Page 1

Weidmuller Ltd.

10 Spy Court

Markham, ON L3R 5H6

Tel: (905)475-1507

Fax: (905)475-5855

Weidmuller Inc.

821 Southlake Blvd.

Richmond, VA 23236 U.S.A.

Tel: (804)794-2877

Fax: (804)794-0252

ISO 9001 Registered

Electronic Interface Modules

G448 Ultra SlimPak®

Bridge/Strain Gauge Input,

Field Configurable Input Isolator

• field configurable via DIP switches for different inputoutput combinations

• provides an isolated, DC output in proportional to a

bridge/strain gauge input

• adjustable bridge excitation 1 to 10V with up to

120mA drive

• 11 field configurable input ranges from ±10mV to

±200mV (0.5mV/V to >50mV/V)

• 5 field configurable output ranges 0-5V, 0-10V, 0-1mA

0-20mA and 4-20mA

• flexible power supply accepts 18 to 30Vdc

• ASIC technology for high reliability

• 3 port isolation 1800Vdc between input to output

power

• CSA approved, UL recognized, CE marked

Page 2

Description

Application

Diagnostic LEDs

The Ultra SlimPak G448 is a DIN rail mount, bridge or strain gauge input signal conditioner with 1800Vdc

isolation between input, output and power. The field configurable input and output offers flexible, wide

ranging capability for bridge or strain gauge input applications from 0.5mV/ V to over 50mV/V.

Wide ranging, precision zero and span pots allow 50% adjustablity of offset and gain within each of the 11

switch selectable input ranges. The output can be set for either 0-5V, 0-10V, 0-1mA, 0-20mA or 4-20mA.

This flexibility, combined with an adjustable (1 to 10Vdc) bridge ex-citation source, provides the user a

reliable, accurate instrument to isolate and condition virtually any bridge or strain gauge input.

The Ultra SlimPak G448 field configurable, bridge input signal conditioner is useful in isolating ground loops

and interfacing bridge sensors to data acquisition and control systems.

Three way isolation completely eliminates ground loops from any source. Isolation protects expensive

SCADA systems from ground faults and provides filtering for noise reduction which can be a significant

problem with small, millivolt, bridge signals.

Wide ranging flexibility allows the user to easily zero out dead-loads in weighing systems or configure bipolar

input ranges for expansion-compression or vacuum-pressure bridge applications.

High density DIN rail mounting offers an extremely compact solution for saving valuable panel space.

The G448 is equipped with a dual function LED signal monitor. The green, front mounted LED indicates both

DC power and input signal status. Active DC power is indicated by an illuminated LED. If the input signal is

more than 110% of the full-scale range, the LED will flash at 8Hz. If this continues to occur, you may wish to

change your full-scale input range setting.

