WEG Electric SSW05 User Guide

INST ALLATION AND

OPERA TION MANUAL

MANUAL DE INSTALACION Y

OPERACION

MANUAL DE INSTALAÇÃO E

OPERAÇÃO

Series / Série / Série: SSW-05 Plus

Software: 2.3X

0899.5119 E, S, P /8

Please take this page out when unpacking the product

Favor sacar esta hoja al desempaquetar el producto

Favor destacar esta folha de rosto ao desembalar o produto

Installation and Operation Manual - SSW-05 Plus

Installation and Operation Manual - SSW-05 Plus

Version 2.3X - 0899.5119 /8

SUMMARY - English

1. Safety Instructions ...........................................................................................................04

2. What is the SSW-05 Plus Soft-Starter..............................................................................04

3. How to identify the SSW-05 Plus .....................................................................................04

4. T echnical Data.................................................................................................................05

5. SSW-05 Plus Description................................................................................................06

6. Table of Powers / Currents / Power Wiring (copper wire at 70°C (158oF)) ........................06

7. T able of Connector T ightening Torque ..............................................................................06

8. Capacity of the Power Supply Line ..................................................................................07

9. T able of Fuses and Contactors ........................................................................................07

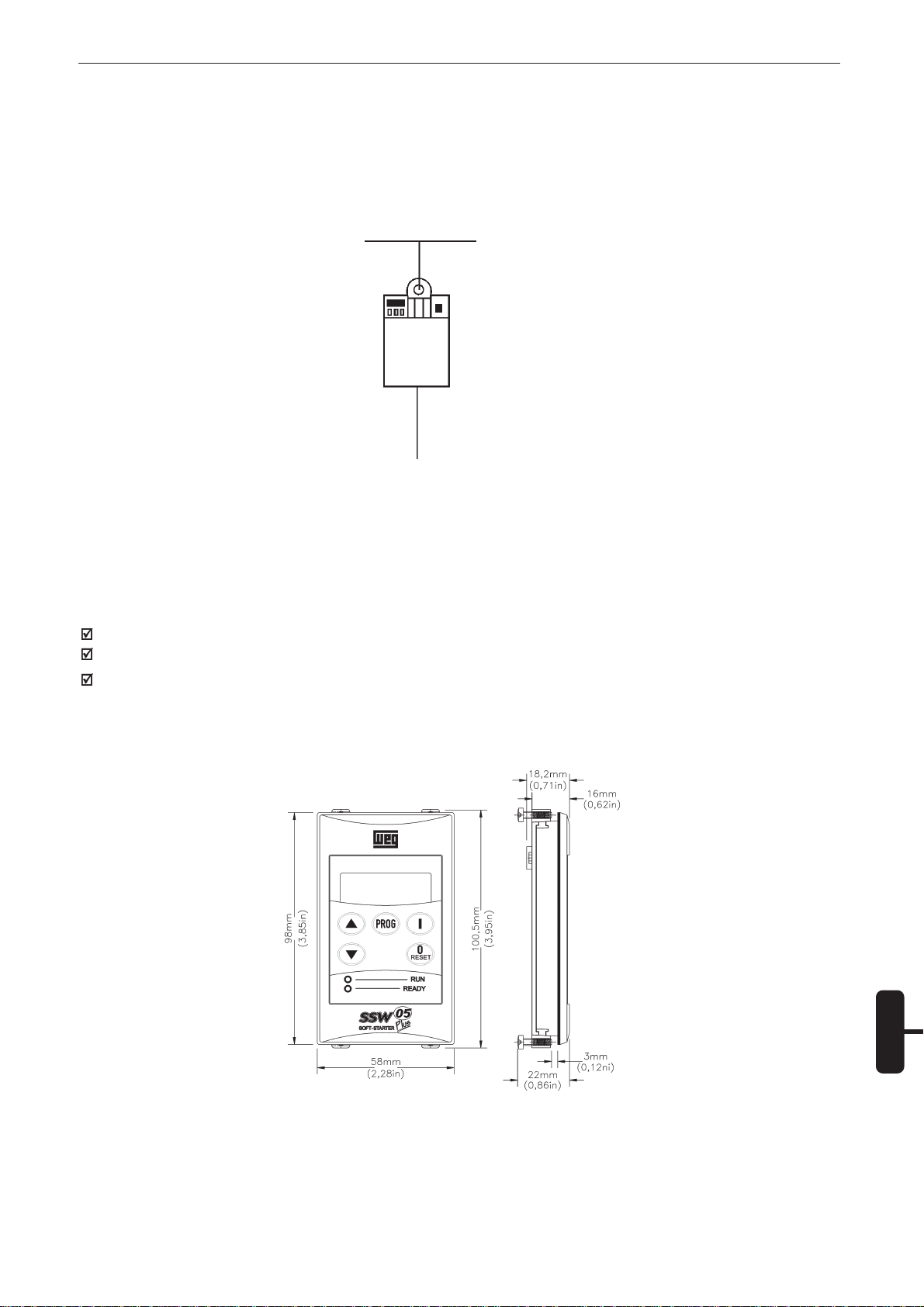

10. Dimensions...................................................................................................................07

1 1. SSW-05 Plus Installation and Connection ......................................................................08

12. SSW-05 Plus Setting ....................................................................................................10

13. Operation of the Digital Relay Outputs ........................................................................... 11

14. Protections and Displays...............................................................................................1 2

15. Overload Protection ......................................................................................................13

16. Reset ............................................................................................................................14

17. Faults and Possibles Causes........................................................................................ 15

18. Solving the most frequent problems ...............................................................................18

19. SSW-05 Options and Accessories ................................................................................18

20. T able of Parameters (for serial communication/HMI-SSW05-RS)...................................23

21. Error code and description (for serial communication / HMI-SSW05-RS).......................24

22. Detailed Parameter Description (for serial communication/HMI-SSW05-RS).................24

23. Appendix for CE Conformance...................................................................................... 30

24. EU Declaration of Conformity ........................................................................................32

Warranty SSW-05 Plus........................................................................................................33

English-3

ENGLISH

Installation and Operation Manual - SSW-05 Plus

SSW-05 - INSTALLATION AND OPERATION MANUAL

INTRODUCTION

The SSW-05 Plus electronic Soft-S tarter has been designed to drive three-phase induction motors

applied to light duty loads, such as centrifugal pumps, small fans and screw compressors. If the

Soft-S tarter shall be applied on heavy duty loads, please contact WEG .

The serial communication is available in the SSW-05 with software versions greater than V2.00.

The manual of the serial communication is available for download on the website www .weg.com.br.

With the serial communication is possible:

a)to connect the Soft-S tarter in an equipment network, like PC, PLC, and others;

b)to use with SuperDrive software for Microsoft Windows, allowing the SSW-05 programming

and operation;

c)to use the remote HMI (human machine interface) for SSW-05 programming and operation.

SAFETY NOTICES:

The following Safety Notices will be used in this Manual:

Danger

If the recommended Safety Notices are not strictly observed, it can lead to serious or fatal

injuries of personnel and/or material damage.

Attention

Failure to observe the recommended Safety Procedures can lead to material damage.

Note

The content of this Manual supplies important information for the correct understanding of

operation and proper performance of the equipment.

1. SAFETY INSTRUCTIONS:

Danger

Always disconnect the power supply from the equipment before attempting any

maintenance work.

Attention

Personnel must review this entire Manual before attempting to install and operate the

SSW-05 Plus Soft-Starter. Only qualified personnel should plan or implement the

installation, start-up, setting, operation and maintenance of this equipment.

2. WHAT IS THE SSW-05 PLUS SOFT-STARTER:

The SSW-05 Plus Soft-S tarter allows smooth start/stop of three-phase induction motors.

3. HOW TO IDENTIFY THE SSW-05 PLUS:

ENGLISH

WEG Series 05

SSW05

Soft-Starter

0003

Rated Output

Current:

0003 = 3A

0010 = 10A

0016 = 16A

0023 = 23A

0030 = 30A

0045 = 45A

0060 = 60A

0085 = 85A

T

Three-phase

Power Supply

2246

Power Supply

Volt age:

2246 =

220 to 460V

4657 =

460 to 575V

E

Manual

Language:

P= Portuguese

E= English

S= Spanish

SSW-05

Version:

P= Plus

P

Z

End of Code

English-4

Installation and Operation Manual - SSW-05 Plus

Example: The code SSW050010T2246PPZ means a 10A SSW-05 Plus, three-phase power

supply in the range from 220 to 460V , manual in Portuguese, PLUS version.

4. TECHNICAL DATA:

Model

Control Voltage (A1 and A2)

90 to 250Vac 50/60 Hz (+/- 6Hz)

AC Input Power

Power supply

(R/1L1, S/3L2, T/5L3)

220 to 460 V ac (+10%,-15%) 50/60 Hz (+/- 5Hz) 3φ

460 to 575 V ac (+10%,-15%) 50/60 Hz (+/- 5Hz) 3φ

Pedestal V oltage

Settings

Acceleration Time

Deceleration Time

Motor Current

Diagnostics

Overcurrent before By-pass

Frequency out of T olerance

Undervoltage at control voltage

Start Duty

Maximum Number of Start s

per hour

4 ( 1 start every 15 minutes)

Starting Cycle

Digital Inputs

DI1 – Enable/Disable Function

(90...250V ac 6mA)

Relay

Outputs (1A 250V ac)

Operation Function (13 – 14/23)

Full Volt age Function (14/23 – 24)

Communication

Temperature

Ambient Humidity

Altitude

0 to 1000m (up to 13,200 ft (4000m) with

10% output current derating/1000m)

Degree of Protection

Polution Degree (UL508)

Mounting

Fastening

Enclosure

DIN 35mm rail or M4 fastening bolts

Electromagnetic Compatibility

S tandards

(EMC)

Low Volt age

(1)

Enable and Programmed only through serial communication or HMI-SSW05-RS.

SSW-05 Plus

200 mA

30 to 80% U

N

1 to 20 s

Off to 20 s

30 to 100% I

N

Motor Overload Protection

Incorrect Phase Sequence

Phase Loss

Immediate Overcurrent

Locked Rotor

Thyristor Overload

Immediate Overload at

By-pass Relay

Internal By-pass Relay

Contact is open

Immediate Undercurrent

3 x IN during 10 seconds

DI2 – Reset Function

Serial Interface (RS232C)

0 to 55°C (32to131°F)

5 to 90% Non Condensing

IP 00 (Chassis)

2

Molded plastic box

Class A (industrial use)

IEC 60947-4-2 Standard

UL 508 / IEC 60947-4-2

(1)

ENGLISH

English-5

Installation and Operation Manual - SSW-05 Plus

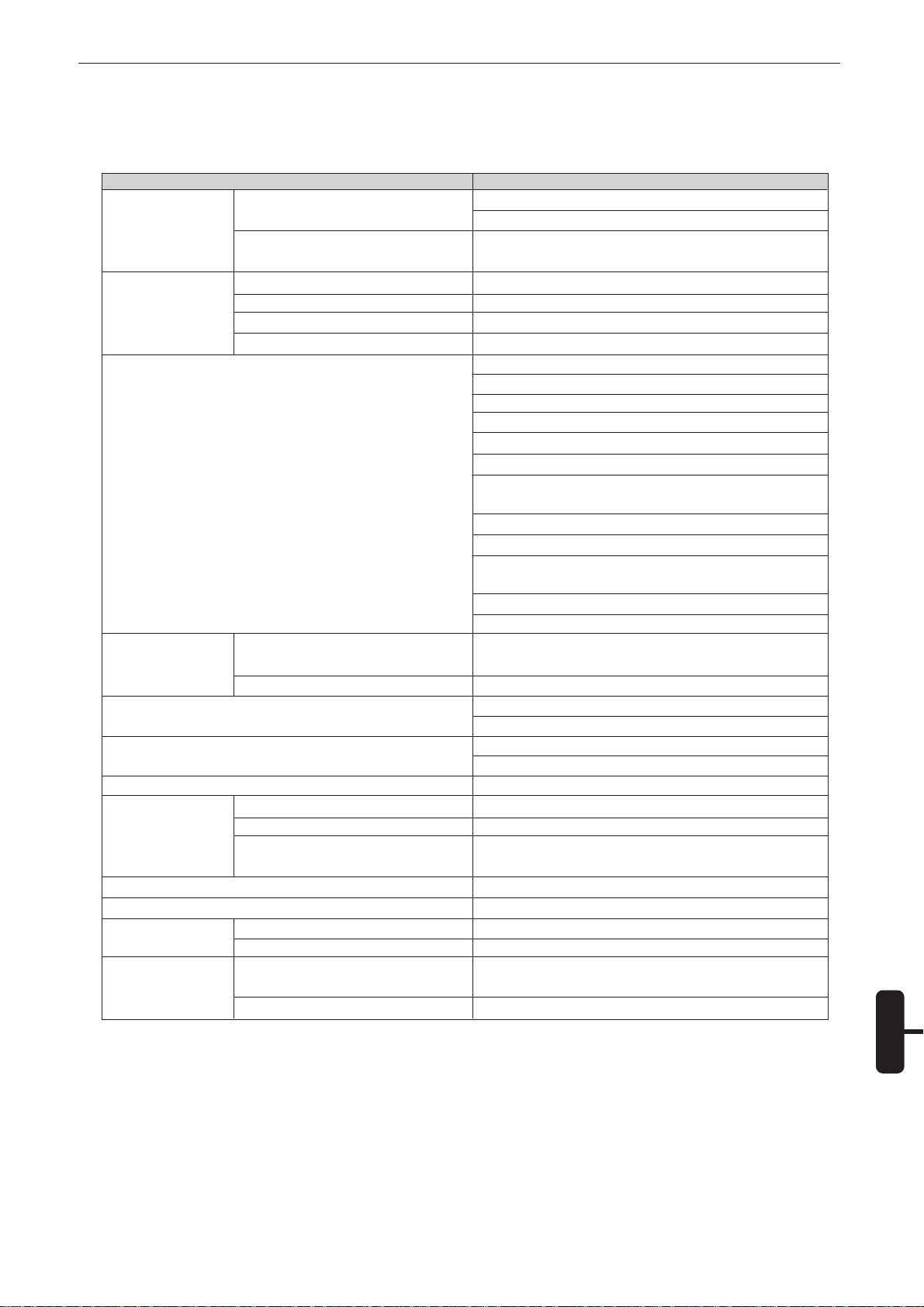

5. SSW-05 PLUS DESCRIPTION:

Dip-switch for

Protection

Enable

Three-phase Input Power Supply

Reset (DI2)

Motor Enable/Disable Command (DI1)

Electronics Power Supply (A1 and A2)

Reset Button

Setting

Trimpots

Figure 5.1 - SSW05 Plus Front view

SSW-05 Plus Status LEDS

Connector for Serial

Interface or HMI

Relay Output (13, 14/23 and 24)

