Page 1

Model No. WESY7974.O

Serial No.

Write the serial number in the

space above for future reference,

Serial Number Decal (under seat)

QUESTIONS?

As a manufacturer, we are com-

mitted to providing complete

customer satisfaction. If you

have questions, or if a part is

damaged or missing, PLEASE

CONTACT OUR CUSTOMER

SERVICE DEPARTMENT

DIRECTLY.

CALLTOLL-FREE:

1-877-992-5999

Mon.-Fri., 6 a.m.-6 p.m. MST

ON THE WEB:

www.weiderservice.com

USER'S MANUAL

www.weiderfitness.com

new products, prizes,

fitness tips, and much more!

Page 2

TABLE OF CONTENTS

WARNING DECAL PLACEMENT ............................................................. 3

IMPORTANT PRECAUTIONS ................................................................ 4

BEFORE YOU BEGIN ...................................................................... 5

ASSEMBLY ............................................................................... 6

ADJUSTMENTS .......................................................................... 16

CONSOLE OPERATION .................................................................... 20

TROUBLESHOOTING ..................................................................... 22

EXERCISE GUIDELINES .................................................................. 23

ORDERING REPLACEMENT PARTS .................................................. Back Cover

LIMITED WARRANTY .............................................................. Back Cover

Note: A PART IDENTIFICATION CHART and a PART LIST/EXPLODED DRAWING are attached in the center of

this manual. Remove the PART IDENTIFICATION CHART and PART LIST/EXPLODED DRAWING before begin-

ning assembly.

WELDER is a registered trademark of ICON IF',Inc.

2

Page 3

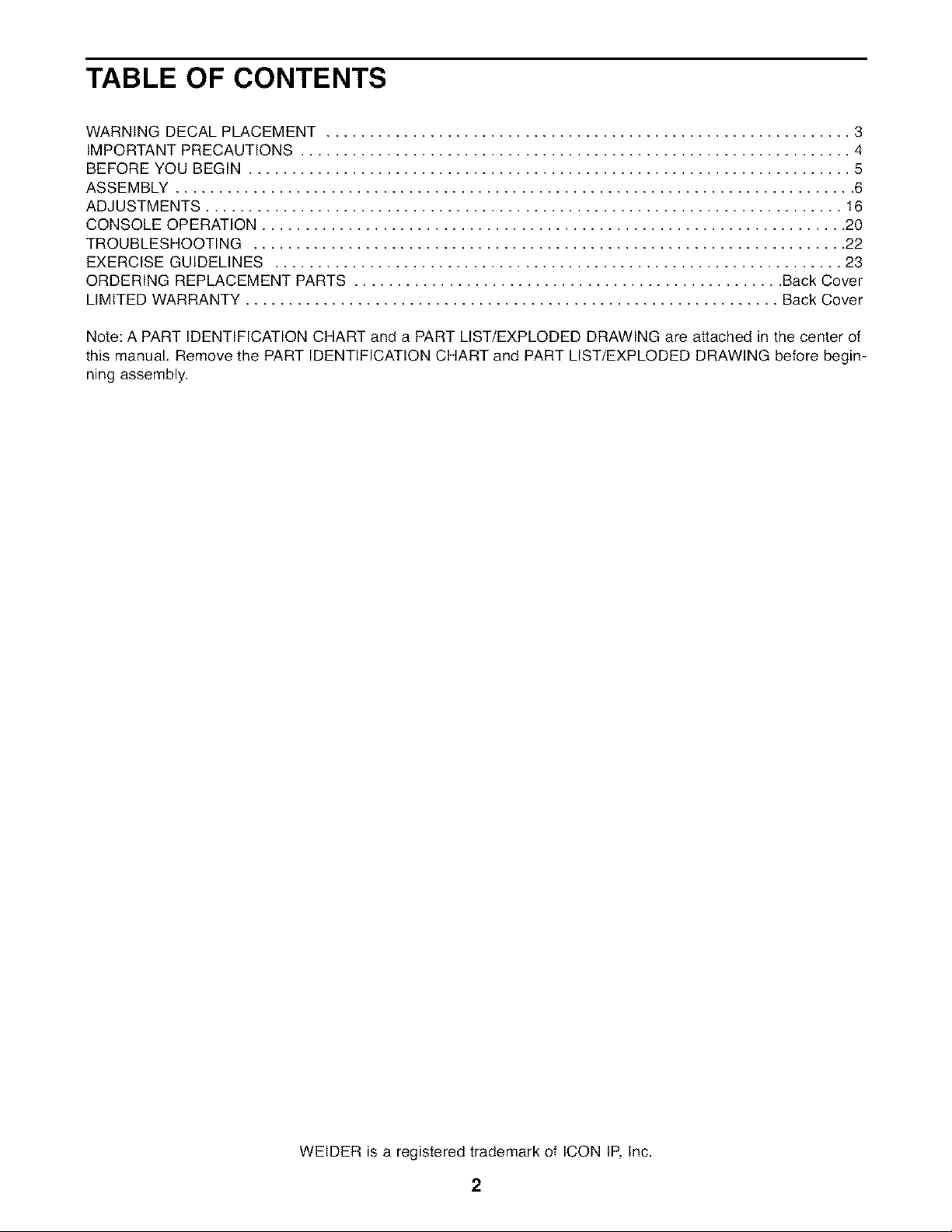

WARNING DECAL PLACEMENT

The decals shown here have been

placed on the resistance system. If a

decal is missing or illegible, call the

toll-free telephone number on the front

cover of this manual and order a free

replacement decal. Apply the decal in

the location shown.

hands and

clear of

area.

• Misuse of this machine

may result in serious

injury.

• Read user's manual

prior to use and follow

all warnings and

instructions.

• Do not allow children

on or around machine.

• Keep body, clothing,

and hair free and clear

of all moving parts.

• Replace label if

damaged, illegible, or

removed.

3

Page 4

IMPORTANT PRECAUTIONS

4

Page 5

BEFORE YOU BEGIN

Thank you for selecting the innovative PLATINUM

PLUS BY WELDER®resistance system. The resistance

system offers a selection of stations designed to devel-

op every major muscle group of the body. Whether your

goal is to tone your body, build dramatic muscle size

and strength, or improve your cardiovascular system,

the resistance system will help you to achieve the spe-

cific results you want.

For your benefit, read this manual carefully before

using the resistance system, If you have questions

after reading this manual, see the front cover of this

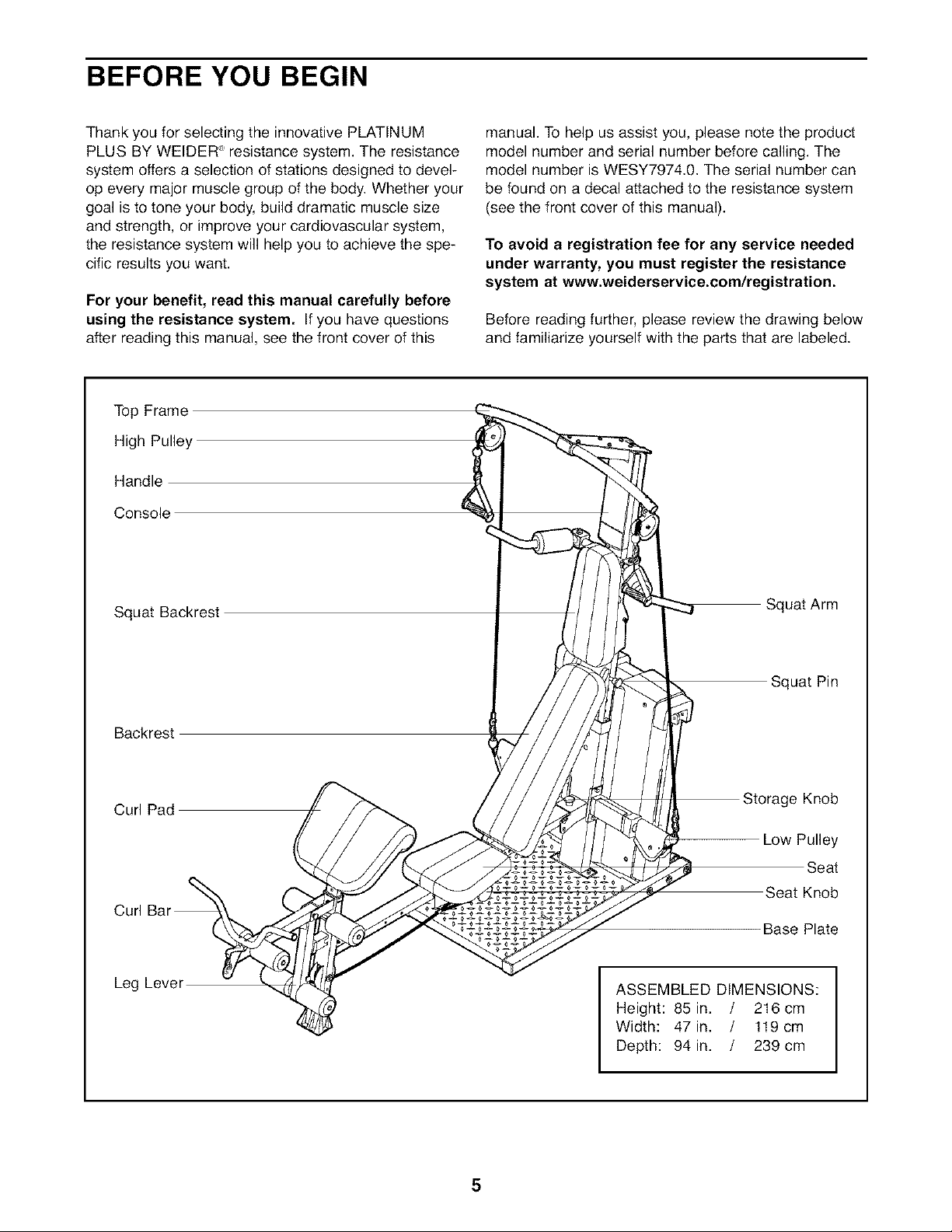

Top Frame

High Pulley

Handle

Console

manual. To help us assist you, please note the product

model number and serial number before calling. The

model number is WESY7974.0. The serial number can

be found on a decal attached to the resistance system

(see the front cover of this manual).

