Page 1

Soft-Starter

SSW-07 / SSW-08

Programming Manual

Motors | Energy | Automation | Coatings

Page 2

Programming Manual

Series: SSW-07 / SSW-08

Language: English

Document Number: 0899.5665 / 05

Software Version: V1.3X

Publication Date: 09/2009

Page 3

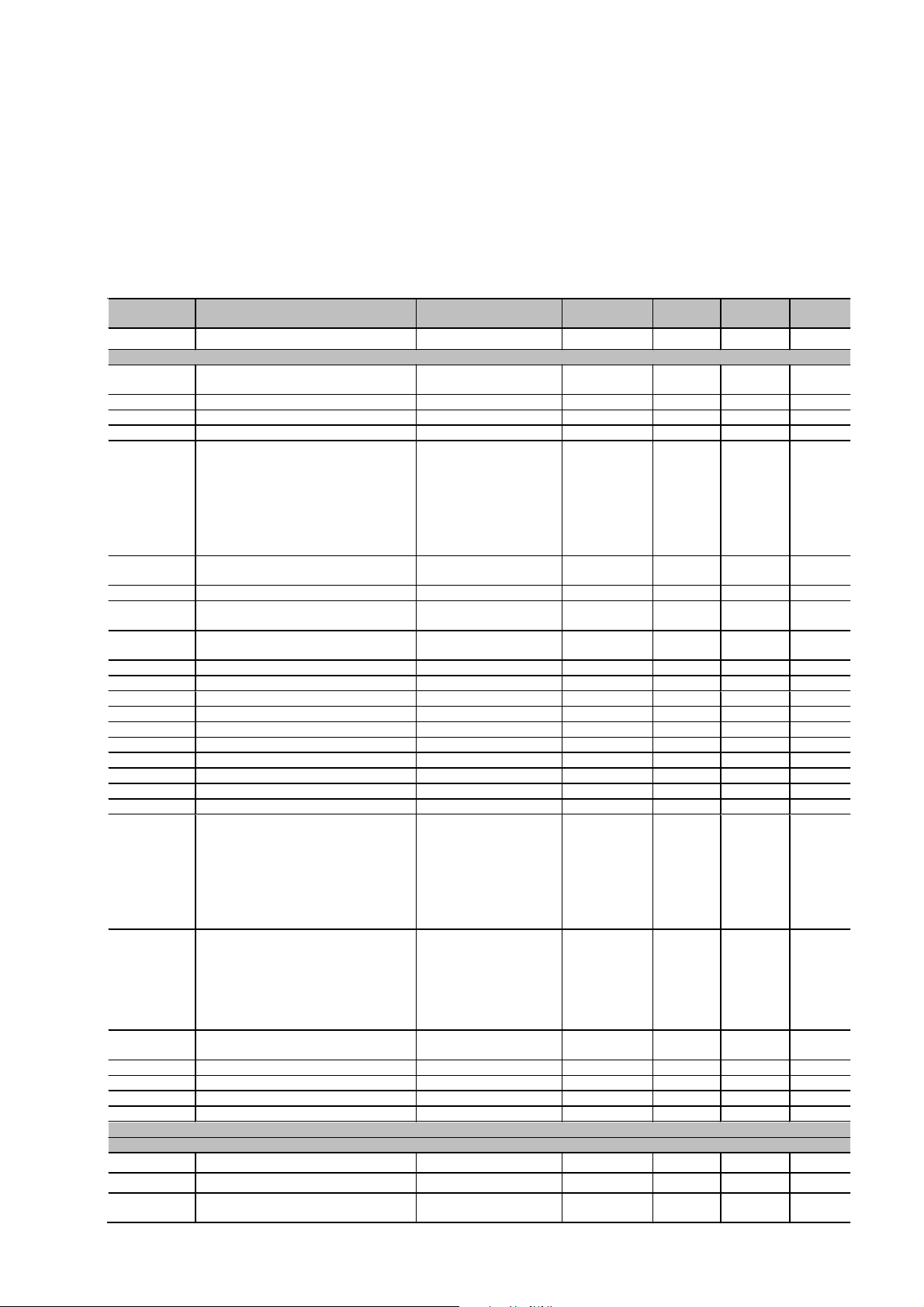

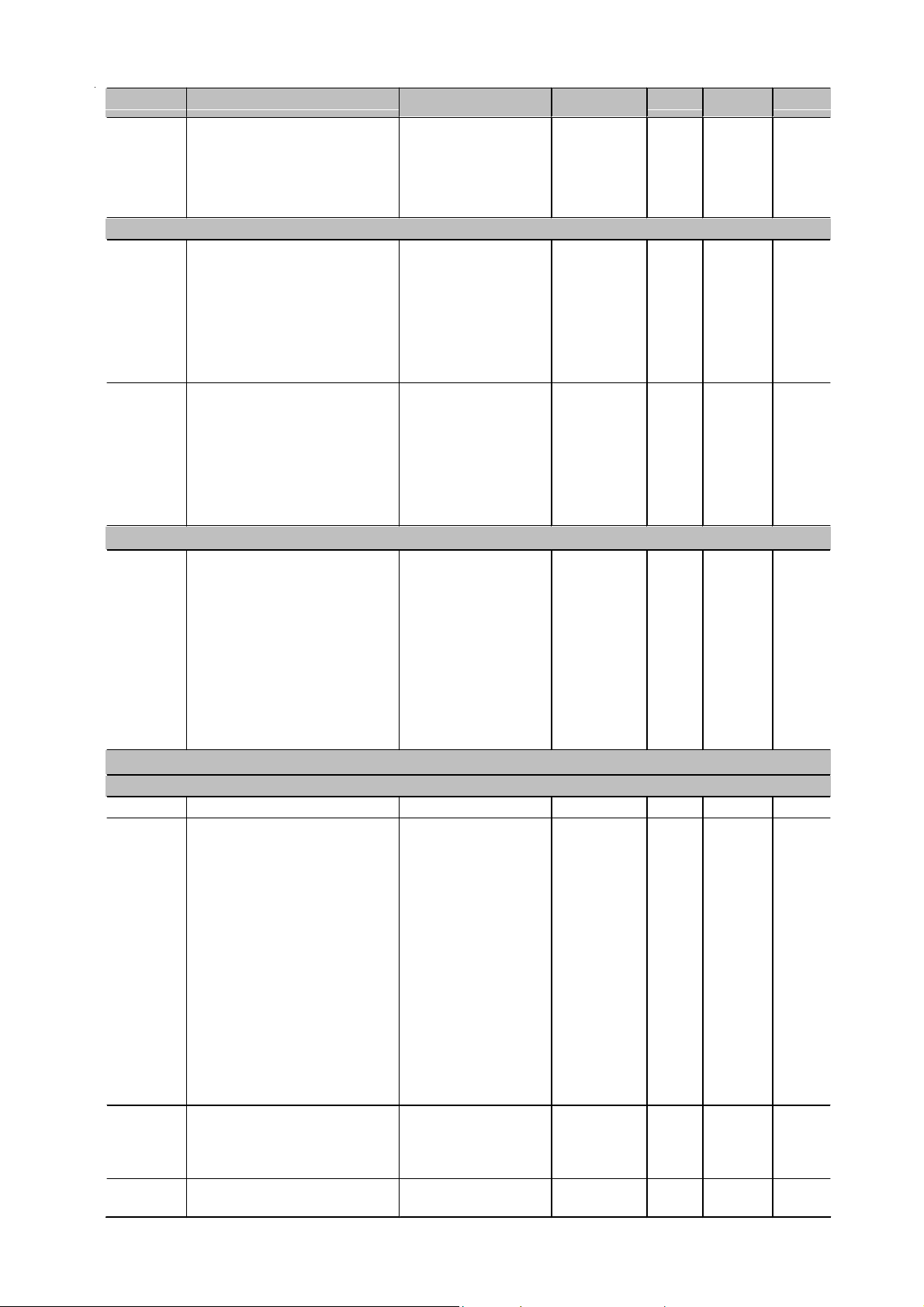

QUICK PARAMETER REFERENCE

Adjustable

Factory

User’s

READ ONLY PARAMETERS

P001 to P099

P001

P002

P003

P005

P006

P007

P011

P012

P01

3

P014

P015

P016

P017

P0

23

P030

P031

P032

P050

P081

P090

P091

P092

P093

P094

P095

P096

REGULATION PARAMETERS

P100 to P199

Ramps

P101

P102

P10

3

(%Un)

99 to 50

FAULT AND STATUS MESSAGES

Software: V1.3x

Application:

Model:

Serial Number:

Responsible:

Date: / / .

I. PARAMETERS

Parameter Function

P000

Access to parameters 0 to 9999 0 (5) - 14

Range

Settings

Unit

Settings

Page

Motor current %In of

SSW-07/SSW-08

Motor current %In of Motor 0.0 to 999.9 - % 14

Motor current 0.0 to 6553 - A 14

Power supply frequency 0.0 to 99.9 - Hz 14

Soft-Starter Status 0= rdy - ready

Voltage imposed by the Soft-Starter

over the load (%Un)

Apparent output power 0.0 to 999.9 - kVA 14

DI1 to DI3 status 0 = Inactive

Relay RL1 and RL2 output status 0 = Inactive

Last fault occurred E00 to E77 - - 15

Second fault occurred E00 to E77 - - 15

Third fault occurred E00 to E77 - - 15

Fourth fault occurred E00 to E77 - - 15

Software version x.xx - - 15

Phase R current 0.0 to 6553 - A 16

Phase S current 0.0 to 6553 - A 16

Phase T current 0.0 to 6553 - A 16

Motor thermal protection status 0 to 250 - % 16

Heatsink temperature 10.0 to 110.0 - ºC 16

CAN Controller Status 0 = Inactive

DeviceNet Network Status 0 = Offline

DeviceNet Master Status 0 = Run

Received CAN Telegram Counter 0 to 9999 - - 16

Transmitted CAN Telegram Counter 0 to 9999 - - 16

Buss Off Error Counter 0 to 9999 - - 16

Lost Can Message Counter 0 to 9999 - - 16

0.0 to 999.9 - % 14

- - 14

2= Exx - Error

3= ruP – Ramp Up

5= PASS – By-pass

7= rdo – Ramp Down

11= dly – Delay P630

12 = G.di – General

Disable

0 to 100 - % 14

- - 14

1 = Active

- - 15

1 = Active

- - 16

1 = Autobaud

2 = Active CAN

Interface

3 = Warning

4 = Error passive

5 = Bus off

6 = No Bus Power

- - 16

1 = Online, Not

Connected

2 = Online, Connected

3 = Expire Connection

4 = Connection Failure

5 = Auto-Baud

- - 16

1 = Idle

(3)

(3)