Output to motor

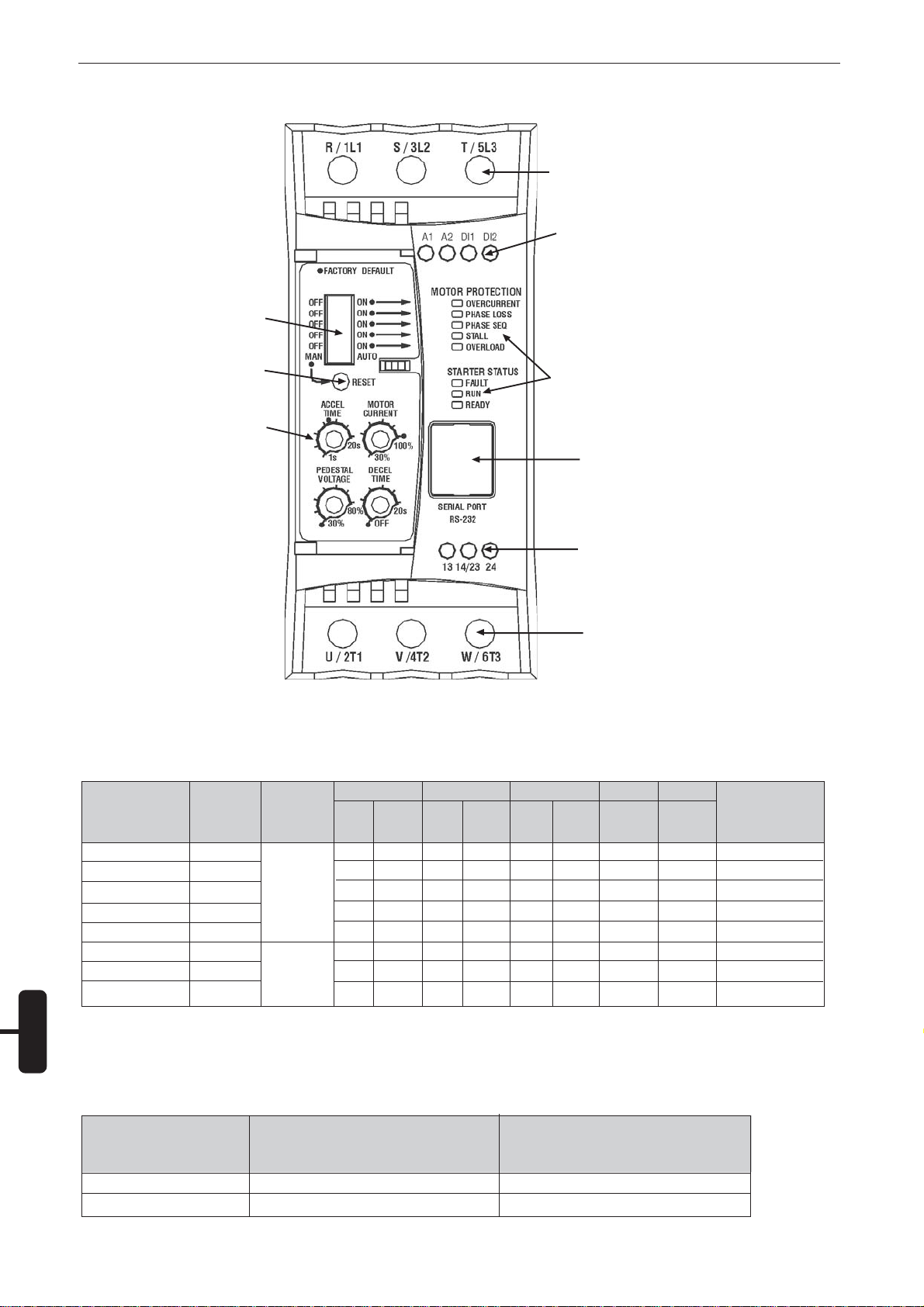

6. TABLE OF POWERS / CURRENTS / POWER WIRING (COPPER WIRE A T 70°C (158OF)):

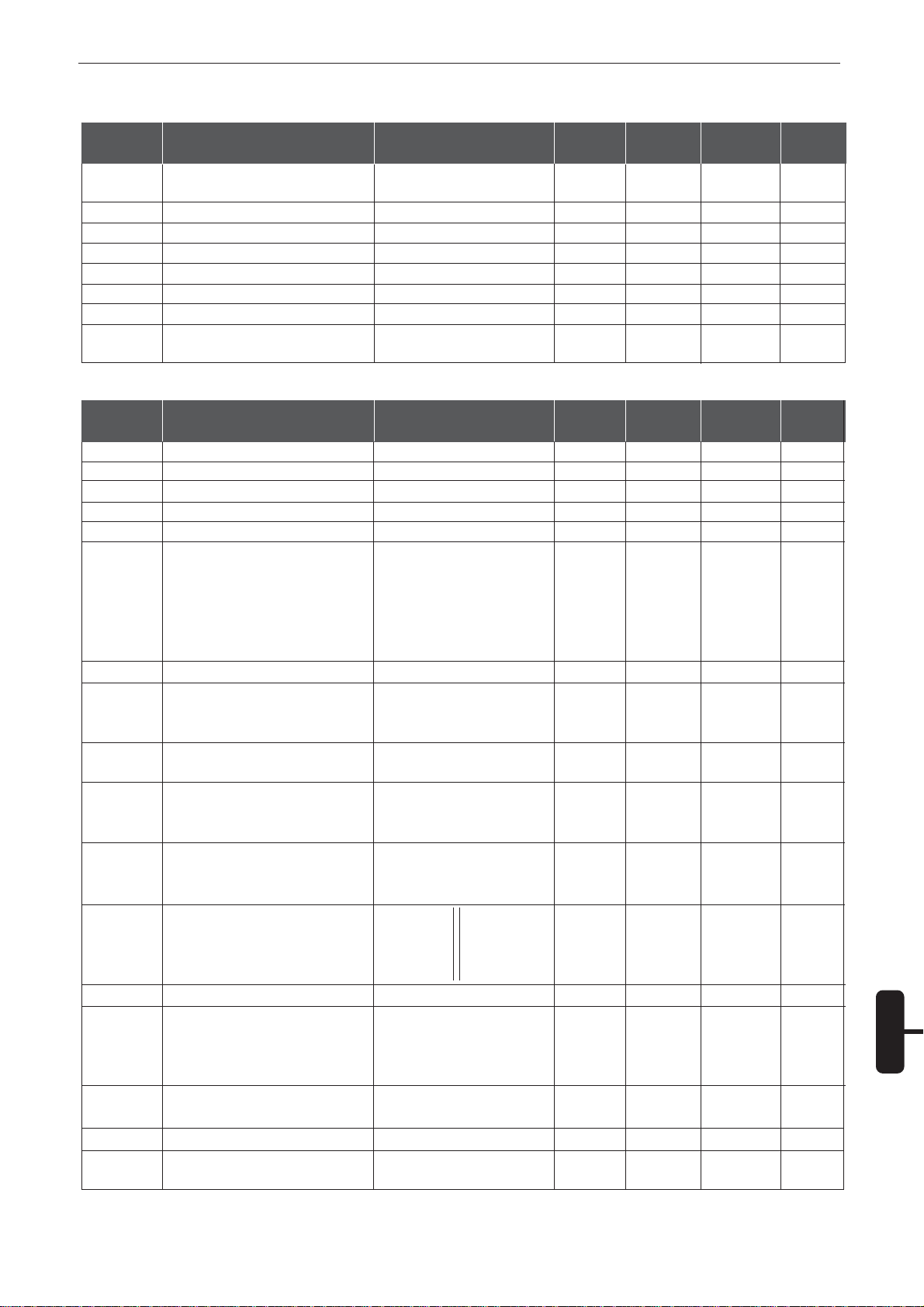

Model

Rated

Current

Size

220Vto240V*

HP kW

380Vto415V*

HP kW

440Vto480V*

HP kW

525V**

kW

575V*

HP

Power Wiring

mm2 (AWG)

SSW-05.3

SSW-05.10

SSW-05.16

SSW-05.23

SSW-05.30

SSW-05.45

SSW-05.60

SSW-05.85

3A

10A

16A

23A

30A

45A

60A

85A

1

2

0.75 0.55

3 2.2

5 3.7

7.5 5.5

10 7.5

15 1 1

20 15

30 22

* According to able 45.2, UL508.

** Valid for S tandard 4 pole WEG motors.

ENGLISH

7. TABLE OF CONNECTOR TORQUE SETTINGS:

SSW-05 Plus

Size

1

2

Torque of

Electronics Terminal

Nm (lb-in)

0.5 (4.5)

0.5 (4.5)

1.5 1.1

5 3.7

7.5 5.5

10 7.5

15 1 1

25 18.5

30 22

50 37

English-6

1.5 1.1

5 3.7

10 7.5

15 1 1

20 15

30 22

40 30

60 45

Torque-Power Terminals

(R, S, T, U, V and W)

1.5

5.5

11

15

18.5

30

45

55

Nm (lb-in)

3.0 (32.7)

5.5 (60.0)

2

7.5

10

20

25

40

50

75

0.75 (18)

1.5 (16)

4 (12)

6 (10)

10 (8)

16 (6)

25 (4)

35 (2)

Installation and Operation Manual - SSW-05 Plus

8. CAPACITY OF THE POWER SUPPLY LINE:

The SSW-05 Plus is suitable to be used in circuits that can not supply more than X A

to table below) symmetric Ampères, Y Volt s maximum:

SSW-05 Plus

Model

3A

10A

16A

23A

30A

45A

60A

85A

Y = 220- 575V

X (kA)

5

5

5

5

5

5

5

10

9. TABLE OF FUSES AND CONTACTORS (SEE ITEM 11):

SSW-05 Plus

Model

3A

10A

16A

23A

30A

45A

60A

85A

Contactor

(K1)

CWM09

CWM12

CWM18

CWM25

CWM32

CWM50

CWM65

CWM95

Fuse

(F1, F2,F3)

Type D 10A

Type D 16A

Type D 25A

Type D 35A

Type D 50A

Type D 63A

Type NH 100A

Type NH 125A

Fuse

(F11, F12, F21)

Type D 6A

(according

RMS

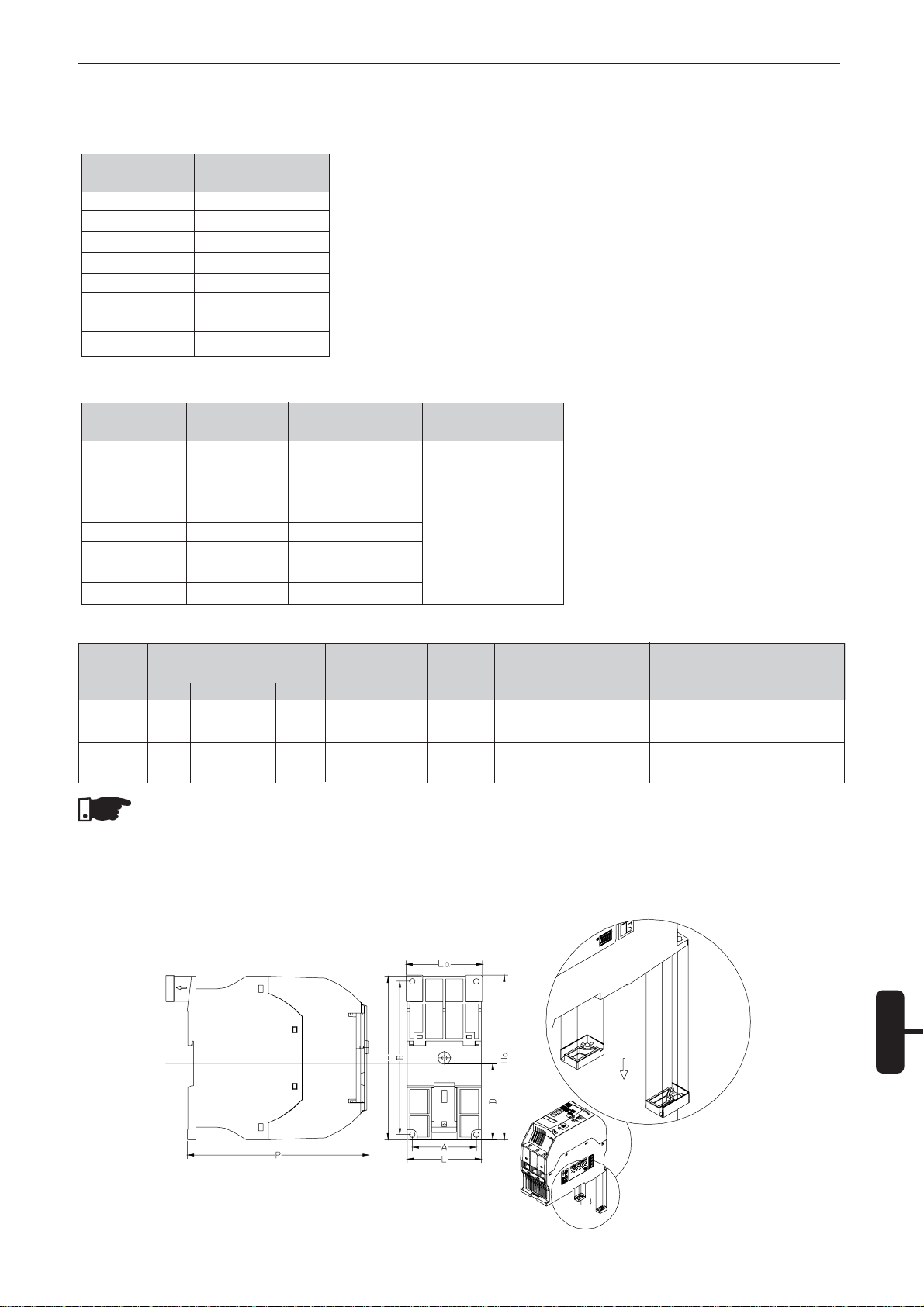

10. DIMENSIONS:

Size

1

2

Width

mm (in)

LLa

59 60.4

(2.32) (2.38)

79 80.4

(3.1 1) (3.17)

Notes

1) The SSW-05 Plus can be fixed on DIN 35mm rail. In this case is necessary to remove

the top fastening support, as shown in Figure below;

2) If the fastening is made through a M4 bolt, bolt tightening torque should not be higher

than 1 Nm (8.85 Ib in). The use of a top fastening support is required.

Height

mm (in)

HHa

130 130.7

(5.12) (5.15)

185 185.7

(7.28) (7.31)

Depth P

mm (in)

145 (5.70)

172 (6.77)

Fixing A

mm (in)

51 (2.00)

71 (2.79)

Fixing B

mm (in)

122 (4.80)

177 (6.17)

Fixing D

mm (in)

61 (2.40)

99 (3.89)

Fixing

M4 screw/ Rail

M4 screw/ Rail

Weight

kg (Lb)

0.74 (1.63)

1.67 (3.68)

ENGLISH

Figure 10.1 - SSW-05 Plus Dimensions

English-7

Installation and Operation Manual - SSW-05 Plus

1 1. SSW-05 PLUS INST ALLA TION AND CONNECTION:

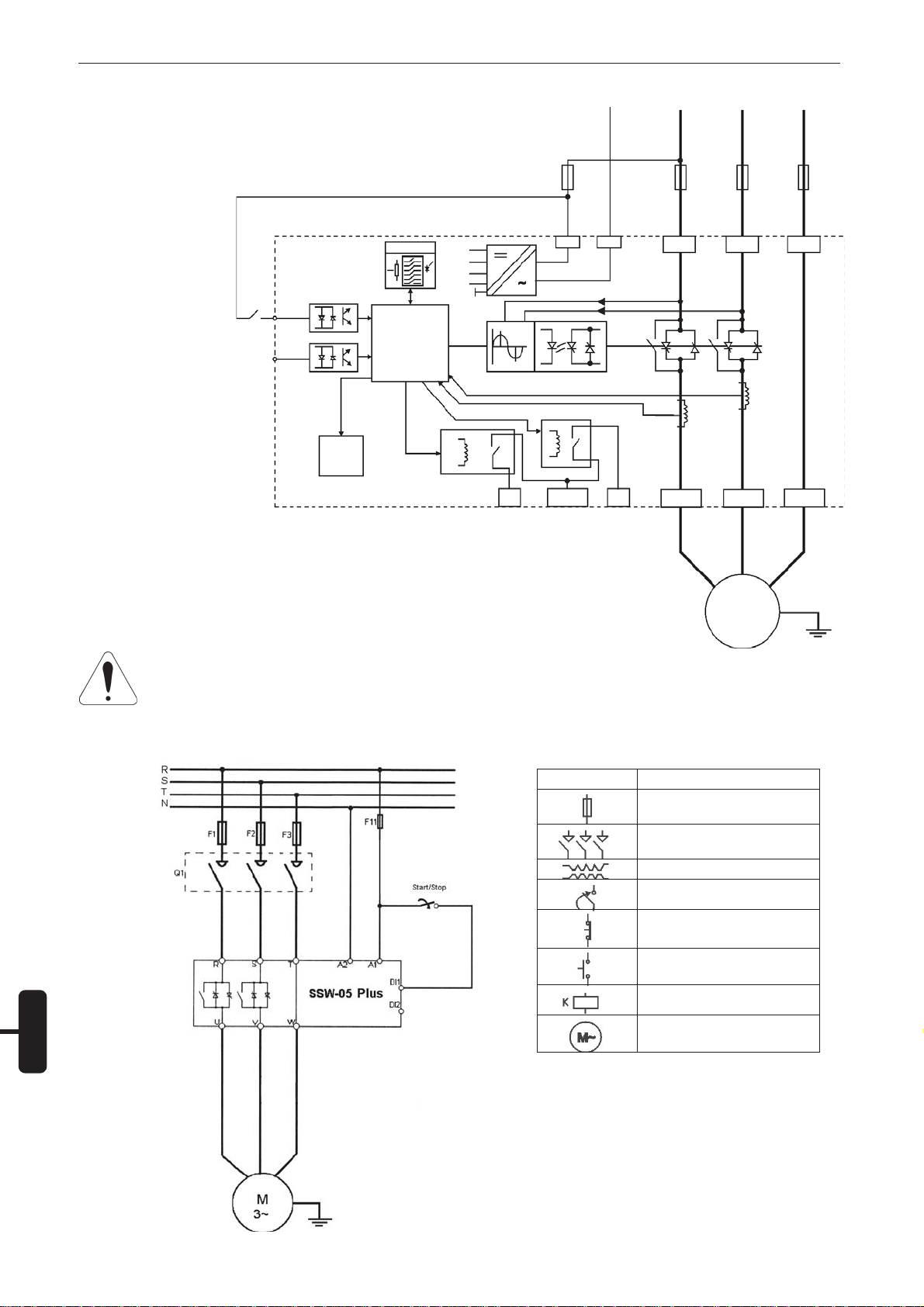

11.1. Blockdiagram SSW-05:

F11

P

3V3

P

5

P

12

N

12

13 14/23 24

Start

SSW-05

Plus

DI

1

DI

2

Serial

Commu-

nication

HMI

Digital

Signal

Processor

DSP

A1 A2

NRST

F1 F2 F3

R/1L1

S/3L2

T/5L3

CT

CT

U/2T1

V/4T2

W/6T3

Figure 1 1.1 - Blockdiagram SSW-05

Attention

When applying the power supply for the first time in the SSW-05, first connect the control

power supply and then the main power supply .

1 1.2. Simplified St art/S top on 230V/400V line:

230/400V

ENGLISH

Symbol

M

3~

Description

Fuse

Disconnecting Switch

(opens under load)

Transformer

N.O. switch (with holding)

N.C. push button

(with automatic return)

N.O. push button

(with automatic return)

Contactor (coil)

Three-phase induction

motor

Figure 1 1.2 - Simplified S tart/Stop on 230V/400 line

English-8

Installation and Operation Manual - SSW-05 Plus

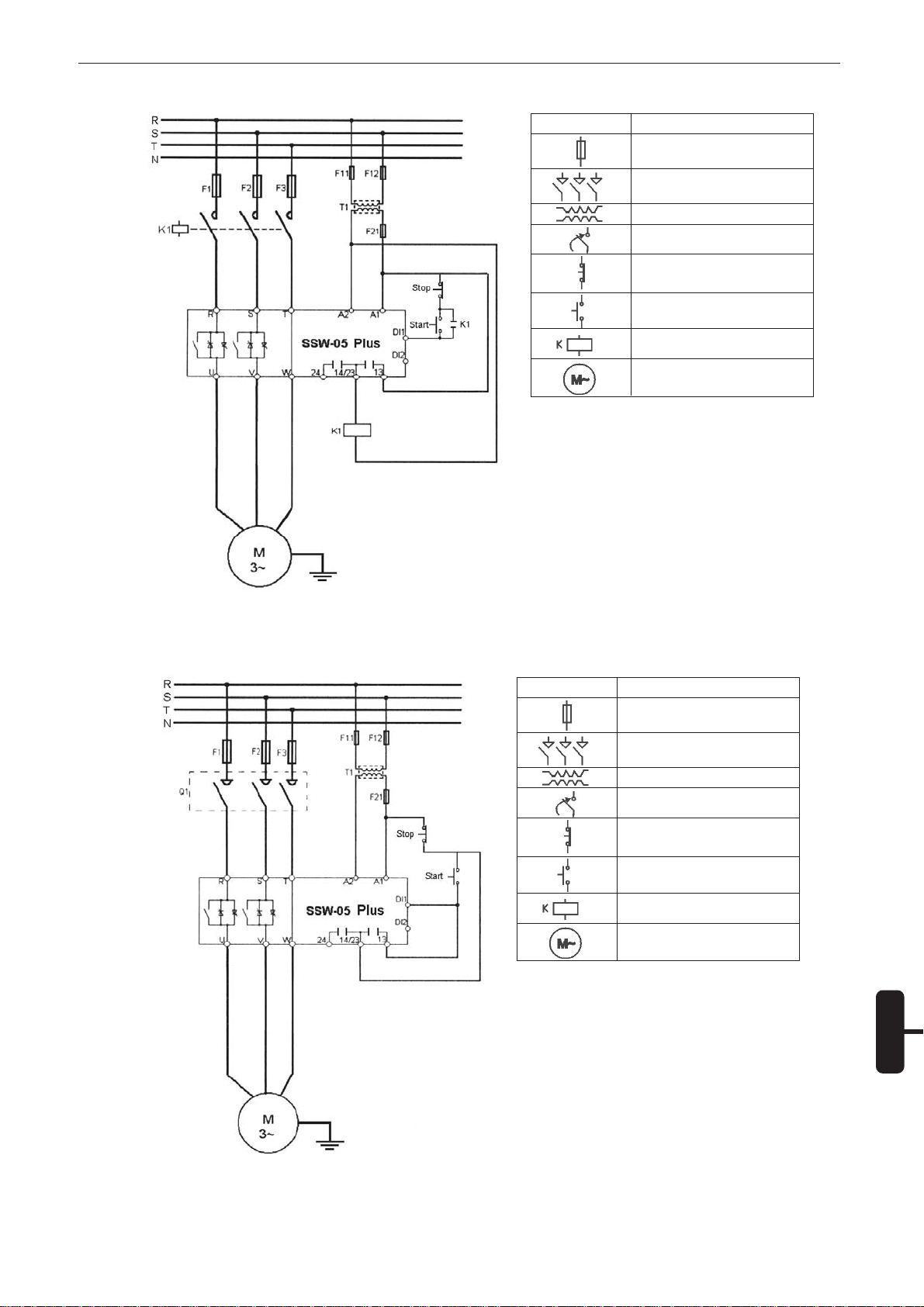

11.3. Starting and Stopping using Contactor and Push Buttons:

Symbol

The “T1” transformer is only required when

the line voltage is out of the range allowed

for the electronics supply (90 – 250Vac).

