Page 1

Soft-Starter

SSW-06 V1.6X

Serial Communication Manual

Language: English

Document: 0899.5731 / 04

Motors | Energy | Automation | Coatings

Page 2

Serial Communication Manual

Series: SSW-06 V1.6X

Language: English

Document Number: 0899.5731 / 04

Publication Date: 08/2009

Page 3

Summary

SUMMARY

INFORMATION ABOUT THE MANUAL.......................................................... 5

GENERAL INFORMATION............................................................................................................................. 5

SAFETY INFORMATION ................................................................................................................................5

USED TERMS .................................................................................................................................................5

NUMERICAL PRESENTATION...................................................................................................................... 5

1 INTRODUCTION........................................................................................... 6

2 SOFT-STARTER SSW-06 PARAMETER SETTING..................................... 7

2.1 P308 – SOFT-STARTER SSW-06 ADDRESS ON THE NETWORK ....................................................... 7

2.2 P312 – SERIAL PROTOCOL TYPE AND COMMUNICATION RATE..................................................... 7

2.3 P313 – ACTION FOR COMMUNICATION ERROR................................................................................. 7

2.4 P314 – TIME FOR TIMEOUT DURING THE MESSAGE RECEPTION................................................... 8

2.5 P220 – LOCAL/REMOTE SELECTION.................................................................................................... 8

2.6 P229 – COMMAND SELECTION – LOCAL MODE.................................................................................8

2.7 P230 – COMMAND SELECTION – REMOTE MODE..............................................................................9

3 INTERFACE DESCRIPTION....................................................................... 10

3.1 RS-232 .................................................................................................................................................... 10

3.2 RS-485 .................................................................................................................................................... 10

3.2.1 Use of the RS-485 Kit for the SSW-06 ........................................................................................ 10

4 ACCESSIBLE DATA VIA SERIAL COMMUNICATION ............................. 12

4.1 PARAMETER OF THE SOFT-STARTER SSW-06 ................................................................................ 12

4.2 AVAILABLE BASIC VARIABLES FOR THE SOFT-STARTER SSW-06 ...............................................12

4.2.1 Basic Variable 0............................................................................................................................. 12

4.2.2 Basic Variable 1............................................................................................................................. 12

4.2.3 Basic Variable 3............................................................................................................................. 13

4.2.4 Basic Variable 6............................................................................................................................. 14

4.2.5 Basic Variable 7............................................................................................................................. 14

4.2.6 Basic Variable 8............................................................................................................................. 15

4.2.7 Basic Variable 9............................................................................................................................. 15

4.2.8 Basic Variable 10........................................................................................................................... 15

4.3 CHANGING OF PARAMETERS AND BASIC VARIABLES................................................................... 15

4.4 VALUES OF THE PARAMETERS ..........................................................................................................16

5 MODBUS-RTU PROTOCOL ...................................................................... 17

5.1 TRANSFER MODES ............................................................................................................................... 17

5.2 MESSAGE STRUCTURE IN RTU MODE .............................................................................................. 17

5.2.1 Address .......................................................................................................................................... 17

5.2.2 Function Code ............................................................................................................................... 17

5.2.3 Data Field....................................................................................................................................... 18

5.2.4 CRC ................................................................................................................................................18

5.2.5 Times Between Messages ........................................................................................................... 18

5.3 OPERATION OF THE SOFT-STARTER SSW-06 ON THE MODBUS-RTU NETWORK ..................... 18

5.3.1 Available Functions and Response Times .................................................................................19

5.3.2 Data Addressing and Offset......................................................................................................... 19

5.4 DETAILED FUNCTION DESCRIPTION ................................................................................................. 20

5.4.1 Function 01 – Read Coils.............................................................................................................. 21

5.4.2 Function 03 – Read Holding Register .........................................................................................21

5.4.3 Function 05 – Write Single Coil....................................................................................................22

5.4.4 Function 06 – Write Single Register ............................................................................................ 23

5.4.5 Function 15 – Write Multiple Coils............................................................................................... 23

5.4.6 Function 16 – Write Multiple Registers....................................................................................... 24

5.4.7 Function 43 – Read Device Identification ................................................................................... 25

Page 4

Summary

5.4.8 Communication Errors ................................................................................................................. 26

APPENDIXES................................................................................................................................................ 28

Page 5

Information About the Manual

INFORMATION ABOUT THE MANUAL

This Manual provides all information required for the Soft-Starter SSW-06 operation using the serial

communication.

GENERAL INFORMATION

■ Read this manual before installing or operating the Soft-Starter SSW-0.

■ All information and safety notice included in this Manual must be strictly followed.

■ To ensure physical integrity during operation and avoid damage to equipment and motors driven by the Soft-

Starters SSW-06, provide electromechanical safety devices.

SAFETY INFORMATION

■ Follow strictly all information given in this Manual relating to the cable interconnection of the two interfaces for

the serial communication.

■ Electronic boards are fitted with components that are sensitive to electrostatic discharge. When these boards

are handled, take following cares:

- Do not touch the components or connections (connectors) directly with the hands. When this is

unavoidable, touch before a grounded metallic object or adopt proper grounding procedures.

- Use always soldering iron with grounded tip.

USED TERMS

■ Parameters

the Human-Machine-Interface (HMI).

■ Basic Variables

communication. The basic variables are used for monitoring the status, commands and equipment

identification.

■ Registers

the basic variables and the parameters.

■ EEPROM:

switched off.

NUMERICAL PRESENTATION

■ Decimal numbers are represented by means of digits without suffix.

■ Hexadecimal numbers are represented through the letter ’h’ after the number.

: are those existing in the Soft-Starters SSW-06 and that can be displayed or changed through

: internal Soft-Starter SSW-06 values that can be accessed only through the serial

: are internal memory addresses of the Soft-Starter. These registers can be used for representing

is the non-volatile memory that saves the Soft-Starter SSW-06 parameter even when equipment is

SSW-06 | 5

Page 6

Introduction

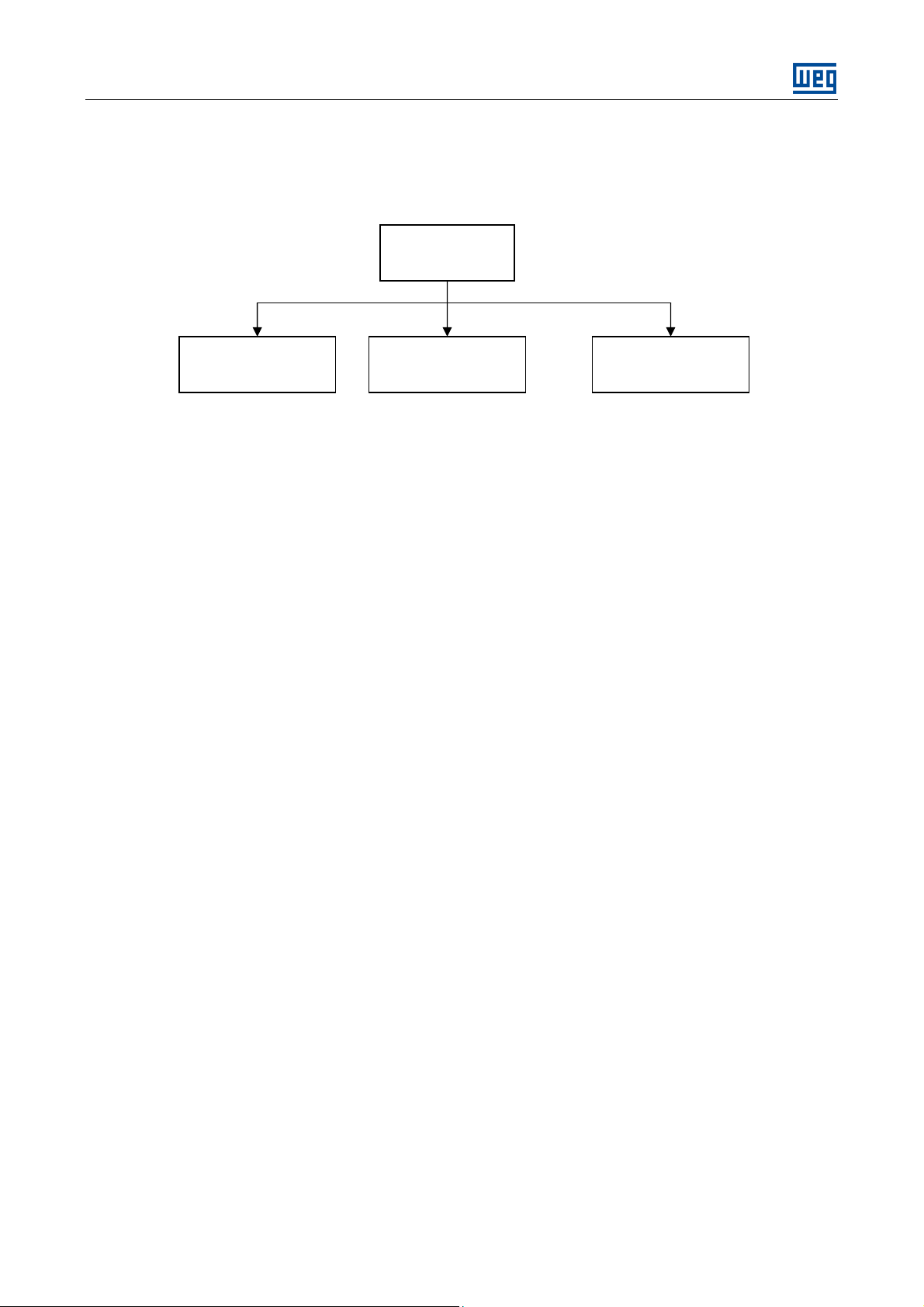

1 INTRODUCTION

The main purpose of the serial communication is the physical connection between two or more equipments on

the network configured as follows:

MESTRE

PC, CLP, etc.

SLAVE 1

(Soft-Starter 1)

By using this interface, the network master can request several services from every slave connected on the

network. These services may be:

■ IDENTIFICATION:

- Equipment Type (frequency inverter, servoconverter, soft-starter)

- Status monitoring

- Error read

■ PARAMETER SETTING

- Parameter read (current, voltage, etc.)

- Parameter write for equipment configuration

■ COMMANDS

- Enable

- FWD/REV

-

Error Reset

The Soft-Starter SSW-06 uses the Modbus-RTU protocol for the communication through the serial interface.

This protocol allows the Soft-Starter SSW-06 integration into different systems, enabling the connection of

several equipments, such as:

■ PC (master) for the parameter setting of one or various Soft-Starters SSW-06 simultaneously.