Initial voltage (%Un) 30 to 90 50 % 16

Acceleration ramp time 1 to 999 20 s 17

Voltage degree at deceleration

100 = Inactive

70 % 18

3

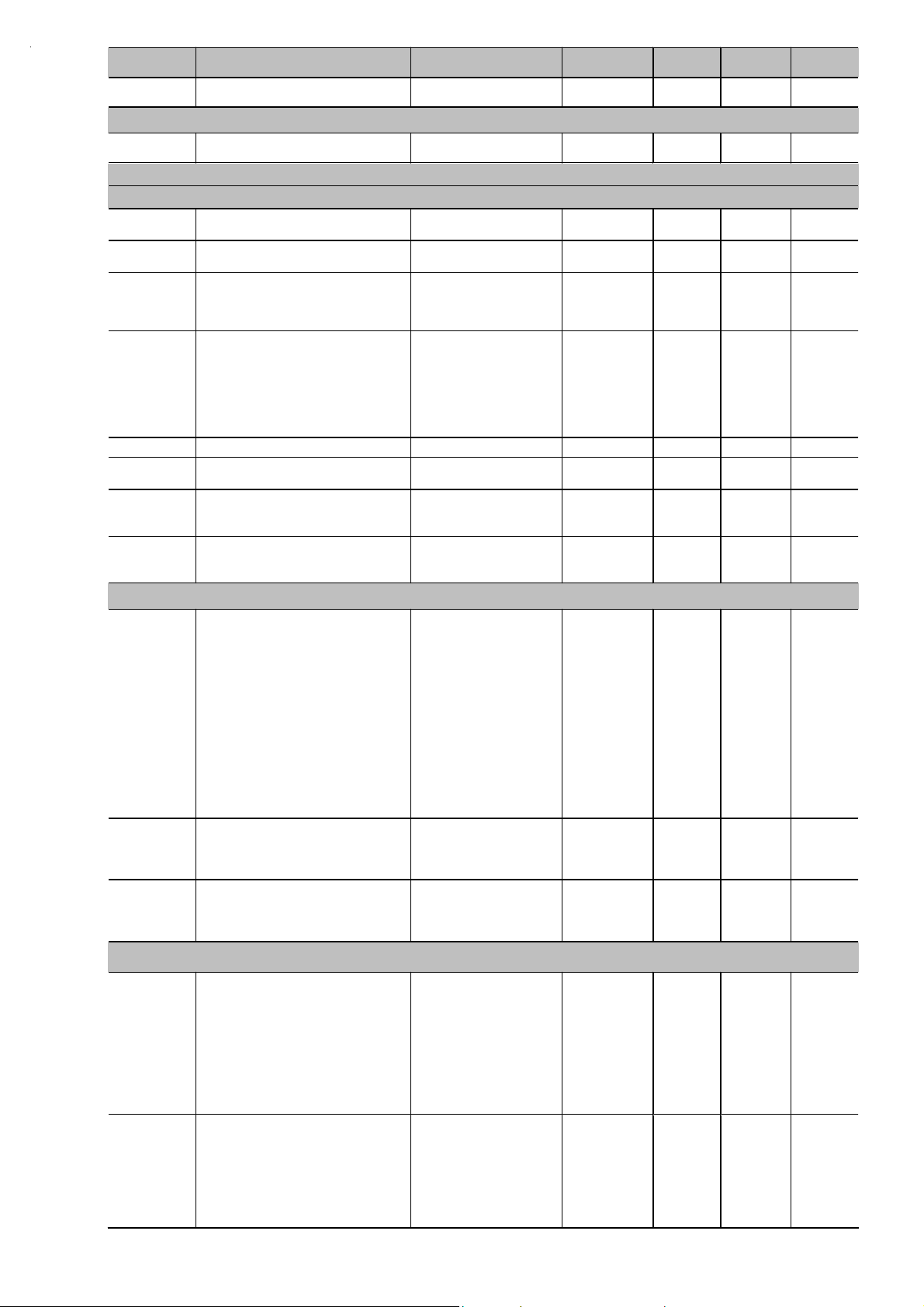

Page 4

Parameter Function

P104

P110

(3)

(3)

Deceleration ramp time 0=Inactive

Current Limitation

Current limitation

(%In of the Soft-Starter)

CONFIGURATION PARAMETERS P200 to P299

Generic Parameters

P200

P202

P203

P204

P205

P206

P215

P219

(1)(3)

(1)

(3)

(1)

(1)

The password is 0 = Inactive

Type of control 0 = Voltage ramp

Fan Control 0 = Fan is always OFF

Load parameters with factory

default values

Reading parameter selection 0 to 999 1 = P001 - 19

Auto-reset time 0 = Inactive

Copy function 0 = Inactive

Parameterization via keypad/

(Trimpots and DIP Switch)

Local/Remote Definition

P220

P229

P230

(1)

(1)

(1)

Local/remote supply selection 0 = Always local

Command selection – local

situation

Command selection – remote

situation

Digital Inputs

(1)

P263

P264

(1)

Input DI1 function 0 = No function

Input DI2 function 0 = No function

Adjustable

Range

Factory

Settings

Unit

User’s

Settings

Page

0=Inactive s 18

1 to 240

30 to 500 300 % 18

1 = Active

1 = Current limit

1 = Fan is always ON

2 = Fan controlled by

1 = Active -

0 = Voltage

Ramp

2 = Fan

controlled by

software

-

-

18

18

19

software

0 = No function

1 = No function

0 = No

function

-

19

2 = No function

3 = No function

4 = No function

5 = Loads factory

default values

900 s 19

1 to 1200

0 = Inactive - 20

1 = SSW Keypad

2 = Keypad SSW

0 = Trimpots and DIP

Switch

1 = Keypad

1 = Always remote

2 = Keypad (local

0 = Trimpots

and DIP

Switch

3 = Keypad

(default

remote)

- 21

- 21

default)

3 = Keypad (remote

default)

4 = DI1 to DI3

5 = Serial (local default)

6 = Serial (remote

default)

7 = Fieldbus (Default

Local)

8 = Fieldbus (Default

Remote)

0 = Keypad

0 = Keypad - 21

1 = Digital Input DIx

2 = Serial

3 = Fieldbus

0 = Keypad

1 = Digital Input DIx

1 = Digital

Input DIx

- 21

2 = Serial

3 = Fieldbus

1 = Enable/Disable (two

wires) or Start (three

1 = Enable/

Disable or

Start

- 22

wires)

2 = Local/Remote

3 = No external fault

4 = No function

5 = No function

6 = Reset

6 = Reset - 22

1 = Stop (three wires)

2 = Local/Remote

3 = No external fault

4 = No function

5 = No function

6 = Reset

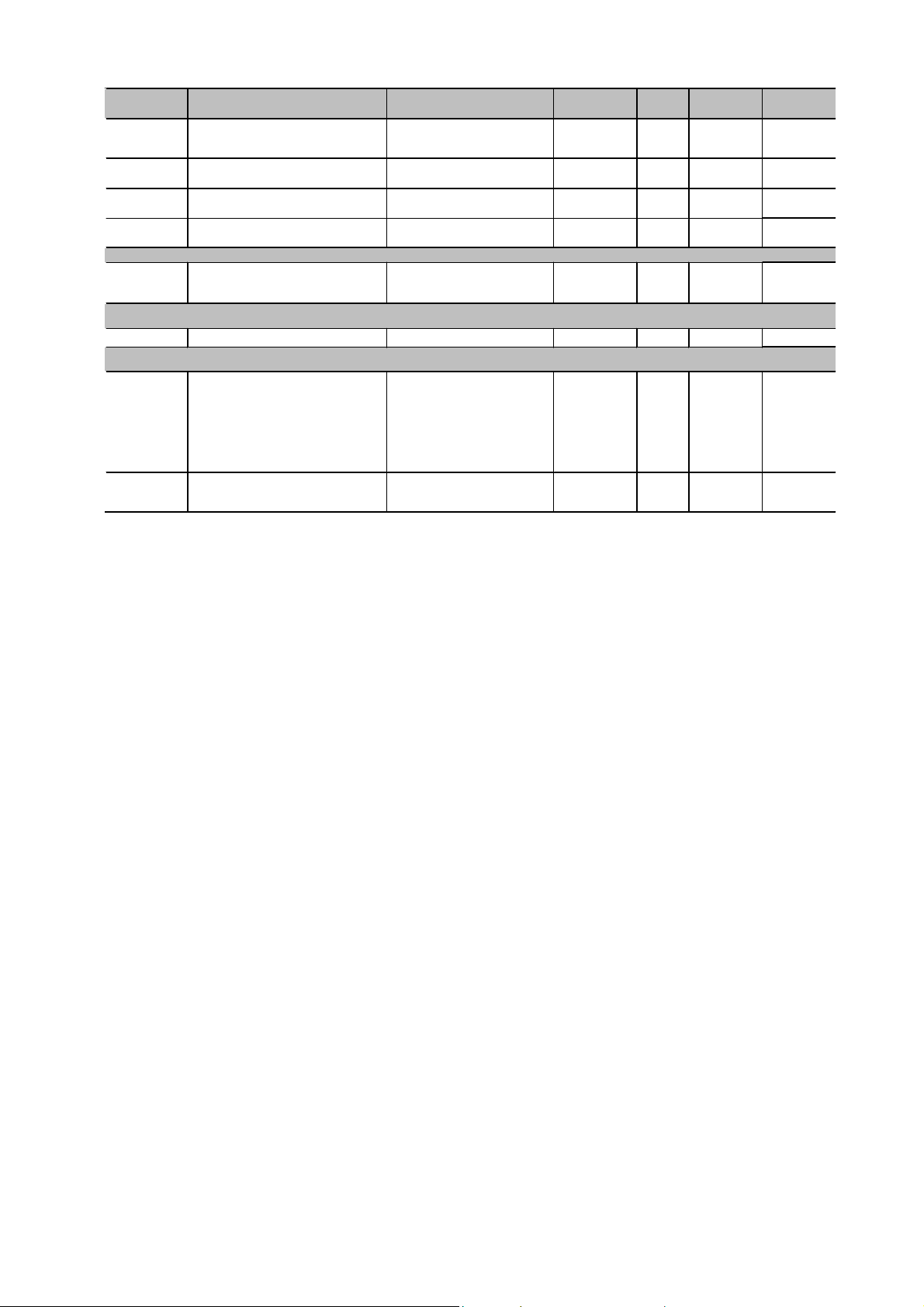

4

Page 5

Parameter Function

(1)

P265

Input DI3 function

Relay Outputs

(1)

P277

P278

(1)

Relay RL1 function

Relay RL2 function

Soft-Starter Data

(1)(2)

P295

Nominal current

COMMUNICATION PARAMETERS P300 to P399

Serial Communication

(1)(2)

P308

P312

(1)(2)

Soft-Starter address 1 to 247 1 - 23

Type of protocol and serial

communication transmission rate

P313

Serial communication error action

(E28)

(3)

