Weider 831153930 Owner’s Manual

Model No. 831.153930

Serial No.

Write the serial number inthe

space above for reference.

Serial Number Decal (under seat)

_" X E: R C I _ E:.

E Q LI I P M E N"V

[-0 Ol_m

HELPLINE!

!-800-736-6879

USER'S MANUAL

SEARS, ROEBUCK AND CO.

HOFFMAN ESTATES, IL 60179

I,ACAUTION

Read alll_'l_autionsand Inl_uru_

tin In _ls martial Ilefom ullng

arts_l_, sa_t_ mimmd

fortUtu_

Patent Pending

r

www.weiderfitness.com

new products, prizes,

fitness tips, and much more!

TABLE OF CONTENTS

IMPORTANT PRECAUTIONS ............................................................. 3

BEFORE YOU BEGIN ................................................................... 4

ASSEMBLY ........................................................................... 5

ADJUSTMENTS ....................................................................... 22

WEIGHT RESISTANCE CHART ........................................................... 24

TROUBLESHOOTING .................................................................. 25

CABLE DIAGRAMS .................................................................... 26

ORDERING REPLACEMENT PARTS ................................................ Back Cover

FULL 90 DAY WARRANTY ....................................................... Back Cover

Note: A PART IDENTIFICATION CHART and a PART LIST/EXPLODED DRAWING are attached in the center of

this manual. Remove the PART IDENTIFICATION CHART and the PART LIST/EXPLODED DRAWING before

beginning assembly.

2

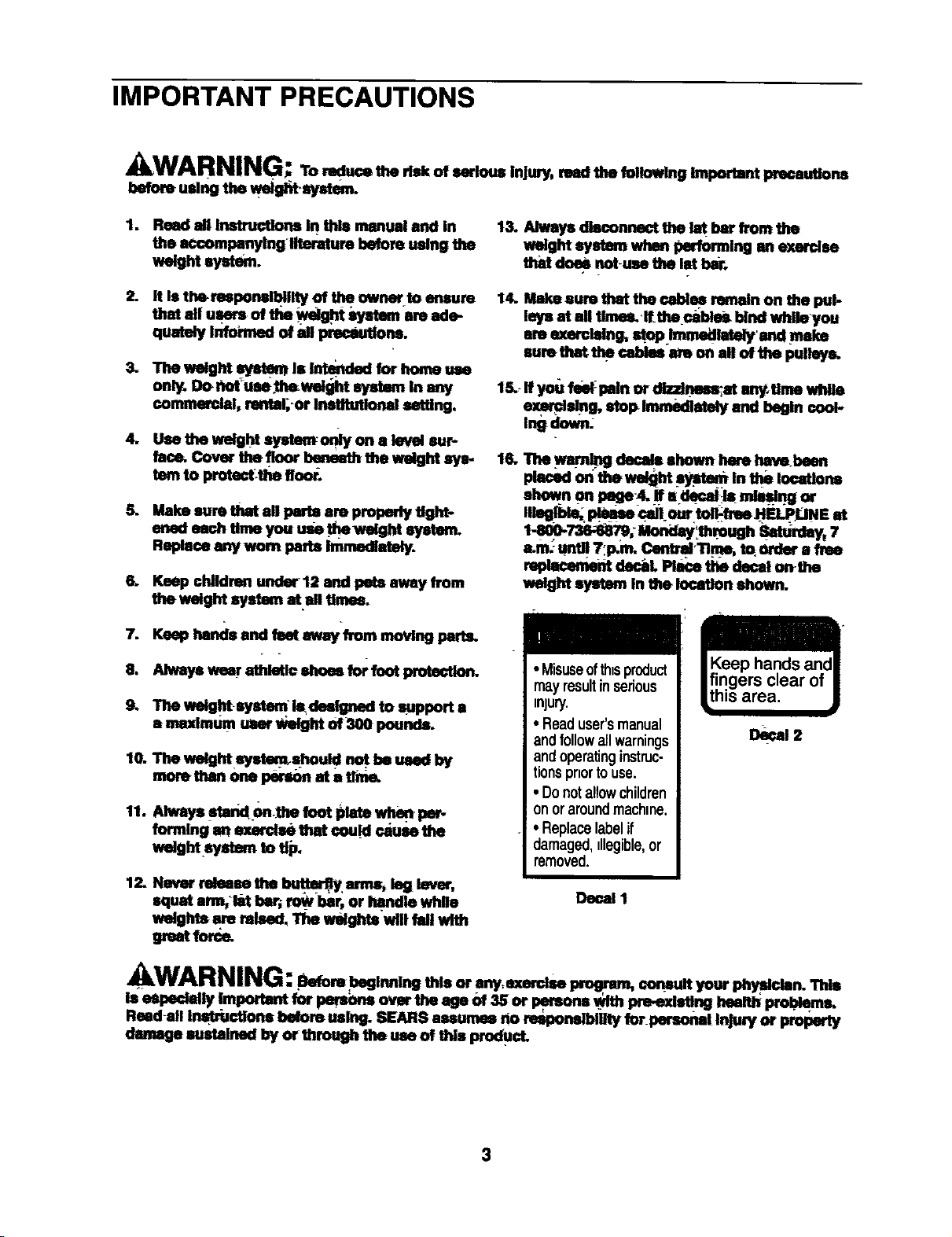

IMPORTANT PRECAUTIONS

1. Read all Instructions in rids manual and in 13. Always disconnect the lat bar from the

• e aCcompanylngltterature before using the weight system when performing an exercise

weight system. U1at_ not-use the lat bar.

2. It Is theresponslbmty of the owner to ensure

that all users of the _ System are ade-

quMely I_ of all IXeCWtlons.

3. "rheweight system Is Int_ded for home use

only.Donot_use_th_weightsystemin any

co_, rental;-or Institutional setUng.

4. Use the weight system mW on a level sur.

face_Coverthe._x=rbeneaththeweightsya-

tent to protect-the ffooi.

5. Make sure that all parbs are properly Ught-

e_d e_.hUmeyo..se _ewe_t symm.

Replace any wom pints in,nedlately.

6+ Keep children under12 and pets away from

the weight system at all 'dmu.

7. Keep hands and feet awayfrom moving parts.

8. Ahvayswearath_c shoes for foot protecU_

9. The weightsystem I_de_ned to supporta

a maximumz,mer_kdght of300 pounds.

10. The weight systomshould not be used by

moreuumonepem_ at=_

=

11. Always standon!_e foot plate when per-

forming an _wcise l_t could cause the

wek=htsystemtotip.

