Page 1

Motors | Automation | Energy | Transmission & Distribution | Coatings

UBW Technical Manual

US.UBW.Tech.Manual.2018

Page 2

Table of Contents

UBW Technical Manual

General Description .............................................................................................................................3

Part Number Description ......................................................................................................................4

Interrupt Capacity Ratings ....................................................................................................................5

UBW 225 Trip Curves (15 - 225A).........................................................................................................6

UBW 250 Trip Curves .........................................................................................................................33

UBW 400 Trip Curves .........................................................................................................................35

UBW 600 Trip Curves .........................................................................................................................37

UBW 800 Trip Curves .........................................................................................................................39

UBW 1200 Trip Curves .......................................................................................................................40

UBW 2500 Trip Curves .......................................................................................................................42

Let Thru Curves .................................................................................................................................46

UBW Dimensions

...............................................................................................................................49

2 Data subject to change without notice.

Page 3

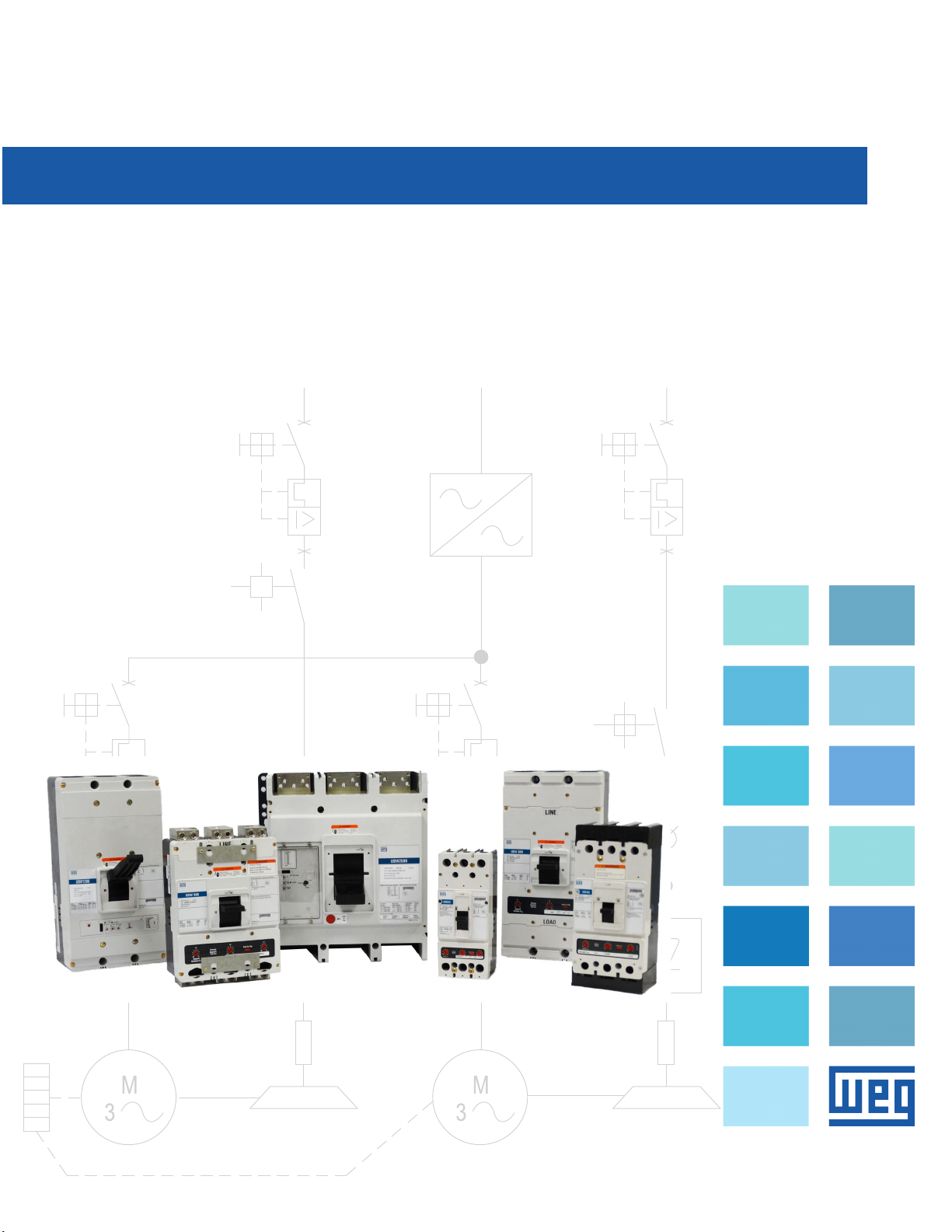

General Description

General Circuit

Breaker Information

WEG’s molded-case circuit breakers are

designed to provide circuit protection for low

voltage distribution systems. They are

described by NEMA as, “. . . a device

for closing and interrupting a circuit between

separable contacts under both normal and

abnormal conditions,” and further- more as,

“. . . a breaker assembled as an integral

unit in a supporting and enclosing housing of

insulating material.” The NEC® describes

them as, “A device designed to open and

close a circuit by non-automatic means, and

to open the circuit automatically on a

predetermined overload of current, without

injury to itself when properly applied within

its rating.”

So designed, WEG circuit breakers protect

conductors against overloads and conductors

and connected apparatus, such as motors

and motor starters, against short circuits.

Circuit Breaker Components and

Functions

Being essentially high interrupting capacity

switches with repetitive elements, WEG’s

circuit breakers are comprised of three main

functional components. These are:

1. Trip elements (thermal-magnetic or

electronic)

2. Operating mechanism

3. Arc extinguishers

1. Trip Elements

The function of the trip element is to trip the

operating mechanism in the event of a

prolonged overload or short-circuit current. To

accomplish this, a thermal- magnetic trip

action is provided.

Thermal-Magnetic Breakers

WEG thermal-magnetic breakers are general

purpose devices suitable for the majority of

breaker applications and are considered the

industry standard. Available from 15–800 A,

thermal-magnetic breakers provide accurate

reliable overload and short- circuit protection

for conductors and connected apparatus.

Thermal trip action is achieved through the

use of a bimetal heated by the load current.

On a sustained over- load, the bimetal will

deflect, causing the operating mechanism to

trip.

Because bimetals are responsive to the heat

emitted by the current flow, they allow a longtime delay on light overloads, yet they have a

fast response on heavier overloads.

Magnetic trip action is achieved through the

use of an electromagnet in series with the

load current. This provides an instantaneous

tripping action when the current reaches a

predetermined value. Front-adjustable

magnetic trip elements are supplied as

standard on 250 A frame circuit breakers and

above 225 are fixed thermal and magnetic

Electronic RMS Trip Breakers

WEG electronic trip breakers are generally

applied for applications where high levels of

system coordination are called for. Available

from 500–2500 A, today’s electronic trip

breakers can provide superior protection and

coordination as well as additional protection

features. Both the overload trip action and the

short-circuit trip action of breakers with

Digitrip electronic trip units are achieved by

the use of current transformers and solidstate circuitry that monitors the current and

initiates tripping through a flux shunt trip

when an overload or a short circuit is present.

All multiple-pole circuit breakers have trip

elements in each pole and a common trip bar.

An abnormal circuit condition in any one pole

will cause all poles to open simultaneously.

Electronic RMS trip breakers can include trip

features such as:

• Adjustable long-time pickup

• Adjustable short-time pickup

• Adjustable long delay time

• Adjustable short delay time

• Adjustable instantaneous pickup

Trip unit adjustments are made by setting

switches on the front of the trip unit or by

programming the trip unit electronically.

All electronic RMS trip breakers are equipped

with a manual push-to-trip mechanism.

Molded-Case Circuit Breakers

2. Operating Mechanism

The function of the operating mechanism is to

provide a means of opening and closing the

breaker contacts. All mechanisms are of the

quick-make, quick-break type and are “trip

free.” “Trip free” mechanisms are designed

so that the contacts cannot be held closed

against an abnormal circuit condition and are

sometimes referred to as an “overcenter

toggle mechanism.” In addition to indicating

whether the breaker is “on” or “off,” the

operating mechanism handle indicates when

the breaker is “tripped” by moving to a

position midway between the extremes. This

distinct trip point is particularly advantageous

where breakers are grouped, as in

panelboard applications, because it clearly

indicates the faulty circuit. The operating

mechanism contains a positive on feature. In

the normal switching operation, the handle of

the circuit breaker will not be capable of

being left readily at or near the off position

when the main contacts are closed.

3. Arc Extinguishers

The function of the DE-ION® arc extinguisher

is to confine, divide

extinguish the arc drawn between opening

breaker contacts. It consists of specially

shaped steel grids isolated from each other

and supported by an insulating housing.

When the contacts are opened, the arc drawn

induces a magnetic field in the grids, which in

turn draws the arc from the contacts and into

the grids. The arc is thus split into a series of

smaller arcs and the heat generated is quickly

dissipated through the metal. These two

actions result in a rapid removal of ions from

the arc, which hastens dielectric build- up

between the contacts and results in

rapid extinction of the arc.

Data subject to change without notice. UBW Technical Manual | 3

Page 4

Molded-Case Circuit Breakers

Description UBW Breakers Frames 225 to 2500

Select trip

Operator type Types of operators: mechanically operated over-center toggle or motor operator

Closing speed Greater than 5-cycle closing for electrically operated devices

Mounting Typically fixed-mounted but large frame sizes may be available in drawout construction

Interrupting rating Interrupting duty at 480 Vac: 22–100 kA

Current limiting Current limiting available with and without fuses up to 200 kA

Relative cost Low

Available frame sizes Large number of frame sizes available. Typical 15–2500 A

Maintenance Very limited maintenance possible on larger frame sizes

Enclosure types Used in enclosures, panelboards, switchboards, MCCs and control panels

Series ratings Available in series ratings

Enclosed rating 80% continuous-current rated

Standards NEMA AB1/AB3 UL 489

Selective trip over a smaller range of fault currents within the interrupting rating (low short-time