P314

Serial communication verification

time

Adjustable

Range

0 = No function

1 = General enable

2 = Local/Remote

3 = No external fault

4 = No function

5 = No function

6 = Reset

0 = No function

1 = Running

2 = Full voltage

3 = No function

4 = No function

5 = No function

6 = No fault

7 = Fault

8 = No function

9 = Serial

0 = No function

1 = Running

2 = Full voltage

3 = No function

4 = No function

5 = No function

6 = No fault

7 = Fault

8 = No function

9 = Serial

0 = 1.7A

1 = 17A

2 = 24A

3 = 30A

4 = 45A

5 = 61A

6 = 85A

7 = 130A

8 = 171A

9 = 200A

10 = 255A

11 = 312A

12 = 365A

13 = 412A

1 = Modbus 9600bps no

parity

2 = Modbus 9600bps

odd parity

3 = Modbus 9600bps

even parity

4 = Modbus 19200bps

no parity

5 = Modbus 19200bps

odd parity

6 = Modbus 19200bps

even parity

7 = Modbus 38400bps

no parity

8 = Modbus 38400bps

odd parity

9 = Modbus 38400bps

even parity

0 = Inactive

1 = Disable

2 = General disable

3 = Change to local

0 = Inactive

1 to 999

Factory

Settings

Unit

User’s

Settings

Page

6 = Reset - 22

1 = Running -

2 = Full

- 23

voltage

According to

A 23

the Soft-

Starter

SSW-07/

SSW-08

nominal

current

1 = Modbus

- 24

9600bps no

parity

1 = Disable - 24

0 = Inactive s 24

23

5

Page 6

Parameter Function

Fieldbus Communication

P331

P332

P333

P335

P336

P337

P338

P339

P340

P341

P342

P343

P344

P345

P346

P347

P348

CAN Address 0 to 63 63 - 24

CAN Baud Rate 0 = 125 Kbps

Bus Off Reset 0 = Manual

DeviceNet I/O Instances 0 = ODVA

DeviceNet Reading Word #2 0 to 999 0 - 24

DeviceNet Reading Word #3 0 to 999 0 - 24

DeviceNet Reading Word #4 0 to 999 0 - 24

DeviceNet Reading Word #5 0 to 999 0 - 24

DeviceNet Reading Word #6 0 to 999 0 - 24

DeviceNet Reading Word #7 0 to 999 0 - 24

DeviceNet Writing Word #2 0 to 999 0 - 24

DeviceNet Writing Word #3 0 to 999 0 - 24

DeviceNet Writing Word #4 0 to 999 0 - 24

DeviceNet Writing Word #5 0 to 999 0 - 24

DeviceNet Writing Word #6 0 to 999 0 - 24

DeviceNet Writing Word #7 0 to 999 0 - 24

Fieldbus communication error

action

MOTOR PARAMETERS P400 to P499

Nominal Parameters

(1)

P400

P401

P406

(1)(3)

(1)

Motor nominal voltage 1 to 999 380 V 25

Motor current setting 30.0 to 100.0 100.0 % 25

Service factor 1.00 to 1.50 1.00 - 25

SPECIAL FUNCTIONS PARAMETERS P500 to P599

Braking

P501

P502

No function - - - 25

No function - - - 25

Kick Start

(1)(3)

P520

Voltage pulse at start

(Kick Start)

(3)

P521

Pulse time at start 0.2 to 2.0 0.2 s 25

Adjustable

Range

1 = 250 Kbps

2 = 500 Kbps

3 = Autobaud

1 = Automatic

1 = WEG Specific 1W

2 = WEG Specific 2W

3 = WEG Specific 3W

4 = WEG Specific 4W

5 = WEG Specific 5W

6 = WEG Specific 6W

7 = WEG Specific 7W

0 = Inactive

1 = Disable

2 = General Disable

3 = Change to local

0 = Inactive

1 = Active

Factory

Settings

Unit

User’s

Settings

Page

24

3 =

Autobaud

0 = Manual -

0 = ODVA

-

24

24

-

1 = Disable

24

-

0 = Inactive - 25

P522

P610

P611

P612

P613

Voltage pulse level at start

(%Un)

PROTECTION PARAMETERS P600 to P699

Current Protections

(1)

(1) (3)

Phase Loss or Immediate

Undercurrent (% In of the Motor)

Immediate undercurrent time or

phase loss

(1)

Immediate overcurrent (%In of

motor)

(1) (3)

Immediate overcurrent time 0 = Inactive

70 to 90 80 % 25

1 to 80 80 % 26

0 = Inactive

1 s 26

1 to 99

1 to 200 100 % 26

1 s 26

1 to 99

6

Page 7

Parameter Function

(1)

P614

Current imbalance between

Adjustable

Range

0 to 30 15 % 27

Factory

Settings

Unit

User’s

Settings

phases (%In of motor)

(1)

P615

P616

P617

(1)

(1)(3)

Current imbalance time between

phases

Undercurrent before By-Pass

closing

0 = Inactive

1 to 99

0 = Inactive

1 = Active

Blocked Rotor 0 = Inactive

0 = Inactive s 27

0 = Inactive - 27

1 = Active - 27

1 = Active

P620

RST phase sequence

0 = Inactive

1 = Active - 27

Phase Sequence

(1) (3)

1 = Active

Interval Between Starts

P630 Time interval after stopping 2 to 999 2 s 28

Motor Thermal Protection

P640

(1) (3)

Motor protection thermal class 0 = Inactive

1 = 5

6 = 30 - 29

2 = 10

3 = 15

4 = 20

5 = 25

6 = 30

0 = Inactive s 31

P641

(1)

Thermal memory auto-reset 0 = Inactive

1 to 600

(1) Changeable parameters only when the motor is disabled.

(2) Unchanged parameters at factory default settings (P204=5).

(3) Changeable parameters only in keypad mode (P219=1). If P219=0 the parameters are read only.

Page

7

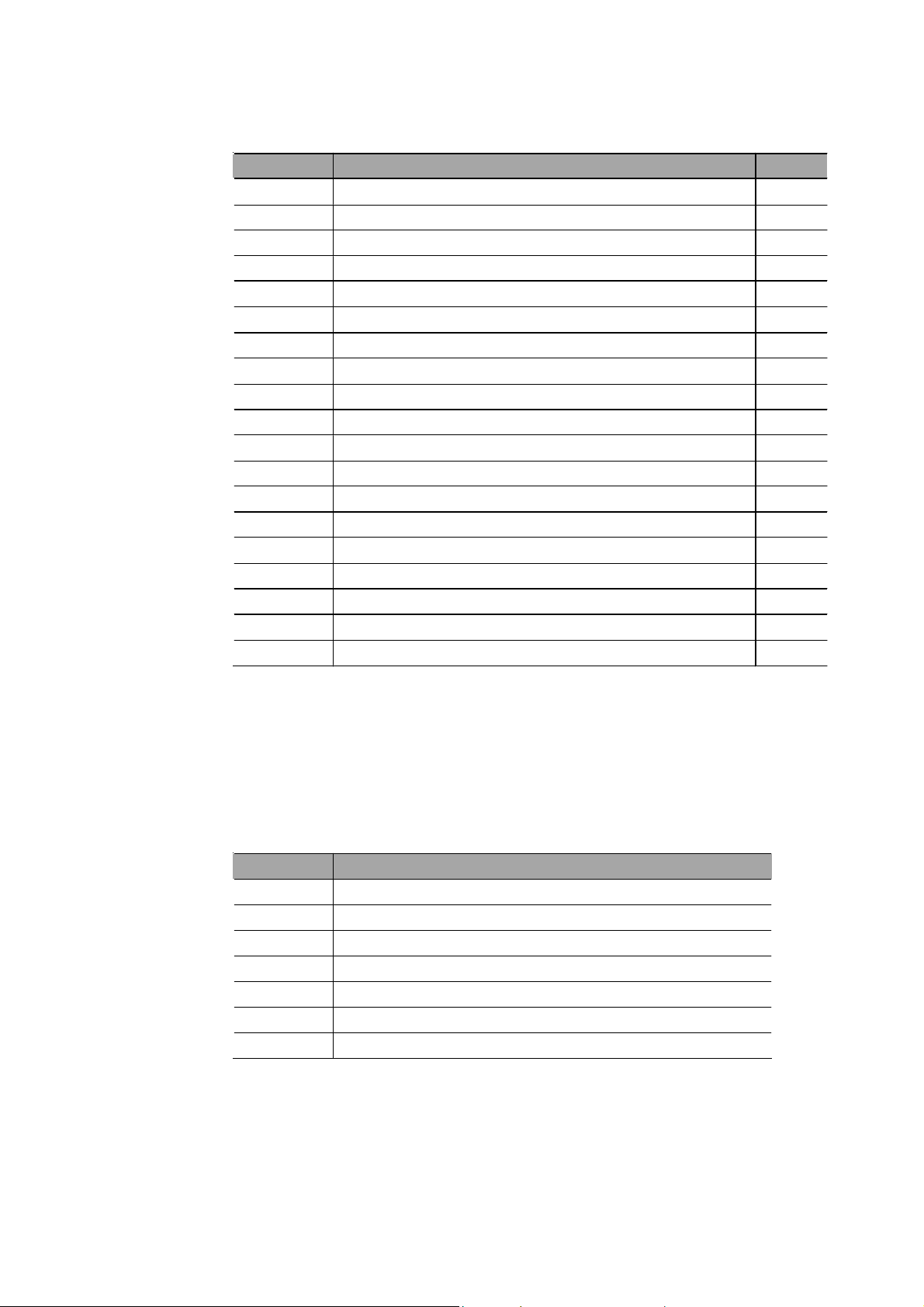

Page 8

ll. FAULT MESSAGES

Indication Meaning Page

E03

E04

E05

E06

E10

E24

E28

E31

E62

E63

E66

E67

E70

E71

E72

E74

E75

E76

E77

Phase loss or un dercu rrent

Overtemperature on power

Overload on m otor

External fa ult (DI)

Function copy fault

Programming fault

Timeo ut fault at telegram r eception

Keypad connection failure

Current limitation start time out

Stall

Overcurrent

Inverted phase sequence

Undervo ltage a t ele ctronic supply

By-pass contact open

Overcurrent before By-pass

Current imbalance

Power supply frequency out of allowed range

Overcurrent before c losing By-pass

Closed by-pass contact or s horted SCR’s

32

32

32

33

33

33

33

33

33

33

34

34

34

34

34

34

35

35

35

lll. OTHER MESSAGES

Indication Meaning

rdy

ruP

PASS

rdo

Exx

dly

G.di

Soft-Starter ready to be on “ready”

Soft-Starter on, at acceleration ramp “ramp up”

Soft-Starter on, at By-Pass “by-pass”

Soft-Starter on, at deceleration ramp “ramp down”

Soft-Starter with error

Soft-Starter waiting for time after stop “delay”

Soft-Starter with general disable “general disable”

8

Page 9

1. GENERAL INFORMATION

This manual contains the necessary information for the correct use of the Soft-Starter SSW-07/

SSW-08.

It was written to be used by trained or technically qualified people to operate this type of equipment.

2. ABOUT THIS MANUAL

This manual gives the necessary description for the configuration of all the functions and parameters

of the Soft-Starter SSW-07/SSW-08. This manual must be used together with the SSW-07/ SSW-08 User’s

Guide.

3. ABOUT THE SSW-07/SSW-08

The Soft-Starter SSW-07/ SSW-08 is a high performance product that allows start control of three

phase induction motors. This way mechanic shocks in the load and current surges in the power supply can

be avoided.

