Weider 831159360 Owner’s Manual

PATENT PENDING

WELDER

Model No. 831.159360

Serial No.

The serial number can be found in the

location shown below. Write the serial

number in the space above.

TM

USER'S MANUAL

Serial Number Decal

F" x E: R C i _._, E:

Eq3, U I P M E N T

HELPLINEI

1-800-736-6879

a_AUTION-

SEARS

BEARB, ROEBUCK AND CO., HOFFMAN ESTATES, IL 60179

TABLE OF CONTENTS

IMPORTANT PRECAUTIONS ............................................................. 2

BEFORE YOU BEGIN ................................................................... 3

ASSEMBLY ........................................................................... 4

ADJUSTMENT ........................................................................ 19

TROUBLE-SHOOTING AND MAINTENANCE ......... ....................................... 22

CABLE DIAGRAM ..................................................................... 23

ORDERING REPLACEMENT PARTS ................................................. Back Cover

FULL 90 DAY WARRANTY ....................................................... Back Cover

Note: An EXPLODED DRAWING/PART LIST and a PART IDENTIFICATION CHART are attached to the center

of this manual, Remove the EXPLODED DRAWING/PART LIST and the PART IDENTIFICATION CHART before

beginning assembly.

7. The be

time.

o Alwya stand on a foot plate when perform-

1, Ing an exeralee th_ _ld _use the home

9Ymay stern to tip. _, _

11.

Never release the press arm, butterfly arms,

squst arm, leg lever, tat bar, or nylon strap

while weights are raised, The weights will fall

with great force.

12. Make sure that the cables remain onthe pul-

leys at all times. If the cables bind while you

are exercising, stop Immediately and make

sure that the cables are on all of the pulleys.

13. Always disconnect the let bar from the home

_oymsystem when oerformlno an exerciQe

that does not use the let bar.