12. Never releue the butt_m-fly_arm_ leg lever,

squat arm;lat bar+roW_bar, or IImndle while

weights m raised, The weighs will fall with

groatfom_

14. Make sum that the cables remain on the pul-

leys at all tbnes., If_thecables bind whReyou

am exercising, s'copin,n_late_yand make

sure that the cablu m on aR o# the pulleys.

l&- If you fe_ pain or dizdnes_at any_gme while

e_ng, stop Immedlsteiy and begin cooF,

,nudow_

16. The wamlng decal= shown here have.been

racedonthewe_ht.-._m_m_-:nmemcaUons

ahownonpage4,p e._cal:Is m,lul.g or

lllllg_+ ._phl call+our _ I_. UNE at

1-80_ m, Monday+mmugh my, 7

=Lm:-untn7:p.m.___c_.lnr_ _ orderafree

replacement decal Place tire decal onthe

weight system In the location shown.

• Misuseofthzsproduct

mayresultinsedous

injury.

• Readuser'smanual

andfollow allwarnings

andoperatinginstruc-

tionspriortouse.

• Donotallowchildren

onoraroundmachine.

•Replacelabelif

damaged,dlegible,or

removed.

Decal I

Decal 2

WARNING: .

.... Innin9 this or any_exend €onsult your physldan. This

_ espedslly Imporlant l_r pemm_ overthe age of 3S or l_mons Wlthixe+xl_ng hea_ _

Read-_dlin_ctions before ush_. SEARS assumes no rupons_bllity lot persona[ InJu_/or property

damage msstalned by or _roug_ the use of this p_

3

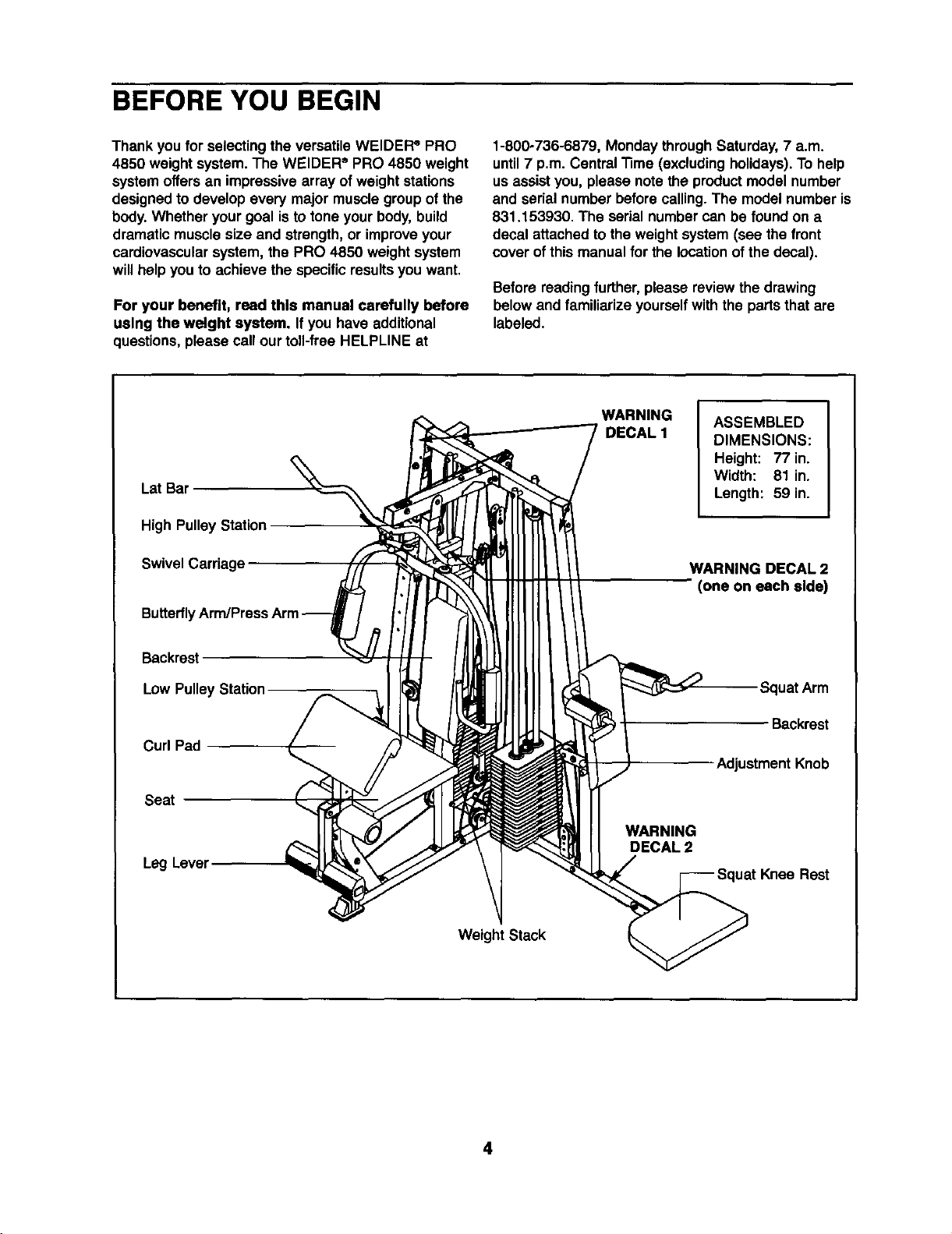

BEFORE YOU BEGIN

Thank you for selectingthe versatile WELDER®PRO

4850 weight system. The WELDER®PRO 4850 weight

systemoffers an impressivearray of weight stations

designedto develop every major muscle groupof the

body.Whether yourgoal is to tone your body, build

dramaticmuscle size and strength,or improveyour

cardiovascularsystem, the PRO 4850 weight system

willhelp you to achieve the specific resultsyou want.

For your benefit, read this manual carefully before

using the weight system. Ifyou have additional

questions, please call our toll-frea HELPLINE at

Lat Bar

High Pulley Station

SwivelCarriage

Butterfl_

1-800-736-6879, Monday throughSaturday, 7 a.m.

until7 p.m. Central "rime(excludingholidays).To help

us assistyou, please note the productmodel number

and serial number beforecalling.The model number is

831.153930. The serial numbercan be found on a

decal attachedto the weightsystem (see the front

cover of this manual for the locationof the decal).

Before readingfurther, please review the drawing

below and familiarize yourselfwith the parts that are

labeled.

WARNING ASSEMBLED

DECAL 1 DIMENSIONS:

Height: 77 in.

Width: 81 in.

Length: 59 in.