ratings). Typically 10–13 times the frame size

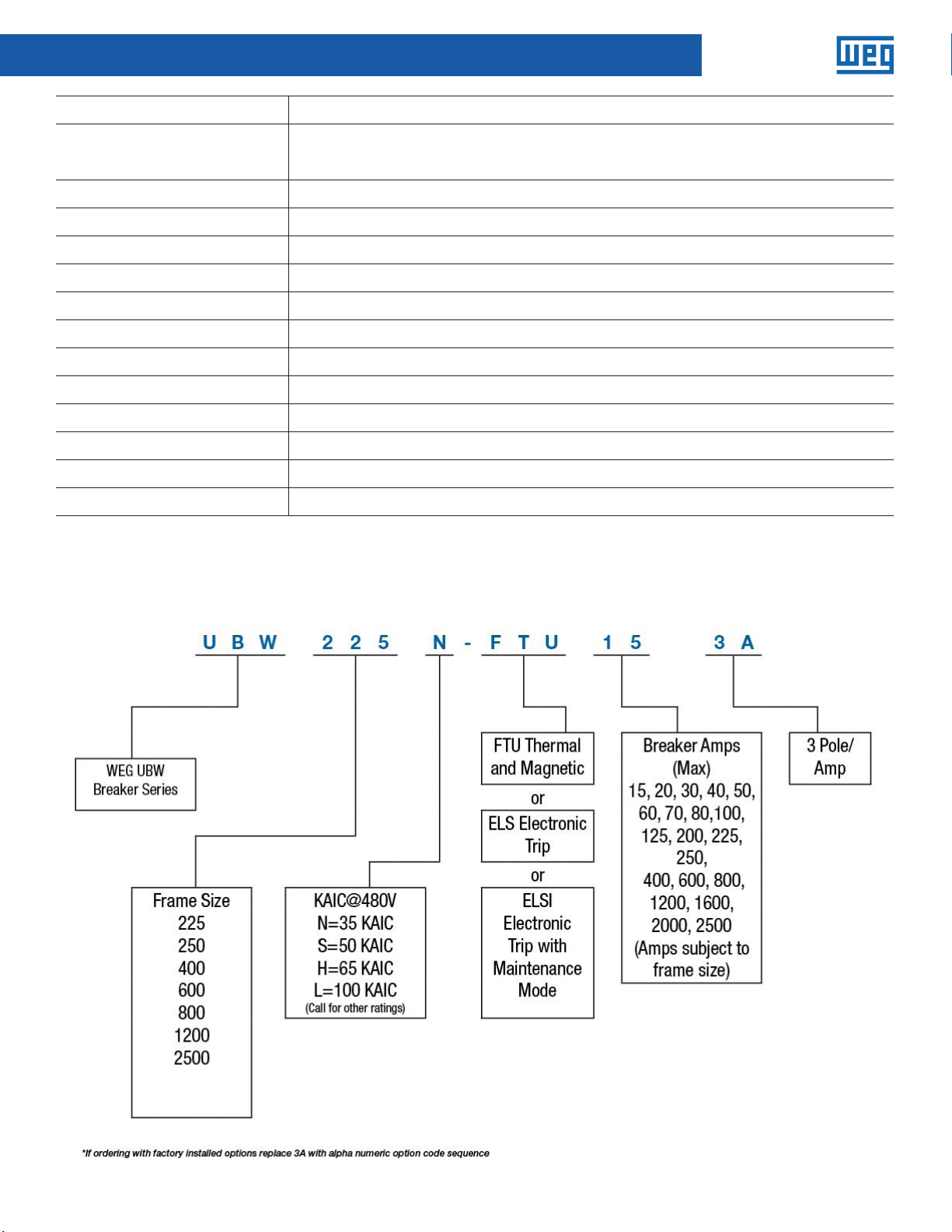

UBW Part Number Sequence

4 Data subject to change without notice.

Page 5

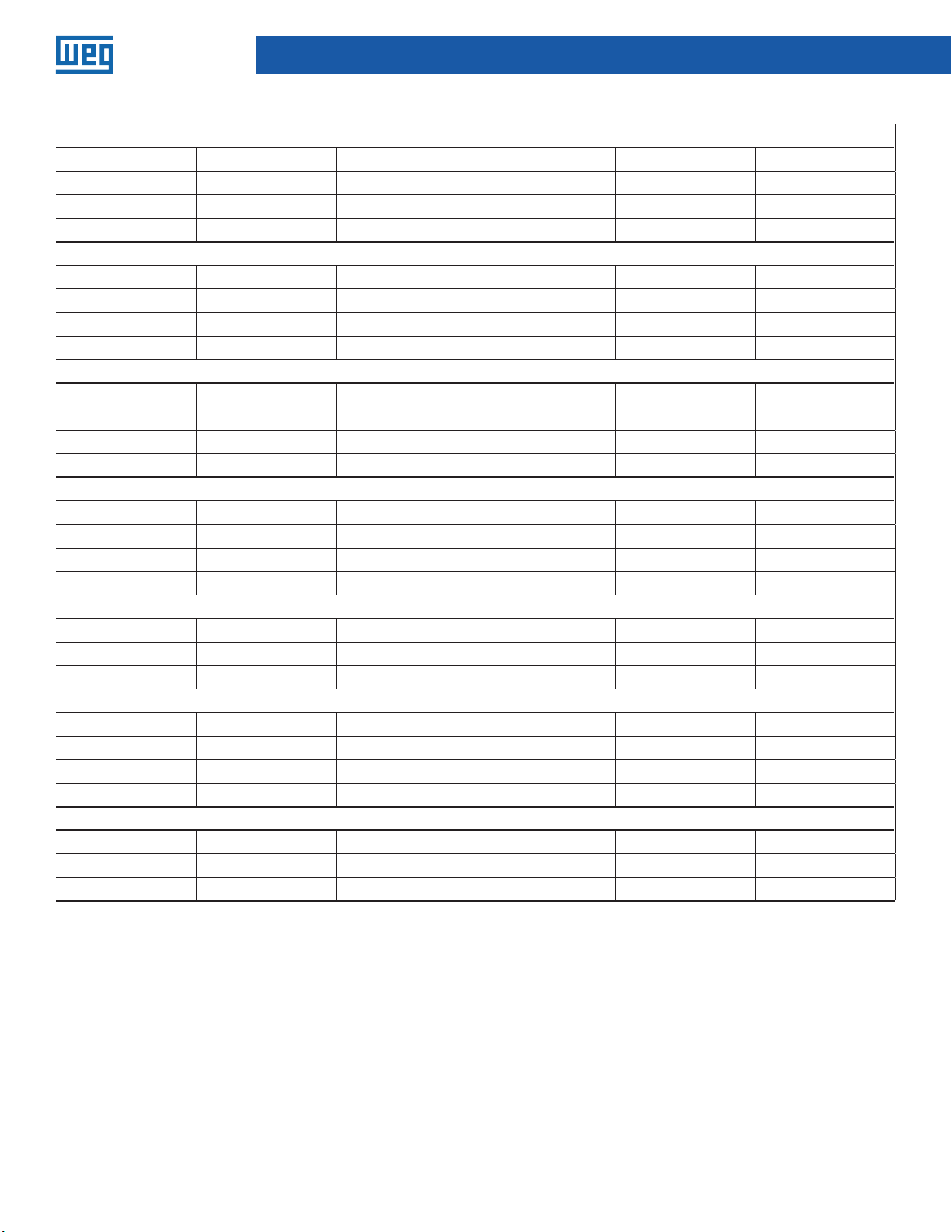

Molded-Case Circuit Breakers

Interupting Capicity Ratings

225 Frame

Type Poles 240ac 480ac 600ac 250dc

N 3 65K 35K N/A 10K

H 3 100K 65K N/A 22K

L 3 200K 100K N/A 22K

250 Frame

Type Poles 240ac 480ac 600ac 250dc

N 3 65K 35K 18K 10K

H 3 100K 65K 25K 22K

L 3 200K 100K N/A 22K

400 Frame

Type Poles 240ac 480ac 600ac 250dc

N 3 65K 35K 18K 10K

H 3 100K 65K 35K 22K

L 3 200K 100K 65K 22K

600 Frame

Type Poles 240ac 480ac 600ac 250dc

N 3 65K 35K 25K 22K

H 3 100K 65K 35K 25K

L 3 200K 100K 50K 30K

800 Frame

Type Poles 240ac 480ac 600ac 250dc

S 3 65K 50K 25K 22K

H 3 100K 65K 35K 25

1200 Frame

Type Poles 240ac 480ac 600ac DC Rated

S 3 85K 50K 25K NO

H 3 100K 65K 35K NO

L 3 N/A 100K 65K NO

2500 Frame

Type Poles 240ac 480ac 600ac DC Rated

H 3 125K 65K 50K NO

L 3 200 100K 65K NO

Data subject to change without notice. UBW Technical Manual | 5

Page 6

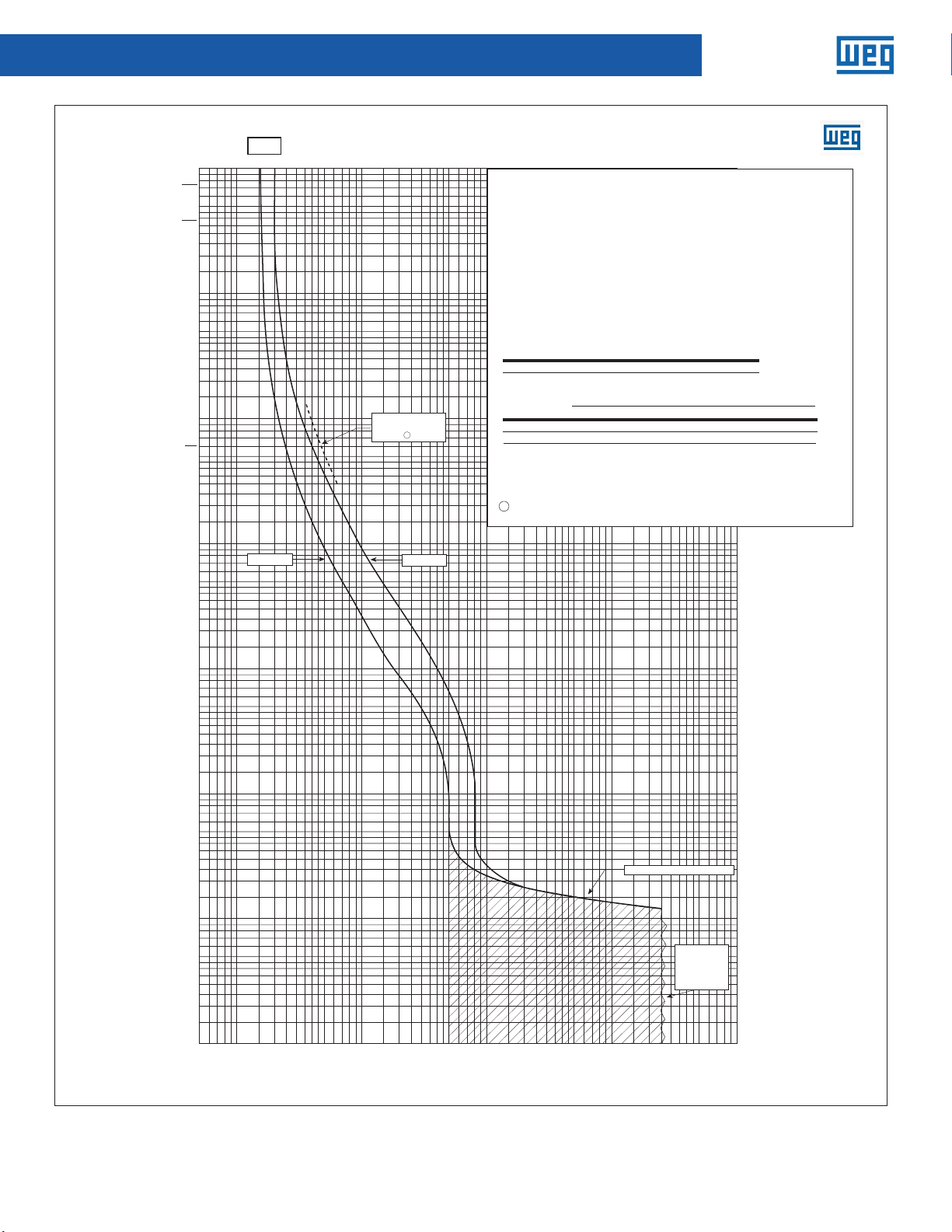

Molded-Case Circuit Breakers

UBW Time Current Curves

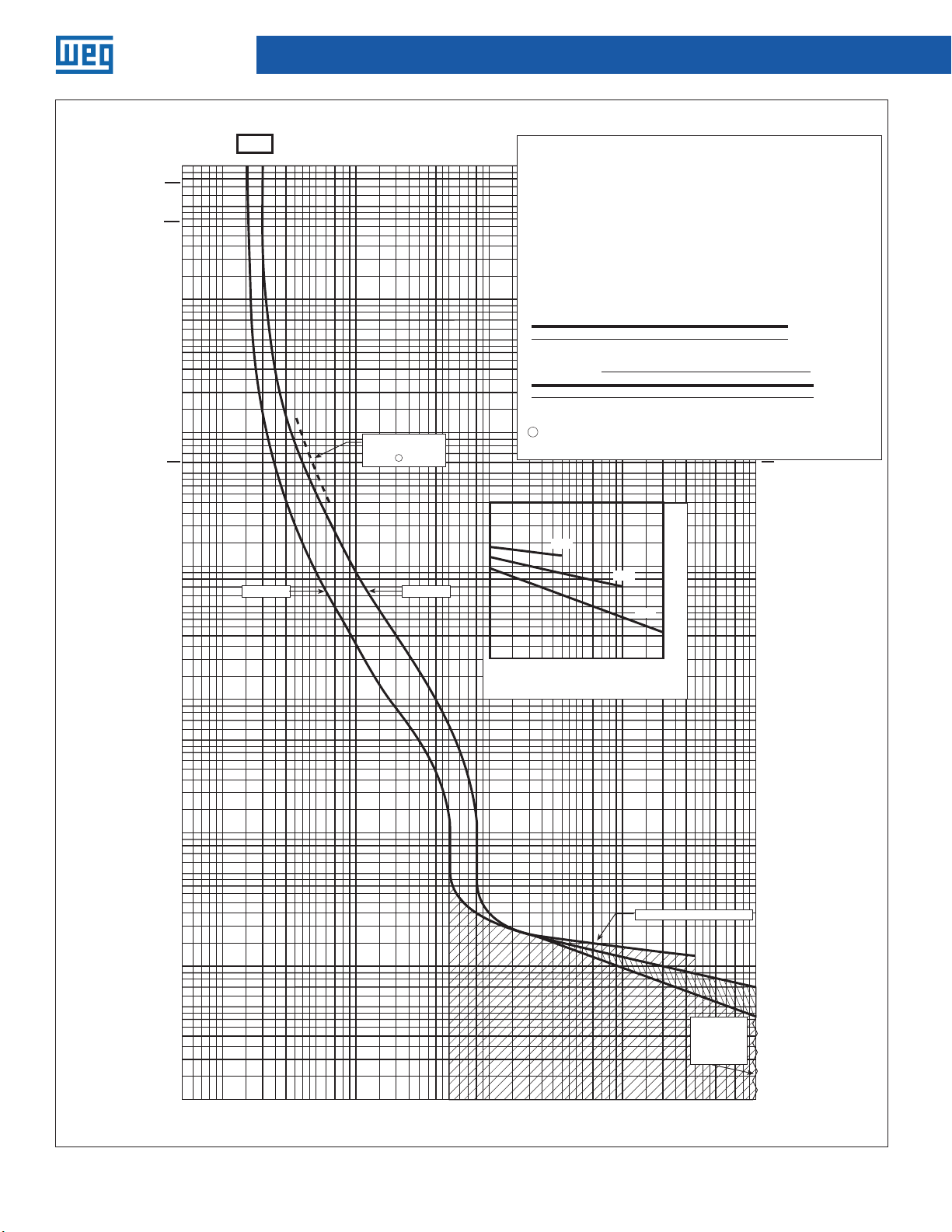

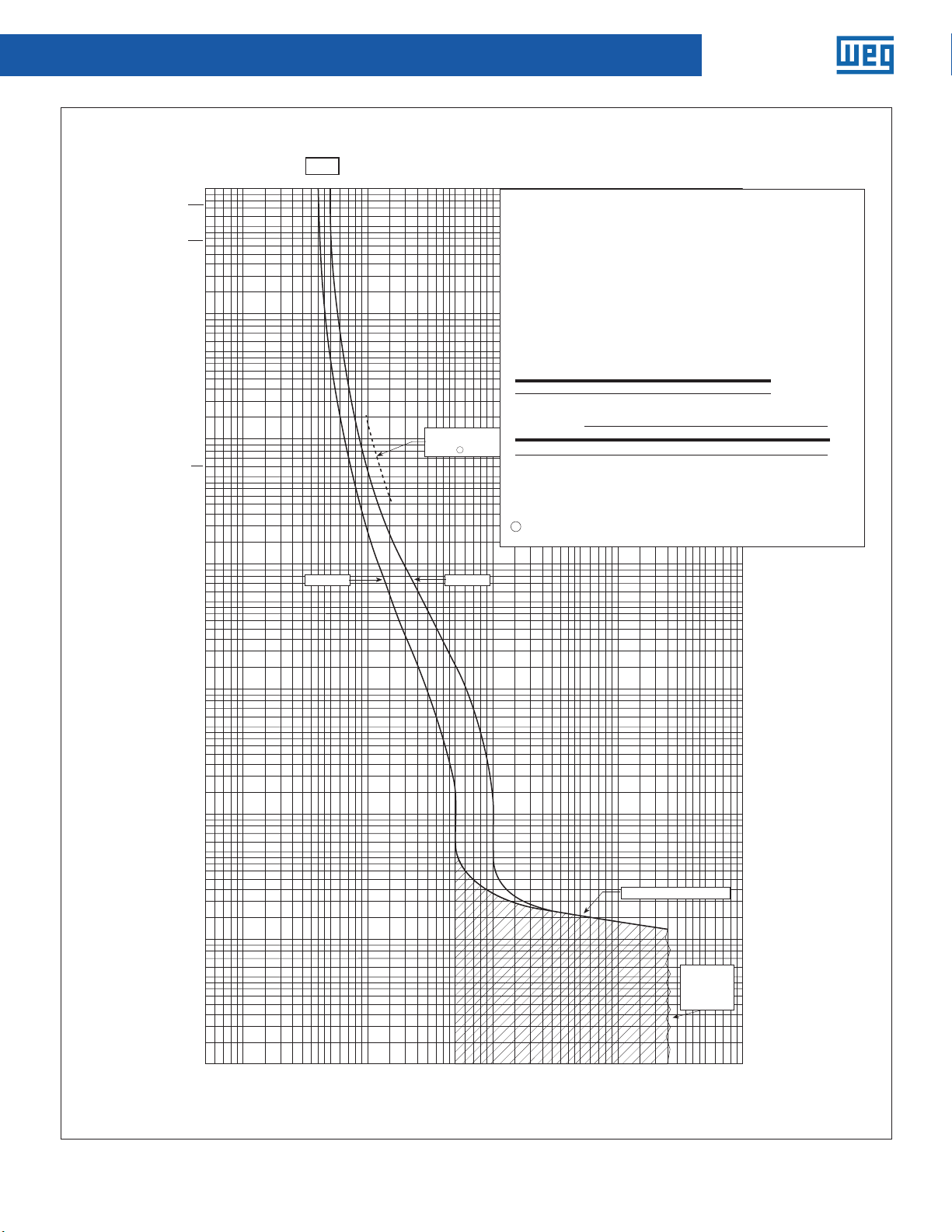

225N/H

10,000

2 HOURS

5,000

1 HOUR

3,000

2,000

1,000

500

300

200

100

50

1 MINUTE

30

20

10

5

15A

Minimum

8060 9070504030201 0 9 8 75 6

100

CURRENT IN AMPERES

300

200

Maximum singlepole trip times

1

at 25°C

Maximum

400

Circuit breaker time/current curves

F-frame circuit breakers

Catalog types ED, EHD, FDB, FD and HFD circuit breakers, two-, three-

and four-poles.

Circuit breaker time/current curves

For application and coordination purposes only.

Series 225 frame circuit breakers

Based on 40˚C ambient, cold start. Connected with four (4) feet of

rated wire (60˚C

Tested in open air with current in all

For application and coordination purposes only. Based on 40°C ambient, cold start.

Maximum Vac: 600 at 50/60 Hz

Connected with four (4) feet of rated wire (60°C up to 125A, 75°C above 125A) per

