Page 1

MANUAL OF THE

SERIAL

COMMUNICATION

SSW-05

Series SSW-05

SERIAL INTERFACE

CODE 0899.4895 E/4

Page 2

Page 3

Series: SSW

-

05

0899.4895 E/4

email: astec@weg.com.br

MANUAL OF THE

SERIAL

COMUNICATION

SSW-05

Software: Version 2.1X

ATTENTION!

It is very important to

check if the software

version is the same as

indicated above.

WEG AUTOMAÇÃO

Av. Pref. Valdemar Grubba, 3000

89256-900 Jaraguá do Sul, SC – Brasil

Tel.(047)372-4000 – Fax(047)372-4020

Page 4

Page 5

_______ Summary _______

1 1 2

3

7 7 7 8 8 8 8 9 9

10 10 11 13 13 14 15 16 16 17 17

18

SAFETY

NOTICES

1

1.1 Safety Notices in the Manual.......................................

1.2 Safety Notices on the Product ....................................

1.3 Preliminary Recommendations....................................

INTRODUCTION

2

COMMUNICATION

INTERFACES

3

DEFINITIONS

4

TELEGRAM

EXAMPLES

5

2.1 About this Manual........................................................

2.2 About WEG Protocol....................................................

3.1 RS-485 Interface..........................................................

3.2 RS-232 Interface.........................................................

3.2.1 RS-232 Electrical Characteristics........................

3.2.2 Cares with RS-232..............................................

3.2.3 RS-232 Connections...........................................

3.2.4 Description of the Soft-Starter Serial Connector.

3.2.5 Definition of the RS-232 Cable............................

3.2.6 Description of the Master Connector (RJ)...........

3.2.7 Definition of the RS-232 PC Cable......................

3.2.8 Description of the PC (DB9) Connector...............

4.1 Used Terms.................................................................

4.2 Block Diagram..............................................................

4.3 Variable Standardization..............................................

4.4 Character Format.........................................................

4.5 Protocol........................................................................

4.5.1 Reading Telegram...............................................

4.5.2 Writing Telegram.................................................

4.6 Execution and Test Telegram......................................

4.7 Telegram Sequence ....................................................

4.8 Variable Code..............................................................

4.9 Times...........................................................................

5.1 Example 1....................................................................

5.2 Example 2....................................................................

3

5

18

Page 6

19 20 22

23 23

24 24 24 24 24 24

24 25 25 26 26 27 30 30 30 32 32 33 33 33

34

34

VARIABLES OF THE

SERIAL

COMMUNICATION

6

ERRORS AND SERIAL

COMMUNICATION

PARAMETERS

7

DETAILED

PARAMETER

DESCRIPTION

8

TROUBLESHOOTING

9

6.1.1 V00 Indication of the Equipment Model...................

6.1.2 V01 Indication of the Soft-Starter Status...................

6.1.3 V02 Indication of the Soft-Starter Errors...................

6.1.4 V03 Logic Command Selection.................................

7.1 Parameters related to the Serial Communication .......

7.2 Errors Related to the Serial Communication ...............

8.1 P000 – Access Parameter...........................................

8.2 P002 – Motor Current Indication (%)...........................

8.3 P003 – Motor Current Indication (A)...........................

8.4 P023 – Software Version.............................................

8.5 P030 – R Phase Current..............................................

8.6 P030 – S Phase Current..............................................

8.7 P030 – T Phase Current..............................................

8.8 P050 – Status Indication of the Motor Thermal

Protection .......................................................

8.9 P101 – Initial Voltage (% Un).......................................

8.10 P102 – Time of Acceleration Ramp (s)......................

8.11 P104 – Time of Deceleration Ramp (s)......................

8.12 P105 – Motor Current Setting (%).............................

8.13 P106 – Protection Configuration...............................

8.14 P204 – Load Factory Setting.....................................

8.15 P206 – Auto-Reset Time............................................

8.16 P215 – Keypad Copy Function..................................

8.17 P220 – HMI / (Trimpots and Dip Switch) Selection....

8.18 P264 – Programmable Digital Input DI 1...................

8.19 P277 – Programmable Relay Output (14/23 – 24)....

8.20 P295 – Rated Current of the Soft-Starter..................

8.21 P308 – Network Address...........................................

8.22 P313 – Action of the Serial Communication

Verification.........................................................................

8.23 P314 – Verification Time of the Serial

Communication..................................................................

Problem and Corrective Action.......................................... 35

19

24

Page 7

1

SAFETY NOTICES 1

This Manual contains all necessary information for the correct use of the Serial

This Manual has been written for qualified personnel with suitable training or technical

qualification to operate serial interfaces and their respective communication protoco ls.

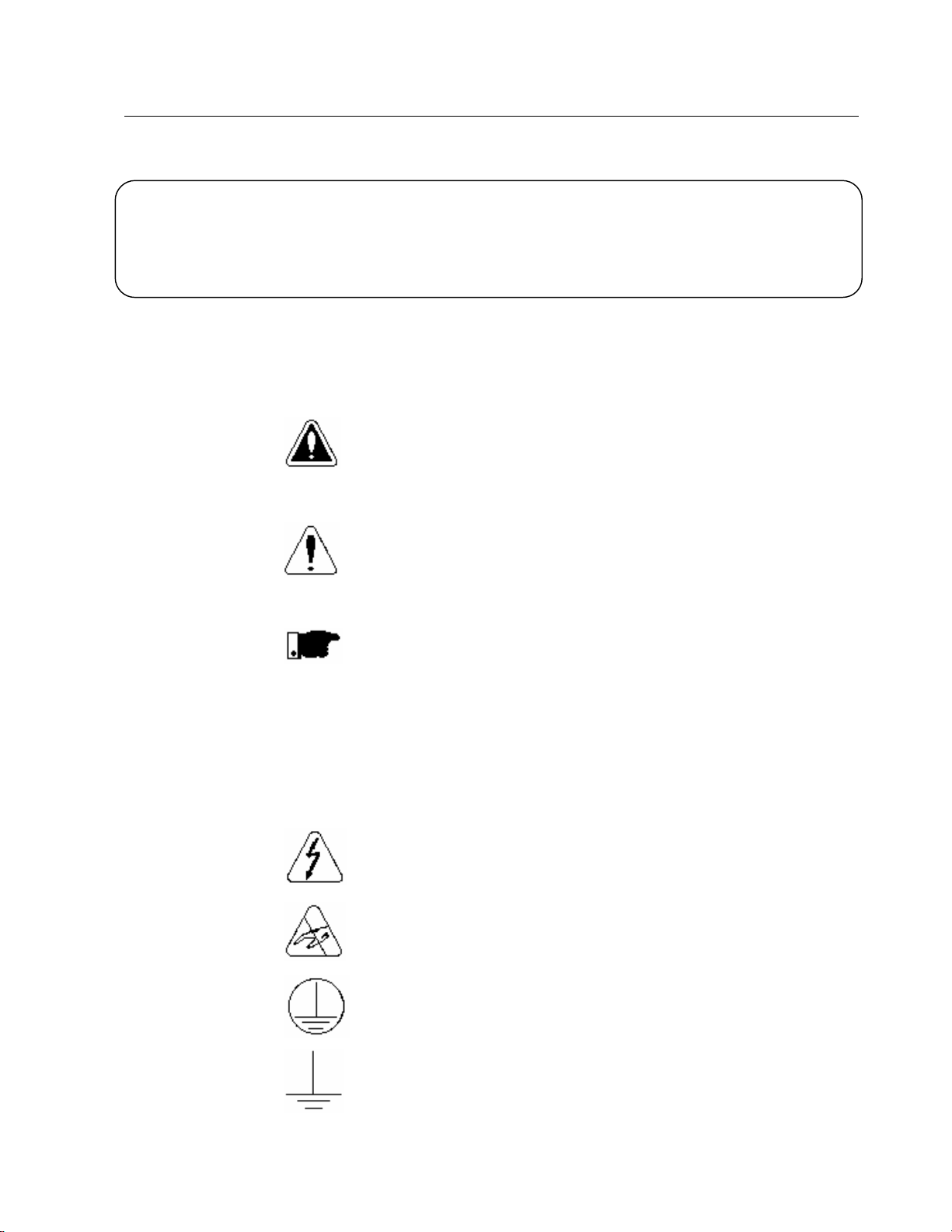

1.1 SAFETY

NOTICES

IN THE MANUAL

1.2 SAFETY

NOTICES ON THE

PRODUCT

Communication of the SSW -05 Soft-Starter.