■ SDCD monitoring Soft-Starter SSW-06 variables and parameters.

SLAVE 2

(Soft-Starter 2)

. .

SLAVE N

(Soft-Starter N)

SSW-06 | 6

Page 7

Soft-Starter SSW-06 Parameter Setting

2 SOFT-STARTER SSW-06 PARAMETER SETTING

Please find below the description of the parameter related to the serial communication and the operation via

Modbus-RTU Protocol of the Soft-Starter SSW-06.

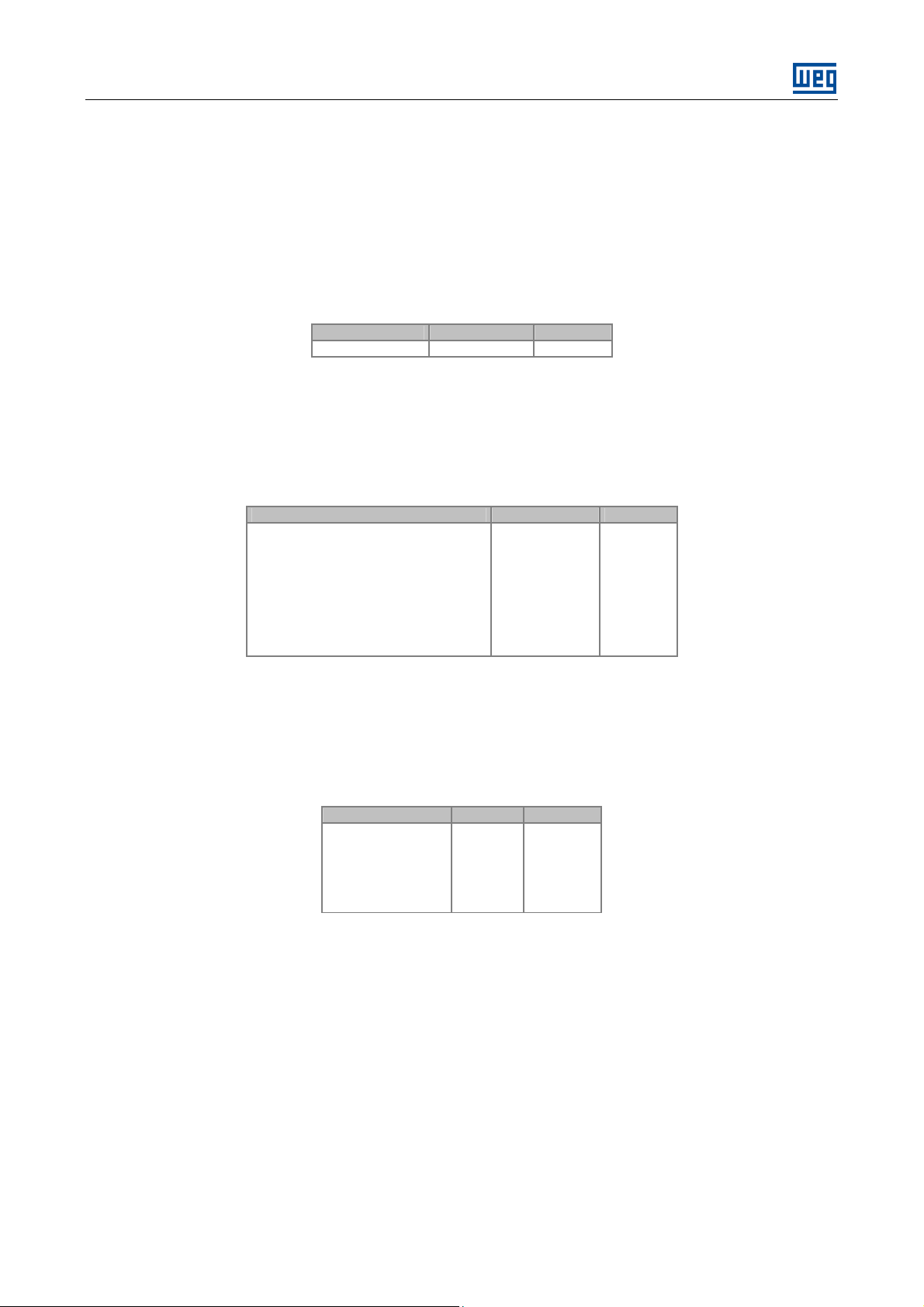

2.1 P308 – SOFT-STARTER SSW-06 ADDRESS ON THE NETWORK

Each slave on the Network shall have a different address, so the master is able to sent the desired message to

the specific slave on the network. This parameter allows setting the Soft-Starter SSW-06 address on the

network.

Adjustable Range Standard Value Access

1 ... 247 1 Read/Write

The use of a repeater is required if more than 30 equipments are used the same communication network.

2.2 P312 – SERIAL PROTOCOL TYPE AND COMMUNICATION RATE

The Soft-Starter SSW-06 has one of the following options for the serial communication through product serial

interface:

Adjustable Range Standard Value Access

1 = Modbus-RTU, 9600 bit/s, no parity

2 = Modbus-RTU, 9600 bit/s, odd parity

3 = Modbus-RTU, 9600 bit/s, even parity

4 = Modbus-RTU, 19200 bit/s, no parity

5 = Modbus-RTU, 19200 bit/s, odd parity

6 = Modbus-RTU, 19200 bit/s, even parity

7 = Modbus-RTU, 38400 bit/s, no parity

8 = Modbus-RTU, 38400 bit/s, odd parity

9 = Modbus-RTU, 38400 bit/s, even parity

It is required that all equipments, operating on the same network, have the same communication configuration.

2.3 P313 – ACTION FOR COMMUNICATION ERROR

This parameter allows programming an action that the drive shall adopt when a communication error is

detected.

Adjustable Range Standard Access

0 = No action

1 = Disable

2 = General disable

3 = Changes to LOC

4 = Not used

5 = Fatal error

■ 0 – No action: if some of the above mentioned error is detected, the drive remains in the current status and

only the detected error is displayed.

■ 1 – Disable: SSW-06 will be disabled via voltage ramp when a communication error is detected.

■ 2 – General Disable: in this option, the starter disconnects the motor power supply and the motor will stop

through inertia.

■ 3 – Changes to LOC: when the switch is operating in remote mode and a communication error is detected,

it must change automatically to Remote Mode.

■ 4 – Not used: the same action of the 0 option.

■ 5 – Cause Fatal Error: when detecting imperfection in the communication the Soft-Starter SSW-06 will go

for the error state, the motor will be disabled and the indication of error will only be removed after to reset the

error of the equipment.

For the serial interface, only the t

be considered as communication error. The

imeout

error during the reception (E28 – Serial Communication is inactive) will

timeout

during the reception is set through the Parameter P314.

0 Read/Write

1 Read/Write

SSW-06 | 7

Page 8

Soft-Starter SSW-06 Parameter Setting

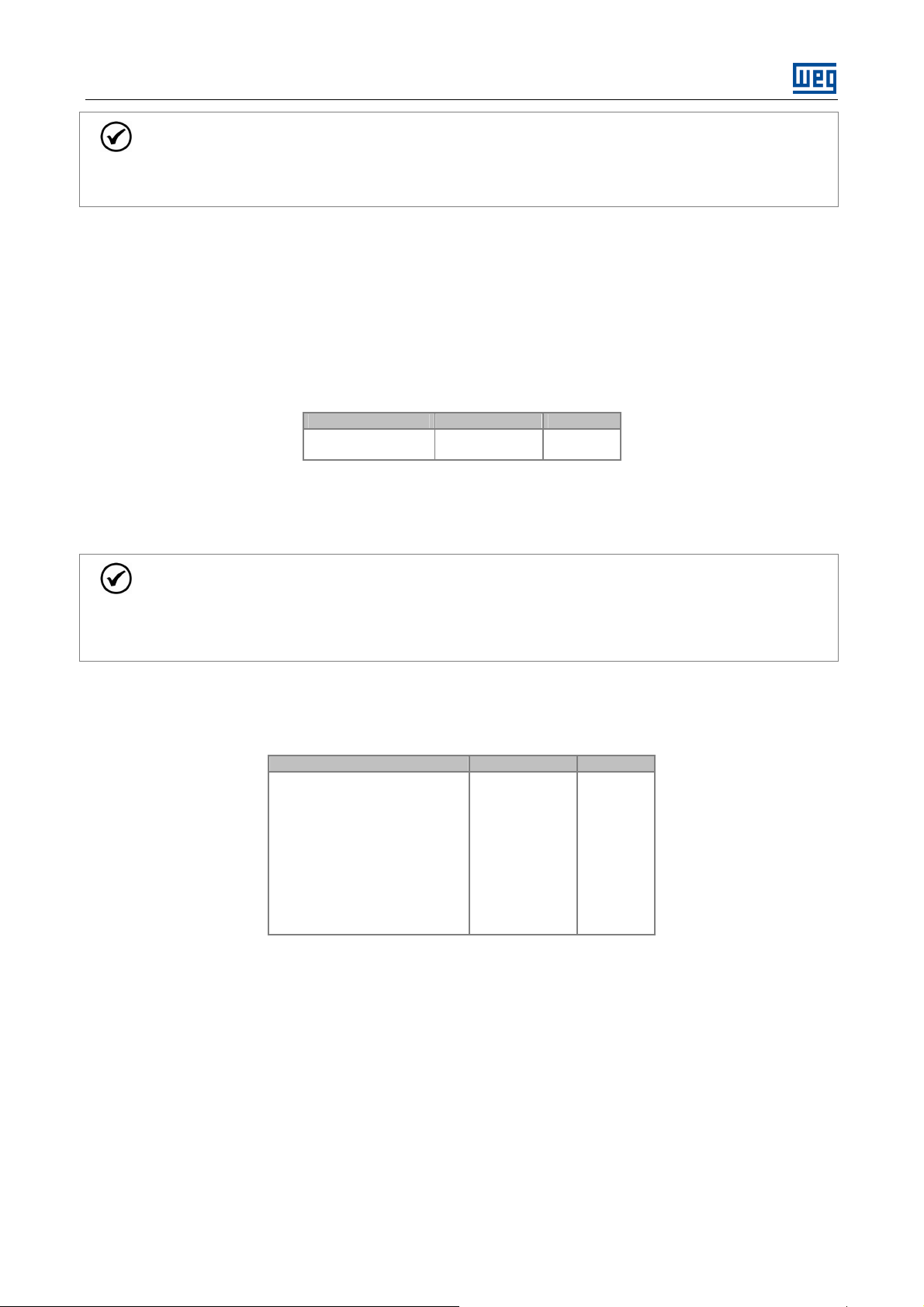

NOTE!