To avoid a registration fee for any service needed

under warranty, you must register the resistance

system at www.weiderservice.com/registration.

Before reading further, please review the drawing below

and familiarize yourself with the parts that are labeled.

Squat Backrest

Backrest

Curl Pad

Curl

Leg Lever

Squat Arm

Squat Pin

Storage Knob

Low Pulley

Seat

Seat Knob

Base Plate

ASSEMBLED DIMENSIONS:

Height: 85 in. / 216 cm

Width: 47 in. / !19 cm

Depth: 94 in. / 239 cm

5

Page 6

ASSEMBLY

Before beginning assembly, carefully read the

following information and instructions:

• Assembly requires two persons.

• Place all parts in a cleared area and remove the

packing materials. Do not dispose of the packing

materials until assembly is completed.

• Tighten all parts as you assemble them, unless

instructed to do otherwise.

• As you assemble the resistance system, make

sure all parts are oriented as shown in the draw-

ings.

E

The included hex keys W and the following

tools (not included) are required for assembly:

• Two adjustable wrenches

• One rubber mallet

• One standard screwdriver

• One Phillips screwdriver

• Lubricant, such as grease or petroleum jelly,

tape, and soapy water.

• For help identifying small parts, use the PART

IDENTIFICATION CHART. Note: Some small

parts may have been pre-attached for shipping. If

a part is not in the parts bag, check to see if it

has been pre-attached.

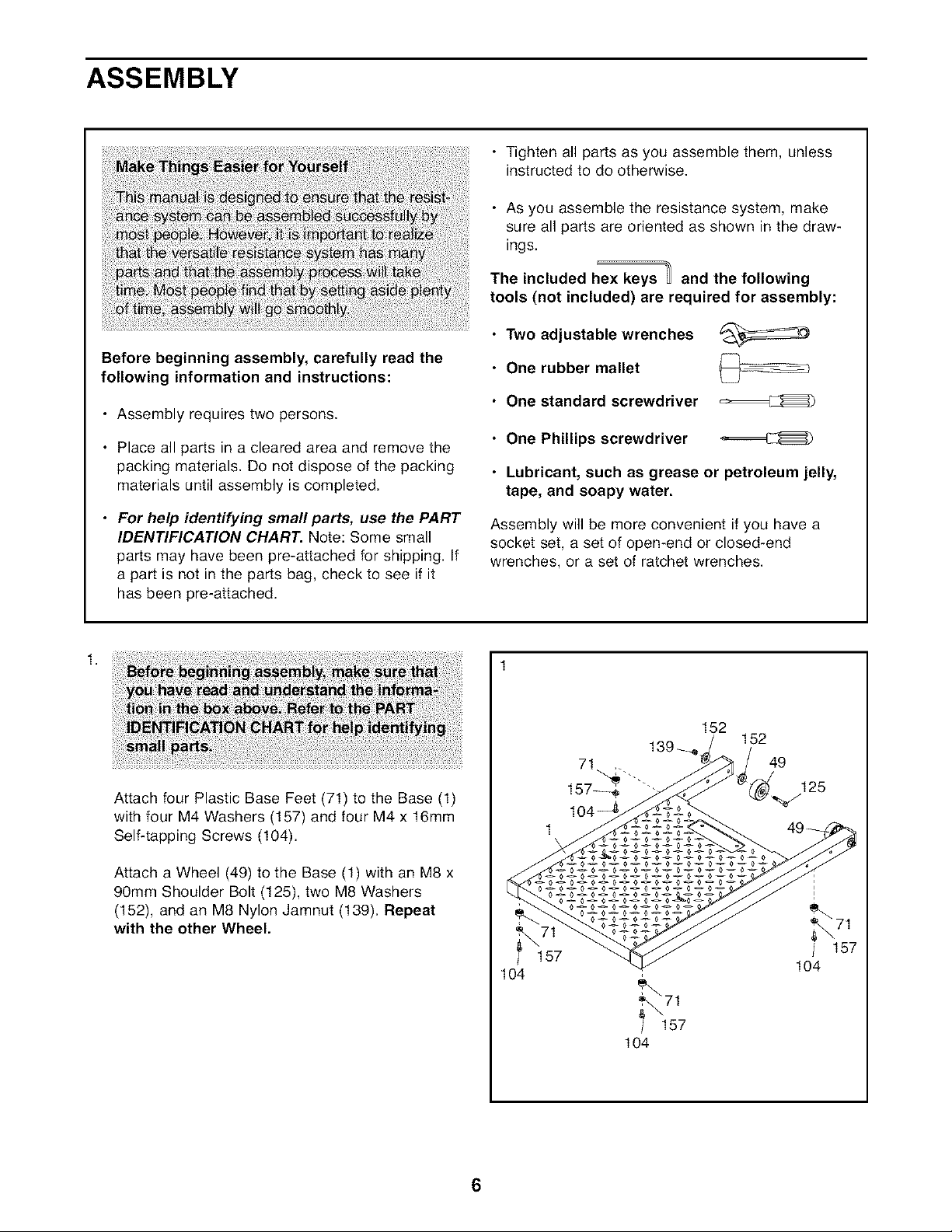

1,

Attach four Plastic Base Feet (71) to the Base (1)

with four M4 Washers (157) and four M4 x 16mm

Self-tapping Screws (104).

Attach a Wheel (49) to the Base (1) with an M8 x

90mm Shoulder Bolt (125), two M8 Washers

(152), and an M8 Nylon Jamnut (139). Repeat

with the other Wheel.

Assembly will be more convenient if you have a

socket set, a set of open-end or closed-end

wrenches, or a set of ratchet wrenches.

152

1

\

_71

_ 157 104

104 _'71

6

\

157

104

Page 7

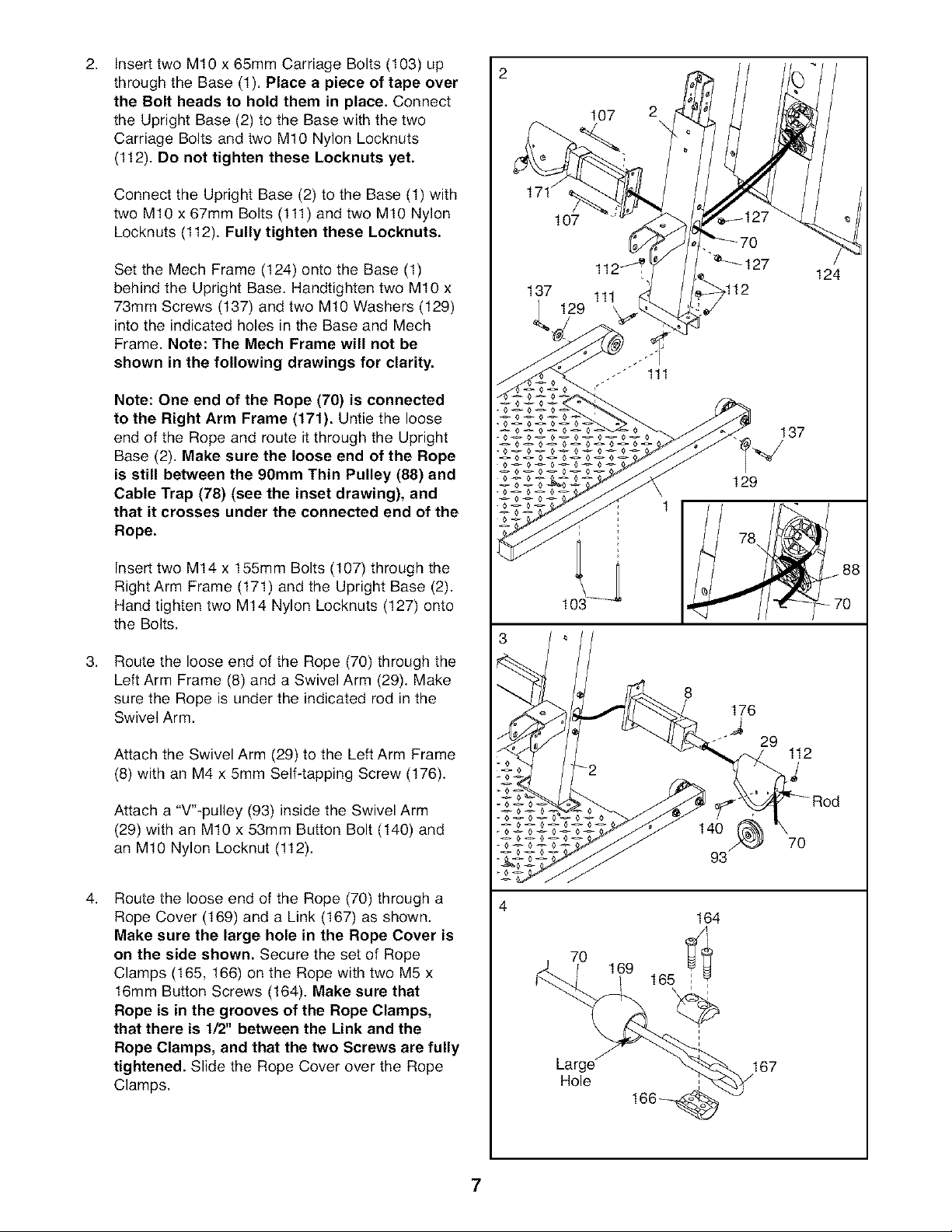

2.

Insert two M10 x 65mm Carriage Bolts (103) up

through the Base (1). Place a piece of tape over

the Bolt heads to hold them in place. Connect

the Upright Base (2) to the Base with the two

Carriage Bolts and two M10 Nylon Locknuts

(!12). Do not tighten these Locknuts yet.