The following Safety Notices will be used in this Manual:

DANGER!

If the Safety Instructions are not strictly observed, it can lead

to serious of fatal injuries of personnel and/or equipment

damage.

ATTENTION!

Failure to observe the recommended Safety Procedures can

lead to material damage.

NOTE!

The text aims at to provide important information for the

correct understanding and proper product performance.

The following symbols may be attached to the product,

serving as Safety Notice:

High Voltages.

Components sensitive to electrostatic discharge.

Do not touch them

Mandatory connection to ground protection (PE).

Shield connection to ground.

Page 8

1 SAFETY NOTICES

2

1.3 PRELIMINARY

RECOMMENDATIONS

DANGER!

Only qualified personnel should plan or implement the

installation, startup, operation and maintenance of serial

interfaces.

Read this manual before attempt any installation and

operation of the Soft-Starter by following ca refully all safety

notices here indicated.

Please follow the safety instructions indicated in this Manual,

in the Soft-Starter Manual and/or defined by local

regulations.

If personnel injuries or equipment damages can occurs due

to motors driven by motor starters, please provide always the

required electromechanical safety devices.

If remote control (via serial interface) is used, please take all

required precautions to avoid personnel injuries and

machine and installations damages.

Failure to comply with these instruction may result in

personnel injury and/or equipment damage.

DANGER!

Always disconnect the equipment from the power supply

before open it.

ATTENTION!

The electronic boards are fitted with components sensitive to

electrostatic discharges. Never touch any electrical

component or connector directly. If necessary to do so, touch

before the properly grounded metallic frame or use a suitable

ground strap.

NOTE!

In general, communication networks are sensitive to

interference generated by other equipment. In this case,

please follow all recommended instructions.

Page 9

3

INTRODUCTION 2

2.1 ABOUT THIS

MANUAL

This Manual describes how to install, start-up, operate and

identify problems related do the serial interface of WEG Soft Starters.

For more information, training or services, please contact:

WEG Service:

WEG AUTOMAÇÃO

Tel. (0800) 475767

Fax: (047) 372-4020

NOTE!

If you need information or services, please make available

following data:

þ model of WEG product;

þ serial number and manufacturing date as indicated on

WEG product nameplate;

þ version of installed software.

2.2 ABOUT WEG

PROTOCOL

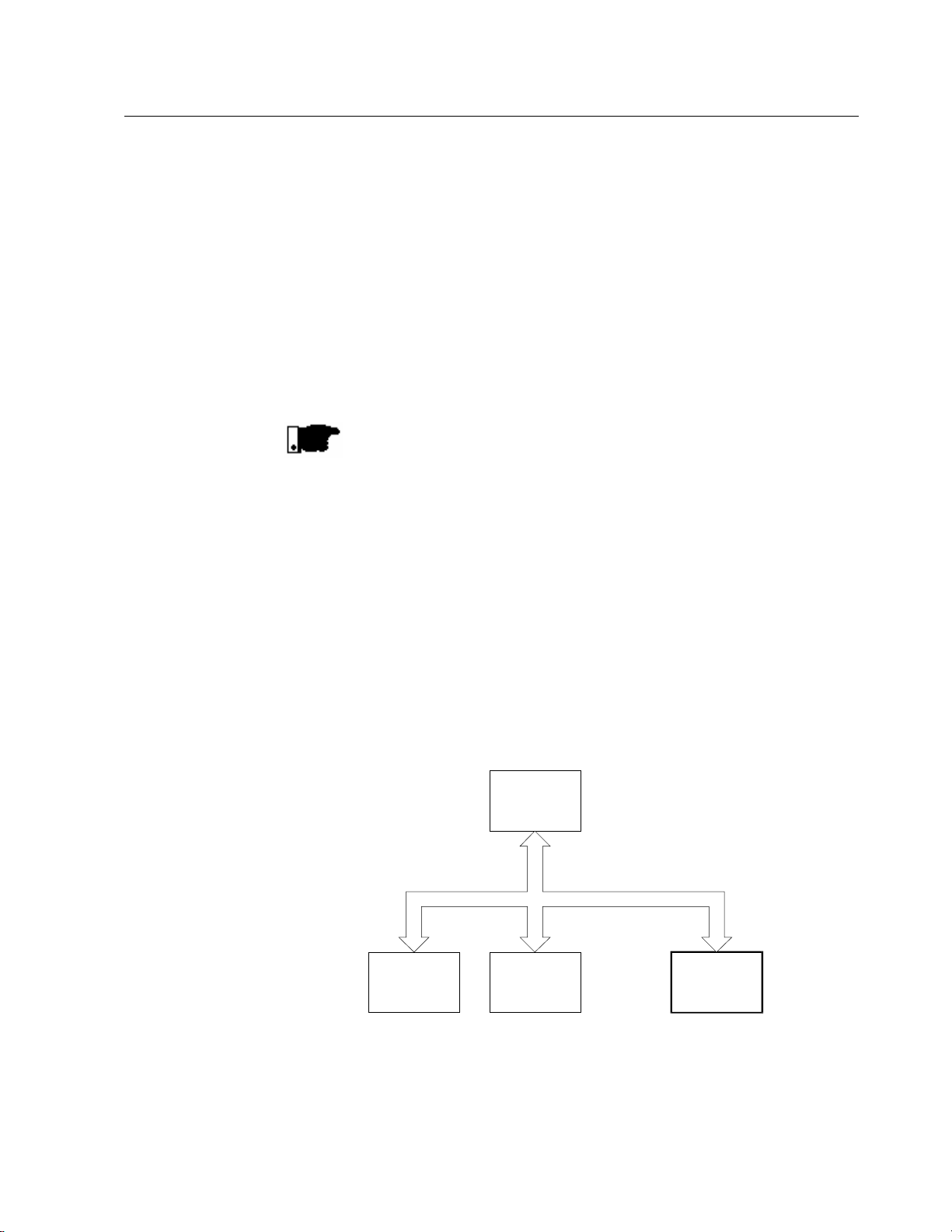

The main purpose of the serial network communication is

the physical connection of several equipment to one or more

masters connected to this network through only one or two

pair of wires:

Master

MESTRE

PC, CLP, etc.

Slave 1

ESCRAVO 1

(inverter)

(conversor)

Slave 2

ESCRAVO 2

(inverter)

(conversor)

. . .

Slave n

ESCRAVO n

(inverter)

(conversor)

n <= 30

WEG Soft-Starters are fitted with control software for the

transmission/reception of data through the serial interface to

enable the data reception sent by the master and the data

sending requested by the same.

Page 10

2 INTRODUCTION

4

The transfer rate is 9.600Bps, following an exchange

protocol, type question/answer, meeting ISO 1745 standard

for the data transmission in code.

The master is able to realize the following operations related

to each WEG equipment connected to the network:

þ Identification:

• Network number;

• Soft-Starter type (model);

• Software version.

