Soft-Starter SSW-07/SSW-08

Serial Communication

Manual

02/2008

Series: SSW-07/SSW-08

Language: English

Document: 0899.5803 / 02

SSW-07/SSW-08

S

ERIAL COMMUNICATION MANUAL

Summary

GENERAL INFORMATION.......................................................................................................................................... 3

SAFETY INFORMATION.............................................................................................................................................. 3

DEFINITIONS.................................................................................................................................................................. 3

USED TERMS ................................................................................................................................................................... 3

NUMERICAL PRESENTATION............................................................................................................................................ 3

1. INTRODUCTION .................................................................................................................................................... 4

2. SOFT-STARTER SSW-07/SSW-08 PARAMETER SETTING ........................................................................... 5

2.1. P308 – SOFT-STARTER SSW-07/SSW-08 ADDRESS ON THE NETWORK ..............................................................5

2.2. P312 – SERIAL PROTOCOL TYPE AND COMMUNICATION RATE ............................................................................ 5

2.3. P313 – ACTION FOR COMMUNICATION ERROR.................................................................................................... 6

2.4. P314 – TIME FOR TIMEOUT DURING THE MESSAGE RECEPTION ............................................................................. 6

2.5. P220 – LOCAL/REMOTE SELECTION ....................................................................................................................7

2.6. P229 – COMMAND SELECTION – LOCAL MODE ................................................................................................... 7

2.7. P230 – COMMAND SELECTION – REMOTE MODE ................................................................................................ 8

3. INTERFACE DESCRIPTION ................................................................................................................................ 9

3.1. RS-232 ................................................................................................................................................................ 9

3.2. RS-485 ................................................................................................................................................................ 9

3.2.1. Use of the RS-485 Kit for the SSW-07/SSW-08......................................................................................... 10

4. ACCESSIBLE DATA VIA SERIAL COMMUNICATION ............................................................................... 11

4.1. PARAMETER OF THE SOFT-STARTER SSW-07/SSW-08 ..................................................................................... 11

4.2. AVAILABLE BASIC VARIABLES FOR THE SOFT-STARTER SSW-07/SSW-08 ...................................................... 11

4.2.1. Basic Variable 1........................................................................................................................................ 12

4.2.2. Basic Variable 3........................................................................................................................................ 13

4.2.3. Basic Variable 8........................................................................................................................................ 14

4.3. CHANGING OF PARAMETERS AND BASIC VARIABLES ........................................................................................14

5. MODBUS-RTU PROTOCOL ............................................................................................................................... 15

5.1. TRANSFER MODES............................................................................................................................................. 15

5.2. MESSAGE STRUCTURE IN RTU MODE ................................................................................................................ 15

5.2.1. Address .....................................................................................................................................................16

5.2.2. Function Code........................................................................................................................................... 16

5.2.3. Data Field................................................................................................................................................. 16

5.2.4. CRC .......................................................................................................................................................... 16

5.2.5. Times between Messages ..........................................................................................................................16

5.3. OPERATION OF THE SOFT-STARTER SSW-07/SSW-08 ON THE MODBUS-RTU NETWORK ................................17

5.3.1. Available Functions and Response Times................................................................................................. 18

5.3.2. Data Addressing and Offset...................................................................................................................... 18

5.4. DETAILED FUNCTION DESCRIPTION................................................................................................................... 20

5.4.1. Function 01 – Read Coils .........................................................................................................................20

5.4.2. Function 03 – Read Holding Register....................................................................................................... 21

5.4.3. Function 05 – Write Single Coil ...............................................................................................................22

5.4.4. Function 06 – Write Single Register ......................................................................................................... 23

5.4.5. Function 15 – Write Multiple Coils ..........................................................................................................24

5.4.6. Function 16 – Write Multiple Registers .................................................................................................... 25

5.4.7. Function 43 – Read Device Identification ................................................................................................ 26

5.4.8. Communication Errors ............................................................................................................................. 28

APPENDIXES................................................................................................................................................................. 30

APPENDIX A - CRC CALCULATION BY USING THE TABLES ............................................................................................ 30

APPENDIX B - CRC CALCULATION BY USING THE REGISTER SHIFT ................................................................................ 31

2

SSW-07/SSW-08

S

ERIAL COMMUNICATION MANUAL

General Information

• Read this manual before installing or operating the Soft-Starter SSW-07/SSW-08.

• All information and safety notice included in this Manual must be strictly followed.