Maximum Vdc: 250

terminal. Tested in open air.

Breaker rating

Continuous amperes Instantaneous trip amperes

Maximum Vac: 600 at 50/60 Hz

15A See curve

Maximum Vdc: 250

Interrupting Rating (UL/CSA Listed)

Breaker

Symmetrical Rms amperes (KA) Amps (KA)

type

Breaker rating

Continuous amperes Instantaneous trip, amperes

15A See curve

Interrupting Rating (UL/CSA Listed)

Breaker Type

N

H

@ 240 Vac @ 480 Vac @ 600 Vac 250 Vac 125V

18

EHD

18

FDB

65

FD

100

HFD

ED 65

1

Single-pole test data at 25˚C based on NEMA procedures

(AB

4-2003

) for verifying performance of molded case

circuit breakers.

Symmetrical RMS amperes (kA)

@240Vac @480Vac @600Vac 250Vac

65 35 18 10

100 65 25 22

pole.

—

14

14

35

65

—

10

14

18

25

—

—

10

—

10

—

22

10

—

5,000

3,000

2,000

1,000

500

300

200

100

50

2 HOURS

1 HOUR

10000

8000

6000

9000

7000

5000

4000

3000

2000

1000

800

600

900

700

500

Notes:

1 Single-pole test data at 25°C based on NEMA procedures (AB 4-2003) for verifying

performance of molded case circuit breakers.

20

10

5

3

2

1

.5

TIME IN SECONDS

.3

.2

.1

.05

.03

.02

.01

.005

.003

.002

.001

56

3

TIME IN SECONDS

2

1

.5

.3

.2

.1

.05

Maximum interrupting time

Interrupting

rating

determines

end of curve

(see above)

60

40

20

987

10

30

80

7050

90

200

100

500

700

800

600

900

400

300

CURRENT IN AMPERES

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

.03

.02

.01

.005

.003

.002

.001

6 Data subject to change without notice.

Page 7

Molded-Case Circuit Breakers

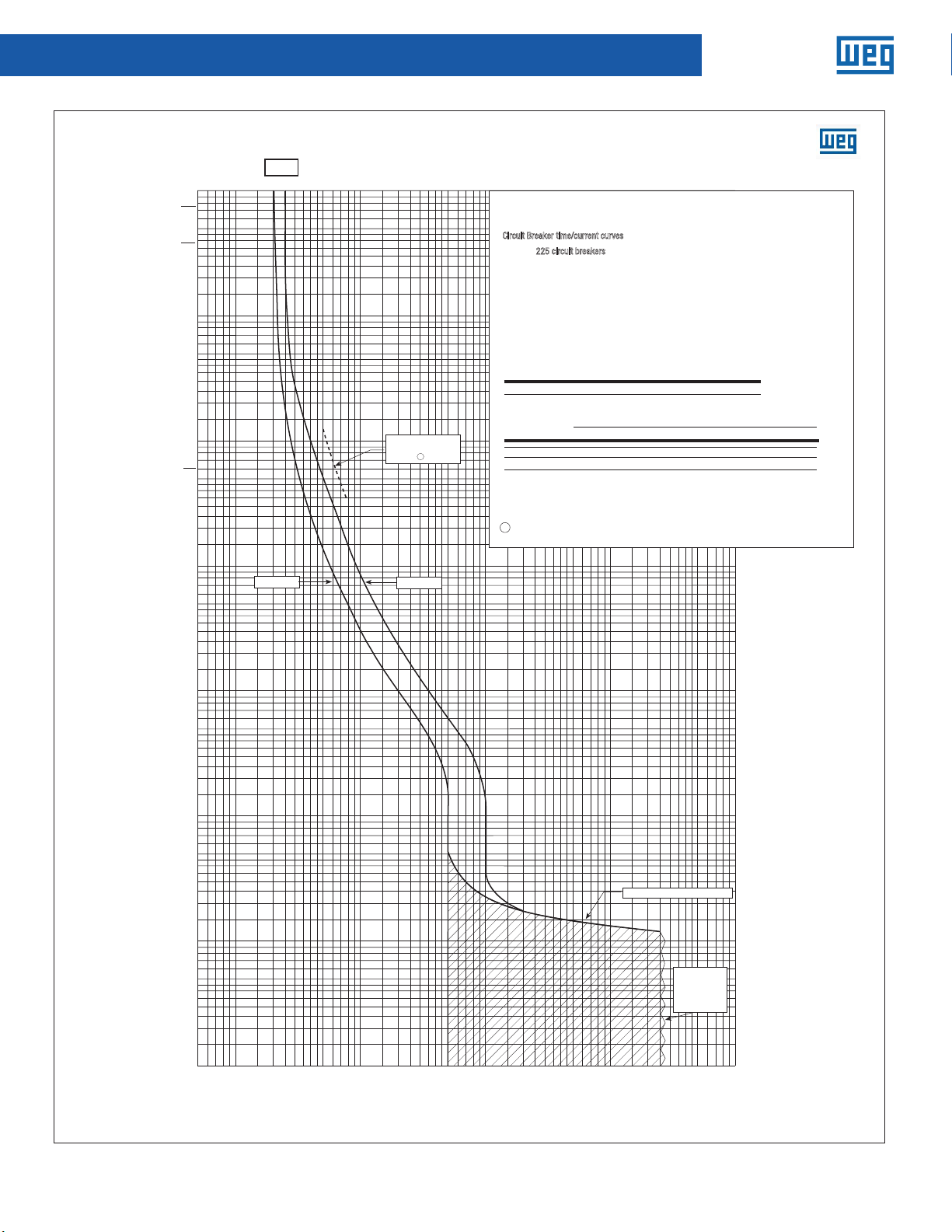

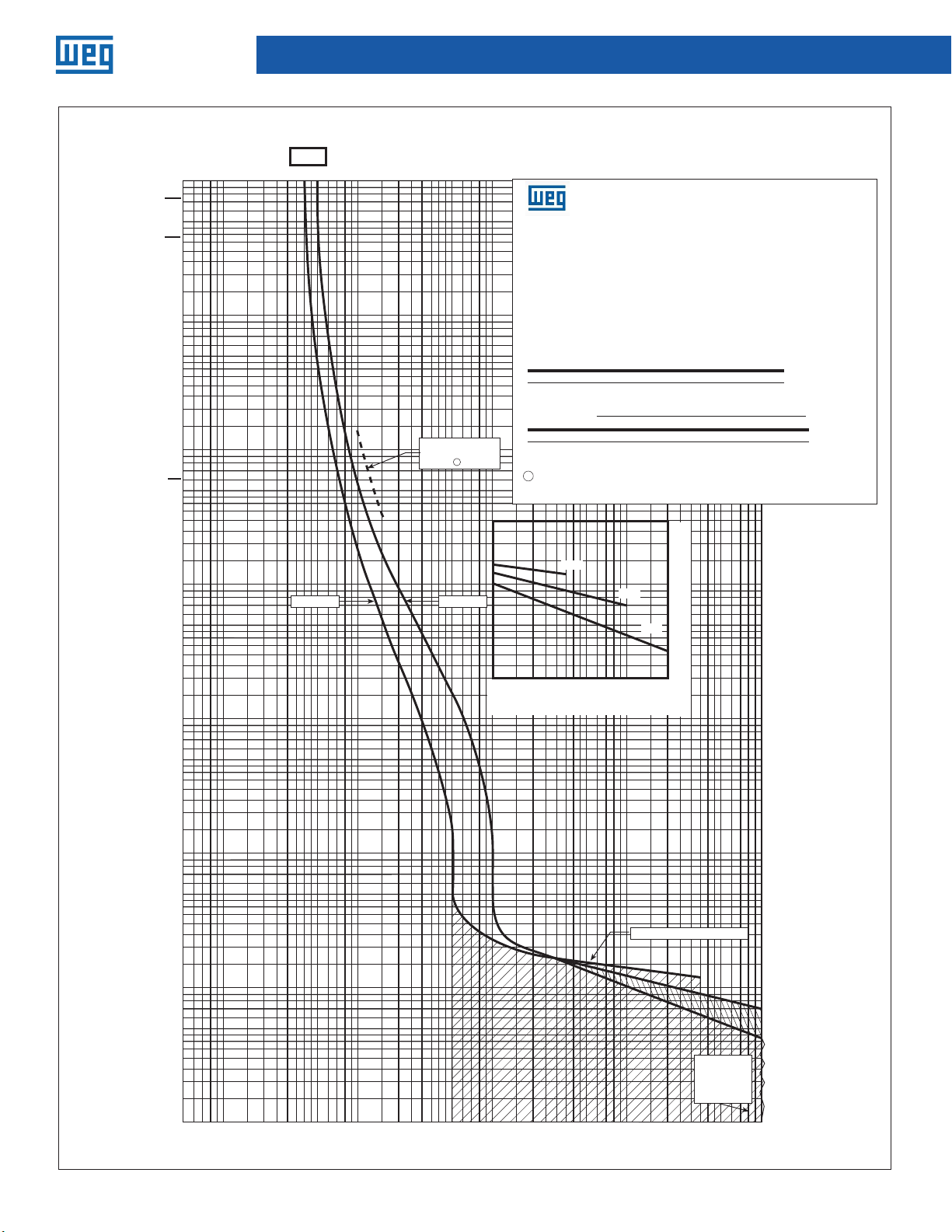

UBW Time Current Curves

225 L

Effective September 2015

CURRENT IN AMPERES

CURRENT IN AMPERES

10,000

2 HOURS

5,000

1 HOUR

3,000

2,000

1,000

1 MINUTE

15A

8060 9070504030201 0 9 8 75 6

100

400

300

200

500

300

200

1000

800

600

900

700

500

Circuit breaker time/current curves

Series C® F-frame circuit breakers

Series C F-frame circuit breakers

Catalog type FDC circuit breaker, two-, three- and four-poles.