The commands Disable and Change to LOC can be executed only when these commands are

controlled via serial communication. This setting is executed through the Parameters P220, P229 e

P230.

2.4 P314 – TIME FOR TIMEOUT DURING THE MESSAGE RECEPTION

This function allows programming the time for the

(zero) disables this function.

When the drive is controlled via serial communication and a communication problem to the Master is detected

(cable rupture, voltage drop, etc.), it will not be possible to send a command to the serial for the equipment

disable. In application where this will be a problem, you can set P314 to a longer interval within the SSW-06 can

receive a valid serial message. Otherwise SSW-06 will interpret this as a serial communication error.

Adjustable Range Standard Value Access

0 = Disabled function

0 ... 999 seconds

When this time has been programmed, however the SSW-06 remains for longer time than the programmed one

without receiving valid serial messages, it will display E28 and it will adopt the action programmed in P313. After

the communication is restored again, the E28 display will be deleted.

NOTES!

■

When this function is disabled, you must ensure that the network master sends messages

periodically to the slave, always considering the set time and thus preventing the timeout error

detection during the communication.

■

The detection of E28 will also reset the values of the basic variables t8, 9 and 10 (see item 4.2).

2.5 P220 – LOCAL/REMOTE SELECTION

timeout

detection during the message reception. The value 0

0 Read/Write

This function enables programming the command source that controls the Local/Remote mode selection.

Adjustable Range Standard Value Access

0 = Always Local

1 = Always Remote

2 = Keypad (standard is local)

3 = Keypad (standard is remote)

4 = DI4...DI5

5 = Serial (standard is local)

6 = Serial (standard is remote)

7 = Fieldbus (standard is local)

8 = Fieldbus (standard is remote)

9 = SoftPLC (standard is local)

10 = SoftPLC (standard is remote)

2 Read/Write

If the control of the operating mode via serial is preferred, you must set this parameter to 5 ou 6. The display

"standard local" or "standard remote" informs which operation mode shall be activated after the equipment has

been started.

2.6 P229 – COMMAND SELECTION – LOCAL MODE

This function allows programming the command source of the Soft-Starter SSW-06 when the Soft-Starter

SSW-06 has been set to Locale mode.

SSW-06 | 8

Page 9

Soft-Starter SSW-06 Parameter Setting

Adjustable Range Standard Value Access

0 = Keypad

1 = DI

2 = Serial

3 = Fieldbus

4 = SoftPLC

0 Read/Write

If the command control via serial communication in local mode is desired, you must set Parameter P229=2.

2.7 P230 – COMMAND SELECTION – REMOTE MODE

This function enables selecting the Soft-Starter SSW-06 command source when the SSW-06 has been set to

Remote Mode.

Adjustable Range Standard Value Access

0 = Keypad

1 = DI

2 = Serial

3 = Fieldbus

4 = SoftPLC

If the command control via serial communication in local mode is desired, you must set P230 = 2.

0 Read/Write

SSW-06 | 9

Page 10

Interface Description

3 INTERFACE DESCRIPTION

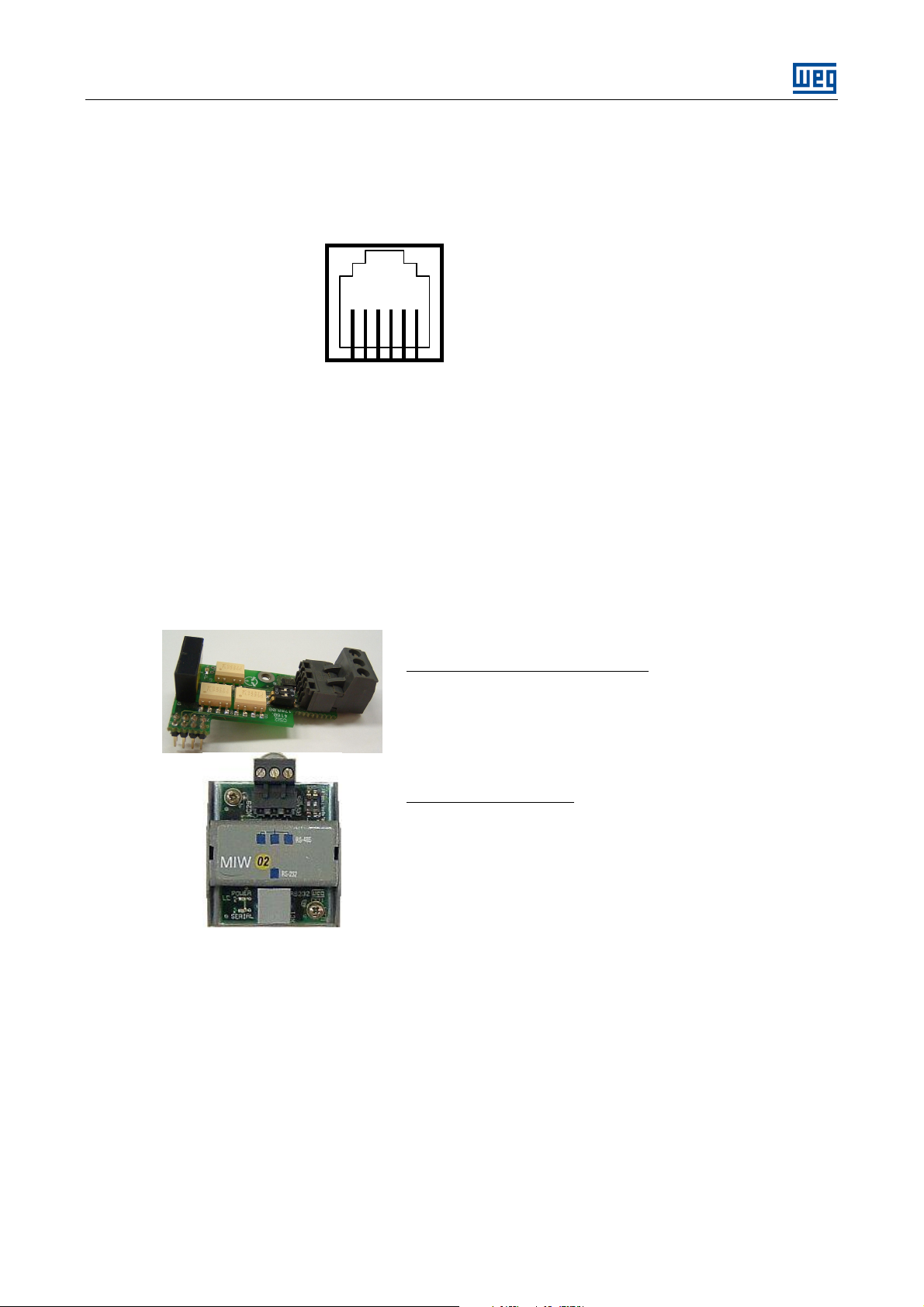

3.1 RS-232

The Soft-Starter SSW-06 is fitted with a serial port RS-232C (connector X2).

1 - 5V

2 - RTS

3 - 0V

4 - RX

5 - 0V

6 - TX

Figure 1: View of the connector X2 (connector model RJ11)

This interface enables the connection of the master to a Soft-Starter SSW-06 (point-to-point) at distances up to

10m. For the communication with the master you must use one wire for the transmission (TX), one wire for the

reception (RX) and one wire for the reference (0V). These signals are present at pins 4, 5 and 6. The signals

present at the pins 1, 2 and 3 are used as power supply and control of the external MIW-02 converter, and

used as one of the option for the RS-485 communication.

3.2 RS-485

The interface RS-485 can be assembled on the Soft-Starter SSW-06 in two different ways:

Optional Kit RS-485 for the SSW-06

■ WEG Item: 10927208.

■ Product intern connected (on the connector XC8 of

the control board).

Optional Module MIW-02

■ WEG Item: 10051677.

■ RS-232 converter to RS-485.

■ Module connected externally to the product,

connected to the interface RS-232 of the SSW-06.

■ For more details, please refer to the MIW02 Manual.

When the interface RS-485 is used, the master can control several drives connected to the same bus. The

Modbus-RTU protocol allows the connection of up to 247 slaves (1 for each address), provided also signal

repeaters are used along the bus.

This interface has a good noise immunity allowing cable lengths up to 1000 m.

