address: Special invoice directive:

Page 34

Page 35

Page 36

www.weidmueller.com

Weidmüller Interface GmbH & Co. KG

Postfach 3030

32720 Detmold

Klingenbergstraße 16

32758 Detmold

Phone +49 (0) 5231 14-0

Fax +49 (0) 5231 14-2083

E-Mail info@weidmuller.com Order number:

Internet www.weidmueller.com 5658600000/00/05.07

Loading...

Loading...