Soft-Starter

Arrancador Suave

Soft-Starter

Sanftanlaufgerät

SSW-06

Motors | Energy | Automation | Coatings

User's Guide

Manual del Usuario

Manual do Usuário

Bedienungsanleitung

SOFT-STARTER

MANUAL

Series: SSW-06

Software:version1.6X

Language:English

Document: 0899.5854 / 12

ATTENTION!

It is very important to check if the

Soft-Starter Software is the same as

mentioned above.

08/2009

Summary of Revisions

The tablebelowdescribes the revisions made to this manual.

Revision Description Section

1 First edition 2 General revision 3 General revision 4 New software version 5 Implementation of the following current: 412A, Chap 3

480A, 604A, 670A, 820A, 950A, 1100A and 1400A. and 10

New software version with: braking methods 3, 4, 6

FWD/REVandJog. and 8

P140 was changed. E73 was eliminated.

E71 and E77 were changed.

6 General revision -

7 New software version with: new states in P006, Chap 4,

full voltage and starting diagnostic functions, 6 and 8

storage of the 6 last errors, consumed energy,

torque and power protections, motor thermal

protection alarm, selection between alarm or fault,

automatic detection of the acceleration end with

voltage ramp, fast visualization of the parameters

through the key, detection of the

Profibus DP master in Stop, and the PLC Software,

inclusion of the E11, E18, E57, E58 and E59.

8 Change of the table 3.1 and figures 10.1, 10.3, Chap 3 and

10.4, 10.5, 10.6 and 10.7. 10

9 Implementation of the following current: -

10A, 16A, 23A, 30A, 45A e 60A.

11 New line voltage of 690V for standard motor -

connection.

12 New software version with: digital inputs -

DI1, DI2 and DI3 programmable for the

same functions, new current models of

1000A and 1300A in P295, new option of

Fatal Fault for P313, disable of the E77 Fault

through the P621 for use in multimotor

applications, new MMC block for SoftPLC,

new P951 parameter for enable of the IOs

expansion card for SoftPLC, new

emergency start through digital input.

Newoptional kits KFB-DNIP, K-USB, K-IOE and K-ECA.

Summary

Quick Parameter Reference,

Fault and Status Messages

IParameters........................................................................................... 09

II FaultorAlarm Messages..................................................................... 20

III OtherMessages................................................................................. 20

CHAPTER 1

Safety Notices

1.1 Safety Notices in the Manual............................................................ 21

1.2 Safety Notices on the Product .......................................................... 21

1.3PreliminaryRecommendations ......................................................... 22

CHAPTER 2

General Information

2.1About this Manual............................................................................. 23

2.2SoftwareVersion............................................................................... 23

2.3Aboutthe Soft-StarterSSW-06 ......................................................... 23

2.4Soft-Starter SSW-06Identification .................................................... 27

2.5Receiving andStorage ...................................................................... 29

CHAPTER 3

Installation and Connection

3.1Mechanical Installation ..................................................................... 30

3.1.1EnvironmentConditions .............................................................. 30

3.1.2Dimensions of the Soft-Starter SSW-06...................................... 30

3.1.3 Positioning / Fixing..................................................................... 31

3.1.3.1 Mounting inside a Panel .................................................... 32

3.1.3.2Mounting on a Surface....................................................... 35

3.2 Electrical Installation......................................................................... 36

3.2.1Power Terminals.......................................................................... 37

3.2.2Locationofthe Power/Grounding,Control Connectionsand

Fan VoltageSelection................................................................. 42

3.2.3Recommended Power/GroundingCables.................................... 43

3.2.4Connectionof the Power Supplyto the Soft-Starter .................... 46

3.2.4.1 Power Supply Capacity ..................................................... 46

3.2.4.2RecommendedFuses ....................................................... 47

3.2.5Connectionof the SSW-06Soft-Startertothe motor................... 48

3.2.5.1 StandardThree-WireConnection (P150=0=Inactive).......... 48

3.2.5.2InsideDeltaMotor Connection(P150=1=Active) ............... 49

3.2.6Grounding Connections .............................................................. 50

3.2.7Fan Connections ........................................................................ 51

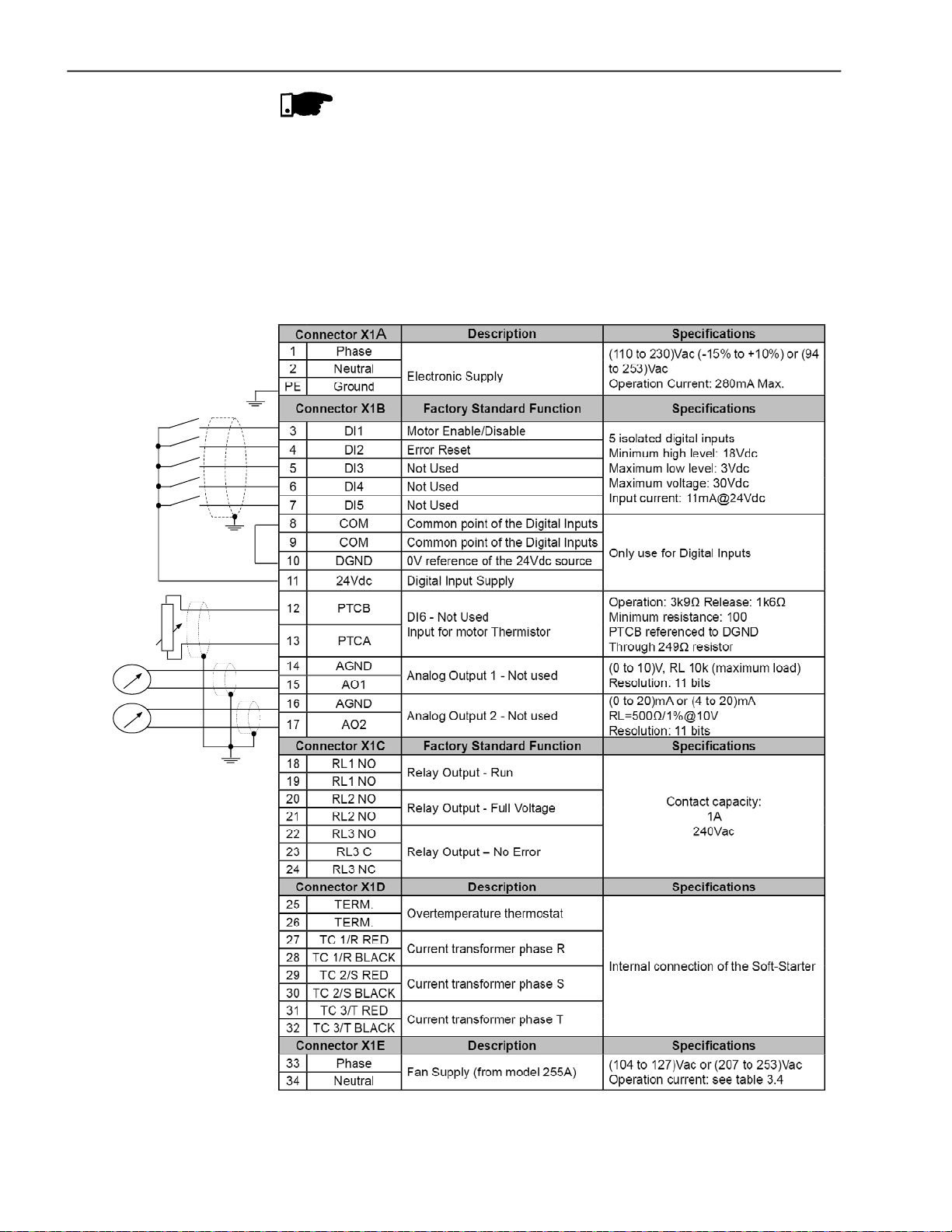

3.2.8Signaland Control Connections.................................................. 52

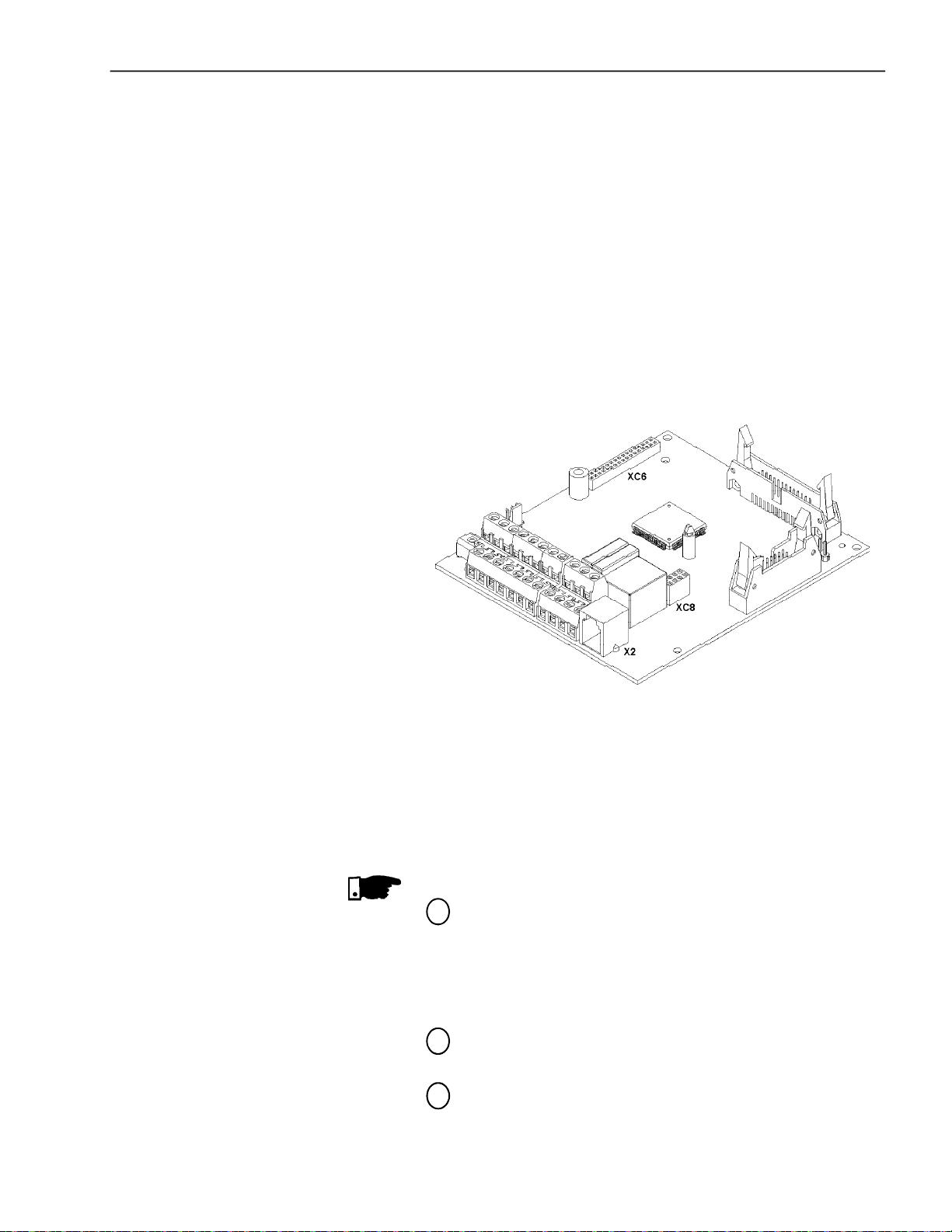

3.2.9RS-232,X2SerialCommunicationConnection ........................... 55

3.2.10XC8SerialCommunication Board Connection .......................... 55

3.2.11XC6FieldbusCommunicationBoardConnection ...................... 55

Summary

3.3RecommendedSet-Ups.................................................................... 55

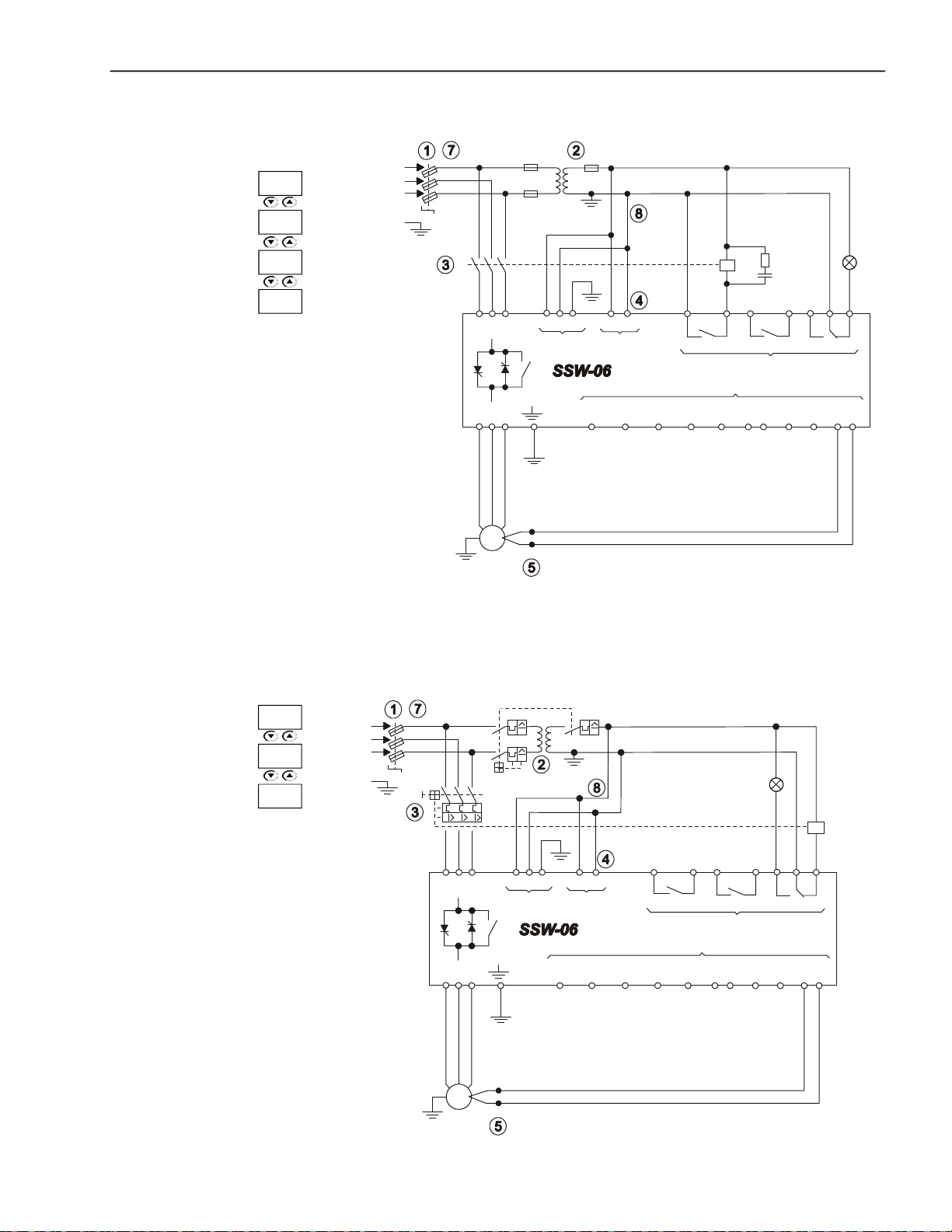

3.3.1RecommendedSet-upsusingKeypadCommand

with Isolating Contactor.............................................................. 57

3.3.2RecommendedSet-upsusingKeypadCommand

withCircuit-breaker .................................................................... 57

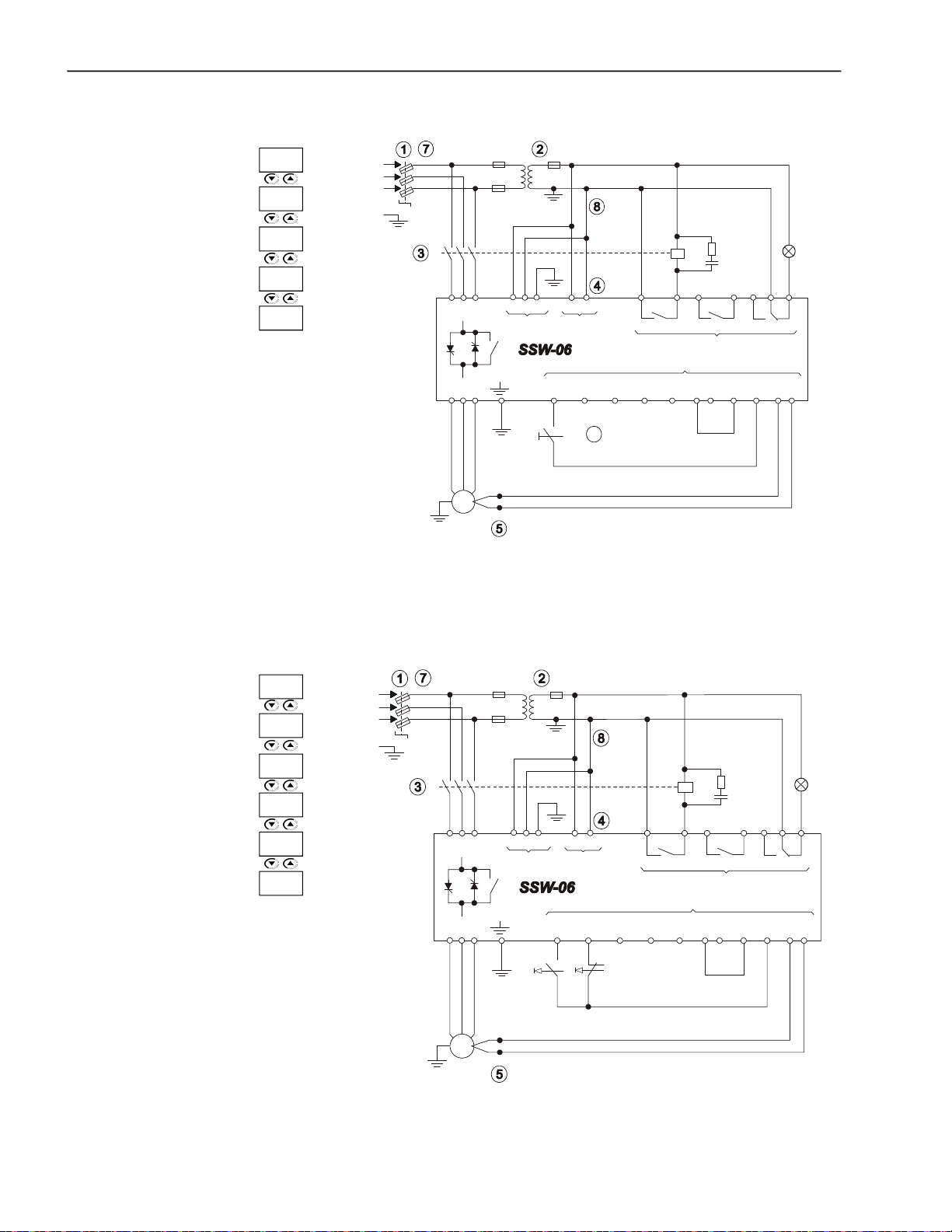

3.3.3Recommended Set-ups withCommandviaTwo-wire

Digital Inputs .............................................................................. 58

3.3.4RecommendedSet-upswith CommandviaThree-wire

Digital Inputs .............................................................................. 58

3.3.5RecommendedSet-upswith CommandviaThree-wire

Digital Input and Inside Delta Motor Connection. ........................ 59

3.3.6RecommendedSet-upswith CommandviaThree-wire

Digital Input or Serial Communication. ....................................... 59

3.3.7RecommendedSet-upswith CommandviaThree-wire

Digital Input or Fieldbus Communication. ................................... 60

3.3.8Recommended Setup withCommand viaDigitalInputs

and direction of rotation............................................................. 60

3.3.9Recommended Setup withCommand viaDigitalInputs

andReverse Braking .................................................................. 61

3.3.10RecommendedSetupwithCommand via Digital Inputs

and Optimal Braking ................................................................ 61

3.3.11 RecommendedSetupwithCommand via Digital Inputs

and DC-Braking......................................................................... 62

3.3.12RecommendedSetupwithCommand via Digital Inputs

and External By-pass Contactor .............................................. 62

3.3.13 Symbols ................................................................................... 63

3.4 EuropeanDirectivesfor ElectromagneticCompatibility

Requirements for Installation ........................................................... 64

3.4.1Installation .................................................................................. 64

CHAPTER 4

Keypad Operation

4.1Descriptionof the Keypad(HMI-SSW-06)......................................... 65

4.2 Use of the Keypad ............................................................................ 67

4.2.1Keypadusefor Soft-Starter SSW-06Operation .......................... 67

4.2.2 Keypad Display - SignallingIndications ...................................... 68

4.2.3Parameterviewing and programming .......................................... 69

CHAPTER 5

Start-up

5.1Power-up Preparation ....................................................................... 71

5.2InitialPower-up (requiredparametersettings) ................................... 72

5.3Start-up .............................................................................................79

5.3.1Start-up:OperationviaKeypadType of Control: VoltageRamp... 79

Summary

CHAPTER6

Detailed Parameter Description

6.1Access and Read Only Parameters - P000 to P099 ......................... 82

6.2 Regulation Parameters - P100 to P199............................................. 92

6.3ConfigurationParameters - P200 to P299......................................... 101

6.4 Serial Communication Parameters - P300 to P399........................... 114

6.5 Motor Parameters - P400 to P499 .................................................... 116

6.6 Special Function Parameters - P500 to P599 ................................... 117

6.7 Protection Parameters - P600 to P699 ............................................. 123

6.8 Selection Between Fault andAlarm - P700 to P790 ......................... 132

6.9 SoftPLC Parameters - P950 to P999 ................................................ 134

CHAPTER7

Programming Information and Suggestions

7.1Applicationsand Programming ......................................................... 135

7.1.1StartingbyVoltageRamp (P202=0)............................................ 137

7.1.2 Startingby Current Limit (P202=1).............................................. 138

7.1.3StartingbyCurrentRamp withHigh Initial Current(P202=4)....... 139

7.1.4StartingbyCurrentRamp withLow Initial Current(P202=4)........ 140

7.1.5StartingwithPump Control(P202=2).......................................... 141

7.1.6Starting with TorqueControl(P202=3)......................................... 143

7.1.6.1Loads with ConstantTorque (P202=3and P120=1 point) ... 144

7.1.6.2Loadswith Higher InitialTorque

(P202=3 and P120=3 points) ............................................. 144

7.1.6.3Loadswith ConstantTorque andS SpeedCurve

(P202=3 and 120=3 points)................................................145

7.1.6.4LoadswithQuadraticTorque and SSpeedCurve

(P202=3 and P120=2 points) .............................................. 145

7.1.6.5LoadswithQuadratic TorqueandLinearSpeedCurve

(P202=3 and P120=3 points) ............................................. 146

7.1.6.6LoadswithQuadraticTorque and Higher InitialTorque

(P202=3 and P120=3 points) .............................................. 146

7.1.6.7HydraulicPump Load Type(P202=3) ................................. 147

7.2ProtectionsandProgramming .......................................................... 150

7.2.1ThermalClasses......................................................................... 150

7.2.1.1 Suggestions on How to Set Thermal Class ........................ 150

7.2.1.2 Example on How to Set the Thermal Class ........................ 151

7.2.1.3TimeReductionWhenChangingfrom ColdStartingto

Hot Starting........................................................................ 152

7.2.1.4ServiceFactor .................................................................... 152

7.2.2Under-andOver-Protections...................................................... 153

7.2.2.1UndervoltageandOvervoltageprotection ............................ 153

7.2.2.2Underload Protection .......................................................... 153

7.2.2.3OverloadProtection ............................................................ 153

Summary

CHAPTER8

Diagnostics and Troubleshooting

8.1 Faults and Possible Causes ............................................................. 155

8.2Troubleshooting ................................................................................ 160

8.3 TechnicalAssistanceContacting ...................................................... 160

8.4PreventiveMaintenance .................................................................... 161

8.4.1CleaningInstructions .................................................................. 162

8.5 SparePart List.................................................................................. 163

CHAPTER 9

Options and Accessories

9.1Remote KeypadandCables ............................................................. 165

9.2RS-485for theSoft-Starter SSW-06 ................................................. 167

9.2.1RS-485CommunicationKit(KRS-485) ....................................... 167

9.2.2OptionalModuleMIW-02 ............................................................ 168

9.3 Fieldbus Communication Kits ........................................................... 168

9.3.1 FieldbusDeviceNetCommunicationKit (KFB-DN) ................... 168

9.3.2 Fieldbus Profibus DP CommunicationKit (KFB-DP) ................ 169

9.3.3 Fieldbus Profibus DP-V1CommunicationKit(KFB-PDPV1) ..... 169

9.3.4 FieldbusDeviceNet DriveProfileCommunication Kit (KFB-DD). 169

9.3.5 Fieldbus EtherNet/IP Communication Kit (KFB-ENIP).............. 170

9.4 USB.................................................................................................. 170

9.4.1 USB Communication Kit (K-USB) .............................................. 170

9.5 DigitalInputs and Outputs Expansion Card ..................................... 170

9.5.1 Digital Inputs and Outputs Expansion Kit (K-IOE)...................... 171

9.6 External CurrentAcquisition ............................................................. 171

9.6.1 External Current Acquisition Kit (K-ECA) ................................... 171

CHAPTER10

Technical Specifications

10.1Currents and RatingsAccording to UL508 ...................................... 173