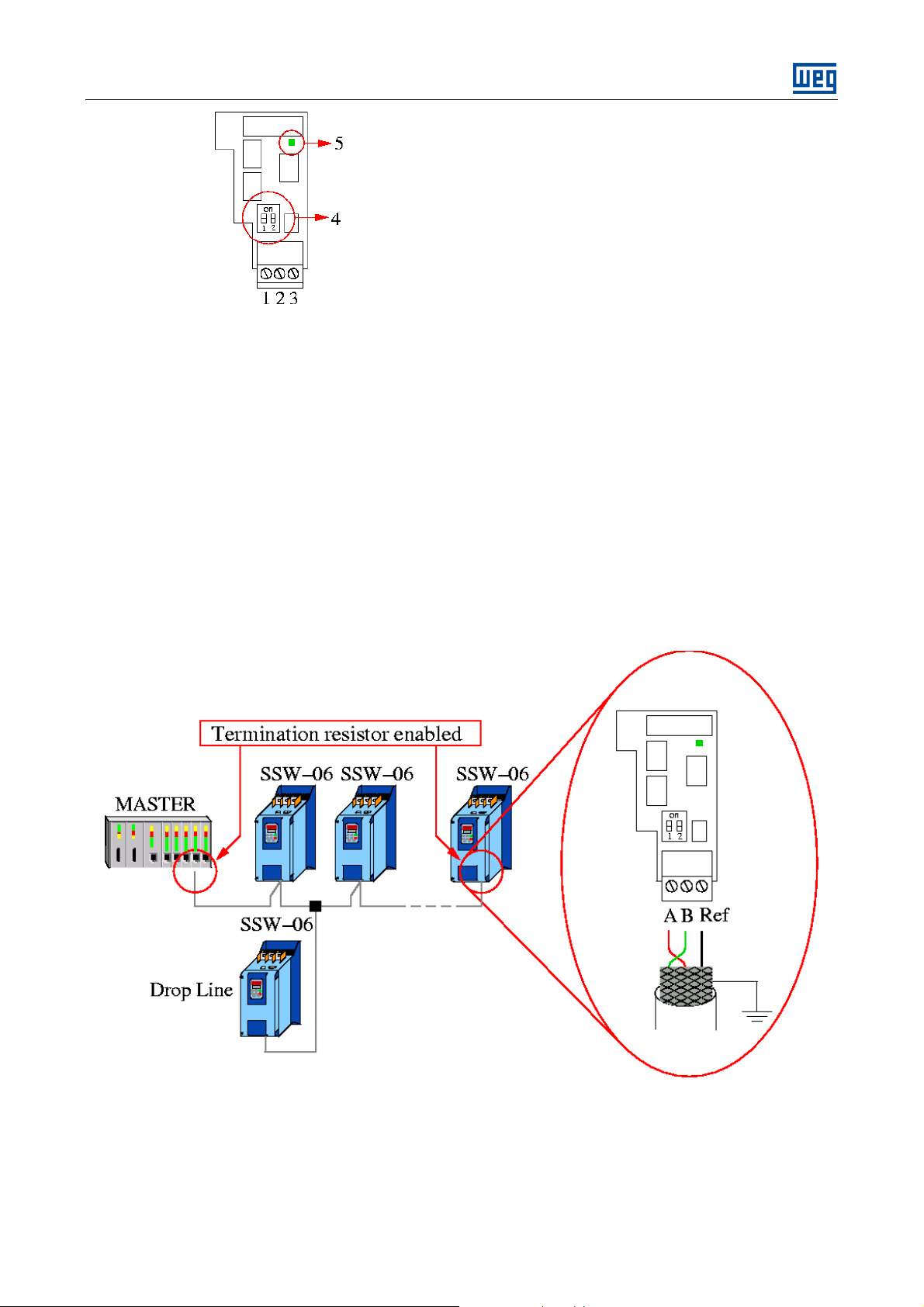

3.2.1 Use of the RS-485 Kit for the SSW-06

The RS-485 Kit of the Soft-Starter SSW-06 comprises basically an interface board and the respective product

installation instructions. Once the SSW-06 has been installed, the board o makes available following elements:

SSW-06 | 10

Page 11

Interface Description

1 → Connector for A signal (or Data +)

2 → Connector for B signal (or Data -)

3 → Connector for reference signal

4 → Switches terminating resistor enable

5 → LED for TX display (On when drive sends

response message)

Following procedures should be adopted during the network installation when this interface is used:

■ For the transmission the signals B and A use a shielded twisted pair of wire. These signals must be connected

to the terminals 1 and 2 of the board.

■ The terminal 3 is used for the connection of the reference signal to the RS-485 circuit. This connection is not

required when this signal is not used.

■ All RS-485 network connected devices must be grounded properly, preferably to the same ground point. Also

the cable shield must be grounded. This grounding can be carried out by connecting the shield to any point of

the Soft-Starter SSW-06 frame.

■ The network cable must be laid separately (if possible) distant from the power supply cables.

■ Terminating resistor must be provided on the first and last device connected to the main bus. The RS-485

interface board is already fitted with witches for enabling this resistor. For this, set both switches S1 to 'on'.

Figure below shows an example of the Soft-Starters SSW-06 installation on a network by using the RS-485

interface board.

Figure 2: Soft-Starters SSW-06 on RS-485 network

SSW-06 | 11

Page 12

Accessible Data Via Serial Communication

4 ACCESSIBLE DATA VIA SERIAL COMMUNICATION

Some data cannot be accessed through the Soft-Starter SSW-06 serial interface for parameter setting,

command and monitoring. On principle these data can be divided into two groups: parameters and basic

variables.

4.1 PARAMETER OF THE SOFT-STARTER SSW-06

The parameters are those that are available though the HMI of the Soft-Starter SSW-06. Practically all drive

parameters can be accessed via serial communication and through these parameter you can program how this

equipment will operate, as well as monitor all important information for the application, as current, voltage,

errors, etc.

For complete parameter listing, please refer to Soft-Starter SSW-06 manual.

4.2 AVAILABLE BASIC VARIABLES FOR THE SOFT-STARTER SSW-06

The basic variables are internal Soft-Starter SSW-06 values that can be accessed only through the serial

product interface. Through these parameters you can monitor the drive status as well s send enable,

commands, etc.

Each basic variable represents a register (16 bits). The Soft-Starter SSW-06 enables following basic parameters:

4.2.1 Basic Variable 0

■

Variable

■

Access

■

Description

SSW-06, this basic variable has the value 15 (000Fh).

4.2.2 Basic Variable 1

■

Variable

■

Access

■

Description

: VB00 – displays the equipment model.

: read-only

: displays a fix value for the equipment type identification on the network. For the Soft-Starter

: VB01 – Soft-Starter SSW-06 Status.

: read-only

: indicates the Soft-Starter SSW-06 status. Each bit of this word provides a different indication:

reset

SSW-06 | 12

Page 13

Accessible Data Via Serial Communication

Bit Description

Bit 0 0 = motor stopped.

Bit 1 0 = when general disable due to any means.

Bit 2 0 = no jog.

Bit 3 0 = is not accelerating.

Bit 4 0 = is not in current limit.

Bit 5 0 = no full voltage is supplied to the motor.

Bit 6 0 = with alarm.

Bit 7 0 = is not decelerating.

Bit 8 0 = local.

Bit 9 0 = is not in dynamic braking.

Bit 10 0 = direction of rotation is not reverted.

Bit 11 0 = CW.

Bit 12 0 = with open bypass.

Bit 13 Reserved

Bit 14 0 = without power supply.

Bit 15 0 = no error.

4.2.3 Basic Variable 3

■

Variable

■

Access

■

Description

: VB00 – displays the equipment model

: read-only

: allows commanding the Soft-Starter SSW-06 via serial communication. It has 16 bits. For a

better understanding of the command, these bits can be divided into two bytes:

Most Significant Byte: it operates as a command mask. Each bit enables the execution of a command and

the effective command value is transmitted through the corresponding least bit.

Least Significant Byte: it has the effective value of each command to be executed. Each bit is responsible for

one command execution. However the command will be only executed when the corresponding most

significant bit has been set to 1. When the mask bit is not =1, the received value in the corresponding least

significant bit will be discarded.

1 = motor running (it stops when the stop command is given).

1 = when general enable due to any means.

1 = with jog.

1 = during the whole acceleration process.

1 = current limit.

1 = full voltage is supplied to the motor.

1 = without alarm.

1 = during the whole deceleration process.

1 = remote.

1 = during dynamic barking process

1 = during the reversal process of the direction of rotation.

1 = CWW.

1 = with closed bypass.

1 = with power supply on the three-phase higher than 15V.

1 = with error.

Bit Description

Bit 8 0 = command inactive.

Bit 9 0 = command inactive.

Bit 10 0 = command inactive.

Bit 11 0 = command inactive.

Bit 12 0 = command inactive..

Bit 13 Reserved

Bit 14 Reserved

Bit 15 0 = command inactive.

1 = command enable / disable active.

1 = command general enable / disable active

1 = command JOG active.

1 = command Direction of Rotation active.

1 = command Local / Remote active.

reset

1 = command

active.

SSW-06 | 13

Page 14

Accessible Data Via Serial Communication

Bit Description

Bit 0 0 = stopping by ramp.

1 = running by ramp.

Bit 1 0 = general disable

1 = general enable.

Bit 2 0 = no JOG.

1 = with JOG.

Bit 3 0 = CW.

1 = CWW.

Bit 4 0 = local.

1 = remote.

Bit 5 Reserved

Bit 6 Reserved

Bit 7 0 = no command.

0 → 1 = executes

Always a command is sent to the Soft-Starter SSW-06, it will accept and execute the command when it has

been programmed to receipt command via serial communication. This programming is performed through the

following parameters:

■ P220 - local / remote source selection.

■ P229 – Command selection in local mode.

■ P230 - Command selection in remote mode.

These commands must be set to the option "Serial" always the command should be executed via network. The

reset

command can be executed via network even when this parameter setting ha been performed, but only

when the Soft-Starter SSW-06 is in error status.

NOTES!

■ Communication board errors (E28, E29 or E30) cannot be reset in this way, since they depend on

settings outside the values sent via network an in this condition the drive cannot establish

communication with the network.

■ So if you try to send a command via network that cannot be executed by the SSW-06 (for

instance, a command that has not been programmed to operate via serial communication), this

command will not be executed.

4.2.4 Basic Variable 6

■

Variable

■

Access

■

Description

: VB06 – indicates the status of the setting mode

: read-only

: this variable allows checking if the Soft-Starter SSW-06 is operating in some special setting

mode. The only used bits in this variable are:

Bit Description

Bit 0 0 = normal operation.

Bit 1 0 = normal operation.

Bit 2 ... 15 Reserved

1 = in setting mode after

1 = in setting mode after P202 has been changed

4.2.5 Basic Variable 7

■

Variable

■

Access

■

Description

: VB07 – commands for setting modes

: read and write

: allows to quit all special setting modes:

Bit Description

Bit 0 0 = no command

Bit 1 0 = no command

Bit 2 ... 15 Reserved

1 = leaves to setting mode after

1 = leaves to setting mode after P202 has been changed

reset

(when in error status).

reset

has been executed to factory setting.

reset

to the factory setting

SSW-06 | 14

Page 15

Accessible Data Via Serial Communication

NOTE!

These commands can be only executed when the drive is in the above mentioned setting mode.

4.2.6 Basic Variable 8

■

Variable

■

Access

■

Description

: VB08 – commands for the digital outputs

: read and write

: it allows commanding the available Soft-Starter SSW-06 relay outputs. This Word has 16 bits,

but only the first three bits has a function:

Bit Description

Bit 0 0 = deactivates the RL1 relay output.

Bit 1 0 = deactivates the RL2 relay output.

Bit 2 0 = deactivates the RL3 relay output.

Bit 3 ... 15 Reserved

1 = activates the RL1 relay output.

1 = activates the RL2 relay output

1 = activates the RL3 relay output

To command the digital outputs via serial communication, you must set its functions to the option "Serial", at

the parameters P277, P278 and P279. When the output is not being controlled via serial communication, the

value received at the corresponding bit will be discarded.

When an error with the network master is detected (E28) the values of the digital outputs will be reset.

4.2.7 Basic Variable 9

■

Variable

■

Access

■

Description

: VB09 – value for the analog output AO1

: read and write

: it allows commanding the analog output AO1.

4.2.8 Basic Variable 10

■

Variable

■

Access

■

Description

: VB10 – value for the analog output AO2

: read and write

: it allows commanding the analog output AO2.

The values received via serial communication for the analog outputs AO1 and AO has a 14

1

bits resolution for

representing 100% of the value for the output, i. e., the value 0 (zero) represents 0 % of the value for the output,

whilst the value 16383 (3FFFh) represents 100 % of the value for the output.