WARNING DECAL 2

(one on each side)

Backrest

Low Pulley Station

Curl Pad

Seat

Leg Level

Squat Arm

Backrest

AdjustmentKnob

WARNING

DECAL 2

u_ Knee Re_

Weight Stack

4

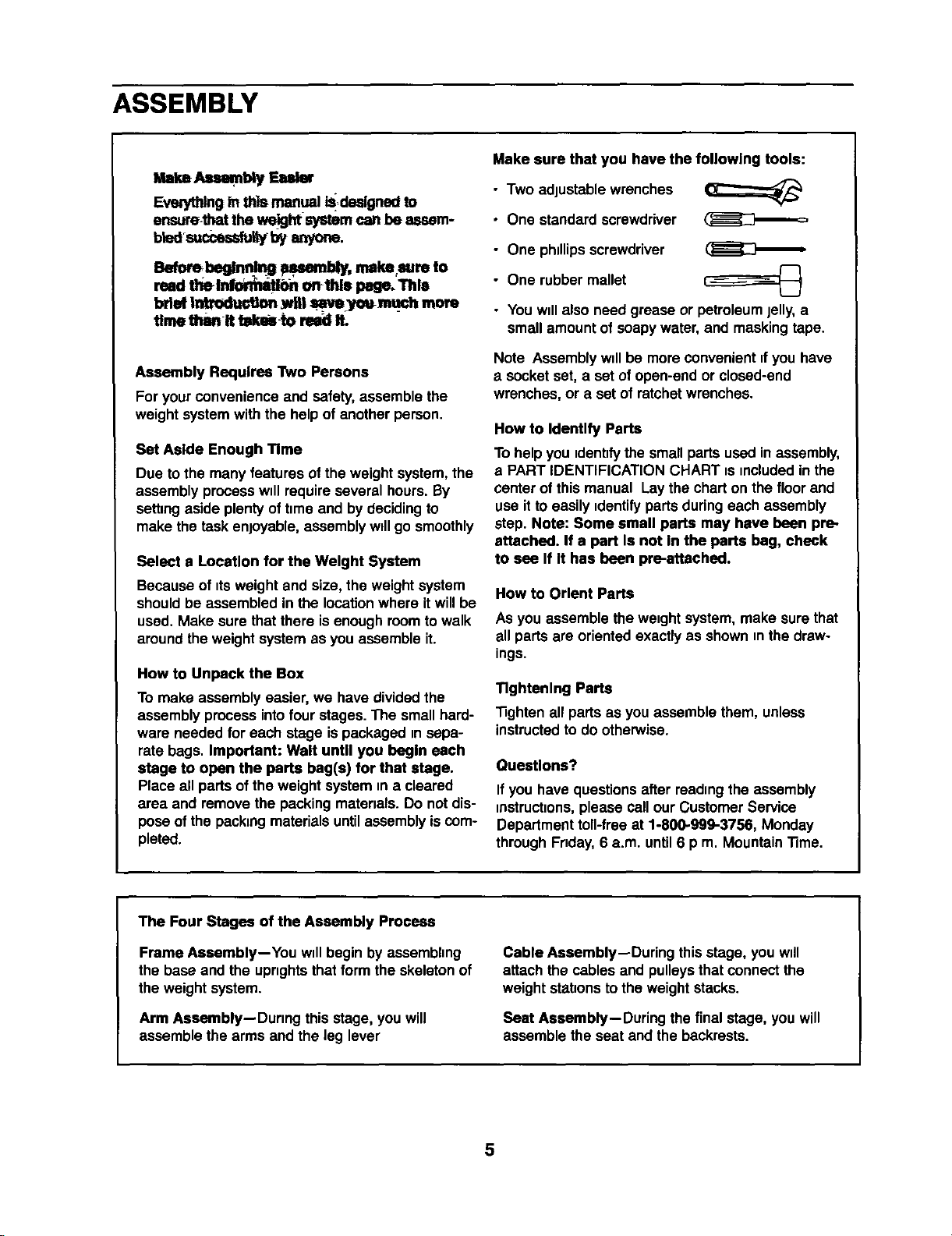

ASSEMBLY

ka/umemu

_lng inrigsmanual _,dealgned to

ensure-thatthe weightsystem can be assem-

btedsuc==du.ybyanyone.

Make sure that you have the following tools:

• Two adjustable wrenches

• One standardscrewdriver

• One phillipsscrewdriver

read t_e_on onthls pege. This

brief_ will_,e_'youm _uchmore

timethanlt tak_ to remHt.

Assembly Requires Two Persons

For yourconvenienceand safety,assemble the

weight system withthe help of another person.

Set Aside Enough Time

Due to the many features of the weight system, the

assembly processwill requireseveral hours.By

settingaside plenty of time and by decidingto

make the task enjoyable, assemblywillgo smoothly

Select a Location for the Weight System

Because of _tsweight and size, the weightsystem

shouldbe assembled in the locationwhere it willbe

used. Make sure that thereis enough room to walk

aroundthe weightsystem as you assemble it.

How to Unpack the Box

To make assembly easier, we have dividedthe

assembly process into fourstages. The small hard-

ware needed for each stage ispackaged in sepa-

rate bags. Important: Walt until you begin each

stage to open the parts bag(s) for that stage.

Place all partsof the weight system m a cleared

area and remove the packingmaterials. Do not dis-

pose of the packingmaterialsuntilassemblyis com-

pleted.

• One rubbermallet

• You will also need grease or petroleumjelly,a

small amount of soapywater, and masking tape.

Note Assemblywillbe more convenientif you have

a socketset, a set of open-end or closed-end

wrenches, or a set of ratchet wrenches.

How to Identify Parts

To help you _denhfythe small parts used inassembly,

a PART IDENTIFICATION CHART _sincludedin the

center of this manual Lay the chart on the floor and

use it to easily _dentify partsduringeach assembly

step. Note: Some small parts may have been pre-

attached. If a part Is not in the parts bag, check

to see If It has been pre-atteched.

How to Orient Parts

As you assemble the weight system, make sure that

all parts are orientedexactly as shown in the draw-

ings.

Tightening Parts

"nghtenall partsas you assemble them, unless

instructedto do otherwise.

Questions?

If you have questions after reading the assembly

instructions,please call ourCustomer Service

Department toll-free at 1-800-999-3756, Monday

through Fnday,6 a.m. until6 p m. MountainTime.

The Four Stages of the Assembly Process

Frame Assembly--You wdlbegin by assembling

the base and the upnghtsthat form the skeleton of

the weight system.

Arm Assembly--During this stage, you will

assemble the arms and the leg lever

Cable Assembly--During this stage, you will

attach the cables and pulleysthat connect the

weight stationsto the weightstacks.

Seat Assembly--During the finalstage, you will

assemble the seat and the backrests.