For application and coordination purposes only.

For application and coordination purposes only. Based on 40°C ambient, cold start.

Based on 40˚C ambient, cold start. Connected with four (4) feet of

rated wire (60˚C up to 125A, 75˚C above 125A) per terminal.

Connected with four (4) feet of rated wire (60°C up to 125A, 75°C above 125A) per

Tested in open air with current in all poles.

terminal. Tested in open air.

Maximum Vac: 600 at 50/60 Hz

Maximum Vac: 600 at 50/60 Hz

Maximum Vdc: 250

Maximum Vdc: 250

Breaker rating

Continuous amperes Instantaneous trip amperes

Breaker rating

15A See curve

Continuous amperes Instantaneous trip, amperes

Interrupting rating (UL/CSA listed)

Breaker

Symmetrical Rms amperes (KA) Amps (KA)

15A See curve

type

@ 240 Vac @ 480 Vac @ 600 Vac 250 Vdc

200FDC 100 35 22

Interrupting Rating (UL/CSA Listed)

1

Single-pole test data at 25˚C based on NEMA procedures

(AB

circuit breakers.

Breaker Type

L

Symmetrical RMS amperes (kA) Amps (KA)

4-2003) for verifying performance of molded case

@240Vac @480Vac @600Vac 250Vdc

200 100 35 22

2 HOURS

1 HOUR

5,000

3,000

2,000

1,000

500

300

200

Notes:

100

50

30

20

Maximum singlepole trip times

1

at 25°C

1 Single-pole test data at 25°C based on NEMA procedures (AB 4-2003) for verifying

performance of molded case circuit breakers.

.02

100

1 MINUTE

50

30

20

600V

10

Minimum

5

3

2

1

Maximum

30,000

20,000

10,000

480V

80,000

60,000

70,000

50,000

40,000

.01

.005

240V

.003

.002

90,000

100,000

200,000

10

5

3

TIME IN SECOND S

2

1

.5

.3

.2

.1

.05

.03

.02

.01

.005

.003

.002

.001

.005

.003

.002

.001

.5

TIME IN SECOND S

.3

.2

.1

.05

.03

.02

.01

60

40

20

56

987

10

30

80

7050

90

200

100

500

700

800

600

400

300

900

2000

1000

5000

4000

3000

Maximum interrupting time

7000

8000

6000

9000

10000

Interrupting

rating

determines

end of curve

(see above)

Data subject to change without notice. UBW Technical Manual | 7

Page 8

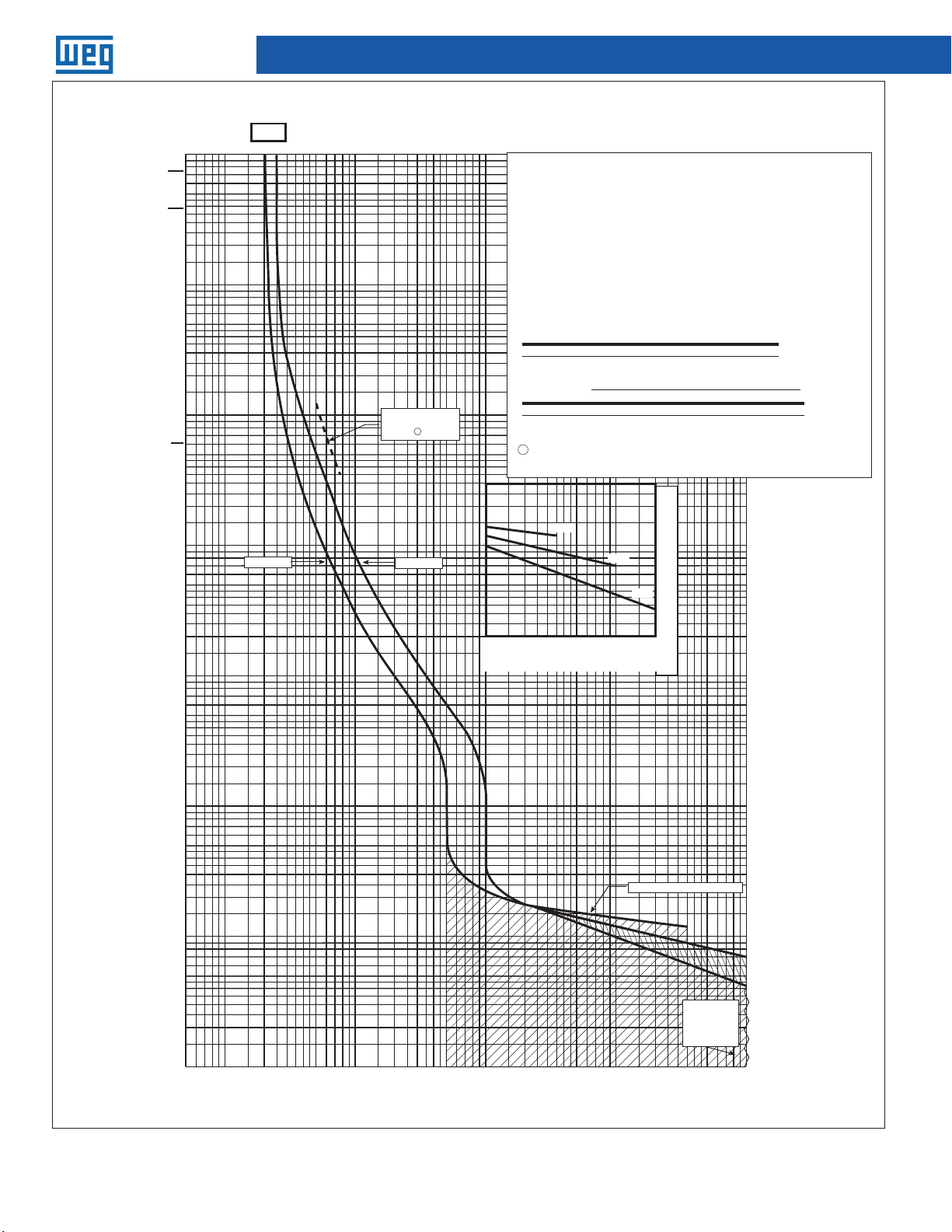

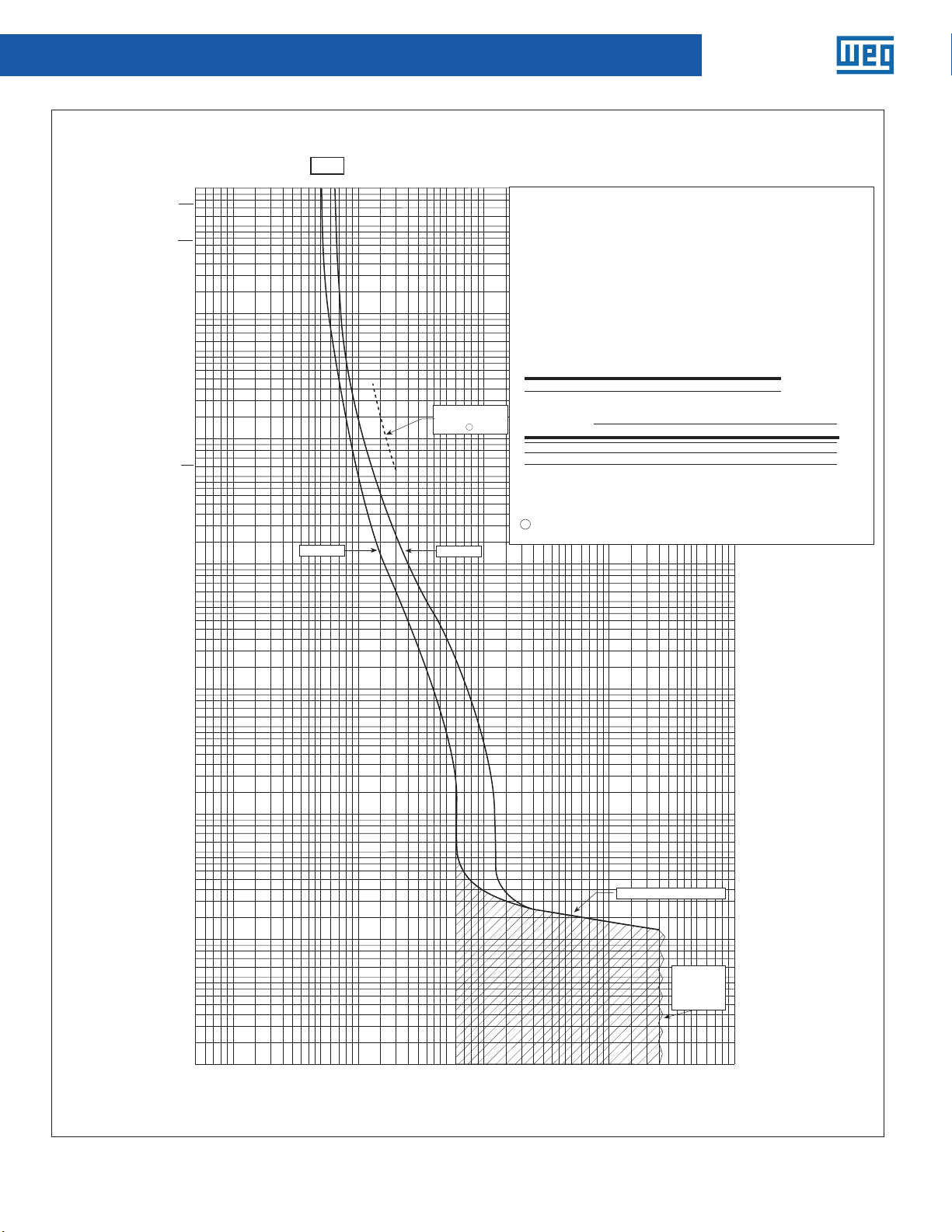

Molded-Case Circuit Breakers

Proof 1 — October 20, 2015 10:24 PM

UBW Time Current Curves

225N/H

10,000

2 HOURS

5,000

1 HOUR

3,000

2,000

1,000

500

300

200

100

50

1 MINUTE

30

20

20A

CURRENT IN AMPERES

8060 9070504030201 0 9 8 75 6

100

Maximum singlepole trip times

at 25°C

1000

800

600

900

700

500

400

300

200

Circuit Breaker time/current curves

Series

For application and coordination purposes only. Based on 40°C ambient, cold start.

Connected with four (4) feet of rated wire (60°C up to 125A, 75°C above 125A) per

terminal. Tested in open air.

Maximum Vac: 600 at 50/60 Hz

Maximum Vdc: 250

Breaker rating

Continuous amperes Instantaneous trip, amperes

20A See curve

Interrupting Rating (UL/CSA Listed)

Breaker Type

1

N

H

Notes:

1 Single-pole test data at 25°C based on NEMA procedures (AB 4-2003) for verifying

performance of molded case circuit breakers.

4000

3000

2000

Series C® F-frame circuit breakers

Catalog types ED, EHD, FDB, FD and HFD circuit breakers, two-, three-

2

25 circuit breakers

Based on 40˚C ambient, cold start. Connected with four (4) feet of

Tested

Maximum Vac: 600 at 50/60 Hz

Maximum Vdc: 250

Breaker rating

Continuous amperes Instantaneous trip amperes

20A See curve

Interrupting rating (UL/CSA listed)

Breaker

Symmetrical Rms amperes (KA) Amps (KA)

@ 240 Vac @ 480 Vac @ 600 Vac 250 Vdc

type

18

EHD

18

FDB

65

FD

100

HFD

ED

65 —

1

Single-pole test data at 25˚C based on NEMA procedures

(AB

4-2003

circuit breakers.