2

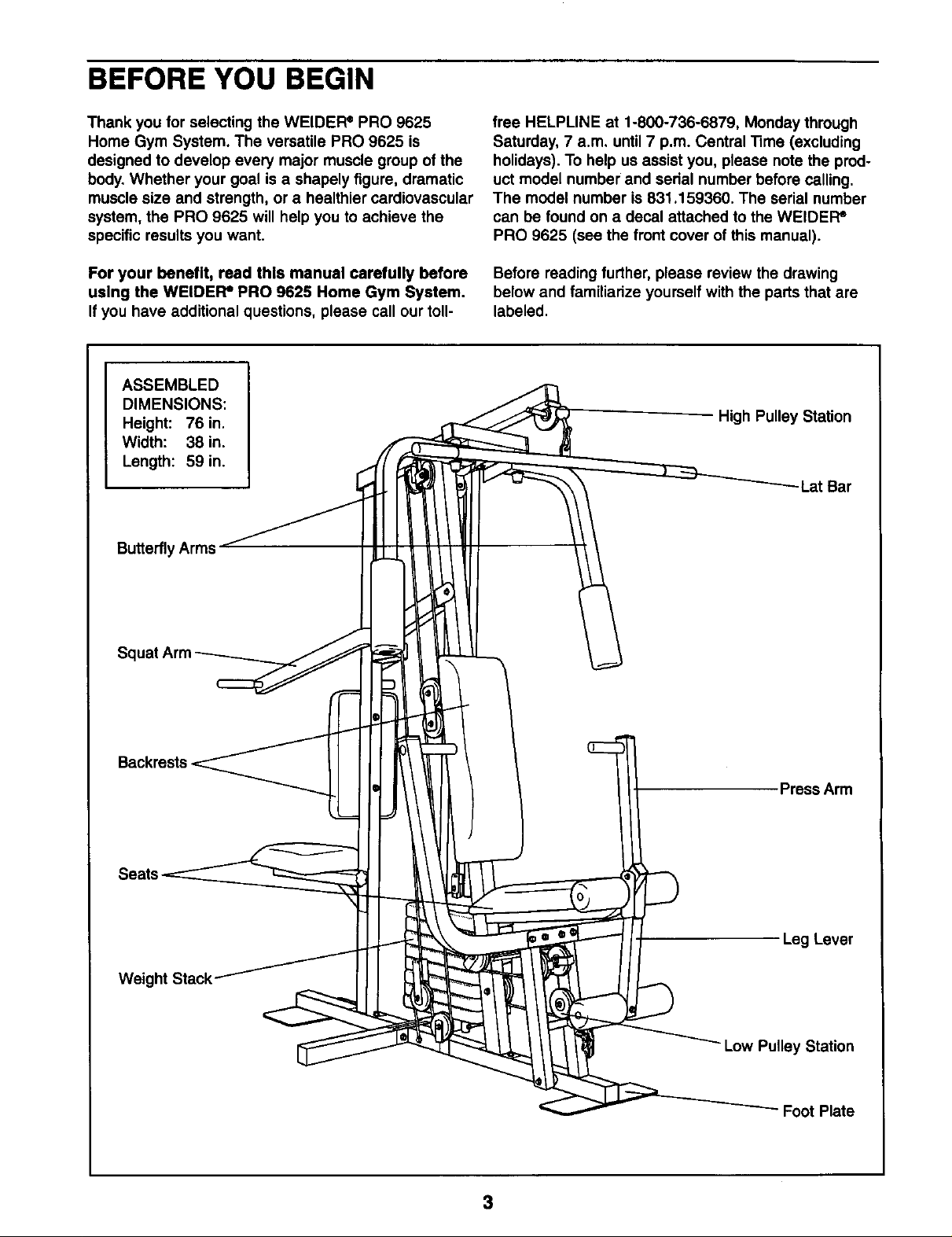

BEFORE YOU BEGIN

Thank you for selecting the WELDER= PRO 9625

Home Gym System. The versatile PRO 9625 is

designed to develop every major muscle group of the

body. Whether your goal is a shapely figure, dramatic

muscle size and strength, or a healthier cardiovascular

system, the PRO 9625 will help you to achieve the

specific results you want.

For your benefit, read this manual carefully before

using the WELDER= PRO 9625 Home Gym System.

If you have additional questions, please call our toll-

ASSEMBLED

DIMENSIONS:

Height: 76 in.

Width: 38 in.

Length: 59 in.

Butterfly Arms

free HELPLINE at 1-800-736-6879, Monday through

Saturday, 7 a.m, until 7 p.m. Central Time (excluding

holidays). To help us assist you, please note the prod-

uct model number and serial number before calling.

The model number is 831.159360. The serial number

can be found on a decal attached to the WELDER=

PRO 9625 (see the front cover of this manual).

Before reading further, please review the drawing

below and familiarize yourself with the parts that are

labeled.