þ Commands:

• general enabling/disabling;

• error reset.

þ Status Recognition:

• enabling/disabling;

• in acceleration;

• at rated voltage;

• in deceleration;

• in error.

þ Parameter Reading or Changing.

Typical examples of WEG network use:

• Supervisory monitoring at the same time several variables

of WEG Soft-Starters;

• PLC controlling the operation of several WEG SoftStarters WEG in an industrial process.

NOTE!

WEG protocol is the same for all WEG equipment, but the

logic command words, the basic variables and the

parameters can differ among equipment.

Page 11

5

RS-485

COMMUNICATION INTERFACES 3

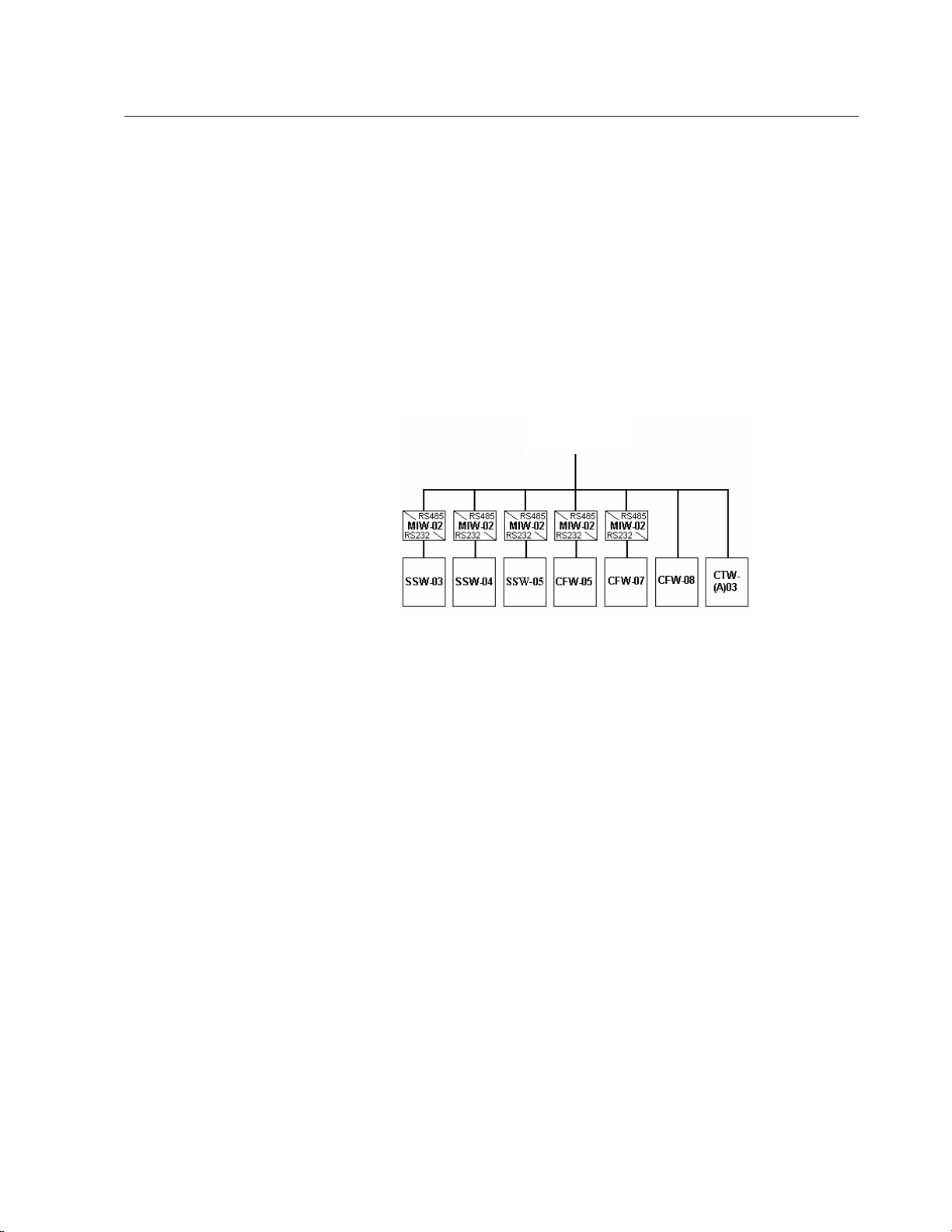

3.1 RS-485 INTERFACE

The physical connection between WEG Soft-Starters is

performed according to one of the standards below:

þ RS-232 point to point, up to 10m (32.8 ft);

þ RS-485 multipoint, with the use of the MIW-02 serial

interface module, with galvanic insulation, up to 1000m

(3280 ft).

For the serial communication of the Soft-Starters at WEG

network.

WEG Network

þ The interface allows the interconnection of up to 30 WEG

Soft-Starters to one master, attributing to each WEG

equipment one address (1 to 30) that has to be set.

þ In addition to these 30 addresses, two additional

addresses are at disposal to perform special tasks:

• Address 0: all WEG Soft-Starters are inquired,

independently of its address. On order to prevent shortcircuits in the interface lines, only one Soft-Starter can be

connected to the network (point-to-point).

• Address 31: a command can be transmitted to all SoftStarters on the network simultaneously, without

acceptance recognition.