5

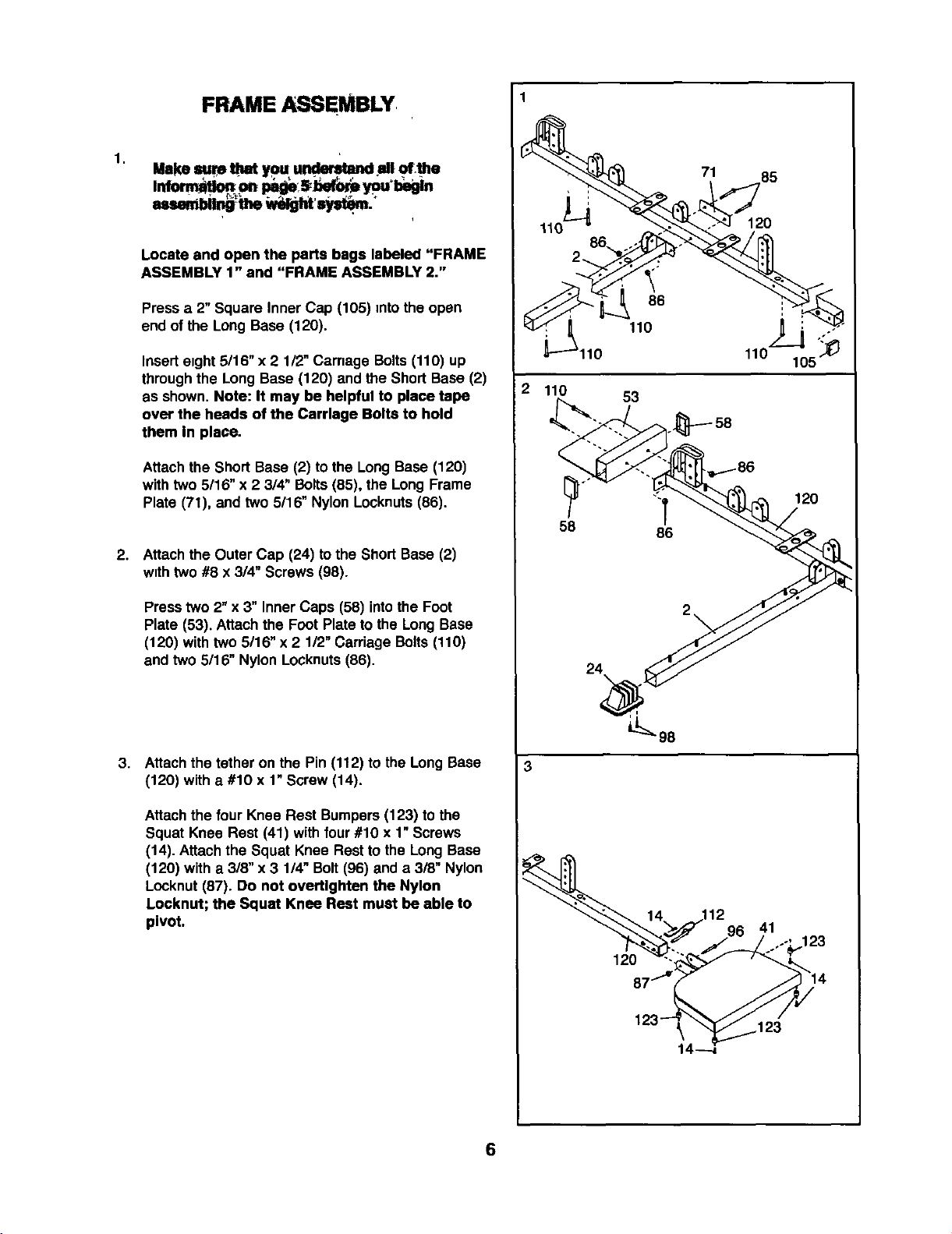

FRAME ASSEMBLY

Locate and open the parts bags labeled "FRAME

ASSEMBLY 1" and "FRAME ASSEMBLY 2."

71 B5

12O

Press a 2" Square Inner Cap (105) intothe open

end of the Long Base (120).

Inserteight 5/16" x 2 1/2" Carnage Bolts (110) up

throughthe Long Base (120) and the Short Base (2)

as shown. Note: It may be helpful to place tape

over the heads of the Carriage Bolts to hold

them In place.

Attach the Short Base (2) to the Long Base (120)

with two 5/16" x 2 3/4" Bolts (85), the Long Frame

Plate (71), and two 5116"Nylon Locknuts(86).

2. Attach the Outer Cap (24) to the Short Base (2)

wtthtwo #8 x 3/4" Screws (98).

Press two 2"x 3" Inner Caps (58) intothe Foot

Plate (53). Attach the Foot Plate tothe Long Base

(120) with two 5/16" x 2 112"Carriage Bolts (110)

and two 5116"Nylon Locknuts(86).

110

110 53

58

24

110

86

86

2\

110

1

120

3.

Attach the tether on the Pin (112) to the Long Base

(120) witha #10 x 1"Screw (14).

Attach the four Knee Rest Bumpers(123) tothe

Squat Knee Rest (41) with four #10 x 1"Screws

(14). Attachthe Squat Knee Rest to the Long Base

(120) with a 3/8" x 3 1/4" Bolt(96) and a 3/8" Nylon

Locknut(87). Do not overtlghten the Nylon

Locknut; the Squat Knee Rest must be able to

pivot.