High Pulley Station

Lat Bar

Squat

Weight

Press Arm

Leg Lever

Low Pulley Station

- Foot Plate

3

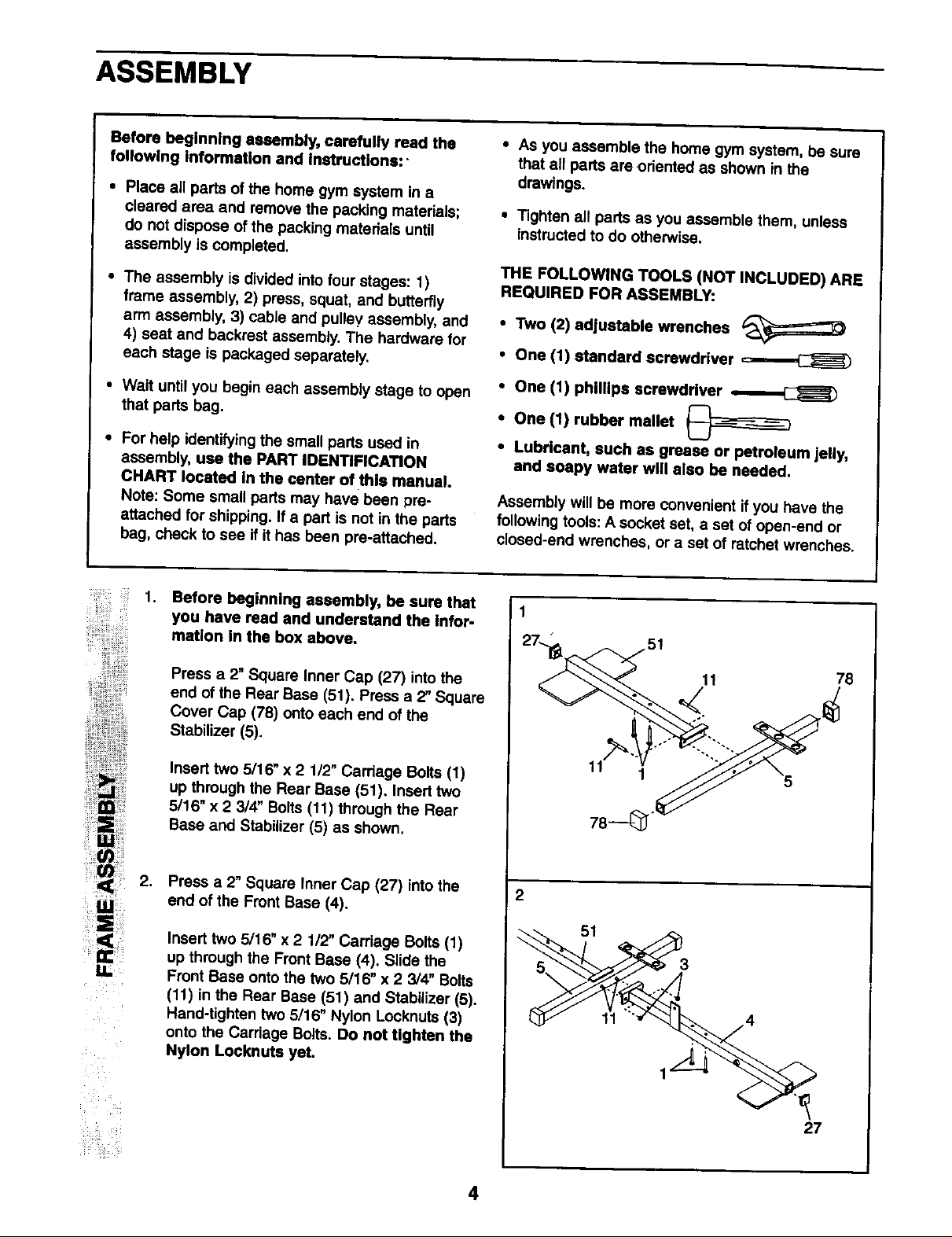

ASSEMBLY

Before beginning assembly, carefully read the

following Information and Instructions:"

• Place all parts of the home gym system in a

cleared area and remove the packing materials;

do not dispose of the packing materials until

assembly is completed.

• The assembly is divided into four stages: 1)

frame assembly, 2) press, squat, and butterfly

arm assembly, 3) cable and pulley assembly, and

4) seat and backrest assembly. The hardware for

each stage is packaged separately.

• Wait until you begin each assembly stage to open

that parts bag.

• For help identi_ing the small parL_used in

assembly, use the PART IDENTIFICATION

CHART located In the center of this manual.

Note: Some smal_ parts may have been pre*

attached for shipping. If a part is not inthe parts

bag, check to see if it has been pre-attashed.

• As you assemble the home gym system, be sure

that all parts are oriented as shown inthe

drawings.

• "Tightenall parts as you assemble them, unless

Instructed to do otherwise.

THE FOLLOWING TOOLS (NOT INCLUDED) ARE

REQUIRED FOR ASSEMBLY:

• Two (2) adjustable wrenches

• One (1) standard screwdriver

• One (1) phillips screwdriver

• One (1) rubber mallet

• Lubdcent, such as grease or petroleum jelly,

and soapy water will also be needed.

Assembly will be more convenient if you have the

following tools: A socket set, a set of open-end or

closed-end wrenches, or a set of ratchet wrenches.

_i_ _¸_¸¸ _!

UL

1.

Before beginning assembly, be sure that

you have read and understand the Infor-

mation In the box above.

Press a 2" Square Inner Cap (27) intothe

end of the Rear Base (51). Press a 2" Square

Cover Cap (78) onto each end of the

Stabilizer (5).

Insert two 5/16" x 2 1/2" Carriage Bolts (1)

up through the Rear Base (51). Insert two

5/16" x 2 3/4" Bolts (11) through the Rear

Base and Stabilizer (5) as shown,

2.

Press a 2" Square Inner Cap (27) into the

end of the Front Base (4).

Insert two 5/16" x 2 112"Carriage Bolts (1)

up through the Front Base (4), Slide the

Front Base onto the two 5/16" x 2 3/4" Bolts

(11) in the Rear Base (51) and Stabilizer (5).

Hand-tighten two 5/16" Nylon Locknuts (3)

onto the Carriage Bolts. Do not tighten the

Nylon Locknuts yet.