Connect the Upright Base (2) to the Base (1) with

two M10 x 67mm Bolts (111) and two M10 Nylon

Locknuts (112). Fully tighten these Locknuts.

f"--. ,1/07 2\/4.,_ 4/ _ /

Set the Mech Frame (!24) onto the Base (1)

behind the Upright Base. Handtighten two M10 x

73mm Screws (137) and two M10 Washers (129)

into the indicated holes in the Base and Mech

Frame, Note: The Mech Frame will not be

shown in the following drawings for clarity.

Note: One end of the Rope (70) is connected

to the Right Arm Frame (17t). Untie the loose

end of the Rope and route it through the Upright

Base (2). Make sure the loose end of the Rope

is still between the 90ram Thin Pulley (88) and

Cable Trap (78) (see the inset drawing), and

that it crosses under the connected end of the

Rope.

Insert two M14 x 155mm Bolts (107) through the

Right Arm Frame (171) and the Upright Base (2).

Hand tighten two M!4 Nylon Locknuts (!27) onto

the Bolts,

3,

Route the loose end of the Rope (70) through the

Left Arm Frame (8) and a Swivel Arm (29). Make

sure the Rope is under the indicated rod in the

Swivel Arm.

_27

___ 137

129

78 88

Attach the Swivel Arm (29) to the Left Arm Frame

(8) with an M4 x 5mm Self-tapping Screw (!76).

Attach a "V"-pulley (93) inside the Swivel Arm

(29) with an M10 x 53mm Button Bolt (140) and

an M10 Nylon Locknut (112),

4.

Route the loose end of the Rope (70) through a

Rope Cover (169) and a Link (167) as shown.

Make sure the large hole in the Rope Cover is

on the side shown. Secure the set of Rope

Clamps (165, 166) on the Rope with two M5 x

16mm Button Screws (164), Make sure that

Rope is in the grooves of the Rope Clamps,

that there is t/2" between the Link and the

Rope Clamps, and that the two Screws are fully

tightened. Slide the Rope Cover over the Rope

Clamps,

---T--T_

- _--o Z_ 93"

4

70 169 _i

Hole 166 67

7

164

Page 8

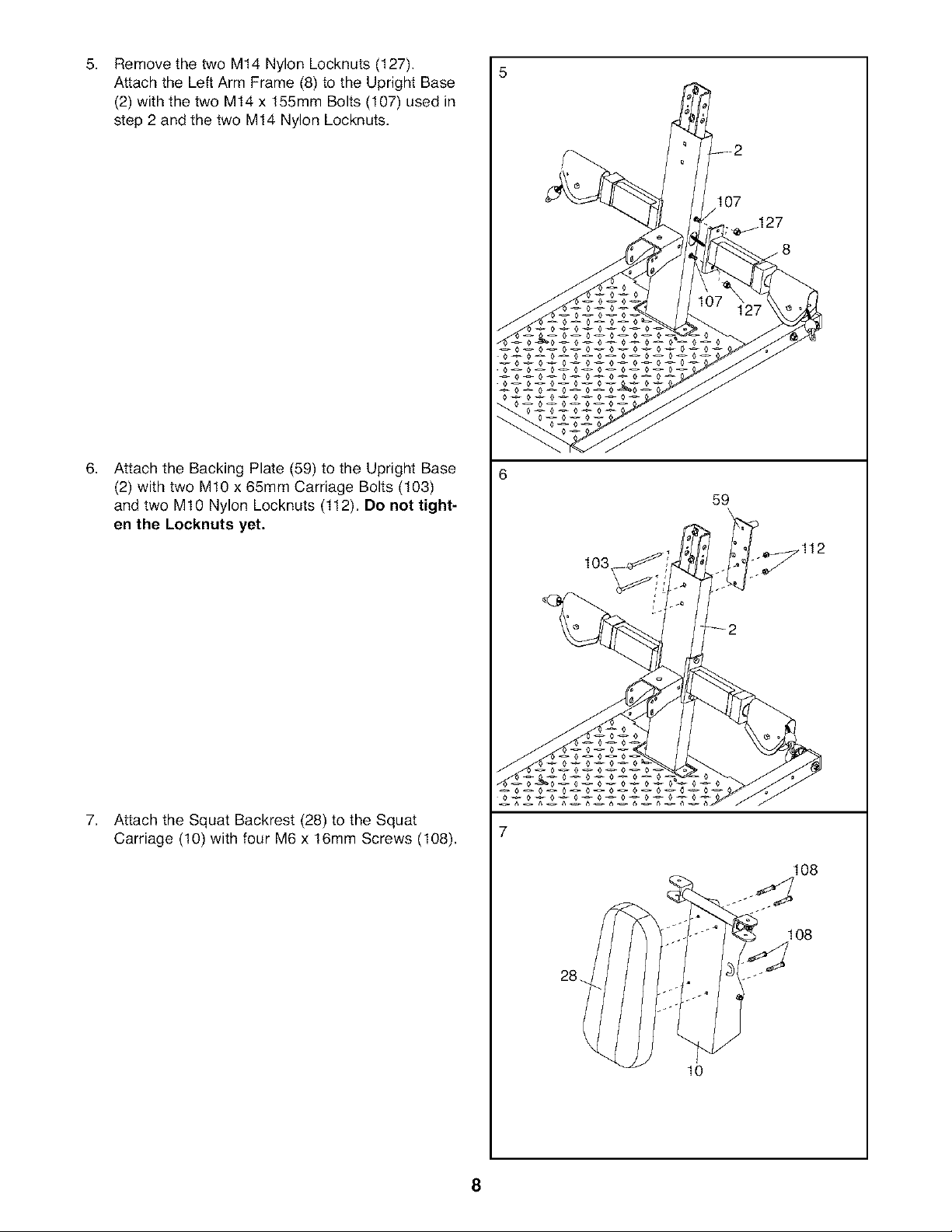

Remove the two M14 Nylon Locknuts (127).

Attach the Left Arm Frame (8) to the Upright Base

(2) with the two M14 x 155mm Bolts (107) used in

step 2 and the two M14 Nylon Locknuts,

6,

Attach the Backing Plate (59) to the Upright Base

(2) with two M!0 x 65mm Carriage Bolts (103)

and two M10 Nylon Lecknuts (112), Do not tight-

en the Locknuts yet.

59

107

127

\

7,

Attach the Squat Backrest (28) to the Squat

Carriage (!0) with four M6 x !6mm Screws (108),

103

7

108

108

lO

8

Page 9

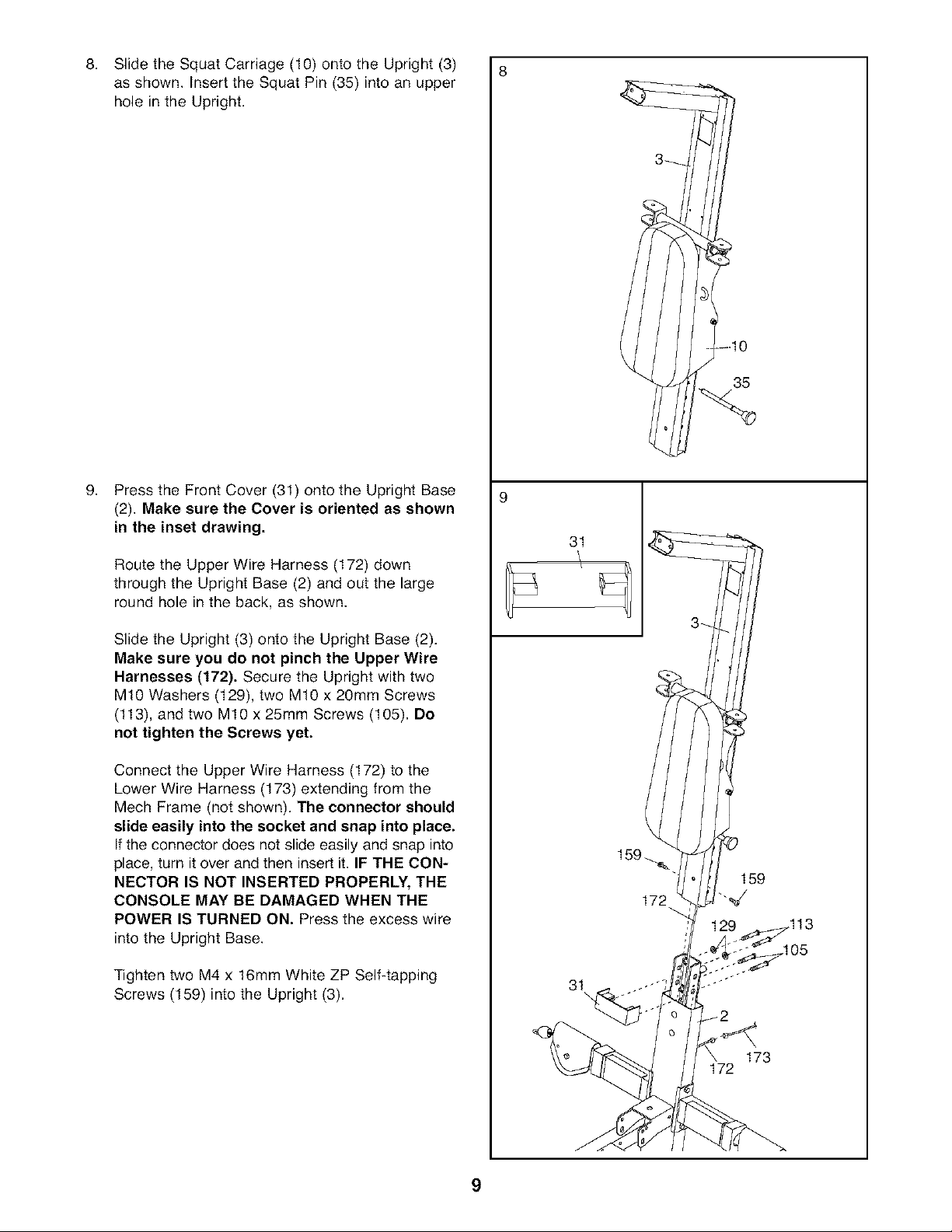

Slide the Squat Carriage (10) onto the Upright (3)

8. 8

as shown. Insert the Squat Pin (35) into an upper

hole in the Upright.