For 400V, use neutral conductor (N) and

one phase.

Figure 1 1.3 - St arting and Stopping using Cont actor and Push Buttons

Description

Fuse

Disconnecting Switch

(opens under load)

Transformer

N.O. switch (with holding)

N.C. push button

(with automatic return)

N.O. push button

(with automatic return)

Contactor (coil)

Three-phase induction

motor

11.4. S tart/S top by using Push Button and Operation Function Relay of the SSW-05 Plus:

Symbol

The “T1” transformer is only required when

the line voltage is out of the range allowed

for the electronics supply (90 – 250Vac).

For 400V , use neutral conductor (N) and one

phase.

Description

Fuse

Disconnecting Switch

(opens under load)

Transformer

N.O. switch (with holding)

N.C. push button

(with automatic return)

N.O. push button

(with automatic return)

Contactor (coil)

Three-phase induction

motor

ENGLISH

Figure 1 1.4 - Start/Stop by using Push Button and Operation Function

Relay of the SSW-05 Plus

English-9

Installation and Operation Manual - SSW-05 Plus

1 1.5. Motor Connection:

UV W U

CORRECT CORRECT

V

W

UV

INCORRECT INCORRECT

W

U

N

V

W

Attention

Only the motor frame shall be grounded.

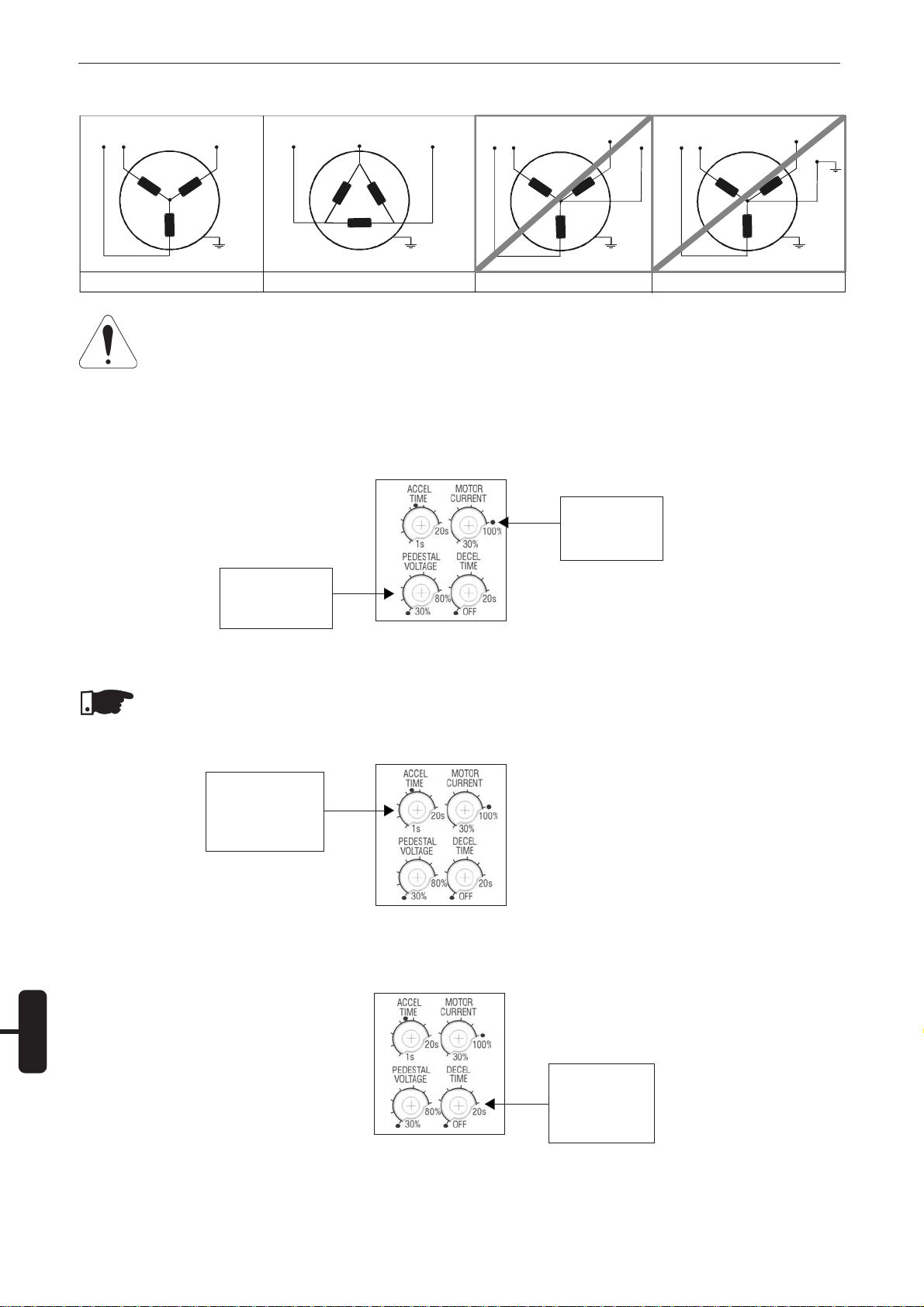

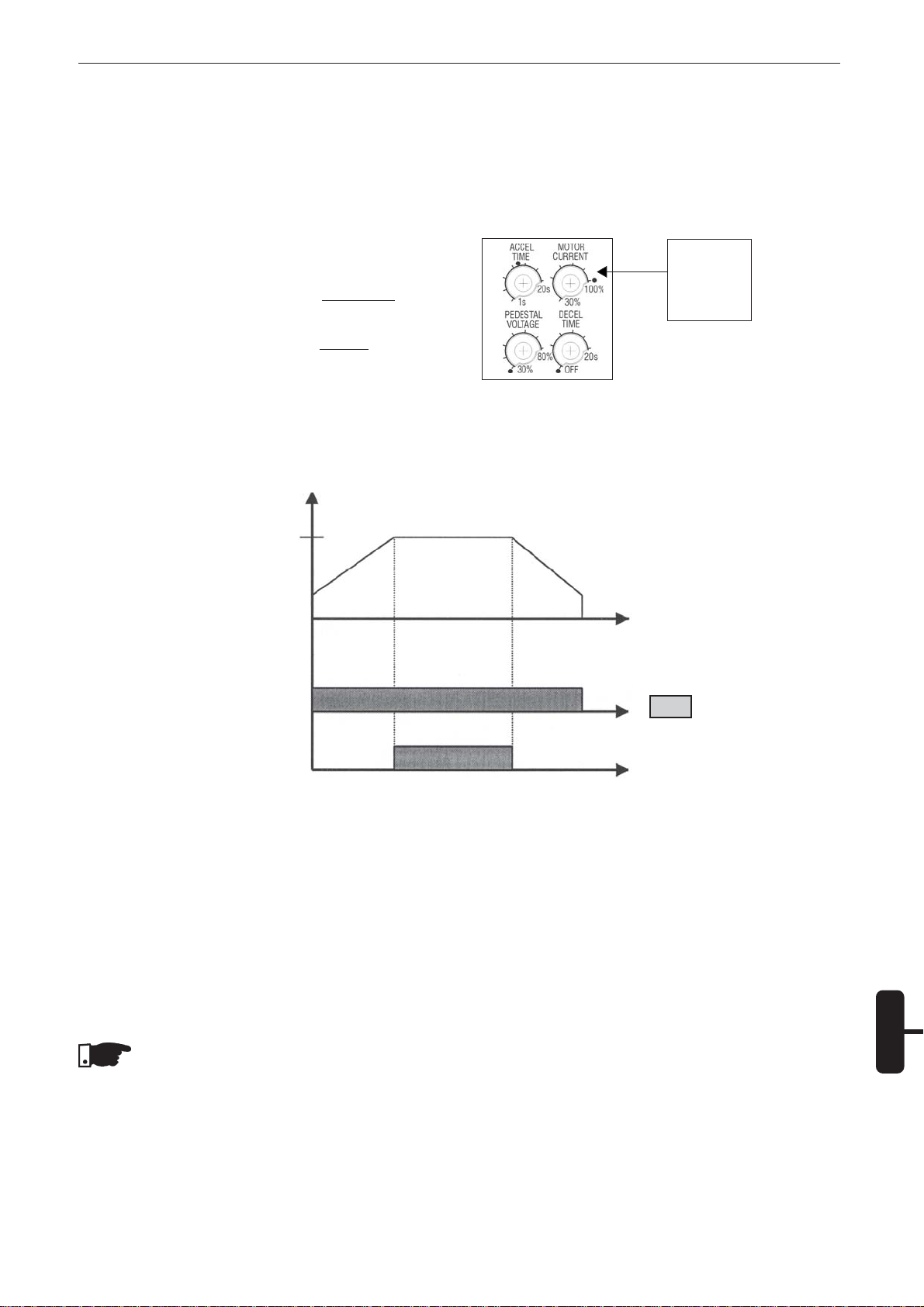

12. SSW-05 PLUS SETTING:

12.1. Pedestal Voltage Setting:

Set the pedestal voltage to a value that the motor starts to run as soon as run command is given by

the SSW-05 Plus.

The dot

indicates the

factory default

Trimpot for the

pedestal voltage

setting

12.2. Setting of the acceleration ramp time:

Set the value so that the motor accelerates to the rated speed.

Note:

Please consider that in the cases where rated SSW-05 Plus current is equal to the rated

motor current, the SSW-05 Plus can be operated, at maximum, during 10 seconds at 3 x

IN.

Trimpot for

the acceleration

Ramp time

setting

12.3. Setting of the deceleration ramp:

This setting should be used only for deceleration of pumps in order to reduce hydraulic shocks.

This setting must be made in order to obtain the best pump performance.

ENGLISH

Trimpot for the

deceleration

Ramp time

setting

English-10

Installation and Operation Manual - SSW-05 Plus

12.4. Setting of the Motor Current:

This setting defines the ratio of the SSW-05 Plus current and the driven motor current. The setting

of this value is very important, since it defines the protection of the motor driven by the SSW-05

Plus. The setting of this function has direct influence over the following motor protections: overcurrent,

overload, locked rotor, phase loss.

Calculation example:

Used SSW-05 Plus: 30A

Used Motor: 25A

I

SSW-05 Plus

25A

=

Motor

Setting of the Motor Current =

I

Setting of the Motor Current

30A

Trimpot for

the motor

current

setting

Setting of the Motor Current = 0.833

Thus it must be set at 83%.

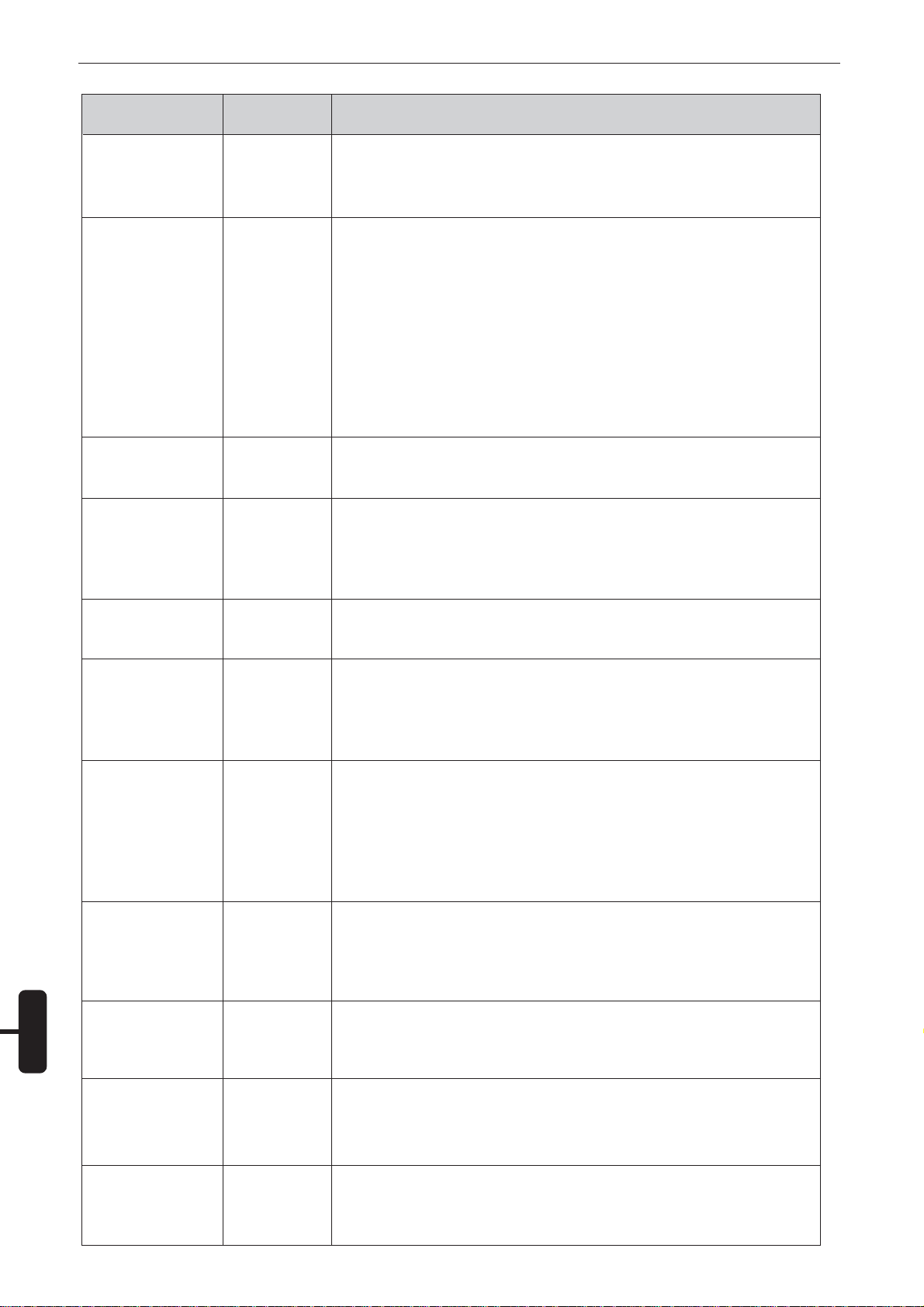

13. OPERATION OF THE DIGITAL RELAY OUTPUTS:

U

(Motor Volt age)

N

100%

t

Operation Function

(13-14/23)

t

Full V oltage Function

(14/23-24)

t

Figure 13 - Operation of the digital relay outputs.

Relay On

The relay of the Operation Function closes its N.O. contact (13-14/23) always when the SSW-05

Plus receives the enable command. This contact is open only at the end of the deceleration ramp

(when it is set via trimpot) or when the SSW-05 Plus receives the disable command.

The relay of the Full Voltage Function closes the N.O. cont act (14/23-24) always when the SSW05 Plus applies 100% voltage to the driven motor. This contact opens when the SSW-05 Plus

receives the disable command.

Note

Depending on the programming of P277 (programmable relay output), the relay output

(14/23-24) may assume other functions. For more details refer to Detailed Parameter

Description.

English-11

ENGLISH

Installation and Operation Manual - SSW-05 Plus

14. PROTECTIONS AND DISPLAYS:

Protection/Display Display

Description

LED

(overcurrent)

Overcurrent*

Phase Loss* LE D

(Phase Loss)

Monitoring is activated only when the SSW-05 Plus is in rated duty

(100% voltage). It trips, when the motor current exceeds 3 times the

value set with the trimpot (Motor Current) during a time longer than 1

second.

- At start: it act s when there is no voltage at the power supply terminals

(R/1L1, S/3L2 e T/5L3), or when motor is disconnected.

- In duty (full voltage – 100%). It acts after 1s after phase loss has been

detected both at the motor input and output. It acts when the current

that flows through the SSW-05 is lower than x% of current set at trimpot

Motor Current.

where:

x%= 20% for trimpot Motor Current or P105 between 50% - 100%

x%= 30% for trimpot Motor Current or P105 between 30% - 50%

It also acts when a current unbalance larger than 30% is detected

between the phases.