10.2 Currents and Ratings for IP55, IV PoleWeg Motor......................... 175

10.3 PowerData..................................................................................... 177

10.4 Electronics/Programming Data....................................................... 177

10.5 MechanicalData............................................................................. 179

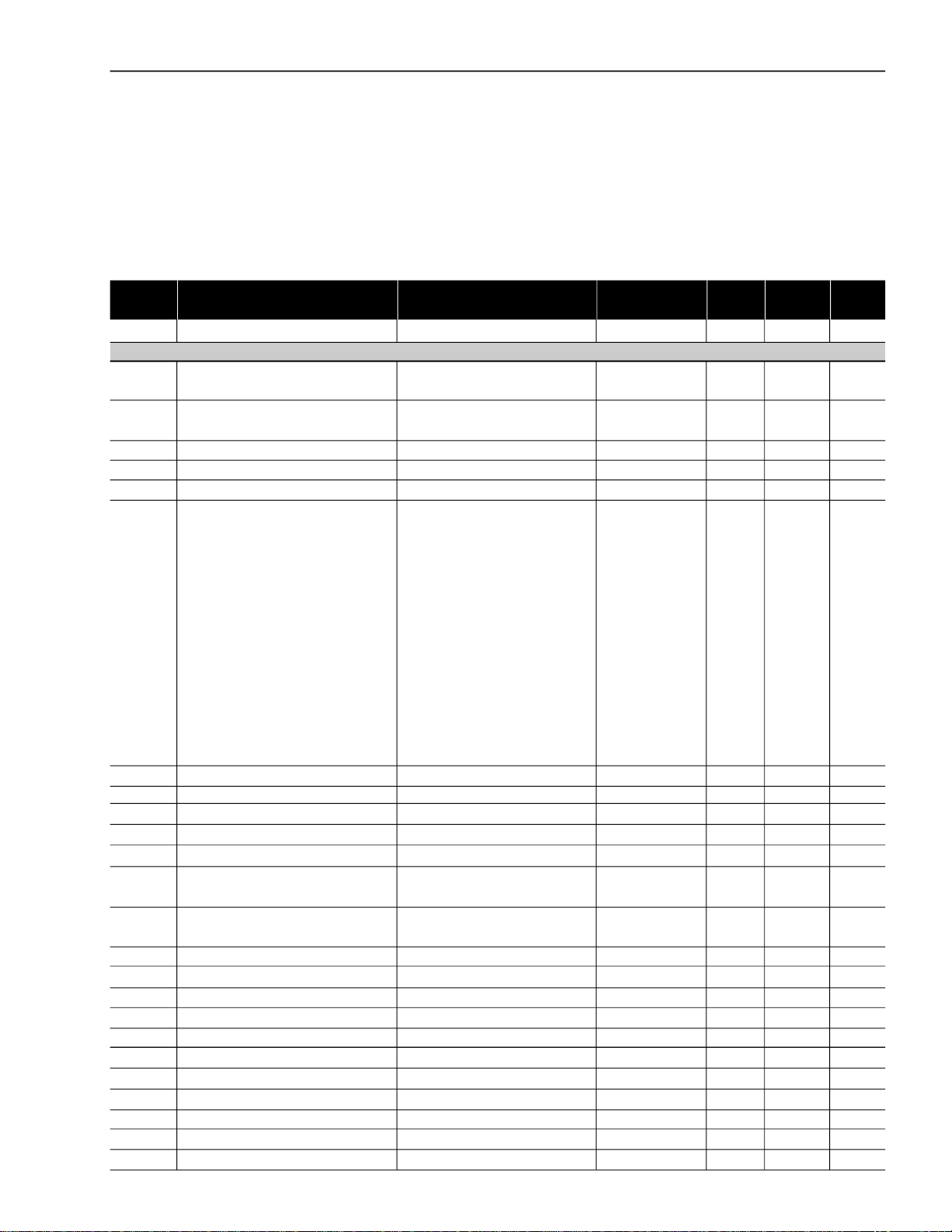

SSW-06- QUICK PARAMETERREFERENCE

QUICK PARAMETER REFERENCE, FAULT AND STATUS MESSAGES

Software:V1.6X

Application:

Model:

SerialNumber:

PersonResponsible:

Date: / / .

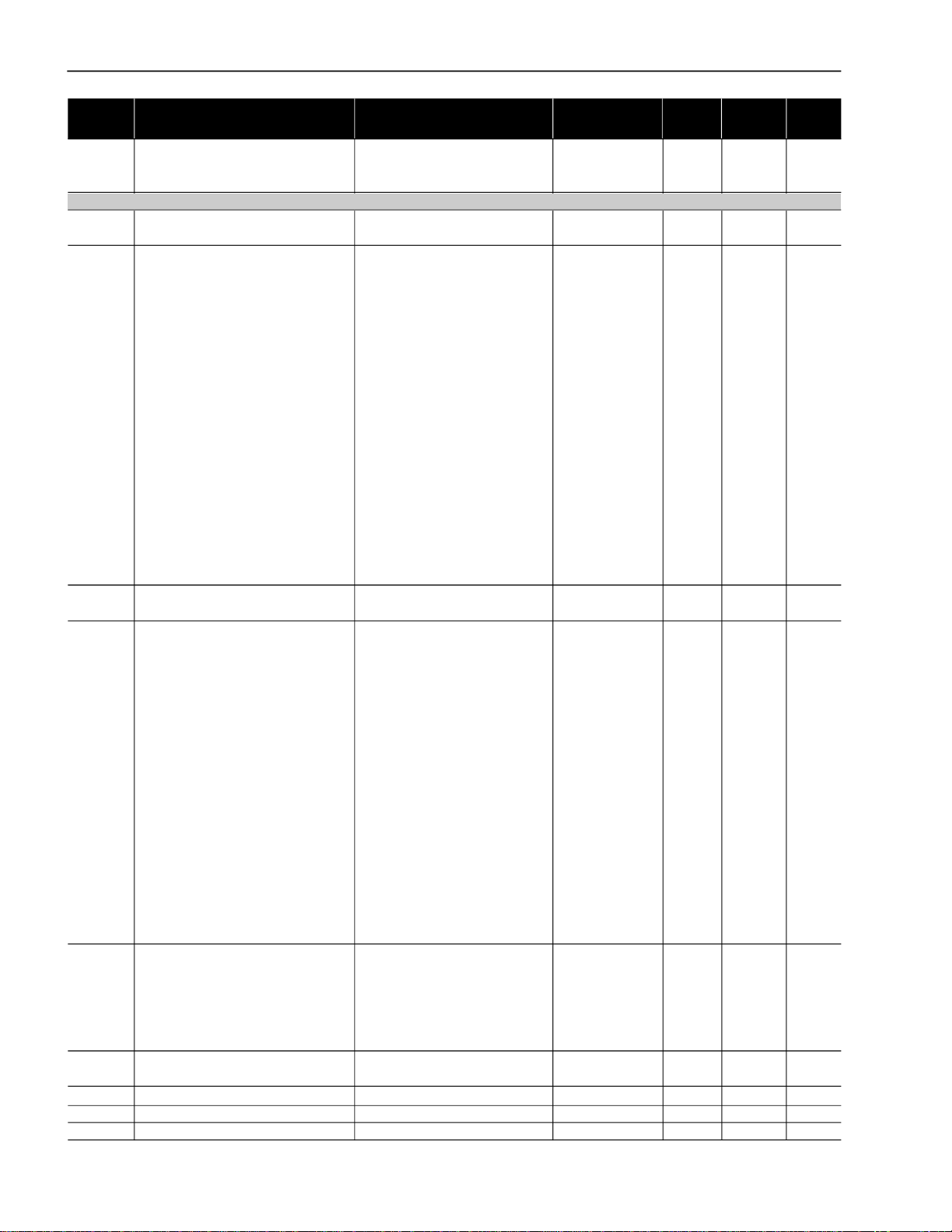

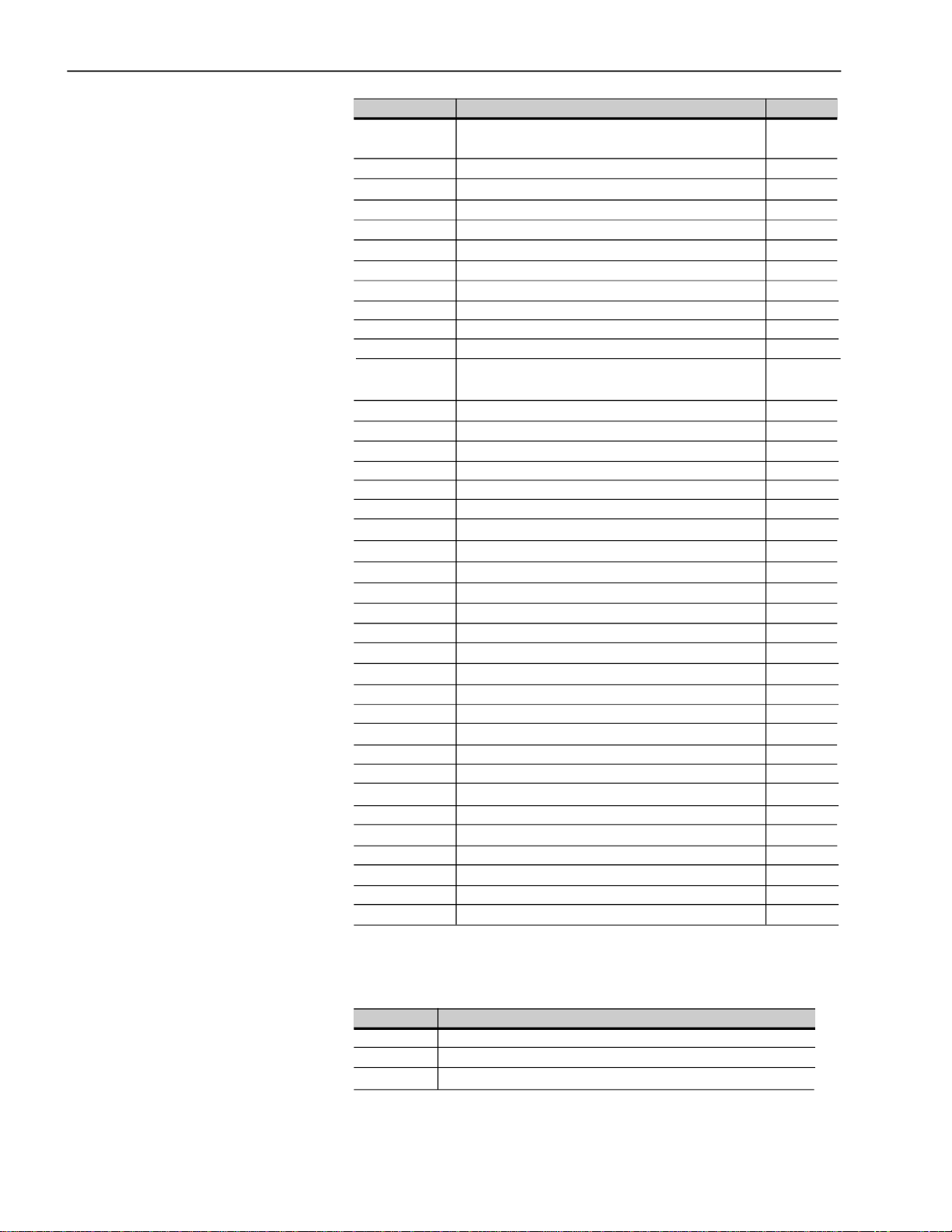

I.Parameters

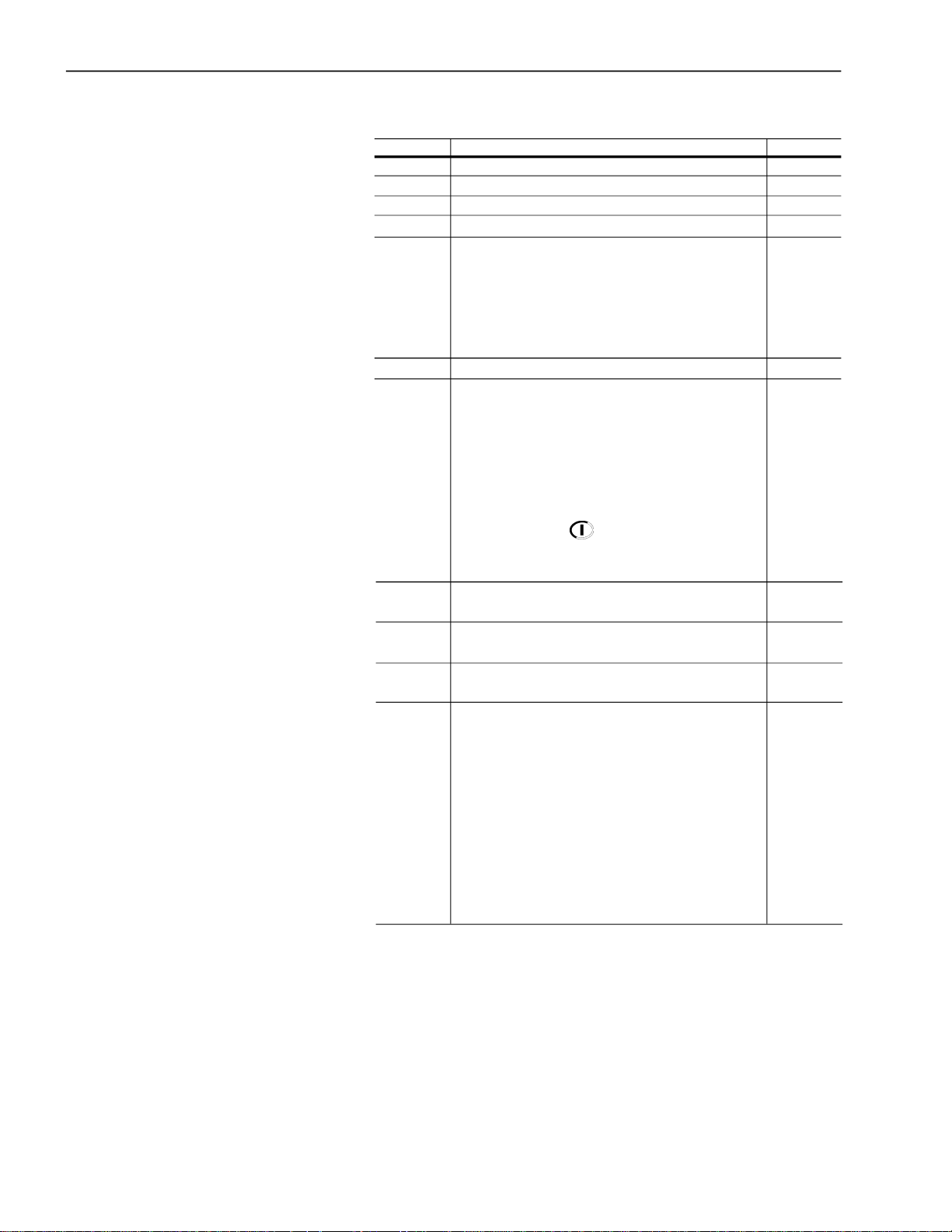

Parameter Description Adjustable Range

P000 Parameter Access 0 to 999 0 - 82

READONLY PARAMETERS P001 to P099

P001 Soft-Starter Current 0 to 999.9 - % 83

(%In of the Soft-Starter)

P002 Motor Current 0 to 999.9 - % 83

(%In of the Motor)