3

41

6

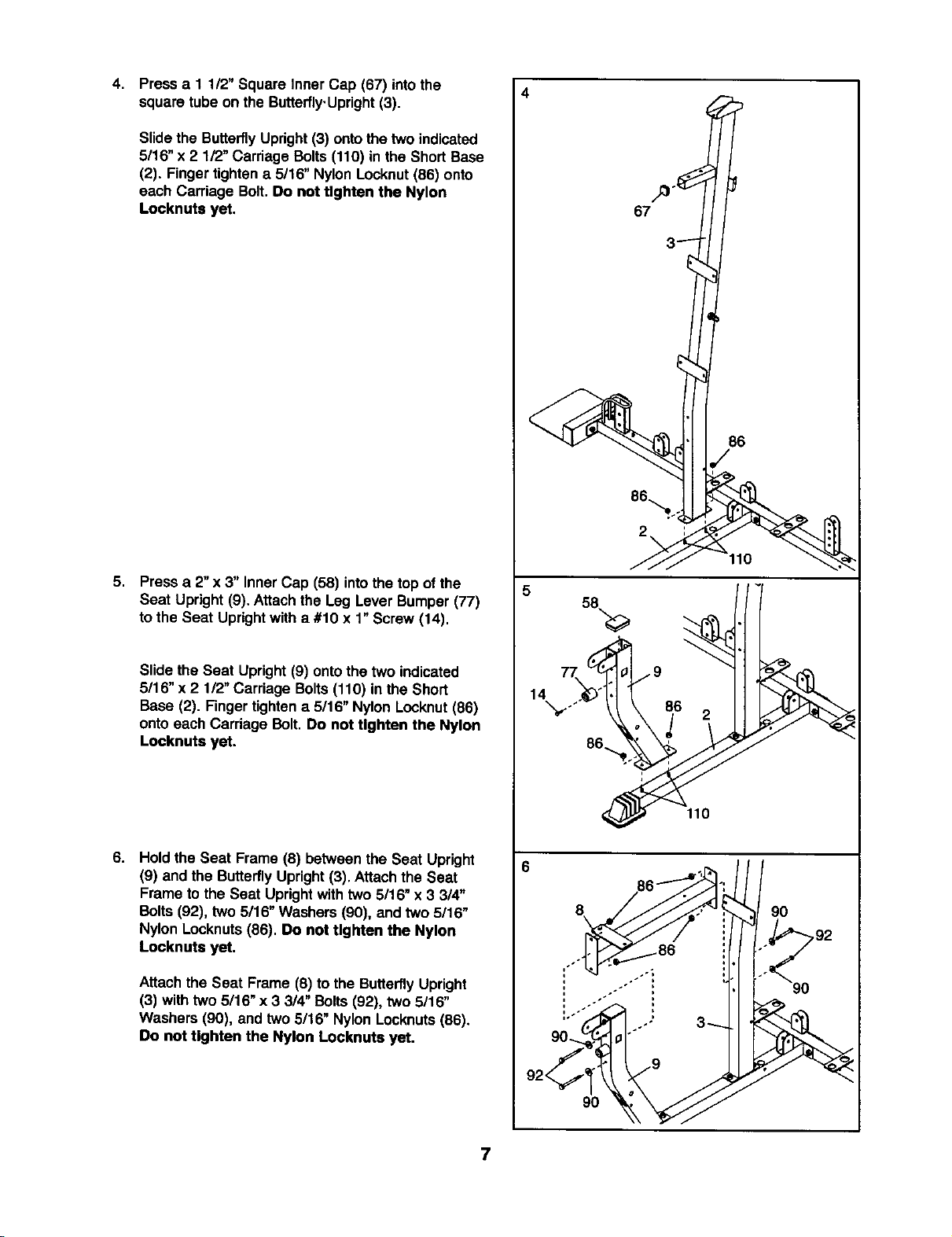

4.

Press a 1 1/2" Square Inner Cap (67) into the

square tube on the Butterfly.Upright(3).

Slide the ButterflyUpright(3) ontothe twoindicated

5/16" x 2 1/2"Carriage Bolts(110) in the ShortBase

(2). Finger tighten a 5/16" Nylon Locknut(86) onto

each Carriage Bolt,Do not tighten the Nylon

Locknuta yet,

67

86

,/

86_

5. Press a 2" x 3" Inner Cap (58) into the top of the

Seat Upright(9). Attachthe Leg Lever Bumper (77)

to the Seat Uprightwith a #10 x 1" Screw (14).

Slidethe Seat Upright(9) onto the two indicated

5/16" x 2 1/2" Carriage Bolts(110) in the Short

Base (2), Finger tightena 5/16" NylonLocknut(86)

ontoeach Carriage Bolt. Do not tighten the Nylon

Locknuts yet.

6. Hold the Seat Frame (8) between the Seat Upright

(9) and the ButterflyUpright(3). Attach the Seat

Frame to the Seat Uprightwith two 5/16" x 3 314"

Bolts (92), two 5/16" Washers (90), and two 5/16"

Nylon Locknuts(86). Do not tighten the Nylon

Locknuts yet.

Attach the Seat Frame (8) to the ButterflyUpright

(3) with two 5/16" x 3 3/4" Bolts(92), two 5/16"

Washers (90), and two 5/16" Nylon Locknuts(86).

Do not tighten the Nylon Locknute yet.

5

58

/909_

7

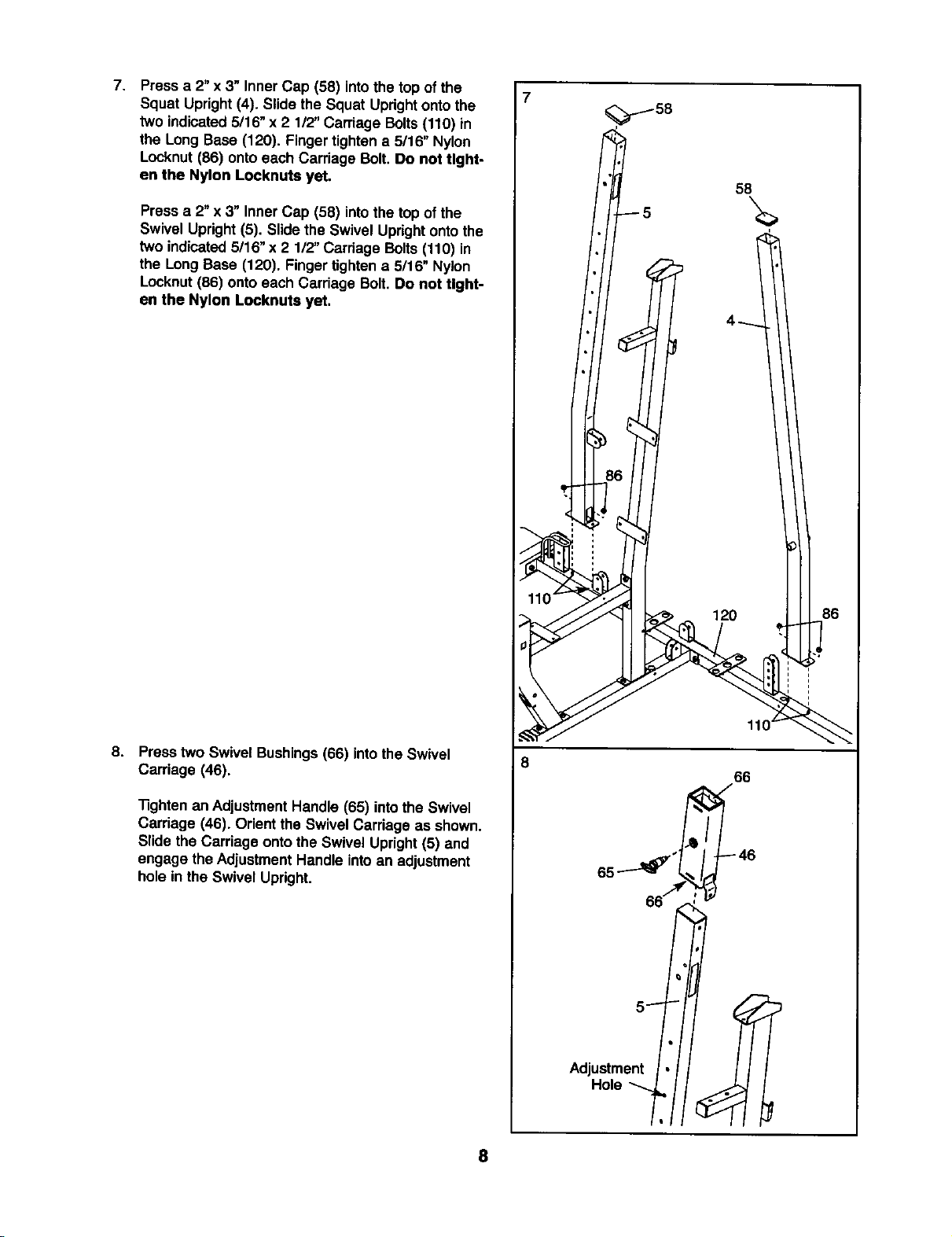

7.