Page 12

3 COMMUNICATION INTERFACES

6

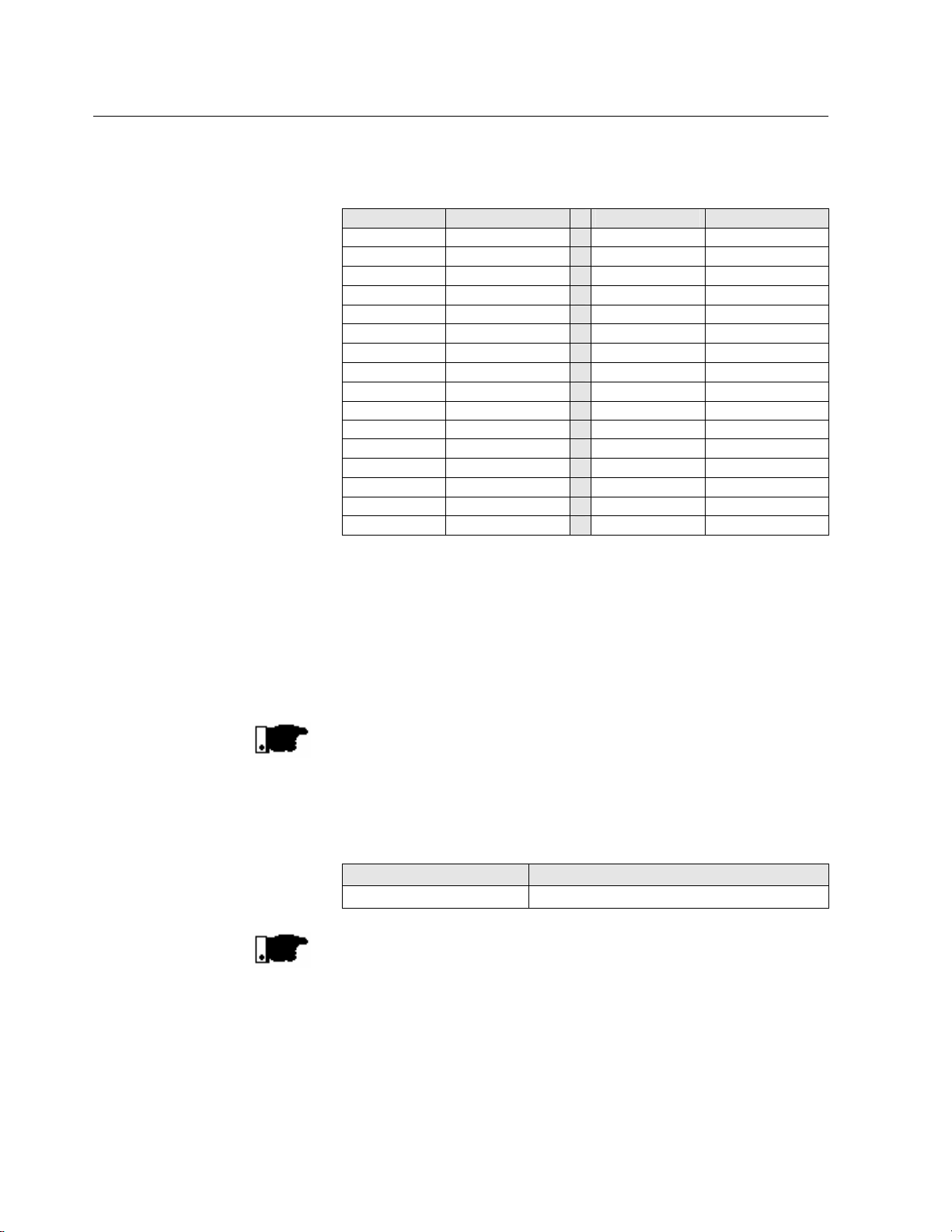

þ List of addresses and corresponding ASCII characters:

Address ASCII Address ASCII

0 @ 16 P

1 A 17 Q

2 B 18 R

3 C 19 S

4 D 20 T

5 E 21 U

6 F 22 V

7 G 23 W

8 H 24 X

9 I 25 Y

10 J 26 Z

11 K 27 [

12 L 28 \

13 M 29 ]

14 N 30 ^

15 O 31 _

þ The connection between the network participants is

realized through a pair of wire.

þ The signal levels are according to EIA STANDARD RS -

485 with differential receivers and transmitters.

NOTE!

WEG SSW-05 Soft-Starter is only fitted with the RS-232

serial interface, thus requiring the use of a MIW-02 serial

interface module, when a RS-485 serial interface is applied.

Module Item WEG

MIW-02 417100543

NOTE!

If master is fitted with only one RS-232 standard serial

interface, you have to apply the serial MIW-02 interface

module, RS-232/RS-485, if fitted with RTS signal, Request

To Send. If the Master is not fitted with the RTS signal, you

must apply a module that is able to generate the RTS signal.

For more details, contact WEG.

Page 13

7

COMMUNICATION INTERFACES 3

3.2 RS-232 INTERFACE

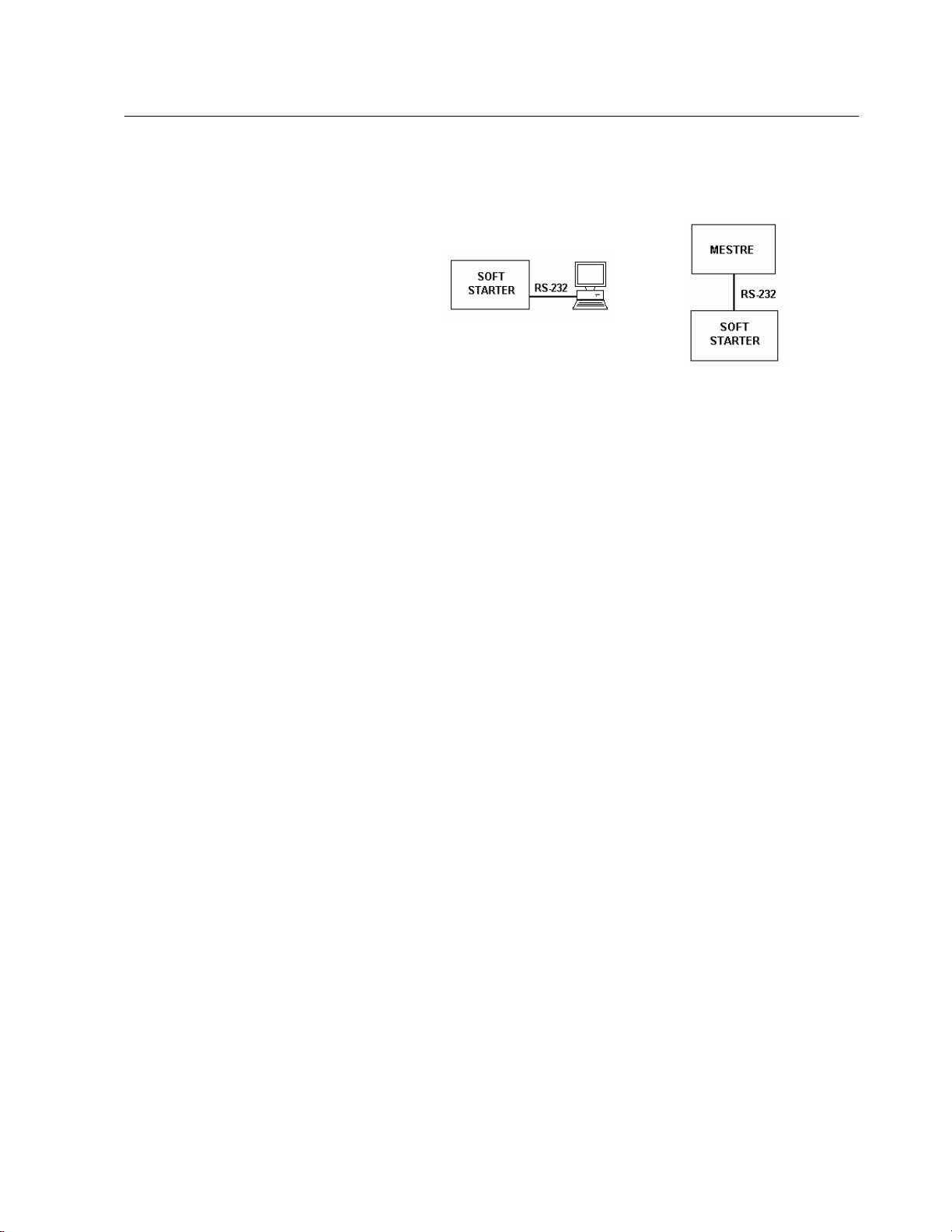

For the point-to-point communication with WEG Soft-Starters.

þ In this case we have the connection of a Master to a Soft-

Starter WEG.

þ The logical levels meet EIA STANDARD RS-232C that

determines the use of balanced signals.

þ Use a connection cable for the RS-232 interface.

3.2.1 RS-232 Electrical

Characteristics

þ RS-232:

• Standard: EIA Standard RS-232C.

• Transmission speed: 9.600Bps.

• Max. Cable length: 10 m (32.8 ft).

þ Receiver:

Max. Input voltage: ± 25V;

Input resistance: > 3KΩ

Level 1 (MARK): < -3V;

Level 0 (SPACE): > +3V.

þ Transmitter:

Current limitation: ~ 10mA;

Output voltage at level 1: < -7V (RL = 3K);

Output voltage at level 0: > +7V (RL = 3K).

3.2.2 Cares with

RS-232

þ Ensure that the interface is not isolated against the

internal electronics of the equipment to which is

connected.

þ Thus you must plan carefully the wiring location by

separating it at least 10 cm (0.33 ft) from the power

wiring.

þ It is also recommended to install the master as near as

possible to RS-232 serial interface of WEG Soft-Starter.