4. ABOUT THE SSW-07/SSW-08 PARAMETER PROGRAMMING

The basic functions of the Soft-Starter SSW-07/SSW-08 can be programmed at the front cover at the

SSW-07/SSW-08 (Trimpots and DIP Switch). To program additional functions and/or visualize reading

parameters, some accessories must be used, as for example: the Software SuperDrive G2, Serial

Communication RS-232 or RS-485, Local or Remote Keypad. For more details see the chapter 7 of the

User’s Guide and the optionals guides of SSW-07/SSW-08.

NOTE!

For communication with the SSW-07/SSW-08 use the 2nd generation programming software SuperDrive

G2. The first generation software named SuperDrive is not compatible with this product.

Parameter P219, Parameterization via Keypad/ (Trimpots and DIP Switch), defines the

programming origin for the protection and acceleration/deceleration ramps. A Soft-Starter SSW-07/

SSW-08 can be programmed via Trimpots and DIP Switches or completely via parameters. See the detailed

description of parameters (P219).

Parameters P220, P229, and P230 (Local/Remote Definitions) program the origin of the enable/

disable command. Factory default settings enable via digital input. To enable/disable by means of keypad or

serial command the settings of P220, P229 and P230 must be changed. See the detailed description of

parameters P220, P229 and P230.

The SSW-07/SSW-08 User’s Guide has a chapter dedicated to Programming Suggestions. It’s

important to read this chapter before starting to program the Soft-Starter SSW-07/SSW-08.

5. KEYPAD(HMI) USE

The keypad is a simple interface that allows the operation and the programming of the Soft-Starter. It

presents the following functions:

- Indication of the Soft-Starter operational status;

- Indication of the errors;

- Visualization and modification of the adjustable parameters;

- Operation of the soft-Starter ( and keys).

9

Page 10

The keypad can be used in the following cases:

- If an keypad for commanding, programmingand/or visualizing SSW-07/SSW-08 parameters were necessary;

- For installation of the keypad at the cabinet door, commanding panel or at the SSW-07/SSW-08 front cover;

- When the copy function were necessary.

The SSW-07/SSW-08 local or remote keypad presents a 7-segment 4-digit LED display, 4 status

LEDs and 8 keys. The figures below show a front view of the remote keypad and of the local keypad.

Remote Keypad Front View Local Keypad Front View

5.1. LEDs Display Functions

It shows the parameter number or its content and also fault and status messages.

5.2. Function of the “Local” and “Remote” LEDs

Soft-Starter in Local mode:

Green LED on and red LED off.

Soft-Starter in Remote mode:

Green LED off and red LED on.

5.3. Function of the Direction of Rotation LEDs (Clockwise and Counterclockwise)

The changing of the direction of rotation function is not available in the software version V1.3x.

5.4. Basic Functions of the Keys

- Enables the motor (start);

- Disables the motor (stop). Resets the Soft-Starter after the occurrence of errors;

- Selects (toggles) the display between the parameter number and its value (position/content);

- Increments the parameter number or the parameter value;

- Decrements the parameter number or the parameter value;

- Selects the origin of the commands between Local or Remote;

- No function in the software V1.3x;

- No function in the software V1.3x.

10

Page 11

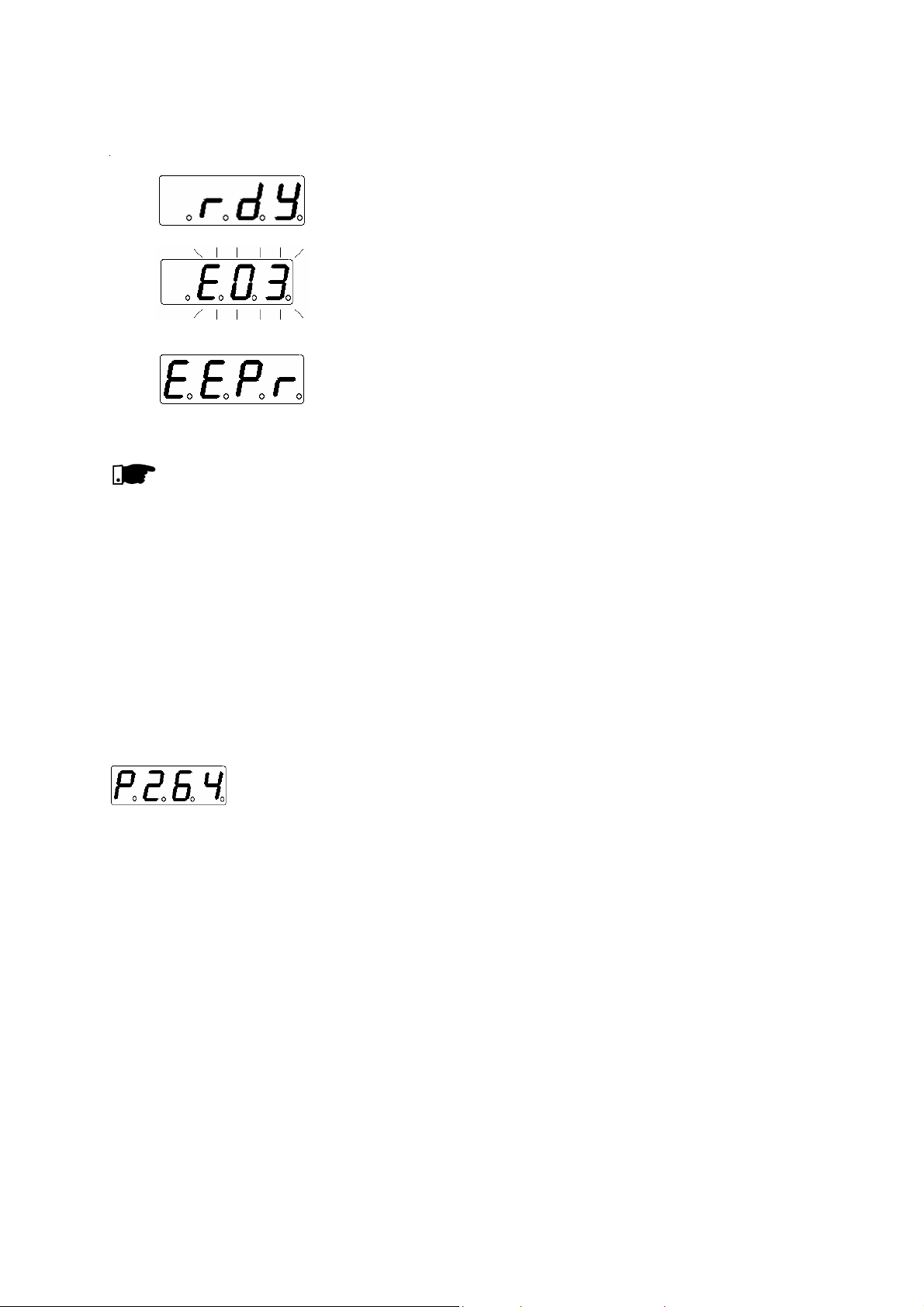

5.5. Signaling/Indications on the Keypad Display

Soft-Starter states:

Soft-Starter ready to enable the motor

Soft-Starter in an error condition. The error code shows up

flashing. In the example we have the E03 indication (phase

Loss).

Soft-Starter executing the function “Load parameters with the

factory default (P204)”.

NOTES!

The display also flashes in the following situations, besides the error condition:

An attempt to change a parameter with an incorrect password (P000 – Access parameter);

An attempt to change a not allowed parameter. For instance one that cannot be changed with the motor

rotating.

5.6. Parameter Viewing/Changing

All the settings of the Soft-Starter can be done through the parameters. The parameters are indicated on the

display by means of the letter P followed by a number:

Example (P264):

264 = number of the parameter

There is a numeric value (content of the parameter) associated to each parameter, which corresponds to the

option chosen among the available ones for that parameter.

The values of the parameters define the Soft-Starter programming or the value of a variable (E.g.: current,

voltage). In order to carry out the soft-Starter programming one must change the content(s) of the parameter(s).

11

Page 12

Example:

ACTION KEYPAD DISPLAY DESCRIPTION

To power up a Soft-Starter

Press

Use the and keys

Press

Use the and keys

Press

Soft-Starter is ready to operate

Locate the desired parameter

Numeric value associated to the

parameter

Adjust the new desired value

(1) (2) (3)

(2)

(2)

NOTES!

(1) By pressing the key after an adjustment, the last adjusted value is automatically stored in the

Soft-Starter nonvolatile memory, being kept until a new modification.

(2) In order to be able to change the value of a parameter, it is necessary to set first P000 = 5. Otherwise it will

only be possible to see the parameters, but not changing them. For more details refer to the P000 description.

(3) If the last value programmed in the parameter is not functionally compatible with other parameter values

already programmed, an E24 –Programming Error -will be displayed.

Example of programming error:

Programming two digital inputs (DIx) with the same function. Refer to Table 5.1 for the list of programming

errors that will generate an E24 Programming Error.

E24 - Programming Error

Table 5.1 - Incompatibility between Parameters - E24

Two o r more param eters be tween P 263 and P265 equal to 2 (L OC/R EM)

12

Page 13

6. DETAILED DESCRIPTION OF THE PARAMATERS

he action and time levels of the

The parameters have been grouped by types to make description easier.

Reading Parameters

Regulation Parameters

Configuration Parameters

Motor Parameters

Special Functions Parameters

Protection Parameters

Variables that can be seen but not ch anged by the user.

Adjustable values to be used the Soft-Starter functions.

Define the Soft-Starter SSW-07/SSW-08 characteristics,

the functions to be carried out, as well as the in put/output

functions of the control card.

The catalog data or m otor plate.

Include the param eters related to the special functions.

Param eters related to t

motor protections.

Symbols and definitions used in this chapter:

(1) Changeable parameters only when the motor is disabled.

(2) Unchanged parameters at factory default settings (P204=5).

(3) Changeable parameters only in keypad mode (P219=1). If P219=0 the parameters are read

only.

13

Page 14

6.1. ACCESS AND READ ONLY PARAMETERS – P000 to P099

Range

[Factory Setting]

UnitParameter Description/ Notes

Permits the access to alter the contents of the parameters.

P000 0 to 9999

Access to [ 0 ]

parameters -

Set with factory default values [P200=1 (Active Password)] it

is necessary to out P000=5 to change the contents of the

parameters.

P001 0.0 to 999.9

Motor current [ - ]

%In of SSW-07/ 0.1%

SSW-08

P002 0.0 to 999.9

Motor current [ - ]

%In of Motor 0.1%

P003 0.0 to 6553

Motor current [ - ]

0.1A

P005 0.0 to 99.9

Power supply [ - ]

frequency 0.1Hz

P006 0 to 12

Soft-Starter Status [ - ]

-

Indicates the Soft-Starter SSW-07/SSW-08 output current at

the nominalcurrent percentage of theSoft-Starter(%In of SSW-07/

SSW-08).

Accuracy of ±2% for full scale. (Full scale is 5 x In of SSW-07/

SSW-08.