Press a 2" x 3" Inner Cap (58) intothe top ofthe

Squat Upright(4). Slide the Squat Upright ontothe

two indicated5/16" x 2 1/2" Carriage Bolts(110) in

the Long Base (120). Finger tightena 5/16" Nylon

Locknut(86) onto each Carriage Bolt. 0o not tight-

en the Nylon Locknuts yet.

Pressa 2"x 3" Inner Cap (58) into the topof the

Swivel Upright(5). Slide the Swivel Uprightonto the

two indicated5/16" x 2 1/2"Carriage Bolts (110) in

the Long Base (120). Finger tighten a 5/16" Nyk_n

Locknut(86) onto each Carriage Bolt. Do not tight-

en the Nylon Locknuta yet,

7

_t58

58

8.

Press two Swivel Bushings(66) into the Swivel

Carriage (46).

"13ghtenan AdjustmentHandle (65) into the Swivel

Carriage (46). Orient the Swivel Carriage as shown.

Slide the Carriage onto the Swivel Upright(5) and

engage the AdjustmentHandle into an adjustment

hole in the Swivel Upright.

120

8

66

65

Adjustment

Hole "_.

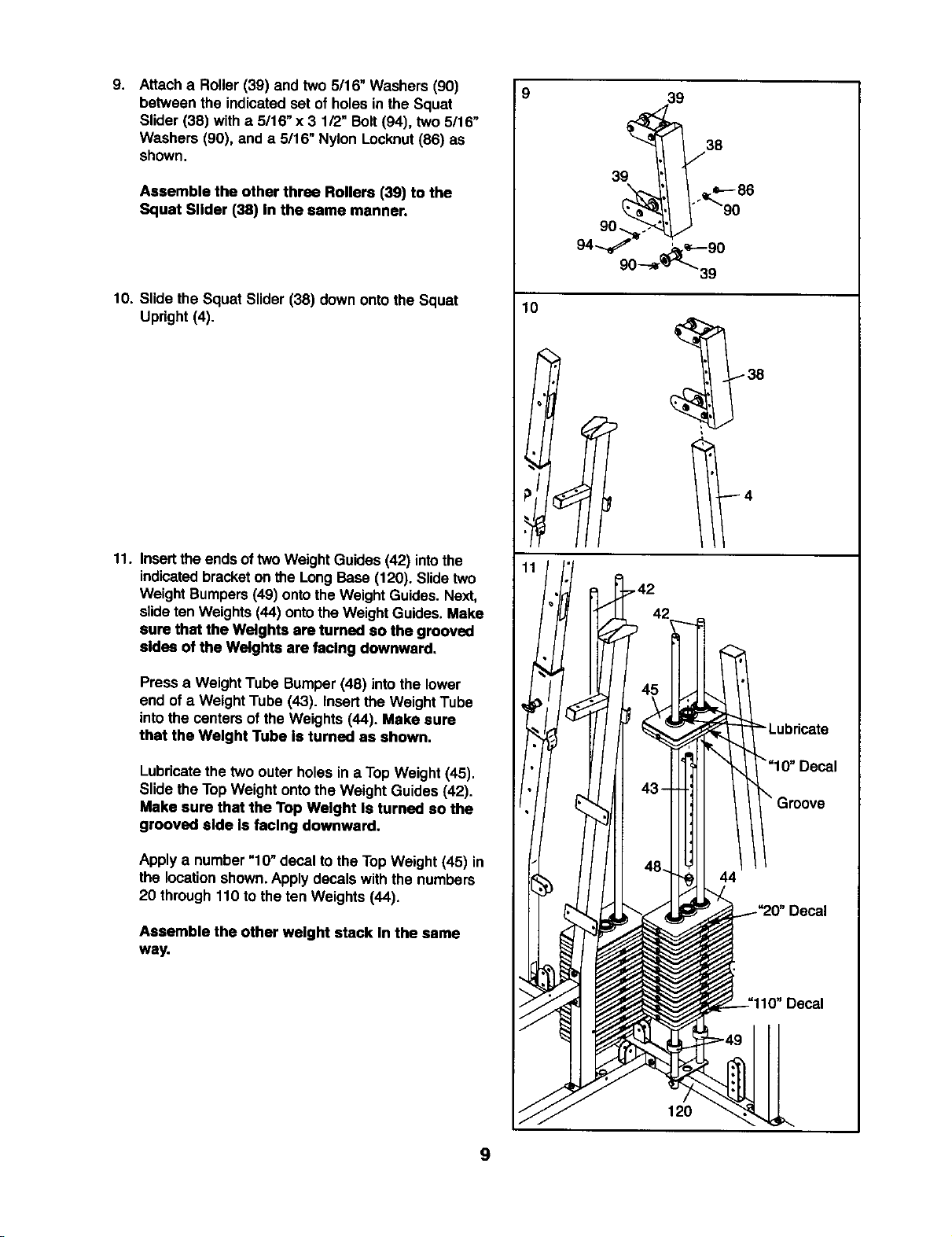

g. Attach a Roller (39) and two 5/16" Washers (90)

between the indicatedset of holes in the Squat

Slider (38) witha 5/16" x3 1/2" Bolt (94), two 5/16"

Washers (90), and a 5/16" Nylon Locknut(86) as

shown.

Assemble the other three Rollers (39) to the

Squat Slider (38) In the same manner.

9

10. Slide the Squat Slider (38) down ontothe Squat

Updght (4).

11. Insertthe ends oftwo WeightGuides (42) intothe

indicatedbracketon the LongBase (120). Slidetwo

Weight Bumpers(49) onto the Weight Guides. Next,

slideten Weights(44) ontothe Weight Guides. Make

sure that the Weights are turned so the grooved

sides of the Weights are facing downward.