To control the analog output via serial communication, you must also set its functions to the option "Serial", at

the parameters P251 and P253. If the output is not being controlled via serial communication, the

corresponding receipt value will be discarded. Please consider that it is also possible to program at the

parameters P252 and P254 a gain for the outputs that will be applied over the received values.

When a communication error with the network master is detected (E28), the values for the analog outputs will

be reset.

4.3 CHANGING OF PARAMETERS AND BASIC VARIABLES

There are some peculiarities relating to the serial access of the Soft-Starter SSW-06 parameters and basic

variable access

■ There is no password for the access via serial communication. The parameter can be changed independent if

the password is active or not.

• The value of P000 is not saved in the non-volatile equipment memory (via HMI it is saved).

1

This resolution is only used for the data transfer. To obtain the effective used resolution, refer to the equipment manual.

SSW-06 | 15

Page 16

Accessible Data Via Serial Communication

■ The Parameters P200 and P215 cannot be accessed via serial communication.

■ When the value of P202 is changed, or a reset to the factory setting with P204 = 5 is made, the drive enters

into special setting modes. In these special setting modes all parameter can be accessed, however the SoftStarter SSW-06 cannot be operated before it leaves this condition. This can be realized via serial

communication though the basic variable 7.

■ After an error

reset

command of after exiting a special operation mode, the equipment is reset. In this

condition, the Soft-Starter SSW-06 cannot answer to the master and the serial communication remains inactive

till all starting routines have been finished.

■ The command writing in the basic variable 3 will be only accept when these commands have been

programmed to be executed via serial communication. In the same way, the command writing in the basic

variable 7 will be allowed only when the drive is in the setting mode shown in the basic variable 6.

■ When the run command of the basic variable is sent during the activation time of P630, the command will no

be accepted, and the drive does not answer to the error.

4.4 VALUES OF THE PARAMETERS

There are some peculiarities relating to the serial access of the Soft-Starter SSW-06 parameters values.

■ The values of the parameters are always 16bits unsigned integer, without dot.

■ In the models of 820A and above, all the parameters related to the current (A) and power (kW and kVA)

indication are divided by ten: P003, P010, P011, P030, P031, P032, P047, P048, P053, P060, P063, P066,

P069, P072, P075.

SSW-06 | 16

Page 17

Modbus-RTU Protocol

5 MODBUS-RTU PROTOCOL

The Modbus Protocol has been developed in 1979. Today the Modbus Protocol is an open protocol widely

used by many equipment manufacturers

The Modbus-RTU communication development of the Soft-Starter SSW-06 has been based on the following

documents:

■ MODBUS Protocol Reference Guide Rev. J, MODICON, June 1996.

■ MODBUS Application Protocol Specification, MODBUS.ORG, May 8

■ MODBUS over Serial Line, MODBUS.ORG, December 2

nd

2002.

These documents define the message format used by the elements that are part of the Modbus network, the

services (or functions) that can be enabled via network, and how these elements are exchanged on the network.

5.1 TRANSFER MODES

In the protocol specification are defined two transfer modes: ASCII e RTU. The modes define the way in which

these message bytes are transferred. It is not allowed to use two transfer modes on the same network.

The Soft-Starter SSW-06 uses only the RTU mode for the message transfer. The bytes are transferred in

hexadecimal format, where each transferred byte has a 1start bit, 8 data bits, 1 parity bit (optional) and 1 stop

bit (2 stop bits, if no parity bit is used). The byte format configuration is made through the parameter P312.

Start bit Bit 0 Bit 1 Bit 2 Bit 3 Bit 4 Bit 5 Bit 6 Bit 7

8data bits

5.2 MESSAGE STRUCTURE IN RTU MODE

The Modbus-RTU network uses the master-slave system for the message exchange. The Modbus-RTU

network can have up to 247 slaves, but only one master. Every communication starts with the master making a

request to a slave and the slave answers according to the request. In both messages (answer and response),

the used structure is the same: Address, Function Code, Data and CRC. Only one data filed can have variable

length, depending on what is being requested.

Master (requesting telegram):

Address

(1 byte)

Function

(1 byte)

Requesting Data

(n bytes)

Slave (answer message):

Address

(1 byte)

Function

(1 byte)

Requesting Data

(n bytes)

5.2.1 Address

The master starts the communication by sending a byte with the slave address to which the message should be

sent. The slave also starts the answer (message) with its own address. The Master can also send a message to

the zero (0) address, which means that the message is sent to all network slaves (

slave will answer to the Master.

5.2.2 Function Code

This field has an only Byte where the Master specifies the service of function type requested from the slave

(read, write, etc.) According to the protocol, each function is used for accessing a specific data type.

th

2002.

Parity or

stop bit

CRC

(2 bytes)

CRC

(2 bytes)

Stop bit

broadcast

). In this case, no

SSW-06 | 17

Page 18

Modbus-RTU Protocol

For the Soft-Starter SSW-06, the data relating to the parameters and basic variables are available as registers of

holding

type (referenced from the address 40000 or '4x' on).

5.2.3 Data Field

Data field with variable length. The format and the content of this field depend on the used function and on the

transmitted values. This field is described jointly the functions (see item 5.4).

5.2.4 CRC

The last part of the message is the filed for checking the transmission errors. The used method is the CRC-16

(Cycling Redundancy Check). This field is formed by two Bytes, where the least significant Byte (CRC-) is

transmitted first, after the most significant Byte (CRC+) is transmitted. The CRC calculation form is described in

the protocol specification, however the information for its implementation is given in the Appendix A and C.

5.2.5 Times Between Messages

There is no specific character in the RTU mode that indicates the beginning or end of a message. Thus, the only

indication for the beginning or the end of a new message is the data transmission absence in the network by 3.5

times the time required for transmission of one data byte (11 bits).

Thus if a message if a message is initiated after elapsing of the minimum time required without transmission, the

network elements assume that the received character represents the beginning of a new message. In similar

mode, after this time has elapsed the network elements will assume that the message has been ended.

If during transmission of a message, the time between the bytes is longer than the required time, the message

will be considered invalid, since the drive will discard the already received bytes and will mount a new message

with the bytes that are being transmitted.

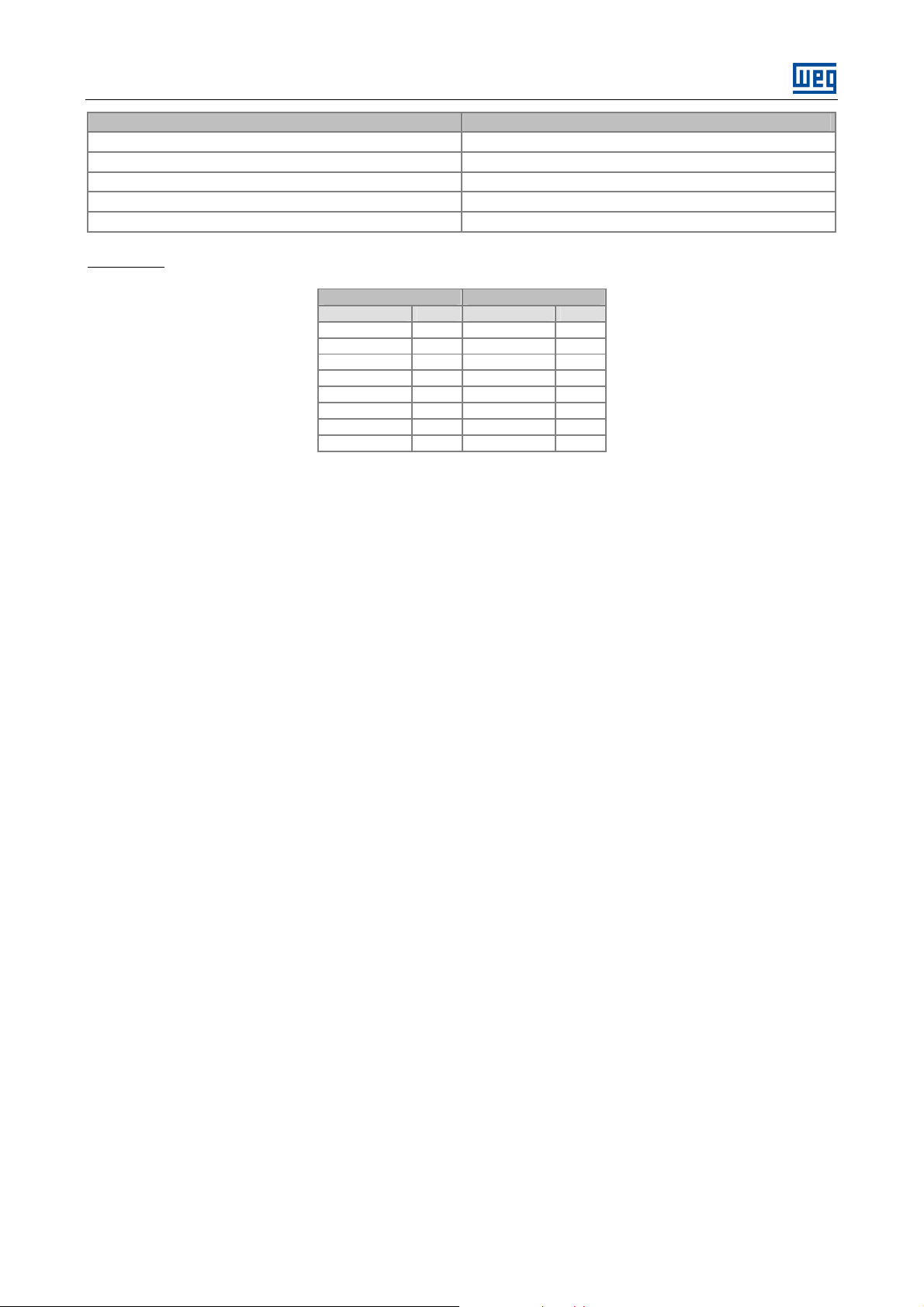

The table below shows the time for the different communication rats.

Communication rate T

9600 bits/sec 1,146 ms 4.010 ms

19200 bits/sec

38400 bits/sec

11 bits

573 μs

573 μs

T

2.005 ms

2.005 ms

3,5x

■ T

■ T

■

= Time to transmit one word of the message.

11 bits

between bytes

T

3,5x

= Time between bytes (can not be longer than T

= Minimum interval to indicate the begin and the end of the

Message (3,5 x T

11bits

).

3,5x

).

For communication rates higher than 19200 bits/s will be considered the same time than those used for 19200

bits/s.