Activation

ENGLISH

Incorrect Phase LED

Sequence* (Phase Seq)

Locked Rotor* LED (Stall)

Motor overload LED

protection* (Overload)

Overcurrent of the LED

SSW-05 Plus (Internal Fault)

By-pass relay Flashes

5 times

LED

Overcurrent before Internal Fault)

By-pass Flashes

4 times

Thyristor LED

overload (Internal Fault)

Flashes

6 times

Frequency out LED

of T olerance (Internal Fault)

Flash Once

The error trips when in incorrect phase sequence

This protection trips during the transition between the end

of the acceleration ramp time and the contact closure of the internal bypass relays of the SSW-05 Plus, when the current flowing through the

SSW-05 Plus is higher than or equal to 2 times the current set with

trimpot (Motor Current).

This protection monitors constantly the motor current and compares it

with the value set by the trimpot (Motor Current).

See Item 15.

This protection monitors only when SSW-05 Plus is operating at full

voltage (100%). Is activated when the current is higher than the adjusted

value for more than 1 second. The activation level is 60A for the following

SSW-05 models: 3A to 30A. For the 45A to 85A models the activation

level is 200A. The internal fault LED flashes 5 times intermittently .

This protection trips during the transition between the end of the

acceleration ramp time and the contact making of the internal bypass

relays of the SSW-05 Plus, when the current flowing through the SSW05 Plus is higher or equal the rated level. The activation level is 37.5A for

the following SSW-05 models: 3A to 30A. For the 45A to 85A models

the activation level is 200A. The internal fault LED flashes 4 times

intermittently.

This protection monitors the current that flows through the SSW-05 Plus

during the acceleration and deceleration ramp time, and compares it

with the rated current of the SSW-05 Plus. Fig. 15.2 shows the trip time

curves when thyristors are overloaded. The internal fault LED flashes 6

times intermittently.

This protection trips when the line frequency is out of range (+/- 10%),

when compared with the rated frequency (50 Hz or 60Hz). The internal

fault LED flashes 1 time intermittently .

.

Internal By-pass LED

relay contact is (Internal Fault)

open Flashes

3 times

LED

Undercurrent (Internal Fault)

Flashes

8 times

This protection monitors, if the contact of the internal by-pass relay of

the SSW-05 Plus is closed ( it operates only when the SSW-05 Plus is

operated at full voltage (100%). The internal fault LED flashes 3 times

intermittently.

Monitoring occurs only when the SSW-05 Plus reaches steady-state (100%

of voltage). It acts when the current that flows throught the SSW-05 is

lower than P610% of current set at trimpot motor current, for a time period

longer than the value set in P61 1.

English-12

Installation and Operation Manual - SSW-05 Plus

Protection/Display

Description

Undervoltage in the LED

Control Supply (Internal Fault)

External Fault LED

Ready to operate (Ready)

In Operation LED

* These protections may be enabled/disabled through the respective dip-switches.

Display

Flashes 2 times

(Internal Fault)

Flashes 7 times

LED

(Run)

Activation

This protection monitors the control supply voltage of the electronics (A1

and A2) const antly and trip always when V ac volt age become lower than

80% of the rated voltage. The internal fault LED flashes 2 times intermittently .

It acts when the DI1Digital Input is open. The DI1 Digital Input must be

programmed to “External Fault” (P264=2). The internal fault LED flashes

intermittently 7 times.

- ON: SSW-05 Plus has been powered, and is waiting for the enable

command, or with full voltage at output.

- Flashing: SSW-05 Plus in acceleration/deceleration ramp time.

It is On only when SSW-05 Plus is operating (motor is operating with full

voltage).

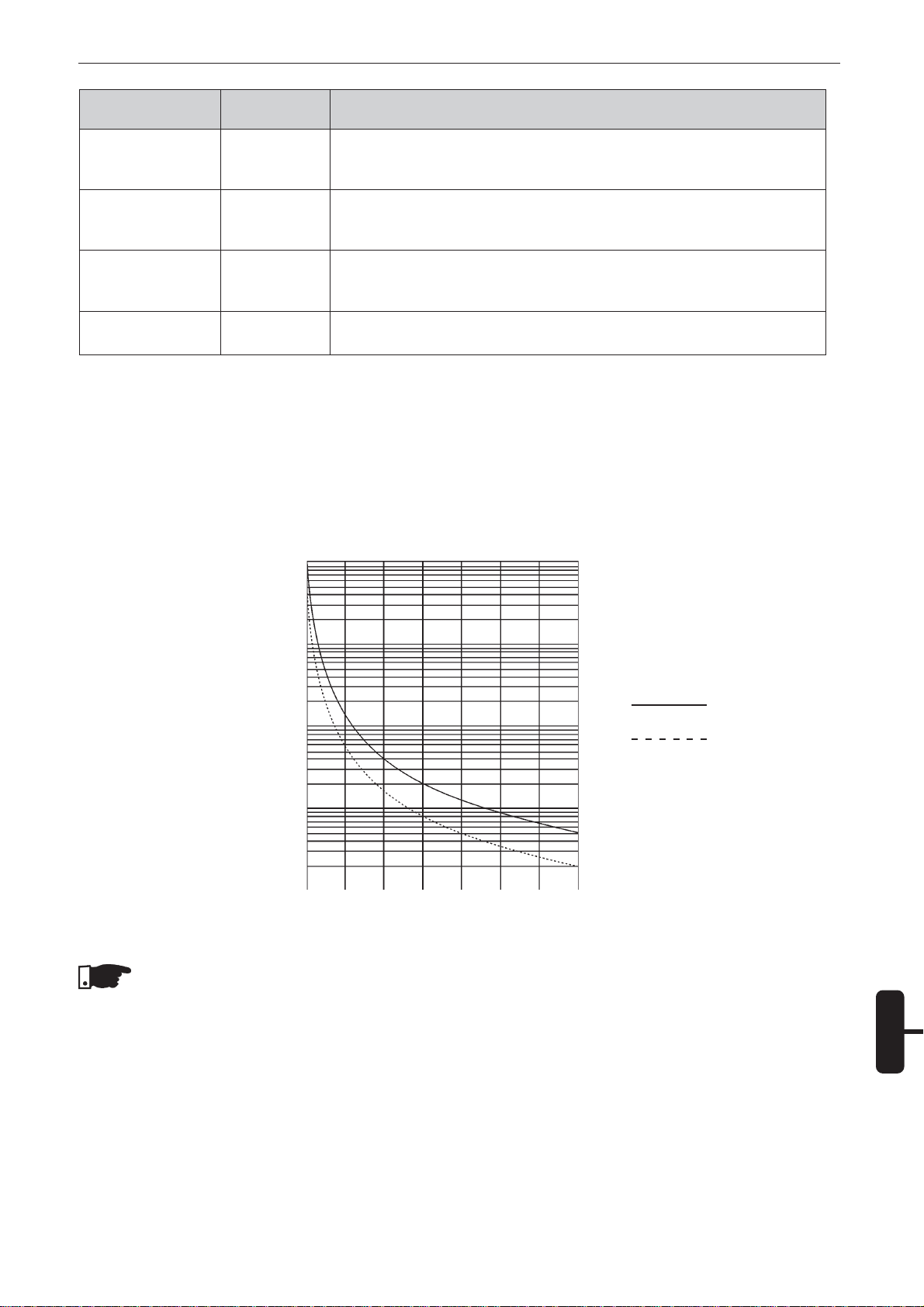

15. OVERLOAD PROTECTION:

15.1. Motor Electronic Overload Protection:

The motor overload electronic protection simulates the heating and cooling of the motor, also

known as thermal image.This heating simulation uses as input data the True RMS current. Fig.

15.1 shows the curve of the actuation time with motor under overload condition. The temperature

class of this function is, according to the IEC 947-4-2, Class 10.

t(s)

1 +

4

10

1 +

3

10

Cold Condition

100

10

1

100 200

Figure 15.1 - Curve of the motor electronic overload protection.

400 500 600 700 800

300

% Ief

Hot Condition

Notes

1) When SSW-05 Plus electronics (A1 and A2) is without power control supply voltage,

the thermal image is saved internally . When the power supply voltage is re-established

again (A1 and A2), the value of the thermal image returns to the value present before

the loss of the power control supply .

2) Always the reset is performed via Digital Input 2 (DI2) or by means of the reset button

(SSW-05 front), the value of the thermal image returns to the value saved previously in

the internal Soft-S tarter memory, i. e., the thermal image value of the last electronics

disable is returned;

ENGLISH

English-13

Installation and Operation Manual - SSW-05 Plus

3) The reset of the electronic overload protection can be set to manual function (man). In this case

the reset must be made via digital input 2 (DI2) or by means of the reset button. If the reset

setting has been set to automatic (auto), the error condition will be reset automatically after the

cooling of the equipment;

4) When the electronic overload protection is disabled via dip-switch, the thermal image is reset.

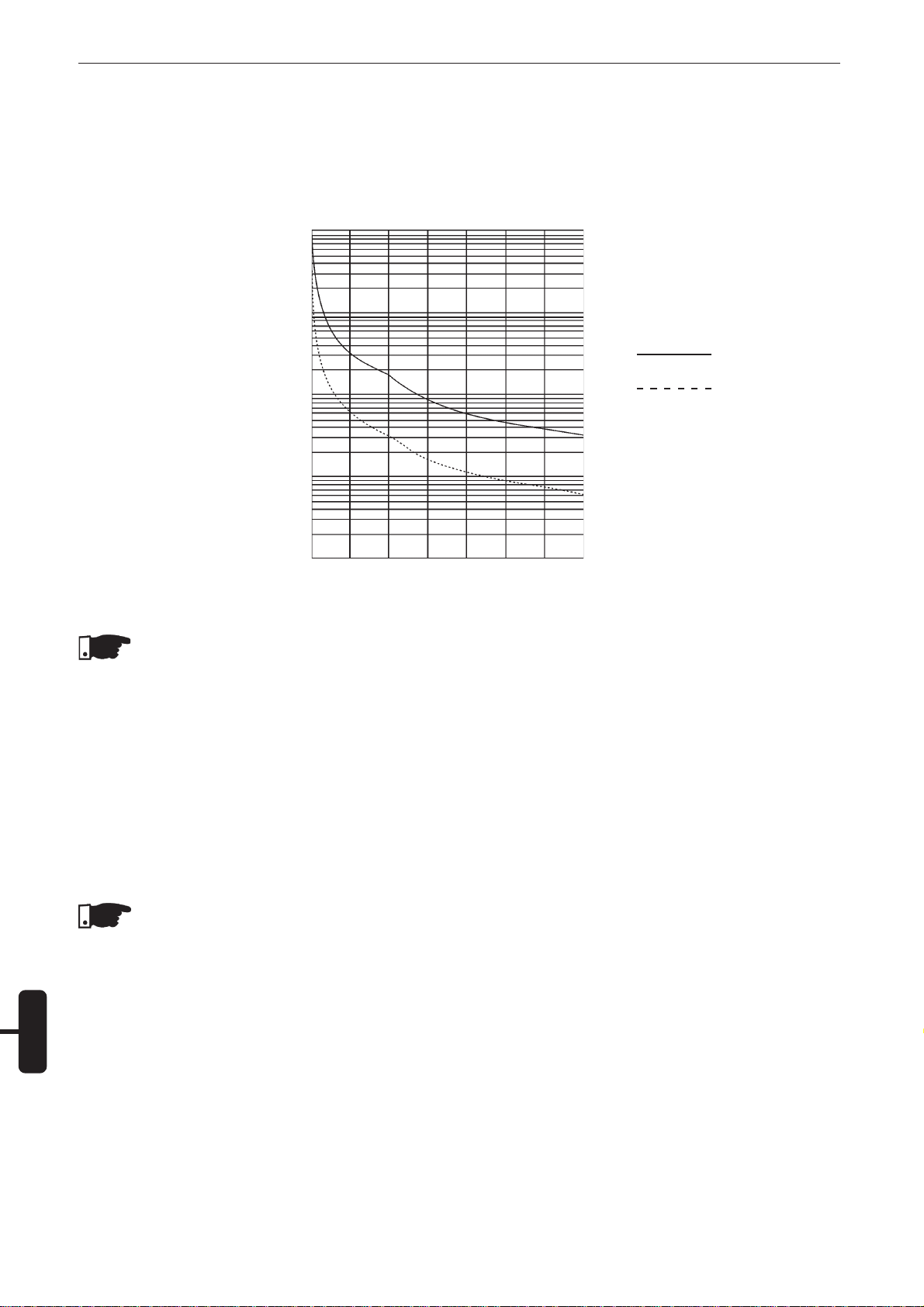

t(s)

1 +

3

10

100

Cold Condition

10

1

0.1

100 200 300 400 500 600 700 800

Figure 15.2 - Curve of the thyristor overload.

% In

Hot Condition

Notes

1)The thermal thyristor image is not saved in the internal Soft-S tarter memory . When the

SSW-05 is enabled/reinitialized, the value of the thermal thyristor image assumes zero;

2)When the motor is running in full voltage, the cooling of the thyristor overload Thermal

Image happens. This is because of the By-pass of the thyristors.

16. RESET:

The error condition can be reset through the reset button at the front of the SSW-05 Plus, or

through a momentary contact closure (0.5 seconds) at DI2 (digital input for reset). Other alternative

to reset the SSW-05 Plus is by switching On/Off the power control supply of the electronics (A1

and A2).

ENGLISH

Notes

The SSW-05 Plus also provides the automatic reset by enabling this function through the

dip-switch (auto):

1)The automatic reset occurs after 15 minutes in the following fault conditions:

- Overcurrent, Phase Loss, Locked Rotor , Immediate overcurrent of the SSW-05 Plus

by-pass relay , Overcurrent before By-pass, Frequency out of tolerance, Contact of the

internal By-pass relay is open, power control supply undervoltage and External Fault.

2)The automatic reset time may be changed at P206. For more details refer to Detailed

Parameter Description.

3)For incorrect phase sequence there is no automatic reset.

4)For motor overload and thyristor overload there is a specific algorithm for the automatic

reset time.

English-14

Installation and Operation Manual - SSW-05 Plus

Attention - Very Import ant

Both digital input (DI2) and reset button of the SSW-05 Plus should be used only for the

reset after a fault condition.

If the reset function is used when the SSW-05 Plus is operating at rated voltage, the

internal by-pass relays will open their contacts under load, thus jeopardizing their life.

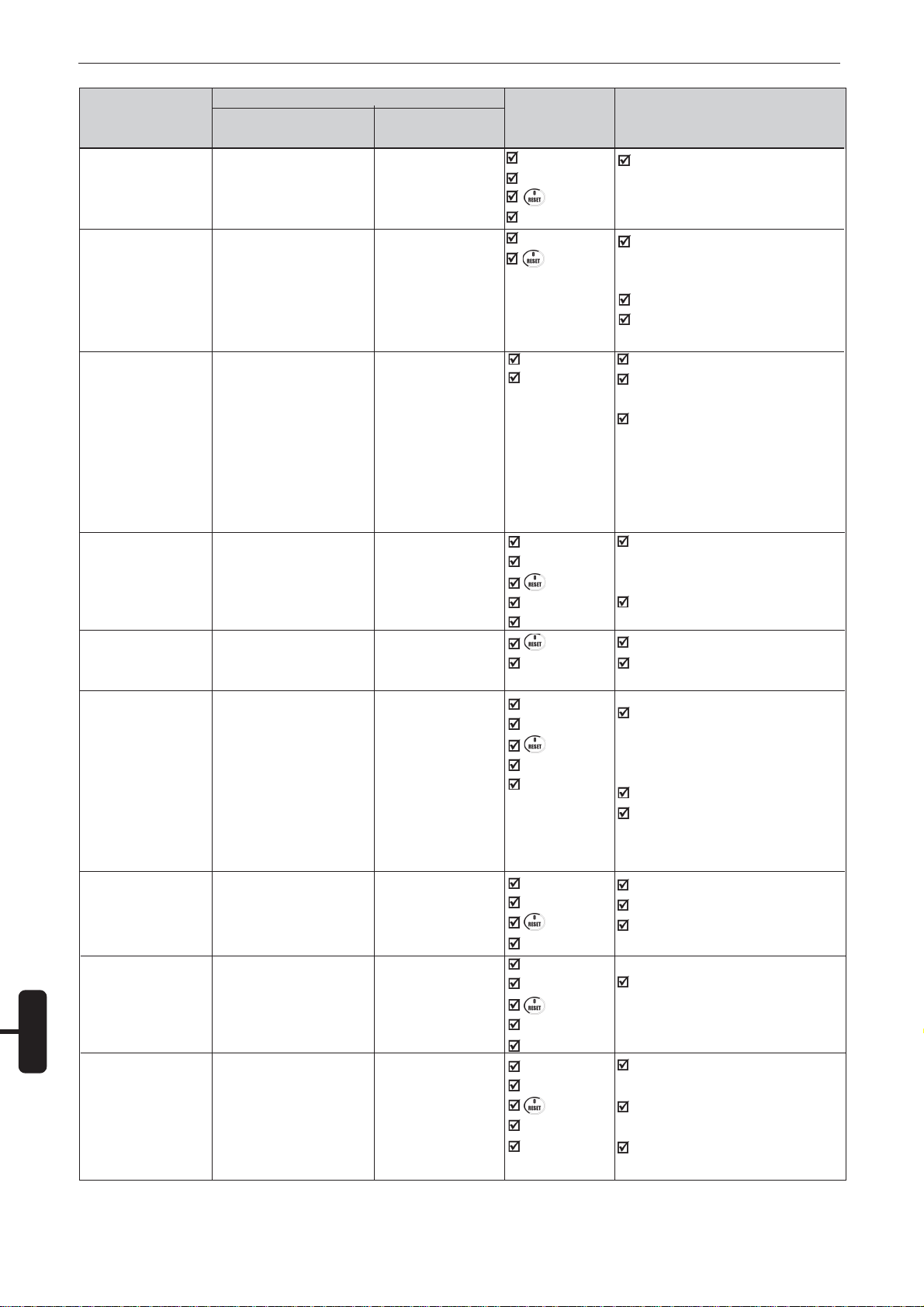

17. FAULTS AND POSSIBLE CAUSES:

When a fault is detected, the Soft-S tarter is disabled and the Fault Code is displayed by flashing

LED´s or on the readout display in the EXX form, where XX is the actual Fault Code.