Pressa WeightTube Bumper (48) into the lower

end of a Weight Tube (43). Insert the WeightTube

intothe centers of the Weights (44). Make sure

that the Weight Tube Is turned as shown.

10

Lubricatethe two outer holes in aTop Weight (45).

Slide the TopWeight onto the Weight Guides (42).

Make sure that the Top Weight Is turned so the

grooved side Is facing downward.

Applya number=10" decalto the TopWeight (45) in

the locationshown.Apply decals with the numbers

20 through 110 to the ten Weights (44).

Assemble the other weight stack In the same

way.

44

Decal

120

9

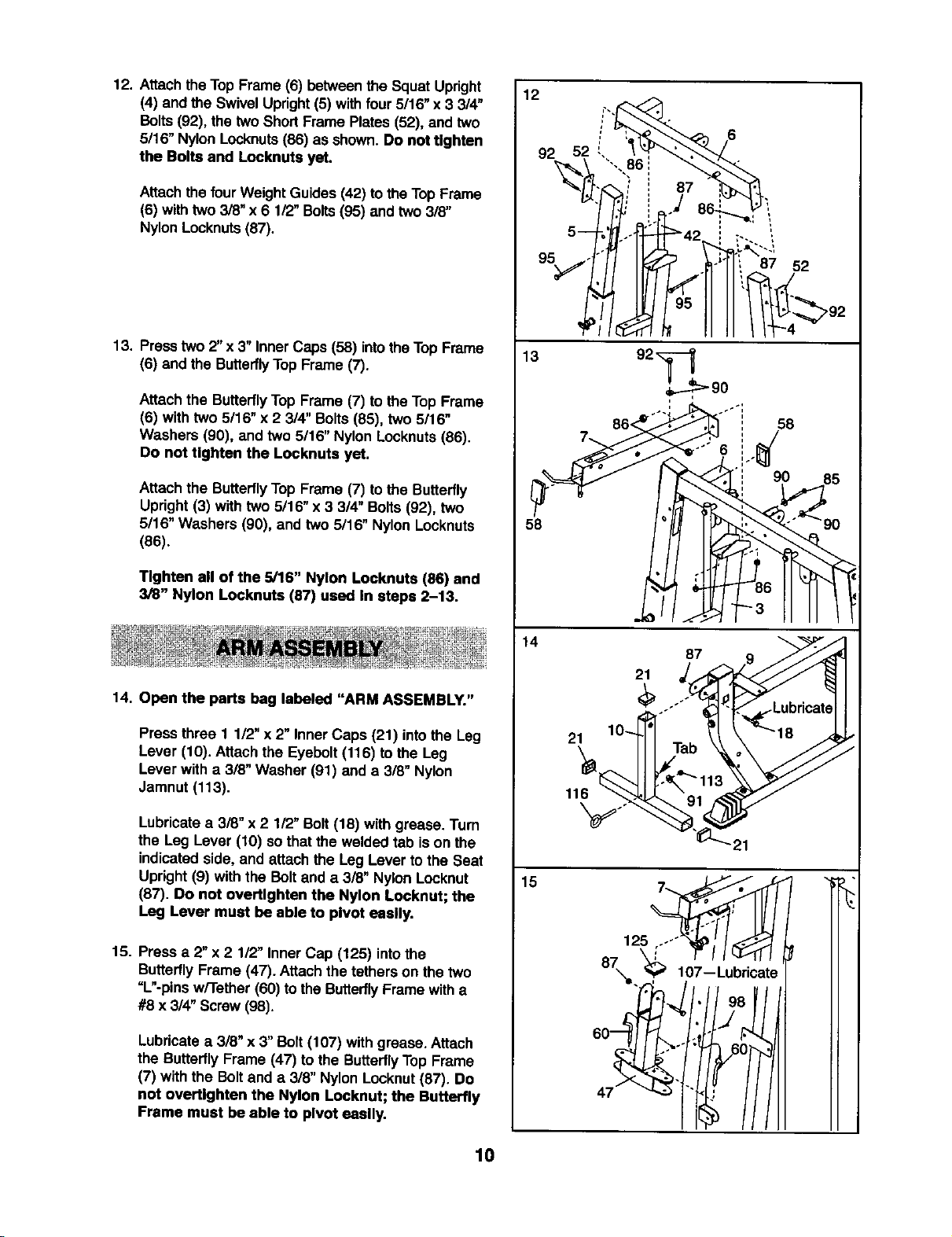

12. Attach theTop Frame (6) betweenthe Squat Upright

(4) and the Swivel Upright(5) withfour 5/16"x 3 3/4"

Bolts(92), the two Short Frame Plates (52), and two

5/16" NylonLocknuts(86) as shown. Do not tlghtsn

the Bolts and Locknuts yet.

Attachthe fourWeight Guides (42) to the TopFrame

(6) withtwo 3/8" x 6 1/2" Bolts(95) and two 318"

Nylon Locknuts(87).

13. Press two 2"x 3" Inner Caps (58) into the Top Frame

(6) and the ButterflyTop Frame (7).

Attachthe ButterflyTop Frame (7) to the TopFrame

(6) with two 5/16" x 2 314"Bolts(85), two 5/16"

Washers (90), and two 5/16" Nylon Locknuts(86).

Do not tighten the Locknuts yet.

Attach the ButterflyTop Frame (7) to the Butterfly

Upright (3) withtwo 5/16" x 3 3/4" Bolts(92), two

5/16" Washers (90), and two 5/16" Nylon Locknuts

(86).

Tighten all of the 5/16" Nylon Locknuts (86) and

3/8" Nylon Locknuts (87) used In steps 2-13.

12

/"_ 6

92 52

5--

95t

t_ 9_': i_v,_92

13 92_90

58

i 90 85

86 '8

14. Open the parts bag labeled "ARM ASSEMBLY."

Press three 1 1/2"x 2" Inner Caps (21) intothe Leg

Lever (10). Attach the Eyebolt(116) to the Leg

Lever with a 3/8" Washer (91) and a 318"Nylon

Jamnut (113).

Lubricate a 3/8" x 2 1/2" Bolt (18) with grease. Turn

the Leg Lever (10) so that the welded tab ison the

indicatedside, and attach the Leg Lever to the Seat

Upright (9) with the Bolt and a 3/8_ Nylon Locknut

(87). Do not overtlghten the Nylon Locknut; the

Leg Lever must be able to pivot easily.

15. Press a 2" x 2 1/2" InnerCap (125) intothe

ButterflyFrame (47). Attachthe tethers on the two

=L"-pins w/Tether (60) to the ButterflyFrame witha

#8 x 314"Screw (98).

Lubricatea 3/8" x 3"Bolt (107) withgrease. Attach

the ButterflyFrame (47) to the ButterflyTop Frame

(7) with the Boltand a 3/8" Nylon Locknut (87). Do

not overUghten the Nylon Locknut; the Butterfly

Frame must be able to pivot euUy.