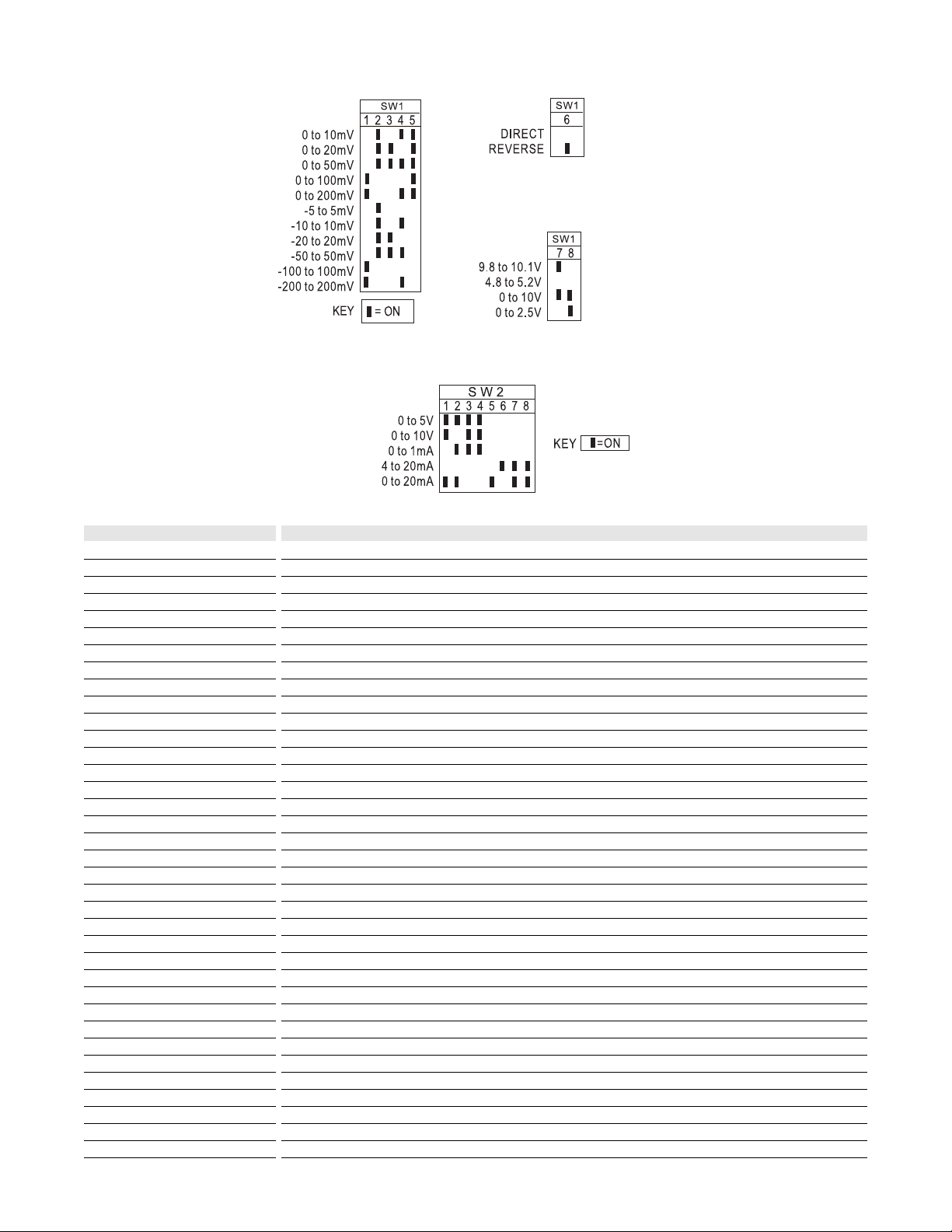

Table 3:

Bridge excitation

selector-switch settings

Table 2:

Direct or reverse

operation setting

Table 1:

Input range selectorswitch settings

Table 4:

Output range

selector-swtich

settings

Page 3

A major advantage of the G448 is its wide ranging capabilities and ease of configuration. The G448 has 11

input range switch settings. Trim potentiometers allow 50% input zero and span adjustablity within each of

the 11 full-scale, input ranges.

For example, the 200mV switch setting in Table 1 configures the input for a 0 to 200mV range. Since the

span can be contracted by 50%, this enables an input span as narrow as 100mV of the range, or 50%. This

span can be positioned anywhere within the 0-200mV range with a zero offset as large as 50% of the full

scale range (e.g. 100 to 200mV input). Unless otherwise specified, the factory presets the Model G448 as

follows:

Input Setting: 0 to 50mV

Input Range: 0 to 30mV (3mV/V)

Excitation: 10V

Operation: Direct

Output: 4 to 20mA

The DC power input accepts any DC source between 18 and 30V, typically a 24Vdc source is used.

For other I/O ranges refer to Tables 1 through 4 and reconfigure switches SW1 and SW2 for the desired

input range, function, excitation and output range.

Do not attempt to change any switch settings with power applied. Severe damage will result!

1. After configuring the DIP switches, connect the input to a calibrated millivolt source. Connect the output

to the actual device load (or a load equivalent to the actual device load value) and apply power. (see Wiring

Diagram).

NOTE: To maximize thermal stability, final calibration should be performed in the operating installation,

allowing approximately 1 to 2 hours for warm up and thermal equilibrium of the system.

2. Set the calibrator to the desired minimum and adjust the zero potentiometer for the desired minimum

output.

3. Set the calibrator to the desired maximum and adjust the span potentiometer for the desired maximum

output.

4. Repeat steps 2 and 3, if necessary for best accuracy.

5. Connect a calibrated voltmeter to the excitation output and adjust the excitation potentiometer to the

desired voltage output.

Configuration

WARNING:

Calibration

Page 4

Rated data

Input

Range

Impedance

Maximum ratings / type of protection

Field device excitation

Other input specification

Other input specification

Output

Range

Load

Burnout level

Zero / Span adjustment

Protection

Other output specification

Other output specification

Supply

Range

Consumption

Other supply specification

General

Accuracy

Linearity

Temperature coefficient (drift)

Transmission frequency

Response time. 90% span

Other general specification

Status LED

Isolation (# of ports)

Operating / Storage temperature

Housing (mounting)

Dimensions (L x W x H)

Wire range (conductor size)

Insulation stripping length

Tightening torque

Approvals

Ordering data

Ultra SlimPak

Heat sink (width)

Shunt resistor

Strain gauge, bridge or load cell device

±5mV to ±200mVdc, DIP switch selectable, direct or reverse operation

1MegM minimum

264Vdc maximum

1 to 10Vdc, 120mA maximum, DIP switch selectable

DC current or voltage

0-1mA, 0-20mA, 4-20mA, 0-5Vdc or 0-10Vdc, DIP switch selectable

<7.5kM (0-1mA), <600M (0/4-20mA), >500M (0-5V), >1000M (0-10V)

0 to 50% of full scale input, / 50 to 100% of full scale input

Noise: 0.1% of span, RMS or 10mV whichever is greater

DC voltage

18 to 30Vdc, inverter isolated

2.5W typ., (one 350M bridge), 4.0W max. (four 350M bridges in parallel)

±0.1% of selected input range at 25°C typ., 0.2% max.

included in accuracy

±0.025% of selected full scale input range/°C typical, ±0.05%/°C maximum

<200mS typical

input green (>110% of input; 8Hz, <0% of input: 4Hz)

1800V (3 port) between input, output and power

0°C to 55°C / -25°C to 70°C

EG12 (TS32 and TS35)

90mm x 17.7mm x 112.7mm max.

22-12AWG (0.5-4.0mm2)

7mm

0-4-0.8Nm

CSA (file LR-42272), UL (file E99775), CE marked (EMC dir. 89/336/EEC, LV dir. 73/23/EEC)

Cat.No.

G448 (factory calibration: 0-30mV In, 10Vdc Exc., direct operation, 4-20mA Out)

HS01-A (1.6mm) (conditionally required depending on installation, see heat sink data)

Note: G448-000X where X is the revision level

Specifications subject to change without notice. 99990008 - 8/98 Printed in Canada

TS32 RAIL

TS35 RAIL

Loading...

Loading...