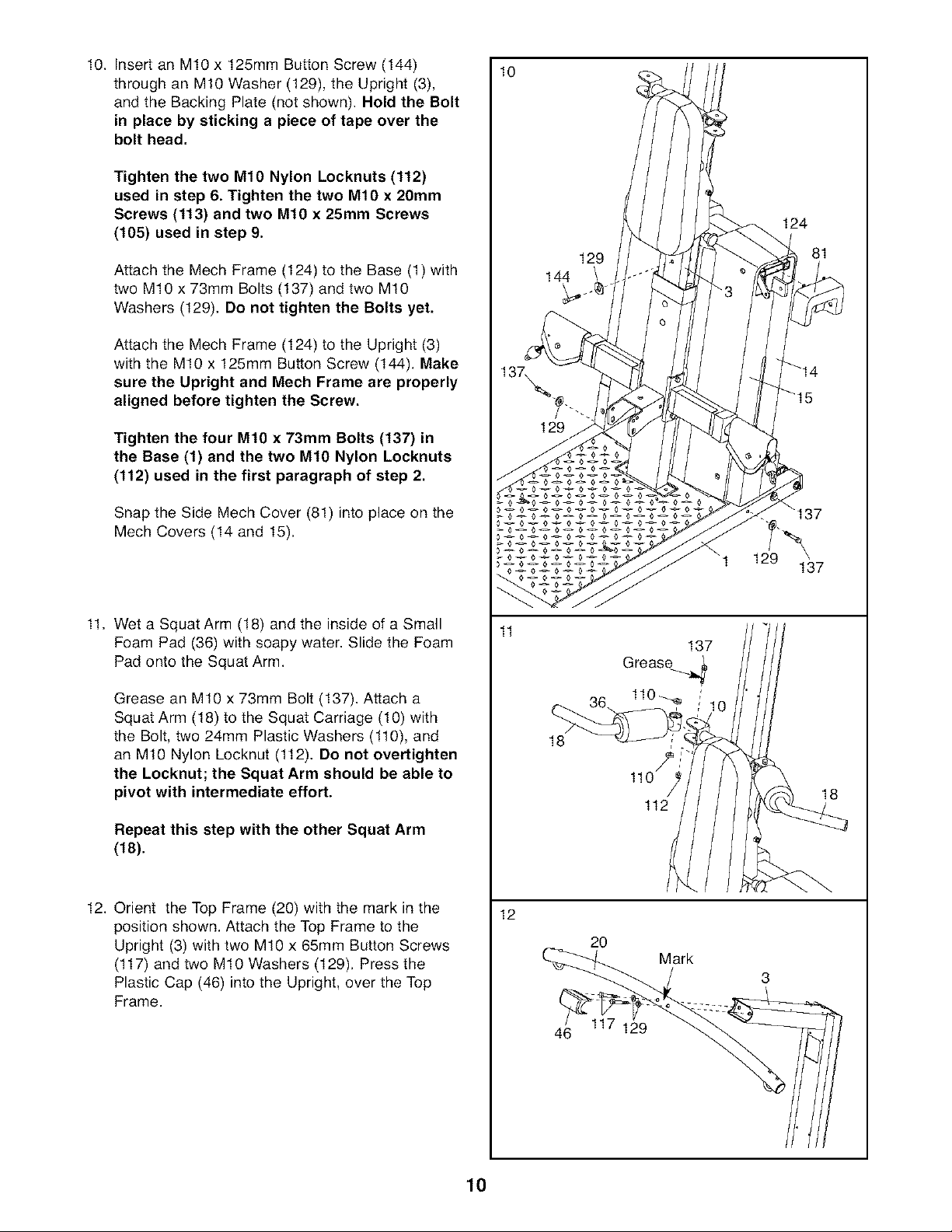

9,

Press the Front Cover (3!) onto the Upright Base

(2). Make sure the Cover is oriented as shown

in the inset drawing.

Route the Upper Wire Harness (172) down

through the Upright Base (2) and out the large

round hole in the back, as shown.

35

9

31

Slide the Upright (3) onto the Upright Base (2).

Make sure you do not pinch the Upper Wire

Harnesses (t72). Secure the Upright with two

M!0 Washers (129), two M10 x 20mm Screws

(113), and two M10 x 25ram Screws (105). Do

not tighten the Screws yet.

Connect the Upper Wire Harness (172) to the

Lower Wire Harness (173) extending from the

Mech Frame (not shown). The connector should

slide easily into the socket and snap into place.

If the connector does not slide easily and snap into

place, turn it over and then insert it. IF THE CON-

NECTOR IS NOT INSERTED PROPERLY, THE

CONSOLE MAY BE DAMAGED WHEN THE

POWER IS TURNED ON. Press the excess wire

into the Upright Base.

Tighten two M4 x !6mm White ZP Self-tapping

Screws (159) into the Upright (3).

31

172

159

113

173

9

Page 10

10. Insert an M1O x 125mm Button Screw (144)

through an M!O Washer (!29), the Upright (3),

and the Backing Plate (not shown). Bold the Bolt

in place by sticking a piece of tape over the

bolt head.

Tighten the two Mt0 Nylon Locknuts (1t2)

used in step 6. Tighten the two Mt0 x 20ram

Screws (tt3) and two Mt0 x 25ram Screws

(t05) used in step 9.

Attach the Mech Frame (124) to the Base (1) with

two M10 x 73ram Bolts (137) and two M1O

Washers (129), Do not tighten the Bolts yet.

Attach the Mech Frame (124) to the Upright (3)

with the M10 x 125mm Button Screw (144). Make

sure the Upright and Mech Frame are properly

aligned before tighten the Screw.

Tighten the four M10 x 73ram Bolts (137) in

the Base (1) and the two Mt0 Nylon Locknuts

(tt2) used in the first paragraph of step 2.

lO

144

129

124

81

Snap the Side Mech Cover (81) into place on the

Mech Covers (14 and 15).

11. Wet a Squat Arm (18) and the inside of a Small

Foam Pad (36) with soapy water. Slide the Foam

Pad onto the Squat Arm.

Grease an M10 x 73mm Bolt (137). Attach a

Squat Arm (18) to the Squat Carriage (!0) with

the Bolt, two 24mm Plastic Washers (110), and

an M1O Nylon Locknut (112). Do not overtighten

the Locknut; the Squat Arm should be able to

pivot with intermediate effort.

Repeat this step with the other Squat Arm

(18).

12. Orient the Top Frame (20) with the mark in the

position shown. Attach the Top Frame to the

Upright (3) with two M10 x 65mm Button Screws

(!17) and two M10 Washers (129). Press the

Plastic Cap (46) into the Upright, over the Top

Frame.

11

12

18

46

Grease_

20

117 129

112

).

"1 129_

137

137

18

Mark

3

10

Page 11

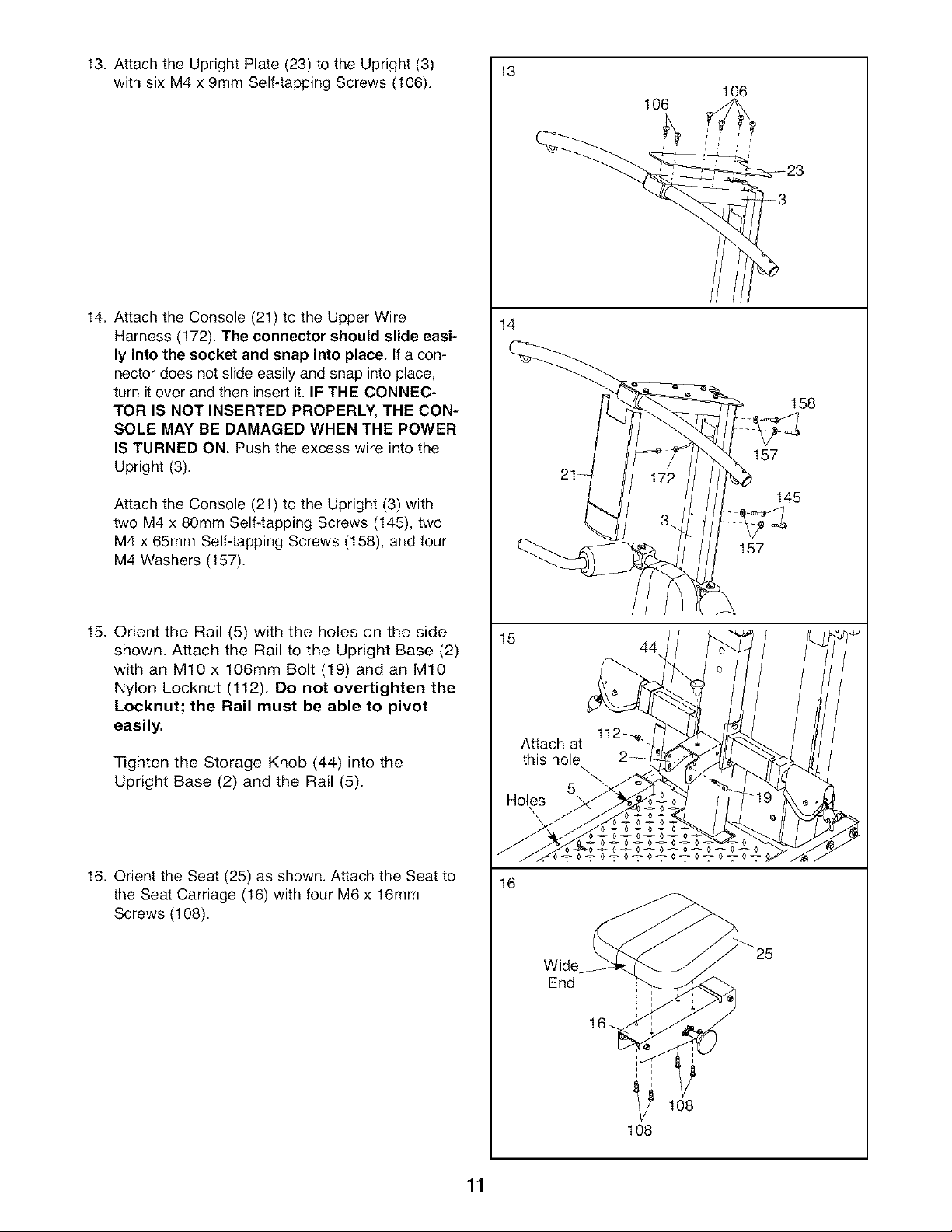

13. Attach the Upright Plate (23) to the Upright (3)

with six M4 x 9mm Self-tapping Screws (106).