T o rest art the Soft-Starter after a fault has occurred, the Sof t-Starter must be reset. In general, the

reset can be made as follows:

disconnecting and reapplying the AC power (power-on reset);

by pressing the key “RESET” on the SSW05-RS front panel (reset key);

through the HMI-SSW05-RS by pressing the key (manual reset);

automatic reset by enabling the function through the dip-switch (auto) or though P106 and P220.

via digital input: DI2.

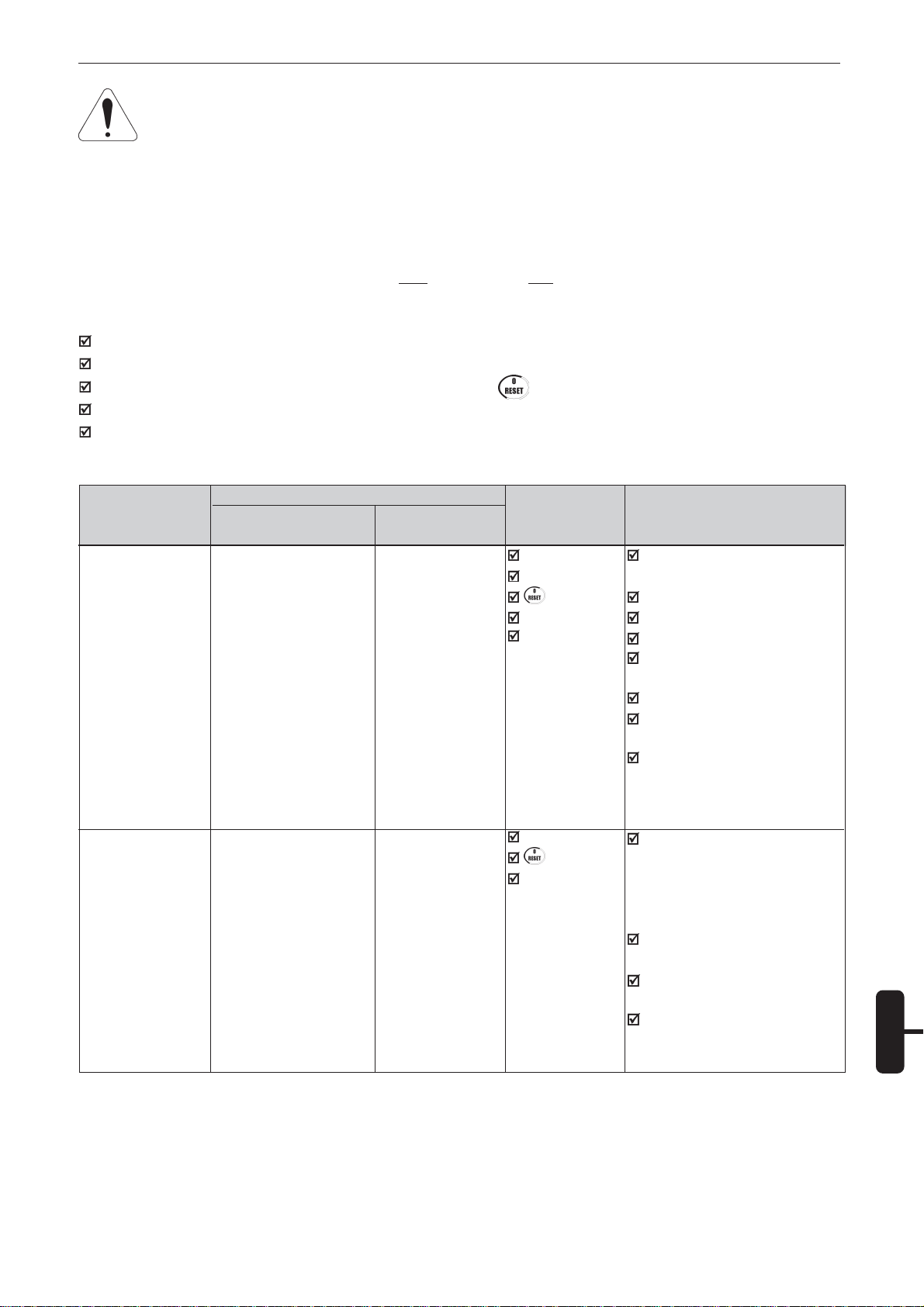

T able below explains how to reset the fault and show the possible causes for each Fault Code.

Protection

Description

Phase Loss

Motor Overload

Fault Display

SSW-05

Front Panel

LED

(Phase Loss)

LED

(Overload)

HMI-SSW05-RS

(see chapter 19.3)

E03

E05

Reset

Power-on

Reset key

key

Auto-reset

DI2.

Power-on

key

Auto-reset

Possibles Causes

Phase fault in the three-phase

network

Short-circuit or thyristor fault

Motor is not connected

Motor connection is not correct

Driving problems with the input

contactor.

Input fuses are blown.

Incorrect programming of the

Motor Current Trimpot or P105.

Motor current consumption

lower than required for

actuation of the phase loss

protection.

“Motor Current” trimpot or

P105 (motor current) has

been set incorrectly . The set

value is too low for the motor

being used.

Load on the motor shaft too

high.

Too much successive motor

starts.

The value of the thermal

protection saved when

switching

ENGLISH

English-15

Installation and Operation Manual - SSW-05 Plus

Protection

Description

External Fault

Error in the Copy

Function

Keypad HMI

Connection Fault

Locked Rotor

Thyristor overload

Undercurrent

Fault Display

SSW-05

Front Panel

LED

(Internal Fault)

flashes 7 times

Available only when

HMI-SSW05-RS is

used

(see chapter 19)

Available only when

HMI-SSW05-RS is

used

(see chapter 19)

LED

(Stall)

LED

(Internal Fault)

flashes 6 times

LED

(Internal Fault)

flashes 8 times

HMI-SSW05-RS

(see chapter 19.3)

E06

E10

E31

E63

E64

E65

Reset

Power-on

Reset key

key

DI2.

Power-on

key

Power-on

This fault

disappears

automa-tically

when HMI

reestablishes

the communication with the

Soft-St arter.

Power-on

Reset key

key

Auto-reset

DI2.

key

Auto-reset

Power-on

Reset button

key

Auto-reset

DI2.

Possibles Causes

off return when switching on

again.

The wiring at DI1 is open (not

connected).

Attempt for copying HMI

Parameters to the Soft-S tarters

with different software versions.

Keypad cable misconnected.

Electrical noise in the installation

(electromagnetic interference).

Keypad cable misconnected.

Electrical noise in the installation

(electromagnetic interference).

Reset is executed through DI2

or reset button.

The time programmed for the

acceleration ramp is shorter than

the actual acceleration time.

Motor shaft is locked.

Load on the motor shaft too high.

Too much successive starts.

Current value programmed in

P610 may be much higher than

the minimum motor operation

current.

Motor at no load.

In applications with hydraulic

pumps, the pump may be

operating at no load.

Overcurrent

Incorrect phase

ENGLISH

Undervoltage in the

Control Supply

sequence

LED

(Overcurrent)

LED

(Phase Seq)

LED

(Internal Fault)

flashes 2 times

E66

E67

E70

English-16

Power-on

Reset key

key

DI2.

Power-on

Reset key

key

Auto-reset

DI2.

Power-on

Reset key

key

Auto-reset

DI2.

Short-circuit between phases.

Momentary motor overload.

Motor shaft is locked.

Network phase sequence

inverted at the input.

Electronics supply lower than the

required one.

Electronic power supply with bad

contact.

Fuse of the electronics power

supply is blown.

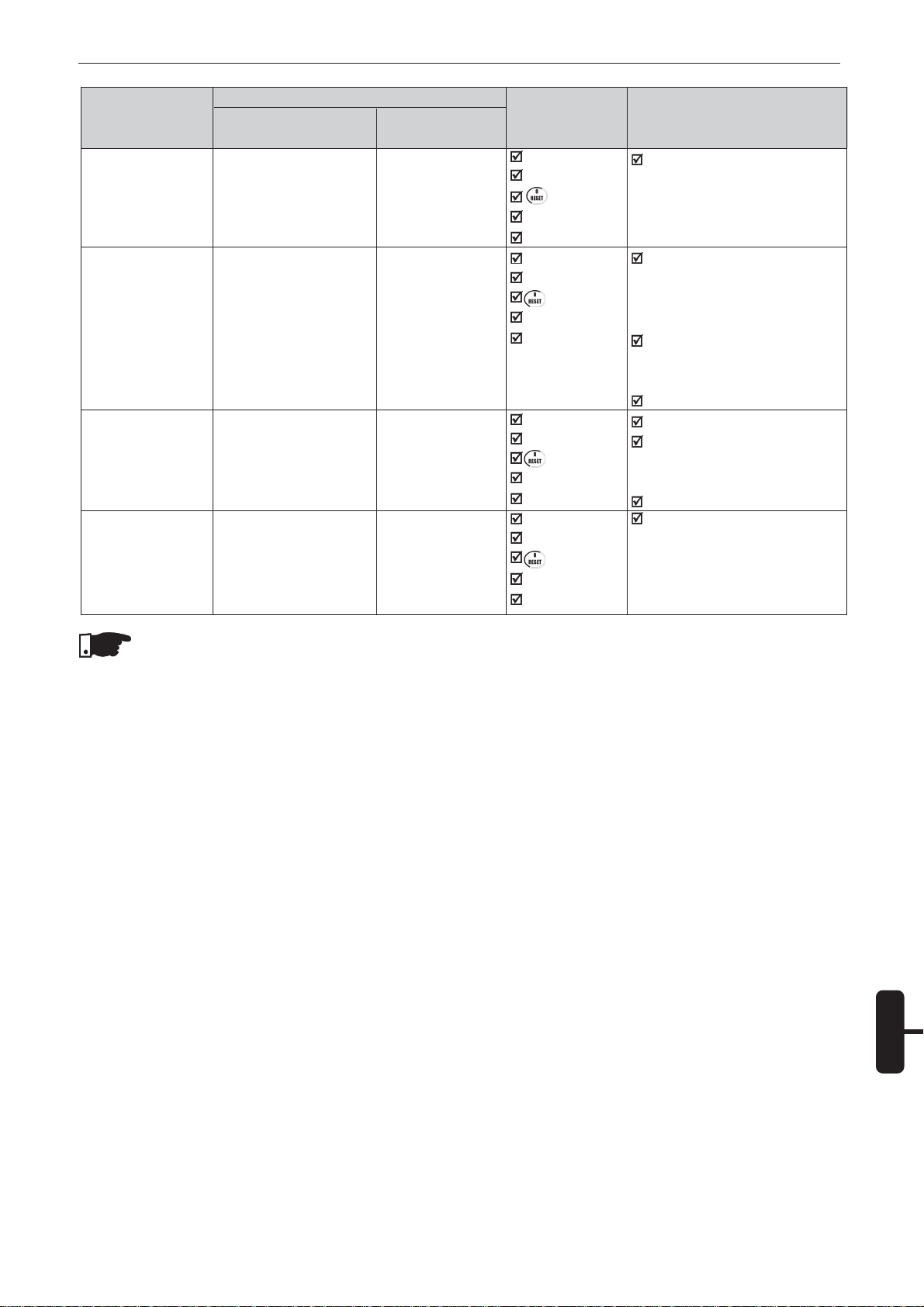

Installation and Operation Manual - SSW-05 Plus

Protection

Description

Internal

By-pass relay

contact is open

Overcurrent before

By-pass

Overcurrent of the

SSW-05 By-pass

relay

Frequency out of

tolerance

Fault Display

SSW-05

Front Panel

LED

(Internal Fault)

flashes 3 times

LED

(Internal Fault)

flashes 4 times

LED

(Internal Fault)

flashes 5 times

LED

(Internal Fault)

flashes 1 time

HMI-SSW05-RS

(see chapter 19.3)

E71

E72

E73

E75

Reset

Power-on

Reset key

key

Auto-reset

DI2.

Power-on

Reset key

key

Auto-reset

DI2.

Power-on

Reset key

key

Auto-reset

DI2.

Power-on

Reset key

key

Auto-reset

DI2.

Possibles Causes

SSW-05 is defective.

The time programmed for the

acceleration ramp is shorter

than the actual acceleration

time.

Rated motor current higher

than the current that can be

supported by the Soft-St arter.

Motor shaft is locked

Short-circuit between phases.

Rated motor current higher

than the current that can be

supported by the Soft-St arter.

Motor shaft is locked.

The line frequency is out of range (+/- 10%), when compared

with the rated frequency (50Hz

or 60Hz).

Note

T o prevent the E31 fault, when HMI-SSW05-RS is applied, please no avoid resetting the

fault through the digital inputs (DI2) and through the reset key located on the SSW-05 front

panel.

ENGLISH

English-17

Installation and Operation Manual - SSW-05 Plus

18. SOLVING THE MOST FREQUENT PROBLEMS:

Problem

Motor does not

runs

Motor speed

oscillates

Points to be checked

Wrong wiring

Power Supply Loss

Setting

Fault

Loose connections

1. Check all power and control connections

1. Check the power supply (R, S, T)

2. Check the power control supply (A1, A2)

1. Check if the settings are correct for the application.

1. Check if the SSW-05 Plus is not in locking condition

(refer to item 14 – Protections and Display).

1. Switch Off the SSW-05 Plus, switch off the power supply and

tighten all connections.

2. Check all internal SSW-05 Plus connections.

Corrective Actions

Motor speed

too high or too low

Shocks during pump

deceleration

Shocks during pump

acceleration

Motor Nameplate Data

Soft-St arter Setting

Soft-St arter Setting

1. Check if the motor has been selected according to the

application.

1. Reduce the time of the deceleration ramp time.

1. Reduce the time of the acceleration ramp time.

2. Reduce the setting of the pedestal voltage.

19. SSW-05 OPTIONS AND ACCESSORIES:

This chapter describes the optional devices that can be used with the SSW-05. The table below

shows a list of existing optional devices.

Name

CAB-RS-1

CAB-RS-2

CAB-RS-3

MIW-02

HMI-SSW05-RS

T able 19.1 - Available optional devices for the SSW-05.

Cable for the remote serial keypad - cable: 1m (3.28ft)

Cable for the remote serial keypad - cable: 2m (6.56ft)

Cable for the remote serial keypad - cable: 3m (9.84ft)

RS-232 to RS-485 conversion module

External serial Keypad HMI. For remote use with the

CAB-RS cable (up to 3m (9.84ft)). Keypad Copy Function.

Function

WEG Item

Number

0307.7827

0307.7828

0307.7829

417100543

417100996

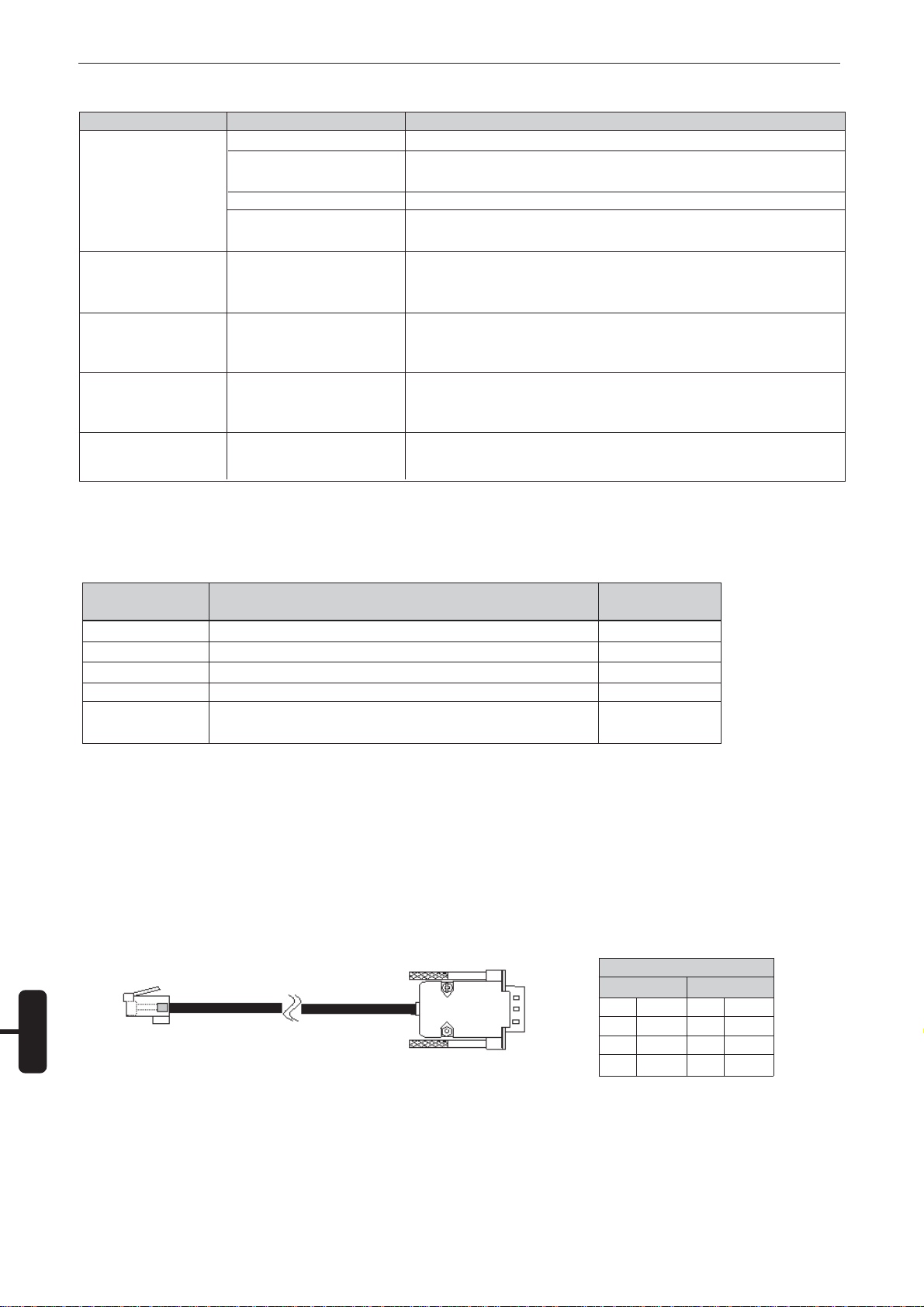

19.1. CAB-RS-1, CAB-RS-2, CAB-RS-3:

Cables used to connect the Soft-S tarter to the external serial interface keypad (HMI-SSW05-RS).