• To ensure physical integrity during operation and avoid damage to equipment and

motors driven by the Soft-Starters SSW-07/SSW-08, provide electromechanical safety

devices.

Safety Information

• Follow strictly all information given in this Manual relating to the cable interconnection

of the two interfaces for the serial communication.

• Electronic boards are fitted with components that are sensitive to electrostatic

discharge. When these boards are handled, take following cares:

- Do not touch the components or connections (connectors) directly with the hands.

When this is unavoidable, touch before a grounded metallic object or adopt proper

grounding procedures.

Definitions

Used Terms

• Parameters: are those existing in the Soft-Starters SSW-07/SSW-08 and that can be

displayed or changed through the Human-Machine-Interface (HMI).

• Basic Variables: internal Soft-Starter SSW-07/SSW-08 values that can be accessed

only through the serial communication. The basic variables are used for monitoring the

status, commands and equipment identification.

• Registers: are internal memory addresses of the Soft-Starter. These registers can be

used for representing the basic variables and the parameters.

• EEPROM: is the non-volatile memory that saves the Soft-Starter SSW-07/SSW-08

parameter even when equipment is switched off.

Numerical Presentation

• Decimal numbers are represented by means of digits without suffix.

• Hexadecimal numbers are represented through the letter ’h’ after the number.

3

SSW-07/SSW-08

S

ERIAL COMMUNICATION MANUAL

1. Introduction

The main purpose of the serial communication is the physical connection between

two or more equipments on the network configured as follows:

MESTRE

PC, CLP, etc.

SLAVE 1

(Soft-Starter 1)

SLAVE 2

(Soft-Starter 2)

. . .

SLAVE N

(Soft-Starter N)

By using this interface, the network master can request several services from every

slave connected on the network. These services may be:

• IDENTIFICATION:

- Equipment Type (frequency inverter, servoconverter, soft-starter)

- Status monitoring

- Error read

• PARAMETER SETTING

- Parameter read (current, voltage, etc.)

- Parameter write for equipment configuration

• COMMANDS

- Enable / Disable

- General Disable

- Error Reset

The Soft-Starter SSW-07/SSW-08 uses the Modbus-RTU protocol for the

communication through the serial interface. This protocol allows the Soft-Starter SSW07/SSW-08 integration into different systems, enabling the connection of several

equipments, such as:

• PC (master) for the parameter setting of one or various Soft-Starters SSW-07/SSW-08

simultaneously.

• SDCD monitoring Soft-Starter SSW-07/SSW-08 variables and parameters.

4

SSW-07/SSW-08

S

ERIAL COMMUNICATION MANUAL

2. Soft-Starter SSW-07/SSW-08 Parameter Setting

Please find below the description of the parameter related to the serial

communication and the operation via Modbus-RTU Protocol of the Soft-Starter SSW07/SSW-08.

2.1. P308 – Soft-Starter SSW-07/SSW-08 Address on the Network

Each slave on the Network shall have a different address, so the master is able to

sent the desired message to the specific slave on the network. This parameter allows

setting the Soft-Starter SSW-07/SSW-08 address on the network.