11 78

<

11' 1

2

3

11 ":'__. 4

27

4

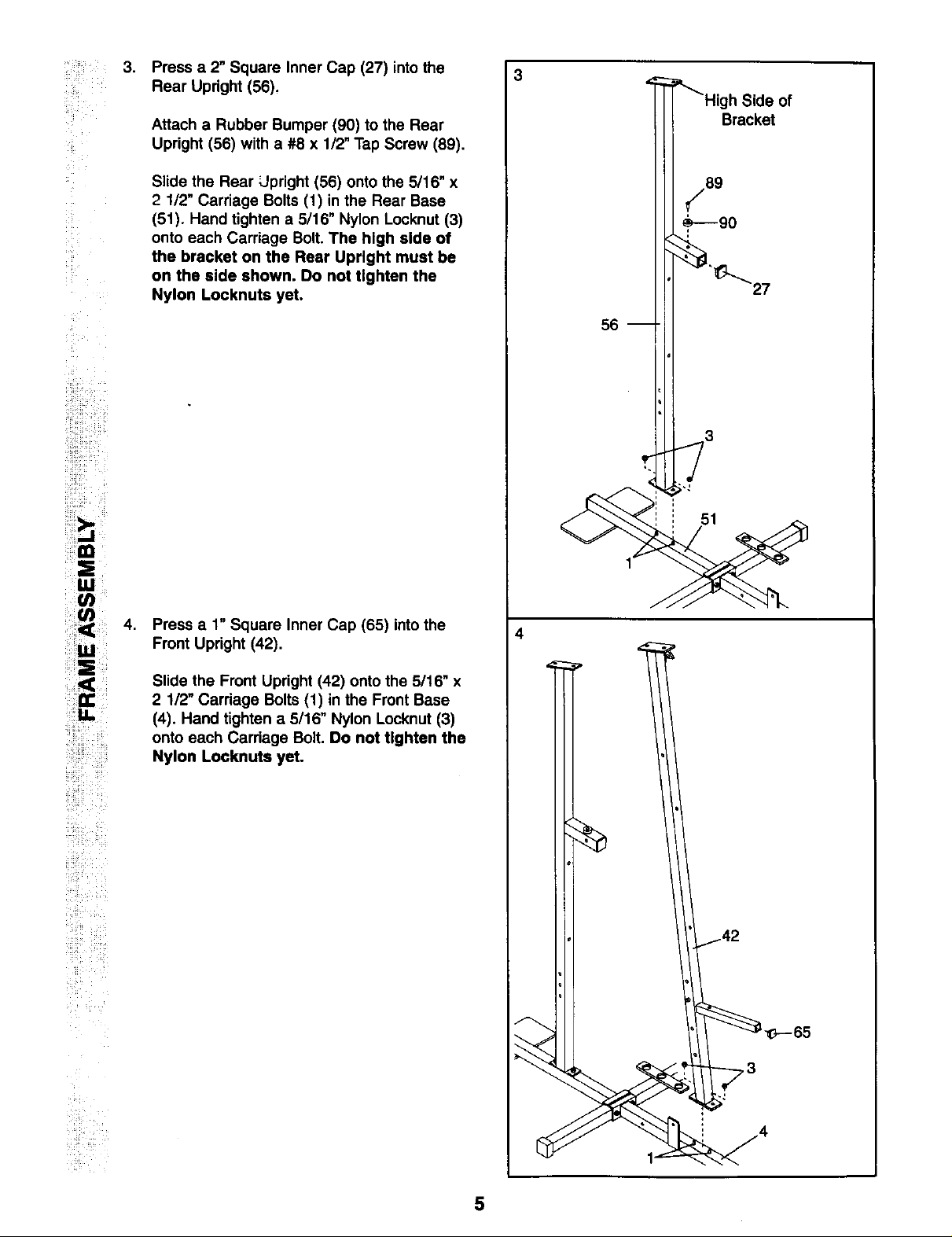

3. Press a 2" Square Inner Cap (27)into the 3

Rear Upright (56),

Attach a Rubber Bumper (90) to the Rear

Upright (56) with a #8 x 112"Tap Screw (89).