P003 Motor Current 0 to 9999.9 - A 83

P004 Line Voltage 0 to 999 - V 83

P005 Line Frequency 0 to 99.9 - Hz 83

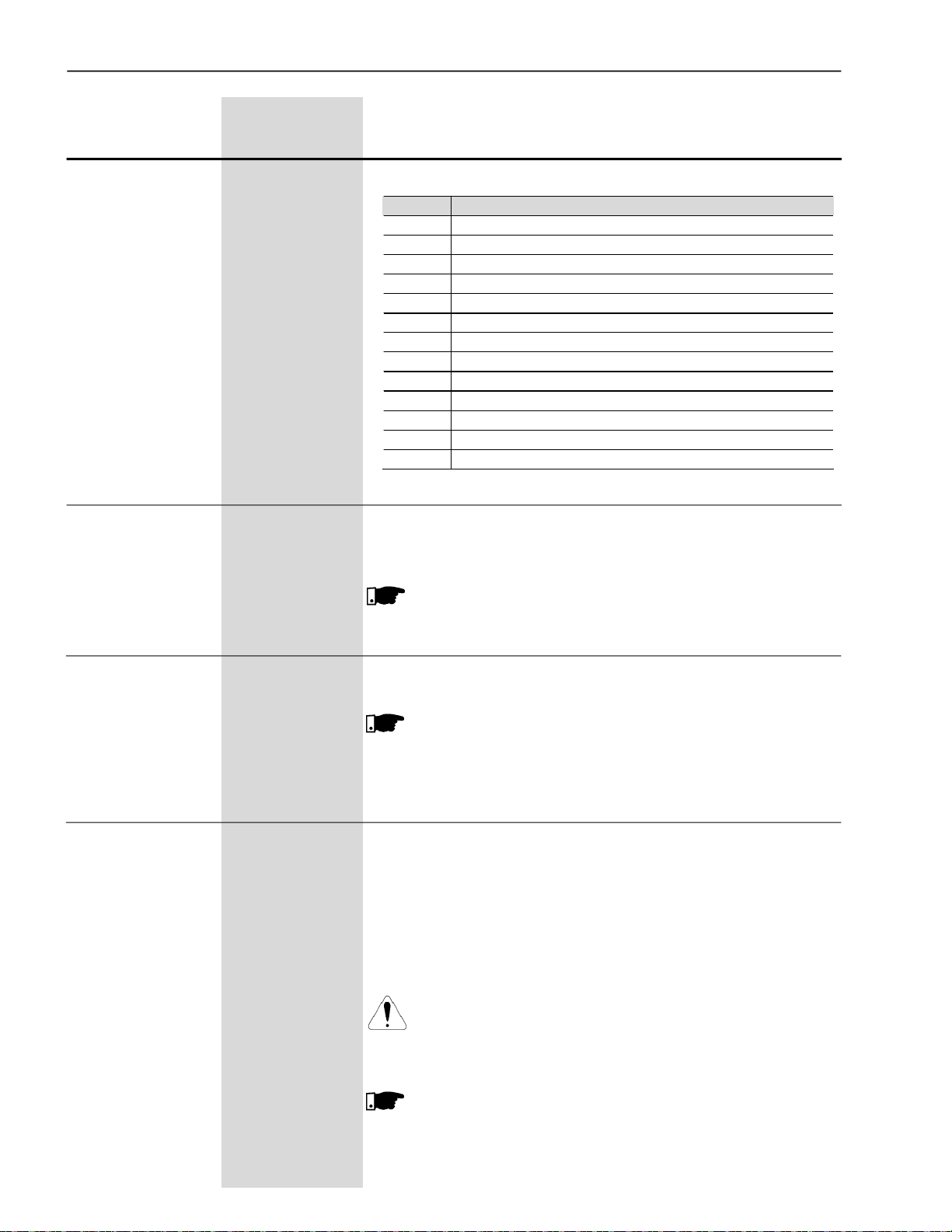

P006 Soft-Starter Status 0=Ready - - 84

1=InitialTest

2=Error

3=Ramp Up

4=FullVoltage

5=By-pass

6=Reserved

7=Ramp Down

8=Braking

9=FWD/REV

10=JOG

11=Delay P630

12=GeneralDisable

P007 Output Voltage 0 to 999 - V 84

P008 Power Factor 0 to 1.00 - - 84

P009 Motor Torque (% Tn of the Motor) 0 to 999.9 - % 84

P010 Output Power 0 to 6553.5 - kW 85

P011 Apparent Output Power 0 to 6553.5 - kVA 85

P012 Dl1toDI6Status 0=Inactive - - 85

1=Active

P013 RL1, RL2 and RL3 Status 0=Inactive - - 86

1=Active

P014 Last Fault 0 to 99 - - 86

P015 Second Previous Fault 0 to 99 - - 86

P016 Third Previous Fault 0 to 99 - - 86

P017 Fourth Previous Fault 0 to 99 - - 86

P018 Fifth Fault 0 to 99 - - 86

P019 Sixth Fault 0 to 99 - - 86

P020 Current Fault 0 to 99 - - 87

P021 CurrentAlarm 0 to 99 - - 87

P023 Software Version X.XX - - 87

P027 AO1 Output Value 0 to 10.000 - V 87

P028 AO2 Output Value 0 to 20.000 or 4.000 to 20.000 - mA 87

Factory

Setting Setting

Unit

User´s

Page

9

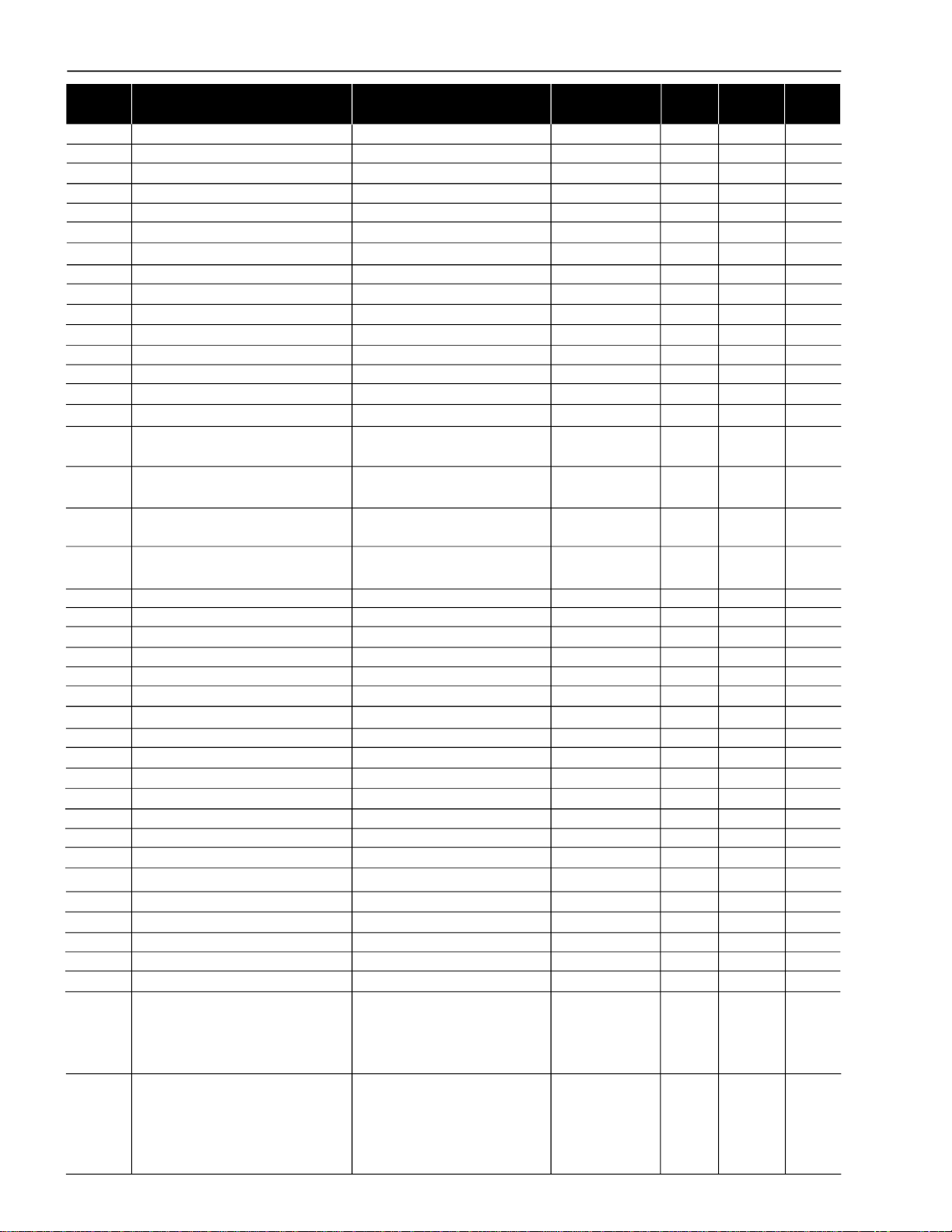

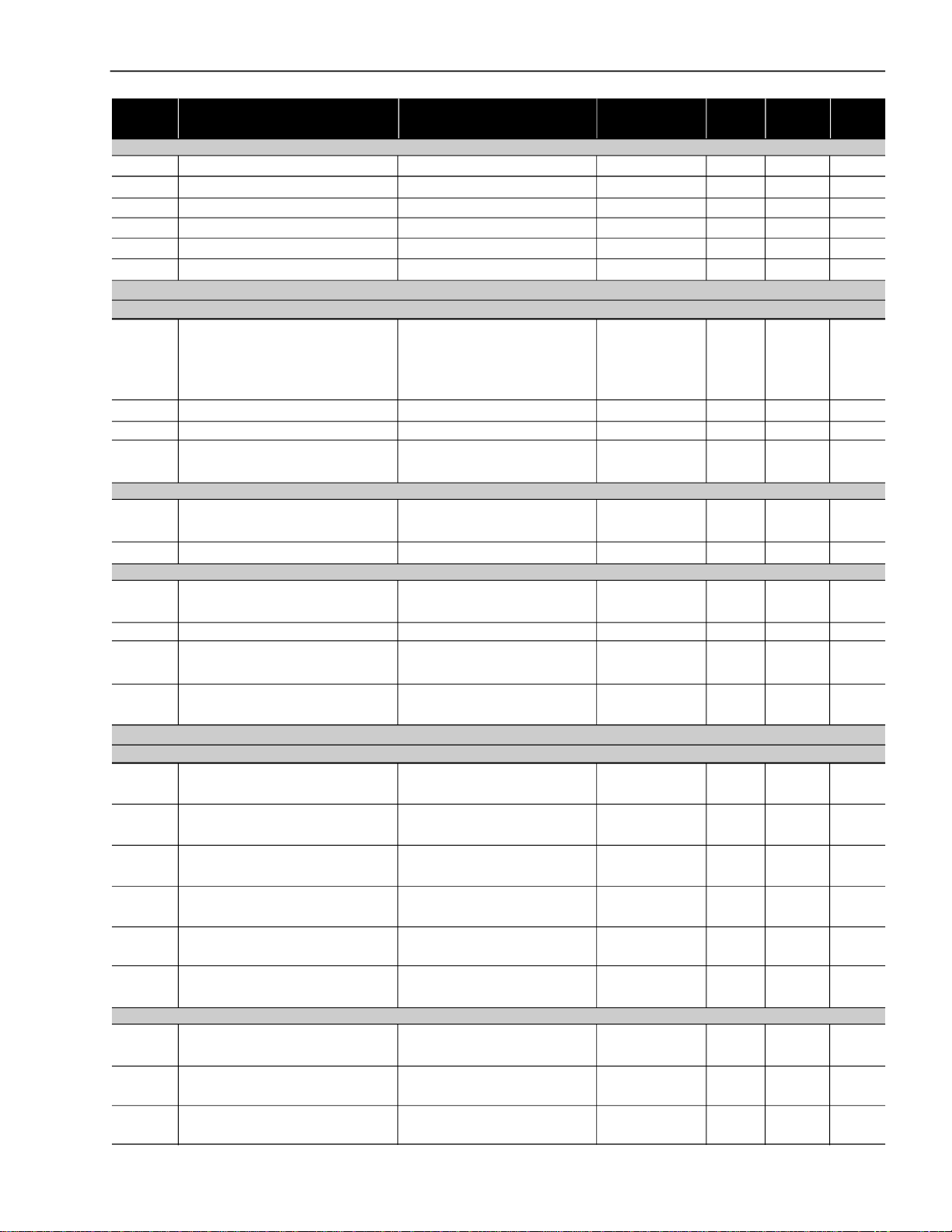

SSW-06- QUICK PARAMETER REFERENCE

Parameter Description Adjustable Range

P030 Current of Phase R 0 to 9999.9 - A 87

P031 Current of Phase S 0 to 9999.9 - A 87

P032 Current of Phase T 0 to 9999.9 - A 87

P033 Line Voltage - R-S 0 to 999 - V 87

P034 Line Voltage - S-T 0 to 999 - V 87

P035 Line Voltage - T-R 0 to 999 - V 87

P042 Time Powered 0 to 65535 - h 88

P043 TimeEnabled 0 to 6553,5 - h 88

P044 kWh Counter 0 to 999.9 - kWh 88

P045 MWhCounter 0 to 9999 - MWh 88

P047 MaximumStartingCurrent 0 to 9999.9 - A 88

P048 Average Starting Current 0 to 9999.9 - A 88

P049 RealStartingTime 0 to 999 - s 88

P050 MotorThermal Protection Status 0 to 250 - % 89

P053 MaximumCurrentat Full Voltage 0 to 9999.9 - A 89

P054 Maximum Line Voltage with the 0 to 999 - V 89

MotorRunning

P055 Minimum Line Voltage with the 0 to 999 - V 89

MotorRunning

P056 Maximum Line Frequency with the 0 to 99 - Hz 89

MotorRunning

P057 Minimum Line Frequency with the 0 to 99 - Hz 90

MotorRunning

P058 Maximum Number of Starts per Hour 0 to 32 - - 90

P059 Total Number of Starts 0 to 65535 - - 90

P060 Current at the Last Fault 0 to 9999.9 - A 90

P061 Voltage at the Last Fault 0 to 999 - V 90

P062 SSW Statusat the Last Fault 0 to 12 - - 90

P063 Current at the Second Fault 0 to 9999.9 - A 90

P064 Voltage at the Second Fault 0 to 999 - V 90

P065 SSW Statusat the Second Fault 0 to 12 - - 90

P066 Current at the Third Fault 0 to 9999.9 - A 90

P067 Voltage at the Third Fault 0 to 999 - V 90

P068 SSW Status at the Third Fault 0 to 12 - - 90

P069 Current at the Fourth Fault 0 to 9999.9 - A 90

P070 Voltage at the Fourth Fault 0 to 999 - V 90

P071 SSW Status at the Fourth Fault 0 to 12 - - 90

P072 Current at the Fifth Fault 0 to 9999.9 - A 90

P073 Voltage at the Fifth Fault 0 to 999 - V 90

P074 SSW Status at the Fifth Fault 0 to 12 - - 90

P075 Current at the Sixth Fault 0 to 9999.9 - A 90

P076 Voltage at the Sixth Fault 0 to 999 - V 90

P077 SSW Status at the Sixth Fault 0 to 12 - - 90

P085 Fieldbus Communication 0=Off - - 91

Board Status 1=Board Inactive

2=Board Active and Offline

3=Board Active and Online

P088 SoftPLCStatus 0=Without - - 91

1=Loading

2=Fault

3=Stopped

4=Running

Factory

Setting Setting

Unit

User´s

Page

10

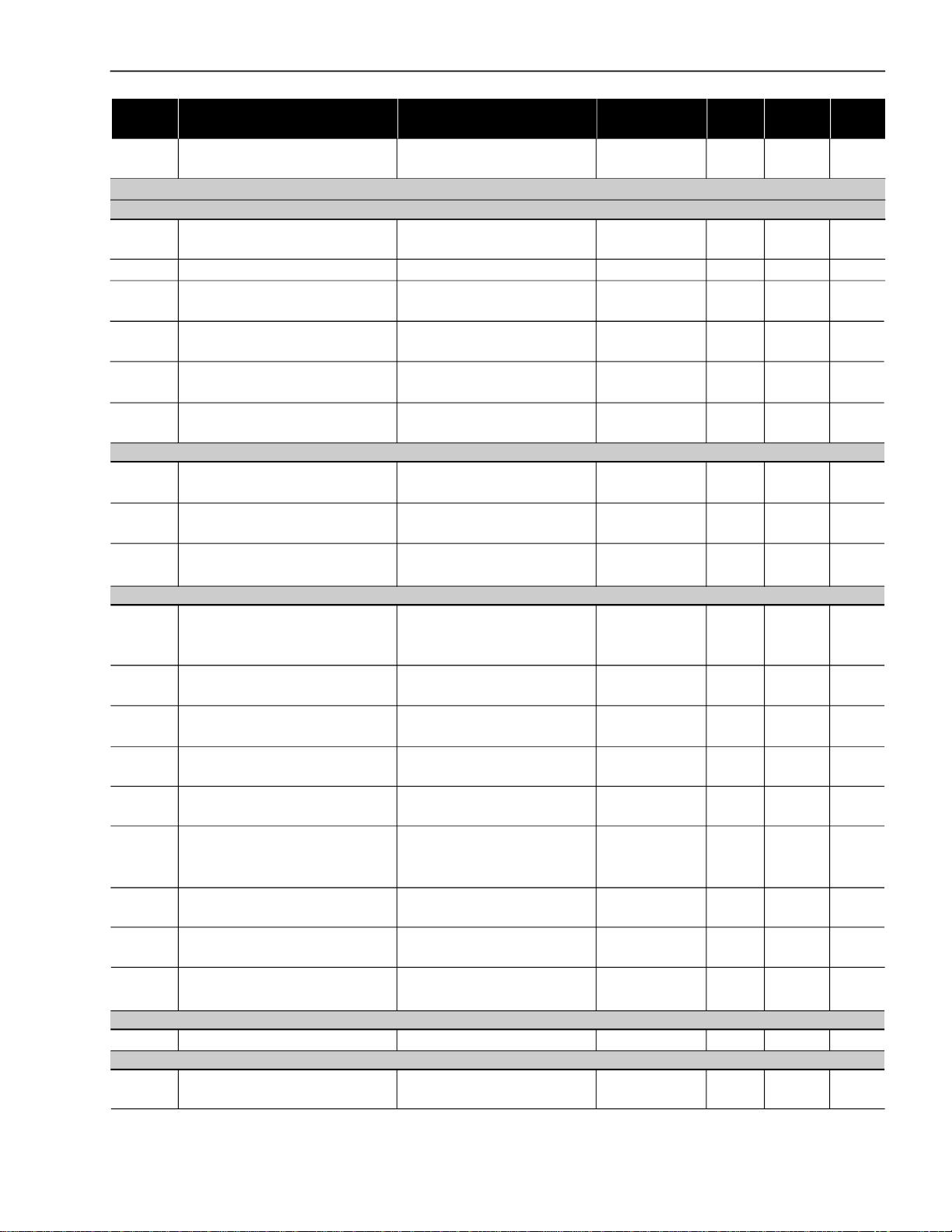

SSW-06- QUICK PARAMETERREFERENCE

Parameter Description Adjustable Range

Factory

Setting Setting

Unit

User´s

Page

P089 Allows SoftPLC 0=No - - 91

1=Yes

REGULATION PARAMETERS P100 to P199

Voltage Ramp

P101 InitialVoltage 25 to 90 30 % 92

(% Un of the motor)

P102 AccelerationRampTime 1 to 999 20 s 92

P103 Deceleration Voltage Step 100=Inactive 100=Inactive % 93

(% Un of the motor) 99 to 60

P104 DecelerationRampTime 0=Inactive 0=Inactive s 93

1 to 299

P105 End Deceleration Voltage 30 to 55 30 % 94

(% Un of the Motor)

(1)

P106

Automatic Detection of the 0=ByTime 0=ByTime - 94

Acceleration End with Voltage Ramp 1=Automatic

Current Limit

P110 CurrentLimit 150 to 500 300 % 94

(%In of the Motor)

P111 Initial Current for the Current Ramp 150 to 500 150 % 95

(% In of the Motor)

P112 Time for the Current Ramp 1 to 99 20 % 95

(% of P102)

Torque Control

(1)

P120

Starting Torque Characteristics 1=Constant 1=Constant - 96

2=Linear

3=Quadratic

P121 InitialStarting Torque 10 to 400 30 % 97

(% Tn of Motor)

P122 End StartingTorque 10 to 400 110 % 97

(% Tn of Motor)

P123 MinimumStartingTorque 10 to 400 27 % 97

(% Tn of the Motor)

P124 TimefortheMinimum StartTorque 1 to 99 20 % 97

(% of P102)

(1)

P125

Stopping Torque Characteristics 1=Constant 1=Constant - 98

2=Linear

3=Quadratic

P126 End StopTorque 10 to 100 20 % 98

(% Tn of the Motor)

P127 MinimumStopTorque 10 to 100 50 % 99

(% Tn of the Motor)

P128 TimefortheMinimumStopTorque 1 to 99 50 % 99

(% of P104)

Pump Control

(1)

P130

PumpControl 0=PumpI 0=PumpI - 99

By-pass

(1)

P140

External By-pass Contactor 0=Inactive 0=Inactive - 99

1=Active

11

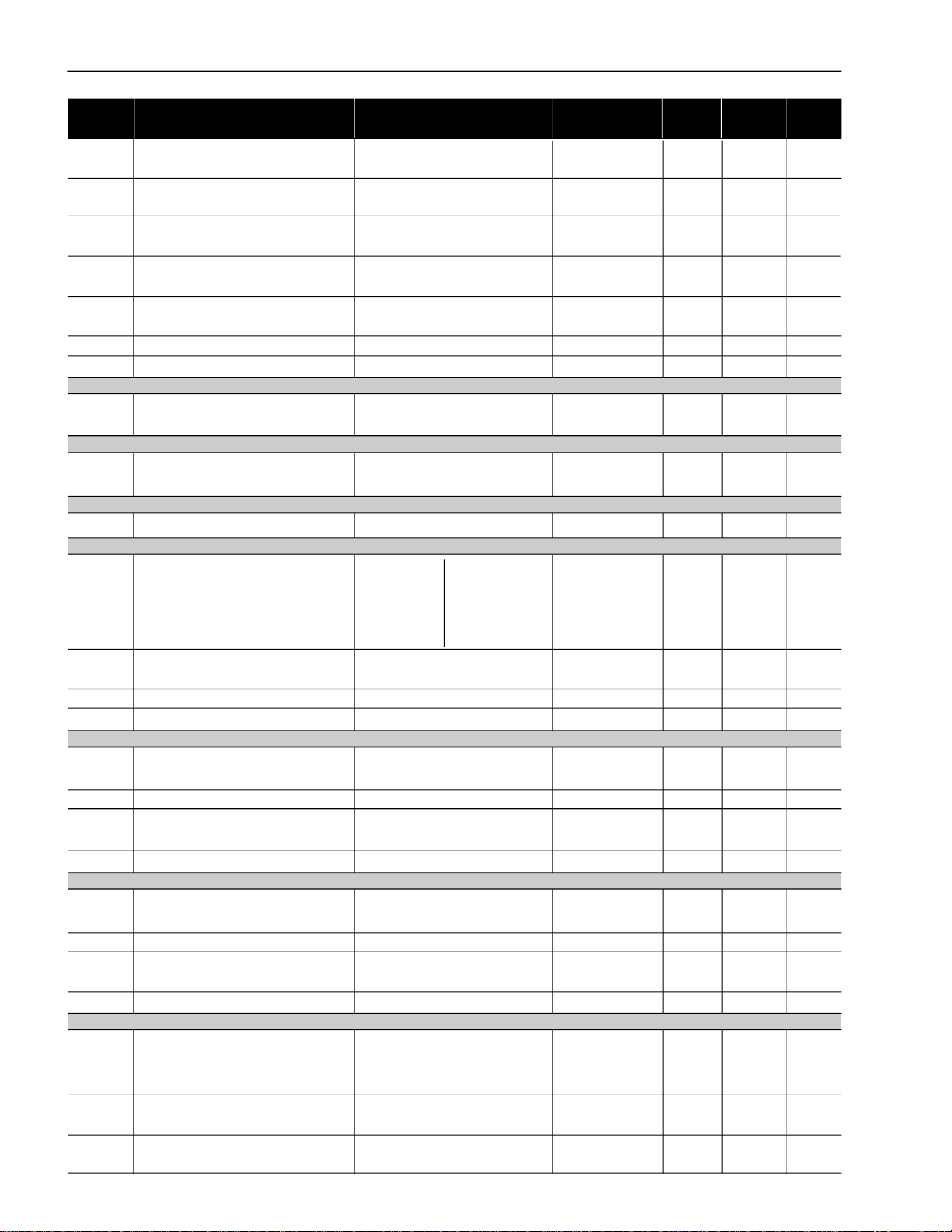

SSW-06- QUICK PARAMETER REFERENCE

Parameter Description Adjustable Range

Factory

Setting Setting

Unit

User´s

Page

Inside Delta

(1)(2)

P150

Inside Delta Motor Connection 0=Inactive 0=Inactive - 100

1=Active

CONFIGURATIONPARAMETERS P200 to P399

P200 Password 0=Inactive 1=Active - 101

1=Active

(2)

P201

Language Selection 0=Português To be defined - 101

1=English by the user

2=Español

3=Deutsch

(1)

P202

Type of Control 0=Voltage Ramp 0=VoltageRamp - 101

1=CurrentLimit

2=PumpControl

3=Torque Control

4=CurrentRamp

(1)

P204

Load/Save Parameters 0=NotUsed 0=NotUsed - 104

1=NotUsed

2=NotUsed

3=Resets P043 to P050

4=Resets P053 to P058

5=Loads Factory Default

6=NotUsed

7=Loads User Default 1

8=Loads User Default 2

9=NotUsed

10=Saves User Default 1

11=Saves User Default 2

12= Not Used

13=Erases SoftPLC

14=Erases SoftPLC User

Parameters

15=Reserved

16=Reserved

P205 Display Default Selection 0=P001 2=P003 - 105

1=P002

2=P003

3=P004

4=P005

5=P006

6=P007

7=P008

8=P009

9=P010

P206 Auto-Reset Time 0=Inactive 0=Inactive s 105

1 to 600

(1)

P215

Copy Function 0=Inactive 0=Inactive - 106

1=SSW HMI

2=HMISSW

P218 LCD Display Contrast Adjust. 0 to 150 127 - 107

12

SSW-06- QUICK PARAMETERREFERENCE

Parameter Description Adjustable Range

Factory

Setting Setting

Unit

User´s

Page

Local/Remote Definition

(1)

P220

Local/Remote Source Selection 0=Always Local 2=Keypad (L) - 107

1=Always Remote

2=Keypad (L)

3=Keypad (R)

4=DI4toDI6

5=Serial (L)

6=Serial (R)

7=Fieldbus (L)

8=Fieldbus (R)

9=SoftPLC(L)

10=SoftPLC(R)

(1)

P229

LocalStatusCommandSelection 0=HMIKey 0=HMIKey - 108

1=DigitalInputs DIx

2=Serial

3=Fieldbus

4=SoftPLC

(1)

P230

RemoteStatus CommandSelection 0=HMIKey 1=Digital InputsDIx - 108

1=DigitalInputs DIx

2=Serial

3=Fieldbus

4=SoftPLC

(1)

P231

FWD/REVSelection 0=Inactive 0=Inactive - 108

1=By Contactor

2=JOGOnly

Analog Outputs

P251 AO1 (0 to 10)V Output Function 0=NotUsed 0=Not Used - 109

1= Current

(%In of the SSW)

2=Input Voltage

(%Un of the SSW)

3=Output Voltage

(%Un of the SSW)

4=Power Factor

5=ThermalProtection

6=Power (in W)

7=Power (in VA)

8=Torque

(%Tn of Motor)

9=Fieldbus

10=Serial

11=SoftPLC

P252 AO1 Analog Output Gain 0.000 to 9.999 1.000 - 109

P253 AO2 (0 to 20)mA or (4 to 20)mA 0=NotUsed 0=Not Used - 109

Output Function 1= Current

(%In of the SSW)

2=Input Voltage

(%Un of the SSW)

3=Output Voltage

(%Un of the SSW)

4=Power Factor

13

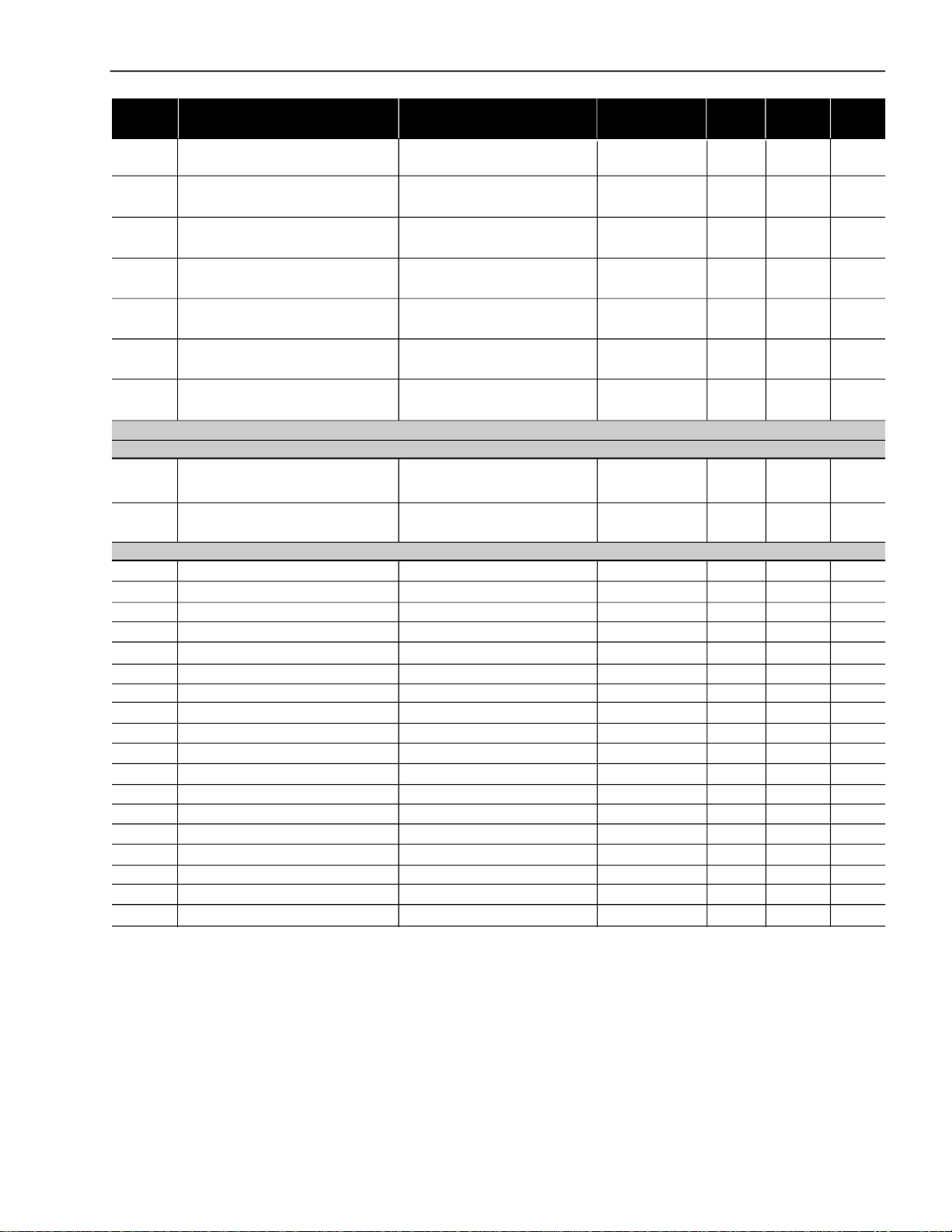

SSW-06- QUICK PARAMETER REFERENCE

Parameter Description Adjustable Range

Factory

Setting Setting

Unit

User´s

Page

5=ThermalProtection

6=Power (in W)

7=Power (in VA)

8=Torque

(%Tn of the Motor)

9=Fieldbus

10=Serial

11=SoftPLC

P254 AO2 Analog Output Gain 0.000 to 9.999 1.000 - 109

P255 AO2 Analog Output Selection 0=0 to 20 0=0 to 20 mA 110

1=4 to 20

Digital Inputs

(1)

P263

Digital Input DI1 Function 0=Not Used 1=Start/Stop 111

1=Start/Stop

2=Start (Three Wires)

3=Stop (Three Wires)

4=General Enabling

5=Reset

(1)

P264

Digital Input DI2 Function 0=Not Used 2=Reset 111

1=Stop (Three-Wires)

2=Reset

3=Start/Stop

4=Start (Three Wires)

5=General Enabling

(1)

P265

Digital Input DI3 Function 0=Not Used 0=Not Used 111

1=General Enabling

2=Reset

3=Start/Stop

4=Start (Three Wires)

5=Stop (Three Wires)

6=Emergency Start

(1)

P266

DI4Digital InputFunction 0=Not Used 0=Not Used - 111

1=FWD/REV

2=Local/Remote

3=NoExternalFault

4=JOG

5=Brake Off

6=Reset

(1)

P267

DI5Digital InputFunction 0=Not Used 0=Not Used - 111

1=FWD/REV

2=Local/Remote

3=NoExternalFault

4=JOG

5=Brake Off

6=Reset

(1)

P268

DI6Digital InputFunction 0=Not Used 0=Not Used - 111

1=FWD/REV

2=Local/Remote

3=NoExternalFault

4=JOG

5=Brake Off

6=Reset

7=MotorThermistor

14

SSW-06- QUICK PARAMETERREFERENCE

Parameter Description Adjustable Range

Digital Outputs

(1)

P277

RL1 Relay Function 0=Not Used 1=Running - 112

1=Running

2=FullVoltage

3=External By-pass

4=FWD/REV-K1

5=DC-Brake

6=NoFault

7=Fault

8=Fieldbus

9=Serial

10=SoftPLC

11=NoAlarm

12=Alarm

(1)

P278

RL2 Relay Function 0=NotUsed 2=FullVoltage - 112

1=Running

2=FullVoltage

3=External By-pass

4=FWD/REV-K2

5=DC-Brake

6=NoFault

7=Fault

8=Fieldbus

9=Serial

10=SoftPLC

11=NoAlarm

12=Alarm

(1)

P279

RL3 Relay Function 0=NotUsed 6=NoFault - 112

1=Running

2=FullVoltage

3=External By-pass

4= Not Used

5=DC-Brake

6=NoFault

7=Fault

8=Fieldbus

9=Serial

10=SoftPLC

11=NoAlarm

12=Alarm

Soft-Starter Data

(1)(2)

P295

SSW NominalCurrent 0=10 11=312 According to A 113

1=16 12=365 Soft-Starter

2=23 13=412 Nominal Current

3=30 14=480

4=45 15=604

5=60 16=670

6=85 17=820

7=130 18=950

8=170 19=1100

9=205 20=1400

10=255 21=1000

22=1300

Factory

Setting Setting

Unit

User´s

Page

15

SSW-06- QUICK PARAMETER REFERENCE

Parameter Description Adjustable Range

(1)(2)