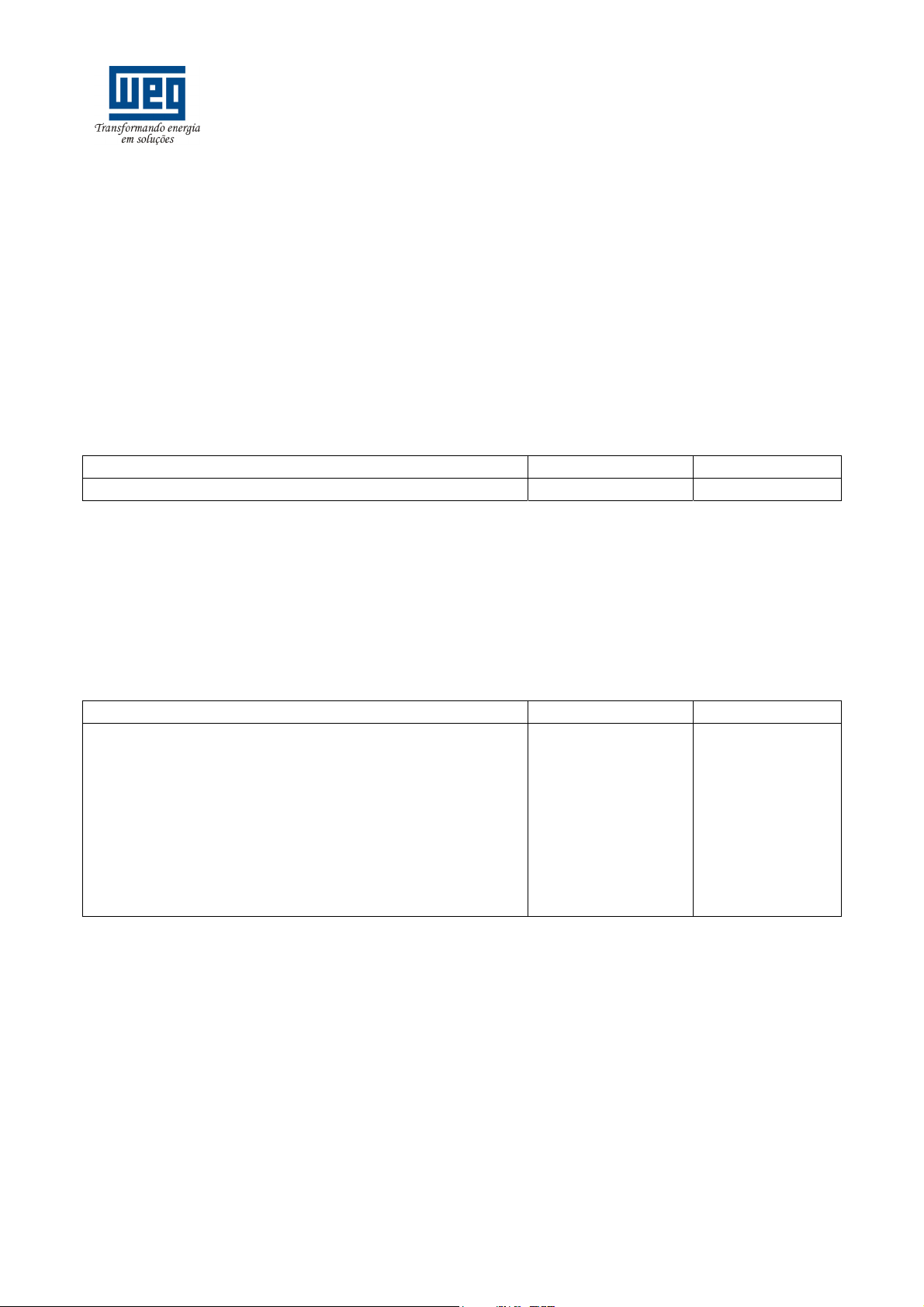

Adjustable Range Factory default Access

1 ... 247 1 Read/Write

The use of a repeater is required if more than 30 equipments are used the same

communication network.

2.2. P312 – Serial Protocol Type and communication rate

The Soft-Starter SSW-07/SSW-08 has one of the following options for the serial

communication through product serial interface:

Adjustable Range Factory default Access

1 = Modbus-RTU, 9600 bit/s, no parity

2 = Modbus-RTU, 9600 bit/s, odd parity

3 = Modbus-RTU, 9600 bit/s, even parity

4 = Modbus-RTU, 19200 bit/s, no parity

5 = Modbus-RTU, 19200 bit/s, odd parity

6 = Modbus-RTU, 19200 bit/s, even parity

7 = Modbus-RTU, 38400 bit/s, no parity

8 = Modbus-RTU, 38400 bit/s, odd parity

9 = Modbus-RTU, 38400 bit/s, even parity

It is required that all equipments, operating on the same network, have the same

communication configuration.

1 Read/Write

5

SSW-07/SSW-08

S

ERIAL COMMUNICATION MANUAL

2.3. P313 – Action for Communication Error

This parameter allows programming an action that the drive shall adopt when a

communication error is detected.

Adjustable Range Factory default Access

0 = No action

1 = Disable

2 = General disable

3 = Changes to LOC

• 0 – No action: if some of the above mentioned error is detected, the SSW-07/SSW-08

remains in the current status and only the detected error is displayed.

• 1 – Disable: SSW-07/SSW-08 will be disabled via voltage ramp when a

communication error is detected.

• 2 – General Disable: in this option, the starter disconnects the motor power supply and

the motor will stop through inertia.

• 3 – Changes to LOC: when the Soft-Starter SSW-07/SSW-08 is operating in remote

mode and a communication error is detected, it changes automatically to local mode.

For the serial interface, only the timeout error during the reception (E28 – Serial

Communication is inactive) will be considered as communication error. The timeout during

the reception is set through the Parameter P314.