Slide the Rear Llpright (56) onto the 5/16" x

2 1/2" Carriage Bolts (1) in the Rear Base

(51). Hand tighten a 5/16" Nylon Locknut (3)

onto each Carriage Bolt. The high side of

the bracket on the Rear Upright must be

on the side shown. Do not tighten the

Nylon Locknuts yet.

h Side of

Bracket

27

56

3

;-J

51

!_IM i

!

!i_i!t,_ 4.

_iii_ i__i_i_

Press a 1" Square Inner Cap (65) into the

Front Upright (42).

Slide the Front Upright (42) onto the 5/16" x

2 1/2" Carriage Bolts (1) in the Front Base

(4). Hand tighten a 5/16" Nylon Locknut (3)

onto each Cardage Bolt. Do not tighten the

Nylon Locknute yet.

4

!iiilil

5

!iii i _ii_i_ i_i

,

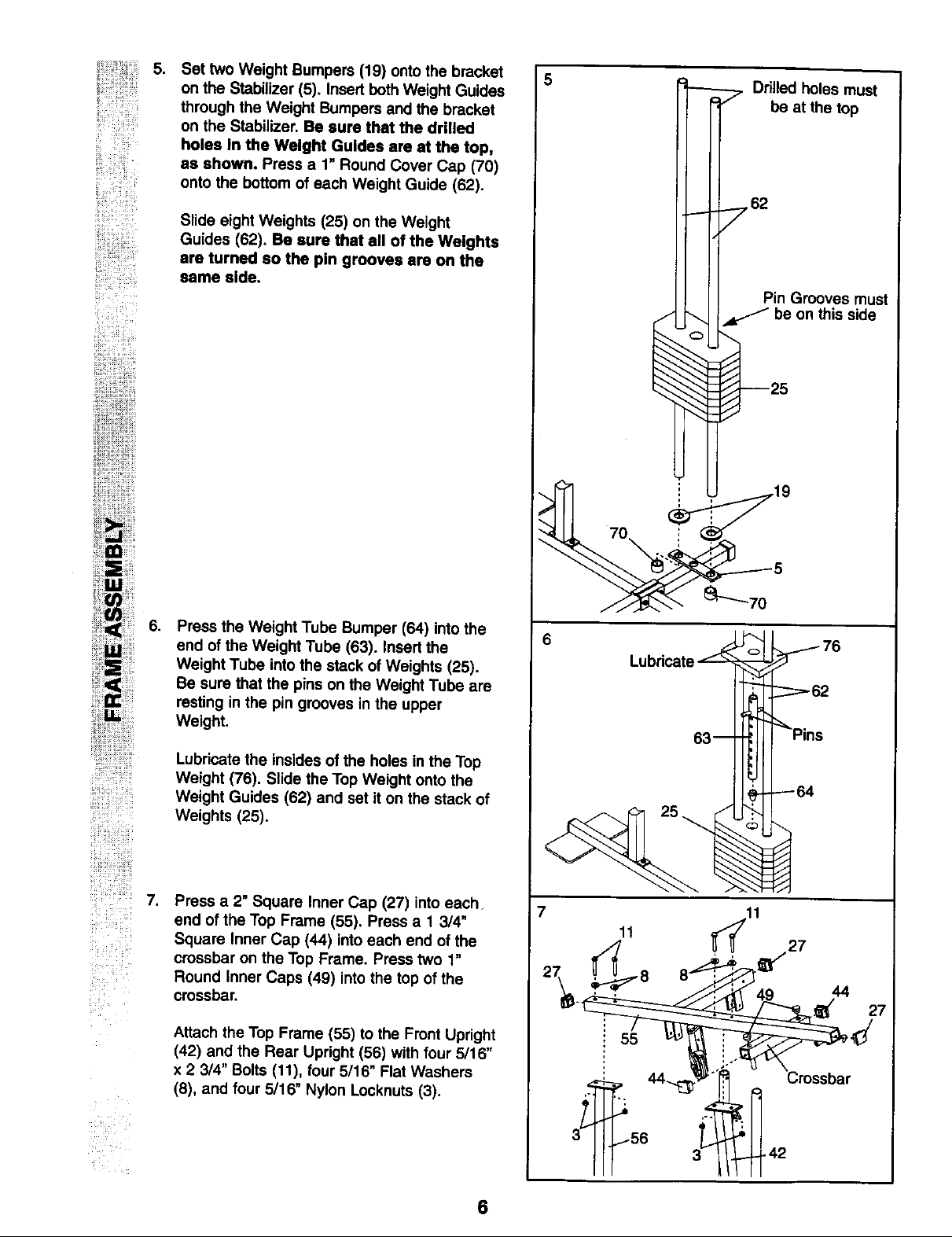

Set two Weight Bumpers (19) onto the bracket

on the Stabilizer (5). Insert bothWeight Guides

through the Weight Bumpers and the bracket

on the Stabilizer. Be sure that the drilled

holes In the Weight Guides are at the top,

as shown. Press a 1" Round Cover Cap (70)

onto the bottom of each Weight Guide (62).