13

14. Attach the Console (21) to the Upper Wire

Harness (172). The connector should slide easi-

ly into the socket and snap into place. If a con-

nector does not slide easily and snap into place,

turn it over and then insert it. IF THE CONNEC-

TOR IS NOT INSERTED PROPERLY, THE CON-

SOLE MAY BE DAMAGED WHEN THE POWER

IS TURNED ON. Push the excess wire into the

Upright (3).

Attach the Console (21) to the Upright (3) with

two M4 x 80mm Self-tapping Screws (145), two

M4 x 65mm Self4apping Screws (158), and four

M4 Washers (!57).

15. Orient the Rail (5) with the holes on the side

shown. Attach the Rail to the Upright Base (2)

with an MIO x 106mm Bolt (19) and an MIO

Nylon Locknut (112). Do not overtighten the

Loeknut; the Rail must be able to pivot

easily.

Tighten the Storage Knob (44) into the

Upright Base (2) and the Rail (5).

14

15

Attach at

this hole

Holes

158

157

145

157

44

112-_e.

\

5

16. Orient the Seat (25) as shown. Attach the Seat to

the Seat Carriage (!6) with four M6 x !6mm

Screws (108).

16

Wide

End

108

108

11

Page 12

17. Press the Front Leg Foot (38) onto the Front Leg

(4). Note: The front of the Front Leg Foot is

taller than the back of the Foot.

17

95 95

Attach the Front Leg (4) to the Rail (5) with four

M8 x 20mm Screws (95) and four M8 Washers

(152).

18. Pull out the Seat Knob (138) as far as it will go,

and set the Seat Carriage (!6) on the Bench Rail

(5).

Loosely attach two 8mm Spacers (123), a 59mm

Spacer (122), and two Seat Wheels (74) to the

bottom holes in the Seat Carriage (16) with an

M8 Nylon Jamnut (139) and an M8 x 102mm Bolt

(119). Make sure the parts are oriented as

shown in the inset drawing.

18

152

Front is

taller _38

119

19. Make sure that the wide sides of all six Seat

Wheels (74) are pressed against the Rail (5).

While a second person presses down on the Seat

(25), hold the bottom Seat Wheels firmly against

the bottom of the Rail and properly tighten the

indicated M8 Nylon Jamnut (139).

Engage the Seat Knob (138) into an adjustment

hole in the Rail (5).

123

Side

123

19

74-

25

5-

74 74 139 138

12

Page 13

20. Attach the Leg Lever (13) to the Front Leg (4) 20

with a Leg Lever Pin (91) and a Cotter Pin (90).

91

21. Route the short end of the Split Cable (72)

through the Front Leg (4) and attach it inside the

Leg Lever (13) with a Leg Lever Pin (91) and a

Cotter Pin (90).

Attach a 90mm Pulley (92) inside the Front Leg

(4), over the Spit Cable (72), with an M10 x

92mm Bolt (116), two M10 Washers (129), two

25mm Spacers (130), and an M10 Nylon Locknut

(112).

22. Insert the two Short Pad Tubes (32) into the Leg

Lever (13). Slide two Large Foam Pads (37) onto

each Short Pad Tube.

21

72

91

112

129_ _ 130

22

Repeat this step with the Long Pad Tube (153)

and the Front Leg (4).

4

37

13

Page 14

23. Attach the Backrest Cap (40) to the Backrest

Frame (17) with two M4 x 16mm Self-tapping

Screws (104).

23

104

Attach a Bumper (168) to the Backrest Frame

(!7) with an M4 x 16mm Self-tapping Screw (!04)

and an M4 Washer (157).

Attach the Right Pinch Guard (42) to the Backrest

Frame (17) with two M4 x 9mm Self4apping

Screws (106). Attach the Left Pinch Guard (41)

in the same manner.

24. Attach the Backrest (24) to the Backrest Frame

(17) with four M6 x 38ram Screws (128) and four

M6 Washers (!26).

168

%

_.104

157

106

4!

24

25. Insert the rod on the Backrest Frame (17) into the

slot in the Seat Carriage (!6). Hold the Backrest

Frame vertically over the Seat Carriage and

slide the rod into the slot, as shown in the

inset drawing.

126

25

14

Page 15

26. Attach the Curl Pad (26) to the Curl Post (12) with 26

two M6 x 16ram Screws (108).

26

108

27. Make sure that all parts have been properly tightened. The use of the remaining parts will be explained in

ADJUSTMENTS, beginning on the next page.

Before using the resistance system, turn on the console and change the resistance setting as

described in CONSOLE OPERATION on page 20.

15

Page 16

ADJUSTMENTS

This section explains how to adjust the resistance system. See the EXERCISE GUIDELINES on page 23 for

important information about how to get the most benefit from your exercise program. Also, see the accompany-

ing exercise guide to see the correct form for each exercise.

Make sure all parts are properly tightened each time the resistance system is used. Replace worn parts immedi-

ately. The resistance system can be cleaned with a damp cloth and a mild, non-abrasive detergent. Do not use

solvents.

ATTACHING THE HIGH PULLEYS

20

To use a high pulley, slide the hook on the Pulley

Housing (27) onto a hook on the Top Frame (20).

Attach the end of the Short Cable (73) without the ball

to the end of the Rope (70) with a Cable Clip (161).

Attach the other high pulley in the same manner.

Remove the high pulleys when not in use.

ATTACHING THE LEG LEVER

To use the Leg Lever (13), attach it to the Front Leg

(4) with a Leg Lever Pin (91) and a Cotter Pin (90).

Attach the Split Cable (72) inside the Leg Lever (13)

with a Leg Lever Pin (9!) and a Cotter Pin (90).

See the inset drawing. Attach one of the long ends

of the Split Cable (72) to one end of the Rope (70)

with a Cable Clip (16!), Attach the other long end

of the Split Cable to the other end of the Rope in

the same manner.

4

72

16

Page 17

ATTACHING THE ACCESSORIES

To attach a Short Handle (84) to a high pulley, first

attach the pulley housings to the resistance system

(see ATTACHING THE HIGH PULLEYS on the previ-

ous page). Then, attach the Handle to a Short Cable

(73) with a Cable Clip (161).

The Long Handles (not shown) and the Ankle Strap

(not shown) can be attached to the Short Cables (73)

or the Rope (not shown) with Cable Clips (161). Attach

the Hip Strap (not shown) to the ends of the Rope with

two Cable Clips.

The Ab Strap (not shown) can be attached to the Rope

(not shown) using the two Extension Straps (not

shown) and four Cable Clips (161).

ATTACHING THE CURL PAD

To attach the Curl Pad (26), insert the Curl Post (12)

into the Front Leg (4). Secure the Curl Post with the

Curl Knob (45).

84

Remove the Curl Pad (26) from the resistance

system when performing an exercise that does

not require it.

ATTACHING THE CURL BAR

To use the Curl Bar (43), first attach the leg lever to

the front leg (see ATTACHING THE LEG LEVER on

the previous page). Attach the Curl Bar to the hook

on the Leg Lever (13).

43

17

13

Page 18

ADJUSTING THE SQUAT ARM

To adjust a Squat Arm (18), pull the Arm to the

desired position.

A']-rACHING THE SQUAT STATION

To use the squat station, first remove the backrest

(see ADJUSTING THE BACKREST below). Next,

adjust the squat arm to the forward position (see

ADJUSTING THE SQUAT ARM above). Then, insert

a Squat Pin (35) into the correct hole in the Upright

(3). Finally, attach each end of the Rope (70) to the

Squat Carriage (10) with an Extension Strap (82) and

two Cable Clips (161).

18

18

_1o

18

82

Note: The Squat Pin (35) will determine the lowest

point to which the Squat Carriage (10) can

descend. The Squat Carriage should not be able to

descend so low that the user could become

trapped under the Squat Arms (18).

ADJUSTING THE BACKREST

The Backrest (24) can be used in a level position or an

inclined position. To use the Backrest in a level posi-

tion, secure the Seat Carriage (16) at the adjustment

hole in the Rail (5) closest to the Front Leg (not shown)

(see ADJUSTING THE SEAT on the next page).

To use the Backrest (24) in an inclined position,

secure the Seat Carriage (16) at one of the other

adjustment holes in the Rail (5). Rest the Backrest

against the Upright Base (2) or the Upright (3). Note:

To use the Backrest in the most inclined position,

the Squat Pin (not shown) must hold the Squat

Carriage (not shown) in the highest position (see

A'TrACHING THE SQUAT STATION above).

161

24

For row exercises, remove the Backrest Frame (17)

from the Seat Carriage (16). Hold the Backrest Frame

vertically over the Seat Carriage and lift the rod out of

the slot (see the inset drawing).

5 16

18

Page 19

ADJUSTING THE SEAT

The Seat (25) can be secured at various positions on

the Rail (5). To move the Seat, pull the Seat Knob

(138) out as far as it will go and slide the Seat to the

desired position. Engage the Seat Knob into an

adjustment hole in the Rail.

To perform row exercises, the hip strap must be

attached to the rope (see ATTACHING THE ACCES-

SORIES on page 17), and the Seat Carriage (16)

must be able to roll along the Rail (5). First, remove

the backrest from the seat carriage (see ADJUSTING

THE BACKREST on page 18). Then, pull the Seat

Knob (138) out as far as it will go, and turn the Seat

Knob so that the pin rests at the end of the "L"-

shaped slot (see the inset drawing).