P296

SSW NominalVoltage 0=220/575 According to V 114

Factory

Setting Setting

Unit

User´s

Page

1=575/690 Soft-StarterNominal

Voltage

SERIAL COMMUNICATION PARAMETERS P300 to P399

(1)(2)

P308

Soft-Starter Address on the Serial 1 to 247 1 - 114

Communication Network

(1)(2)

P309

Fieldbus Communication 0=Inactive 0=Inactive - 114

BoardEnabling 1=Profibus-DP

(1 Input and 1 Output)

2=Profibus-DP

(4 Inputs and 4 Outputs)

3=Profibus-DP

(7 Inputs and 7 Outputs)

4=DeviceNet

(1 Input and 1 Output)

5=DeviceNet

(4 Inputs and 4 Outputs)

6=DeviceNet

(7 Inputs and 7 Outputs)

7=EtherNet/IP

(1 Input and 1 Output)

8=EtherNet/IP

(4 Input and 4 Output)

9=EtherNet/IP

(7 Input and 7 Output)

P310 Profibus Master Stop Detection 0=Inactive 0=Inactive - 114

1=Active

(1)(2)

P312

Protocol Type and Serial 1=Modbus-RTU 1=Modbus-RTU - 115

Communication Transfer Rate (9600bps, no parity) (9600bps,

2=Modbus-RTU no parity)

(9600bps, odd)

3=Modbus-RTU

(9600bps, even)

4=Modbus-RTU

(19200bps, no parity)

5=Modbus-RTU

(19200bps, odd)

6=Modbus-RTU

(19200bps, even)

7=Modbus-RTU

(38400bps, no parity)

8=Modbus-RTU

(38400bps, odd)

9=Modbus-RTU

(38400bps, even)

P313 Serialand Fieldbus Communication 0=Inactive 0=Inactive - 115

ErrorActions (E28, E29 and E30) 1=Disable

2=GeneralDisable

3=Changes to Local

4=Inactive

5=FatalFault

(1)

P314

TimeoutTime forSerial 0 to 999 0=Not Used s 115

CommunicationTelegram Reception

(1)

P315

P316

P317

Read Parameter via Fieldbus 1 0 to 999 0 - 115

(1)

Read Parameter via Fieldbus 2 0 to 999 0 - 116

(1)

Read Parameter via Fieldbus 3 0 to 999 0 - 116

16

SSW-06- QUICK PARAMETERREFERENCE

Parameter Description Adjustable Range

Factory

Setting Setting

Unit

User´s

Page

MOTOR PARAMETERS P400 to P499

(1)

P400

P401

P402

P404

P405

P406

NominalMotorVoltage 0 to 999 380 V 116

(1)

NominalMotorCurrent 0 to 2424 20 A 116

(1)

NominalMotorSpeed 400 to 3600 1780 rpm 116

(1)

Nominal Motor Power 0.1 to 2650 75 kW 116

(1)

Motor Power Factor 0 to 1.00 0.89 - 116

(1)

Service Factor 0 to 1.50 1.00 - 117

SPECIALFUNCTIONPARAMETERS P500 to P599

Braking

(1)

P500

Braking Methods 0=Inactive 0=Inactive - 117

1=Reverse Braking

2=OptimalBraking

3=DC-Braking

P501 BrakingTime 1 to 299 10 s 120

P502 Braking Voltage Level 30 to 70 30 % 120

P503 BrakingEndDetection 0=Inactive 0=Inactive - 120

1=Automatic

JOG

(1)

P510

Jog 0=Inactive 0=Inactive - 121

1=Active

P511 Jog Level 10 to 100 30 % 121

Kick Start

(1)

P520

Kick Start Torque Pulse 0=Inactive 0=Inactive - 122

(according to P202) 1=Active

P521 KickStartPulse Time 0.1 to 2 0.1 s 122

P522 Kick StartVoltage Pulse Level 70 to 90 70 % 122

(% Un of the Motor)

P523 Kick StartCurrent Pulse Level 300 to 700 500 % 122

(% In of the Motor)

PROTECTION PARAMETERS P600 to P699

Voltage Protection

(1)

P600

ImmediateUndervoltage 0 to 30 20 % 123

(% Un of the Motor)

(1)

P601

ImmediateUndervoltageTime 0=Inactive 1 s 123

1 to 99

(1)

P602

ImmediateOvervoltage 0 to 30 15 % 123

(% Un of the Motor)

(1)

P603

ImmediateOvervoltageTime 0=Inactive 1 s 123

1 to 99

(1)

P604

Voltage Imbalance between Phases 0 to 30 15 % 123

(% Un of the Motor)

(1)

P605

Voltage Imbalance between 0=Inactive 1 s 123

PhasesTime 1 to 99

Current Protection

(1)

P610

Immediate Undercurrent 0 to 99 20 % 124

(% In of the Motor)

(1)

P611

ImmediateUndercurrentTime 0=Inactive 0=Inactive s 124

1 to 99

(1)

P612

Immediate Overcurrent 0 to 99 20 % 124

(% In of the Motor)

17

SSW-06- QUICK PARAMETER REFERENCE

Parameter Description Adjustable Range

(1)

P613

ImmediateOvercurrent Time 0=Inactive 0=Inactive s 124

Factory

Setting Setting

Unit

User´s

Page

1 to 99

(1)

P614

Current Imbalance between Phases 0 to 30 15 % 124

(% In of the Motor)

(1)

P615

Current Imbalance between 0=Inactive 1 s 124

PhasesTime 1 to 99

(1)

P616

Undercurrent before 0=Inactive 1=Active - 125

By-pass Closing 1=Active

(1)

P617

Locked Rotor at the 0=Inactive 1=Active - 125

StartEnd 1=Active

(1)

P618

P619

Ground Fault 10 to 30 20 % 125

(1)

GroundFault Time 0 to 10.0 0=Inactive s 125

Phase Sequence

(1)

P620

RST Phase Sequence 0=Inactive 0=Inactive - 125

1=Active

By-pass Contactor Closed Detection

(1)

P621

By-pass Contactor Closed 0=Inactive 1=Active 125

1=Active

Interval between Starts

P630 Interval of Time after Stop 2 to 999 2 s 125

Motor Thermal Protection

(1)

P640

MotorProtection Thermal Class 0=Inactive 5=25 6=30 - 127

1=5 6=30

2=10 7=35

3=15 8=40

4=20 9=45

(1)

P641

Auto-Reset of the Thermal Memory 0=Inactive 0=Inactive s 130

1 to 600

P642 MotorThermal ProtectionAlarm 0 to 250 230 % 131

P643 MotorThermal ProtectionAlarm Reset 0 to 250 210 % 131

Torque Protections

(1)

P650

ImmediateUndertorque 0 to 99 30 % 131

(% Tn of the Motor)

(1)

P651

P652

ImmediateUndertorque Time 0 to 99 0=Inactive s 131

(1)

ImmediateOvertorque 0 to 99 30 % 131

(% Tn of the Motor)

(1)

P653

ImmediateOvertorqueTime 0 to 99 0=Inactive s 131

Power Protections

(1)

P660

Immediate Underpower 0 to 99 30 % 132

(% kWn of the Motor)

(1)

P661

P662

Immediate Underpower Time 0 to 99 0=Inactive s 132

(1)

Immediate Overpower 0 to 99 30 % 132

(% kWn of the Motor)

(1)

P663

Immediate Overpower Time 0 to 99 0=Inactive s 132

SELECTION BETWEEN FAULT OR ALARM P700 to P790

P705 MotorThermalProtectionTrip 0=FaultE05 0=FaultE05 - 132

1=Alarm A05

2=Fault andAlarm

P706 OpenDIxProtection Trip 0=Fault E06 0=FaultE06 - 133

1=Alarm A06

P716 Line Overvoltage Trip 0=FaultE16 0=Fault E16 - 133

1=Alarm A16

18

SSW-06- QUICK PARAMETERREFERENCE

Parameter Description Adjustable Range

P732 Motor Overtemperature – PTC – Trip 0=Fault E32 0=FaultE32 - 133

1=Alarm A32

P765 Motor Undercurrent Trip 0=FaultE65 0=FaultE65 - 133

1=Alarm A65

P766 Motor Overcurrent Trip 0=Fault E66 0=FaultE66 - 133

1=Alarm A66

P778 Motor Undertorque Trip 0=FaultE78 0=FaultE78 - 133

1=Alarm A78

P779 Motor Overtorque Trip 0=FaultE79 0=FaultE79 - 133

1=Alarm A79

P780 Motor Underpower Trip 0=Fault E80 0=FaultE80 - 133

1=Alarm A80

P781 Motor Overpower Trip 0=FaultE81 0=Fault E81 - 133

1=Alarm A81

SOFTPLCPARAMETERS P950 to P999

Control Parameters

(2)

P950

P951 Digital Inputs and Outputs Expansion 0=No 0=No 134

P952 First SoftPLC User Parameter 0 to 65535 0 - 134

P953 Second SoftPLC User Parameter 0 to 65535 0 - 134

P954 ThirdSoftPLCUser Parameter 0 to 65535 0 - 134

P955 Fourth SoftPLC User Parameter 0 to 65535 0 - 134

P956 Fifth SoftPLC User Parameter 0 to 65535 0 - 134

P957 Sixth SoftPLC User Parameter 0 to 65535 0 - 134

P958 Seventh SoftPLC User Parameter 0 to 65535 0 - 134

P959 EighthSoftPLCUserParameter 0 to 65535 0 - 134

P960 NinthSoftPLCUserParameter 0 to 65535 0 - 134

P961 Tenth SoftPLC User Parameter 0 to 65535 0 - 134

P962 EleventhSoftPLCUserParameter 0 to 65535 0 - 134

P963 Twelfth SoftPLC User Parameter 0 to 65535 0 - 134

P964 ThirteenthSoftPLC User Parameter 0 to 65535 0 - 134

P965 Fourteenth SoftPLC User Parameter 0 to 65535 0 - 134

P966 Fifteenth SoftPLC User Parameter 0 to 65535 0 - 134

P967 Sixteenth SoftPLC User Parameter 0 to 65535 0 - 134

P968 Seventeenth SoftPLC User Parameter 0 to 65535 0 - 134

P969 EighteenthSoftPLCUserParameter 0 to 65535 0 - 134

EnableSoftPLC 0=No 0=No - 134

1=Yes

CardEnable 1=Yes

User Parameters

Factory

Setting Setting

Unit

User´s

Page

NotespresentedonQuick Parameter Reference:

(1) This parameter can onlybe changedwith the motor stopped;

(2)Thisparameterdoesnotchangewhenfactorydefaultsareloaded(P204=5).

19

SSW-06- QUICK PARAMETER REFERENCE

II.FaultorAlarmMessages

Display Description Page

E03 Undervoltage, Phase Fault or Phase 155

Unbalancing

E04 Overtemperature at the Power Assembly 155

E05 or A05 Motor Overload 155

E06 or A06 External Fault or Alarm (DI) 155

E10 Copy Function Fault 155

E11 Ground Fault 156

E15 Motor is not Connected or SCRs in Short-circuit 156

E16 or A16 Overvoltage 156

E18 Wrong Motor Connection 156

E24 ProgrammingError 156

E28 Timeout Errorin the Telegram Reception 156

E29 Inactive Fieldbus communication or Profibus 156

master in Stop Fault

E30 Fieldbus Board is Inactive 156

E31 Keypad Connection Fault 156

E32 or A32 Motor Overtemperature (DI) 157

E41 Self-Diagnosis Fault 157

E57 Failure inSCRR-U 157

E58 Failure in SCR S-V 157

E59 Failure inSCRT-W 157

E62 StartLimitingTime 157

E63 Locked Rotor 157

E65 or A65 Undercurrent 157

E66 or A66 Overcurrent 157

E67 Inverted Phase Sequence 157

E70 Undervoltage at the Electronics 157

E71 By-pass Contact is Open 158

E72 Overcurrent before By-pass Contact 158

E74 Current Imbalance 158

E75 Frequency of Supply Line out of Permitted Range 158

E76 Undercurrent before By-pass 158

E77 By-pass Contact is closed or SCRs in Short-circuit 158

E78 or A78 Undertorque 158

E79 or A79 Overtorque 158

E80 or A80 Underpower 158

E81 or A81 Overpower 158

E85 Without SoftPLC 159

E86 to E89 SoftPLC user errors 159

A90 to A93 SoftPLC user alarms 159

For more details see table 8.1 in chapter 8.

III.OtherMessages

20

Display Description

rdy Soft-Starter is ready to be enabled

Exx Soft-Starter fault

Axx Soft-Starter with alarm

CHAPTER 1

SAFETY NOTICES

ThisManualcontainsallnecessaryinformationforthecorrectinstallation

andoperationof the SSW-06 Soft-Starter.

TheSSW-06InstructionManualhasbeenwritten for qualifiedpersonnel

with suitable training or technical qualifications to operate this type of

equipment.

1.1 SAFETYNOTICES INTHEMANUAL

1.2 SAFETYNOTICESON THEPRODUCT

The following Safety Notices will be used in this Manual:

DANGER!

Iftherecommended SafetyInstructionsarenotstrictlyobserved,serious

orfatalinjuries ofpersonneland/or equipment damagecan occur.

ATTENTION!

Failure to observe the recommended Safety Procedures can lead to

materialdamage.

NOTE!

ThecontentofthisManualsupplies importantinformation for thecorrect

understandingof operationandproperperformanceof the equipment.

Thefollowingsymbolsmaybeattachedtotheproduct, servingas Safety

Notices:

High Voltages.

Componentsaresensitivetoelectrostaticdischarge.Do not touch

them without following proper grounding procedures.

Mandatory connection to ground protection (PE).

Shield connection to ground.

21

CHAPTER 1 - SAFETY NOTICES

1.3 PRELIMINARY RECOMMENDATIONS

DANGER!

Only qualified personnel should plan or implement the installation, start-up,

operationandmaintenanceofthisequipment.Personnelmustreviewthisentire

Manualbefore attemptingtoinstall,operate or troubleshoot the SSW-06.

These personnel must follow all safety instructions included in this Manual

and/ordefined by local regulations.

Failure to complywith these instructions mayresult in personal injuryand/or

equipment damage.

NOTE!

In this Manual,qualified personnel are defined as peoplethat aretrained to:

1. Install,ground, power-up and operate theSSW-06 accordingto this

Manual and the local requiredsafetyprocedures;

2. Use of safety equipment according to the local regulations;

3. Administer First Aid Treatment.

DANGER!

Always disconnect the main power supply before touching any electrical

component associated with the SSW-06 Soft-Starter.

High voltages and spinningparts (fans) may be present even after switching

offthepowersupply.Wait at least3minutesfor the completedischargeofthe

capacitors and until the fans stopped.

Always connect the equipment frame to the protection earth (PE) in the

appropriateplacefor this.

ATTENTION!

All electronic boards have components that are sensitive to electrostatic

discharges.Nevertouchanyoftheelectricalcomponentsor connectorswithout

followingproper groundingprocedures.Ifnecessarytodoso,touchtheproperly

groundedmetallic frame or use a suitableground strap.

Do not apply a high voltage (High Pot) test on the Soft-Starter SSW-06!

If this test is necessary, contact the manufacturer.

NOTE!

Soft-StarterSSW-06 can interfere withotherelectronicequipment.In orderto

reduce this interference, adopt the measures recommended in Section 3

“Installation”.

NOTE!

Readthisentire manualcarefullyandcompletelybeforeinstalling or operating

theSoft-Starter SSW-06.

22

CHAPTER 2

GENERAL INFORMATION

This chapter defines the contents and purpose of this manual and

describes the main characteristics of the SSW-06 Soft-Starter.

Identification of the SSW-06, receiving and storage requirements are

alsoprovided.

2.1 ABOUT THISMANUAL

This manual is divided into 10 chapters, providing information to the

user on how to receive, install, start-up and operate the Soft-Starter

SSW-06.

Chapter1- Safety Notices;

Chapter2- Generalinformation,receivingandstoringoftheSSW-06;

Chapter3- Informationaboutinstallationandconnectionof the

Soft-Starter SSW-06 power and control circuit, how to

installoptions and recommended setups;

Chapter4- Usingthe Keypad(Human Machine Interface - HMI);

Chapter5- Informationaboutrunningandsteps to befollowed;

Chapter6- Detaileddescription of all Soft-StarterSSW-06

programmingparameters;

Chapter7- Information and suggestions on how to program the

types of control and protections;

Chapter8- Informationaboutdiagnostics andtroubleshooting,

cleaninginstructionsandpreventive maintenance;

Chapter9- SSW-06Soft-Starter optionaldevices;

Chapter10- Tables and technical informationabout the powerlines

of the Soft-Starter SSW-06.

Thismanualprovidesinformationforthecorrectuse of theSoft-Starter

SSW-06.Duetothevariousfunctions oftheSoft-StarterSSW-06many

differentmodesof operationarepossible.

As the Soft-Starter SSW-06 can be applied in several ways, it is

impossible to describe here all application possibilities, neither can

WEG assume any responsibility when the Soft-Starter SSW-06 is not

used according to this manual.

No part of this manual maybe reproduced in any form, withoutwritten

permissionfrom WEG.

2.2 SOFTWARE VERSION

2.3 ABOUT THE SOFT-STARTER SSW-06

It is important to note the software version installed in the Soft-Starter

SSW-06,sinceitdefinesthefunctionsandtheprogrammingparameters

ofthe Soft-Starter.Thismanualrefersto the software versionindicated

on the inside cover. For example, the version 1.0X applies to versions

1.00 to1.09,where“X”isavariablethatwillchangeduetominorsoftware

revisions.

Thesoftwareversion can bereadin the parameterP023.

TheSoft-StarterSSW-06is a highperformance Drive that permits the

start control of three-phase AC induction motors. The Soft-Starter

SSW-06 prevents mechanical shocks on the load and current peaks

in the supply line.

Amongthemaincharacteristics of thisproduct is its lineandconnection

faultdetection capacity thus enablingthe customer to choose the best

wayof protecting his motor, such as:

23

CHAPTER2 - GENERALINFORMATION

Programmableprotectionsagainstlineundervoltageandovervoltage,

andline phase imbalance;

Programmable protections against motor undercurrent and

overcurrent,andcurrentimbalancebetweenphasesofthe motor;

ThermalclassmaybeprogrammeduptoClass45for largemotors.

Thethermal memoryissavedon EEPROMincaseof anelectronic

supply fault.

Specialfunctions such as:

Displayofthenumberof hours, runningtime,supplyvoltagephase,

motor current per phase, motor current in amperes, motor current

asa % of the Soft-StarterSSW-06nominalcurrentand the nominal

current as a % of the motor current, status of the digital inputs and

outputs;

Setting sequence after reset to factory default;

Veryflexibleselectionofstart/stopcontroltype,enablingthefollowing

selections: VoltageRamp, Constant Current Limiting or by Ramp,

PumpControland Constant,Linear or QuadraticTorqueControl;

Totally flexibleTorque Control providing very high performance for

themost demanding applications;

Possibility of using all digital inputs, digital outputs and analog

outputs as remote PLC via Serial and Fieldbus communication;

Possibilityofline voltagemeasurements monitoringbyasupervisory

implementedthroughSerialor Fieldbus communication;

Monitoring and programmingviasoftwareSuperDriveG2.

Indication of starting and full voltagediagnostics, and faults.

Control Hardware:

Keypad, referred to as the Human Machine Interface (HMI) with

Liquid-Crystal Displayandeasyprogramming.Faultconditionscan

bedisplayedinseverallanguages.

32Bit Microprocessor calculates the True rms voltageand current;

Measurement of the voltageand currentin the three phases;

Isolated digital input for the motor PTC;

Fieldbus boards and RS-485as options.

Power Hardware:

Compact size;

Power supply input and output connections:

Models from 10A to 820A - Input from the top and output at the

bottom of the SSW-06, with built-in By-pass contactor;

Models from 950A to 1400A - Input and output from the bottom,

without built-in By-pass contactor;

Easy assembly and maintenance;

Measurements of heatsink temperature in models 255A to 820A

through two thermostats:One thermostat to switch-on the internal

fansand the other to monitorover-heating;

Soft-Starter SSW-06 can be coupled to the motor by a standard

connection or an inside delta motor connection without requiring

optionaldevices.

Built-inBy-pass contactor makesthe Soft-StarterSSW- 06(Models

from 10Ato 820A):

More resistant to supply line oscillations after starting;

Save energy that would be dissipated through the thyristors after

thestart,thus reducingthenumber of fans requiredforcontrolpanel

cooling.

24

CHAPTER2 - GENERALINFORMATION

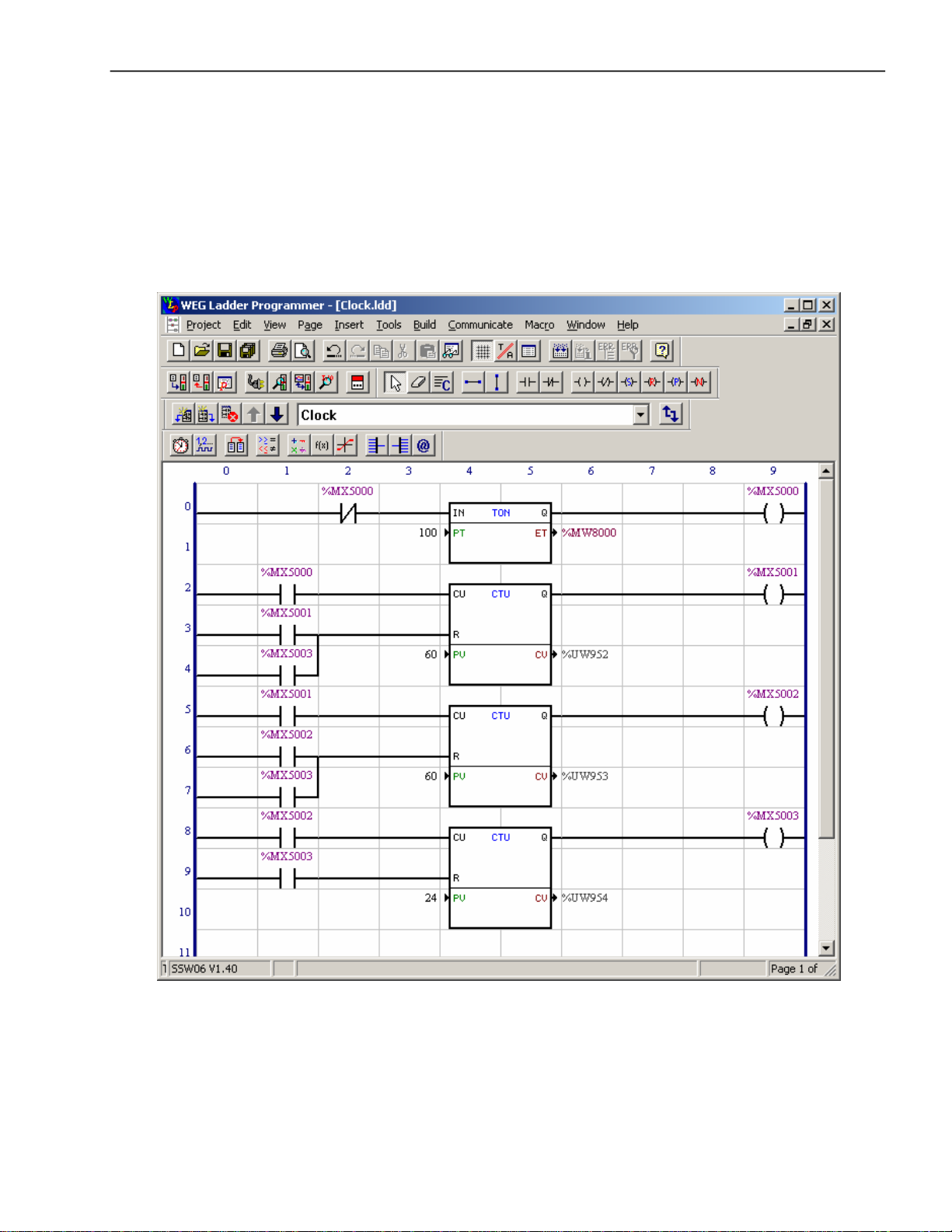

PLC Software Function - SoftPLC

TheSSW-06Soft-Starterallowstheimplementation ofprogrammable

logic controller software in ladder language, the SoftPLC, with an

applicativeprogram capacity of 1 Kbyte.

With the SoftPLC, interlocking logics between digital inputs and

outputs, analog outputs, motor starting logics, among others, can

becreated.

ThisSoftPLCisprogrammablethroughtheWLP software,according

to the WLP manual.