Page 14

3 COMMUNICATION INTERFACES

8

TERMINAL

SYMBOL

DESCRIPTION

1 +5V

+5V

±5%

4 Rx Data recepti

on

6 Tx Data transmission

Length

WEG Item

Cable of serial RS

-

232

with 0.17m (0.56ft)

0307.4790

Cable of serial RS

-

232 with 1m (3.28ft)

0307.4820

Cable of serial RS

-

232 with 2m (6.56ft)

0307.4838

Cable of s

erial RS

-

232 with 3m (9.84ft)

0307.4846

TERMINAL

SYMBOL

DESCRIPTION

1 Rx Data reception

4 GND

0V

6 nc Not connecte

d

Connector of

Connector of

3.2.3 RS-232

CONNECTION

þ The RS-232 must be connected directly point-to-point.

þ There are two standard WEG cables, as described below.

3.2.4 Description of the

Soft-Starter Serial

Connector

3.2.5 Definition of the

RS-232 Cable

þ SSW-05 connector (Serial Port).

2 RTS Request To Send

3 GND 0V

5 GND 0V

þ The used cable is the standard one for WEG serial

communication, equipment x serial HMI of WEG

inverters (Human Machine Interface).

the SSW-05

Serial Port

the Master

Serial Interface

3.2.6 Description of the

Cable of serial RS-232 with 0,23m (0.75ft) 0307.4803

Cable of serial RS-232 with 0,32m (1.05ft) 0307.4811

þ Master connector with RJ.

Master Connector

(RJ)

2 GND 0V

3 Tx Data transmission

5 nc Not connected

Page 15

9

Length

WEG Item

Cable of the serial RS

-

232 PC with 3m (9.8

ft) 0307.5460

TERMINAL

SYMBOL

DESCRIPTION

1

Not connected

4

Not connected

5 0V

6

Not connected

7

Not connected

8

Not con

nected

9

Not connected

Connector of

Connector of the

3.2.7 Definition of the

RS-232 PC Cable

COMMUNICATION INTERFACES 3

þ The cable to be used is the standard one for WEG serial

communication, equipment x PC.

þ It must be connected directly to the serial PC interface.

3.2.8 Description of the

PC (DB9)

Connector

the SSW-05

Serial Port

PC Serial Interface

þ Serial Connector of the PC (DB9).

2 Data reception

3 Data transmission

NOTE!

Take care with equipment connected to different grounds,

since there can be different voltages among them, and as

they are connected through their serial interfaces they can be

damaged.

ATTENTION!

Do not use the neutral conductor for grounding purpose.

For long distances, use always serial interfaces at RS-485.

Page 16

4 DEFINITIONS

10

4.1 USED TERMS

4.2 BLOCK DIAGRAM

The protocol used for the serial communication between

WEG equipment.

þ Parameters: are those existing in WEG equipment, which

visualization or alteration is possible through the HMI

(Human x Machine Interface) or SuperDrive Software;

þ Variables: are values that have specific functions on

WEG equipment and that can be read and, in some

cases, changed by the Master;

þ Basic variables: are those that can be accessed only

through the serial interface.

Page 17

11

The variable exchange is subject to the following

4.3 VARIABLE

STANDARDIZATION

Value and Function Table of the Parameter of V2.1X software version to implement:

changing, and commands via serial communication.

Parameter

(2)

P000

P002

P003

P023

P030

P031

P032

P050

Parameter

P101

P102

P104

(1)

P105

(1)

P106

(1)

P204

P206

Parameter Function

Parameter Access

Motor Current Indication (%)

Motor Current Indication (A)

Software Version 24

R Phase Current

S Phase Current

T Phase Current

Status Indication of the motor

overload protection

Parameter Function

(Reading and Writing)

Time of the Acceleration Ramp

Time of the Deceleration Ramp

Motor Current Setting 30 ... 100 (%) 100 26

Protection Configuration

Load Factory Setting

Auto-Reset Time 1 ... 1200 s 900 30

DEFINITIONS 4

standardization.

Range of the

(Reading)

internal values

0 ... 4, 6... 9999

= Read

5 = Alteration

000,0 ... 999,9

(% In)

000,0 ... 999,9

(A)

000.0 ... 999,9

(A)

000.0 ... 999,9

(A)

000.0 ... 999,9

(A)

0 ... 250

250 = error

Range of the

internal values

Initial voltage 30 ... 80 (% Un) 30 25

1 ... 20 (s) 10 25

0 ... 20 (s) 0 = off 26

0 ... 3F

Hexadecimal

0 = No function

1 = No function

2 = No function

3 = No function

4 = No function

5 = Load factory

default

Factory

Setting

User

Setting

0 24

24

24

24

24

24

24

Factory

Setting

1F

User

Setting

Hex.

0

Page

Page

27

30

Page 18

4 DEFINITIONS

12

Parameter

(1)

P215

(1)

P220

(1)

P264

(1)

P277

(1) (2)

P295

P308

P313

P314

Parameter Function

(Reading and Writing)

Keypad Copy Function

HMI / (Trimpots and Dip Switch)

Selection

Programmable Digital Input

DI 1

Programmable relay output

(14/23 - 24)

Rated current of the Soft-

Starter

Network Address 1 ... 30 1 33

Action of the serial

communication verification

Verification Time of the Serial

Communication

Range of the

internal values

0 = Off

1 = Copy

(SSW -> keypad)

2 = Paste

(keypad -> SSW)

0 = Trimpots and

Dip Switch

1 = HMI

0 = Not used

1 = Enable /

Disable

2 = External

Fault

1 = Full voltage

2 = Error

3 = Serial Com.

0 = 3 A

1 = 10 A

2 = 16 A

3 = 23 A

4 = 30 A

5 = 45 A

6 = 60 A

7 = 85 A

1 = only Error

2 = ramp

disabling

3 = General

disabling

4 = P264 → 1

0 ... 5 (s)

0 = oFF

Factory

Setting

User

Setting

0 30

0 32

1

32

1 33

According

to the

model

33

1

0 = off

Page

34

34

(1)

These parameters can be changed only with stopped motor.

(2)

These parameters are not changed through the function “Loads Parameters with Factory Setting” (P204).

Page 19

13

according to ISO 646 and complemented for even parity

possible.

4.4 CHARACTER

FORMAT

4.5 PROTOCOL

DEFINITIONS 4

þ 1 start bit;

þ 8 information bits [they codify the text characters and

transmission characters, remove from the 7 bits code,

(eight bit)];

þ 1 stop bit;

After the start bit, follows the less significant bit:

start

bit

B2 B3 B4 B5 B6 B7 B8B1START

8 bits of information

STOP

stop

bit

The transmission protocol meets ISO 1745 standard for data

transmission in code.

Are used only text character sequences without headers.

The errors monitoring is made through transmission related

to the parity of the individual 7 bit characters, according to

ISO 646.

The parity monitoring is made according to DIN 66219 (even

parity). The master uses two type of messages:

þ READING TELEGRAM: for inquiring on the Soft-Starter

variable content;

þ WRITING TELEGRAM: to c hange the variable content or

to send controls to the Soft-Starters.

Note: No transmission between two inverters is

The master has the control of the bus access.

Page 20

4 DEFINITIONS

14

4.5.1 Reading

Telegram

The telegram permits the receive from the Soft-Starter the

content corresponding to the inquiry code.

In the answer telegram, the Soft-Starter transmits the data

requested by the master and it finishes the transmission with

EOT.

1) Master

1) Mestre:

EOT ADR ENQ

CÓDIGO

CODE

2) Soft Starter:

ADR STX = ETX BCC

CÓDIGO VAL

CODE

TEXT

TEXTO

þ Format of the reading telegram:

• EOT: control character of End Of Transmission;

• ADR: inverter address (ASCII@, A, B, C, ...) (ADRess);

• CODE: address of the 5-digit variable coded in ASCII;

• ENQ: control character of ENQuiry (enquiry)

þ Format of the Soft-Starter answer telegram:

• ADR: 1 character – Soft-Starter address;

• STX: control character - Start of TeXt;

• TEXT: consists in:

• CODE: Address of the variable;

• “ = “: separation character;

• VAL: 4 digit value (HEXADECIMAL);

• ETX: control character - End of TeXt;

• BCC: CheCksum Byte - EXCLUSIVE OR all the bytes

between STX (excluded) and ETX (included).