5.3 OPERATION OF THE SOFT-STARTER SSW-06 ON THE MODBUS-RTU NETWORK

The Soft-Starter SSW-06 will have following characteristics when operated on the Modbus-RTU network:

■ Network connection via serial interface RS-232 or RS-485 (see item 3).

■ Addressing, communication rate and bytes format defined through the parameters (see item 2).

SSW-06 | 18

Page 19

Modbus-RTU Protocol

■ It allows the parameter setting and the equipment control through the access to parameters and basic

variables.

5.3.1 Available Functions and Response Times

In the Modbus-RTU protocol is defined the functions used for accessing different types of registers. In the SoftStarter SSW-06, both parameters and basic variables are defines as being

those registers, you can also access the internal bits and the monitoring bits, designated as

Following services (or functions) are available for accessing these bits and register):

■

Read Coils

Description: reading of internal register blocks or coils.

Function code: 01.

Response time: 5 to 10 ms.

■

Read Holding Registers

Description: reading of register blocks of

Function code: 03.

Response time: 5 to 10 ms.

■

Write Single Coil

Description: reading of a single internal bit or coil.

Function code: 05.

Response time: 5 to 10 ms.

■

Write Single Register

Description: reading of a single register of

Function code: 06.

Response time: 5 to 10 ms.

■

Write Multiple Coils

Description: writing of internal bit blocks or coils.

Function code: 15

Response time: 5 to 10 ms.

■

Write Multiple Registers

Description: writing in register blocks of

Function code: 16.

Response time: 10 ms for each written register.

■

Read Device Identification

Description: Identification of the drive model.

Function code: 43.

Response time: 5 to 10 ms.

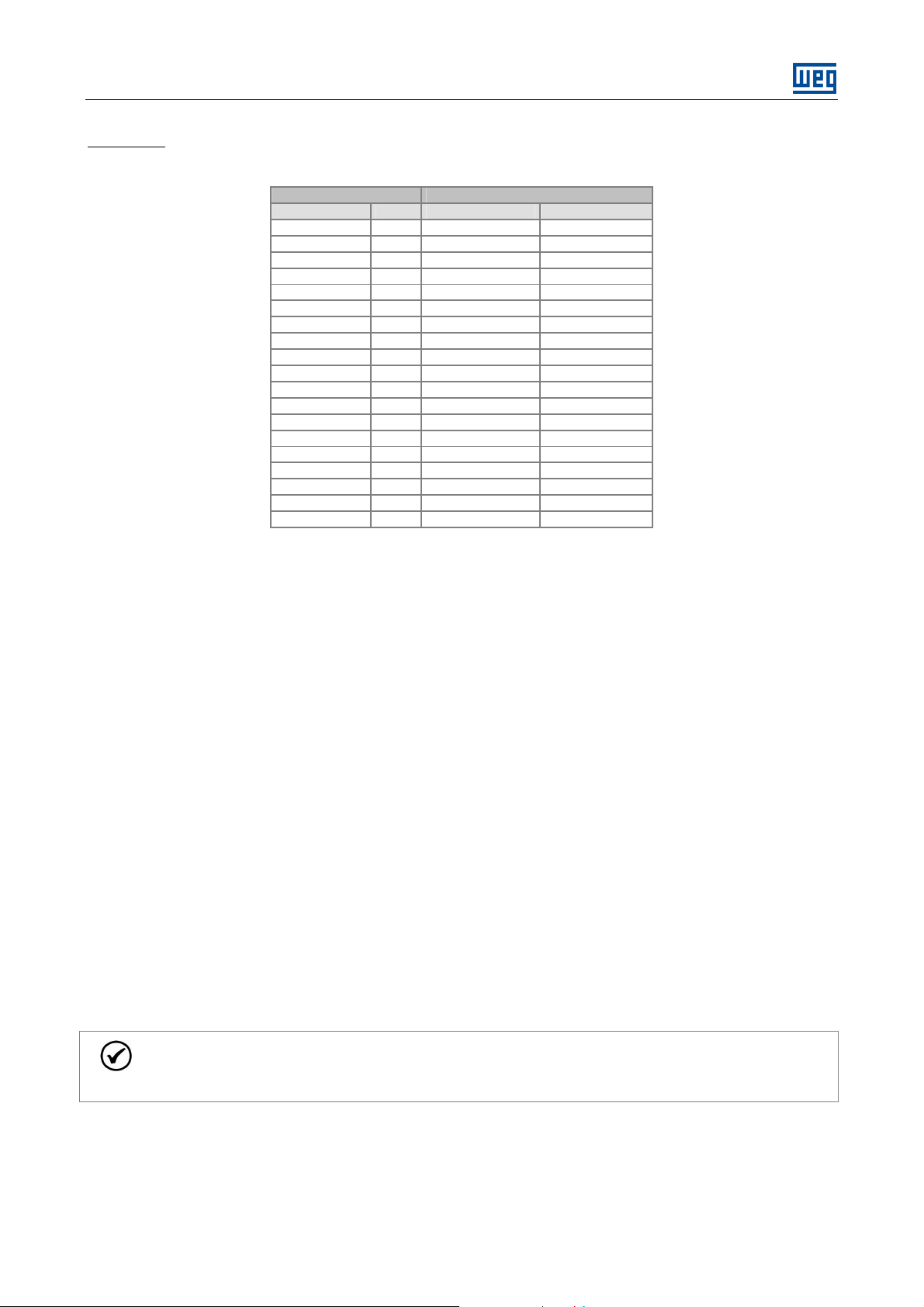

5.3.2 Data Addressing and Offset

holding

holding

holding

type

type

type

holding

type registers. In addition to

coils

directly.

The Soft-Starter SSW-06 data addressing is realized with an offset equal to zero, which means that the address

number is equal to the data number. The parameters are available from address 0 (zero) on, whilst the basic

variables are available from the address 5000 on. In the same way, the status bits are made available from

address 0 (zero) and the control bits are made available from address 100 on. Table below shows the

addressing of the parameters and basic variables:

SSW-06 | 19

Page 20

Modbus-RTU Protocol

PARAMETERS

Parameter Number

P000 0 0x0000

P001 1 0x0001

...

P100 100 0x0064

...

BASIC VARIABLES

Number of the Basic Variable

V00 5000 0x1388

V01 5001 0x1389

...

V08 5008 0x1390

STATUS BITS

Bit Number

Bit 0 00 00h

Bit 1 01 01h

...

Modbus Address

Decimal Hexadecimal

...

...

Modbus Address

Decimal Hexadecimal

...

Modbus Address

Decimal Hexadecimal

...

...

...

...

...

Bit 15 15 0Fh

COMMAND BITS

Bit Number

Bit 100 100 64h

Bit 101 101 65h

...

Bit 107 107 6Bh

Modbus Address

Decimal Hexadecimal

...

...

The Status Bits (0 to15) have the same function of each bit of the basic variable 1 (see item 4.2.2), whilst the

command bits (100 to 107) have the same function of the least significant bits of the basic variable 3, without

required the us of the mask for the SSW-06 control (see item 4.2.3).

NOTE!

All registers (parameters and basic variables) are considered as holding type registers. Depending on

the used master, these registers are referenced from the basic address 4000 or 4x on. In this case,

the address of a parameter or basic variable that should be set on the master is the address shown

in the table above added to the basic address. In the same way, the bits are referenced from 0000

or 0x o, designated as coils. For more information on how access the registers of holding type and

coils, refer to the documents about the master.

5.4 DETAILED FUNCTION DESCRIPTION

In the section is given a detailed of the functions that are available in the SCA-05 for the Modbus-RTU

communication. For the message preparation, please consider following:

■ The values are always transmitted as hexadecimal values.

■ The address of one data, the data number and the value of the register are always represented through 16

bits. Thus these fields are transmitted by using two bytes (

■ The messages, both for enquiry and for response, cannot be longer than 256 bytes.

high

and

low

).

SSW-06 | 20

Page 21

Modbus-RTU Protocol

■ The transmitted values are always integer numbers, independent if they are represented by decimal place or

not. Thus the value of 9.5 will be transmitted as 95 via serial communication. Relating to the used resolution for

each parameter, refer to the SCA-05 manual.

5.4.1 Function 01 – Read Coils

It reads the content of an internal group of bits that must be compulsory in a numerical sequence. This function

has the following structure for the read and response messages (the values are always hexadecimal, and each

field represents one byte):

Query (Master) Response (Slave)

Salve address Slave address

Function Function

Initial bit address (byte high) Byte Count Field (number of data bytes)

Initial bit address (byte low) Byte 1

Number of bits (byte high) Byte 2

Number of bits (byte low) Byte 3

CRC- etc...

CRC+ CRC CRC+

Each response bit is placed at a position of the bytes data sent by the slave. The first byte receives the first 8

bits from the initial address indicated by the master. The other bytes (if the number of the read bits is higher than

8) remain in the same sequence.

If the number of the read bits is not a multiple of 8, the remaining bits of the last byte should be filled out with 0

(zero).

Example: reading of the status bits for general enable (bit 1) and JOG (bit 2) of the SSW-06 at the address 1

(supposing General Enable active and JOG inactive):

■ Address: 1 = 01h (1 byte)

■ Number of the initial bit: 1 = 0001h (2 bytes)

■ Number of the read bits: 2 = 0002h (2 bytes)

Query (Master) Response (Slave)

Field Value Filed Value

Slave address 01h Slave address 01h

Function 01h Function 01h

Initial Bit (high) 00h Byte Count 01h

Initial Bit (low) 01h Status of the bits 1 and 2 01h

Number of bits (high) 00h CRC- D0h

Number of bits (low) 02h CRC+ 49h

CRC- ECh

CRC+ 0Bh

As the number of read bits in the example is smaller than 8, the slave required only 1 byte for the response. The

value of the byte was 01h that, as binary value, will have the form 0000 0010. As the number of read bits is

equal to 2, only the two less significant bits, that have the value 1 = general enable and 0 = no JOG are of

interest. The other bits, as they did not be requested, are filled out with 0 (zero).

5.4.2 Function 03 – Read Holding Register

It reads the content of a group of registers that must be compulsorily in a numerical sequence. This function has

following structure for the read and response messages (the values are always hexadecimal values, and each

field represents one byte):

SSW-06 | 21

Page 22

Modbus-RTU Protocol

Query (Master) Response (Slave)

Slave address Slave address

Function Function

Initial bit address (byte high) Byte Count Field

Initial bit address (byte low) Data 1 (high)

Number of bits (byte high) Data 1 (low)

Number of bits (byte low) Data 2 (high)

CRC- Data 2 (low)

CRC+

etc.