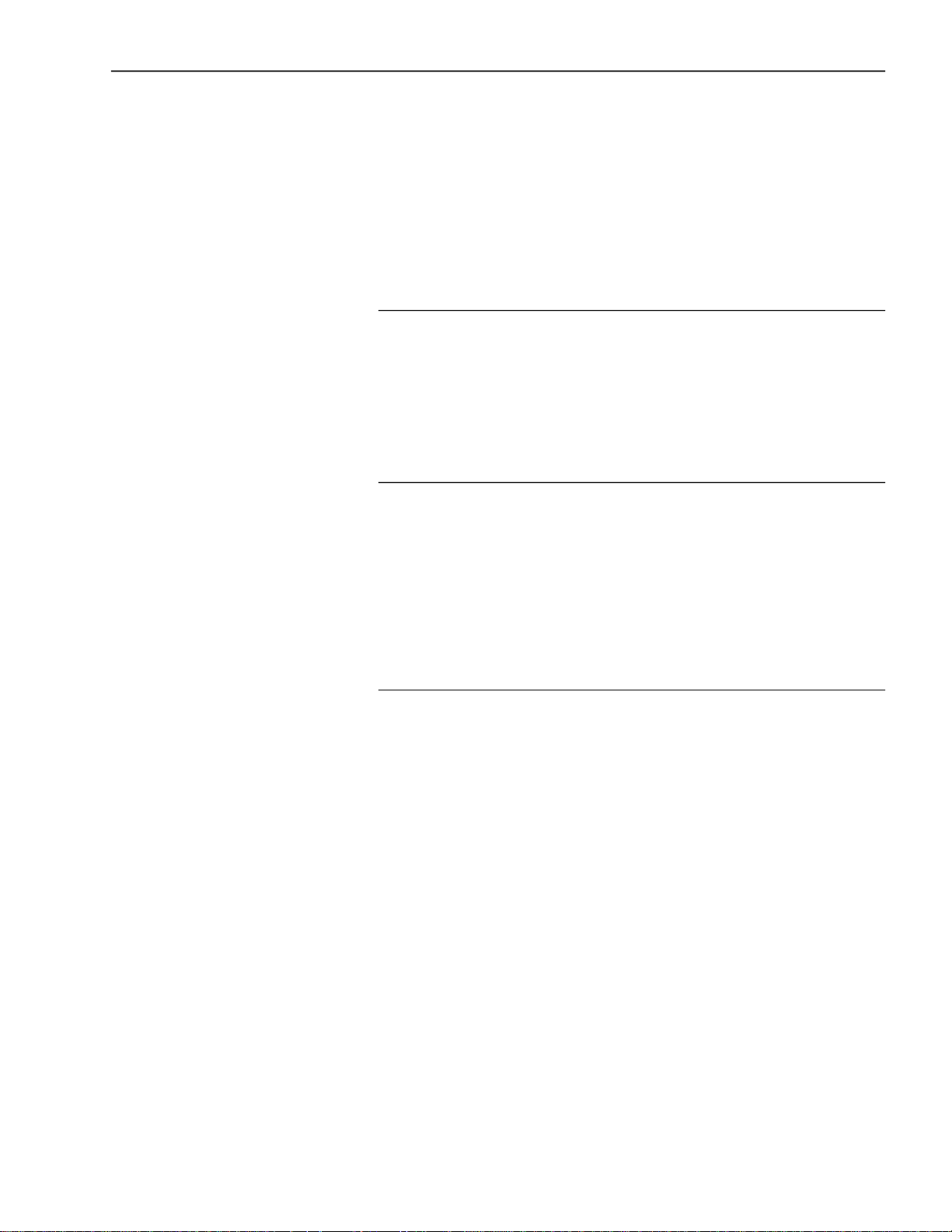

Figure 2.1 - Example of SoftPLC software with the WLP editing tool

Theexample aboveistheimplementationofaclock withhours,minutes

and seconds. The hours are showed in parameter P954, the minutes

inparameter P953 and the seconds in parameterP952.

25

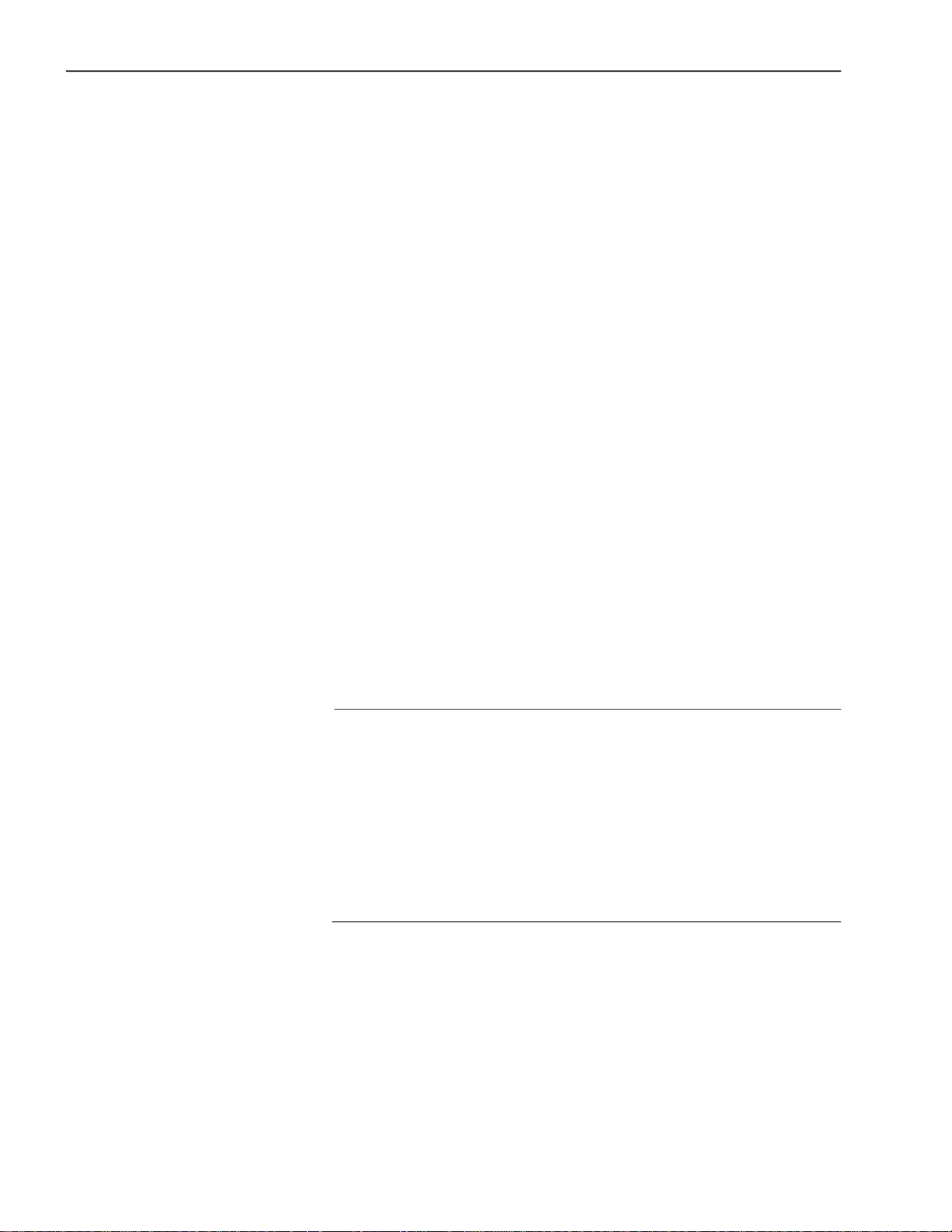

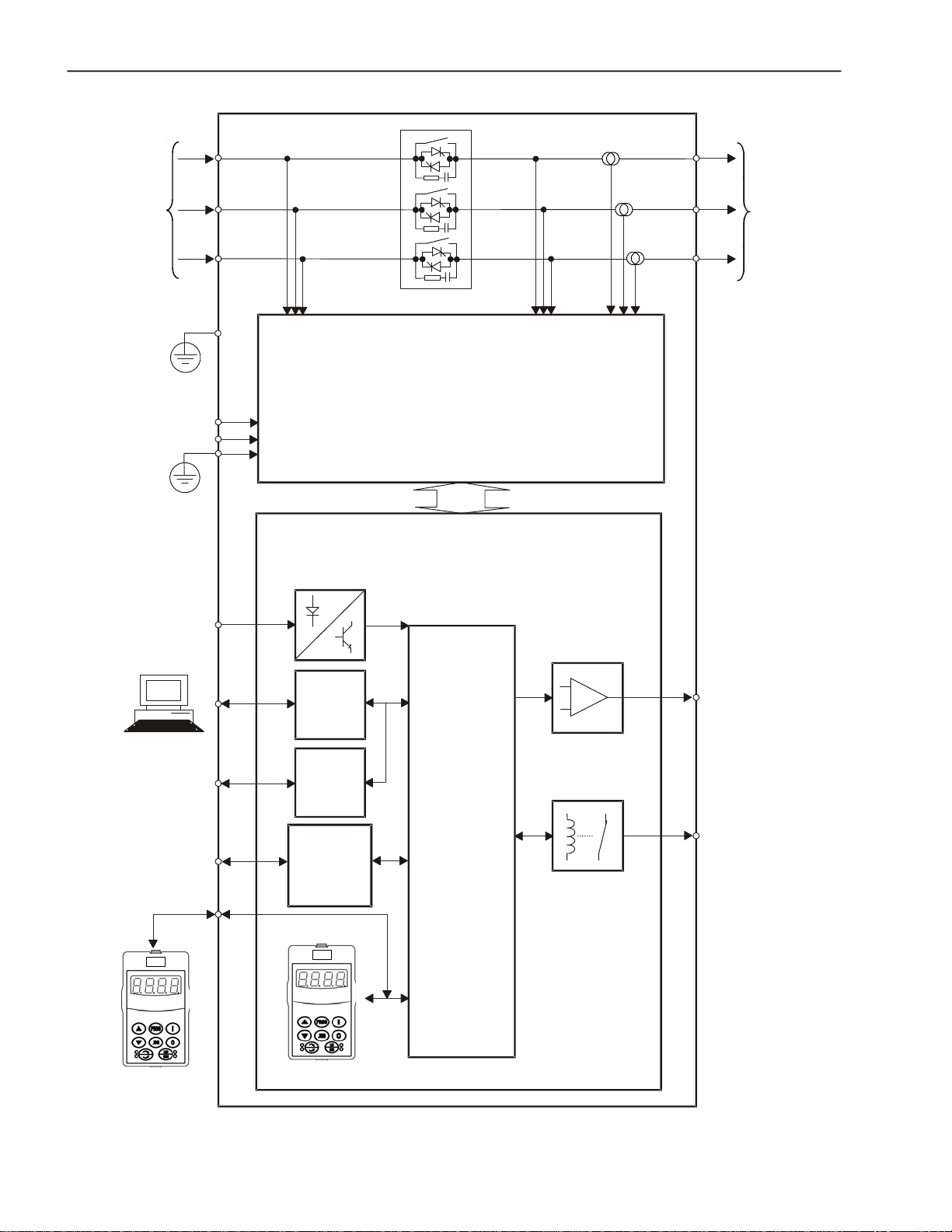

CHAPTER2 - GENERALINFORMATION

(1)

Three-Phase

Power Supply

Programmable

DigitalInputs

DI1to DI6

PE

Control

Supply

PE

Input Voltage

Supply

DigitalInputs

(1)

(1)

POWERBOARD

CONTROL BOARD

Output

Voltage

Analog Outputs

Three-Phase

Motor

Current

PC,PLC,MFW,

SuperDrive G2

ModBUS-RTU

PC,PLC

Keypad

(Remote)

Serial

Interface

CPU

RS-232

Serial

Interface

(optional)

DigitalOutputs

RS-485

Fieldbus

(optional)

- ProfibusDP

- DeviceNet

Keypad

(1) Models 950A, 1100A and 1400A do not have an internal By-pass contactor.

Programmable

Analog Outputs

AO1 to AO2

Programmable

DigitalOutputs

RL1 to RL3

26

Figure 2.2 - Soft-Starter SSW-06 block diagram

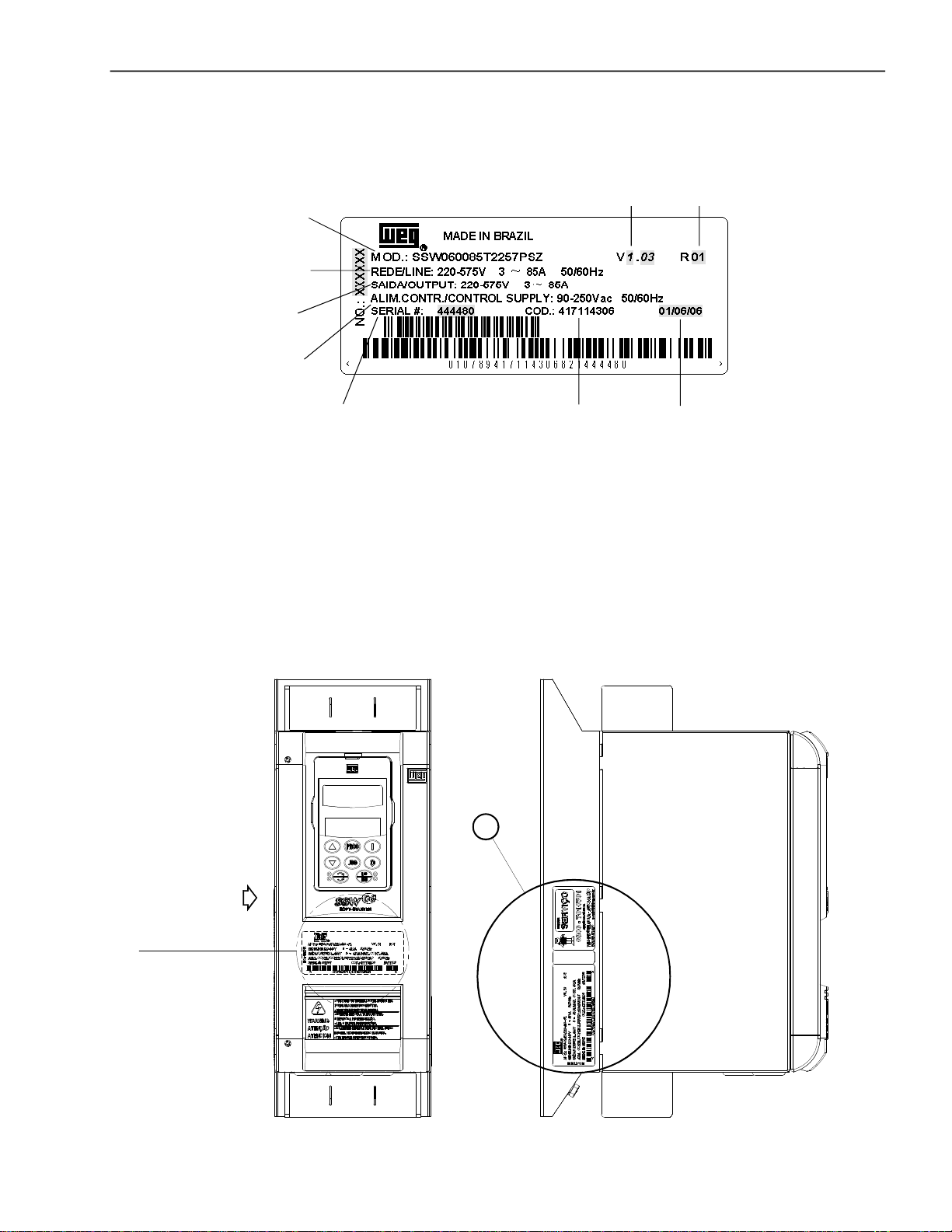

2.4 SOFT-STARTERSSW-06IDENTIFICATION

CHAPTER2 - GENERALINFORMATION

SSW-06 Model

Input Data (Voltage,Number of

Phases, Current, Frequency)

Output Data (Voltage, Number

of Phases, Current)

Control Power Supply Data

(Voltage, Frequency)

SerialNumber

Figure 2.3 - Soft-Starter SSW-06 nameplate

Software

Version

WEGItem

Number

Hardware

Revision

Manufacturing

Date

LocationofSoft-Starter SSW-06 nameplate:

X

VER DETALHE "A"

View Detail A

Identificationnameplate

of the SSW-06

(Internal Cover)

FRONT VIEW VIEW X

FRONTAL

VISTA DE X

A

Figure 2.4 - Detail of the Soft-Starter SSW-06 nameplate

27

CHAPTER2 - GENERALINFORMATION

End of

code

Special

software:

Blank =

standard

S1=special

software

Special

hardware:

Blank =

standard

H1 = 115V

ventilation

(model 950A)

H2 = 230V

ventilation

(models

950A,1100A

and1400A)

Human-

Machine

Interface

(Keypad):

Blank =

standard

SI= without

keypad

Options:

S=standard

O=with options

Manual

language:

P=portuguese

E=english

S=spanish

G=german

HOW TO SPECIFY THE SSW-06 MODEL:

Power supply

voltage:

2257=

(220 to 575)V

5769=

(575 to 690)V

Thee-phase

power supply

(1)

(1)

(1)

(1)

Nominal

output

current:

0010=10A

0016=16A

0023=23A

0030=30A

0045=45A

0060=60A

0085=85A

0130=130A

0170=170A

0205=205A

0255=255A

0312=312A

0365=365A

0412=412A

0480=480A

0604=604A

0670=670A

0820=820A

0950=950A

1100=1100A

1400=1400A

28

SSW-06 0085 T 2257 E S _ _ _ _ _ _ Z

Soft-Starter

SSW-06

WEG Series

NOTE!

The optionfield (S or O) defines if the Soft-Starter SSW-06 is a standard version or if it is equipped withany optional devices. If the standard version is

required, the code ends here. The modelnumber always has the letter Z at the end. For example:

SSW060085T2257ESZ = StandardSoft-StarterSSW-06 with current of 85A and 220V to 575V with manual in English.

If there are accessories, the spaces must be filled out in the correct sequence until the code ends with the letter Z.

Thestandard product is defined as describedhere:

Degree of protection: IP20 from10A to30A.

Degree of protection:IP00from 45Ato 1400A.

Human-MachineInterface:HMI-SSW06 (with LCD and LEDdisplays).

Note: The communication kits are optional, see chapter 9.

(1) Model 10A, 16A, 23Aand 30Anot available in the line 690V.

CHAPTER2 - GENERALINFORMATION

2.5 RECEIVINGAND STORAGE

The SSW-06 is supplied in packaging according to the model:

- Models 10A to 205A in a cardboard box;

-Models 255Ato 365Ain a cardboard box over a wooden box;

- Models 412A to 1400A in a wooden box.

The outside of the packing container has a nameplate that is identical

tothatonthe Soft-Starter SSW-06.Pleasecheckif the nameplatedata

matches the ordereddata.

Themodels upto 205A mustbe placed and openedona table withthe

helpof twoor more people,open thebox, remove thefoam protection

andremoveSoft-StarterSSW-06.

Models greater than 255Amust be opened on the floor. Open the box

and,remove theboltsthatfastentheSoft-StarterSSW-06 onthepallet.

The Soft-Starter SSW-06 must be handled witha hoist.

Check if:

The Soft-Starter SSW-06 nameplate data matches the purchase

order;

The equipmenthasnot been damaged during transportation.If any

problem is detected, contact the carrier immediately.

If theSoft-Starter SSW-06 is nottobe installedimmediately, store it

within its original cardboard box in a clean and dry room (Storage

temperatures between-25°C(-13°F) and 65°C(149ºF)).

29

3.1 MECHANICAL INSTALLATION

CHAPTER 3

INSTALLATION AND CONNECTION

Thischapterdescribes theelectricandmechanicinstallationprocedures

of the SSW-06 Soft-Starters. The orientations and suggestions must

befollowedforcorrect product functioning.

3.1.1Environment Conditions

3.1.2 Dimensions of the

Soft-StarterSSW-06

A

The location of the Soft-Starter SSW-06 installation is an important

factorto assure good performance and highproduct reliability.

ForproperinstallationoftheSSW-06Soft-Starter,wemakethefollowing

recommendations:

Avoiddirectexposure tosunlight,rain,excessivemoisture or marine

environment;

Avoidexplosiveor corrosive gases andliquids;

Avoidexcessivevibration,dustormetallicand/oroilparticles intheair.

Allowed Environment Conditions:

Temperature:0ºCto 55ºC (32ºF to 131ºF) –Nominal conditionsfor

models 10A to 820A; 0ºC to 40ºC (32ºF to 104ºF) – Nominal

conditions for models950Ato 1400A.2%currentreduction for each

degreeCelsius above the specification in the nominal conditions.

RelativeAirMoisture: 5% to 90%, non-condensing.

Maximum Altitude:1000m (3,300ft) - nominal conditions.

From 1000mto4000m(3,300ftto13,200ft)-with1%currentreduction

foreach100m(330ft) above1000m (3,300ft).

From 2000m to 4000m (6,600ft to 13,200ft) - with 1.1% voltage

reductionfor each 100m(330ft)above2000m (6,600ft)sealevel.

Degree of Pollution:2 (according toUL508).

Water,condensationor conductivedust/particlesarenotallowedin

the air.