NOTE: In some cases there may be a soft-starter answer

with:

ADR

NAK

Page 21

15

DEFINITIONS 4

4.5.2 Writing Telegram

This telegram sends data to the Soft-Starter variables.

The Soft-Starter answers by indicating if the data have been

accepted or not.

1) Master

1) Mestre:

1) Mestre:

EOT ADR STX = ETX BCC

2) Soft Starter:

ADR ACK ADR NAK

CÓDIGO VAL

CODE

TEXTO

TEXT

OU

or

þ Format of the Writing Telegram:

• EOT: control character of End Of Transmission;

• ADR: Soft-Starter address;

• STX: Control Character of Start of TeXt;

TEXT: consists in:

• CODE: variable address;

• “ = “: separation character;

• VAL: 4 digit HEXADECIMAL value

• ETX: control character of End of TeXt;

• BCC: CheCksum Byte - EXCLUSIVE OR all bytes

between STX (excluded) and ETX (included).

þ Format of the Soft-Starter answer telegram:

Acceptance:

• ADR: Soft-Starter address;

• ACK: ACKnowledge control character;

Not acceptance:

• ADR: Soft-Starter address;

• NAK: Not AcKnowledge control character.

This means that the data were not accepted and the

addressed variables continue with its old value.

Page 22

4 DEFINITIONS

16

4.6 EXECUTION AND

TEST TELEGRAM

4.7 TELEGRAM

SEQUENCE

The Soft-Starters and the master test the telegram syntax.

The answers for the respective verified conditions are

defined as follows:

þ Reading Telegram:

• No answer: with wrong telegram structure, control

characters were received incorrectly of Soft-Starter

address in wrong;

• NAK: CODE corresponding to a no-existing variable or

write only variable;

• TEXT: with valid telegrams.

þ Writing Telegram:

• No answer: with wrong telegram structure, control

characters received incorrectly or wrong Soft-Starter

address;

• NAK: code corresponding to a non-existing variable,

wrong BCC (checksum byte), read-only variable, VAL out

of permitted range for the concerned variable, operation

parameter out of the alteration mode;

• ACK: with valid telegrams;

The Soft-Starters process the telegrams in determined

intervals. Therefore, a larger pause than the times of the

involved telegrams should be ensured between two

telegrams addressed to the same Soft-Starter (see item

4.9).

Page 23

17

address and the basic variables formed by 5 digits (ASCII

Starters WEG is

4.8 VARIABLE CODE

DEFINITIONS 4

The filed designated with CODE contains the parameter

characters) as follows:

Equal to zero (0)

4.9 TIMES

þ The transmission speed of WEG Soft-

9600bps.

þ WEG protocol times:

Data reception/transmission speed is 9600bps 1bit / 104.2us

Each data word has 10bits 1.04ms

An enquiry telegram has 8 words 8.33ms

An answer telegram to an enquiry has 14 words 14.58ms

A changing telegram has 15 words 15.63ms

An answer telegram to a changing has 2 words 2.08ms

Updating to a requested variable (with prompt answer) 22.91ms

Changing of a write variable (with prompt answer) 17.71ms

Page 24

5 TELEGRAM EXAMPLES

18

5.1 EXAMPLE 1 þ Changing of the rated SSW-05 current (P295) to 4 = 30A,

at the Soft-Starter 7 (“>” = SSW-05).

5.2 EXAMPLE 2 þ Output Current Reading of (P002) of the Soft-Starter 10,

by supposing that the same current was equal to 100.0%

of In at the moment of the enquiry (“>” = SSW-05).

Page 25

VARIABLES OF THE SERIAL COMMUNICATION 6

19

0 =

0 =

0 =

0 =

0 =

0 =

0 =

0 =

0 =

independently of the P294 programming (DI 1 programmable

6.1 BASIC VARIABLES

6.1.1 V00

6.1.2 V01

LSB

MSB

(code 00>00)

þ Indication of the equipment model.

þ Read Variable;

(code 00>01)

þ Indication of the Soft-Starter status.

þ Read variables which bits have the following meaning:

0 0 = disabled 1 = enabled

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

general disabled 1 = general enabled

reserved

not used 1 = at acceleration

reserved

not used 1 = at rated voltage

reserved

not used 1 = at deceleration

DI 1 opened 1 = DI 1 closed

reserved

reserved

reserved

relay output disabled 1 = relay output enabled

not used 1 = with hardware error

without power supply 1 = with power supply

without error 1 = with error

NOTE!

The bit 8 of V01 indicates the status of the DI 1 digital input,

digital input).

Page 26

6 VARIABLES OF THE SERIAL COMMUNICATION

20

6.1.3 V02

Errors:

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

MSB LSB

Error code: hexadecimal error number

Ex.: E03 Ü 03H

E06 Ü 06H

E10 Ü 0AH

(code 00>02)

þ Indication of the Soft-Starter errors.

þ Read variable which bits have following meaning:

Serial error (byte-high)

Hardware error (byte-low)

Serial Error Hardware error

Page 27

VARIABLES OF THE SERIAL COMMUNICATION 6

21

Error code and description:

DISPLAY DESCRIPTION

E03

E05

E06

E10

E2x

E22

E24

E25

E26

Phase loss

Output overload (Ixt function)

External fault

Error in the copy function

Serial communication error

Longitudinal parity fault

Parameterization fault

Variable or parameter not existing

Expected value out of the allowed limits

E27

E29

E31

E63

E64

E66

E67

E70

E71

E72

E73

E75

Writing attempt in a read only variable or logical control disabled

Error of the cyclic serial communication interrupted

Keypad conection fault

Locked rotor

Thyristor overload

Overcurrent

Incorrect phase sequence

Undervoltage in the control supply

Internal By-pass relay contact is open

Overcurrent before the By-pass

Overcurrent of the SSW-05 By-pass relay

Frequency out of tolerance

Page 28

6 VARIABLES OF THE SERIAL COMMUNICATION

22

0 =

0 =

0 =

0 =

1 =

1 =

1 =

6.1.4 V03

LSB

0

1

2

3

4

5

6

7

8 1 = enabling/disabling

9

10

11

12

13

14

15

MSB

(code 00>03)

þ Logic command selection.

þ Write variable, whose bits have following meanings:

disabling 1 = enabling

general disabling 1 = general enabling

reserved

reserved

opens relay output

contact

reserved

reserved

Not used 1 = reset

general enabling/disabling

reserved

reserved

opens/closes relay output contact

reserved

reserved

Soft-Starter “ reset “ when in error

þ BYTE HIGH (8-15): desired action mask. The

corresponding bit should be set to 1, so the action

happens.

þ BYTE LOW (0-7): logical level of the desired action.

NOTE!

Reset acts only if Soft-Starter has hardware error.

1 = closes relay output

contact

Page 29

23

7.1 PARAMETERS

RELATED TO

THE SERIAL

COMMUNICATION

7.2 ERRORS RELATED

TO THE SERIAL

COMMUNICATION

ERROS E PARÂMETROS DA SERIAL 7

þ P264 - Commands via HMI and Serial or via Digital

Inputs.

þ P308 – Address of the Soft-Starter at the communication

network.

þ P313 – Action of the Serial Communication Verification.

þ P314 – Time of the Serial Communication Verification.

þ They do not disable WEG Soft-Starters;

þ They do not disable the defective relay;

þ They are informed in the word of the logical status.