Slide eight Weights (25) on the Weight

Guides (62). Be sure that all of the Weights

are turned so the pin grooves are on the

same side.

5

Drilled holes must

7 be at the top

7 62

Pin Grooves must

be on this side

ii_ii_ i_:_i_i!iiii_

ill _:_!_iiii_i

!i!!_i!__i!_ii_

.

Press the Weight Tube Bumper (64) into the

end of the Weight Tube (63). Insert the

Weight Tube into the stack of Weights (25).

Be sure that the pins on the Weight Tube are

resting in the pin grooves inthe upper

Weight.

Lubricate the insides of the holes in the Top

Weight (76). Slide the Top Weight onto the

Weight Guides (62) and set it on the stack of

Weights (25).

.

Press a 2" Square Inner Cap (27) into each.

end of the Top Frame (55). Press a 1 3/4"

Square Inner Cap (44) into each end of the

crossbar on the Top Frame. Press two 1"

Round Inner Caps (49) into the top of the

crossbar.

Attach the Top Frame (55) to the Front Upright

(42) and the Rear Upright (56) with four 5/16"

x 2 3/4" Bolts (11), four 5/16" Flat Washe_'s

(8), and four 5/16" Nylon Locknuts (3).

6

7

11

55

__iii_ii_ii_

_i_ _ i_i

6

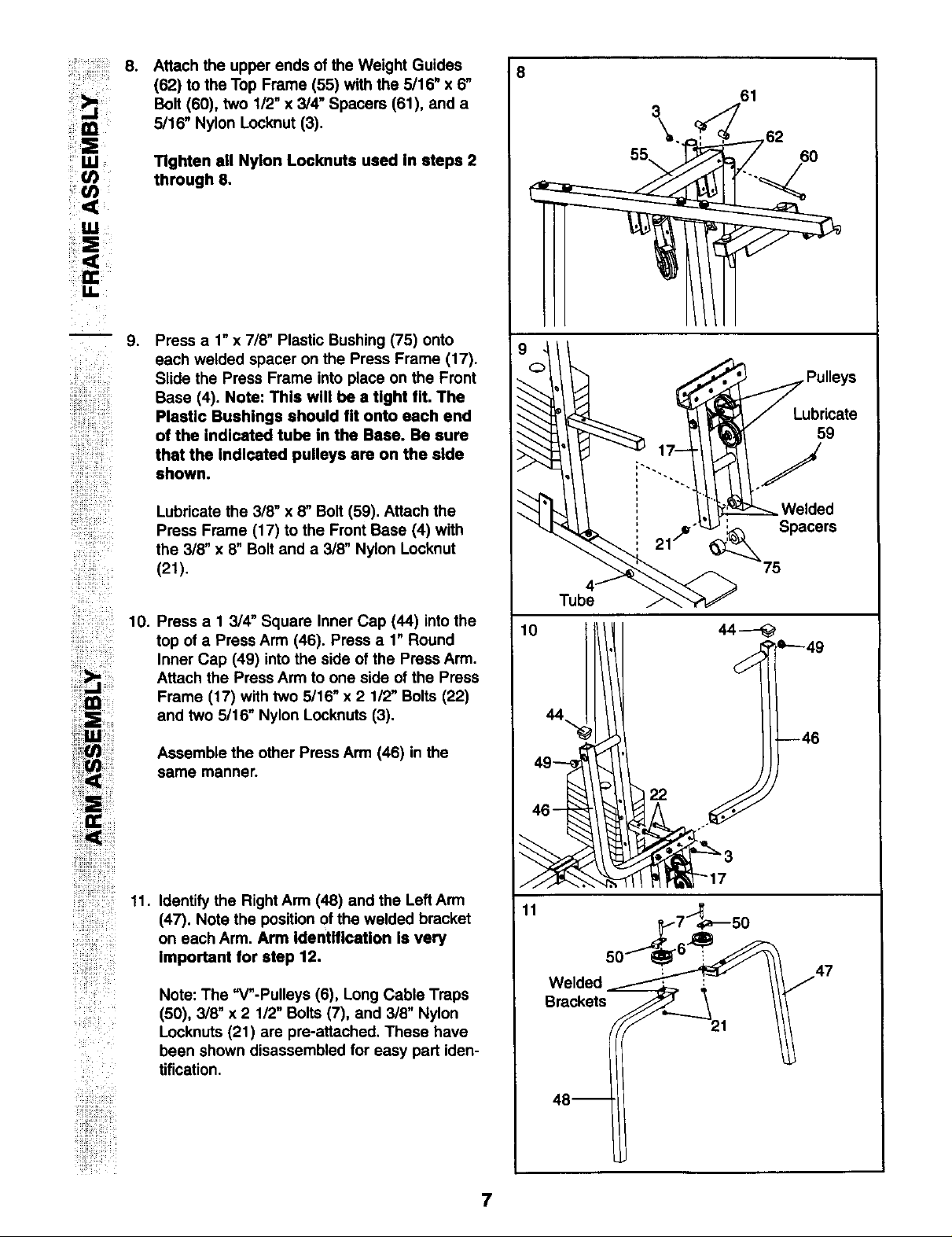

:: 8. Attach the upper ends of the Weight Guides

(62) to the Top Frame (55) with the 5/16" x 6"

Bolt (60), two 1/2" x 3/4" Spacers (61), and a

5/16" Nylon Locknut (3).

Tighten all Nylon Locknute used In steps 2