10000

8000

6000

9000

7000

5000

time/current curves

5,000

3,000

2,000

1,000

500

125 Vdc

14

—

14

14

35

18

65

25

) for verifying performance of molded case

Symmetrical RMS amperes (kA)

@240Vac @480Vac @600Vac 250Vac

65 35 18 10

100 65 25 22

—

—

10

10

—

300

—

10

—

22

10

—

200

100

50

30

20

2 HOURS

1 HOUR

10

5

3

2

1

.5

TIME IN SECONDS

.3

.2

.1

.05

.03

.02

.01

.005

.003

.002

Minimum

Maximum

Maximum interrupting time

Interrupting

rating

determines

end of curve

(see above)

10

5

3

TIME IN SECONDS

2

1

.5

.3

.2

.1

.05

.03

.02

.01

.005

.003

.002

.001

56

20

987

10

60

40

80

7050

30

90

200

100

500

700

800

600

900

400

300

CURRENT IN AMPERES

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

.001

8 Data subject to change without notice.

Page 9

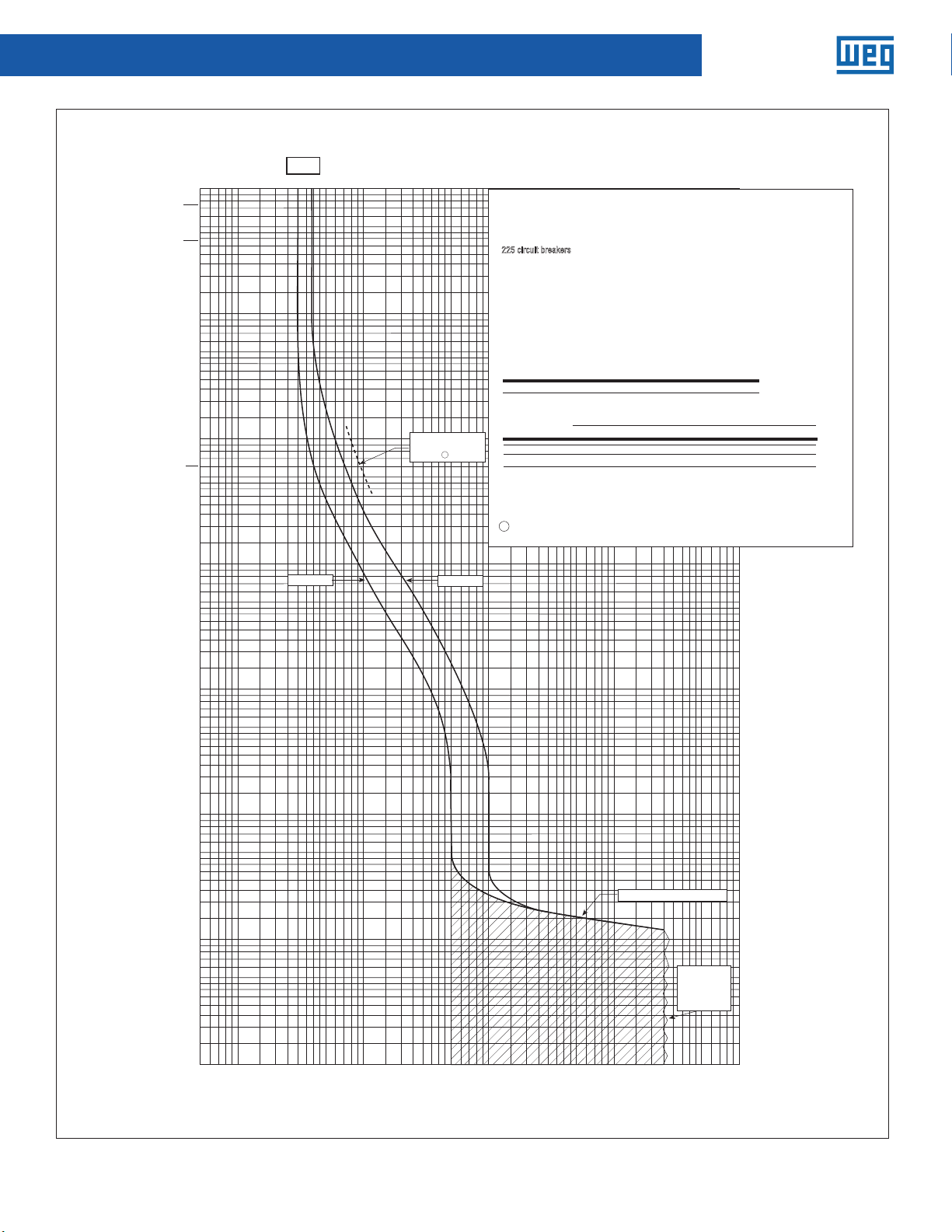

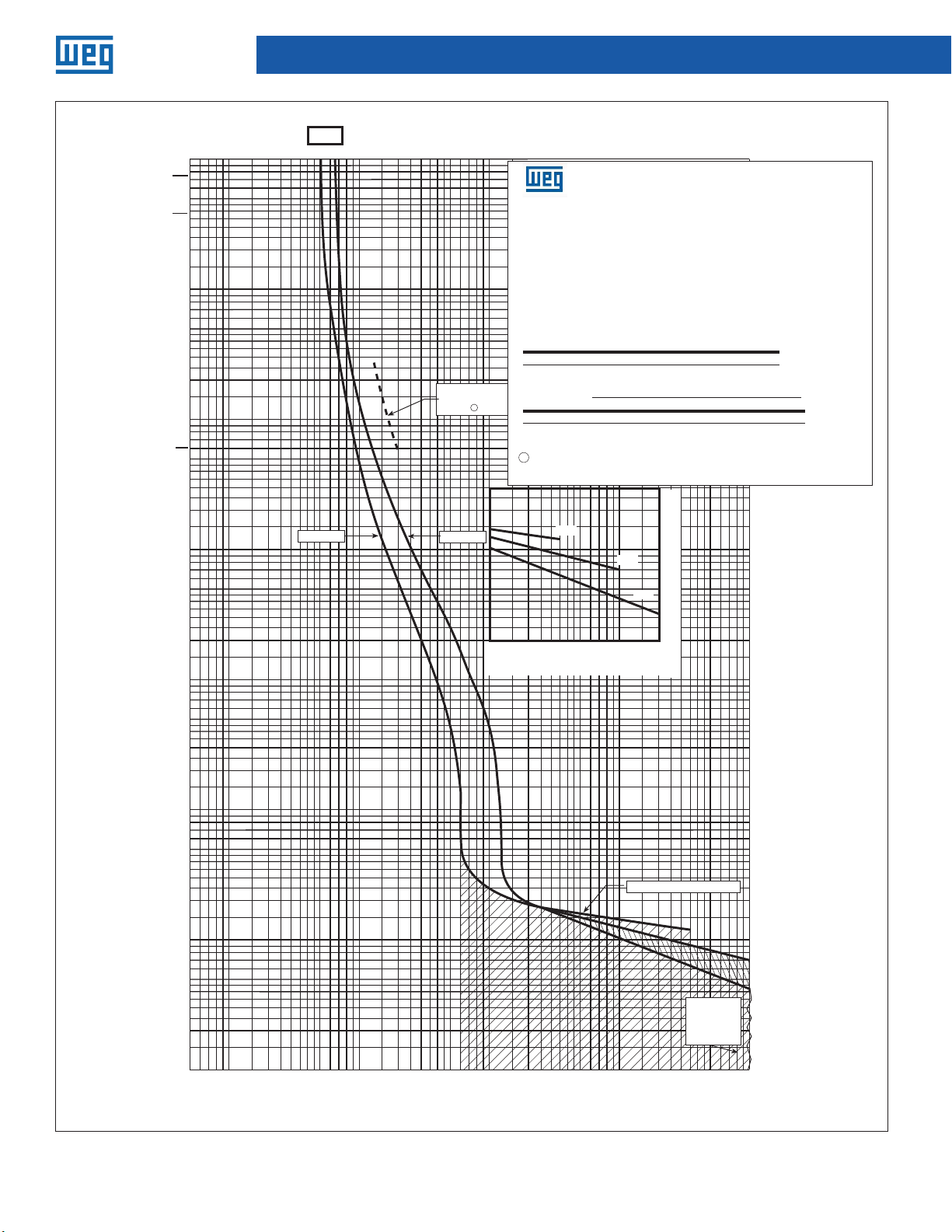

UBW Time Current Curves

225 L

Series C

F-Frame

CURRENT IN AMPERES

10,000

CURRENT IN AMPERES

Proof 1 — October 20, 2015 10:24 PM

2 HOURS

5,000

1 HOUR

3,000

2,000

1,000

500

300

200

100

50

1 MINUTE

30

20

10

5

3

2

1

20A

Minimum

8060 9070504030201 0 9 8 75 6

100

Maximum singlepole trip times

at 25°C

300

200

1

Maximum

Molded-Case Circuit Breakers

10000

8000

6000

9000

7000

5000

4000

3000

2000

1000

800

600

900

700

500

400

time/current curves

Series C F-frame circuit breakers

Catalog type FDC circuit breaker, two-, three- and four-poles.

Circuit breaker time/current curves

For application and coordination purposes only.

Series C F-frame circuit breakers

Based on 40˚C ambient, cold start. Connected with four (4) feet of

rated wire (60˚C up to 125A, 75˚C above 125A) per terminal.

For application and coordination purposes only. Based on 40°C ambient, cold start.

Maximum Vac: 600 at 50/60 Hz

Maximum Vdc: 250

Connected with four (4) feet of rated wire (60°C up to 125A, 75°C above 125A) per

terminal. Tested in open air.

Breaker rating

Continuous amperes Instantaneous trip amperes

Maximum Vac: 600 at 50/60 Hz

20A See curve

Maximum Vdc: 250

Interrupting rating (UL/CSA listed)

Breaker

Symmetrical Rms amperes (KA) Amps (KA)

Breaker rating

type

@ 240 Vac @ 480 Vac @ 600 Vac 250 Vdc

200FDC 100 35 22

Continuous amperes Instantaneous trip, amperes

1

Single-pole test data at 25˚C based on NEMA procedures

20A See curve

4-2003) for verifying performance of molded case

(AB

circuit breakers.

Interrupting Rating (UL/CSA Listed)

Breaker Type

L

Symmetrical RMS amperes (kA) Amps (KA)

@240Vac @480Vac @600Vac 250Vdc

200 100 35 22

Notes:

1 Single-pole test data at 25°C based on NEMA procedures (AB 4-2003) for verifying

performance of molded case circuit breakers.

.02

600V

480V

80,000

60,000

70,000

50,000

40,000

30,000

20,000

10,000

.01

.005

240V

.003

.002

90,000

100,000

200,000

2 HOURS

1 HOUR

5,000

3,000

2,000

1,000

500

300

200

100

1 MINUTE

50

30

20

10

5

3

TIME IN SECOND S

2

1

.005

.003

.002

.001

.5

TIME IN SECOND S

.3

.2

.1

.05

.03

.02

.01

60

40

20

56

987

10

30

80

7050

90

200

100

500

700

800

600

900

400

300

1000

2000

3000

4000

5000

Maximum interrupting time

7000

8000

6000

9000

10000

Interrupting

rating

determines

end of curve

(see above)

.5

.3

.2

.1

.05

.03

.02

.01

.005

.003

.002

.001

Data subject to change without notice. UBW Technical Manual | 9

Page 10

Molded-Case Circuit Breakers

Time Current Curves

225 N., H.

30A

10,000

2 HOURS

5,000

1 HOUR

3,000

2,000

1,000

500

300

200

100

50

1 MINUTE

30

20

CURRENT IN AMPERES

8060 9070504030201 0 9 8 75 6

100

400

300

200

1000

800

600

900

700

500

2000

3000

4000

Circuit breaker time/current curves

Series C® F-frame circuit breakers

Catalog types ED, EHD, FDB, FD and HFD circuit breakers, two-, three-

and four-poles.

Circuit breaker time/current curves

For application and coordination purposes only.

225 circuit breakers

Based on 40˚C ambient, cold start. Connected with four (4) feet of

Tested in open air with current in all poles.

For application and coordination purposes only. Based on 40°C ambient, cold start.

Maximum Vac: 600 at 50/60 Hz

Connected with four (4) feet of rated wire (60°C up to 125A, 75°C above 125A) per

Maximum Vdc: 250

terminal. Tested in open air.

Breaker Rating

Continuous amperes Instantaneous trip amperes

Maximum Vac: 600 at 50/60 Hz

30A See curve

Maximum Vdc: 250

Interrupting rating (UL/CSA listed)

Symmetrical RMS amperes (KA) Amps (KA)

Breaker

@ 240 Vac @ 480 Vac @ 600 Vac 250 Vdc 125 Vdc

type

18

EHD

18

FDB

65

FD

100

HFD

65 —

ED

1

Single-pole test data at 25˚C based on NEMA procedures

4-2003

) for verifying performance of molded case

(AB

circuit breakers.

Maximum singlepole trip times

1

at 25°C

Breaker rating

Continuous amperes Instantaneous trip, amperes

30A See curve

Interrupting Rating (UL/CSA Listed)

Breaker Type

N

H

10000

8000

6000

9000

7000

5000

5,000

125A, 75˚C above 125A) per terminal.

14

—

14

35

65

Symmetrical RMS amperes (kA)

@240Vac @480Vac @600Vac 250Vac

65 35 18 10

100 65 25 22

10

14

10

18

10

25

22

—

—

3,000

2,000

1,000

500

—

—

—

300

—

10

200

100

50

2 HOURS

1 HOUR

1 MINUTE

Notes:

1 Single-pole test data at 25°C based on NEMA procedures (AB 4-2003) for verifying

performance of molded case circuit breakers.

30

20

10

5

3

2

1

.5

TIME IN SECONDS

.3

.2

.1

.05

.03

.02

.01

.005

.003

.002

Minimum

Maximum

Maximum interrupting time

Interrupting

rating

determines

end of curve

(see above)

10

5

3

TIME IN SECONDS

2

1

.5

.3

.2

.1

.05

.03

.02

.01

.005

.003

.002

.001

56

20

987

10

60

40

80

30

7050

90

200

100

500

700

800

600

900

400

300

CURRENT IN AMPERES

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

.001

10 Data subject to change without notice.

Page 11

UBW Time Current Curves

225 L

Series C

F-Frame

CURRENT IN AMPERES

10,000

CURRENT IN AMPERES

Proof 1 — October 20, 2015 10:24 PM

2 HOURS

5,000

1 HOUR

3,000

2,000

1,000

500

300

200

100

50

1 MINUTE

30

20

10

5

3

2

1

30A

Minimum

Molded-Case Circuit Breakers

8060 9070504030201 0 9 8 75 6

100

400

300

200

1000

800

600

900

700

500

4000

3000

2000

10000

8000

6000

9000

7000

5000

time/current curves

Series C F-frame circuit breakers

Catalog type FDC circuit breaker, two-, three- and four-poles.

Circuit breaker time/current curves

For application and coordination purposes only.

Series C F-frame circuit breakers

Based on 40˚C ambient, cold start. Connected with four (4) feet of

rated wire (60˚C up to 125A, 75˚C above 125A) per terminal.

For application and coordination purposes only. Based on 40°C ambient, cold start.

Maximum Vac: 600 at 50/60 Hz

Connected with four (4) feet of rated wire (60°C up to 125A, 75°C above 125A) per

Maximum Vdc: 250

terminal. Tested in open air.