Fault Types:

• E22: longitudinal parity fault (BCC);

• E24: parameterization fault;

• E25: variable or parameter not existing;

• E26: expected value out of the permitted limits;

• E27: writing attempt in a read only variable or logical

control disabled;

• E29: error of the cyclic serial communication interrupted.

Note:

These errors can be noted by reading the status variable of

WEG equipment.

NOTE!

The fault E29 can disable the Soft-Starters.

This protection is used in installations, where the Soft-Starter

has to take a decision in case of a communication fault

between the master and the Soft-Starter.

NOTE!

Please take care of the function incompatibilities between the

parameters as indicated in WEG Soft-Starter Manual.

Page 30

8 DETAILED PARAMETER DESCRIPTION

24

8.1 -

8.2 -

8.3 -

8.4 -

8.5 -

8.6 -

8.7 -

8.8 -

P000 – Access

Parameter

P002 – Motor

Current Indication

(%)

P003 – Motor

Current Indication

(A)

P023 – Software

Version

P030 – R Phase

Current

P023 – S Face

Current

P023 – T Face

Current

P050 – Status

Indication of the

Motor Thermal

protection

þ Releases the access to change the parameter values.

þ The password is 5.

þ Indicates the In-% output current of the Soft-Starter.

þ Accuracy of ± 10% @ 1xIn of the SSW-05.

þ Indicates directly in A the Soft-Starter output current.

þ Is necessary to program P295 correctly. This is important

in the correct indication value in amperes

þ Accuracy of ± 10% @ 1xIn of the SSW-05.

þ Indicates the version of the software installed in the CPU.

þ It indicates the current of the R Phase.

þ Accuracy of ± 10% @ 1xIn of the SSW-05.

þ It indicates the current of the R Phase.

þ Accuracy of ± 10% @ 1xIn of the SSW-05.

þ It indicates the current of the T Phase.

þ The indicated value is estimated from the instantaneous

current of the R and S Phases.

þ Indicates in percentage the status of the thermal motor

protection (0 ... 250). 250 is the point where the thermal

motor protection is activated, E05.

Page 31

25

8.9 - P101 – Initial

Voltage (%Un)

8.10 - P102 – Time of the

Acceleration Ramp

(s)

DETAI LED PARAMETER DESCRIPTION 8

þ It sets the start voltage (%Un) that will be applied to the

motor according to Figure 8.1.

þ When P220 = 0, the parameter content indicates the

value that has been set through the trimpot. When the

trimpot has been set to the maximum value, the value

indicated at the Parameter may be lower than expected.

This is due to mechanical limits variations. The

parameter content cannot be changed through the

keypad when P220 = 0.

þ With P220=1, the content of the parameter indicates the

value programmed through the communication or HMI.

þ It defines the ramp time of the voltage increment, as

shown in Fig. 8.1.

þ When P220 = 0, the parameter content indicates the

value that has been set through the trimpot. When the

trimpot has been set to the maximum value, the value

indicated at the Parameter may be lower than expected.

This is due to mechanical limits variations. The

parameter content cannot be changed through the

keypad when P220 = 0.

þ With P220=1, the content of the parameter indicates the

value programmed through the communication or HMI.

NOTE!

Due to the back-EMF (electromotive Force) generated by the

motor, motors without load or with small loads will have a

shorter acceleration time than the time that has been

programmed at P102.

Page 32

8 DETAILED PARAMETER DESCRIPTION

26

8.11 - P104 – Time of the

Deceleration

Ramp (s)

8.12 - P105 – Motor

Current Setting (%)

þ Used on pump application.

þ Defines the ramp time of the voltage decrement

þ When P220 = 0, the parameter content indicates the

value that has been set through the trimpot. When the

trimpot has been set to the maximum value, the value

indicated at the Parameter may be lower than expected.

This is due to mechanical limits variations. The

parameter content cannot be changed through the

keypad when P220 = 0.

þ With P220=1, the content of the parameter indicates the

value programmed through the communication or HMI.

NOTE!

This function is used to delay the normal deceleration time of

a load and in that way to not force a shorter time than that

imposed by the own load.

þ It sets the motor current in percent relating to the rated

Soft-Starter current.

þ The indica ted value is related directly to the activation

levels of the following motor protection devices: phase

loss, overload, overcurrent and locked rotor.

þ When P220 = 0, the parameter content indicates the

value that has been set through the trimpot. When the

trimpot has been set to the maximum value, the value

indicated at the Parameter may be lower than expected.

This is due to mechanical limits variations. The

parameter content cannot be changed through the

keypad when P220 = 0.

þ With P220=1, the content of the parameter indicates the

value programmed through the communication or HMI.

Page 33

27

8.13 - P106 – Protection

configuration

Example:

P106 = 13 Hex

1 - Enabled

1 - Enabled

0 - Disabled

0 - Disabled

1 - Enabled

0 - Disabled

13Hex = 010011bin

DETAI LED PARAMETER DESCRIPTION 8

þ With P220=0, the content of the parameter indicates the

value programmed through Dip Switch. In this case the

alteration of the content of the parameter through HMI is

not possible.

þ With P220=1, the content of the parameter indicates the

value programmed through the communication or HMI.

þ It configures the protections that are enabled.

þ The value is indicated as Hexadecimal value. Please find

below the protection and the corresponding bit.

LSB

0 Overcurrent

1

2

3

4

5

6

7

8 -

9

10

11

12

13

14

15

MSB

Phase loss

Incorrect phase sequence

Locked rotor

Motor overload

Automatic reset

-

-

-

-

-

-

-

-

-

- Overcurrent

- Phase loss

- Incorrect phase sequence

- Locked rotor

- Motor overload

- Automatic reset

Page 34

8 DETAILED PARAMETER DESCRIPTION

28

þ The Table below shows the combination of the enabled

protections and the corresponding value to be

programmed at P106.

Protection Configuration

Value

programmed

at P106

(hexadecimal)

Automatic Reset

Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Motor Overload

Stall

Incorrect

Phase sequence

Phase Loss

þ

þ þ

þ

þ

4

þ þ

þ þ þ

þ

þ

þ

þ

þ þ

þ þ

8

þ

þ þ

C

þ þ þ

þ þ þ þ

þ

þ

þ

þ

þ

þ

þ

þ

þ þ

þ þ

þ þ

þ þ

þ þ þ

þ þ þ

10

þ

þ

þ þ

þ þ þ

18

þ

þ þ

14

þ

þ þ

1C

þ þ þ þ

Overcurrent

þ

2

þ

6

þ

A

þ

E

þ

12

þ

16

þ

1A

þ

1E

1

3

5

7

9

B

D

F

11

13

15

17

19

1B

1D

Page 35

29

DETAI LED PARAMETER DESCRIPTION 8

Protection Configuration

Value

programmed

at P106

(hexadecimal)

Automatic Reset

Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

þ

þ

þ

þ

þ

þ

þ

þ

þ

þ

þ

þ

þ

þ

þ

þ

þ þ

þ þ

þ þ

þ þ

þ þ

þ þ

þ þ

þ þ

þ þ þ

þ þ þ

þ þ þ

þ þ þ

þ þ þ þ

þ þ þ þ

þ þ þ þ þ

þ þ þ þ þ þ

Motor Overload

Stall

Incorrect

Phase sequence

Phase Loss

Overcurrent

þ þ þ þ þ

20

þ

þ

þ

þ

þ þ

þ þ

þ þ þ

þ þ þ þ

30

þ

þ

þ þ

þ þ þ

þ

þ

þ þ

þ þ þ

28

38

þ

þ þ

þ

þ þ

þ

þ þ

þ

þ þ

24

2C

34

3C

þ

22

þ

26

þ

2A

þ

2E

þ

32

þ

36

þ

3A

þ

3E

1F

21

23

25

27

29

2B

2D

2F

31

33

35

37

39

3B

3D

3F

þ = proteção habilitada

Page 36

8 DETAILED PARAMETER DESCRIPTION

30

8.14 - P204 - Load

Factory Setting

8.15 - P206 – Auto-Reset

Time

8.16 - P215 – Keypad

Copy Function

Note: The Keypad

Copy Function is

only available when

using HMI-SSW05RS

þ Programs all parameters to the standard factory default,

when P204=5.