Indicates the Soft-Starter SSW-07/SSW-08 output current at

the nominal current percentage of the Motor (%In of Motor).

Accuracy of ±2% for full scale. (Full scale is 5 x In of SSW-07/

SSW-08).

Indicates the Soft-Starter SSW-07/SSW-08 output current in

Amperes (A).

Accuracy of ±2% for full scale. (Full scale is 5 x In of SSW-07/

SSW-08).

Indicates the power supply frequency in Hertz (Hz).

Accuracy of ±5% of the power supply nominal frequency.

Indicates the current status of the Soft-Starter SSW-07/

SSW-08.

0= rdy – Ready to be on “ready”.

2= Exx – With error.

3= ruP – Turned on at acceleration ramp “ramp up.

5= PASS – On with enabled “by-pass”.

7= rdo – On at deceleration ramp “ramp down.

11= dly – Waiting for time after stop “delay”.

12 = G.di – With “general disable”.

P007 0 to 100

Voltage imposed by [ - ]

the Soft-Starter over 1%

the load (%Un)

P011 0.0 to 999.9

Apparent output [ - ]

power 0.1kVA

P012 0 to 224

DI1 to DI3 Status DisplayLED=

0 or 1

[ - ]

-

Indicates the voltage imposed by Soft-Starter over the load,

not taking stator emf generated by the motor into consideration.

Indicates the apparent power of the average of the three

Soft-Starter SSW-07/SSW-08 output phases in kiloVolt Amperes

(kVA).

Indicates the status of the three control card digital inputs (DI1

to DI3).

On the keypad display the digital inputs status is shown by

numbers 0 = Inactiveand 1 =Active in the following order, DI1, DI2

and DI3. The indication is binary and DI1 represents the most

significant bit. The 5 less significant bits are not shown on the

keypad display.

Example:

DI1 = Active

DI2 = Inactive

DI3 = Active

14

Page 15

Range

[Factory Setting]

UnitParameter Description/ Notes

Which is the equivalent to the sequence of bits:

10100000b.

In decimal it corresponds to 160.

The binary indication on the keypad is:

P013

Relay RL1 and RL2

output status

0 to 192

DisplayLED=

0 or 1

[ - ]

-

P014 E00 to E77

Last fault [ - ]

occurred -

P015 E00 to E77

Second fault [ - ]

occurred -

Indicates the status of the 2 control card relay outputs RL1

and RL2).

On the keypad display the relay output status is shown by

numbers (0 = Inactive) and (1= Active), in the following order, RL1

and RL2. The indication is binary and RL1 represents the most

significant bit. The 5 less significant bits are not shown on the

keypad display.

Example:

RL1 = Active

RL2 = Active

Which is the equivalent to the sequence of bits:

11000000b.

In decimal it corresponds to 160.

The binary indication on the keypad is:

Indicates the numbers of the last, second, third and fourth

previous faults occurred, respectively.

Registration systematic:

Exy P014 P015 P016 P017

P016 E00 to E77

Third fault [ - ]

occurred -

P017 E00 to E77

Fourth fault [ - ]

occurred -

P023 X. XX

Software Version [ - ]

-

Indicates the Software version in the microcontroler memory

(DSP) on the control board.

15

Page 16

Range

[Factory Setting]

UnitParameter Description/ Notes

P030

Phase R current

P031

Phase S current

P032

Phase T current

P050

Motor thermal

protection status

P081

Heatsink

temperature

0.0 to 6553

[ - ]

0.1A

0.0 to 6553

[ - ]

0.1A

0.0 to 6553

[ - ]

0.1A

0 to 250

[ - ]

1%

10.0 to 110.0

[ - ]

0.1oC

Indicates the output currents of phases R, S and T in Amperes.

The True RMS current is indicated individually for each phase.

Accuracy of ±2% for the full scale. (Full scale is 5 x In of

SSW-07/SSW-08).

Indication of the state of motor thermal protection in a scale of

0% to 250%. Being 250 the thermal protection functioning point

of the motor, indicating an error.

The value indicated in this parameter depends on the motor

working condition and how long it has been in this condition, for

example:stopped, starting or in full operation. The thermal class

selected and the nominal power of the motor also influence in this

parameter.

Only a value of approximately 160 can be read if the motor is

operating in full load for over 2 hours with a current equal to the

nominal current times the service factor (In x S.F.@2h).

Indicates the SCR heatsink temperature in ºC.

Range: 10.0°C (50.0°F) to 110.0°C (230.0°F).

P090 to P096

Parameters Regarding

the DeviceNet

Communication

-

Parameters for the DeviceNet interface configuration and

operation. In order to get a detailed description, refer to the

DeviceNet Communication Manual, supplied in electronic format

on the CD-ROM that comes with the product.

6.2. REGULATION PARAMETERS - P100 to P199

(3)

P101

Initial voltage (%Un)

30 to 90

[ 50 ]

1%Un of Motor

Used only on the Voltage Ramp control.

Sets the initial valueof nominal voltage (%Un)thatwill beapplied

to the motor as in figure 6.1.

This parameter must be set to the minimum value to get the

motor rotating.

The initial voltage is applied at a greater or equal to 0.5s after

the Soft-Starter receives the command to start on the motor. This

is the delay time for the power supply isolation contactor to close

the contacts.

U(V)

P101

Start

0

P102

0.5s

Enable

Figure 6.1 - Initial time in a start with voltage ramp

16

Page 17

(3)

P102

Acceleration ramp

time

Range

[Factory Setting]

UnitParameter Description/ Notes

1 to 999

[ 20 ]

1s

When the Soft-Starter is programmed with Voltage Ramp

control, this is the voltage increment ramp time, as seen in the

figure 6.2.

U(V)

P101

0

Figure 6.2 - Acceleration ramp by voltage ramp

When the Soft-Starter is programmed with Current Limitation

Start

P102

Enable Voltage Ramp Disable

100%Un

t(s)

control, this time serves as the maximum starting time, operating

as a protection against blocked rotor.

I(A)

Start

P110

0

I Limitation

I Nominal

Maximum Time

P102

Enable Current Limitation Disable

Figure 6.3 - Current limitation acceleration ramp

t(s)

NOTE!

The time programmed at P102 is not the exact motor acceleration

time, but, the voltage ramp time or the maximum starting time.

Th e mot or acc eler atio n tim e will depe nd on the mo tor

characteristics as well as the load.

17

Page 18

Range

[Factory Setting]

UnitParameter Description/ Notes

P103

Deceleration voltage

degree (%Un)

(3)

P104

Deceleration

ramp time

(3)

P110

Start by current

limitation (%In of the

Soft-Starter)

100 = Inactive

99 to 50

[ 70 ]

1%

0 = Inactive

1 to 240

[ 0 ]

1s

30 to 500

[ 300 ]

1%In of the

Soft-Starter

Used in applications with hydraulic pumps.

Sets the nominal voltage value (%Un) that will be applied to

the motor immediately after the Soft-Starter receives the

deceleration by ramp command.

NOTE!

For this function to turn on a deceleration ramp time must be

programmed.

Used in applications with hydraulic pumps.

Enables and sets the voltage decrement ramp time.

NOTE!

This function is used to lengthen the normal deceleration time of a

load and not to force a lower time than the one imposed by the

load.

Defines the maximum current limit during a motor start as a

percentage of the Soft-Started nominal current.

If the current limit is reached during the motor start, the

Soft-Starter will maintain the current of this limit until the motor

reaches the end of the start.

If the current limit is not reached, the motor will start

immediately.

To select the Control by Current Limitation, see P202.

6.3. CONFIGURATION PARAMETERS - P200 to P299

P200

The password is

(activate/deactivate

password)

(1)(3)

P202

Type of control

0 or 1

[ 1 ]

-

0 or 1

[ 0 = Voltage

Ramp ]

-

P200 Action

0 (Inactive)

1 (Active)

The value of the password is P000=5.

Soft-StarterSSW-07/SSW-08 has two types of starting controls

to best adapt itself to the needs of its application.

Table 6.1 - Enabling the password

Allows the parameter contents to be altered

independent of P000.

Only allows parameter content alterations when P000 is

equal to the password value.

Table 6.2 - Type of control

P202 Description

0 Voltage ramp

1 Current limitation

18

Page 19

Range

[Factory Setting]

UnitParameter Description/ Notes

Starting with voltage ramp:

This is the most commonly used method.

The Soft-Starter imposes the voltage on the motor without any

kind of voltage or current feedback applied to the motor. This is

applied to loads with lower initial torques or quadratic torques.

This kind of control can be used as an initial working test.

Starting by current limitation:

The maximum current level is maintained during the start, being

set according to the needs of the application.

Applied to loads with higher initial torques or constant torques.

This type of control is used to adapt the start to the capacity

limits of the supply network.

P203

Fan Control

(1)

P204

Loads parameters

with factory default

values

0 to 2

[ 2 ]

-

0 to 5

[ 0 ]

-

P203 defines the operation mode of the heatsink cooling fan.

The ventilation kit is an option. Refer to the Optional Devices

Chapter on the User Manual.

The SSW-07/SSW-08 from 17 to 30A models do not need the

ventilation kit.

When in the “fan controlled by software” mode (P203 = 2), the

fan is switched ON when the SCR’s are conducing or when the

heatsink temperature is higher than 65°C. The fan is switched

OFF when the SCR’s are not conducing and the temperature is

lower than 55°C.

Table 6.3 - Options for the fan control

P203 Action

0 The Fan is always OFF

1 The fan is always ON

2 The fan is controlled by software

Reprograms all the parameters to the factory default values,

making P204=5.

Parameters P000,P295, P308 and P312 are not changed when

P204=5 (factory default).

Table 6.4 - Loads parameters with factory default

P204 Action

0 to 4 No function

5 Loads factory default

P205

Selection of the

reading parameter

(3)

P206

Auto-Reset time

0 to 999

[ 1 ]

-

0 = Inactive

1 to 1200

[ 900 ]

1s

Selects which parameters will be shown on the display after

the Soft-Starter is energized.

The value programmedat P205isequal to theparameternumber

that will be shown on the display after it is energized.

If the programmed value corresponds to a non-existent

parameter, the adopted value will be 1=P001.

When an error occurs, except for E04, E10, E24, E28, E3x,

E67 and E77,the Soft-Starter will reset automatically, after passing

the time given by P206.

After the auto-reset, if the same error occurs again three times

consecutively, the auto-reset function will be inhibited. If an error

appears again up to 30 seconds after the auto-reset is executed,

it is considered to be a reoccurrence,

Therefore, if an error occurs four times consecutively, this error

will continue being indicated (and the Soft-Starter will continue to

be disabled) permanently.

NOTE!

For Electronic Motor Overload and Power Overtemperature there

is a specific algorithm for the automatic reset time.

19

Page 20

(1)

P215

Copy function

Range

[Factory Setting]

UnitParameter Description/ Observation

0 to 2

[ 0 ]

-

The copy function is used to transfer the parameter contents

of a Soft-Starter.

Table 6.5 - Copy function

P215 Action Explanation

0 Inactive -

Transfers the present parameter contents of

1

2

Procedure to be used to copy the parameterization of Soft-

Copy

(SSW Keypad)

Paste

(Keypad SSW)

the Soft-Starter to the non-volatile memory

of the keypad (EEPROM).