25

\

Adjustment

Hole

STORING THE RESISTANCE SYSTEM

To store the resistance system, first remove the Curl

Pad (not shown) and the Leg Lever (not shown) from

the resistance system. Secure the Seat (25) at the

position closest to the Front Leg (4) (see ADJUSTING

THE SEAT above). Next, remove the Storage Knob

(44) from the Upright Base (2). Lift the Front Leg

toward the Top Frame (20). Tighten the Storage Knob

into the side of the Upright Base and into the Rail (5).

To move the resistance system, stand behind the

Upright (3) and place the toe of your shoe on the end

of the Base (!). Tilt the resistance system back onto

the Wheels (49) and roll it to the new location.

25

44

Pin

2

\

138

19

\

49

1

Page 20

CONSOLE OPERATION

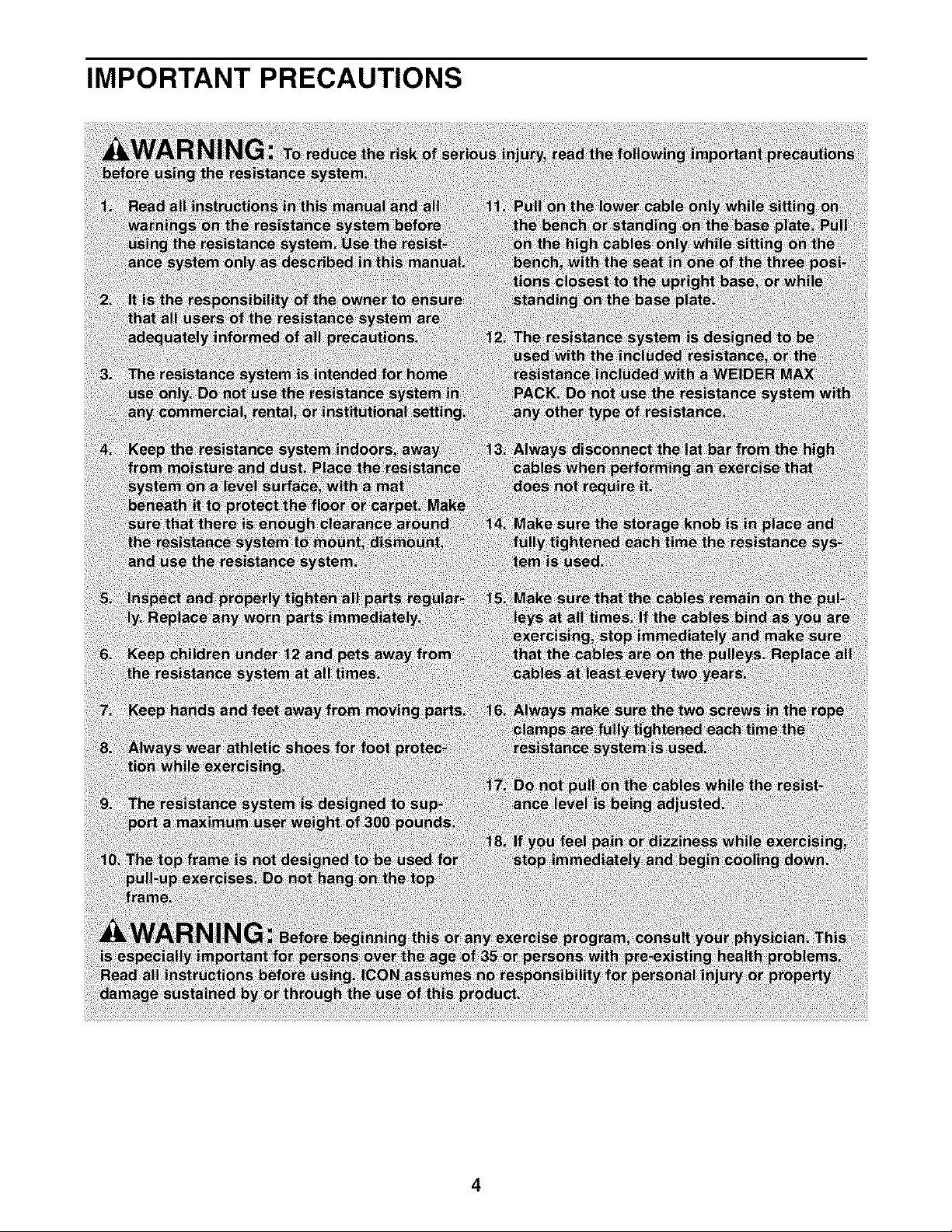

FEATURES OF THE CONSOLE

Console

CERTIFIED_

INCLINE pR

PEC FLY

CHEST PRESS

BICEP CURL

SHOULDER PR

ARMP,alSE iii!_i

DECLINE PRE_

TRICEP EXTE

UPPER BODY

ABS & BACK LOWER BODY

Program

Buttons

TRAIN

[ OlROUIT O_1

WEIGHT

Lose

[[

[[ o1 o]]

Main

Display

CERTIFIED PERSONALTRAINER EXERCISE

Resistance

LE5 r, ,o,

NEXT I_I i--I

Display

Lur_L

PROGRAMS

SQUAT

EXYENSION

ADDUCTION

GLUTE KICK

_ LEG CUR L

PLUGGING IN THE RESISTANCE SYSTEM

Plug the indicated

end of the

Transformer (181)

into the Rear Mech

Cover (14). Plug the

other end of the

Transformer into a

120-volt outlet. All

indicators and dis-

18!

plays on the console

will flash once; the console will then be ready for use.

The motor may be heard while the resistance system

calibrates itself. Important: Always plug in the trans-

former when using the resistance system.

MANUAL OPERATION

1. Plug in the transformer.

Plug the transformer into a 120-volt outlet (see

PLUGGING IN THE RESISTANCE SYSTEM

above). Important: Always plug in the trans-

former when using the resistance system.

Note: When the power is on, the words MANUAL

MODE will appear in the main display. To use a pro-

gram, see PROGRAM OPERATION on page 21. If

you want to return to the manual mode while the

console is running a program, press and hold the

NEXT button.

Sets

_r

Display

Reps

EsEts -REPs

The heart of the resistance system is the digital resist-

ance training console. The console offers both a manu-

al mode and nine workout programs. When the manual

mode is selected, the resistance setting can be

changed with the touch of a button. When a program is

selected, the console will guide you through an effec-

tive upper body, ab and back, or lower body workout.

To use the manual mode of the console, follow the

steps at the right. To use a program, see page 21.

If no buttons are pressed and no cables are pulled

for ten minutes, the console will go to sleep. Press

any button to resume exercising.

2. Select a resistance setting.

The current resistance setting will appear in the

resistance display. To select a different resistance

setting, first make sure that no cables are being

pulled. Next, press the resistance + or - buttons.

Each time a button is pressed, the resistance set-

ting will increase or decrease by 1 pound. To

change the resistance setting quickly, hold down

one of the buttons.

Note: While the resistance setting is changing, the

motor will be heard. To prevent damage to the

motor, do not pull any of the cables while the

resistance setting is changing. If a cable is

pulled, the words RELEASE HANDLES AND

READJUST RESISTANCE AS DESIRED may

appear in the main display.

20

Page 21

3. Enter the numbers of sets and repetitions that

you plan to complete for an exercise.

perform the cardio row exercise while the main dis-

play counts down from 5 minutes.

To enter the number of sets that you plan to do,

press the SETS + or - buttons. To enter the number

of repetitions that you plan to do, press the REPS +

or - buttons.

Note: If you do not enter the numbers of sets and

repetitions that you plan to do, the console will

count the total number of repetitions that you com-

plete during your workout.

4. Perform the exercise.

If you have entered numbers of sets and repeti-

tions, the console will count down the repetitions

and sets you have completed. When you complete

the exercise, repeat steps 2 and 3 above for the

next exercises.

5. Unplug the transformer.

When you complete your workout, unplug the trans-

former from the 120-volt outlet.

PROGRAM OPERATION

t. Plug in the transformer.

Plug the transformer into a 120-volt outlet (see

PLUGGING IN THE RESISTANCE SYSTEM on

page 20). Important: Always plug in the trans-

former when using the resistance system.

Note: If no buttons are pressed and no cables are

pulled for ten minutes, the console will go to sleep.

Press any button to resume exercising.

2. Select a program.

When the power is on, the words MANUAL MODE

will appear in the main display. To select a program,

press one of the nine program buttons. The indica-

tor on the button you press will light.

Note: The console offers three upper body pro-

grams, three ab and back programs, and three

lower body programs. If you wish to exercise your

upper body and if your goal is to lose weight, for

example, press the LOSE WEIGHT button below

the words UPPER BODY.

3. Row for five minutes to warm up.

When a program is selected, the words CARDIO

ROW will appear in the main display. To warm up,

Note: To see the correct form for the cardio row

exercise, see the included exercise guide. If the

resistance setting is too high or too low, select a dif-

ferent resistance setting by pressing the resistance

+ or - buttons.

4. Adjust the resistance setting and the numbers of

sets and repetitions for the exercise if desired.

The name of an exercise in the program will appear

in the main display. The recommended resistance

setting and the recommended numbers of sets and

repetitions for the exercise will appear in the three

displays below the main display.

The recommended resistance setting and the rec-

ommended numbers of sets and repetitions may be

too high or too low for you, depending on such fac-

tors as your body size and your physical condition. If

desired, adjust the resistance setting and the num-

bers of sets and repetitions by pressing the + or -

buttons below each display.

5. Perform the exercise.

As you perform the exercise, the console will count

down the numbers of sets and repetitions you have

completed.

When you complete the exercise, the word REST-

ING will appear in the main display. It is recom-

mended that you rest while the main display counts

down.