CRC-

CRC+

Example 2

: Read of the motor current as percentage (P002) and read of the motor current in Amperes (P003)

of the Soft-Starter SSW-06 at the address 1 (supposing P002 = 50.0% and P003 = 40.0 A).

■ Address: 1 = 01h (1 byte)

■ Number of the first parameter: 2 = 0002h (2 bytes)

■ Number of the read parameters: 2 = 0002h (2 bytes)

■ Read value of the first parameter: 500 = 01F4h (2 bytes)

■ Read value of the second parameter: 400 = 0190h (2 bytes)

Query (Master) Response (Slave)

Field Value Field Value

Slave address 01h Slave address 01h

Function 03h Function 03h

Initial register (high) 00h Byte Count 04h

Initial register (low) 02h P002 (high) 01h

Number of registers (high) 00h P002 (low) F4h

Number of registers (low) 02h P003 (high) 01h

CRC- 65h P003 (low) 90h

CRC+ CBh CRC- BBh

CRC+ C1h

5.4.3 Function 05 – Write Single Coil

This function is used to write a value to a single bit (

FF00h represents the bit that is equal to 1, and 0000h represents the bit that is equal to 0 (zero). It has the

following structure (the values are always hexadecimal, and each field represents one byte):

Query (Master) Response (Slave)

Slave address Slave address

Function Function

Bit address (byte high) Bit address (byte high)

Bit address (byte low) Bit address (byte low)

Bit value (byte high) Bit value (byte high)

Bit value (byte low) Bit value (byte low)

CRC- CRCCRC+ CRC+

Example 3

: write of the

reset

command (bit 107) in a Soft-Starter at address 1.

■ Address: 1 = 01h (1 byte)

■ Bit number: 107 = 006Bh (2 bytes)

■ Bit value:

reset

= 1, so the value to be written is FF00h

Coil

). The bit value is represented by using two bytes, where

SSW-06 | 22

Page 23

Modbus-RTU Protocol

Query (Master) Response (Slave)

Field Value Field Value

Slave address 01h Slave address 01h

Function 05h Function 05h

Bit number (high) 00h Bit number (high) 00h

Bit number (low) 6Bh Bit number (low) 6Bh

Bit value (high) FFh Bit value (high) FFh

Bit value (low) 00h Bit value (low) 00h

CRC- FDh CRC- FDh

CRC+ E6h CRC+ E6h

Please note, that for this function, the response of the slave will be an identical copy of the query made by the

master.

5.4.4 Function 06 – Write Single Register

This function is used to write a value to a single register. This function has following structure (values are always

hexadecimal values, and each field represents one byte):

Query (Master) Response (Slave)

Slave address Slave address

Function Function

Register address (byte high) Register address (byte high)

Register address (byte low) Register address (byte low)

Register value (byte high) Register value (byte high)

Register value (byte low) Register value (byte low)

CRC- CRCCRC+ CRC+

Example 4

: Write of a logic command (basic variable 3) with the ramp enable command and the general enable

command for the Soft-Starter SSW-06 at address 3.

■ Address: 3 = 03h (1 byte)

■ Number of the variable: VB03, addressed in the register 5003 = 138Bh (2 bytes)

■ Value of the variable: ramp enable → mask in 1 (bit 8) and command in 1 (bit 0)

General enable → mask in 1 (bit 9) and command in 1 (bit 1)

Thus the value for the command is = 0303h (2 bytes)

Query (Master) Response (Slave)

Field Value Field Value

Slave address 03h Slave address 03h

Function 06h Function 06h

Register (high) 13h Register (high) 13h

Register (low) 8Bh Register (low) 8Bh

Value (high) 03h Value (high) 03h

Value (low) 03h Value (low) 03h

CRC- BCh CRC- BCh

CRC+ 77h CRC+ 77h

Please note, that for this function, the response of the slave will be an identical copy of the query made by the

master.

5.4.5 Function 15 – Write Multiple Coils

This function allows writing values for a bit group (

be also used to write a single bit (the values are always hexadecimal, and each field represents one byte).

coils

) that must be in numerical sequence. This function can

SSW-06 | 23

Page 24

Modbus-RTU Protocol

Query (Master) Response (Slave)

Slave address Slave address

Function Function

Initial bit address (byte high) Initial bit address (byte high)

Initial bit address (byte low) Initial bit address (byte low)

Number of bits (byte high) Number of bits (byte high)

Number of bits (byte low) Number of bits (byte low)

Byte Count Filed (number of data bytes) CRCByte 1 CRC+

Byte 2

Byte 3

etc...

CRC-

CRC+

Slave address

The value of each bit that is being sent is placed at a position of the data bytes sent by the master. The first byte

receives the 8 first bits by starting from the initial address indicated by the master. The other bytes (if the

number of inscribed bits is higher than 8) remain in sequence. If the number of inscribed bits is not a multiple of

8, the remaining bits of the last byte should be filled in with 0 (zero).

Example 5

: write of the bits 100 and 101 for ramp enable and general enable of a Soft-Starter SSW-06 at the

address 20

■ Address: 20 = 14h (1 byte)

■ Number of the first bit: 100 = 0064h (2 bytes)

■ Number of bits: 2 = 0002h (2 bytes)

■ Value of the bits: the two bits must be placed at 1, then the value will be = 03h (1 byte)

Query (Master) Response (Slave)

Field Value Field Value

Slave address 14h Slave address 14h

Function 0Fh Function 0Fh

Initial bit (byte high) 00h Initial bit (byte high) 00h

Initial bit (byte low) 64h Initial bit (byte low) 64h

Number of bits (byte high) 00h Number of bits (byte high) 00h

Number of bits (byte low) 02h Number of bits (byte low) 02h

Byte Count 01h CRC- 97h

Value of the bits 03h CRC+ 10h

CRC- 2Eh

CRC+ 6Dh

5.4.6 Function 16 – Write Multiple Registers

This function allows writing values to a register group that must be in numerical sequence. This function can

also be used to write a single register (the values are always hexadecimal values and each field represents one

byte).

Query (Master) Response (Slave)

Slave address Slave address

Function Function

Address of the initial register (byte high) Address of the initial register (byte high)

Address of the initial register (byte low) Address of the initial register (byte low)

Number of registers (byte high) Number of registers (byte high)

Number of registers (byte low) Number of registers (byte low)

Byte Count Filed (number of data bytes CRCData 1 (high) CRC+

Data 1 (low)

Data 2 (high)

Data 2 (low)

etc...

CRC-

CRC+

SSW-06 | 24

Page 25

Modbus-RTU Protocol

Example 6: write of the value to the analog outputs AO1 and AO2 through the basic variables 9 and 10 for a

Soft-Starter SSW-06 at the address 15. The output AO1 should be equal to 50% (resolution of 14 bits, 50% =

8191) and AO2 should be equal to 25% (resolution of 14 bits, 25% = 4095).

■ Address: 15 = 0Fh (1 byte)

■ Number of the first variable: VB09, addressed in the register 5009 = 1391h (2 bytes)

■ Value of the first parameter: 8191 = 1FFFh (2 bytes)

■ Value of the second parameter: 4095 = 0FFFh (2 bytes)

Query (Master) Response (Slave)

Field Value Field Value

Slave address 0Fh Slave address 0Fh

Function 10h Function 10h

Initial register (high) 13h Register (high) 13h

Initial register (low) 91h Register (low) 91h

Number of register (high) 00h Value (high) 00h

Number of register (low) 02h Value (low) 02h

Byte Count 04h CRC- 15h

VB09 (high) 1Fh CRC+ 8Fh

VB09 (low) FFh

VB10 (high) 0Fh

VB10 (low) FFh

CRC- A4h

CRC+ 83h

5.4.7 Function 43 – Read Device Identification

Auxiliary function that allows to read the manufacturer name, the model and version of the product firmware. It

has following structure:

Query (Master) Response (Slave)

Slave address Slave address

Function Function

MEI Type MEI Type

Read code Conformity Level

Object number More Follows

CRC- Next object

CRC+ Number of objects

Code of the first object

Length of the first object

Value of the first object (n bytes)

Code of the second object

Length of the second object

Value of the second object (n bytes)

etc...

CRC CRC+

This function permits reading three information categories: Basic, Regular and Extended and each category are

formed by a group of objects. Each object is formed by a sequence of ASCII characters For the Soft-Starter

SSW-06 are available only basic information formed by three objects:

■ Object 0x00 - VendorName: always 'WEG'.

■ Object 0x01 - ProductCode: formed by the product code (SSW-06), plus the rated drive current (ex. 'SSW-06

85.0A').

■ Object 0x02 - MajorMinorRevision: it indicates the drive firmware version, in 'VX.XX' format.

The read code indicates which information categories are being read and if the objects are accessed individually

of by sequence.

In the example, the SSW-06 supports the codes 01 (basic information in sequence), and 04 (individual access

to the objects).

SSW-06 | 25

Page 26

Modbus-RTU Protocol

The other fields for the SSW-06 have fixed values.

Example 7

: read of the basic information in sequence, starting from the object 00h of a Soft-Starter SSW-06 at

the address 1:

Query (Master) Response (Slave)

Field Value Field Value

Slave address 01h

Function 2Bh Slave address 2Bh

MEI Type 0Eh Function 0Eh

Read Code 01h MEI Type 01h

Object Number 00h Conformity Level 81h

CRC- 70h More Follows 00h

CRC+ 77h Next Object 00h

Number of Objects 03h

Object Code 00h

Object length 03h

Object value 'WEG'

Object Code 01h

Object length 14h

Object value 'SSW-06 85.0A'

Object Code 02h

Object length 05h

Object value 'V1.11'

CRC- 6Fh

CRC+ 10h

Field

01h

In the example the Object Value has not been represented as hexadecimal value, but with corresponding ASCII

characters. For instance, for the object 00, the ´WEG‘ value has been transmitted as being three ASCII

characters, that as hexadecimal representation have the values 57h ('W'), 45h ('E') and 47h ('G').

5.4.8 Communication Errors

Errors can occur during the message transmission on network, or in the content of the received messages.

Depending on the error type, Soft-Starter-06 may answer or not to the master. When the master sends a

message to a slave configured at determined network address, the slave wills not response to the master if:

■ Error in the parity bit.

■ Error in CRC.

■

Timeout

In this case the master must detect a

message is received with success, the drive can detect problems during the message processing and send an

error message by indicating the detected problem:

■ Function is not valid (error code = 1): the requested function is not implemented for the equipment.

■ Data address is not valid (error code = 2): the data address (parameter) does not exist.

■ The data value is not valid (error code = 3): this error is detected in the following conditions:

If some error has been detected, the slave must return a message to the master indicating the type of error that

has been detected. The messages sent by the slave have the flowing structure:

between transmitted bytes (3.5 times the time required for transmitting one byte).

timeout

error during the time he was waiting for the slave response. When

- Value is out of range.