The Error LED of the communication module indicates the E28 error. The error E28

is active when the LED is flashing.

NOTE!

The commands Disable and Change to LOC can be executed only when these commands

are controlled via serial communication. This setting is executed through the Parameters

P220, P229 e P230.

1 Read/Write

2.4. P314 – Time for timeout during the message reception

This function allows programming the time for the timeout detection during the

message reception. The value 0 (zero) disables this function.

When the drive is controlled via serial communication and a communication

problem to the Master is detected (cable rupture, voltage drop, etc.), it will not be possible

to send a command to the serial for the equipment disable. In application where this will be

a problem, you can set P314 to a longer interval within the SSW-07/SSW-08 can receive a

valid serial message. Otherwise SSW-07/SSW-08 will interpret this as a serial

communication error.

6

SSW-07/SSW-08

S

ERIAL COMMUNICATION MANUAL

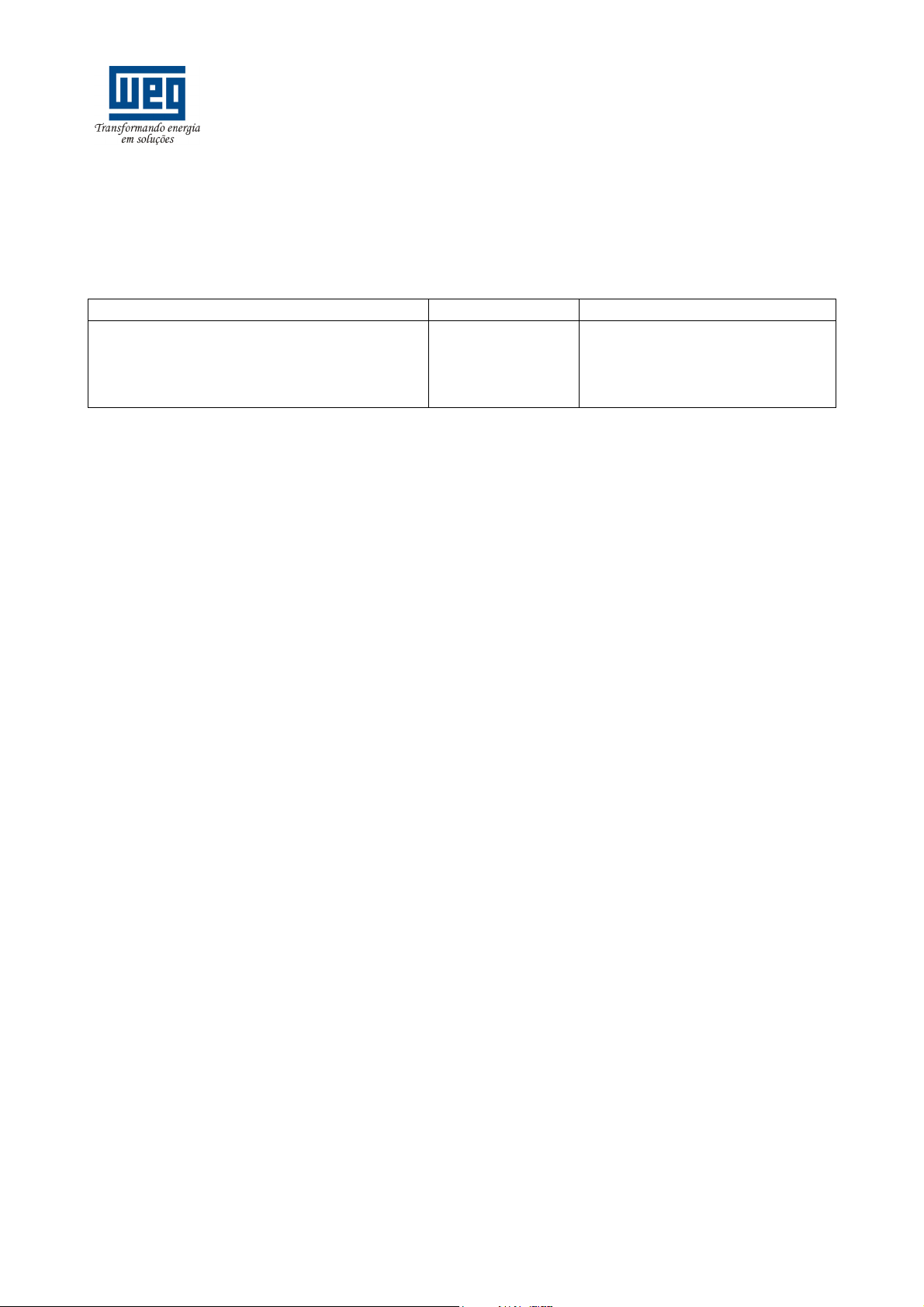

Adjustable Range Factory default Access

0 = Disabled function

0 ... 999 seconds

When this time has been programmed, however the SSW-07/SSW-08 remains for

longer time than the programmed one without receiving valid serial messages, it will

display E28 and it will adopt the action programmed in P313. After the communication is

restored again, the E28 display will be deleted.