The present parameters of the Soft-Starter

remain unaltered.

Transfers the contents of the non-volatile

memory of the keypad (EEPROM) to the

present parameters of the Soft-Starter.

Starter A to Soft-Starter B:

1. Connect the keypad to the Soft-Starter from which one wishes

to copy the parameters (Soft-Starter A– source).

2. Set P215=1 (copy) to transfer the parameters of Soft-Starter A

to the keypad. Press the key .

While the copy function is being processed, “COPY” appears on

the display. P215 returns automatically to 0 (Inactive) when the

transfer is concluded.

3. Remove the keypad from Soft-Starter (A).

4. Connect this same keypad to the Soft-Starter which one wishes

to transfer the parameters (Soft-Starter B – destiny).

5. Set P215=2 (paste) to transfer the contents of the non-volatile

memory of the keypad (EEPROM- containing the parameters of

Soft-Starter A) to Soft-Starter B. Press the key. While the

keypad is processing the paste function, “PAST”, an abbreviation

of paste, will appear on the display. When P215 returns to 0 and

is reset, the transfer of the parameters will be concluded. From

this moment on, Soft-Starters A and B will have the same

parameter contents.

Please remember:

If Soft-Starters Aand B command different motors, please check

the motor parameters of Soft-Starter A and B.

For copying the parameter contents of Soft-Starter A to other SoftStarters, repeat procedures 4 and 5 above.

Soft-Starter

A

Parameters

SSW Keypad(copy)

P215=1

Press.

EEPR OM

Figure 6.4 - Copy of the parameters from

“Soft-Starter A” to “Soft-Starter B”

Soft-Starter

B

Parameters

EEPR OM

HMIHMI

Keypad SSW (paste)

P215=2

Press.

20

Page 21

Range

[Factory Setting]

Parameter Description/ Notes

Unit

NOTE!

If the Keypad has saved parameters of a “different version” than

that installed in Soft-Starter SSW-07/SSW-08 to which it is trying

to copy the parameters, the operation will not be executed and

Soft-Starter SSW-07/SSW-08 will display error E10 (Error: Copy

Function not permitted). “Different Version” are those that are

different in “x” or “y”, supposing that the numbering of Software

Versions is described as Vx.yz.

(1)

P219

Parameterization via

keypad / (Trimpots

and DIP Switch)

0 or 1

[ 0 = Trimpots and

DIP Switch ]

-

Defines the programming mode of the following parameters:

P101, P102, P104, P110, P202, P206, P401, P520, P521, P611,

P613, P617, P620 and P640. These parameters are marked in the

quick parameter reference with the observation

0 – “(TrimpotandDIPSwitch) Mode”, programming of the parameters

mentioned above is done through the Trimpots and DIP Switches.

The parameters function as reading parameters, only showing the

programmedvalues through Trimpotsand DIP Switches. The values

programmed through serial communication are not used.

1 – “Keypad Mode”, programming of the parameters mentioned

aboveis done through serial communication or keypad.The values

set in the Trimpots and DIP Switches are not used.

(3)

.

(1)

P220

LOCAL/REMOTE

Source Selection

(1)

P229

Command

selection – local

situation

(1)

P230

Command

selection – remote

situation

0 to 8

[ 3 = Keypad

(Remote Default) ]

-

0 to 3

[ 0 = Keypad ]

-

0 to 3

[ 1 = Terminals ]

-

Defines the supply origin of the command that will select

between the Local and Remote situations.

Table 6.6 – Local/remote origin

P220 Local/Remote Selection Default Situation

0 Always Local Situation Local

1 Always Remote Situation Remote

2 “Loc/Rem” Keypad Local

3 “Loc/Rem” Keypad Remote

4 Digital inputs DI1 to DI3 Status DIx

5 Serial Communication Local

6 Serial Communication Remote

7 Fieldbus Local

8 Fieldbus Remote

Default Situation = When the Soft-Starter is energized

(initialization).

Definesthe origin ofthe on and off commands of the Soft-Starter.

Table 6.7 – Origin of the motor on/off

P229/P230 Origin of the Commands

0 Keypad

1 DIx Digital Inputs

2 Serial Communication

3 Fieldbus

21

Page 22

(1)

P263

DI1 Input function

(1)

P264

DI2 Input function

(1)

P265

DI3 Input function

Range

[Factory Setting]

UnitParameter Description/ Notes

0 to 6

[ 1 = Enable/

Disable (Two

wires) or Start

(Three wires) ]

-

0 to 6

[ 6 = Reset ]

-

0 to 6

[ 6 = Reset ]

-

Check the options available on table 6.8.

The status of the digital inputs can be monitored in parameter

P012.

“Enable/Disable” = DI1 input is Closed/Open, respectively.

Requires the programming of P263 = 1, P264 1 (Enable/Disable

with two wires) and the programming of the Enable/Disable

commands by digital input.

“Start/Stop” = When programming P263 = 1 and P264 = 1

(Start/Stop with Three Wires), inputs DI1 and DI2 become

DI1 = Start and DI2 = Stop. Use push button, DI1 Normally Open

andDI2 Normally Closed. Requires the programmingof the Enable/

Disable commands by digital input.

“Local/Remote” = The digital input is Op en/Closed,

respectively. Do not program more than one digital input for this

function.

“Error Reset” = Resets the errors when the digital input is

closed. Use only push button. When the input remains closed,

the error reset will not act.

“No External Error” = There is no external error if the digital

input is closed.

“General Enable/General Disable” = The digital input is

Closed/Open, respectively. This function allows the motor to turn

on when it is on General Enable and to turn off the motor without a

deceleration ramp when the General Disable command is given.

There is no need to program general enable to turn on the motor

via digital input. If general enable is programmed by digital input,

then it must be closed to allow the motor to turn on, even if the

commands are not by digital inputs.

Table 6.8 – Digital input functions

DIx Parameter

Function

No Function 0 0 0

Enable/Disable or Start (two or

three wires)

Stop (three wires) - 1 -

General Enable - - 1

Local/Remote 2 2 2

No External Error 3 3 3

No Function 4 4 4

No Function 5 5 5

Error Reset 6 6 6

P263

P264

(DI1)

(DI2)

1 - -

P265

(DI3)

22

Page 23

(1)

P277

RL1 Relay function

Range

[Factory Setting]

UnitParameter Description/ Notes

0 to 9

[ 1=Running ]

-

Check the options available on table 6.9.

The status of the relay outputs can be monitored in parameter

P013.

When the function programmed for the relay output is true, the

relay output will be turned on.

(1)

P278

RL2 Relay function

0 to 9

[ 2=Full Voltage ]

-

“No Function” = Relay outputs always turned off.

“Running” = The output is turned on when the Soft-Starter

receives an enabled signal. The output is turned off when the SoftStarter receives the turn off command, or at the end of the

deceleration ramp, if it is programmed.

“Full Voltage” =The output is turned on when the Soft-Starter

reaches 100%Un and turned offwhen itreceives an off command.

“No Fault” =The output is enabled, if the Soft-Starter

SSW-07/SSW-08 is not disabled due to any error.

“Fault” = The output is enabled, if the Soft-Starter SSW-07/

SSW-08 is disabled due to any error.

“Serial” = See the Serial Communication Manual.

Table 6.9 – Relay output functions

RLx Parameter

Function

No Function 0 0

Running 1 1

Full Voltage 2 2

No Function 3 3

No Function 4 4

No Function 5 5

No Fault 6 6

Fault 7 7

No Function 8 8

Serial 9 9

P277

(RL1)

P278

(RL2)

(1)(2)

P295

Nominal current

(1)(2)

P308

Soft-Starter

address

0 to 13

[ According to the

nominal current of

the Soft-Starter

SSW-07/

SSW-08 ]

A

1 to 247

[ 1 ]

-

Table 6.10 – Nominal current configuration

P295 Nominal Current (A)

0 1.7

1 17

2 24

3 30

4 45

5 61

6 85

7 130

8 171

9 200

10 255

11 312

12 365

13 412

ATTENTION!

Never program thisparameter with a current valuethat isnotexactly

like the one for your Soft-Starter SSW-07/SSW-08 model. If this

parameter is programmed incorrectly it can damage the SoftStarter.

Defines the Soft-Starter address in the Modbus-RTU serial

communication network.

For more details, see the Soft-Starter SSW-07/SSW-08 Serial

Communication Manual.

23

Page 24

6.4. COMMUNICATION PARAMETERS – P300 to P399

Range

[Factory Setting]

UnitParameter Description/ Notes

(1)(2)

P312

Type of protocol and

transmission rate of

the serial

communication

P313

Serial

communication

error action (E28)

1 to 9

[ 1=Modbus-RTU

(9600bps, no

parity) ]

-

0 to 3

[ 1=Disable ]

-

Defines the protocol standards of the Modbus-RTU serial

communication.

For more details, see the Soft-Starter SSW-07/SSW-08 Serial

Communication Manual.

Table 6.11 - Modbus-RTU standard and protocol

P312 Action

1

2

3

4

5

6

7

8

9

Table 6.12 – Serial communication error action

Modbus-RTU (9600bps, no parity)

Modbus-RTU (9600bps, odd parity)

Modbus-RTU (9600bps, even parity)

Modbus-RTU (19200bps, no parity)

Modbus-RTU (19200bps, odd parity)

Modbus-RTU (19200bps, even parity)

Modbus-RTU (38400bps, no parity)

Modbus-RTU (38400bps, odd parity)

Modbus-RTU (38400bps, even parity)

P313 Action

0 Inactive

1 Disable

2 General Disable

3 Change to Local

(1)

P314

Serial communication

verification time

0 to 999

[ 0=Inactive ]

1s

Defines the action to be taken if one of the errors related to the

serial communication occurs.

For more details, see the Soft-Starter SSW-07/SSW-08 Serial

Communication Manual.

NOTES!

The Remote /Local k eypad exchanges data with the

microprocessor through serial communication, therefore this

function is also valid for the communication between the keypad

and the Soft-Starter.

If the serial communication is not being used, this parameter

must remain at 0 (Inactive).

If the Soft-Starter does not receive any valid serial telegram

after the time programmed in P314 has passed, a serial error will

occur and the Soft-Starter will take on the action programmed at

P313.

For more details, see the Soft-Starter SSW-07/SSW-08 Serial

Communication Manual.

NOTES!

Th e Remote/Local keyp ad exchanges da ta with the

microprocessor through serial communication, therefore this

function is also valid for the communication between the keypad

and the Soft-Starter.

P331 to P348

Parameters

Regarding the

DeviceNet

Communication

If the serial communication is not being used, this parameter

must remain at 0 (Inactive).

Parameters for the DeviceNet interface configuration and

-

operation. In order to get a detailed description, refer to the

DeviceNet Communication Manual, supplied in electronic format

on the CD-ROM that comes with the product.