Breaker rating

Continuous amperes Instantaneous trip amperes

Maximum Vac: 600 at 50/60 Hz

30A See curve

Maximum Vdc: 250

Interrupting rating (UL/CSA listed)

Breaker

Symmetrical Rms amperes (KA) Amps (KA )

Breaker rating

@ 240 Vac @ 480 Vac @ 600 Vac 250 Vdc

type

200FDC 100 35 22

Continuous amperes Instantaneous trip, amperes

1

Single-pole test data at 25˚C based on NEMA procedures

30A See curve

(AB

4-2003) for verifying performance of molded case

circuit breakers.

Maximum singlepole trip times

1

at 25°C

Interrupting Rating (UL/CSA Listed)

Breaker Type

L

Notes:

1 Single-pole test data at 25°C based on NEMA procedures (AB 4-2003) for verifying

performance of molded case circuit breakers.

Symmetrical RMS amperes (kA) Amps (KA)

@240Vac @480Vac @600Vac 250Vdc

200 100 35 22

.02

600V

.01

.005

240V

.003

.002

90,000

100,000

200,000

Maximum

480V

80,000

60,000

70,000

50,000

40,000

30,000

20,000

10,000

2 HOURS

1 HOUR

5,000

3,000

2,000

1,000

500

300

200

100

1 MINUTE

50

30

20

10

5

3

TIME IN SECOND S

2

1

.005

.003

.002

.001

.5

TIME IN SECOND S

.3

.2

.1

.05

.03

.02

.01

60

40

20

56

987

10

30

80

7050

90

200

100

500

700

800

600

900

400

300

1000

4000

3000

2000

Maximum interrupting time

7000

8000

6000

9000

5000

10000

Interrupting

rating

determines

end of curve

(see above)

.5

.3

.2

.1

.05

.03

.02

.01

.005

.003

.002

.001

Data subject to change without notice. UBW Technical Manual | 11

Page 12

Molded-Case Circuit Breakers

Time Current Curves

225 N/H

10,000

2 HOURS

5,000

1 HOUR

3,000

2,000

1,000

500

300

200

100

50

1 MINUTE

30

20

10

5

40A

8060 9070504030201 0 9 8 75 6

100

CURRENT IN AMPERES

600

500

400

300

200

Maximum singlepole trip times

1

at 25°C

Minimum Maximum

10000

8000

6000

9000

7000

5000

4000

3000

2000

1000

800

900

700

Circuit breaker time/current curves

Catalog types ED, EHD, FDB, FD and HFD circuit breakers, two-, three -

and four-poles.

Circuit breaker time/current curves

For application and coordination purposes only.

Series C F-frame circuit breakers

Based on 40˚C ambient, cold start. Connected with four (4) feet of

rated wire (60˚C up to 125A, 75˚C above 125A) per terminal.

Catalog Types: ED, HED FDB, FD and HFD circuit breakers, two-, three- and four-pole.

Tested in open air with current in all poles.

For application and coordination purposes only. Based on 40°C ambient, cold start.

Maximum Vac: 600 at 50/60 Hz

Connected with four (4) feet of rated wire (60°C up to 125A, 75°C above 125A) per

Maximum Vdc: 250

terminal. Tested in open air.

Breaker Rating

Continuous amperes Instantaneous trip amperes

Maximum Vac: 600 at 50/60 Hz

40A See curve

Maximum Vdc: 250

Interrupting rating (UL/CSA listed)

Symmetrical Rms amperes (KA) Amps (KA)

Breaker

Breaker rating

Continuous amperes Instantaneous trip, amperes

40A See curve

Interrupting Rating (UL/CSA Listed)

Breaker Type

N

H

@ 240 Vac @ 480 Vac @ 600 Vac 250 Vdc 125 Vdc

type

18

EHD

FDB

FD

HFD

ED

1

Single-pole test data at 25˚C based on NEMA procedures

4-2003

(AB

circuit breakers.

14

18

14

65

35

100

65

—

) for verifying performance of molded case

Symmetrical RMS amperes (kA)

@240Vac @480Vac @600Vac 250Vac

65 35 18 10

100 65 25 22

10

—

14

10

18

10

25

22

—

—

Notes:

1 Single-pole test data at 25°C based on NEMA procedures (AB 4-2003) for verifying

performance of molded case circuit breakers.

5,000

3,000

2,000

1,000

500

—

—

300

—

—

0156

200

100

50

30

20

10

5

2 HOURS

1 HOUR

1 MINUTE

3

2

1

.5

TIME IN SECONDS

.3

.2

.1

.05

.03

.02

.01

.005

.003

.002

.001

56

3

TIME IN SECONDS

2

1

.5

.3

.2

.1

.05

Maximum interrupting time

Interrupting

rating

determines

end of curve

(see above)

60

40

20

987

10

30

80

7050

90

200

100

500

700

800

600

900

400

300

CURRENT IN AMPERES

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

.03

.02

.01

.005

.003

.002

.001

12 Data subject to change without notice.

Page 13

Molded-Case Circuit Breakers

UBW Time Current Curves

225 L

CURRENT IN AMPERES

10,000

2 HOURS

5,000

1 HOUR

3,000

2,000

1,000

1 MINUTE

40A

100

8060 9070504030201 0 9 8 75 6

500

300

200

100

50

30

20

CURRENT IN AMPERES

600

500

400

300

200

Maximum singlepole trip times

1

at 25°C

700

time/current curves

Series C F-frame circuit breakers

Catalog type FDC circuit breaker, two-, three- and four-poles.

Circuit breaker time/current curves

225 circuit breaker

For application and coordination purposes only. Based on 40°C ambient, cold start.

Maximum Vac: 600 at 50/60 Hz

Connected with four (4) feet of rated wire (60°C up to 125A, 75°C above 125A) per

Maximum Vdc: 250

terminal. Tested in open air.

Breaker rating

Continuous amperes Instantaneous trip amperes

Maximum Vac: 600 at 50/60 Hz

40A See curve

Maximum Vdc: 250

Interrupting rating (UL/CSA listed)

Breaker

Breaker rating

type

Continuous amperes Instantaneous trip, amperes

1

Single-pole test data at 25˚C based on NEMA procedures

40A See curve

(AB

4-2003) for verifying performance of molded case

circuit breakers.

Interrupting Rating (UL/CSA Listed)

Breaker Type

L

cold start. Connected with four (4) feet of

75˚C above 125A) per terminal.

Symmetrical Rms amperes (KA) Amps (KA)

@ 240 Vac @ 480 Vac @ 600 Vac 250 Vdc

200FDC 100 35 22

Symmetrical RMS amperes (kA) Amps (KA)

@240Vac @480Vac @600Vac 250Vdc

200 100 35 22

Notes:

1 Single-pole test data at 25°C based on NEMA procedures (AB 4-2003) for verifying

performance of molded case circuit breakers.

.02

5,000

3,000

2,000

1,000

500

300

200

100

50

30

20

2 HOURS

1 HOUR

1 MINUTE

10000

8000

6000

9000

7000

5000

4000

3000

2000

1000

800

900

600V

10

Minimum Maximum

5

480V

240V

.01

.005

10

5

.005

.003

.002

.001

3

2

80,000

60,000

70,000

50,000

40,000

30,000

20,000

10,000

1

.5

TIME IN SECO NDS

.3

.2

.1

.05

.03

.02

.01

60

40

20

56

987

10

30

80

7050

90

200

100

500

700

800

600

400

300

900

1000

3000

2000

7000

8000

6000

5000

4000

.003

.002

90,000

100,000

200,000

Maximum interrupting time

Interrupting

rating

determines

end of curve

(see above)

9000

10000

3

2

1

.5

.3

.2

.1

.05

.03

.02

.01

.005

.003

.002

.001

TIME IN SECO NDS

Data subject to change without notice. UBW Technical Manual | 13

Page 14

Molded-Case Circuit Breakers

Time Current Curves

225 N., H.

10,000

2 HOURS

5,000

1 HOUR

3,000

2,000

1,000

500

300

200

100

50

1 MINUTE

30

20

10

5

50A

Minimum

CURRENT IN AMPERES

8060 9070504030201 0 9 8 75 6

100

200

400

300

Maximum singlepole trip times

at 25°C

1000

800

600

900

700

500

1

4000

3000

2000

Catalog types ED, EHD, FDB, FD and HFD circuit breakers, two-, three-

and four-poles.

Circuit breaker time/current curves

225 Circuit breaker

Based on 40˚C ambient, cold start. Connected with four (4) feet of

Tested in open air with current in all poles.

For application and coordination purposes only. Based on 40°C ambient, cold start.

Maximum Vac: 600 at 50/60 Hz

Connected with four (4) feet of rated wire (60°C up to 125A, 75°C above 125A) per

Maximum Vdc: 250

terminal. Tested in open air.

Breaker rating

Continuous amperes Instantaneous trip amperes

Maximum Vac: 600 at 50/60 Hz

50A See curve

Maximum Vdc: 250

Interrupting rating (UL/CSA listed)

Symmetrical Rms amperes (KA) Amps (KA)Breaker

Breaker rating

type @ 240 Vac @ 480 Vac @ 600 Vac 250 Vdc 125 Vdc

18

EHD

Continuous amperes Instantaneous trip, amperes

18

FDB

65

FD

50A See curve

100

HFD

ED

65

1

Single-pole test data at 25˚C based on NEMA procedures

Interrupting Rating (UL/CSA Listed)

4-2003

(AB

circuit breakers.

Breaker Type

FD

H

10000

8000

6000

9000

7000

5000

time/current curves

circuit breakers

14

--

10

14

14

35

18

65

25

—

) for verifying performance of molded case

—

Symmetrical RMS amperes (kA)

@240Vac @480Vac @600Vac 250Vac

65 35 18 10

100 65 25 22

—

10

—

—

10

—

22

10

—

5,000

3,000

2,000

1,000

500

300

200

100

50

2 HOURS

1 HOUR

1 MINUTE

Notes:

Maximum

1 Single-pole test data at 25°C based on NEMA procedures (AB 4-2003) for verifying

performance of molded case circuit breakers.

20

10

5

3

2

1

.5

TIME IN SECONDS

.3

.2

.1

.05

.03

.02

.01

.005

.003

.002

.001

56

3

TIME IN SECONDS

2

1

.5

.3

.2

.1

.05

Maximum interrupting time

Interrupting

rating

determines

end of curve

(see above)

60

40

20

987

10

30

80

7050

90

200

100

500

700

800

600

900

400

300

CURRENT IN AMPERES

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

.03

.02

.01

.005

.003

.002

.001

14 Data subject to change without notice.

Page 15

UBW Time Current Curves

225L

Series C

F-Frame

CURRENT IN AMPERES

Proof 1 — October 20, 2015 10:24 PM

10,000

2 HOURS

5,000

1 HOUR

3,000

2,000

1,000

500

300

200

100

50

1 MINUTE

30

20

10

50A

Minimum

8060 9070504030201 0 9 8 75 6

100

CURRENT IN AMPERES

600

500

400

300

200

Maximum singlepole trip times

at 25°C

Maximum

3000

2000

1000

800

900

700

Circuit breaker time/current curves

Catalog type FDC circuit breaker, two-, three- and four-poles.

Circuit breaker time/current curves

For application and coordination purposes only.

225 circuit breakers

rated wire (60˚C up to 125A, 75˚C above 125A) per terminal.

Maximum Vac: 600 at 50/60 Hz

For application and coordination purposes only. Based on 40°C ambient, cold start.

Maximum Vdc: 250

Connected with four (4) feet of rated wire (60°C up to 125A, 75°C above 125A) per

terminal. Tested in open air.

Breaker rating

Continuous amperes Instantaneous trip amperes

50A See curve

Maximum Vac: 600 at 50/60 Hz

Maximum Vdc: 250

Interrupting rating (UL/CSA listed)

Breaker

type

Breaker rating

Continuous amperes Instantaneous trip, amperes

1

Single-pole test data at 25˚C based on NEMA procedures

4-2003) for verifying performance of molded case

(AB

50A See curve

circuit breakers.

Interrupting Rating (UL/CSA Listed)

1

Breaker Type

L

Notes:

1 Single-pole test data at 25°C based on NEMA procedures (AB 4-2003) for verifying

performance of molded case circuit breakers.

Molded-Case Circuit Breakers

10000

8000

6000

9000

7000

5000

4000

circuit breakers

cold start. Connected with four (4) feet of

Symmetrical Rms amperes (KA) Amps (KA)

@ 240 Vac @ 480 Vac @ 600 Vac 250 Vdc

200FDC 100 35 22

Symmetrical RMS amperes (kA) Amps (KA)

@240Vac @480Vac @600Vac 250Vdc

200 100 35 22

.02

600V

.01

480V

2 HOURS

1 HOUR

5,000

3,000

2,000

1,000

500

300

200

100

1 MINUTE

50

30

20

10

.005

.003

.002

5

3

2

80,000

60,000

70,000

50,000

40,000

30,000

20,000

10,000

1

.5

TIME IN SECOND S

.3

.2

.1

.05

.03

.02

.01

.005

240V

.003

.002

90,000

100,000

200,000

Maximum interrupting time

Interrupting

rating

determines

end of curve

(see above)

5

3

1

.5

.3

.2

.1

.05

.03

.02

.01

.005

.003

.002

TIME IN SECOND S

2

.001

56

987

10

30

80

7050

90

200

100

500

700

800

600

400

300

900

1000

3000

2000

7000

8000

6000

9000

5000

4000

10000

60

40

20

.001

Data subject to change without notice. UBW Technical Manual | 15

Page 16

Molded-Case Circuit Breakers

Time Current Curves

225 N., H.

10,000

2 HOURS

5,000

1 HOUR

3,000

2,000

1,000

500

300

200

100

50

1 MINUTE

30

20

10

5

60A

Minimum

CURRENT IN AMPERES

8060 9070504030201 0 9 8 75 6

100

400

300

200

1000

800

600

900

700

500

2000

3000

4000

Circuit beake

Catalog types ED, EHD, FDB, FD and HFD circuit breakers, two-, three-

and four-poles.