There are 3 cables options ranging in lenghts from 1m (3.28ft) to 3m (9.84ft). The user must select

among these lengths according to his requirement. Y ou must plan carefully the wiring location by

separating it at least 10cm (3.9in) from the power wiring.

ENGLISH

HMI

Soft-Starter

RJ Connector

DB9 Connector

Figure 19.1 - Cable CAB-RS for HMI-SSW05-RS.

CABLE CONECTIONS

DB9 PINS

1 Vdc

2RX

3TX

5 GND

RJ PINS

1 Vdc

6TX

4RX

5 GND

English-18

Installation and Operation Manual - SSW-05 Plus

19.2. MIW-02:

External module for conversion from RS-232 to RS-485: it allows the connection of the SSW-05 to

a standard RS-485 line. So the Soft-S tarter can participate in a multipoint line up to 1000m (3280ft)

without the use of transducers.

For more details about this connection, see the MIW-02 USER MANUAL, available for download

on the website www.weg.com.br .

Weg Network

RS-485

RS-232

SSW-05 RJ Connector

Serial Port RS-232

RS-485

MIW-02

Figure 19.2 - Connection of the SSW-05 to a standard RS-485 communication network.

19.3. HMI-SSW05-RS:

Remote serial keypad: this interface is mounted external to the Soft-S tarter and can be used in the

following cases:

applications that require a remote keypad;

installation on panel door;

when the keypad copy function is required for the transfer of parameter values from one SoftStarter to another .

It operates with the cable CAB-RS-X, which length must be chosen according to the needs (up to

9.84ft).

Figure 19.3 - Dimensions of the HMI-SSW05-RS.

English-19

ENGLISH

Installation and Operation Manual - SSW-05 Plus

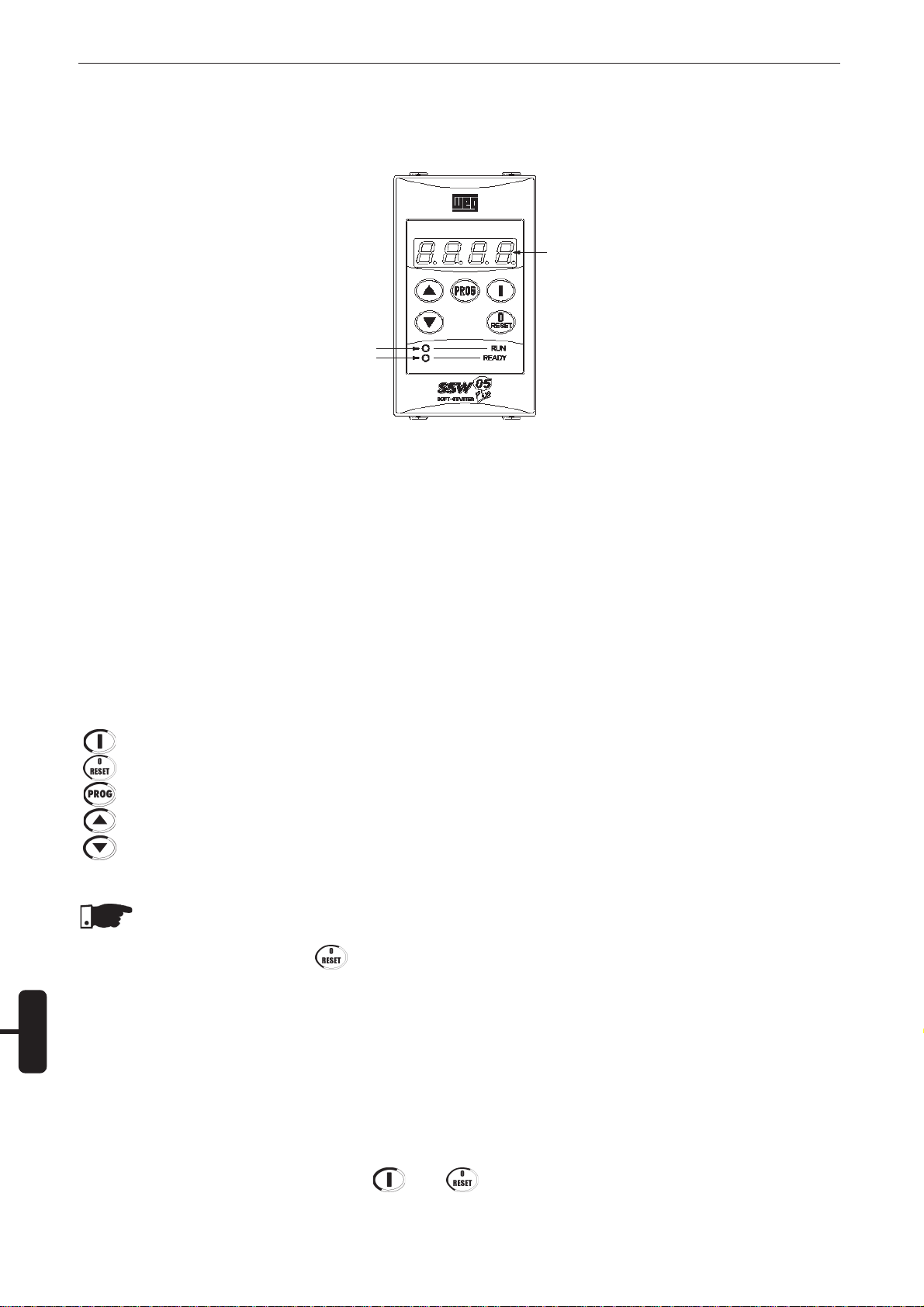

19.3.1. HMI-SSW05-RS Description:

The HMI-SSW05-RS has a LED display with 4 digits of 7 segments, 2 status LEDs and 5 keys.

The figure below shows the front view of the keypad.

LED

Display

Led “Run”

Led “Ready”

Figure 19.4 - Front view of the HMI-SSW05-RS.

Functions of the LED Display:

The LED display shows the parameter number and its value. It also shows the fault codes and

status.

Functions of the “ready” and “run” LEDs:

Ready:On - SSW-05 Plus has been powered, and is waiting for the enable command, or with full

voltage at output.

Flashing - SSW-05 in acceleration or deceleration ramp time.

Run: It is On only when SSW-05 is operating (motor is operating with full voltage).

Basic Functions of the Keys:

- Enable the Soft-St arter (Start);

- Disable the Soft-S tarter (Stop). Also resets the Sof t-Starter after a fault has occurred;

- T oggles the LED display between parameter number and it s value (number/value);

- Increases the parameter number or the parameter value.

- Decreases the parameter number or the parameter value.

Note

In the occurrence of errors when using an HMI-SSW05-RS, the reset of errors must be

done through the key . Reset through the key present in the frontal of the Soft-St arter

causes loss of communication of the HMI, resulting in E31. To re-establish the

communication between the HMI and the Soft-Starter it is necessary to detach and to

reconnect the serial cable, or else to power down and to power up the Soft-St arter again.

ENGLISH

19.3.2. Use of the keypad:

The keypad is used for programming and operating the SSW-05, allowing the following functions:

- indication of the Soft-St arter status and operation variables;

- fault indication and diagnostics;

- viewing and programming parameters;

- operation of the Soft-S tarter (Keys and ).

English-20

Installation and Operation Manual - SSW-05 Plus

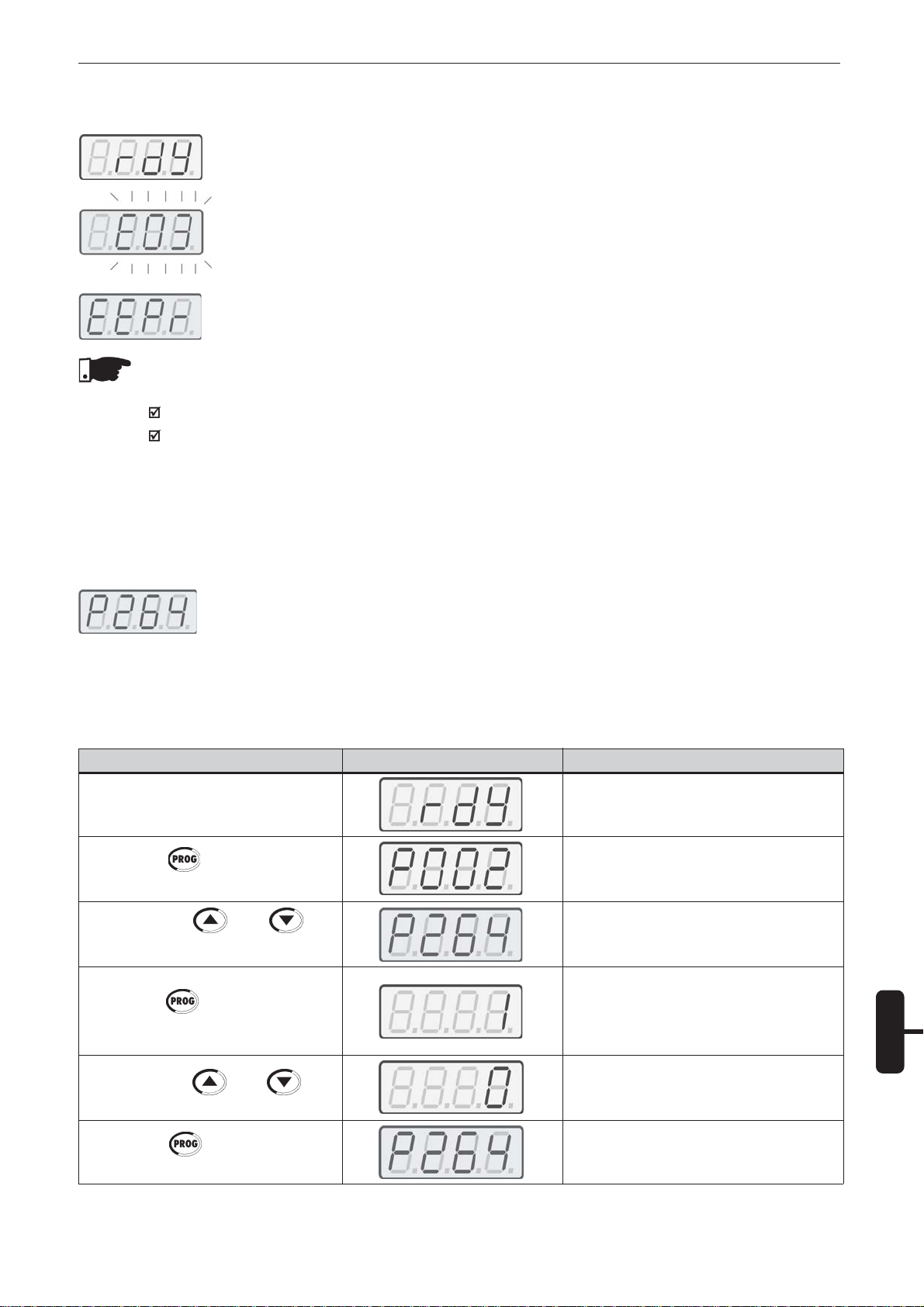

19.3.3. Signaling/Indications on the HMI-SSW05-RS Display:

Soft-S tarter Status:

Soft-S tarter is ready to be started.

Soft-Starter is in fault condition. The code is flashing. In our example, the fault

message is E03 (Phase Loss).

Soft-St arter is executing the function “Load factory setting (P204)”

Note

The display also flashes, besides the fault condition, in the following condition:

Attempt to change parameter with incorrect password (P000 – Access Parameter);

Attempt to change not permitted parameter . Example: Parameters that cannot be

changed with running motor.

19.3.4. Parameter Viewing and Programming:

All SSW-05 settings can be made through parameters. The parameter are shown on the display

by the letter P followed by a number:

Example (P264):

264 = parameter number

Each parameter is associated with a numerical value (parameter value), that corresponds to the

selected option among the available ones for this parameter .

The parameter values define the Soft-S tarter programming or the value of a variable (e.g.: current,

voltage). For Soft-S tarter programming you should change the parameter content(s).

ACTION HMI DISPLA Y DESCRIPTION

Turn ON the Soft-S tarter

Press the key

Use the keys and

to reach P264

Soft-Starter is ready to be operated

Select the desired parameter

Press the Key

Use the keys and

Press the Key

English-21

Numerical value associated with the

parameter

Set the new desired value

(1) (2)

(2)

(2)

ENGLISH

Installation and Operation Manual - SSW-05 Plus

Note

(1)By pressing the key after the reprogramming, the new programmed value will be

stored automatically and will remain stored until a new value is programmed.

(2) To allow the reprogramming of any parameter (except for P000) it is required to set

P000 = 5. Otherwise you can only read the parameter values, but not reprogram them.

For more details, see P000 detailed description.

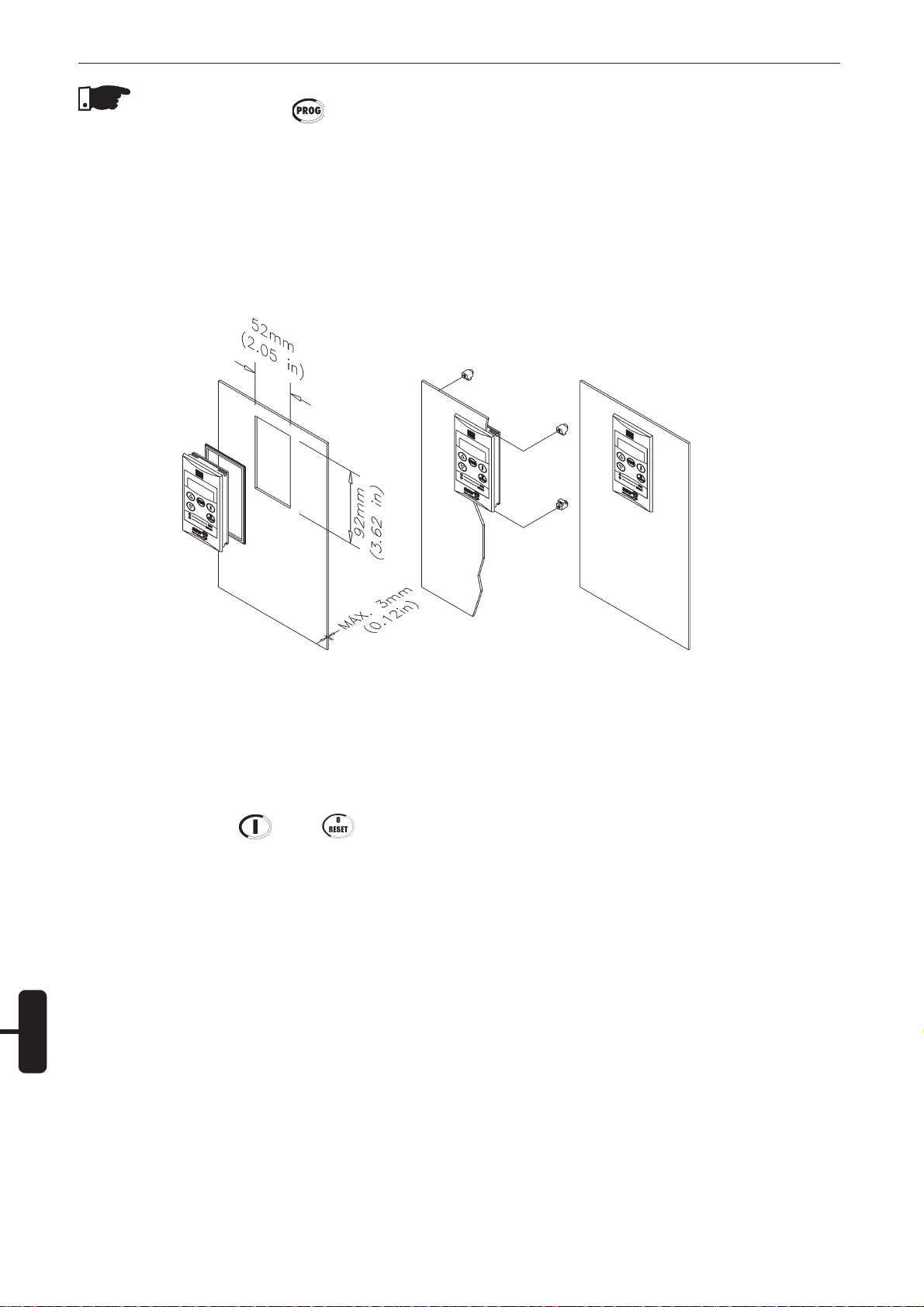

19.3.5. HMI-SSW05-RS Installation:

The HMI-SSW05-RS can be installed directly on the panel door 1 to 3mm (0.04in to 0.12in), as shown in the

figure below:

Figure 19.5 - HMI-SSW05-RS Installation.

19.3.6. HMI-SSW05-RS Start-up:

After installation (including interconnecting cable), power up the Soft-S tarter.

The HMI-SSW05-RS must display “rdy”.

To enable the keys and of the HMI-SSW05-RS, is necessary to program P264 ≠ 1.

19.3.7. Keypad Copy Function:

The HMI-SSW05-RS keypad still has an additional function: the Keypad Copy Function. This function

is useful when one wants to copy the settings of one Soft-S tarter (source Soft-S tarter) to another

(target Soft-S tarter) or one needs to program several Soft-S tarters with the same settings.

This is done as follows: the parameters of the source Soft-Starter are copied to a non-volatile

memory of the HMI-SSW05-RS Keypad, and then from this keypad to another Soft-S tarter (“target

Soft-St arter”). The keypad copy function is controlled by the parameter P215.

For further information on this function, refer to detailed parameter description of P215.