24

Page 25

6.5. MOTOR PARAMETERS – P400 to P499

Range

[Factory Setting]

UnitParameter Description/ Notes

(1)

P400

Motor nominal

voltage

1 to 999

[ 380 ]

1V

Set according to the data on the motor plate and corresponding

to the type of attachment.

(1)

P401

Motor current setting

30.0 to 100.0

[ 100.0 ]

0.1%

Sets the value of the motor current in percentage in relation to

the nominal current of the Soft-Starter.

P401 = In_Motor

The value of this parameter is directly related to the actuation

In_SSW

x 100%

levels of the motor current protections.

With P219=0, the parameter content indicates the value set

through the Motor Current trimpot.

With P219=1, the parameter content indicates the value set

through serial communication or keypad.

(1)

P406

Service factor

1.00 to 1.50

[ 1.00 ]

Set the service factor according to the data on the motor plate.

-

6.6. PARAMETERS OF THE SPECIAL FUNCTIONS – P500 to P599

(1)(3)

P520

Voltage pulse at the

start (Kick Start)

(3)

P521

Pulse time at the

start

0 or 1

[ 0=Inactive ]

-

0.2 to 2.0

[ 0.2 ]

0.1s

The Soft-Starter allows for the use of a voltage pulse in the start

for loads that present a great initial resistance to the movement.

Enabled through P520=1 and with the duration time adjustable

at P521.

The voltage level applied during the voltage pulse is defined at

P522.

The voltage pulse works equallyfor voltageramp control and for

current limitation.

P522

Voltage pulse level at

the start (%Un)

70 to 90

[ 80 ]

1%

NOTE!

Only use this function for specific applications where necessary.

U(V)

P522

P101

0 P102

Start 100%Un

t(s)

P521

Enable Voltage Ramp Disable

Figure 6.5 – Voltage pulse at the start

25

Page 26

6.7. PROTECTION PARAMETERS – P600 to P699

InMot

InMot

Range

[Factory Setting]

UnitParameter Description/ Notes

(1)

P610

Phase Loss or

Immediate

Undercurrent

(% In of the Motor)

(1)(3)

P611

Immediate

undercurrent time

or phase loss

(1)

P612

Immediate

overcurrent

(1)(3)

P613

Immediate

overcurrent time

1 to 80

[ 80 ]

1%In of the motor

0=Inactive

1 to 99

[ 1 ]

1s

1 to 200

[ 100 ]

1%In of the motor

0=Inactive

1 to 99

[ 1 ]

1s

The immediate undercurrent parameter P610 defines the

percentage of the motor current below the motor nominal current

that causes a trip.

610P

The immediate undercurrent protection trips when the motor

current remains below motor nominal current by the percentage

set in P610 for the time period set in P611. When it trips, the soft

starter disables the motor andindicates phase loss orundercurrent

error. The undercurrent protection is especially useful in pump

applications, which cannot operate without load.

NOTE!

Even before starting the motor the phase loss is already detected

by means of the synchronism pulses, i.e., this error is detected

through the voltage applied to the power terminals.

The immediate overcurrent parameter P612 defines the

percentage of the motor current above the motor nominal current

that causes the trip.

Imin

inImInMot

%100*

Imax

612P

InMotaxIm

%100*

The immediate overcurrent protection trips when the motor

current remains above motor nominal current by the percentage

set in P612 for the time period set in P613. When it trips, the soft

starter disables the motor and indicates overcurrent error.

NOTE!

Theimmediateovercurrent protectionis activeonlywithfullvoltage,

after the motor has started.

I(A)

P611

Area of Application

Nominal

I(A)

Tripping

t

t(s)

Nominal

Disable

P613

t(s)

Tripping

Overcurrent

t(s)

Start

P612

P610

0

Enable

I(A)

P612

Nominal

P610

Under-

t

Figure 6.6 – Actuation levels for over and undercurrent

Curren t

NOTE!

In order to achieve correct operation of the under- and overcurrent

protection, adjust the motor nominal current, either via trimpot or

via P401.

26

Page 27

(1)

P614

Current imbalance

between phases

(%In of the Motor)

(1)

P615

Current imbalance

time between

phases

Range

[Factory Setting]

UnitParameter Description/ Notes

0 to 30

[ 15 ]

1%In of the

Motor

0=Inactive

1 to 99

[ 0 ]

1s

The current imbalance values are set as a percentage of the

nominal motor current.

P614 sets the maximumvalue of the current difference among

thethree motorphases,which can operate without problems during

the time set at P615. After this time the Soft-Stater turns off,

indicating a current imbalance error.

NOTE!

These functions only work in full voltage, after the motor start.

(1)

P616

Undercurrentbefore

By-pass closing

(1) (3)

P617

Blocked Rotor

(1)(3)

P620

RST Phase

sequence

0 or 1

[ 0=Inactive ]

-

0 or 1

[ 1=Active ]

-

0 or 1

[ 0=Inactive ]

-

When enabled, this function permits undercurrent protection

before the By-pass closing. In other words, it prevents the Bypass from closing during a fault in the power supply network or in

some thyristor.

When disabled, it allows motors to start with a nominal current

lower than 10% of the Soft-Starter nominal current.

When enabled, this function permits protection against a

blocked rotor at the end of the start. In other words, it keeps the

By-pass from closing with an overcurrent greater or equal to 2

times the nominal motor current.

NOTE!

Only disable this function in cases where the motor withstands

superior current duties.

Its function is to protect loads that can only rotate in a single

direction. When enabled, it only allows the phase sequence

R/1L1, S/3L2, T/5L3.

When enabled, the phase sequence is detected every time

the motor is turned on.

Frequently used in applications with hydraulic pumps that

cannot rotate in the opposite direction.

27

Page 28

Range

[Factory Setting]

UnitParameter Description/ Notes

P630

Time interval after

stopping

2 to 999

[ 2 ]

1s

This protection limits the minimum time interval between

the starts after the end of the deceleration ramp.

Un

P630 = 10s

Un

Figure 6.7 – Activation via three wire, digital inputs (DI1 and DI2)

P104 = 0

t

P104 = 6s

t

P630 = 4s

Un

P630 = 10s

Un

Figure 6.8 - Activation via two wire, digital inputs (DI1)

P104 = 0

P104 = 6s

P630 = 4s

t

t

OBSERVATION:

The activate command will only be dealt with after the time

interval programmed at P630 has passed.

NOTES!

1) The time interval initiates its count at the end of the

deceleration ramp.

2) If the control card supply is removed, there will be no time

count.

28

Page 29

(1)(3)

P640

Motor protection

thermal class

Range

[Factory Setting]

UnitParameter Description/ Notes

0=Inactive

1 to 6

[ 6 ]

-

Table 6.13 – Thermal classes

P640 Thermal Class

0 Inactive

1 Class 5

2 Class 10

3 Class 15

4 Class 20

5 Class 25

6 Class 30

Soft-Starter SSW-07/SSW-08 has a rigid,effective andtotally

programmableThermal Protectionto protect your motor.All SoftStarterSSW-07/SSW-08 models havethis protection,which upon

actuation,indicates an overload error and turns the motor off.

This Thermal Protection has curves that simulate the motor

heating and cooling. All calculationsare done through a complex

software that estimates the motor temperature through theTrue

RMS current supplied.

The actuation curves of the motor Thermal Protection are

based on IEC 60947-4-2 standards.

The heating and cooling curves of the motor are based on

many years of WEG motor development. They adopt the IP55

Three Phase Motor as a standardand also consider if the motor

is cooling while activated or not.

The cooling time of the thermal image depends on the motor

power. Inother words, for eachpower there is a different cooling

time. Where there is a need to decrease this time, the P641

can be used.

The estimated value of the motor temperature is saved in

non-volatile memory every time the control card supply is

removed. Therefore, after supplying the control card, the last

saved value will be returned.

The thermal image can be reset, disabling and enabling the

motor overload protection.

Time

t (s)

10000

1000

100

10

S.F. =1

S.F.=1.15

1

1X 2X 3X 4X 5X 6X 7X 8X

1X 2X 3X 4X 5X 6X 7X 8X 9X

9X

10X

Figure 6.9 – Thermal class protection for cold motor

Class 30

Class 25

Class 20

Class 15

Class 10

Class 5

XInmotor

Current

29

Page 30

Range

[Factory Setting]

UnitParameter Description/ Notes

Table 6.14 - Thermal class protection times for cold motor with S.F.=1

ClassMotor

Current

30 20 10

3xIn 101.2s 67.5s 33.7s

5xIn 36.1s 24s 12s

7xIn 18.3s 12.2s 6.1s

Table 6.15 - Thermal class protection times for cold motor with S.F.=1.15

ClassMotor

Current

30 20 10

3xIn 135.1s 90.1s 45.1s

5xIn 47.7s 31.8s 15.9s

7xIn 24.3s 16.2s 8.1s

Time

t (s)

1000

100

10

1

0.1

1X 2X 3X 4X 5X 6X 7X 8X 9X S.F.= 1

Figure 6.10 - Thermal class protection for hot motor with

100%In

Table 6.16 - Thermal class protection times for hot motor

ClassMotor

Current

30 20 10

3xIn 34.4s 23.6s 11.8s

5xIn 12.6s 8.4s 4.2s

7xIn 6.4s 4.2s 2.1s

Class 30

Class 25

Class 20

Class 15

Class 10

Class 5

XIn motor

Current

Table 6.17 – Multiplication factor of the thermal class protection times

for cold motor to obtain the thermal class times for hot motor

Current as a %In of

the Motor

Factor

0%(cold) 1

20% 0,87

40% 0,74

60% 0,61

80% 0,48

100% (rated load) 0,35

30

Page 31

(1)

P641

Thermal memory

auto-reset

Range

[Factory Setting]

UnitParameter Description/ Notes

0 to 600

[ 0=Inactive ]

1s

NOTE!

If there are various thermal classes it is because it is necessary

to program exactly one that best adapts to its application and

protects the motor inside its permitted work duty.

When using a motor with a PTC thermal sensor or thermostat

connected internally to the Soft-Starter, there is no need to enable

the thermal classes, therefore, disable the motor overload

protection. To connect a PTC thermal sensor to the Soft-Starter

SSW-07/SSW-08, it is necessary to use an optional module. See

the chapter Options and Accessories in the SSW-07/SSW-08

User’s Guide.

Sets the time for the auto-reset of the motor thermal image.

This function can be used in applications that need various

starts per hour or shorter time intervals between the motor start

and stop.

The thermal image cooling time depends on the power of the

motor. In other words, for each power there is a different cooling

time.

The thermal image canalso be reset by disablingand enabling

the motor overload protection.

Motor

Tripping

level

Motor

Tripping

level

On

Off

On

Off

Auto-reset

time

Figure 6.11 - Thermal memory auto-reset

E05

Without reset

E05

With reset

t

t

t

t

NOTE!

Remember that using this function can decrease the lifetime of

the motor winding used.

31

Page 32

7. ERRORS AND POSSIBLE CAUSES

When an error is detected, the motor is deactivated and the error is displayed.

To return the Soft-Starter to normal operation after the occurrence of an error, it is necessary to reset it.