through 6.

i ¸ Ul

,

Press a 1" x 7/8" Plastic Bushing (75) onto

each welded spacer on the Press Frame (17).

Slide the Press Frame into place on the Front

Base (4). Note: This will be a fight fit. The

Plastic Bushings should fit onto each end

of the indicated tube in the Base. Be sure

that the indicated pulleys are on the side

shown.

Lubricate the 3/8" x 8" Bolt (59). Attach the

Press Frame (17) to the Front Base (4) with

the 3/8" x 8" Bolt and a 3/8" Nylon Locknut

(21).

8

61

3 . ,

i!!!iiiiiiii!iii!!il110

Press a I 3/4" Square Inner Cap (44) into the

top of a Press Arm (46). Press a 1" Round

Inner Cap (49) into the side of the Press Arm.

Attach the Press Arm to one side of the Press

Frame (17) with two 5116" x 2 1/2" Bolts (22)

and two 5116" Nylon Locknuts (3).

Assemble the other Press Arm (46) in the

same manner.

ii!iiiiiiiiii_ili_i;iiiiii!_

i!!iiiiiiii!!iiliil11.

Identify the Right Arm (48) and the LeftArm

(47). Note the position Of the welded bracket

on each Arm. Arm Identification Is very

Important for step 12.

iiiiliili

Note: The "V"-Pulleys (6), Long Cable Traps

(50), 3/8" x 2 1/2" Bolts (7), and 3/8" Nylon

ii ¸

Locknuts (21) are pre-attached. These have

been shown disassembled for easy part iden-

tification.

Tube

10

11

_7_-_50

We,ded // 47

Brackets_ '_21

i;!;i_i!i:ii;iii!