ENGLISH

English-22

Installation and Operation Manual - SSW-05 Plus

20. T ABLE OF PARAMETERS (FOR SERIAL COMMUNICATION / HMI-SSW05-RS):

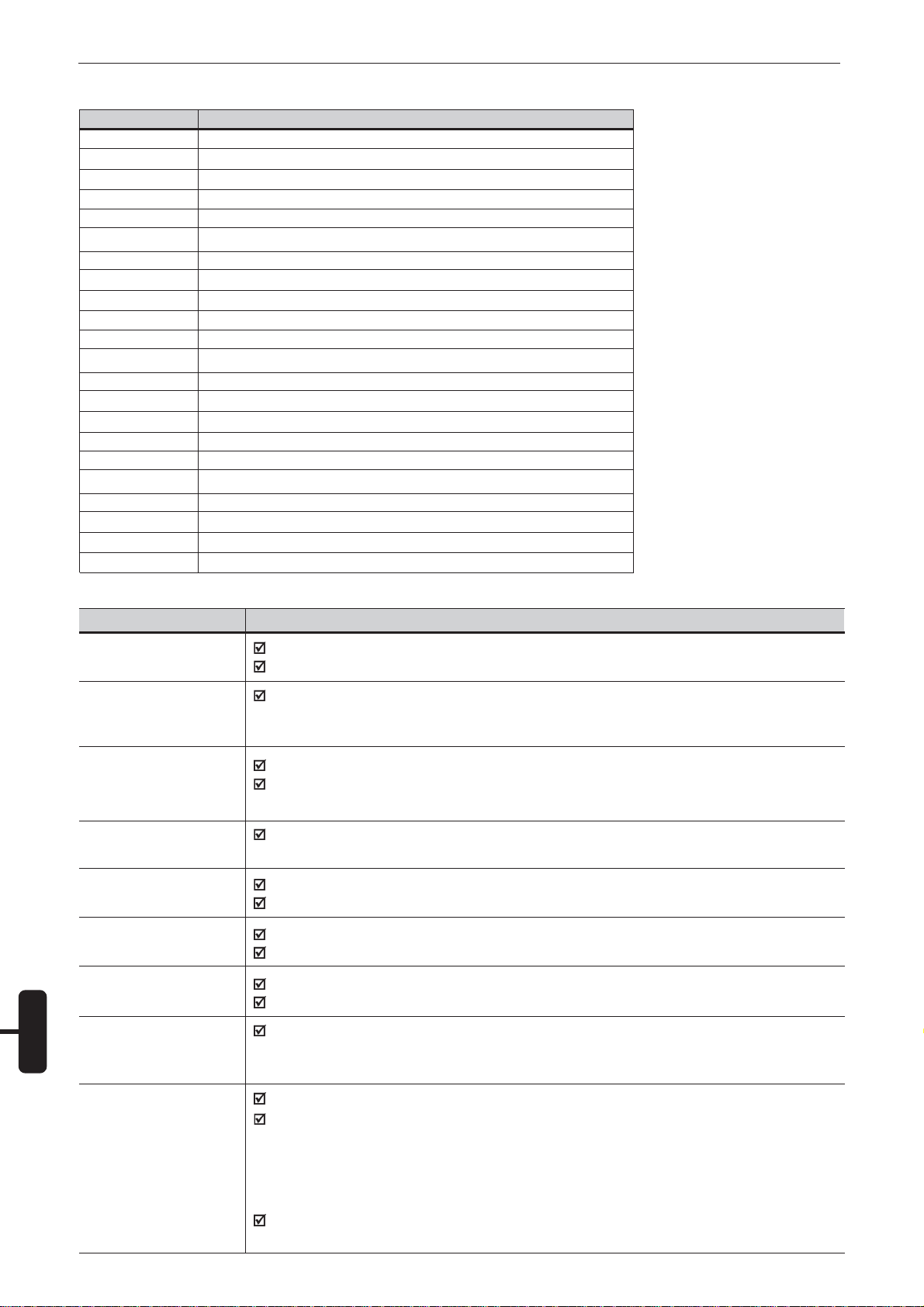

Parameter

(2)

P000

Parameter Function Range of the Factory

(Reading) Internal Values Setting Setting

Parameter Access

0 ... 4, 6... 9999 = Read

5 = Alteration

Unit

0- 24

User

P002 Motor Current Indication (%) 000,0 to 999,9 % In 24

P003 Motor Current Indication (A) 000,0 to 999,9 A 24

P023 Software Version - 24

P030 R Phase Current 000,0 to 999,9 A 2 4

P031 S Phase Current 000,0 to 999,9 A 2 4

P032 T Phase Current 000,0 to 999,9 A 24

P050

Parameter

S tatus Indication of the 0 to 250 motor overload protection 250 = error

Parameter Function Range of the Factory

(Reading and Writing) Internal Values Setting Setting

Unit

User

P101 Initial voltage 30 to 80 30 % Un 24

P102 Time of the Acceleration Ramp 1 to 20 10 s 24

P104 Time of the Deceleration Ramp 0 to 20 0 = off s 2 5

(1)

P105

P106

Motor Current Setting 30 to 100 100 % 25

(1)

Protection Configuration 0 to 3F Hexadecimal 1F Hex. - 2 5

0 = No function

1 = No function

P204

(1)

Load Factory Setting

2 = No function

3 = No function

0- 28

4 = No function

5 = Load factory default

P206 Auto-Reset Time 1 to 1200 90 0 s 2 8

0 = Off

1 = Copy (SSW->keypad)

0- 28

P215

(1)

Keypad Copy Function

2 = Paste (keypad->SSW)

P220

P264

P277

P295

Selection 1 = HMI

Programmable Digital Input

(1)

DI 1

Programmable relay output

(1)

(14/23 - 24)

(1) (2)

Rated current of the Soft-S tarter

0 = Not used

1 = Enable / Disable

2 = External Fault

1 = Full voltage

2 = Error

3 = Serial Com.

0 = 3 A

1 = 10 A

2 = 16 A

3 = 23 A

4 = 30 A

5 = 45 A

6 = 60 A

7 = 85 A

0- 29

1- 29

1- 29

According

to the

-29

Type

HMI/(Trimpots and Dip Switch) 0 = Trimpots and Dip Switch

(1)

P308 Network Address 1 to 30 1 - 30

P313

Action of the serial

communication verification

1 = only Error

2 = ramp disabling

3 = General disabling

1

-

4 = P264 → 1

P314

Verification Time of the

Serial Communication

0 to 5 0 = OFF s 3 0

P610 Immediate Undercurrent 30 to 100 30 (%) 30

P61 1 Immediate Undercurrent Time

(1)

These Parameters can be changed only with stopped motor.

(2)

These Parameters are not changed through the function “Loads Parameters with Factory Setting” (P204).

1 to 99

0 = Disabled

0 (s) 30

Page

24

Page

30

ENGLISH

English-23

Installation and Operation Manual - SSW-05 Plus

21. ERROR CODE AND DESCRIPTION (FOR SERIAL COMMUNICATION / HMI-SSW05-RS):

Display Description

E03 Phase loss

E05 Output overload (Ixt function)

E06 External fault

E10 Error in the copy function

E2x Serial communication error

E22 Longitudinal parity fault

E24 Parameterization fault

E25 Variable or parameter not existing

E26 Expected value out of the allowed limits

E27 Writing attempt in a read only variable or logical control disabled

E29 Error of the cyclic serial communication interrupted

E31 Keypad connection fault

E63 Locked rotor

E64 Thyristor overload

E65 Immediate Undercurrent

E66 Overcurrent

E67 Incorrect phase sequence

E70 Undervoltage in the control supply

E71 Internal By-pass relay contact is open

E72 Overcurrent before the By-pass

E73 Overcurrent of the SSW-05 By-pass relay

E75 Frequency out of tolerance

22. DET AILED PARAMETER DESCRIPTION (FOR SERIAL COMMUNICA TION/HMI-SSW05-RS):

Parameter Description / Notes

ENGLISH

P000

Access Parameter

P002

Motor Current Indication

(%)

P003

Motor Current Indication

(A)

P023

Software Version

P030

R Current Phase

P031

S Current Phase

P032

T Current Phase

P050

Status Indication of the

Motor Thermal Protection

Releases the access to change the parameter values.

The password is 5.

Indicates the motor current in percent (%) of nominal current.

Indicates the motor current directly in Amps.

Is necessary to program P295 correctly. This is important in the correct indication

value in amperes

Indicates the version of the software installed in the CPU.

It indicates the current of the R Phase.

Accuracy of ± 10% @ 1xIn of the SSW-05.

It indicates the current of the S Phase.

Accuracy of ± 10% @ 1xIn of the SSW-05.

It indicates the current of the T Phase.

The indicated value is estimated from the instantaneous current of the R and S Phases.

Indicates in percentage the status of the thermal motor protection (0 ... 250). 250 is

the point where the thermal motor protection trips, E05.

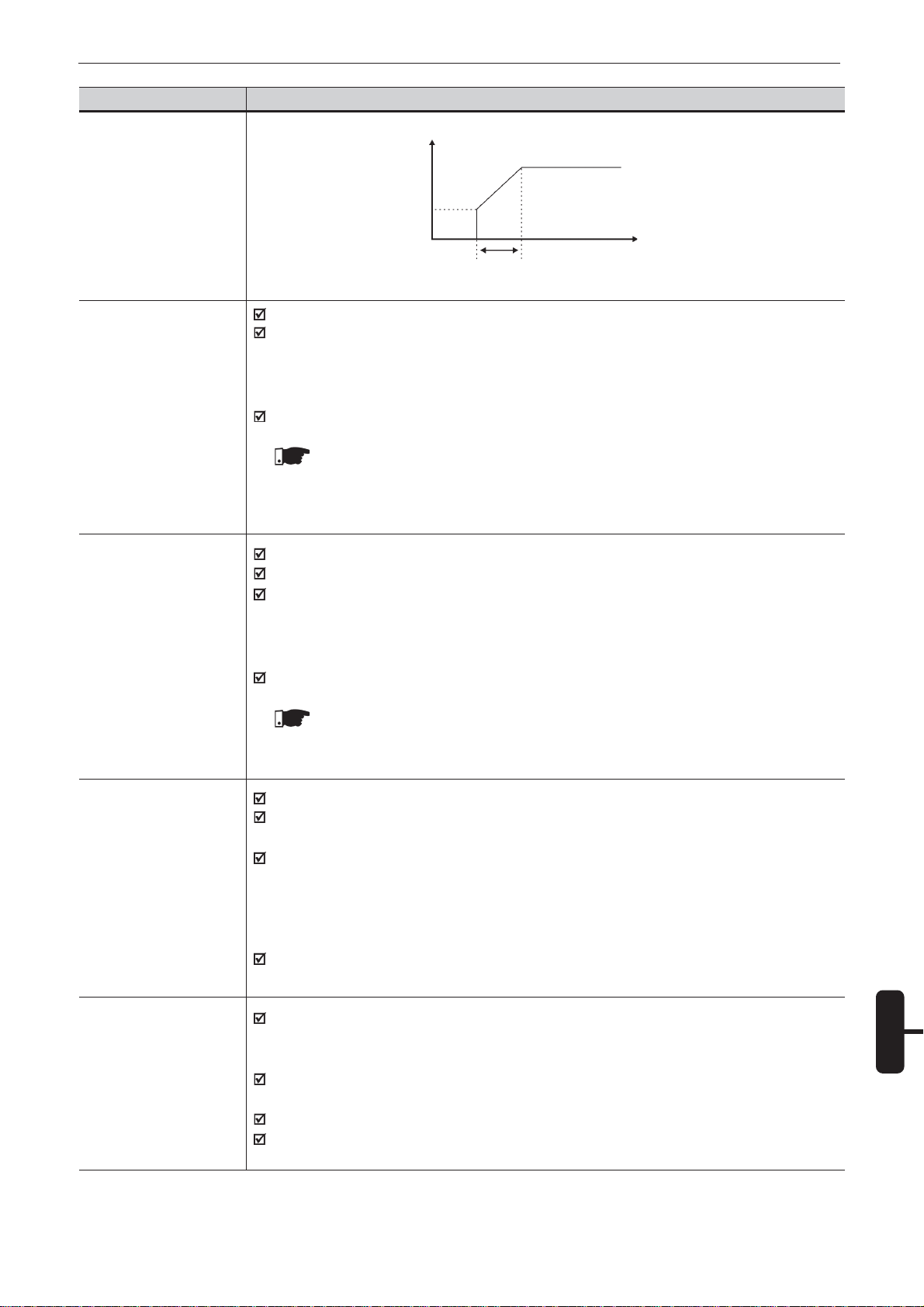

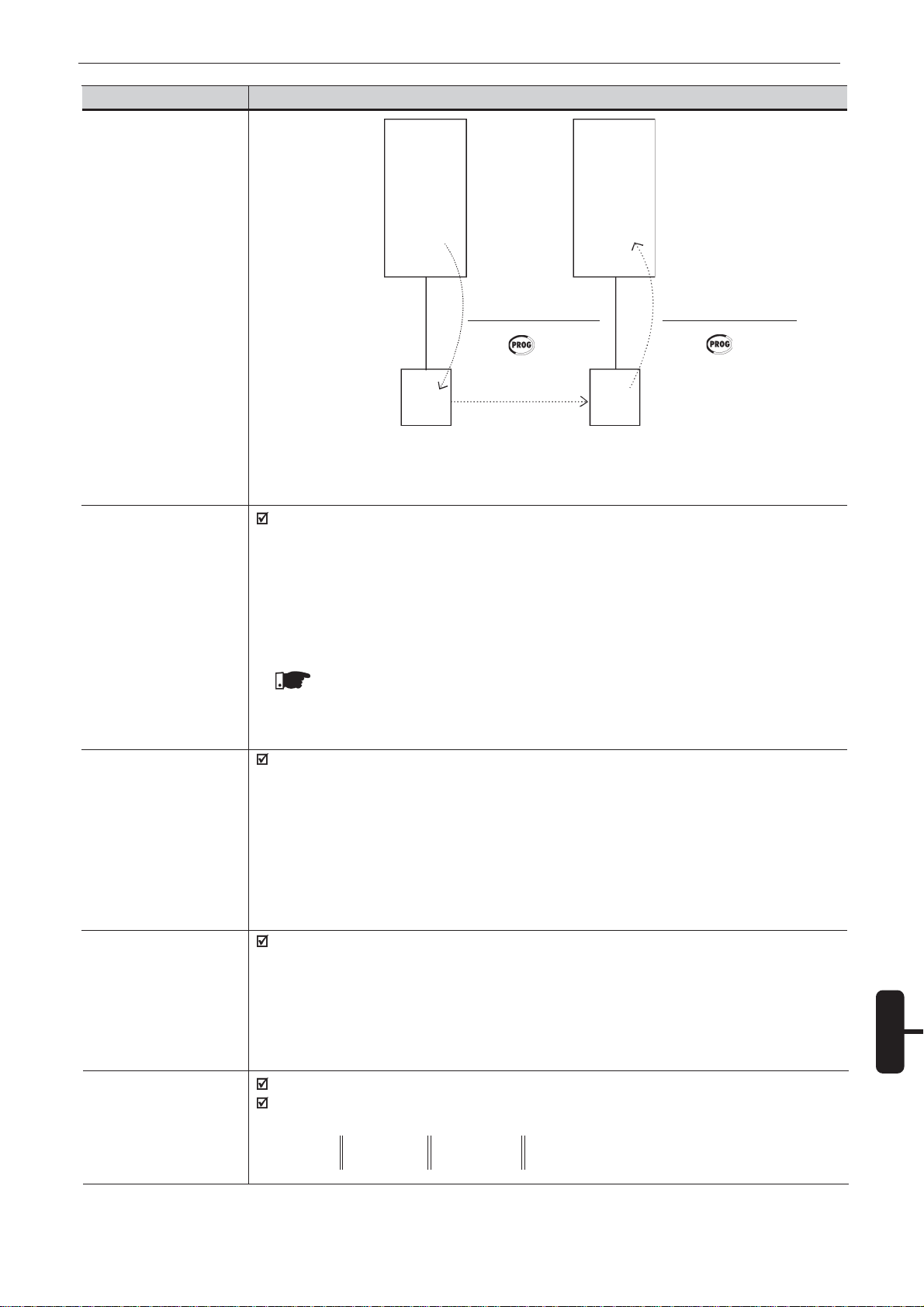

P101

Initial Voltage (%Un)

It sets the start voltage (%Un) that will be applied to the motor according to Figure 22.1.

When P220 = 0, the parameter content indicates the value that has been set through

the trimpot. When the trimpot has been set to the maximum value, the value indicated

at the Parameter may be lower than expected. This is due to mechanical limits

variations. The parameter content cannot be changed through the keypad when

P220 = 0.

With P220=1, the content of the parameter indicates the value programmed through

the serial communication or HMI.

English-24

Parameter Description / Notes

Installation and Operation Manual - SSW-05 Plus

UN

P101

t(s)

P102

Figure 22.1 - Acceleration Ramp

P102

Time of the

Acceleration Ramp (s)

P104

Time of the

Deceleration Ramp (s)

It defines the ramp time of the voltage increment, as shown in Figure 22.1.

When P220 = 0, the parameter content indicates the value that has been set through the

trimpot. When the trimpot has been set to the maximum value, the value indicated at the

Parameter may be lower than expected. This is due to mechanical limits variations. The

parameter content cannot be changed through the keypad when P220 = 0.

With P220=1, the content of the parameter indicates the value programmed through

the serial communication or HMI.

Note:

Due to the back-EMF (electromotive Force) generated by the motor, motors

without load or with small loads will have a shorter acceleration time than the

time that has been programmed at P102.

Used on pump application.

Defines the ramp time of the voltage decrement

When P220 = 0, the parameter content indicates the value that has been set through the

trimpot. When the trimpot has been set to the maximum value, the value indicated at the

Parameter may be lower than expected. This is due to mechanical limits variations. The

parameter content cannot be changed through the keypad when P220 = 0.

With P220=1, the content of the parameter indicates the value programmed through

the serial communication or HMI.

Note:

This function is used to delay the normal deceleration time of a load and in that

way to not force a shorter time than that imposed by the own load.

P105

Motor Current Setting

(%)

P106

Diagnostic Configuration

It sets the motor current in percent relating to the rated Soft-S tarter current.

The indicated value is related directly to the activation levels of the following motor

protection devices: overload, overcurrent, locked rotor and phase loss.

When P220 = 0, the parameter content indicates the value that has been set through

the trimpot. When the trimpot has been set to the maximum value, the value indicated

at the Parameter may be lower than expected. This is due to mechanical limits

variations. The parameter content cannot be changed through the keypad when P220

= 0.