This can generally be done in the following ways:

By turning off the power supply and turning it back on (Power-on reset);

Through the reset button in the front panel of the Soft-Starter SSW-07/SSW-08 (Reset button);

Automatically, through the automatic reset (auto-reset);

Via digital inputs (DIx);

By pressing the key of the keypad (manual reset);

By serial communication (Serial).

Description of

the Prote ction

and Fault

Display

Phase loss or

undercurrent

E03

(LED Phase

Loss)

Flashing

Acti vation Description

- At starting:

It occurs when there is no voltage in the

power supply terminals (R/1L1, S/3L2 and

T/5L3) or when the motor is disconnected.

- At full voltage: It trips when the current stays

below the programmed value longer than the

programmed time.

Referring the motor nominal current.

When the parameters are set with the factory

default values, then this protection trips after

elapsing 1 second with phase loss either at

the input or the at the output (motor). It trips

whe n the current c irculating through the

SSW-07/SSW-08 is less than 20% of the

value adjusted at the Motor Current trimpot.

Prob ab le Ca uses

- Percentage values programmed as

the maximum acceptable limit of the

undercurrent (P610) is below the

necessary value for the motor and the

application.

- In hydraulic pump application, it may

be running without load.

- Phase loss in the three-phase

network.

- Short-circuit or thyristor or By-pass

fault.

- Motor not connected.

- Motor connection is incorrect.

- Loose contact in the connections.

- Starting problems with the input

contactor.

- Input fuses are blown.

- Undersized input transformers.

- Incorrect programming of the Motor

Current trimpot.

- Motor with a current consumption

lower than required for phase loss

protection to work.

Rela te d

Par a m eter s

P610

P611

P401

Re set

Power-on.

Manual reset.

Reset key.

Auto-reset.

DIx.

Serial.

Overtemperature

in the power

section

E04

(LED Fault)

Flashes once

(LED Ready)

On

Electronic motor

overload

E05

(LED Overload)

Flashing

- When the heatsink temperature is higher

than the limit value.

- Also works when the temperature sensor

is not connected.

- When the times given by the programmed

thermal class curves are exceeded.

- Load on the shaft too great.

- Elevated number of successive

starts.

- Internal temperature sensor not

connected.

- “Motor Current” trimpot incorrectly set

(setting of the motor current). The set

value too low for the motor being used.

- Starting sequence greater that

allowed.

- Programmed thermal class below the

duty permitted by the motor.

- Time between stopping and starting

below what is permitted by the cooling

time for that motor power.

- Load on the shaft too high.

- Thermal protection saved when the

control is turned off and brought back

when turned back on.

-

Power-on.

Manual reset.

Reset key.

Auto-reset.

DIx.

Serial.

P640

P641

P401

Power-on.

Manual reset.

Reset key.

Auto-reset.

DIx.

Serial.

32

Page 33

Description of

the Prote ction

and Fault

Display

External fault

(DI)

E06

(LED Fault)

Flashes 3 times

(LED Ready)

On

Acti vation Description

-When there is the opening for the digital

input programmed for external fault.

Prob ab le Ca uses

- Open digital input wiring programmed

for external fault.

Rela te d

Par a m eter s

P263

P264

P265

Re set

Power-on.

Manual reset.

Reset key.

DIx.

Serial.

Fault in the Copy

function

E10

Programming

fault

E24

Timeout fault in

telegram

reception

E28

(Communication

module LED

Error)

Flashes once

Keypad

connection fault

E31

Excess current

limit start timeout

E62

(LED Fault)

Flashes twice

(LED Ready)

On

- When the keypad is loaded with

parameters of a different version than

the Soft-Starter.

- When there is an attempt to set a

parameter that is incompatible with the

others.

- When the Soft-Starter stops receiving

telegrams from the master for a period

longer than the one programmed in P314.

- When the physical connection between

the keypad and the Soft-Starter is

interrupted.

- When the starting time is longer than the

time set in the acceleration ramp trimpot.

Active only with a current limit starting.

- Attempt to copy the keypad

parameters to Soft-Starters with

incompatible software versions.

- Attempt to set a parameter that is

incompatible with the others. See table

5.1.

- The timeout time programmed in P314

is shorter than the time between the

telegrams sent by the network master.

- The network master does not send

telegrams cyclically, program P314=0.

- If the serial communication is not

being used, program P314=0.

- For further details, see the Serial

Communication Manual of Soft-Starter

SSW-07/SSW-08.

- Bad-contact in the keypad cable.

- Electric noise in the installation

(electromagnetic interference).

- Time programmed for the acceleration

ramp shorter than what is necessary.

- Programmed current limitation value

too low.

- Locked motor, blocked rotor.

P215

-

P313

P314

-

P102

P110

P202

Power-on.

Manual reset.

Reset key.

DIx.

Serial.

Automatic

reset after

fault

correction.

Automatic

reset after

fault

correction.

Automatic

reset after

fault

correction.

Power-on.

Manual reset.

Reset key.

Auto-reset.

DIx.

Serial.

Stall

E63

(LED Stall)

Flashing

- Activates before full voltage, if the

current is greater than twice the nominal

motor current.

- Programmed acceleration ramp time

lower than the actual acceleration time.

- Locked motor shaft (blocked).

- The transformer that supplies the

motor can be saturating and taking too

much time to recover from the starting

current.

P617

P401

Power-on.

Manual reset.

Reset key.

Auto-reset.

DIx.

Serial.

33

Page 34

Description of

the Prote ction

and Fault

Display

Overcu rrent

E66

(LED

Overcurrent)

Flashing

Acti vation Description

- When the current value is above the

value programmed during the time

programmed. In reference to the nominal

motor current.

- It is only monitored when the SSW-07/

SSW-08 is in full voltage (100% of the

voltage).

- With parameters programmed at factory

default values, this protection turns on

when the motor current passes the value

in 3 times the nominal motor current, for

more than 1s.

Prob ab le Ca uses

- Short-circuit between the phases.

- Momentary motor overload.

- Locked motor shaft, blocked rotor.

Rela te d

Par a m eter s

P612

P613

P401

Re set

Power-on.

Manual reset.

Reset key.

Auto-reset.

DIx.

Serial.

Incorrect

phase

sequence

E67

(LED Phase

Seq)

Flashing

Undervoltage

in the control

suppl y

E70

(LED Fault)

Flashes twice

(LED Ready)

Of f

Internal Bypass relay

contact open

E71

(LED Fault)

Flashes 3

times

- When the sequence of synchronism

signal interruptions does not follow the

RST sequence.

- Activates on when the control supply

voltage is lower than 93Vac.

- When there is a fault with the internal

By-pass relay contacts at full voltage.

- Inverted input network phase

sequence.

- May have been changed in another

place of the supply network.

- Electronic supply lower than the

minimum value.

- Electronics power supply with loose

contact.

- Electronics power supply fuse are

bl own.

- Loose contact in the starting cables

of the internal By-pass relays.

- Defective By-pass relay contacts due

to an overload.

P620

Power-on.

Manual reset.

Reset key.

DIx.

Serial.

-

Power-on.

Manual reset.

Reset key.

Auto-reset.

DIx.

Serial.

-

Power-on.

Manual reset.

Reset key.

Auto-reset.

DIx.

Serial.

(LED Ready)

Of f

Overcu rrent

before the Bypass

E72

(LED Fault)

Flashes 4

times

(LED Ready)

Of f

Current

imbalance

E74

(LED Fault)

Flashes 5

times

(LED Ready)

On

- Activates before the closing of the Bypass if the current is greater than:

37.5A for the SSW models up to 30A;

200A for the SSW models of 45 to 85 A;

260A for the SSW models of 130A;

400A for the SSW models of 171 to 200A.

- When the current value of one of the

phases is above or below the value

programmed, during the time

programmed. In reference to the other

motor phases.

- Programmed acceleration ramp time

shorter than the actual acceleration

time.

- Nominal motor current above the

current tolerated by the Soft-Starter.

- Locked motor shaft, blocked rotor.

- Value programmed at P614 and P615

is beyond the limits tolerated for its

application.

- Voltage loss in one or more phase of

the supply network.

- Phase loss in the supply network.

- Under-dimensioned input

transformers.

- Open input fuses.

- Bad contact in the motor connections

or in the supply network.

-

Power-on.

Manual reset.

Reset key.

Auto-reset.

DIx.

Serial.

P614

P615

Power-on.

Manual reset.

Reset key.

Auto-reset.

DIx.

Serial.

34

Page 35

Description of

the Prote ction

and Fault

Display

Supply network

frequency out

of tolerated

range

E75

(LED Fault)

Flashes once

(LED Ready)

Of f

Acti vation Description

- When the frequency is higher or lower

than the limits of 45Hz to 66Hz.

Prob ab le Ca uses

- The line frequency is out of range.

- When the Soft-Starter + the motor are

being supplied by a generator that is

not supporting the full load regime or

the start of the motor.

Rela te d

Par a m eter s

-

Re set

Power-on.

Manual reset.

Reset key.

Auto-reset.

DIx.

Serial.

Undercurrent

before the Bypass closing

E76

(LED Fault)

Flashes 4 times

(LED Ready)

On

Closed by-pass

contact or

shorted SCR’s

E77

(Fault LED)

flashes 6 times

(Ready LED) is

off

- When at the end of the acceleration

ramp and before the internal By-pass

relay closing, the current is lower than

0.1x the Soft-Starter nominal current

(P295x0.1).

- When there is no opening of the

internal by-pass contact circuit.

- Supply network voltage fault or fault

in the thyristor before the By-pass

closing.

- Incorrect Soft-Starter nominal

current programmed at P295.

- Nominal motor current below the

minimum current.

- P616=0 can be set for tests.

- Bad contact in the relay activation

cables, at either internal or external

by-pas s.

- Defective contacts due to an

overload.

- A short-circuit in parallel or external.

P616

Power-on.

Manual reset.

Reset key.

Auto-reset.

DIx.

Serial.

-

Power-on.

Manual reset.

Reset key.

DIx.

OBSERVATIONS:

When E04 message is displayed (Soft-Starter overtemperature), wait a few minutes for it to cool down

before it can be reset.

When E05 message is displayed (motor overload) wait a few minutes for it to cool down the motor slightly

before the Soft-Starter can be reset.

NOTES!

Fault Actuation Forms:

E24

- Indicates the error code on the keypad display.

- Motor can not be started.

- Switches off the relay that has been programmed to “No Fault”.

- Switches on the relay that has been programmed to “Fault”.

E28:

- Indicates the code in the LED display.

- The actuation form can be configured at P313.

35

Page 36

E31:

- The Soft-Starter proceeds operation normally, depending on how it is programmed at P313 and P314.

- No Keypad commands are accepted.

- Indicates the code on the keypad display.

E70:

- It will not be saved in the last six faults memorywhen the power supply is switched off (line disconnection)

with stopped motor.

OTHER FAULTS:

- Relay is switched off when programmed to “No Fault”.

- Relay is switched on when programmed to “Fault”.

- Motor is switched off, when it is enabled.

- Indicates the fault code in the keypad display and/or on the front cover of SSW-07/SSW-08.

36

Loading...

Loading...