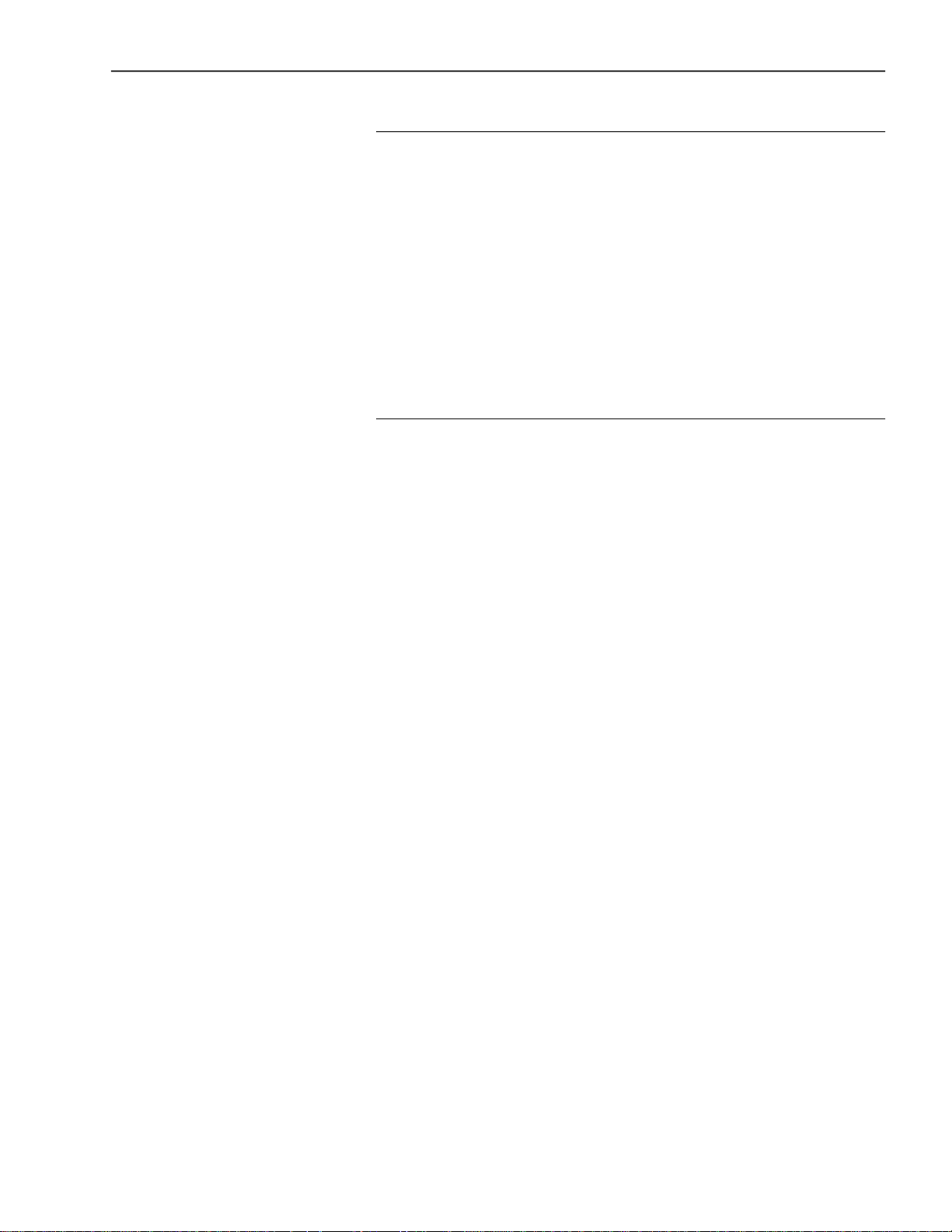

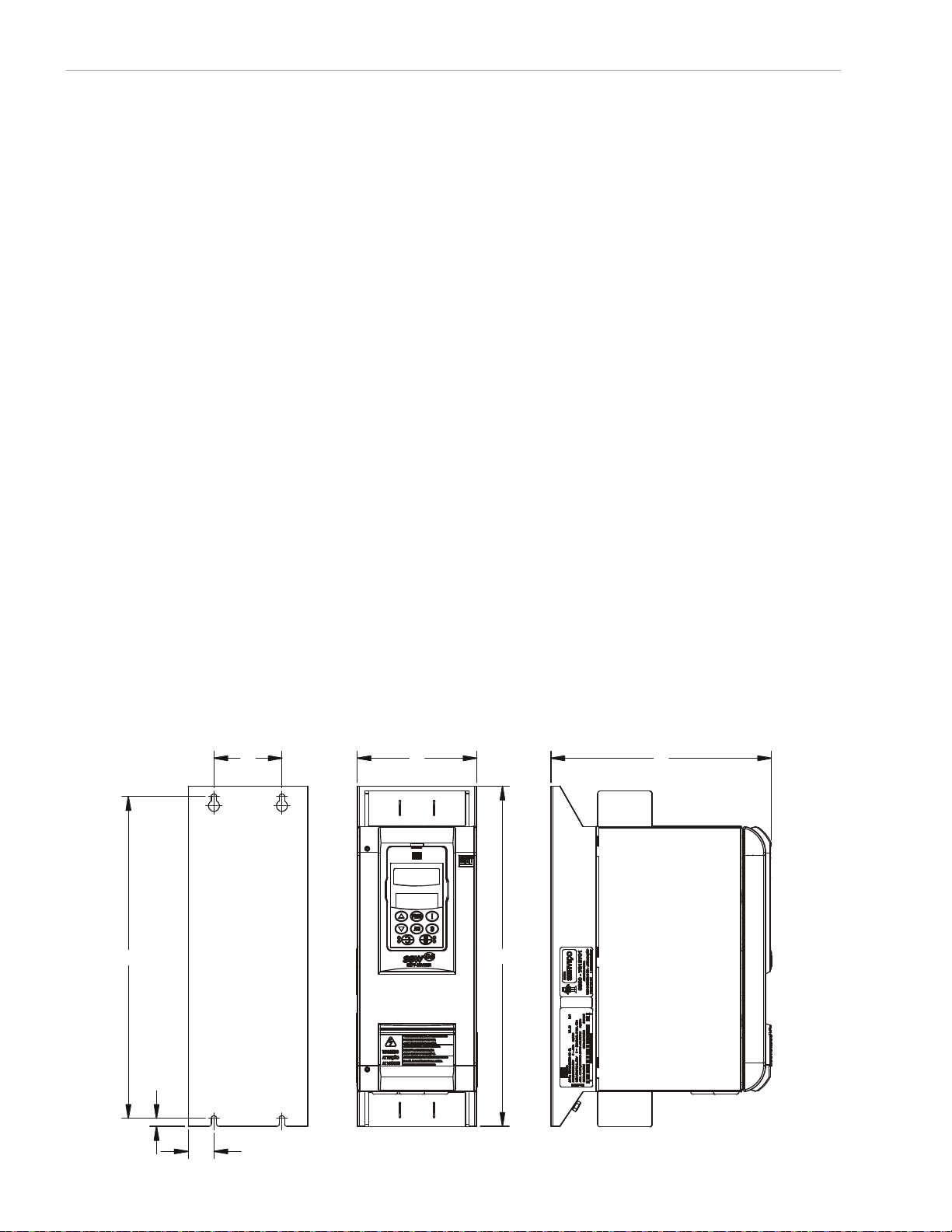

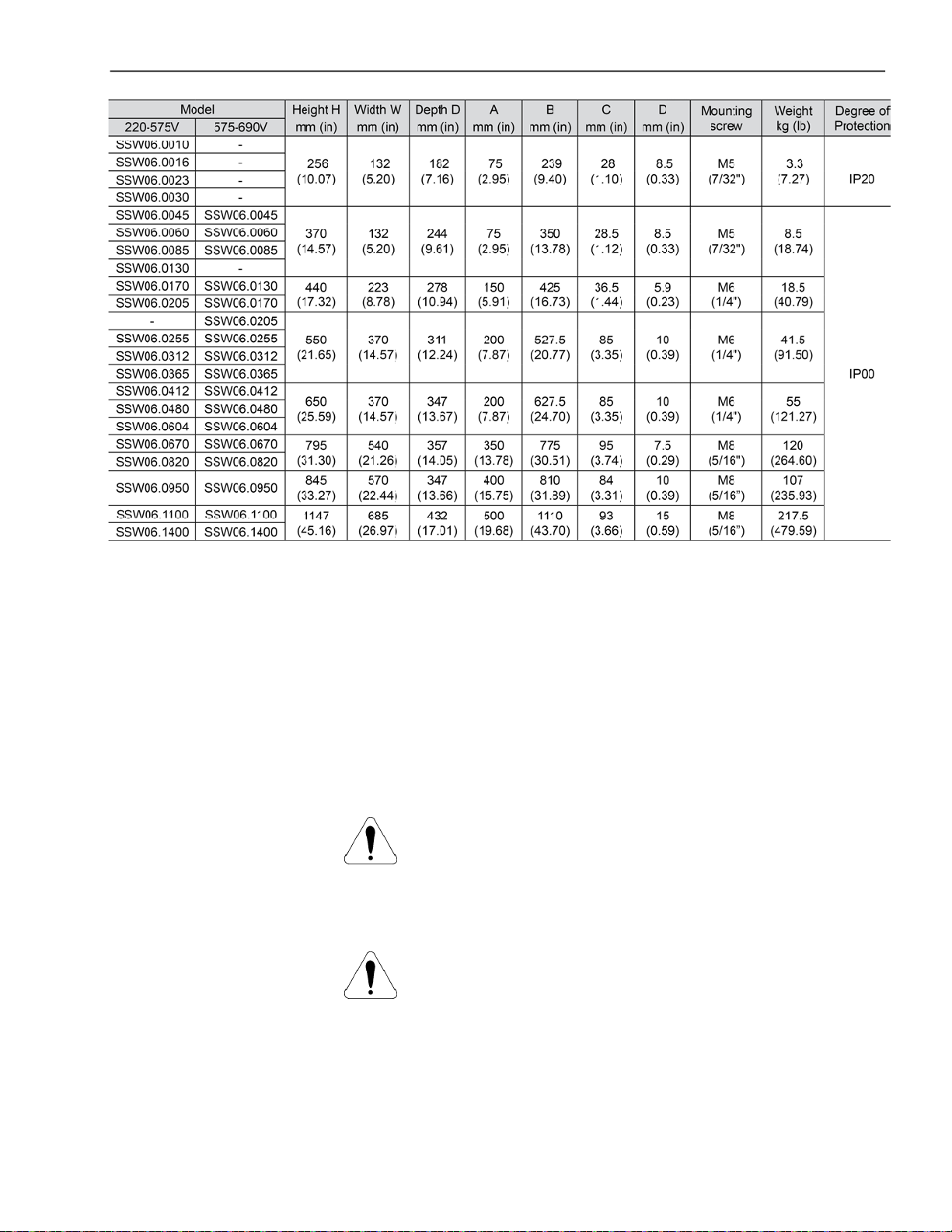

Externaldimensionsandmountingholes followFigure3.1andTable3.1.

W

D

30

B

C

D2

Figure 3.1 - Dimensional Drawings of the Soft-Starter SSW-06

H

CHAPTER3- INSTALLATIONANDCONNECTION

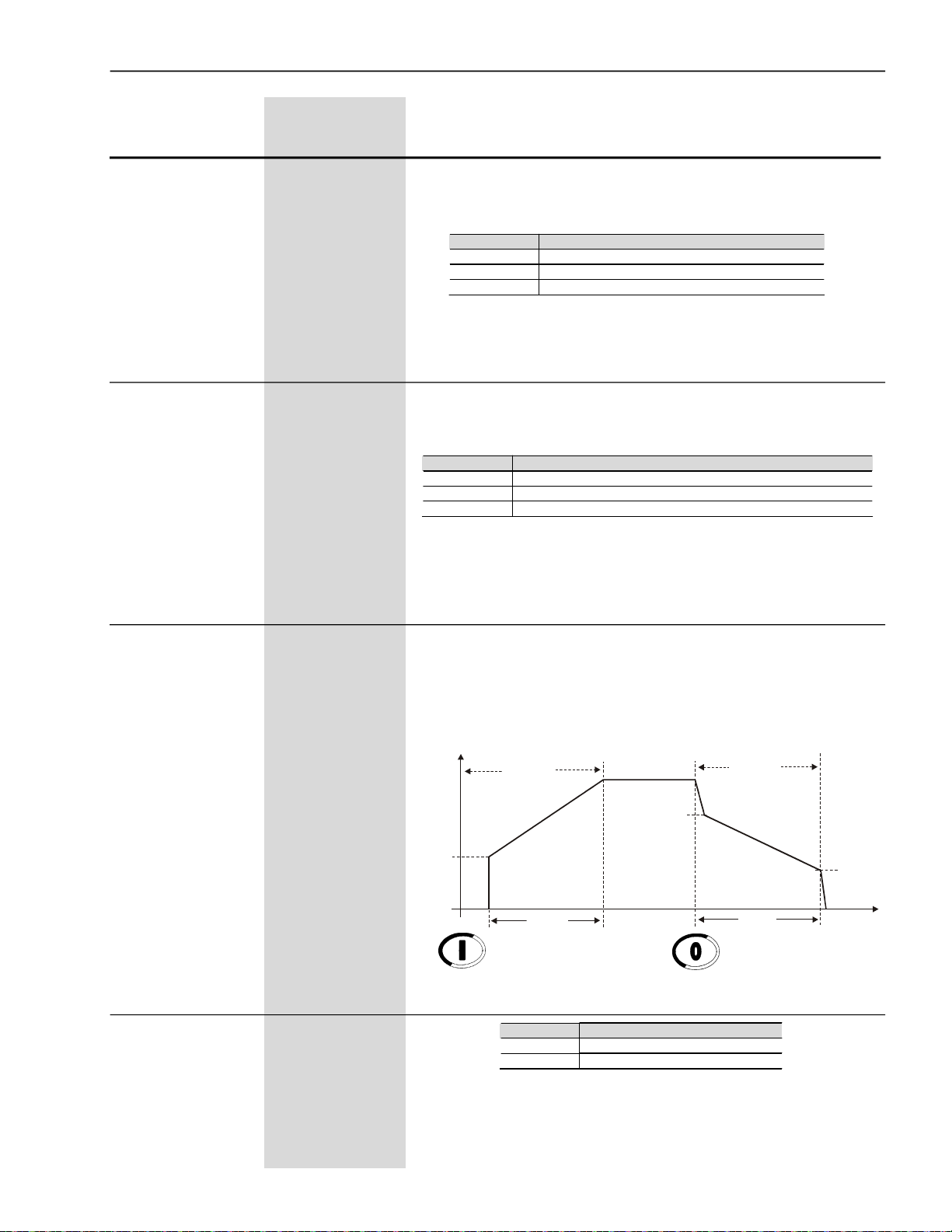

3.1.3 Positioning / Fixing

Table 3.1 - Installation Data with dimensions in mm (in)

Free space for coolingairflowmustbe left open around the SSW-06

Soft-Starter, according to figure 3.2. Thedimensions of each space

are describedin table 3.2.

InstalltheSoft-Starter SSW-06inthe verticalpositionaccordingto the

followingrecommendations:

1) Install the SSW-06 Soft-Starteron a flat surface;

2) Do not place heat sensitive components above the SSW-06 SoftStarter.

ATTENTION!

If the Soft-Starters are installed one next to the other, use minimum

distance B.

When a Soft-Starter is installedaboveanother, use minimumdistance

A+CandavoidtheSoft-Starter abovefrom thehotairthat comesfrom

theSoft-Starter below.

ATTENTION!

Foreseeindependentconduitsor electroducts for physicallyseparating

the signal, control and power conductors (see item 3.2, Electrical

Installation).

31

CHAPTER3- INSTALLATIONANDCONNECTION

C

AYB

Air Flow Outlet

B

Air Flow Inlet

Figure 3.2 - Free spaces for cooling

Model

SSW-06.0010

SSW-06.0016

SSW-06.0023

SSW-06.0030

SSW-06.0045

SSW-06.0060

SSW-06.0085

SSW-06.0130

SSW-06.0170

SSW-06.0205

SSW-06.0255

SSW-06.0312

SSW-06.0365

SSW-06.0412

SSW-06.0480

SSW-06.0604

SSW-06.0670

SSW-06.0820

SSW-06.0950

SSW-06.1100

SSW-06.1400

A

mm(in)

150 (5.90)

150 (5.90)

150 (5.90)

150 (5.90)

150 (5.90)

150 (5.90)

150 (5.90)

150 (5.90)

B

mm(in)

30 (1.18)

30 (1.18)

30 (1.18)

30 (1.18)

30 (1.18)

30 (1.18)

30 (1.18)

100 (3.93)

C

mm(in)

150 (5.90)

150 (5.90)

150 (5.90)

150 (5.90)

150 (5.90)

150 (5.90)

150 (5.90)

150 (5.90)

Y

mm(in)

50 (1.96)

50 (1.96)

50 (1.96)

50 (1.96)

50 (1.96)

50 (1.96)

50 (1.96)

50 (1.96)

Table 3.2 - Recommended free spaces

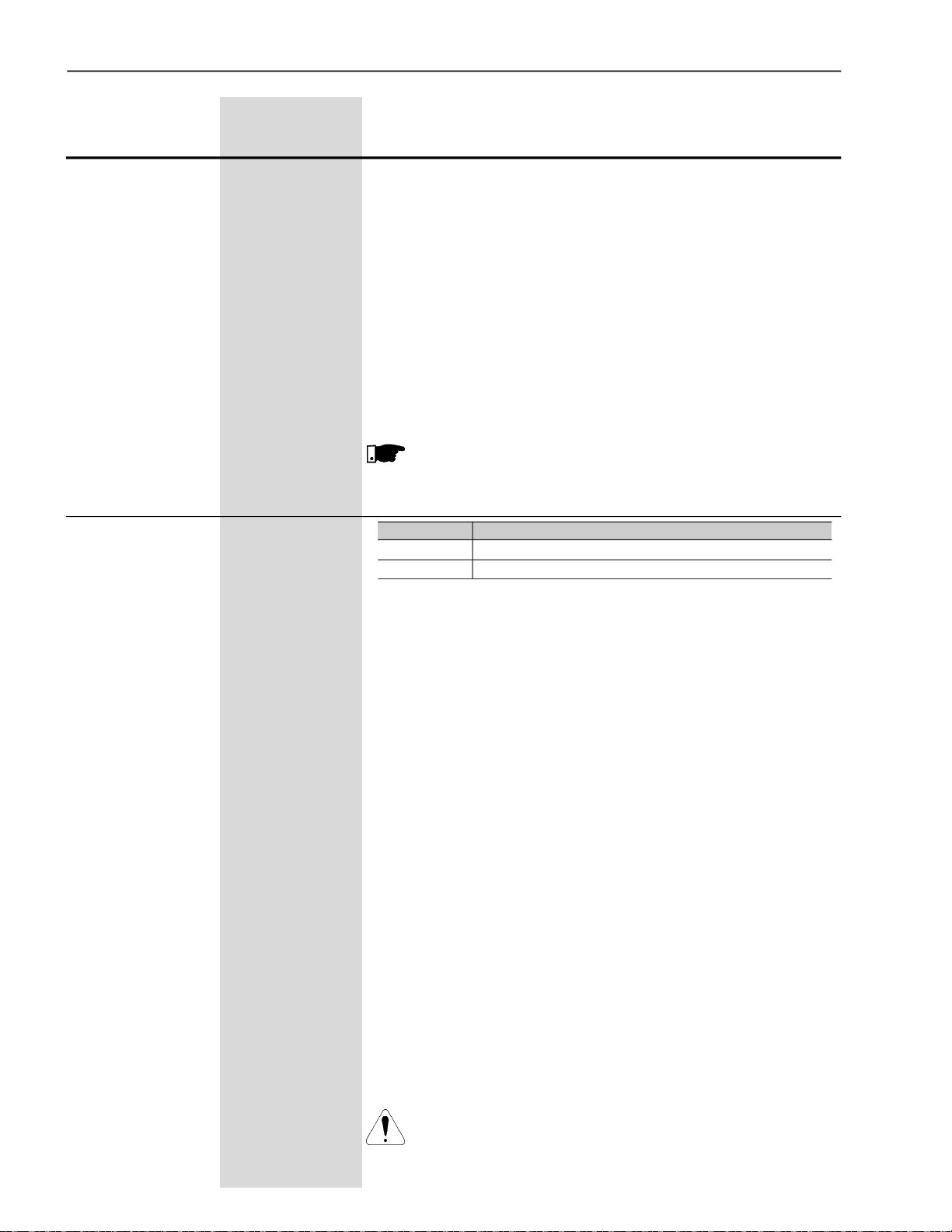

3.1.3.1Mounting insidea Panel

WhentheSoft-StartersSSW-06areinstalledinpanelsor closedmetallic

boxes, adequate cooling is required to ensure that the temperature

aroundtheinverterwillnot exceed the maximum allowedtemperature.

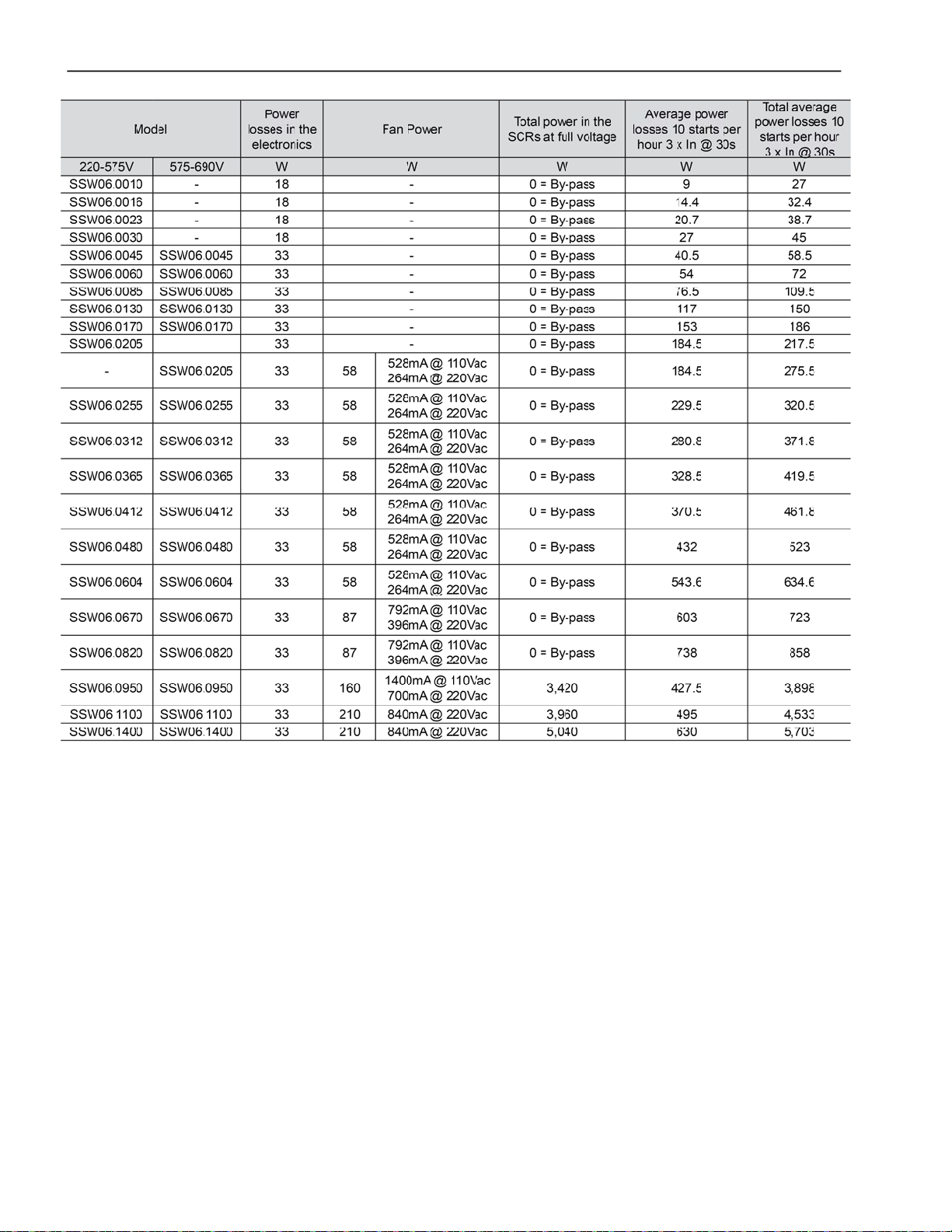

See dissipated power in the table 3.4.

32

CHAPTER3- INSTALLATIONANDCONNECTION

Use the minimum recommended panel dimensions and its cooling

requirements:

Table 3.3 - Panel Dimensions and Cooling Requirements

NOTE!

The fans recommended in table 3.3 are base on:

- a working cycle of 10 starts per hour with 3 x In of the SSW-06 for

30sat an ambient temperatureof 55°C (131°F) for the modelsfrom

10A to 820A;

- a working cycle of 5 starts per hour with 30s at an ambient

temperature of 40°C (104°F)for the modelsfrom 950A to 1400A.

33

CHAPTER3- INSTALLATIONANDCONNECTION

34

Table 3.4 - Power losses for panel fan dimensioning

CHAPTER3- INSTALLATIONANDCONNECTION

tc

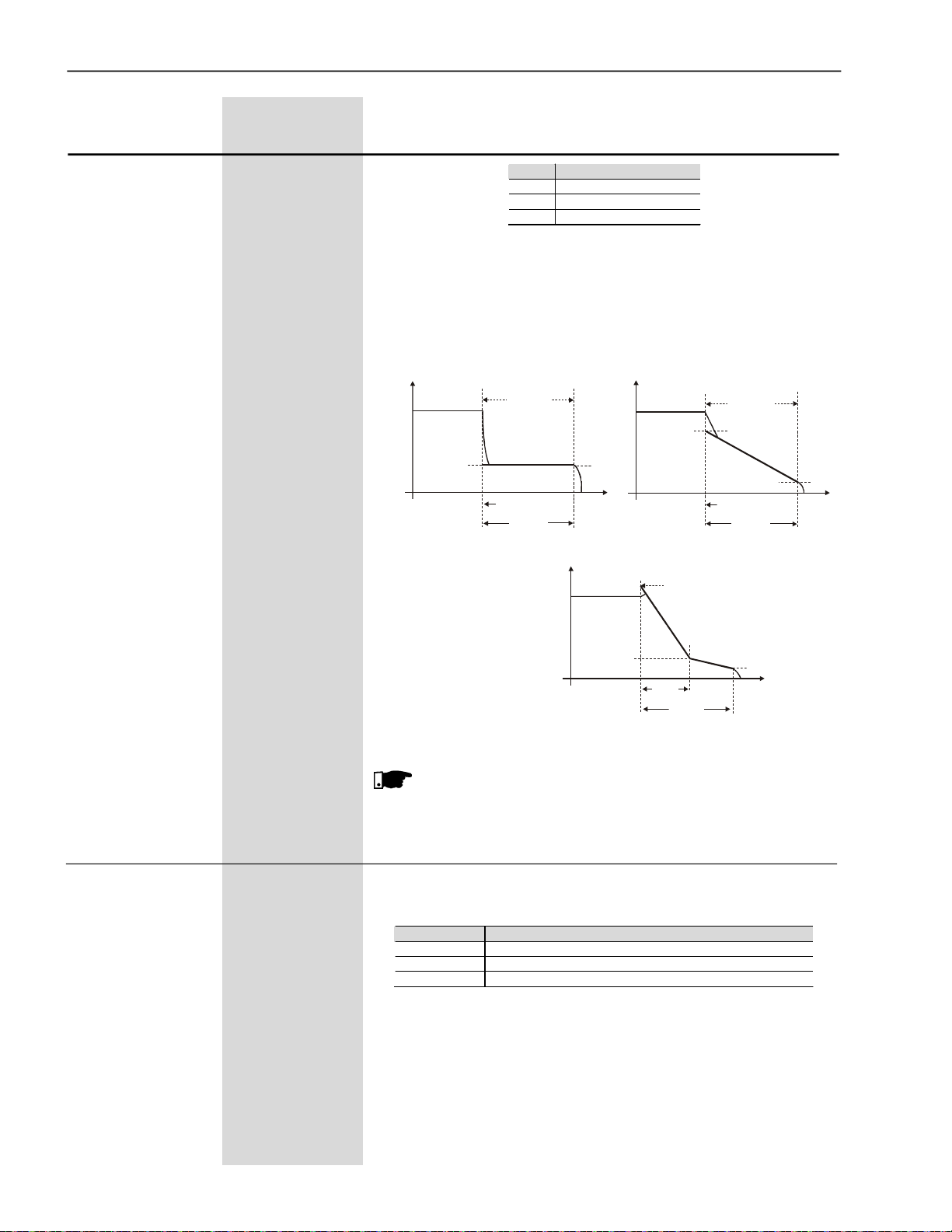

Thetotal power losses canbe determined throughtheequationbelow:

trInVtpIpVtcPe

)32.1()32.1()(

Ptd

where:

Pe = power losses at the electronics (W)

tc = working cycle time (s)

Ip = start current (A)

tp = start time (s)

In = current at nominal duty (A), with By-pass In=0

tr = nominal duty time (Full Voltage) (s)

Ptd = total power losses (W)

3.1.3.2 Mountingona Surface

P(W)

I(A)

0

Ip

In

Pe

tp

Figure 3.3 - Soft-Starter SSW-06 working cycle for

tr

tc

power loss determination

t(s)

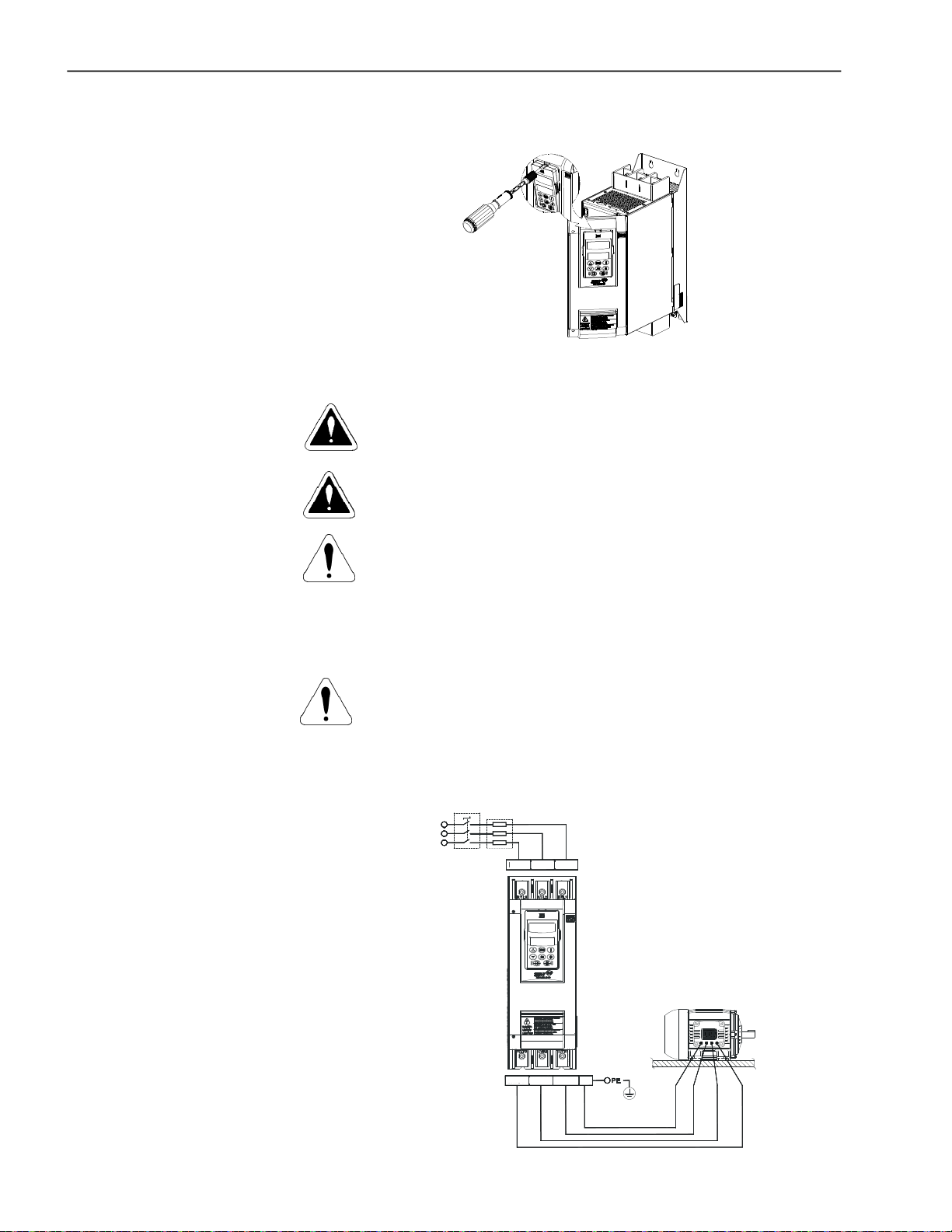

The figure 3.4 shows the installationof the Soft-Starter SSW-06 on a

mountingplate.