14

15

87

21

21

116

21

) -

125_

10

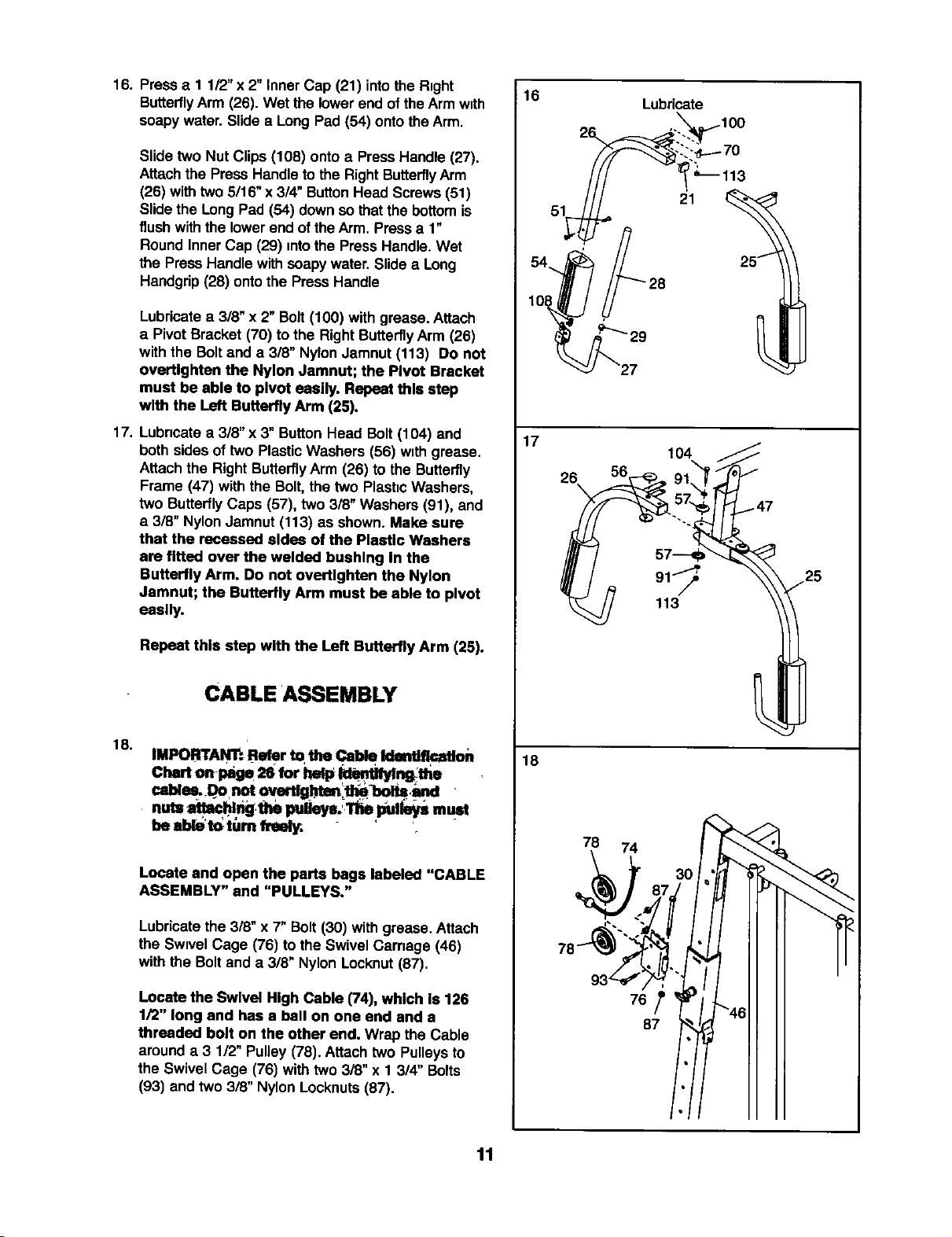

16. Press a 1 112"x 2" Inner Cap (21) intothe R_ght

ButterflyArm (26). Wet the lowerend of the Arm with

soapy water. Slidea LongPad (54) onto the Arm.

Slidetwo Nut Clips (106) onto a PressHandle (27).

Attachthe Press Handle to the RightButterflyArm

(26) withtwo 5/16" x 3/4" ButtonHead Screws (51)

Slidethe Long Pad (54) down so that the bottomis

flushwiththe lowerend of the Arm. Press a 1"

Round InnerCap (29) intothe Press Handle. Wet

the Press Handle withsoapy water.Slide a Long

Handgrip(28) onto the Press Handle

Lubricatea 3/8" x 2" Bolt(100) with grease. Attach

a Pivot Bracket (70) to the Right ButterflyArm (26)

with the Boltand a 318"NylonJamnut (113) Do not

overtlghten the Nylon Jamnut; the Pivot Bracket

must be able to pivot easily. Repeat this step

with the Left Butterfly Arm (25).

17. Lubricate a 3/8" x 3" ButtonHead Bolt (104) and

both sides of two Plastic Washers (56) withgrease.

Attach the Right Butterfly Arm (26) to the Butterfly

Frame (47) with the Bolt, the two Plashc Washers,

two Butterfly Caps (57), two 3/8" Washers (91), and

a 3/8" Nylon Jamnut (113) as shown. Make sure

that the recessed sides of the Plastic Washers

are fitted over the welded bushing In the

Butterfly Arm. Do not overtlghten the Nylon

Jamnut; the Butterfly Arm must be able to pivot

easily.

16 Lubricate

III , .-113

. 1.27

17

26 56

104

113

Repeat this step with the Left Butterfly Arm (25).

CABLE ASSEMBLY

18.

IMPORTANT=imkt4Perta the Cable

¢Im_ onileige 26 lot hell+ _the ,

, nuts +a+t_,_,hln+ the pmlleys.'Tite I_IIWI muet

beabh*tot,',m + ' '+

Locate and open the parts bags labeled "CABLE

ASSEMBLY" and "PULLEYS."

Lubricatethe 3/8" x 7" Bolt (30) withgrease. Attach

the Swivel Cage (76) to the Swivel Carnage (46)

with the Boltand a 3/8" Nylon Locknut(87).

Locate the Swivel High Cable (74), which Is 126

1/2" long and has a ball on one end and a

threaded bolt on the other end. Wrap the Cable

arounda 3 1/2" Pulley (78). Attach two Pulleysto

the Swivel Cage (76) with two 3/8" x 1 3/4" Bolts

(93) and two 3/8" Nylon Locknuts(87).

18

,

76 74

76/"

87

11

Loading...

Loading...