6. Perform the remaining exercises in the program,

After you have completed an exercise in the pro-

gram, press the NEXT button and the name of the

next exercise will appear in the main display. Repeat

steps 4 and 5 above for the exercise.

Note: The program may include the same exercise

twice, with different resistance settings and different

numbers of sets and repetitions. If you wish to skip

any part of the program, press the NEXT button to

advance to the next part of the program.

When you complete the program, the words WORK-

OUT COMPLETE will appear in the main display.

7. Unplug the transformer.

When you complete your workout, unplug the trans-

former from the 120-volt outlet.

21

Page 22

TROUBLESHOOTING

RECALIBRATING THE CONSOLE

To recalibrate the Console (21), first plug in the resist-

ance system (see PLUGGING IN THE RESISTANCE

SYSTEM on page 20). Then, press and hold the

NEXT button and the MOTORIZED WEIGHT

ADJUSTMENT + button for five seconds. When the

buttons are released, a number will appear in the

REPS display. Press the NEXT button again, and

then press the MOTORIZED WEIGHT ADJUSTMENT

+ button; this will start the recalibration process. This

may take a few seconds as the motor moves between

the lowest and highest resistance settings. When the

motor finishes, unplug the transformer from the !20-

volt outlet.

The Console (21) will be recalibrated. Use the resist-

ance system as described in the CONSOLE OPERA-

TION section, starting on page 20.

TIGHTENING THE ROPE

The type of rope used on the resistance system can

stretch slightly when it is first used. If there is slack in

the rope before resistance is felt, the rope should be

tightened.

29

70

To tighten the Rope (70), first set the system resist-

ance level to 100 pounds. Locate the end of the Rope

with the Rope Clamps (165, 166) and pull it out until

the Rope is tight. Then, measure the distance between

the Rope Cover (169) and the Swivel Arm (29).

Set the system resistance to the lowest level. Have a

second peron pull the Rope (70) out and hold it while

the Rope is adjusted. Push the Rope Cover (!69)

down the Rope and loosen the two M5 x 16mm

Button Screws (164). Pull the Rope through the Link

(!67) and the Rope Clamps (165, 166) to shorten the

Rope by the measured amount. Then, retighten the

two Screws and cover the Rope Clamps with the

Rope Cover. Note: There should be t/2" between

the Link and the Rope Clamps.

Measure 169

Distance

164

169

70

167

166

22

Page 23

EXERCISE GUIDELINES

THE FOUR BASIC TYPES OF WORKOUTS

Muscle Building

To increase the size and strength of your muscles,

push them close to their maximum capacity. Your mus-

cles will continually adapt and grow as you progres-

sively increase the intensity of your exercise. You can

adjust the intensity level of an individual exercise in

two ways:

• by changing the amount of resistance used

•by changing the number of repetitions or sets per-

formed. (A "repetition" is one complete cycle of an

exercise, such as one sit-up. A "set" is a series of

repetitions.)

The proper amount of resistance for each exercise

depends upon the individual user. You must gauge

your limits and select the amount of resistance that is

right for you. Begin with 3 sets of 8 repetitions for each

exercise you perform. Rest for 3 minutes after each

set. When you can complete 3 sets of 12 repetitions

without difficulty, increase the amount of resistance.

Toning

You can tone your muscles by pushing them to a mod-

erate percentage of their capacity. Select a moderate

amount of resistance and increase the number of rep-

etitions in each set. Complete as many sets of 15 to

20 repetitions as possible without discomfort. Rest for

1 minute after each set. Work your muscles by com-

pleting more sets rather than by using high amounts of

resistance.

Weight Loss

To lose weight, use a low amount of resistance and

increase the number of repetitions in each set.

Exercise for 20 to 30 minutes, resting for a maximum

of 30 seconds between sets.

Cross Training

Cross training is an efficient way to get a complete and

well-balanced fitness program. An example of a bal-

anced program is:

• Plan strength training workouts on Monday,

Wednesday, and Friday.

• Plan 20 to 30 minutes of aerobic exercise, such as

running on a treadmill or riding on an elliptical or

exercise bike, on Tuesday and Thursday.

• Rest from both strength training and aerobic exercise

for at least one full day each week to give your body

time to regenerate.

The combination of strength training and aerobic exer-

cise will reshape and strengthen your body, plus devel-

op your heart and lungs.

PERSONALIZING YOUR EXERCISE PROGRAM

Determining the exact length of time for each workout,

as well as the number of repetitions or sets completed,

is an individual matter. It is important to avoid overdo-

ing it during the first few months of your exercise pro-

gram. You should progress at your own pace and be

sensitive to your body's signals. If you experience pain

or dizziness at any time while exercising, stop immedi-

ately and begin cooling down. Find out what is wrong

before continuing. Remember that adequate rest and a

proper diet are important factors in any exercise pro-

gram.

WARMING UP

Begin each workout with 5 to 10 minutes of stretching

and light exercise to warm up. Warming up prepares

your body for more strenuous exercise by increasing

circulation, raising your body temperature and deliver-

ing more oxygen to your muscles.

WORKING OUT

Each workout should include 6 to 10 different exercis-

es. Select exercises for every major muscle group,

emphasizing areas that you want to develop most. To

give balance and variety to your workouts, vary the

exercises from session to session.

Schedule your workouts for the time of day when your

energy level is the highest. Each workout should be

followed by at least one day of rest. Once you find the

schedule that is right for you, stick with it.

EXERCISE FORM

Maintaining proper form is an essential part of an

effective exercise program. This requires moving

through the full range of motion for each exercise, and

moving only the appropriate parts of the body.

Exercising in an uncontrolled manner will leave you

feeling exhausted. On the exercise guide accompany-

ing this manual you will find photographs showing the

correct form for several exercises, and a list of the

muscles affected. Refer to the muscle chart on the

next page to find the names of the muscles.

The repetitions in each set should be performed

smoothly and without pausing. The exertion stage of

each repetition should last about half as long as the

return stage. Proper breathing is important. Exhale

during the exertion stage of each repetition and inhale

during the return stroke. Never hold your breath.

23

Page 24

Rest for a short period of time after each set. The

ideal resting periods are:

• Rest for three minutes after each set for a muscle

building workout.

• Rest for one minute after each set for a toning work-

out.

• Rest for 30 seconds after each set for a weight loss

workout.

Plan to spend the first couple of weeks familiarizing

yourself with the equipment and learning the proper

form for each exercise.

COOLING DOWN

End each workout with 5 to !0 minutes of stretching.

Include stretches for both your arms and legs. Move

L

D

slowly as you stretch and do not bounce. Ease into

each stretch gradually and go only as far as you can

without strain. Stretching at the end of each workout

is an effective way to increase flexibility.

STAYING MOTIVATED

For motivation, keep a record of each workout. The

chart on pages 25 and 26 of this manual can be pho-

tocopied and used to schedule and record your work-

outs. List the date, the exercises performed, the resist-

ance used, and the numbers of sets and repetitions

completed. Record your weight and key body meas-

urements at the end of every month. Remember, the

key to achieving the greatest results is to make exer-

cise a regular and enjoyable part of your everyday life.

MUSCLE CHART

A. Sternomastoid (neck)

B. Pectoralis Major (chest)

C. Biceps (front of arm)

D. Obliques (waist)

E. Brachioradials (forearm)

R Hip Flexors (upper thigh)

S

T

G. Abductor (outerthigh)

H. Quadriceps (front of thigh)

I. Sartorius (front of thigh)

J. Tibialis Anterior (front of calf)

K. Soleus (front of calf)

L. Anterior Deltoid (shoulder)

M. RectusAbdominus (stomach)

N. Adductor (inner thigh)

O. Trapezius (upper back)

R Rhomboideus (upper back)

Q. Posterior Deltoid (shoulder)

R. Triceps (back of arm)

S. Latissimus Dorsi (mid back)

T. Spinae Erectors (lower back)

U. Gluteus Medius (hip)

V. Gluteus Maximus (buttocks)

W. Hamstring (back of leg)

X. Gastrocnemius (back of calf)

24

Page 25

MONDAY EXERCISE WEIGHT SETS REPS

Date:

/ /

TUESDAY

Date:

AEROBIC EXERCISE

/ /

WEDNESDAY EXERCISE WEIGHT SETS REPS

Date:

/ /

THURSDAY

Date:

/ /

AEROBIC EXERCISE

FRIDAY EXERCISE WEIGHT SETS REPS

Date:

/ /

Make photocopies of this page for scheduling and recording your workouts.

25

Page 26

MONDAY EXERCISE WEIGHT SETS REPS

Date:

/ /

TUESDAY

Date:

AEROBIC EXERCISE

/ /

WEDNESDAY EXERCISE WEIGHT SETS REPS

Date:

/ /

THURSDAY

Date:

/ /

AEROBIC EXERCISE

FRIDAY EXERCISE WEIGHT SETS REPS

Date:

/ /

Make photocopies of this page for scheduling and recording your workouts.

26

Page 27

NOTES

27

Page 28

PART IDENTIFICATION CHART--Model No. WESY7974.0

M6 x 38mm Screw (!28)

M10 Nylon Locknut (112)

M8 Nylon Jamnut (139)

M10 x 53mm Button Bolt (!40)

M4 x 65mm Self-tapping Screw (!58)

M14 Nylon Locknut (127)

M!0 x 25ram Screw (105)

M10 x 20ram Screw (113)

(

M8 x 20ram Screw (95)

M6 x 16ram Screw (108)

{

M5 x 16ram Button

Screw (164)

M10 Washer (129)

M8 Washer (152)

M6 Washer (126)

@B

M4 Washer (157)

M4 x 5mm Self-tapping

Screw (176)

M10 x 65mm Carriage Bolt (103)

M10 x 65mm Button Screw (!17)

M!0 x 67mm Bolt (111)

I M10 73mm Bolt

M4 x 80mm Self-tapping Screw (145)

M8 x 90mm Shoulder Bolt (!25)

x

(137)

M4 x 16ram Self-tapping

Screw (104)

M4 x 16mm White ZP

Self-tapping Screw (159)

M4 x 9mm Self-tapping

Screw (106)

M!0 x 92ram Bolt (!16)

(..................................................................................................................