7

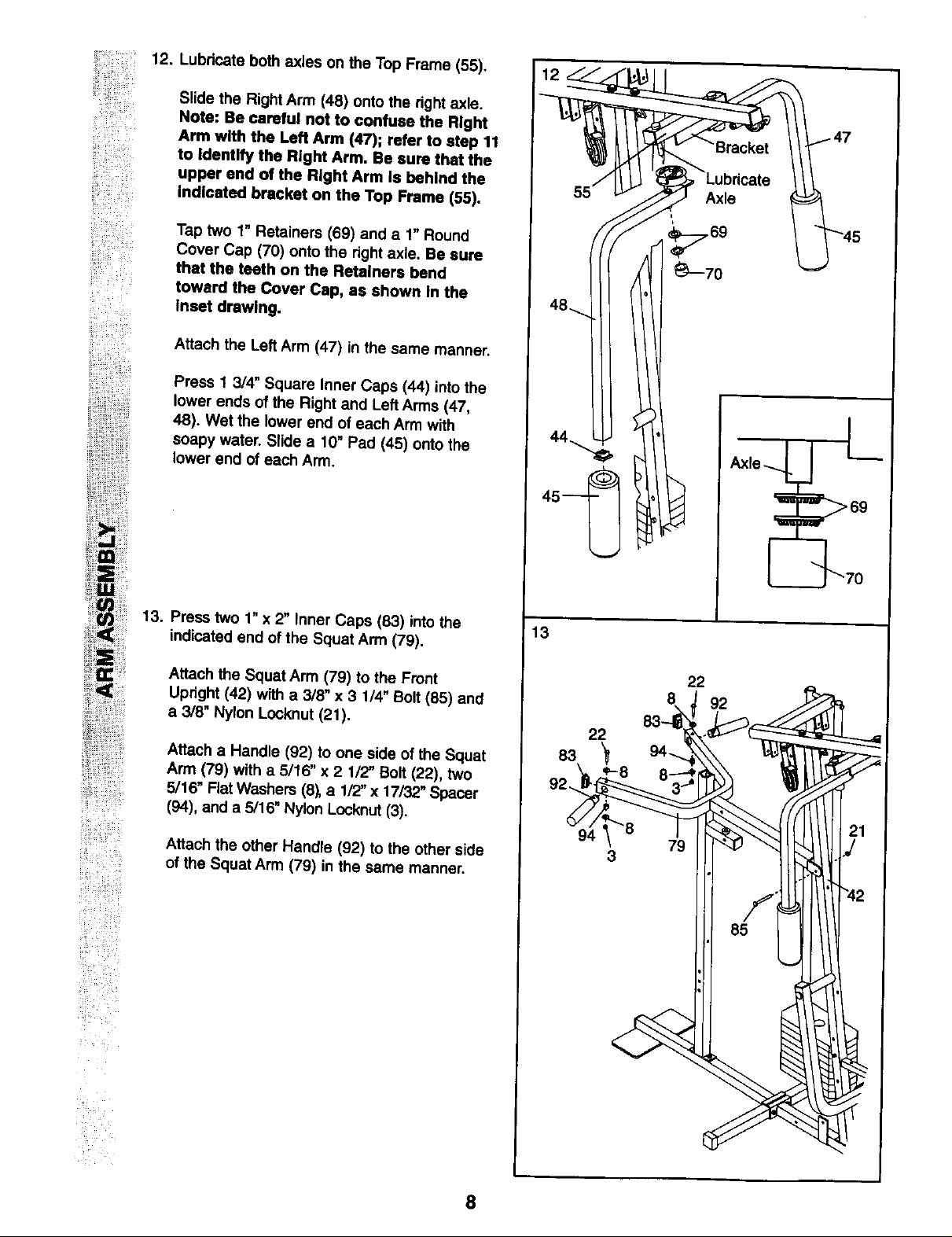

12. Lubricate both axles on the Top Frame (55),

Slide the Right Arm (48) onto the right axle.

Note: Be careful not to confuse the Right

Arm with the Left Arm (47); refer to step 11

to Identify the Right Arm. Be sure that the

upper end of the Right Arm is behind the

indicated bracket on the Top Frame (55).

ii ¸

Tap two 1" Retainers (69) and a 1" Round

Cover Cap (70) onto the right axle. Be sure

that the teeth on the Retainers bend

toward the Cover Cap, as shown In the

Inset drawing.

Attach the Lef_Arm (47) in the same manner.

Press 1 3/4" Square Inner Caps (44) into the

lower ends of the Right and Left Arms (47,

48). Wet the lower end of each Arm with

soapy water. Slide a 10" Pad (45) onto the

lower end of each Arm,

{ i¸¸ :=i

13.

Press two 1" x 2" Inner Caps (83) into the

indicated end of the Squat Arm (79).

Attach the Squat Arm (79) to the Front

Upright (42) with a 3/8" x 3 1/4" Bolt (85) and

a 3/8" Nylon Locknut (21).

Attach a Handle (92) to one side of the Squat

Arm (79) with a 5/16" x 2 1/2" Bolt (22), two

5/16" Rat Washers (8_ a 1/2"x 17132"Spacer

(94), and a 5/16" NylonLocknut (3).

Attach the other Handle (92) to the other side

of the Squat Arm (79) in the same manner.

13

22

92

22

83

-8

94

3

i ¸

:

8

Loading...

Loading...