Circuit breaker time/current curves

225 circuit breakers

Based on 40˚C ambient, cold start. Connected with four (4) feet of

oen air with current in all

For application and coordination purposes only. Based on 40°C ambient, cold start.

Maximum Vac: 600 at 50/60 Hz

Connected with four (4) feet of rated wire (60°C up to 125A, 75°C above 125A) per

Maximum Vdc: 250

terminal. Tested in open air.

Breaker rating

Continuous amperes Instantaneous trip amperes

Maximum Vac: 600 at 50/60 Hz

60A See curve

Maximum Vdc: 250

Interrupting rating (UL/CSA listed)

Breaker

Symmetrical Rms amperes (KA) Amps (KA)

Breaker rating

@ 240 Vac @ 480 Vac @ 600 Vac 250 Vdc 125 Vdc

type

18

EHD

Continuous amperes Instantaneous trip, amperes

18

FDB

65

FD

100

HFD

60A See curve

65

ED

1

Single-pole test data at 25˚C based on NEMA procedures

Interrupting Rating (UL/CSA Listed)

4-2003

Maximum singlepole trip times

1

at 25°C

(AB

circuit breakers.

Breaker Type

N

H

Notes:

1 Single-pole test data at 25°C based on NEMA procedures (AB 4-2003) for verifying

performance of molded case circuit breakers.

Maximum

10000

8000

6000

9000

7000

5000

time/current curves

125A, 75˚C above 125A) per terminal.

poles.

14

—

10

14

14

35

18

65

25

—

—

) for verifying performance of molded case

Symmetrical RMS amperes (kA)

@240Vac @480Vac @600Vac 250Vac

65 35 18 10

100 65 25 22

—

10

—

—

10

—

22

—

10

5,000

3,000

2,000

1,000

500

300

200

100

50

30

20

10

5

2 HOURS

1 HOUR

1 MINUTE

3

2

1

.5

TIME IN SECONDS

.3

.2

.1

.05

.03

.02

.01

.005

.003

.002

.001

56

3

TIME IN SECONDS

2

1

.5

.3

.2

.1

.05

Maximum interrupting time

Interrupting

rating

determines

end of curve

(see above)

60

40

20

987

10

30

80

7050

90

200

100

500

700

800

600

900

400

300

CURRENT IN AMPERES

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

.03

.02

.01

.005

.003

.002

.001

16 Data subject to change without notice.

Page 17

Effective September 2015

Series C

F-Frame

CURRENT IN AMPERES

CURRENT IN AMPERES

Proof 1 — October 20, 2015 10:24 PMProof 1 — October 20, 2015 10:24 PM

UBW Time Current Curves

225L

10,000

2 HOURS

5,000

1 HOUR

3,000

2,000

1,000

500

300

200

100

50

1 MINUTE

30

20

10

60A

1000

800

600

900

700

500

400

300

200

100

8060 9070504030201 0 9 8 75 6

Maximum single-

pole trip times

1

at 25°C

Minimum

Maximum

Molded-Case Circuit Breakers

10000

8000

6000

9000

7000

5000

4000

3000

2000

Circuit breaker time/current curves

Series C®F-frame circuit breakers

Catalog type FDC circuit breaker, two-, three- and four-poles.

Circuit breaker time/current curves

For application and coordination purposes only.

UBW 225L circuit breakers

rated wire (60˚C up to 125A, 75˚C above 125A) per terminal.

For application and coordination purposes only. Based on 40°C ambient, cold start.

Maximum Vac: 600 at 50/60 Hz

Maximum Vdc: 250

Connected with four (4) feet of rated wire (60°C up to 125A, 75°C above 125A) per

terminal. Tested in open air.

Breaker rating

Continuous amperes Instantaneous trip amperes

Maximum Vac: 600 at 50/60 Hz

60A See curve

Maximum Vdc: 250

Interrupting rating (UL/CSA listed)

Breaker

Breaker rating

type

Continuous amperes Instantaneous trip, amperes

1

Single-pole test data at 25˚C based on NEMA procedures

60A See curve

(AB

4-2003) for verifying performance of molded case

circuit breakers.

Interrupting Rating (UL/CSA Listed)

Breaker Type

L

cold start. Connected with four (4) feet of

Symmetrical Rms amperes (KA) Amps (KA)

@ 240 Vac @ 480 Vac @ 600 Vac 250 Vdc

200FDC 100 35 22

Symmetrical RMS amperes (kA) Amps (KA)

@240Vac @480Vac @600Vac 250Vdc

200 100 35 22

Notes:

1 Single-pole test data at 25°C based on NEMA procedures (AB 4-2003) for verifying

performance of molded case circuit breakers.

600V

480V

5,000

3,000

2,000

1,000

500

300

200

100

50

30

.02

.01

20

10

2 HOURS

1 HOUR

1 MINUTE

.005

.003

.002

5

3

2

80,000

60,000

70,000

50,000

40,000

30,000

20,000

10,000

1

.5

TIME IN SECONDS

.3

.2

.1

.05

.03

.02

.01

.005

240V

.003

.002

90,000

200,000

100,000

Maximum interrupting time

Interrupting

rating

determines

end of curve

(see above)

5

3

2

1

.5

.3

.2

.1

.05

.03

.02

.01

.005

.003

.002

TIME IN SECONDS

.001

56

987

10

30

80

7050

90

200

100

500

700

800

600

400

300

900

2000

1000

7000

8000

6000

9000

5000

4000

3000

10000

60

40

20

.001

Data subject to change without notice. UBW Technical Manual | 17

Page 18

Molded-Case Circuit Breakers

Time Current Curves

225 N., H.

10,000

2 HOURS

5,000

1 HOUR

3,000

2,000

1,000

500

300

200

100

50

1 MINUTE

30

20

10

5

70A

8060 9070504030201 0 9 8 75 6

Minimum

CURRENT IN AMPERES

100

Circuit breaker time/current curves

Series

Catalog types ED, EHD, FDB, FD and HFD circuit breakers, two-, three-

and four-poles.

Circuit breaker time/current curves

225 circuit breakers

Based on 40˚C ambient, cold start. Connected with four (4) feet of

rated wire (60˚C

Tested in

For application and coordination purposes only. Based on 40°C ambient, cold start.

Maximum Vac: 600 at 50/60 Hz

Connected with four (4) feet of rated wire (60°C up to 125A, 75°C above 125A) per

Maximum Vdc: 250

terminal. Tested in open air.

Breaker rating

Continuous amperes Instantaneous trip amperes

Maximum Vac: 600 at 50/60 Hz

70A See curve

Maximum Vdc: 250

Interrupting rating (UL/CSA listed)

Symmetrical Rms amperes (KA) Amps (KA)Breaker

Breaker rating

Maximum singlepole trip times

1

at 25°C

type @ 240 Vac @ 480 Vac @ 600Vac 250 Vdc 125 Vdc

18

EHD

Continuous amperes Instantaneous trip, amperes

FDB

FD

70A See curve

HFD

ED 65

1

Single-pole test data at 25˚C based on NEMA procedures

Interrupting Rating (UL/CSA Listed)

(AB

circuit breakers.

Breaker Type

N

H

14

18

14

65

35

100

65

——

) for verifying performance of molded case

4-2003

Symmetrical RMS amperes (kA)

@240Vac @480Vac @600Vac 250Vac

65 35 18 10

100 65 25 22

10

—

14

18

25

—

10

—

—

10

—

22

10

Notes:

1 Single-pole test data at 25°C based on NEMA procedures (AB 4-2003) for verifying

performance of molded case circuit breakers.

5,000

3,000

2,000

1,000

500

300

200

100

50

30

20

2 HOURS

1 HOUR

1 MINUTE

10000

8000

6000

9000

7000

5000

4000

3000

2000

1000

800

600

900

700

500

400

300

200

Maximum

10

5

3

2

1

.5

TIME IN SECONDS

.3

.2

.1

.05

.03

.02

.01

.005

.003

.002

.001

56

3

TIME IN SECONDS

2

1

.5

.3

.2

.1

.05

Maximum interrupting time

Interrupting

rating

determines

end of curve

(see above)

60

40

20

987

10

30

80

7050

90

200

100

500

700

800

600

900

400

300

CURRENT IN AMPERES

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

.03

.02

.01

.005

.003

.002

.001

18 Data subject to change without notice.

Page 19

UBW Time Current Curves

225L

Series C

F-Frame

CURRENT IN AMPERES

Proof 1 — October 20, 2015 10:24 PM

Molded-Case Circuit Breakers

10,000

2 HOURS

5,000

1 HOUR

3,000

2,000

1,000

500

300

200

100

50

1 MINUTE

30

20

10

5

70A

8060 907050

100

200

500

400

300

Maximum singlepole trip times

at 25°C

100,000

80,000

60,000

90,000

70,000

50,000

40,000

30,000

1000

800

600

900

700

1

3000

2000

8000

6000

9000

7000

5000

4000

20,000

10000

Circuit breaker time/current curves

Catalog type FDC circuit breaker, two-, three- and four-poles.

Circuit breaker time/current curves

For application and coordination purposes only.

225 L

Maximum Vac: 600 at 50/60 Hz

For application and coordination purposes only. Based on 40°C ambient, cold start.

Maximum Vdc: 250

Connected with four (4) feet of rated wire (60°C up to 125A, 75°C above 125A) per

terminal. Tested in open air.

Breaker rating

Continuous amperes Instantaneous trip amperes

70A See curve

Maximum Vac: 600 at 50/60 Hz

Maximum Vdc: 250

Interrupting rating (UL/CSA listed)

Breaker

type

Breaker rating

Continuous amperes Instantaneous trip, amperes

1

Single-pole test data at 25˚C based on NEMA procedures

(AB

70A See curve

circuit breakers.

Interrupting Rating (UL/CSA Listed)

Breaker Type

L

circuit breakers

circuit breakers

125A,

Symmetrical Rms amperes (KA) Amps (KA)

@ 240 Vac @ 480 Vac @ 600 Vac 250 Vdc

200FDC 100 35 22

4-2003) for verifying performance of molded case

Symmetrical RMS amperes (kA) Amps (KA)

@240Vac @480Vac @600Vac 250Vdc

(4) feet of

200 100 35 22

Notes:

1 Single-pole test data at 25°C based on NEMA procedures (AB 4-2003) for verifying

performance of molded case circuit breakers.

2 HOURS

1 HOUR

5,000

3,000

2,000

1,000

500

300

200

100

1 MINUTE

50

30

20

10

5

.005

.003

.002

.001

3

Minimum

2

1

.5

TIME IN SECO NDS

.3

.2

.1

.05

.03

.02

Maximum

Maximum interrupting ti me

3

TIME IN SECO NDS

2

1

.5

.3

.2

.1

.05

.03

.02

600V

.01

480V

.01

.005

240V

.003

.002

60

80

7050

90

200

100

500

700

800

600

900

400

300

1000

3000

2000

CURRENT IN AMPERES

7000

8000

6000

9000

5000

4000

10000

30,000

20,000

80,000

60,000

90,000

70,000

50,000

40,000

100,000

200,000

.001

Data subject to change without notice. UBW Technical Manual | 19

Page 20

Molded-Case Circuit Breakers

Time Current Curves

225 N., H.

10,000

2 HOURS

5,000

1 HOUR

3,000

2,000

1,000

500

300

200

100

50

1 MINUTE

30

20

10

5

80A

8060 9070504030201 0 9 8 75 6

CURRENT IN AMPERES

10000

8000

6000

9000

7000

5000

4000

3000

2000

1000

800

600

900

700

500

400

300

200

100

Series circuit breakers

Catalog types ED, EHD, FDB, FD and HFD circuit breakers, two-, three-

and four-poles.

Circuit breaker time/current curves

C F-frame circuit breakers

Based on 40˚C ambient, cold start. Connected with four (4) feet of

rated wire (60˚C

open air with current in all poles.

For application and coordination purposes only. Based on 40°C ambient, cold start.

Maximum Vac: 600 at 50/60 Hz

Connected with four (4) feet of rated wire (60°C up to 125A, 75°C above 125A) per

Maximum Vdc: 250

terminal. Tested in open air.

Breaker rating

Continuous amperes Instantaneous trip amperes

Maximum Vac: 600 at 50/60 Hz

80A See curve

Maximum Vdc: 250

Interrupting rating (UL/CSA listed)

Symmetrical Rms amperes (KA) Amps (KA)Breaker

type

Breaker rating

Maximum singlepole trip times

1

at 25°C

@ 240 Vac @ 480 Vac @ 600 Vac 250 Vdc 125 Vdc

18

EHD

Continuous amperes Instantaneous trip, amperes

18

FDB

65

FD

100

HFD

80A See curve

ED 65 — — — 10

1

Single-pole test data at 25˚C based on NEMA procedures

Interrupting Rating (UL/CSA Listed)

(AB

4-2003

) for verifying performance of molded case

circuit breakers.