M!0 x !06mm Bolt (19)

M10 x 125mm Button Screw (144)

M14 x 155mm Bolt (107)

Page 29

PART LIST--Model No. WESY7974.0 R1005A

Key No. Qty. Description Key No. Qty. Description

1 1

2 1

3 1

4 1

5 !

6 !

7 1

8 !

9 1

10 1

11 6

12 1

13 1

14 !

15 !

16 1

17 !

18 2

19 1

20 !

21 1

22 4

23 !

24 !

25 1

26 !

27 2

28 1

29 2

30 2

31 1

32 2

33 6

34 2

35 !

36 2

37 6

38 !

39 1

40 1

41 1

42 !

43 1

44 1

45 1

46 1

47 2

48 6

49 2

50 1

51 4

52 1

53 1

Base

Upright Base

Upright

Front Leg

Rail

Right Squat Rail

Left Squat Rail

Left Arm Frame

Base Plate

Squat Carriage

M4 x 12ram Screw

Curl Post

Leg Lever

Rear Mech Cover

Front Mech Cover

Seat Carriage

Backrest Frame

Squat Arm

M10 x 106ram Bolt

Top Frame

Console

Gas Spring End

Upright Plate

Backrest

Seat

Curl Pad

Pulley Housing

Squat Backrest

Swivel Arm

50mm x 75mm Plastic Spacer

Front Cover

Short Pad Tube

Wire Harness

Grip Tape

Squat Pin

Small Foam Pad

Large Foam Pad

Front Leg Foot

Bushing

Backrest Cap

Left Pinch Guard

Right Pinch Guard

Curl Bar

Storage Knob

Curl Knob

Plastic Cap

M12 x 72ram Bolt

19ram Round Inner Cap

Wheel

Lat Bar

Squat Carriage Wheel

Mech Arm

Mech Link Arm

54 1

55 !

56 2

57 1

58 2

59 !

60 1

61 4

62 2

63 2

64 2

65 2

66 2

67 2

68 2

69 4

70 1

71 4

72 1

73 2

74 6

75 1

76 1

77 2

78 3

79 !

80 4

81 1

82 2

83 1

84 2

85 2

86 1

87 1

88 !4

89 1

90 2

91 2

92 3

93 2

94 4

95 4

96 1

97 2

98 2

99 2

100 2

101 1

102 3

103 4

104 16

105 2

106 !3

Max Pack Frame

Motor Assembly

Mech Arm Plate

Lower Pulley Plate

M12 Washer

Backing Plate

Rep Counter

Band Wheel

Rod

Steel Washer

Limit Switch

38mm Round Inner Cap

25mm Round Inner Cap

Foam Grip

32mm Round Inner Cap

Arm Bushing

Rope

Plastic Base Foot

Split Cable

Short Cable

Seat Wheel

45ram Square Outer Cap

M10 x 95mm Button Bolt

Gas Spring

Cable Trap

Small Cable Trap

16mm Spacer

Side Mech Cover

Extension Strap

Ankle Strap

Short Handle

Long Handle

Ab Strap

Hip Strap

90ram Thin Pulley

M!2 x 45mm Bolt

Cotter Pin

Leg Lever Pin

90mm Pulley

"V'-pulley

50ram Square Inner Cap

M8 x 20mm Screw

Clip

M10 x 25mm Button Bolt

M6 x 12mm Screw

M10 x 15mm Button Bolt

5ram Spacer

M10 x 95ram Bolt

M10 x 35mm Bolt

M10 x 65mm Carriage Bolt

M4 x !6mm Self4apping Screw

M10 x 25mm Screw

M4 x 9ram Self-tapping Screw

Page 30

KeyNo. Qty. Description Key No. Qty. Description

107 2 M14 x 155mm Bolt 149 1 50mm x 75mm Square Inner Cap

108 10 M6 x 16mm Screw 150 1 45mm Rhombus Inner Cap

109 1 M5 x 35mm Bolt 151 1 45mm Square Inner Cap

110 4 24mm Plastic Washer 152 8 M8 Washer

111 2 M10 x 67mm Bolt 153 1 Long Pad Tube

112 28 M10 Nylon Locknut 154 1 Rail Cap

113 2 M10 x 20mm Screw 155 2 25ram Square Inner Cap

114 4 17ram Spacer 156 4 M4 x 37mm Self-tapping Screw

115 2 32mm Thick Round Inner Cap 157 13 M4 Washer

116 3 M10 x 92mm Bolt 158 2 M4 x 65ram Self-tapping Screw

117 2 M10 x 65mm Button Screw 159 12 M4 x 16ram White ZP Self-tapping

118 1 M12 Nut Screw

119 3 M8 x 102mm Bolt 160 4 M6 Nylon Locknut

120 2 M10 Lock Washer 161 4 Cable Clip

121 2 M6 Washer 162 4 M3 Nut

122 3 59ram Spacer 163 4 M10 Nylon Jamnut

123 6 8mm Spacer 164 2 M5 x 16mm Button Screw

124 1 Mech Frame 165 1 Top Rope Clamp

125 2 M8 x 90ram Shoulder Bolt 166 1 Bottom Rope Clamp

126 4 M6 Washer 167 1 Link

127 2 M14 Nylon Locknut 168 1 Bumper

128 4 M6 x 38ram Screw 169 2 Rope Cover

129 11 M10 Washer 170 2 Spring

130 2 25mm Spacer 17! 1 Right Arm Frame

131 2 6mm Spacer 172 1 Upper Wire Harness

132 1 Copper Unit 173 1 Lower Wire Harness

133 4 M3 x 20mm Screw 174 1 73ram Spacer

134 1 70mm Pulley 175 4 M3 Lock Washer

135 2 Plastic Cap 176 2 M4 x 5mm Self-tapping Screw

136 2 M6 x 16mm Bolt 177 1 M5 Washer

137 6 M10 x 73mm Bolt 178 1 Inductor

138 1 Seat Knob 179 1 M5 Nylon Locknut

139 5 M8 Nylon Jamnut 180 1 76mm Spacer

140 2 M10 x 53mm Button Bolt 181 1 Transformer

141 6 M10 x 42mm Button Bolt 182 1 M10 x 92ram Grade 8 Bolt

142 1 M!0 x 46ram Bolt 183 1 Cover Plate

143 1 M10 x 109mm Bolt 184 0 not used

144 1 M10 x 125mm Button Screw # 1 User's Manual

145 2 M4 x 80mm Self-tapping Screw # 1 Exercise Guide

146 2 M6 x 90ram Bolt # 2 Hex Key

147 1 77mm Spacer # 2 Grease Pack

148 2 4mm Spacer

Note: "#" indicates a non-illustrated part, Specifications are subject to change without notice, See the back cover

of the user's manual for information about ordering replacement parts,

Page 31

EXPLODED DRAWING A--Model No. WESY7974.0 m008A

I i i

1!9

108119 123

74

121

/123

26

108

104

104

128

106,

106

42 _,

155 106

112 154

66

5

48

32

32 153

150

91

15!_

161

72

37

91

-4 1!6

37

@38

Page 32

EXPLODED DRAWING B--Model No. WESY7974.0

47

106

106

R1005A

68

18 1!0 _'

67

36 r

115

14%

®

93

.145

157

159

30 107 103

129

17! _

i57/_ 71:

104 156

107

1391

176

69

30 140 _9

152

i_-139 93 164

169

37 _70S1_ 5

166 167

112

Page 33

EXPLODED DRAWING C--Model No. WESY7974.0 m006A

86

22

87

144-

_4

112

14

lO4

81

#

170

104

13

132

163.

147

62

Page 34

ORDERING REPLACEMENT PARTS

To order replacement parts, see the front cover of this manual. To help us assist you, please be prepared to give

the following information:

• the MODEL NUMBER of the product (WESY7974.0)

• the NAME of the product (PLATINUM PLUS BY WELDER resistance system)

• the SERIAL NUMBER of the product (see the front cover of this manual)

• the KEY NUMBER and DESCRIPTION of the part(s) (see the PART LIST and EXPLODED DRAWING in the

center of this manual)

LIMITED WARRANTY

ICON Health & Fitness, Inc. (ICON), warrants this product to be free from defects in workmanship and

material, under normal use and service conditions, for a period of ten (10) years from the date of pur-

chase. This warranty extends only to the original purchaser. ICON's obligation under this warranty is lim-

ited to replacing or repairing, at ICON's option, the product through one of its authorized service centers.

All repairs for which warranty claims are made must be pre-authorized by ICON. If the product is shipped

to a service center, freight charges to and from the service center will be the customer's responsibility. For

in-home service, the customer will be responsible for a minimal trip charge. This warranty does not extend

to any product or damage to a product caused by or attributable to freight damage, abuse, misuse,

improper or abnormal usage or repairs not provided by an ICON authorized service center; products used

for commercial or rental purposes; or products used as store display models. No other warranty beyond

that specifically set forth above is authorized by ICON.

ICON is not responsible or liable for indirect, special or consequential damages arising out of or in con-

nection with the use or performance of the product or damages with respect to any economic loss, loss

of property, loss of revenues or profits, loss of enjoyment or use, costs of removal or installation or other

consequential damages of whatsoever nature. Some states do not allow the exclusion or limitation of inci-

dental or consequential damages. Accordingly, the above limitation may not apply to you.

The warranty extended hereunder is in lieu of any and all other warranties and any implied warranties of

merchantability or fitness for a particular purpose is limited in its scope and duration to the terms set forth

herein. Some states do not allow limitations on how long an implied warranty lasts. Accordingly, the above

limitation may not apply to you.

This warranty gives you specific legal rights. You may also have other rights which vary from state to state.

ICON HEALTH & FITNESS, INC., t500 S. t000 W., LOGAN, UT 8432t-98t3

Part No. 218674 R1005A Printed in China © 2004 ICON IF',Inc.

Loading...

Loading...