Figure 3.4 - Mounting procedures for the SSW-06 on a flat surface

35

CHAPTER3- INSTALLATIONANDCONNECTION

First install and partiallytighten the mounting bolts, in agreement with

figures3.1 and 3.4and table 3.1, then installtheSoft-StarterSSW-06

and tighten the mounting bolts.

Figure 3.5 - Procedures for keypad removal and front cover

opening for the control connections exposure

3.2 ELECTRICAL INSTALLATION

DANGER!

Be sure that the AC input power is disconnected before making any

terminalconnections.

DANGER!

TheSoft-StarterSSW-06cannotbeusedas anemergencystopdevice.

ATTENTION!

The information below willbe a guideto achieve a proper installation.

Also follow all applicable local standards for electrical installations.

Provide at least a 0.25m (10 in) space between sensitive equipment

andwiringfrom the Soft-Starter SSW-06, andthe cablesbetweenthe

Soft-StarterSSW-06andthemotor.Example:PLC,temperaturewiring,

thermocouple cables, etc.

ATTENTION!

On the first power-up of models 45A to 365A, if a contactor is not

used to isolate the power input, and which will fall out upon under

voltage, then the control supply must be connected first and the

minimum necessary parameters must be programmed after which

the main power may be connected.

Circuit-breaker

T

S

R

Line

Fuses

R/1L1

S/3L2 T/5L3

36

U/2T1 W/6T3 PEV/4T2

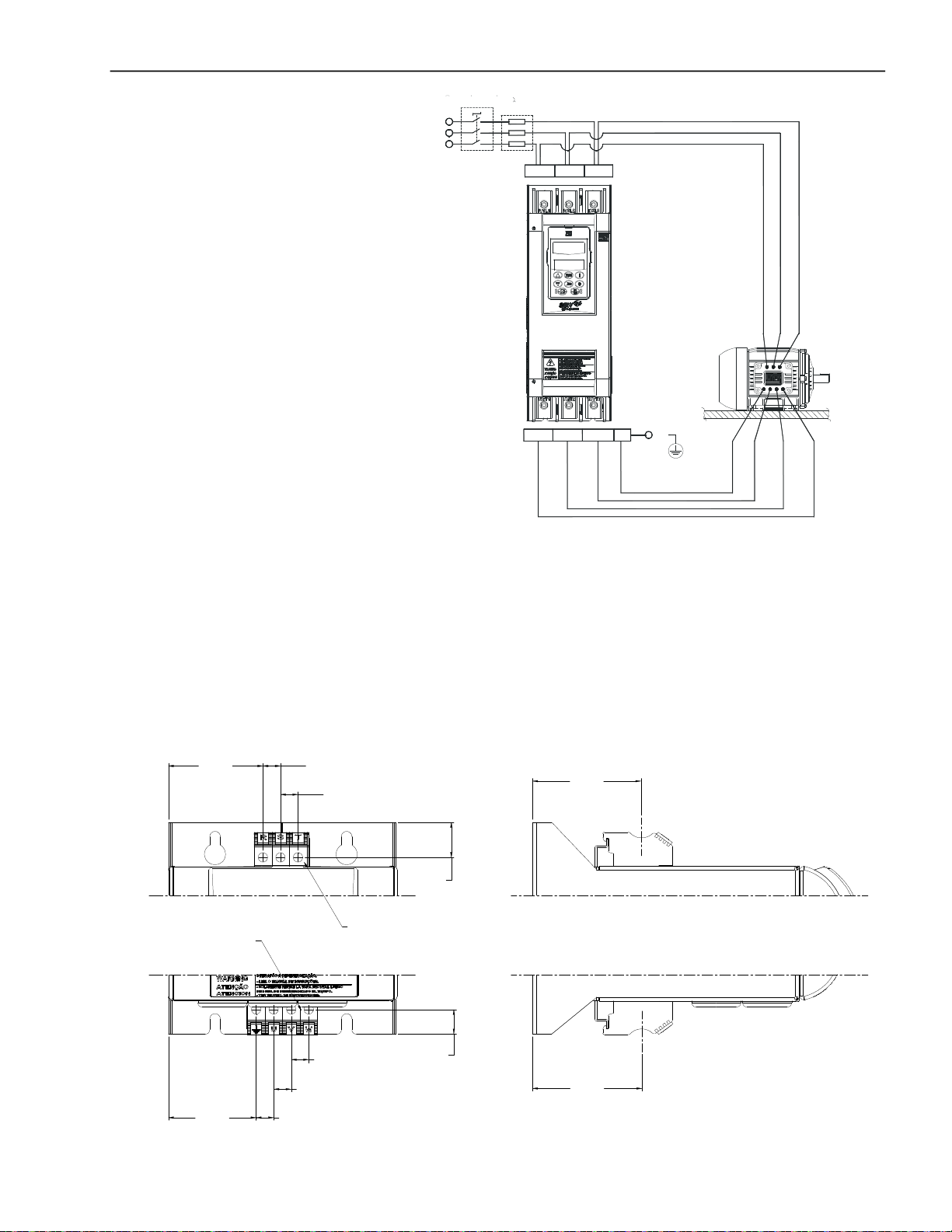

Figure 3.6 - Standard power/grounding connections

U/2T1 V/4T2 W/6T3 PE

R/1T1 S/3T2 T/5T3

PE

Circuit-breaker

T

S

R

Line

Fuses

CHAPTER3- INSTALLATIONANDCONNECTION

S/3L2

R/1L1

T/5L3

3.2.1 PowerTerminals

a) Models: 10A to 30A

54

(2.12)

OUTPUT TERMINAL

POWER

10(0.39)

10(0.39)

Figure 3.7 - Power/Grounding connections for inside delta motor connection

The power connection terminals can be of different sizes and

configurations,dependingontheSoft-StarterSSW-06modelasshown

in Figures 3.8 and 3.9.

Terminals:

R / 1L1, S / 3L2 and T / 5L3: AC supply line

U / 2T1, V / 4T2 and W / 6T3: Motor connection.

62

(2.44)

20

(0.79)

INPUT TERMINAL

POWER

50

(1.96)

10(0.39)

10(0.39)

10(0.39)

14

(0.55)

62

(2.44)

Figure 3.8 a) - Power Terminals

37

CHAPTER3- INSTALLATIONANDCONNECTION

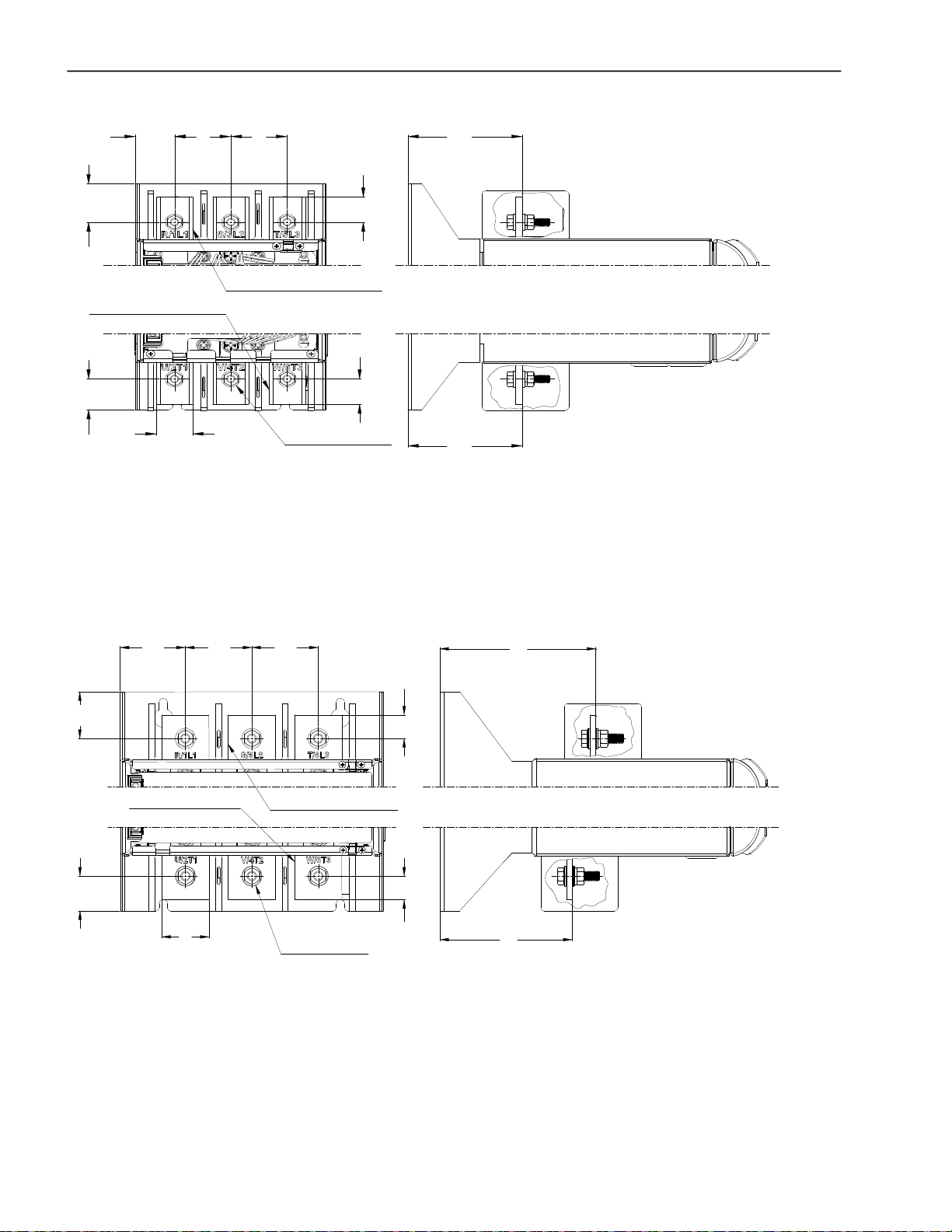

b) Models: 45A to 130A (220 - 575V) or 45A to 85A (575 - 690V)

27

(1.06)

30.6

20)

(1.

(1.54)

OUTPUT TERMINAL

POW ER

24.5

(0.96)

*Dimensionsin mm (in)

39

(1.54)

INPUT TERMINAL

POW ER

25

(0.98)

39

0

2

(0.79)

20

(0.79)

M6 (6x)

79.5

(3.13)

79.5

(3.13)

c) Models: 170A and 205A (220 - 575V) or 130A and 170A (575 - 690V)

)

39.5

(1.56

29.4

(1.16)

55.3

(2.18)

OUTPUT TERMINAL

POWER

(2.22)

40

(1.57)

56.3

56.3

(2.22)

INPUT TERMINAL

POWER

M8 (6x)

20

0.79)

(

20

(0.79)

*Dimensionsin mm (in)

Figure 3.8 b) c) - Power Terminals

(5.20)

112

(4.41)

132

38

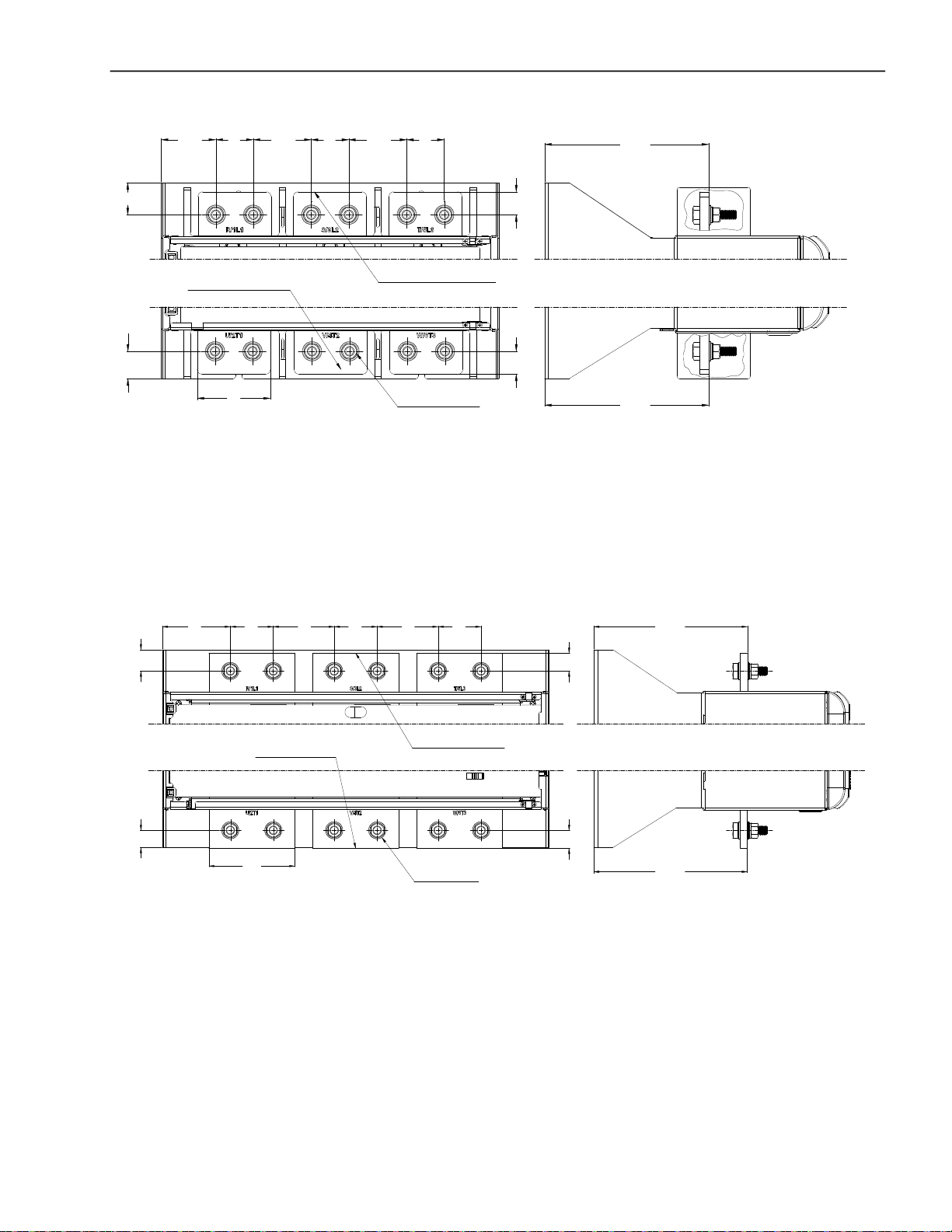

d) Models: 255A to 604A (220 - 575V) or 205A to 604A (575-690V)

CHAPTER3- INSTALLATIONANDCONNECTION

41

(1.61)(2.35) (2.50)

35

(1.38)

OUTPUT TERMINAL

POWER

30

(1.18)

80

(3.15)

*Dimensionsin mm (in)

e) Models: 670A and 820A

63.559.8

(1.61)

41

63.5

41

(1.61)(2.50)

INPUT TERMINAL

POWER

179.5

(7.07)

25

(0.98)(0.98)

25

M10 (12x)

179.5

(7.07)

95

29.7

(3.74)

(1.17)

23.9

(0.94)

*Dimensionsin mm (in)

60 85

(2.36)

120

(4.72)

(3.35)

OUTPUT TERMINAL

POWER

60

(2.36) (2.36)

85

(3.35)

60

INPUT TERMINAL

POWER

M12 (12x)

Figure 3.8 d) e) - Power terminals

214.3

25

(0.98)

25

(0.98)

(8.44)

214.3

(8.44)

39

CHAPTER3- INSTALLATIONANDCONNECTION

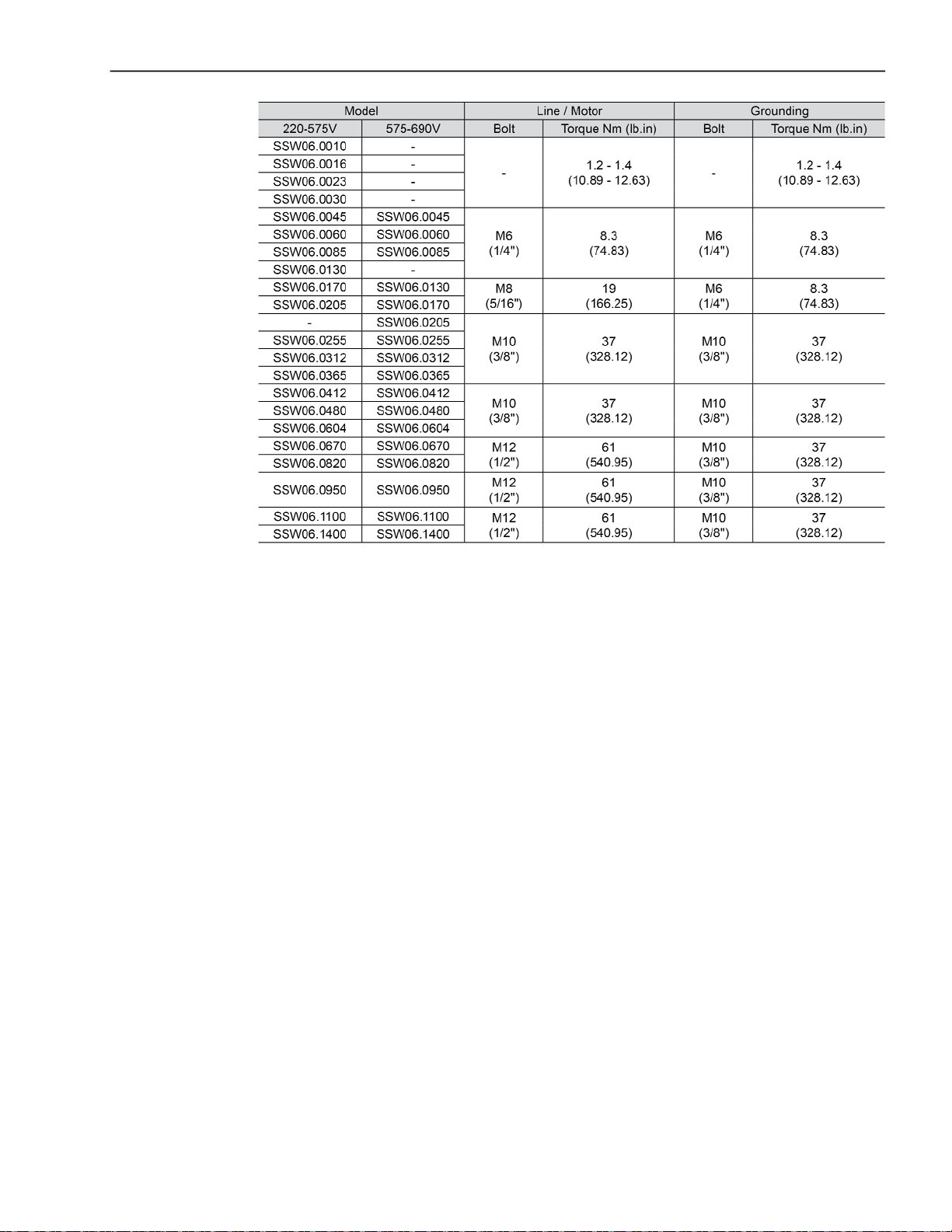

f) Models: 950A

M12 (12x)

04)

51.7

(2.

49.798.8

(1.96)

(3.89)

95)

49.5

(1.

53.4 22

(2.10)

(0.87)

*Dimensionsin mm (in)

g) Models: 1100Aand 1400A

110.3 49.7

(4.34)

156

(6.14)

(1.96) (1.96)

100

(3.94)

22

(0.87)

110.3

(4.34)

M10 (6x)

156

(6.14)

49.7

(0.87)

(1.97)

22

50

40

(1.57)

20

INPUT TERMINAL

POWER

(0.79)

14

(0.55)

OUTPUT TERMINAL

POWER

212.2

(8.35)

22

(0.87)

66.1

(2.60)

.3

60

(2.37)

(1.57)

50

(1.97)

40

58

(2.28)

(5.09)

104.5

(4.11)

129.4

*Dimensionsin mm (in)

158

(6.22)

163

(6.42)

40

(1.57)

120

(4.72)

(1.97)

100

(3.94)

158

(6.22)

M12 (12x)

16350

(6.42)

M12 (12x)

40

(1.57)

(1.97)

INPUT TERMINAL

POWER

50

OUTPUT TERMINAL

POWER

Figure 3.8 f) g) - Power terminals

20 40

40

20

(1.57)(0.79)

(1.57)

(0.79)

89

(3.50)

261.8

(10.31)

40

CHAPTER3- INSTALLATIONANDCONNECTION

Table 3.5 - Maximum tightening Torque for power connection

41

CHAPTER3- INSTALLATIONANDCONNECTION

FUN SUPPLY

POWER

FUN VOLTAGE

INPUT TERMINAL

OUTPUT TERMINAL

CONTROL

INPUT TERMINAL

POWER

3.2.2 Location of thePower/Grounding, ControlConnectionsandFanVoltageSelection

b) MODELS 45A to 130A

(220 - 575V) or

45A to 85A (575 - 690V)

a) MODELS 10A to 30A

c) MODELS 170A and 205A

(220 - 575V) or

130A and 170A (575 - 690V)

GROUNDING

INPUT TERMINAL

POWER

OUTPUT TERMINAL

POWER

d) MODELS 255A, to 365A

(220 - 575V) or

205A to 365A (575 - 690V)

POWER

CONTROL

GROUNDING

INPUT TERMINAL

POWER

OUTPUT TERMINAL

POWER

e) MODELS 412A to 604A

GROUNDING

POWER

POWER

CONTROL

POWER

f) MODELS 670AAND 820A

42

GROUNDING

POWER

GROUNDING

INPUT TERMINAL

GROUNDING

INPUT TERMINAL

POWER

OUTPUT TERMINAL

POWER

ATTENTION!

SELECTTHEFANVOLTAGEINACCORDANCE

WITHTHEVOLTAGEAPPLIEDTOTHE

TERMINALSX1:33ANDX1:34

!

ATENCION!

SELECCIONARLATENSIONDELOSVENTILADORES

DEACUERDOCONLATENSIONAPLICADAALOS

BORNESX1:33YX1:34

ATENÇÃO!