With P220=1, the content of the parameter indicates the value programmed through

the serial communication or HMI.

With P220=0, the content of the parameter indicates the value programmed through

dip switch. In this case the alteration of the content of the parameter through HMI is

not possible.

With P220=1, the content of the parameter indicates the value programmed through

the serial communication or HMI.

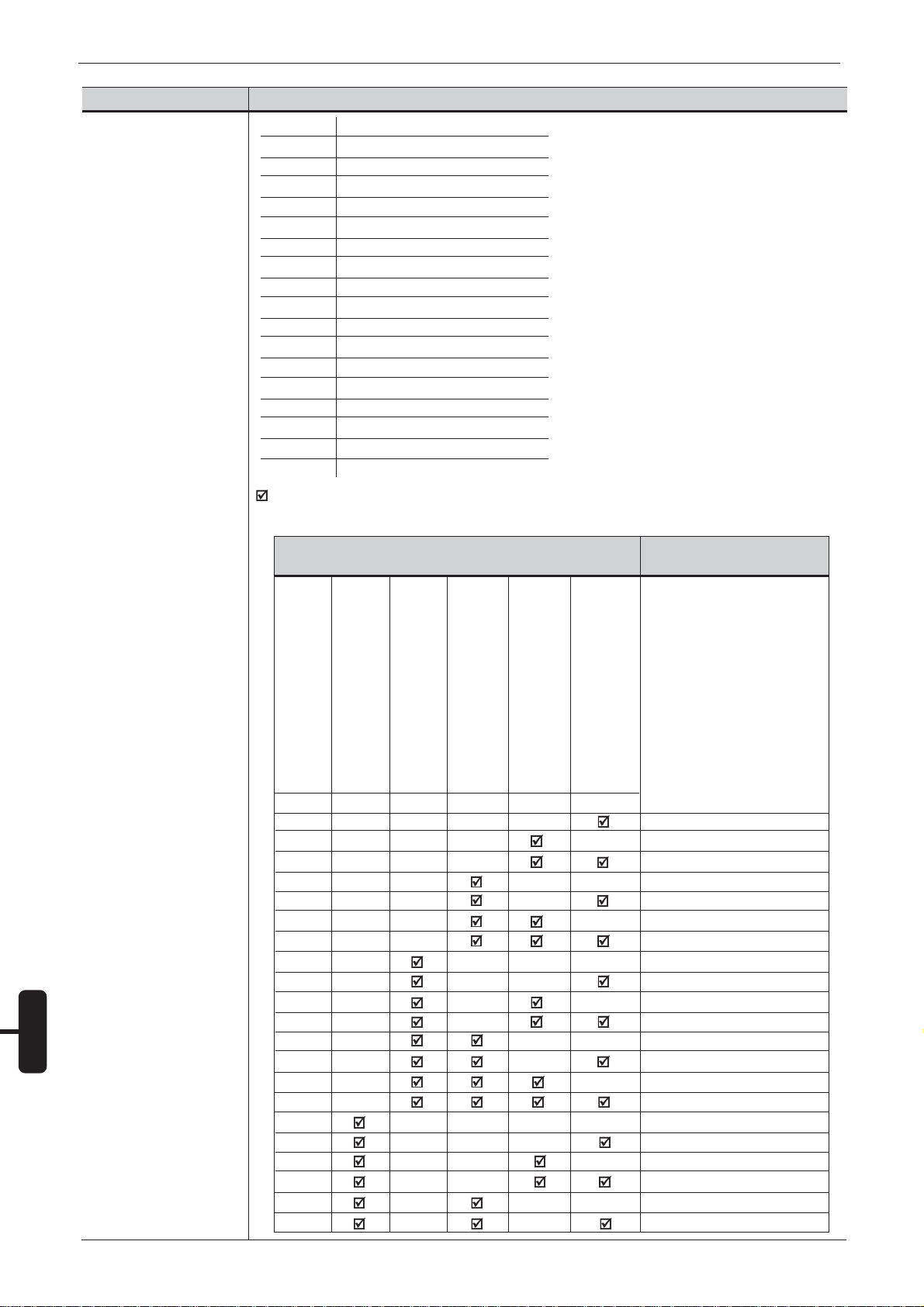

It configures the protections that are enabled.

The value is indicated as Hexadecimal value. Please find below the protection and the

corresponding bit.

ENGLISH

English-25

Installation and Operation Manual - SSW-05 Plus

Parameter Description / Notes

LSB

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

MSB

Overcurrent

Phase loss

Incorrect phase sequence

Locked rotor

Motor overload

Automatic reset

-

-

-

-

-

-

-

-

-

-

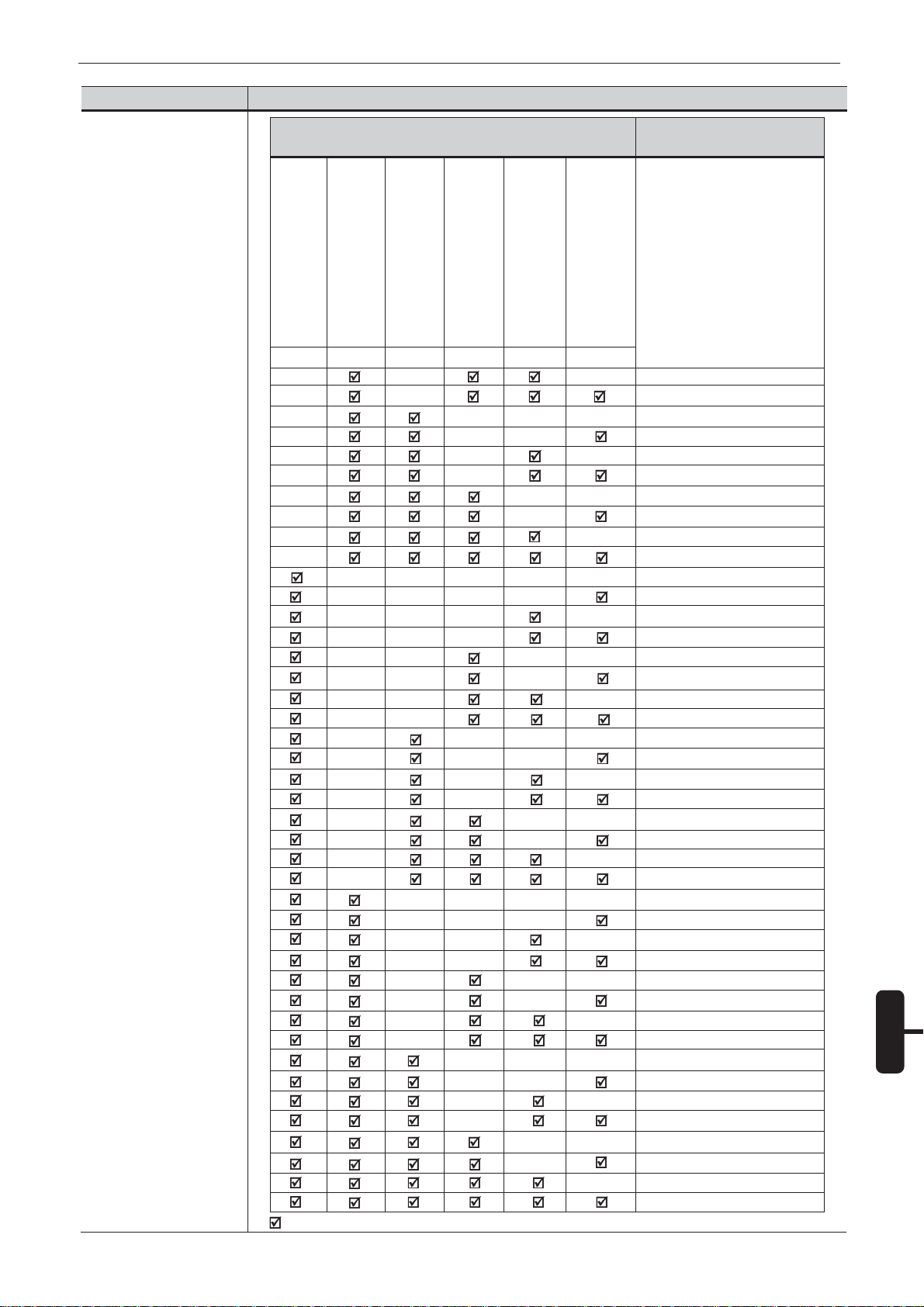

The T able below shows the combination of the enabled diagnostics and

the corresponding value to be programmed at P106.

Diagnostic Configuration

Example:

P106 = 13 Hex

1 - Enabled - Overcurrent

1 - Enabled - Phase loss

0 - Disabled - Incorrect phase sequence

0 - Disabled - Locked rotor

1 - Enabled - Motor overload

0 - Disabled - Automatic reset

13Hex = 010011bin

V alue Programmed

at P106 (hexadecimal)

ENGLISH

Automatic Reset

Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Motor Overload

Stall

Incorrect

Phase sequence

Phase Loss

Overcurrent

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

10

11

12

13

14

15

English-26

Parameter Description / Notes

Installation and Operation Manual - SSW-05 Plus

Diagnostic Configuration

Automatic Reset

Motor Overload

Stall

Incorrect

Phase sequence

Phase Loss

Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

= enabled diagnostic

at P106 (hexadecimal)

Overcurrent

V alue Programmed

16

17

18

19

1A

1B

1C

1D

1E

1F

20

21

22

23

24

25

26

27

28

29

2A

2B

2C

2D

2E

2F

30

31

32

33

34

35

36

37

38

39

3A

3B

3C

3D

3E

3F

ENGLISH

English-27

Installation and Operation Manual - SSW-05 Plus

Parameter Description / Notes

P204

Load Factory Setting

P206

Auto-Reset Time

P215

Keypad Copy Function

Programs all parameters to the standard factory default, when P204=5.

The parameters P000 and P295 are not changed when the factory default parameters

are loaded through P204=5.

When any fault is detected, excepting E10, E24, E29, E31 and E67, the Soft-Starter

SSW-05 can cause an automatic reset after the time programmed at P206 has elapsed

If after an “auto-reset” the same fault is repeated three times consecutively , the AutoReset function will be disabled. A fault is considered consecutive if it happens again

within 30 second after an auto-reset has been executed.

This is fault is repeated four times consecutively , it will be displayed permanently and

the Soft-Starter will be disabled.

Auto-Reset Enable/Disable is executed through the Dip Switch (Man Auto) or by means

of P106 and P220.

Note: For motor overload and thyristor overload there is a specific algorithm for

the automatic reset time.

The keypad copy function is used to transfer the content of the parameters from one

SSW to another .

Note: The Keypad Copy Function is only available when using HMI-SSW05-RS.

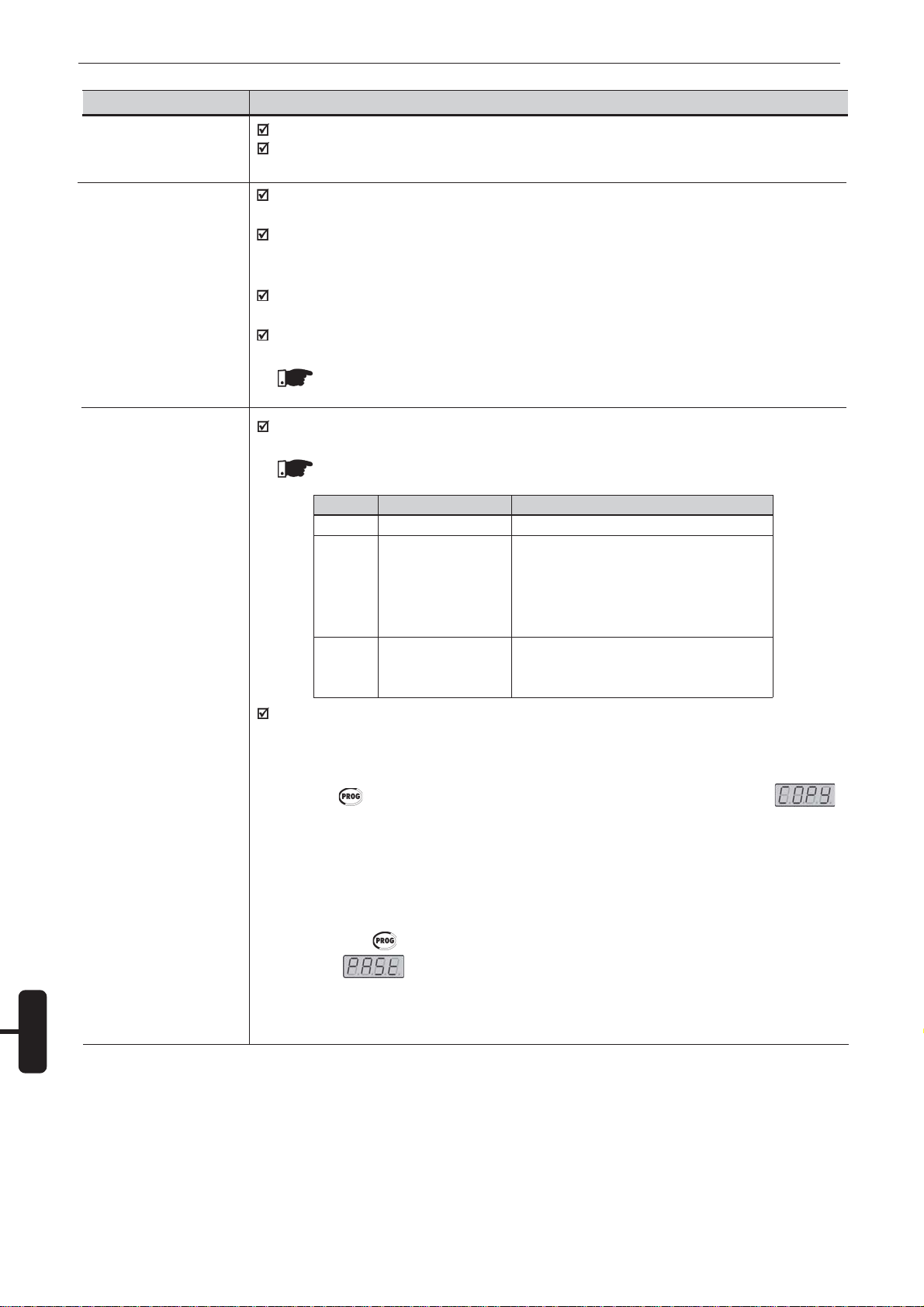

P215

0

1

2

Procedure is as follows:

1. Connect the keypad (HMI-SSW05-RS) to the SSW from which the parameters willl

be copied (SSW A - source SSW).

2. Set P215=1 (copy) to transfer the parameter values from the SSW A to the keyp ad.

Action

Off

Copy

(SSW→ keypad)

Paste

(keypad → SSW)

Transfers the actual parameter values

of the SSW to non volatile memory

(EEPROM) of the HMI-SSW05-RS

keypad. The actual SSW parameters

are not changed.

Transfers the content of the non volatile

memory of the keypad (EEPROM) to

the SSW parameters.

Notes

-

ENGLISH

Press key . During running of the Copy Function, display will show .

P215 resets automatically to 0 (Off) after transfer has been completed.

3. Disconnect the keypad from the SSW (A).

4. Connect the same keypad to the SSW to which the parameters will be transferred

(SSW B - target SSW).

5. Set P215=2 (paste) to transfer the content of the of the keypad (EEPROM has the

SSW A parameters) to SSW B.

Press the key. While the keypad is running the paste function, the display

shows , an abbreviation for paste. When P215 returns to 0, the parameter

transfer has been concluded. Now SSWs A and B will have the same parameter

values. T o copy the p arameter content of the SSW A to other SSW(s), repeat steps

4 to 5 above.

English-28

Parameter Description / Notes

Installation and Operation Manual - SSW-05 Plus

P220

HMI/(Trimpots and Dip

Switch) Selection

P264

Programmable

Digital Input DI 1

P277

Programmable

Relay Output

(14/23 – 24)

P295

Rated Current of the

Soft-Starter

Soft-Starter

A

Parameters

SSW→HMI (Copy)

P215 = 1

Press

EEPROM

HMI-SSW05-RS

Soft-Starter

B

Parameters

HMI→SSW (Paste)

P215 = 2

Press

EEPROM

HMI-SSW05-RS

Figure 22.2 - Copying the parameters from the SSW A to the SSW B, by using the Copy

Function and the HMI-SSW05-RS keypad.

It configures the operation mode of the Soft-St arter, in T rimpots and Dip Switch mode or

HMI mode.

0 “(Trimpot and Dip Switch)” – the programming of the initial voltage, ramp time, motor

current setting and enabling of the protection devices is performed by means of the

trimpots and dip switch. The values programmed through the serial communication is not

used.

1 “HMI” - the programming is performed through the serial communication. The values

programmed through trimpots and dip switch is not used.

Note:

In HMI mode (P220=1) the trimpots and dip switch programming is ignored. The

start voltage, ramp times, motor current setting and the protection enabling is

programmed through the parameters P101, P102, P104, P105 and P106.

It configures the DI 1 digital input to operate according to the codes described below.

0- “Not used”, DI 1 digital input is disabled. The enabling commands are only accept via

serial communication (V03).

1- “Enable/Disable”, enabling only via digital input. The enabling commands via serial

communication are ignored.

2- “External Fault”, it acts only if the DI 1 digital input is open. It can also be used as

additional load protection. Example: thermal protection of the motor through dry contact

(without voltage) of a protection relay (Thermostat).

The enabling commands are only accepted via serial communication (V03).

It enables the relay (14/23 – 24) to operate according to the following parameter setting:

1- Function “Full voltage” – the relay closes the contact only after the Soft-S tarter reached

100% of Un (By-pass), and opens the contact when the Soft-Starter has received a

switch-Off order.

2- Function “Error”, the relay closes the N.O. contact when the SSW-05 is with no error.

3- Function “Logic Command”, the relay opens and closes the relay contact according to

the BIT 5 status of the V03 basic variable.

Configures the SSW-05 models.

Its function is to set the software so the current indication in ampére (P003) is correct.

This parameter also sets the activation level of the By-pass relay protection.

0 = 3A 2 = 16A 4 = 30A 6 = 60A

1 = 10A 3 = 23A 5 = 45A 7 = 85A

ENGLISH

English-29

Loading...

Loading...