- Data write cannot be changed (read-only register).

- Command is not enabled for serial execution.

NOTE!

It is important to identify in the master the type of error that has been detected so you are able to

diagnose the problems during the communication process.

SSW-06 | 26

Page 27

Modbus-RTU Protocol

Query (Master) Response (Slave)

Slave address Slave address

Function Function (with the most significant bit at 1)

Data Error code

CRC- CRCCRC+ CRC+

Example 8

: master requests to the slave at address 1 the write in parameter 89 (non existing parameter):

Query (Master) Response (Slave)

Field Value Field Value

Slave address 0x01 Slave address 0x01

Function 0x06 Function 0x86

Register (high) 0x00 Error code 0x02

Register (low) 0x59 CRC- 0xC3

Value (high) 0x00 CRC+ 0xA1

Value (low) 0x00

CRC- 0x59

CRC+ 0xD9

SSW-06 | 27

Page 28

Appendixes

APPENDIXES

Appendix A - CRC calculation by using the tables

Please find below a function that uses de “C” programming language and that implements the CRC calculation

for the Modbus-RTU protocol. The calculation uses two tables for supplying pre-calculated shift values required

for the calculation. More information about the algorithm can be obtained in the referenced documents in 1.

/* Table of CRC values for high–order byte */

static unsigned char auchCRCHi[] = {

0x00, 0xC1, 0x81, 0x40, 0x01, 0xC0, 0x80, 0x41, 0x01, 0xC0, 0x80, 0x41, 0x00, 0xC1, 0x81, 0x40,

0x01, 0xC0, 0x80, 0x41, 0x00, 0xC1, 0x81, 0x40, 0x00, 0xC1, 0x81, 0x40, 0x01, 0xC0, 0x80, 0x41,

0x01, 0xC0, 0x80, 0x41, 0x00, 0xC1, 0x81, 0x40, 0x00, 0xC1, 0x81, 0x40, 0x01, 0xC0, 0x80, 0x41,

0x00, 0xC1, 0x81, 0x40, 0x01, 0xC0, 0x80, 0x41, 0x01, 0xC0, 0x80, 0x41, 0x00, 0xC1, 0x81, 0x40,

0x01, 0xC0, 0x80, 0x41, 0x00, 0xC1, 0x81, 0x40, 0x00, 0xC1, 0x81, 0x40, 0x01, 0xC0, 0x80, 0x41,

0x00, 0xC1, 0x81, 0x40, 0x01, 0xC0, 0x80, 0x41, 0x01, 0xC0, 0x80, 0x41, 0x00, 0xC1, 0x81, 0x40,

0x00, 0xC1, 0x81, 0x40, 0x01, 0xC0, 0x80, 0x41, 0x01, 0xC0, 0x80, 0x41, 0x00, 0xC1, 0x81, 0x40,

0x01, 0xC0, 0x80, 0x41, 0x00, 0xC1, 0x81, 0x40, 0x00, 0xC1, 0x81, 0x40, 0x01, 0xC0, 0x80, 0x41,

0x01, 0xC0, 0x80, 0x41, 0x00, 0xC1, 0x81, 0x40, 0x00, 0xC1, 0x81, 0x40, 0x01, 0xC0, 0x80, 0x41,

0x00, 0xC1, 0x81, 0x40, 0x01, 0xC0, 0x80, 0x41, 0x01, 0xC0, 0x80, 0x41, 0x00, 0xC1, 0x81, 0x40,

0x00, 0xC1, 0x81, 0x40, 0x01, 0xC0, 0x80, 0x41, 0x01, 0xC0, 0x80, 0x41, 0x00, 0xC1, 0x81, 0x40,

0x01, 0xC0, 0x80, 0x41, 0x00, 0xC1, 0x81, 0x40, 0x00, 0xC1, 0x81, 0x40, 0x01, 0xC0, 0x80, 0x41,

0x00, 0xC1, 0x81, 0x40, 0x01, 0xC0, 0x80, 0x41, 0x01, 0xC0, 0x80, 0x41, 0x00, 0xC1, 0x81, 0x40,

0x01, 0xC0, 0x80, 0x41, 0x00, 0xC1, 0x81, 0x40, 0x00, 0xC1, 0x81, 0x40, 0x01, 0xC0, 0x80, 0x41,

0x01, 0xC0, 0x80, 0x41, 0x00, 0xC1, 0x81, 0x40, 0x00, 0xC1, 0x81, 0x40, 0x01, 0xC0, 0x80, 0x41,

0x00, 0xC1, 0x81, 0x40, 0x01, 0xC0, 0x80, 0x41, 0x01, 0xC0, 0x80, 0x41, 0x00, 0xC1, 0x81, 0x40};

/* Table of CRC values for low–order byte */

static char auchCRCLo[] = {

0x00, 0xC0, 0xC1, 0x01, 0xC3, 0x03, 0x02, 0xC2, 0xC6, 0x06, 0x07, 0xC7, 0x05, 0xC5, 0xC4, 0x04,

0xCC, 0x0C, 0x0D, 0xCD, 0x0F, 0xCF, 0xCE, 0x0E, 0x0A, 0xCA, 0xCB, 0x0B, 0xC9, 0x09, 0x08, 0xC8,

0xD8, 0x18, 0x19, 0xD9, 0x1B, 0xDB, 0xDA, 0x1A, 0x1E, 0xDE, 0xDF, 0x1F, 0xDD, 0x1D, 0x1C, 0xDC,

0x14, 0xD4, 0xD5, 0x15, 0xD7, 0x17, 0x16, 0xD6, 0xD2, 0x12, 0x13, 0xD3, 0x11, 0xD1, 0xD0, 0x10,

0xF0, 0x30, 0x31, 0xF1, 0x33, 0xF3, 0xF2, 0x32, 0x36, 0xF6, 0xF7, 0x37, 0xF5, 0x35, 0x34, 0xF4,

0x3C, 0xFC, 0xFD, 0x3D, 0xFF, 0x3F, 0x3E, 0xFE, 0xFA, 0x3A, 0x3B, 0xFB, 0x39, 0xF9, 0xF8, 0x38,

0x28, 0xE8, 0xE9, 0x29, 0xEB, 0x2B, 0x2A, 0xEA, 0xEE, 0x2E, 0x2F, 0xEF, 0x2D, 0xED, 0xEC, 0x2C,

0xE4, 0x24, 0x25, 0xE5, 0x27, 0xE7, 0xE6, 0x26, 0x22, 0xE2, 0xE3, 0x23, 0xE1, 0x21, 0x20, 0xE0,

0xA0, 0x60, 0x61, 0xA1, 0x63, 0xA3, 0xA2, 0x62, 0x66, 0xA6, 0xA7, 0x67, 0xA5, 0x65, 0x64, 0xA4,

0x6C, 0xAC, 0xAD, 0x6D, 0xAF, 0x6F, 0x6E, 0xAE, 0xAA, 0x6A, 0x6B, 0xAB, 0x69, 0xA9, 0xA8, 0x68,

0x78, 0xB8, 0xB9, 0x79, 0xBB, 0x7B, 0x7A, 0xBA, 0xBE, 0x7E, 0x7F, 0xBF, 0x7D, 0xBD, 0xBC, 0x7C,

0xB4, 0x74, 0x75, 0xB5, 0x77, 0xB7, 0xB6, 0x76, 0x72, 0xB2, 0xB3, 0x73, 0xB1, 0x71, 0x70, 0xB0,

0x50, 0x90, 0x91, 0x51, 0x93, 0x53, 0x52, 0x92, 0x96, 0x56, 0x57, 0x97, 0x55, 0x95, 0x94, 0x54,

0x9C, 0x5C, 0x5D, 0x9D, 0x5F, 0x9F, 0x9E, 0x5E, 0x5A, 0x9A, 0x9B, 0x5B, 0x99, 0x59, 0x58, 0x98,

0x88, 0x48, 0x49, 0x89, 0x4B, 0x8B, 0x8A, 0x4A, 0x4E, 0x8E, 0x8F, 0x4F, 0x8D, 0x4D, 0x4C, 0x8C,

0x44, 0x84, 0x85, 0x45, 0x87, 0x47, 0x46, 0x86, 0x82, 0x42, 0x43, 0x83, 0x41, 0x81, 0x80, 0x40};

/* The function returns the CRC as a unsigned short type */

unsigned short CRC16(puchMsg, usDataLen)

unsigned char *puchMsg; /* message to calculate CRC upon */

unsigned short usDataLen; /* quantity of bytes in message */

{

unsigned char uchCRCHi = 0xFF; /* high byte of CRC initialized */

unsigned char uchCRCLo = 0xFF; /* low byte of CRC initialized */

unsigned uIndex; /* will index into CRC lookup table */

while (usDataLen--) /* pass through message buffer */

{

uIndex = uchCRCLo ^ *puchMsgg++; /* calculate the CRC */

uchCRCLo = uchCRCHi ^ auchCRCHi[uIndex};

uchCRCHi = auchCRCLo[uIndex];

SSW-06 | 28

Page 29

Appendixes

}

return (uchCRCHi << 8 | uchCRCLo);

}

Appendix B - CRC calculation by using the register shift

In this section is described the algorithm for the CRC calculation used in the Modbus-RTU communication

through the register shift; More information about the algorithm can be found in the referenced documents in

item 5.

The CRC calculation is started by loading a 16 bits variable (afterwards designated as CRC variable) with the

value of 0xFFFF. After proceed according to the following routines:

1. Submit the first byte of the message (only the data bits - start bit, parity bit and stop bit are not used) to a

logic XOR (OR exclusive) with the 8 least significant bits of the CRC variable, returning the result in the own

CRC variable.

2. Then the CRC variables is shift one place to right, to the direction of the least significant bit, and the place of

the most significant bit is filled in with 0 (zero).

3. After this shift, the

flag

bit (the bit that has been shifted outside the CRC variable) is analyzed, and:

■ If the bit value is 0 (zero), no measure is adopted.

■ If the bit value is 1, the variable content is submitted to a logic XOR with a constant 0xA001 value and the

result is returned to the CRC variable.

4. Steps 2 and 3 are repeated till eight shifts are executed.

5. Steps 1 to 4 are repeated by using the next message byte till the complete message has been processed.

The end content of the CRC variable is the value of the CRC field that is transmitted in the end message. The

least significant part is transmitted first (CRC-) and in sequence the most significant part is transmitted (CRC+).

SSW-06 | 29

Loading...

Loading...