SELECIONEATENSÃODOSVENTILADORES

DEACORDOCOMATENSÃOAPLICADAAOS

BORNESX1:33EX1:34

X1E

FAN VOLTAGE

SELECTION

110/220V

FAN SUPPLY

POWER

CONTROL

POWER

OUTPUT TERMINAL

POWER

CONTROL

POWER

FAN SUPPLY

FAN VOLTAGE

SELECTION

110/220V

OUTPUT TERMINAL

POWER

SELECTION

110/220V

CONTROL

Figure 3.9 a) to f) - Location of the Power/ Grounding, Control Connections and Fan Voltage Selection

CHAPTER3- INSTALLATIONANDCONNECTION

Figure 3.9 g) and h) - Location of the Power/ Grounding, Control Connections and Fan Voltage Selection

3.2.3 RecommendedPower/ GroundingCables

Thedescribed specifications intables3.6 and 3.7are validonlyforthe

following conditions:

Copper wires for 70°C (158°F) with PVC insulation, with ambient

temperatureof 40°C(104°F),installedin horizontalorverticalholed

conduits, with cables arranged in a single layer.

Nakedor silvercoatedcopperbusbars withroundedges and radius

equal to 1mm with room temperature of 40°C (104ºF) and bus

temperature of 80°C(176ºF).

Note: When external By-pass contactors are applied, use the same

cablesor busbar applied forthe motor connection.

NOTE!

Forcorrectcablesizing, considertheinstallationcondition,themaximum

permittedlinevoltage drop,andfollowelectrical instructionsdefined by

localregulations.

43

CHAPTER3- INSTALLATIONANDCONNECTION

Table 3.6 - Recommended cables or bus bars for standard connection,

according to UL508 and IEC 60092-352

44

CHAPTER3- INSTALLATIONANDCONNECTION

Table 3.7 - Recommended cables or bus bars for delta inside motor connection, according to UL508 and IEC 60092-352

45

CHAPTER3- INSTALLATIONANDCONNECTION

3.2.4 Connection of the Power Supplytothe Soft-Starter

DANGER!

TheAC inputvoltage mustbe compatiblewiththeSoft-StarterSSW-06

nominalvoltage.

DANGER!

Provideapowersupplydisconnectingswitch.Thisdisconnectingswitch

must disconnect the AC input voltage from the Soft-Starter SSW-06,

wheneverrequired (for instanceduringmaintenance services).

DANGER!

If a disconnect switch or a contactor is inserted in the motor supply

line,DO NOT operate these devices witha runningmotor or when the

Soft-Starter SSW-06 is enabled.

ATTENTION!

Controlof overvoltageintheline that suppliesthe Soft-Startermust be

madeusing surge protectionwithavoltageof 680Vac(phasetophase

connection) and energy absorption capacity of 40 joules (for models

from10Ato205A)and80 joules(formodelsfrom255Ato1400A),allfor

220 to 575 Vac models.

3.2.4.1 PowerSupplyCapacity

46

NOTE!

Use wire sizing and fuses as recommended in tables 3.6, 3.7 and 3.9.

The connector tightening torque is as indicated in table 3.5. Use 70ºC

(158ºF)copper wiresonly.

The SSW-06 Soft-Starter is suitable to use in a circuit capable of

supplying at most the current (symmetric Arms) established for each

model, and, respective voltage (V) according to table 3.8. This, when

protected by high speed semiconductor fuses.

Standard

Model

SSW-06.0010

SSW-06.0016

SSW-06.0023

SSW-06.0030

SSW-06.0045

SSW-06.0060

SSW-06.0085

SSW-06.0130

SSW-06.0170

SSW-06.0205

SSW-06.0255

SSW-06.0312

SSW-06.0365

SSW-06.0412

SSW-06.0480

SSW-06.0604

SSW-06.0670

SSW-06.0820

SSW-06.0950

SSW-06.1100

SSW-06.1400

Table 3.8 - Maximum current capacity of the power supply

Connection

220-575V (kA)

5

5

5

5

5

5

5

10

10

10

10

18

18

18

30

30

42

42

85

85

85

Inside - Delta

Connection

220-575V (kA)

-

-

-

10

10

10

18

18

18

30

30

42

42

42

85

85

85

100

100

125

CHAPTER3- INSTALLATIONANDCONNECTION

3.2.4.2 RecommendedFuses

The fuses to be used on the input must be high speed semiconductor

fuses with l2t lower or equal to 75% of the SCR valueindicated in table

3.9. (A2s).

These fuses will protect the SCRs in case of a short-circuit. Normal

fuses can also be used, instead of the high speed, which will protect

the installation from short-circuits, but the SCRs will not be protected.

Model

SSW-06.0010

SSW-06.0016

SSW-06.0023

SSW-06.0030

SSW-06.0045

SSW-06.0060

SSW-06.0085

SSW-06.0130

SSW-06.0170

SSW-06.0205

SSW-06.0255

SSW-06.0312

SSW-06.0365

SSW-06.0412

SSW-06.0480

SSW-06.0604

SSW-06.0670

SSW-06.0820

SSW-06.0950

SSW-06.1100

SSW-06.1400

Standard

Connection

In (A)

50

50

80

80

125

125

200

250

450

500

500

500

550

700

900

900

900

1400

1600

1600

2000

Table 3.9 - Recommended Fuses

Delta-Inside

Connection

In (A)

-

-

-

125

160

315

350

500

550

700

700

700

1250

1400

1600

1600

2000

2200

2500

3000

I²t of the SCR

(kA2S)

0.72

0.72

4

4

10

15

80

84

245

320

238

238

320

1452

4250

4250

4250

4250

14000

14000

15125

47

CHAPTER3- INSTALLATIONANDCONNECTION

3.2.5 Connectionofthe SSW-06Soft-Starter tothe motor

DANGER!

Powerfactor correction capacitorsshould never be fitted to the output

of the Soft-Starter SSW-06 (U / 2T1, V / 4T2 and W / 6T3).

ATTENTION!

For the protection based on the current reading and indication to work

correctly,in case of overloadprotection,thenominalcurrentof the motor cannot be lower than 30% of the nominalcurrent of the SSW-06

Soft-Starter.

It is not recommended to use motors with the load working duty lower

than 50% of its nominal current.

NOTE!

Use wire sizingand fuses as recommended in Table 3.6, 3.7 and 3.9.

The connector tighteningtorque is as indicated in Table3.5.Use 70ºC

(158ºF)copper wiresonly.

NOTE!

Soft-Starter SSW-06 is provided with anelectronic protection against

motor overload. This protection must be set according to the specific

motor. When several motors are connected to the same Soft-Starter

SSW-06, use individualoverload relays for each motor.

The SSW-06 Soft-Starter can be connected to the motor in two ways,

according to items 3.2.5.1 and 3.2.5.2.

3.2.5.1 StandardThree-Wire Connection (P150=0=Inactive)

The standard 3 wire connection allows the SSW-06 Soft-Starter line

current to be equal to the motor current.

R

S

T

N

PE

R

U

S

V

4/U2

6/W2

1/U1

3/W1

Figure 3.10 - Soft-Starter SSW-06 with standard connection

T

2/V1

5/V2

R

S

T

N

PE

1/U1

2/V1

4/U2

S

V

5/V2

6/W2

3/W1

R

W

U

T

W

48

CHAPTER3- INSTALLATIONANDCONNECTION

3.2.5.2 InsideDelta MotorConnection (P150=1=Active)

Inthiskind of connection,theSSW-06 Soft-Starter linecurrentisequal

to approximately58% of the nominal current of the motor.

R

S

T

N

PE

S

4/U2

U

1/U1

R

R

6/W2

3/W1

Figure 3.11 - Soft-Starter SSW-06 Inside Delta Motor Connection

R

S

T

N

PE

S

10/U4

S

2/V1

V

5/V2

W

T

T

S

2/V1

3/W1

V

8/V3

5/V2

W

11/V4

T

T

4/U2

7/U3

U

1/U1

R

12/W4

R

6/W2

9/W3

Figure 3.12 - Soft-Starter SSW-06 Inside Delta Motor Connection - motor with

double delta series connected

R

S

T

N

PE

S

4/U2

1/U1

10/U4

U

7/U3

R

12/W4 9/W3

R

S

V

2/V1

8/V3

11/V4

5/V2

W

T

T

6/W2 3/W1

Figure 3.13 - Soft-Starter SSW-06 Inside Delta Motor Connection - motor with

double delta parallel connected

49

CHAPTER3- INSTALLATIONANDCONNECTION

ATTENTION!

For inside delta motor connection, the motor must have a nominal

voltagefor deltaconnection.

Theinside deltamotorconnection cannotbeusedfor 690Vlinevoltage.

NOTES!

1) For motor inside delta connection, the SSW-06 Soft-Starter

connection cables to the power supply, fuses and/or the main

contactormustsupportthenominalcurrentof the motor. Themotor

connection cables to the Soft-Starter and/or the external By-pass

contactor connection must support 58% of the nominal current of

themotor.

2) Due to the presence of high currents and large cable size

requirements, we also recommend the use of copper busbars for

connecting the Soft-StarterSSW-06 to the power supply.

3) Duringstarting,themotorcurrentinrelationtotheSoft-Startercurrent

is1.50.However,at full voltage(afterthestarttimeof the motor) the

current relationis 1.73.

ATTENTION!

Payattentiontothe connectionof themotortotheSSW-06Soft-Starter,

respecttheconnection diagramsshowninthefiguresaboveaccording

to the type of motor windings. If it is necessary to change the motor

rotating direction, only invert the SSW-06 Soft-Starter connections to

the power supply.

Keepthe electronics turned off during the connection changes.

3.2.6 GroundingConnections

ATTENTION!

EnsurecorrectsettingofParameterP150beforethemotor is switched

ON.Soft-StarterSSW-06maybedamaged,whenthisparametersetting

is not correct.

P150 Action

0 (Inactive) Soft-Starter SSW-06 with standard connection to motor

1 (Active) Soft-Starter SSW-06 with inside delta motor connection

Table 3.10 - Connection of the Soft-Starter to the motor

DANGER!

TheSoft-Starter SSW-06 must begroundedfor safetypurposes(PE).

Theearthorground connectionmustcomplywiththelocalregulations.

For grounding, use cables with cross sections as indicated in Table

3.6. Make the ground connection to a grounding bar or to the general

groundingpoint(resistance 10 ohms).

DANGER!

TheACinputfor the Soft-StarterSSW-06 must be grounded.

DANGER!

Donotusetheneutralconductor forgroundingpurposes.Usea specific

groundconductor.

50

ATTENTION!

Do not share the ground wiring with other equipment that operate with

highcurrents(forinstance,highvoltagemotors,weldingmachines,etc.).

When more than one Soft-StarterSSW-06 is used, see figure 3.14.

CHAPTER3- INSTALLATIONANDCONNECTION

3.2.7 Fan Connections

Groundingbar

Internalto thePanel

Groundingbar

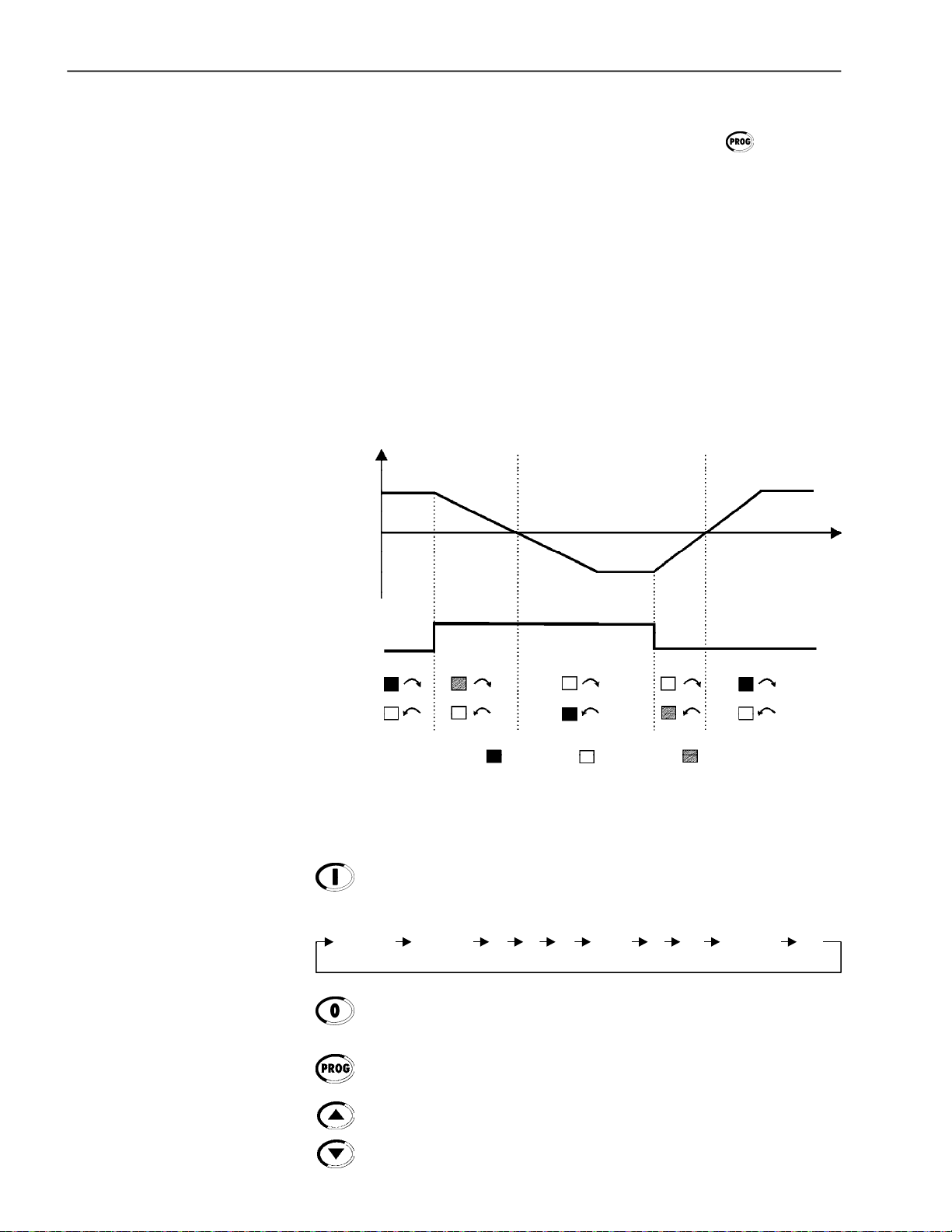

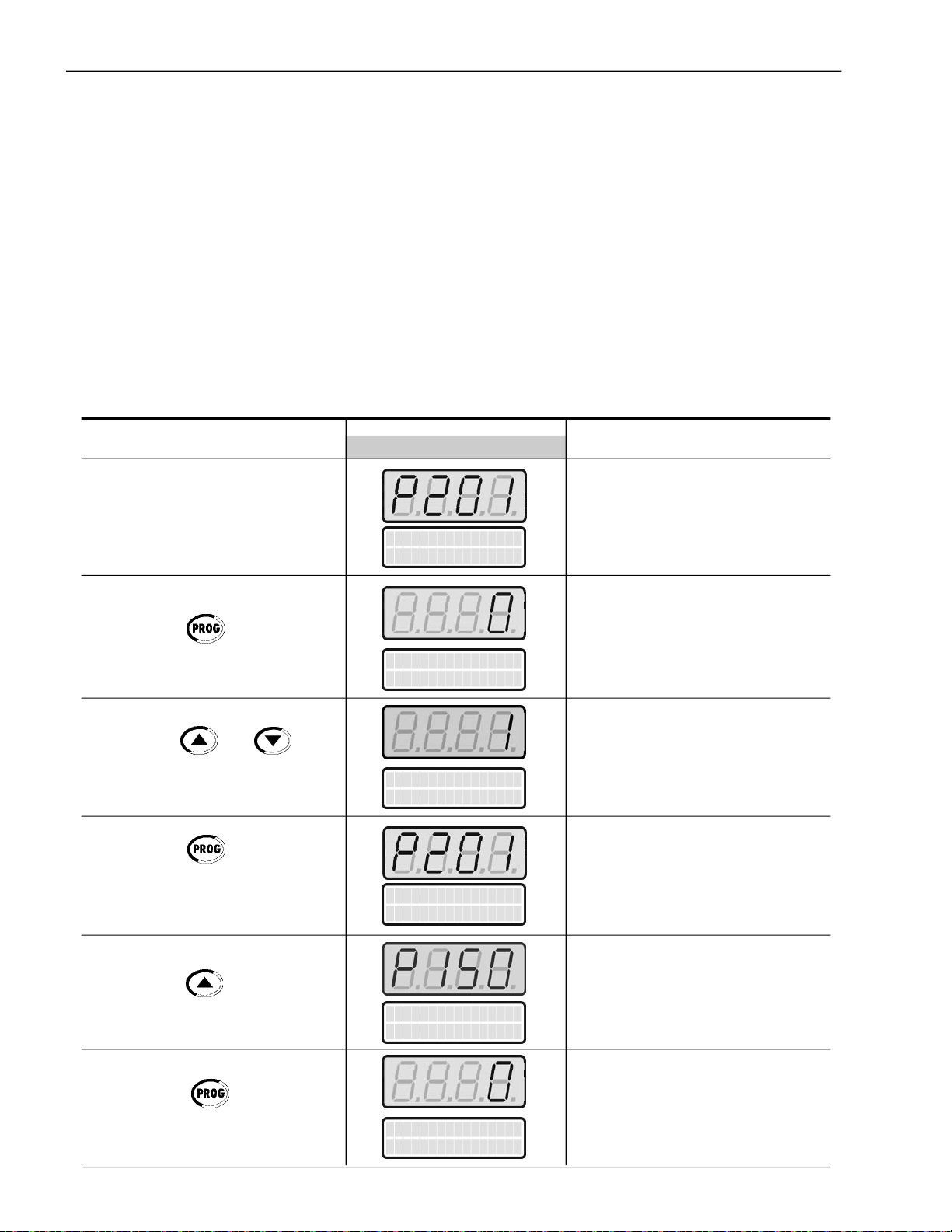

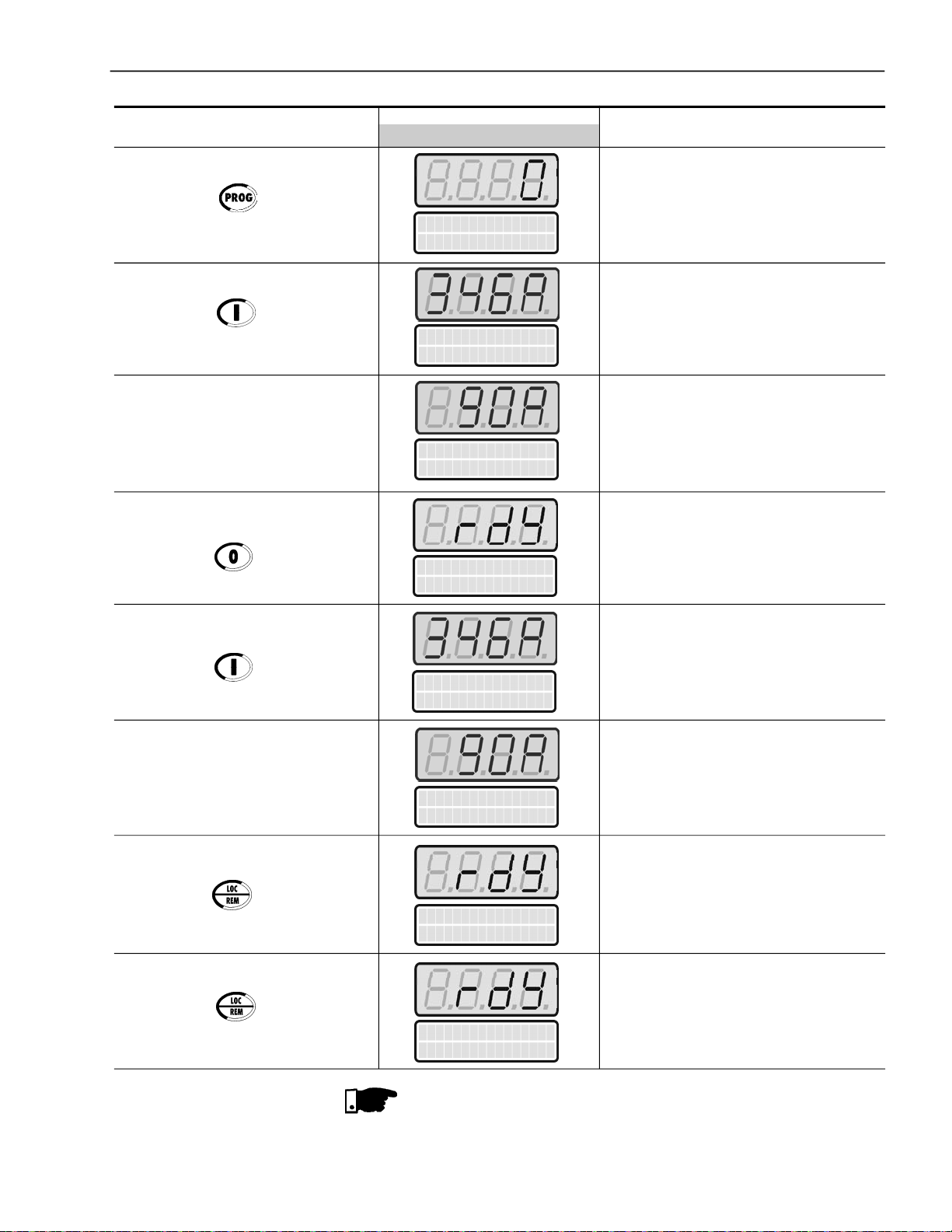

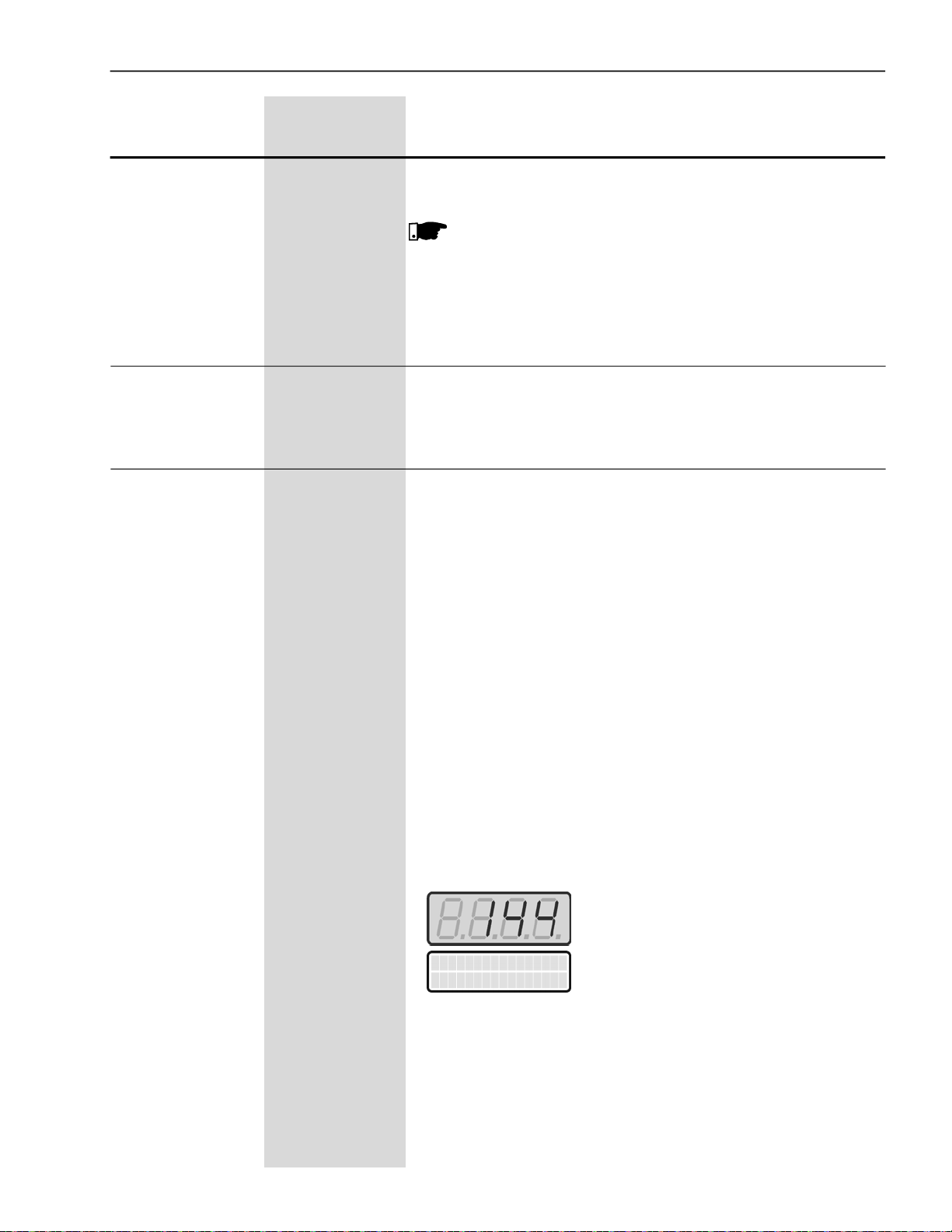

Internalto thePanel