NOTE!

• When this function is disabled, you must ensure that the network master sends

messages periodically to the slave, always considering the set time and thus

preventing the timeout error detection during the communication.

• The detection of E28 will also reset the values of the basic variables 8 (see item 4.2).

0 Read/Write

2.5. P220 – Local/Remote Selection

This function enables programming the command source that controls the

Local/Remote mode selection.

Adjustable Range Factory default Access

0 = Always Local

1 = Always Remote

2 = Keypad (standard is local)

3 = Keypad (standard is remote)

4 = DI1...DI3

5 = Serial (standard is local)

6 = Serial (standard is remote)

7 = Fieldbus (standard is local)

8 = Fieldbus (standard is remote)

If the control of the operating mode via serial is preferred, you must set this

parameter to 5 or 6. The display "standard local" or "standard remote" informs which

operation mode shall be activated after the equipment has been started.

3 Read/Write

2.6. P229 – Command Selection – Local Mode

This function allows programming the command source of the Soft-Starter SSW07/SSW-08 when the Soft-Starter SSW-07/SSW-08 has been set to Locale mode.

7

SSW-07/SSW-08

S

ERIAL COMMUNICATION MANUAL

Adjustable Range Factory default Access

0 = Keypad

1 = DI

2 = Serial

3 = Fieldbus

If the command control via serial communication in local mode is desired, you must

set Parameter P229=2.

0 Read/Write

2.7. P230 – Command Selection – Remote Mode

This function enables selecting the Soft-Starter SSW-07/SSW-08 command source

when the SSW-07/SSW-08 has been set to Remote Mode.

Adjustable Range Factory default Access

0 = Keypad

1 = DI

2 = Serial

3 = Fieldbus

If the command control via serial communication in local mode is desired, you must

set P230 = 2.

1 Read/Write

8

3. Interface Description

3.1. RS-232

To use the RS-232 with the Soft-Starter SSW-07/SSW-08 is necessary to install the

Modbus RTU RS-232 Kit.

For more information see the RS-232 Installation Guide.

SSW-07/SSW-08

S

ERIAL COMMUNICATION MANUAL

This interface enables the connection of the master to a Soft-Starter SSW-07/SSW08 (point-to-point) at distances up to 10m. For the communication with the master you

must use one wire for the transmission (TX), one wire for the reception (RX) and one wire

for the reference (PE).

3.2. RS-485

To use the RS-485 with the Soft-Starter SSW-07/SSW-08 is necessary to install the

Modbus RTU RS-485 Kit.

For more information see the RS-485 Installation Guide.

When the interface RS-485 is used, the master can control several drives

connected to the same bus. The Modbus-RTU protocol allows the connection of up to 247

slaves (1 for each address), provided also signal repeaters are used along the bus.

This interface has a good noise immunity allowing cable lengths up to 1000 m.

9

SSW-07/SSW-08

S

ERIAL COMMUNICATION MANUAL

3.2.1. Use of the RS-485 Kit for the SSW-07/SSW-08

The RS-485 Kit of the Soft-Starter SSW-07/SSW-08 comprises basically an

interface board and the respective product installation instructions.

Following procedures should be adopted during the network installation when this

interface is used:

• For the transmission the signals A and B use a shielded twisted pair of wire. These

signals must be connected to the terminals A and B.

• The terminal COM is used for the connection of the reference signal to the RS-485

circuit. This connection is not required when this signal is not used.

• All RS-485 network connected devices must be grounded properly, preferably to the

same ground point. Also the cable shield must be grounded. The shielding can be

grounded at the connector XC42. If the shielding is grounded in another point, use the

COM connection for the shielding.

• The network cable must be laid separately (if possible) distant from the power supply

cables.

• Terminating resistor must be provided on the first and last device connected to the

main bus. The RS-485 interface board is already fitted with witches for enabling this

resistor. For this, set both switches to 'on'.

10

Loading...

Loading...