þ The parameters P000 and P295 are not changed when

the factory default parameters are loaded through

P204=5.

þ When any fault is detected, excepting E10, E24, E29,

E31 e E67, the Soft-Starter SSW-05 can cause an

automatic reset after the time programmed at P206 has

elapsed

þ If after an “auto-reset” the same fault is repeated three

times consecutively, the Auto-Reset function will be

disabled. A fault is considered consecutive if it happens

again within 30 second after an auto-reset has been

executed.

þ This is fault is repeated four times consecutively, it will be

displayed permanently and the Soft-Starter will be

disabled.

þ Auto-Reset Enable/Disable is executed through the Dip

Switch (Man Auto) or by means of P106 and P220.

þ The keypad copy function is used to transfer the content

of the parameters from one SSW to another.

P215 Action Notes

0 Off -

1

2

(SSW -> Keypad)

(Keypad -> SSW)

Copy

Paste

Transfers the current

parameter values of the SSW

to non volatile memory

(EEPROM) of the HMISSW05-RS Keypad. The

current SSW parameters are

not changed.

Transfers the content of the

non volatile memory of the

keypad (EEPROM) to the

current SSW parameters.

Page 37

31

DETAI LED PARAMETER DESCRIPTION 8

þ Procedure is as follows:

1. Connect the keypad (HMI-SSW05-RS) to the inver ter

from which the parameters will be copied (SSW A –

source Soft-Starter).

2. Set P215=1 (copy) to transfer the parameter values

from the SSW A to the keypad. Press key.

During running of the copy function, display will show

. P215 resets automatically to 0 (Off) after

transfer has been completed.

3. Disconnect the keypad from the SSW (A).

4. Connect the same keypad to the SSW to which the

parameters will be transferred (SSW B – target SoftStarter).

5. Set P215=2 (paste) to transfer the content of the

keypad (EEPROM has the SSW A parameters) to

SSW B. Press the key. While the keypad is

running the paste function, the display shows ,

an abreviation for paste. When P215 returns to 0, the

parameter transfer has been concluded. Now SSWs

A and B will have the same parameter values.

To copy the parameter content of the SSW A to other

SSW(s), repeat steps 4 to 5 above.

Fig. 8.2 – Copying the parameters from the SSW A to the SSW B, by using the

Copy Function and the HMI-SSW05-RS keypad

Page 38

8 DETAILED PARAMETER DESCRIPTION

32

8.17 - P220 –

HMI / (Trimpots

and Dip Switch)

Selection

8.18 - P264–

Programmable

Digital Input DI 1

þ It configures the operation mode of the Soft-Starter, in

“Trimpot and Dip Switch” mode or “HMI” mode.

0 - “(Trimpot and Dip Switch)” – the programming of the initial

voltage, ramp time, motor current setting and enabling of

the protection devices is performed by means of the

trimpots and dip switch. The values programmed through

the serial communication is not used.

1 - “HMI” – the programming is performed through the serial

communication. The values programed through trimpots

and dip switch is not used.

NOTE !

In “HMI” mode (P220=1) the trimpots and dip switch

programming is ignored. The start voltage, ramp times, motor

current setting and the protection enabling is programmed

through the parameters P101, P102, P104, P105 and P106.

þ It configures the DI 1 digital input to operate according to

the codes described below.

0 - “Not used”, DI 1 digital input is disabled. The enabling

commands are only accept via serial communication

(V03).

1 - “Enable/Disable”, enabling only via digital input. The

enabling commands via serial communication are

ignored.

2 - “External Fault”, it acts only if the DI 1 digital input is

open. It can also be used as additional load protection.

Example: thermal protection of the motor through dry

contact (without voltage) of a protection relay

(Thermostat).

The enabling commands are only accepted via serial

communication (V03).

Page 39

33

8.19 - P277 –

Programmable

Relay Output

(14/23 – 24)

DETAI LED PARAMETER DESCRIPTION 8

þ It enables the relay (14/23 – 24) to operate according to

the following parameter setting:

1 - Function “Full voltage” – the relay closes the contact only

after the Soft-Starter reached 100% of Un (By-pass), and

opens the contact when the Soft -Starter has received a

switch-Off order.

2 - Function “Error”, the relay closes the NO contact when

the SSW-05 is with no error.

3 - Function “Logic Command”, the relay opens and closes

the relay contact according to the BIT 5 status of the V03

basic variable.

8.20 - P295 – Rated

Current of the

Soft-Starter

8.21 - P308 - Network

Address

þ Configures the SSW-05 models.

þ Its function is to set the software so the current indication

in Ampere (P003) is correct.

The possible configurations of the SSW-05 model are:

0 = 3A

1 = 10A

2 = 16A

3 = 23A

4 = 30A

5 = 45A

6 = 60A

7 = 85A

þ It defines the address at which the Soft-Starter will

respond on the communication network between all

equipment connected to this network.

Page 40

8 DETAILED PARAMETER DESCRIPTION

34

8.22 - P313 – Action of

the Serial

Communication

Verification

þ This parameter has the purpose to set the action to be

taken when an error indication occurs.

NOTE!

To attribute a function to this parameter, set P314 different

from 0 = Off.

Values for P313: 1- It indicates only error.

2- Indicates error and disables the Soft-

3- Indicates error and causes general

4- Indicates error and program P264 with

Starter by ramp. If the programmed

deceleration time is equal to 0 sec, the

motor driven by the Soft-Starter will be

stopped by inertia.

disabling of the Soft-Starter. It can be

used as emergency stopping.

the value 1. The bit 0 of V03 is reseted.

8.23 - P314 – Verification

Time of the Serial

Communication

þ This parameter has the function to enable or disable, as

well as to set the verification time of the serial

communication. This protection acts when the serial

communication between the master and the Soft-Starter

is interrupted generating the respective indication or

introducing an action as set at parameter P313.

NOTE!

Enable this function only if there is a cyclic serial

communication with a master.

Set the verification time according to the time of the

telegrams sent by the master.

Page 41

35

485 is applied and the master is using a

TROUBLESHOOTING 9

Problem

Corrective Action

þ Check if the telegrams are assembled correctly.

• Equipment code;

• Byte of correct BCC;

• Parity;

• Word length.

No communication to the

Soft-Starter:

þ Check if all connections of the serial communication

cables and required power cables are correct.

þ Check if the master transfer rate is 9600bps.

þ Check if the address of the Soft-Starter (P308) is the

same to which the master is sending the telegrams.

þ When RS-

RS-232/RS-485 inverter, check if RTS signal is present.

þ Check if the changing telegrams are assembled

Master reads but does not

change the Soft-Starter

parameters:

correctly.

þ Check if there is no write attempt on a read-only variable.

þ Check if the variable can be changed with running motor.

Random indication of serial

errors in the serial

communication:

þ When connected in communication network with RS-485:

• Check if all serial cable connection at the network and

their respective shields were performed correctly

• Check if all grounding points are grounded correctly.

• Check if only the network terminals have terminating

connectors.

þ Check if all cables of the RS-232 connections are as

short as possible and laid at the recommended distances

from the power cables.

Loading...

Loading...