Breaker Type

N

H

—

14

14

14

35

18

25

65

Symmetrical RMS amperes (kA)

@240Vac @480Vac @600Vac 250Vac

65 35 18 10

100 65 25 22

—

10

—

10

—

10

22

—

Notes:

1 Single-pole test data at 25°C based on NEMA procedures (AB 4-2003) for verifying

performance of molded case circuit breakers.

5,000

3,000

2,000

1,000

500

300

200

100

50

30

20

10

5

2 HOURS

1 HOUR

1 MINUTE

3

2

1

.5

TIME IN SECONDS

.3

.2

.1

.05

.03

.02

.01

.005

.003

.002

.001

56

3

Minimum

Maximum

Maximum interrupting time

Interrupting

rating

determines

end of curve

(see above)

60

40

20

987

10

30

80

7050

90

200

100

500

700

800

600

900

400

300

CURRENT IN AMPERES

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

TIME IN SECONDS

2

1

.5

.3

.2

.1

.05

.03

.02

.01

.005

.003

.002

.001

20 Data subject to change without notice.

Page 21

Molded-Case Circuit Breakers

Effective September 2015

Series C

F-Frame

CURRENT IN AMPERES

Proof 1 — October 20, 2015 10:24 PMProof 1 — October 20, 2015 10:24 PM

UBW Time Current Curves

225L

10,000

2 HOURS

5,000

1 HOUR

3,000

2,000

1,000

500

300

200

100

50

1 MINUTE

30

20

10

8060 907050

100

80A

1000

800

600

900

700

500

400

300

200

Maximum singlepole trip times

1

at 25°C

CURRENT IN AMPERES

6000

5000

4000

3000

2000

8000

9000

7000

10000

Circuit breaker time/current curves

Series C F-frame circuit breaker

Catalog type FDC circuit breaker, two-, three- and four-poles.

Circuit breaker time/current curves

UBW 225L current curves

For application and coordination purposes only. Based on 40°C ambient, cold start.

Connected with four (4) feet of rated wire (60°C up to 125A, 75°C above 125A) per

terminal. Tested in open air.

Maximum Vac: 600 at 50/60 Hz

Maximum Vdc: 250

Breaker rating

Continuous amperes Instantaneous trip, amperes

80A See curve

Interrupting Rating (UL/CSA Listed)

Breaker Type

L

and coordination purposes only.

rated wire (60˚C up to 125A, 75˚C above 125A) per terminal.

Tested in open air with current in all poles.

Maximum Vac: 600 at 50/60 Hz

Maximum Vdc: 250

Breaker rating

Continuous amperes Instantaneous trip amperes

80A See curve

Interrupting rating (UL/CSA listed)

Breaker

type

1

Single-pole test data at 25˚C based on NEMA procedures

4-2003) for verifying performance of molded case

(AB

circuit breakers.

cold start. Connected with four (4) feet of

Symmetrical Rms amperes (KA) Amps (KA)

@ 240 Vac @ 480 Vac @ 600 Vac 250 Vdc

200FDC 100 35 22

Symmetrical RMS amperes (kA) Amps (KA)

@240Vac @480Vac @600Vac 250Vdc

200 100 35 22

Notes:

1 Single-pole test data at 25°C based on NEMA procedures (AB 4-2003) for verifying

performance of molded case circuit breakers.

5,000

3,000

2,000

1,000

500

300

200

100

50

30

20

10

2 HOURS

1 HOUR

1 MINUTE

100,000

80,000

60,000

90,000

70,000

50,000

40,000

30,000

20,000

.005

.003

.002

5

3

2

1

.5

TIME IN SECOND S

.3

.2

.1

.05

.03

.02

MaximumMinimum

Maximum interrupting time

5

3

TIME IN SECONDS

2

1

.5

.3

.2

.1

.05

.03

.02

600V

.01

480V

.01

.005

240V

.003

.002

.001

60

80

7050

90

200

100

500

700

800

600

400

300

900

1000

3000

2000

7000

8000

6000

9000

5000

4000

10000

30,000

20,000

80,000

60,000

90,000

70,000

50,000

40,000

100,000

200,000

.001

Data subject to change without notice. UBW Technical Manual | 21

Page 22

Molded-Case Circuit Breakers

Time Current Curves

225 N., H.

10,000

2 HOURS

5,000

1 HOUR

3,000

2,000

1,000

500

300

200

100

50

1 MINUTE

30

20

10

5

90A

8060 9070504030201 0 9 8 75 6

Minimum

CURRENT IN AMPERES

10000

8000

6000

9000

7000

5000

4000

3000

2000

1000

800

600

900

700

500

400

300

200

100

Circuit breaker time/current curves

225 circuit breakers

For application and coordination purposes only. Based on 40°C ambient, cold start.

600 at 50/60 Hz

Connected with four (4) feet of rated wire (60°C up to 125A, 75°C above 125A) per

250

terminal. Tested in open air.

Maximum Vac: 600 at 50/60 Hz

Maximum Vdc: 250

Symmetrical Rms amperes (KA) Amps (KA)

Breaker rating

@ 240 Vac @ 480 Vac @ 600 Vac 250 Vdc 125 Vdc

18

14

—

10

—

10

—

—

10

—

22

Maximum singlepole trip times

1

at 25°C

Continuous amperes Instantaneous trip, amperes

18

14

65

90A See curve

100

Interrupting Rating (UL/CSA Listed)

) for verifying performance of molded case

Breaker Type

N

H

14

35

18

65

25

Symmetrical RMS amperes (kA)

@240Vac @480Vac @600Vac 250Vac

65 35 18 10

100 65 25 22

Notes:

1 Single-pole test data at 25°C based on NEMA procedures (AB 4-2003) for verifying

performance of molded case circuit breakers.

Maximum

5,000

3,000

2,000

1,000

500

300

200

100

50

30

20

10

5

2 HOURS

1 HOUR

1 MINUTE

3

2

1

.5

TIME IN SECONDS

.3

.2

.1

.05

.03

.02

.01

.005

.003

.002

.001

56

3

TIME IN SECONDS

2

1

.5

.3

.2

.1

.05

Maximum interrupting time

Interrupting

rating

determines

end of curve

(see above)

60

40

20

987

10

30

80

7050

90

200

100

500

700

800

600

900

400

300

CURRENT IN AMPERES

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

.03

.02

.01

.005

.003

.002

.001

22 Data subject to change without notice.

Page 23

Time Current Curves

225L

Series C

F-Frame

CURRENT IN AMPERES

Proof 1 — October 20, 2015 10:24 PM

Molded-Case Circuit Breakers

10,000

2 HOURS

5,000

1 HOUR

3,000

2,000

1,000

500

300

200

100

50

1 MINUTE

30

20

10

8060 907050

100

90A

400

300

200

1000

800

600

900

700

500

Maximum singlepole trip times

1

at 25°C

2000

3000

4000

5000

6000

7000

8000

9000

10000

20,000

100,000

80,000

60,000

90,000

70,000

50,000

40,000

30,000

Circuit breaker time/current curves

Series C F-frame circuit breakers

Catalog type FDC circuit breaker, two-, three- and four-poles.

Circuit breaker time/current curves

For application and coordination purposes only.

225L Circuit Breakers

rated wire (60˚C up to 125A, 75˚C above 125A) per terminal.

For application and coordination purposes only. Based on 40°C ambient, cold start.

Maximum Vac: 600 at 50/60 Hz

Maximum Vdc: 250

Connected with four (4) feet of rated wire (60°C up to 125A, 75°C above 125A) per

terminal. Tested in open air.

Breaker rating

Continuous amperes Instantaneous trip amperes

Maximum Vac: 600 at 50/60 Hz

100A See curve

Maximum Vdc: 250

Interrupting rating (UL/CSA listed)

Breaker

Breaker rating

Continuous amperes Instantaneous trip, amperes

90A See curve

Interrupting Rating (UL/CSA Listed)

Breaker Type

L

Symmetrical Rms amperes (KA) Amps (KA)

@ 240 Vac @ 480 Vac @ 600 Vac 250 Vdc

type

200FDC 100 35 22

1

Single-pole test data at 25˚C based on NEMA procedures

4-2003) for verifying performance of molded case

(AB

circuit breakers.

Symmetrical RMS amperes (kA) Amps (KA)

@240Vac @480Vac @600Vac 250Vdc

200 100 35 22

(4) feet of

Notes:

1 Single-pole test data at 25°C based on NEMA procedures (AB 4-2003) for verifying

performance of molded case circuit breakers.

2 HOURS

1 HOUR

5,000

3,000

2,000

1,000

500

300

200

100

1 MINUTE

50

30

20

10

.005

.003

.002

Minimum

5

3

2

1

.5

TIME IN SECO NDS

.3

.2

.1

.05

.03

.02

Maximum

Maximum interrupting time

5

3

TIME IN SECO NDS

2

1

.5

.3

.2

.1

.05

.03

.02

600V

.01

480V

.01

.005

240V

.003

.002

.001

60

80

7050

90

200

100

500

700

800

600

900

400

300

1000

3000

2000

CURRENT IN AMPERES

4000

5000

6000

7000

8000

9000

10000

20,000

80,000

60,000

200,000

100,000

90,000

70,000

50,000

40,000

30,000

.001

Data subject to change without notice. UBW Technical Manual | 23

Page 24

Molded-Case Circuit Breakers

Time Current Curves

225 N., H.

10,000

2 HOURS

5,000

1 HOUR

3,000

2,000

1,000

500

300

200

100

50

1 MINUTE

30

20

10

5

100A

8060 9070504030201 0 9 8 75 6

100

CURRENT IN AMPERES

600

500

400

300

200

Maximum singlepole trip times

at 25°C

1000

800

900

700

Circuit breaker time/current curves

®

F-frame circuit breakers

Series C

225 circuit breakers

Based on

rated wire (60˚C up to 125A, 75˚C above 125A) per terminal.

For application and coordination purposes only. Based on 40°C ambient, cold start.

Tested in open air with current in all poles.

Maximum Vac: 600 at 50/60 Hz

Connected with four (4) feet of rated wire (60°C up to 125A, 75°C above 125A) per

Maximum Vdc: 250

terminal. Tested in open air.

Breaker rating

Continuous amperes Instantaneous trip amperes

Maximum Vac: 600 at 50/60 Hz

100A See curve

Maximum Vdc: 250

Interrupting rating (UL/CSA listed)

Breaker

Symmetrical Rms amperes (KA) Amps (KA)

type

@ 240 Vac @ 480 Vac @ 600 Vac 250 Vdc 125 Vdc

Breaker rating

ED

65 — — — 10

EDB

22 — — — 10

Continuous amperes Instantaneous trip, amperes

EDS

42 — — — 10

EDH

100 — — — 10

100A See curve

EDC

200 — — — 10

EHD

18 14 — 10 —

FDB

18 14 14 10 —

FD

65 35 18 10 —

Interrupting Rating (UL/CSA Listed)

HFD

100 65 25 22 —

Single-pole test data at 25˚C based on NEMA procedures

1

(AB

4-2003

Breaker Type

1

circuit breakers.

N

H

Symmetrical RMS amperes (kA)

) for verifying performance of molded case

@240Vac @480Vac @600Vac 250Vac

65 35 18 10

100 65 25 22

Notes:

1 Single-pole test data at 25°C based on NEMA procedures (AB 4-2003) for verifying

performance of molded case circuit breakers.

MaximumMinimum

2 HOURS

1 HOUR

2,000

1,000

500

300

200

30

20

10

5

3

2

1

.5

TIME IN SECONDS

.3

.2

.1

.05

.03

.02

.01

.005

.003

.002

.001

56

3

TIME IN SECONDS

2

1

.5

.3

.2

.1

.05

Maximum interrupting time

Interrupting

rating

determines

end of curve

(see above)

60

40

20

987

10

30

80

7050

90

200

100

500

700

800

600

900

400

300

CURRENT IN AMPERES

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

.03

.02

.01

.005

.003

.002

.001

24 Data subject to change without notice.

Page 25

Molded-Case Circuit Breakers

Effective September 2015

Series C

F-Frame

CURRENT IN AMPERES

Proof 1 — October 20, 2015 10:24 PMProof 1 — October 20, 2015 10:24 PM

UBW Time Current Curves

225L

100

8060 907050

10,000

2 HOURS

5,000

1 HOUR

3,000

2,000

1,000

500

300

200

100

50

1 MINUTE

30

20

10

100A

1000

800

600

900

700

500

400

300

200

Maximum singlepole trip times

1

at 25°C

2000

3000

4000

5000

6000

7000

100,000

80,000

60,000

90,000

70,000

50,000

40,000

30,000

20,000

10000

8000

9000

Circuit breaker time/current curves

Series C®F-frame circuit breakers

Catalog type FDC circuit breaker, two-, three- and four-poles.

Circuit breaker time/current curves

225L Circuit Breakers

Based on 40˚C ambient, cold start. Connected with four (4) feet of

Tested in open air with current in all poles.

For application and coordination purposes only. Based on 40°C ambient, cold start.

Maximum Vac: 600 at 50/60 Hz

Connected with four (4) feet of rated wire (60°C up to 125A, 75°C above 125A) per

Maximum Vdc: 250

terminal. Tested in open air.

Breaker rating

Continuous amperes Instantaneous trip amperes

Maximum Vac: 600 at 50/60 Hz

100A See curve

Maximum Vdc: 250

Interrupting rating (UL/CSA listed)

Breaker rating

Breaker

Symmetrical Rms amperes (KA) Amps (KA)

@ 240 Vac @ 480 Vac @ 600 Vac 250 Vdc

type