Quick Start Guide

SSW04

Motors | Automation | Energy | Coatings

g

5 to 30HP (16 to 85A) 230V

g

10 to 75HP (16 to 85A) 460V

g

15 to 75HP (16 to 85A) 575V

QS006SSW04

Power Connections and Keypad Operation:

LED Display –

indicates fault

codes, status,

parameter number

and value.

Power Connections and Keypad Operation:

The SSW04 Quick Start Guide is a supplement to help get the SSW04 started quickly using the most common in stallation

and configuration options. This SSW04 Quick Start Guide is not meant to replace the SSW04 User’s Manual. For detailed

instructions, safety precautions, proper mounting, installation, configuration, and operation please re fer to the SSW04

User’s Guide. Warning: Only qualified personnel sh ould plan or implement the install ation, start-up, op eration and

maintenance of this equipmen t. Pers onnel must read the entire SSW04 User’s Guide before attempting to install, operate

or troubleshoot the SSW04.

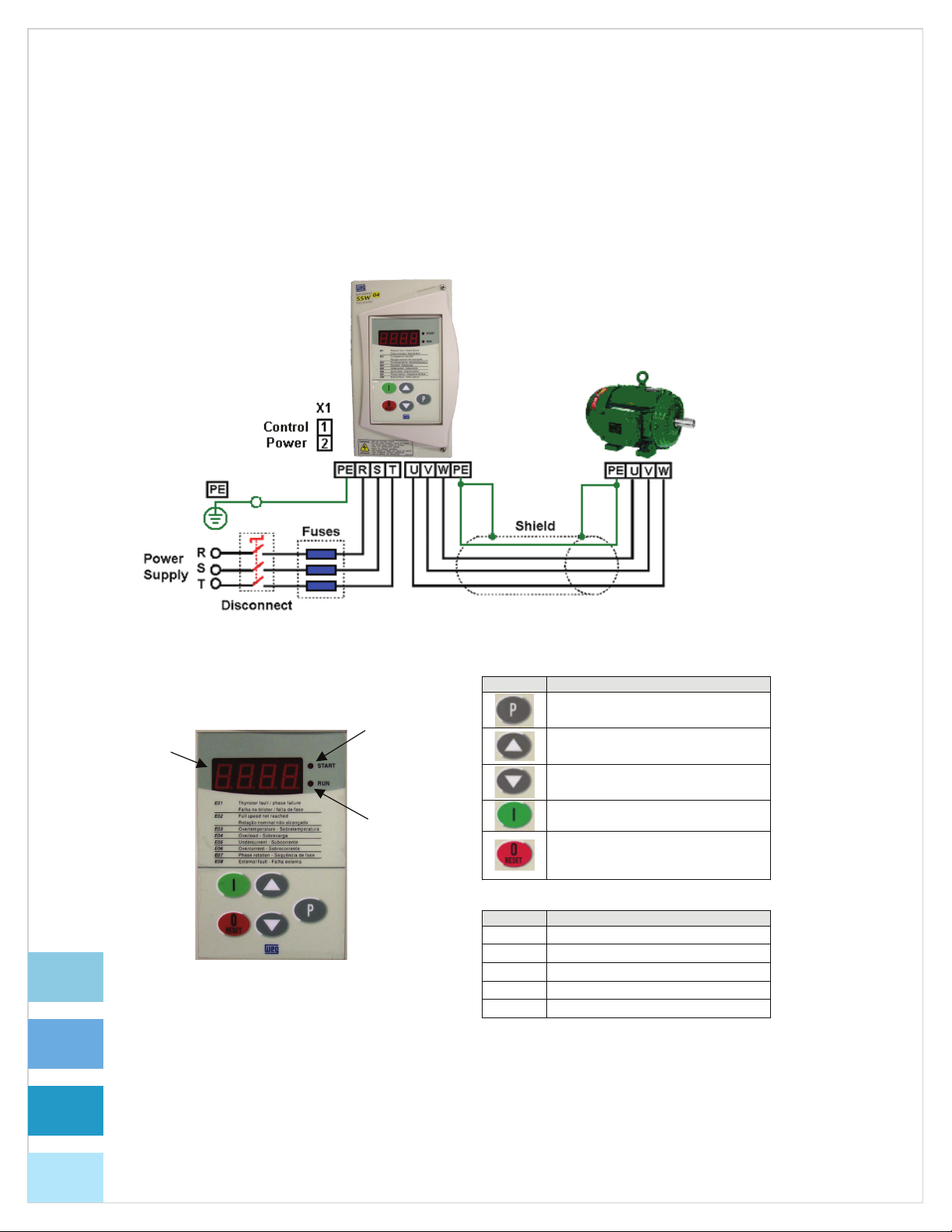

Figure 1 - Power and Gro unding Connections

Figure 2 – Keypad Operation

Key

Description

Switches the display between

parameter number and content.

Increases Parameter

number/content.

Decreases Parameter

number/content.

Starts (Enables) the motor.

Stops (Disables) the motor, and

resets the Soft Starter after a fault

has occurred.

Display

Description

rdy

Soft Starter is ready to be enabled

Pup

Loading pump control parameters

EEP

Loading “Default” values

on

Function enabled

oFF

Function disabled

Start - R ed LED

Run - Red LED

Basic Wiring:

Basic Wiring:

1. Mount the SSW04 to a flat vertical surface.

2. Connect th e three-ph ase incoming power leads to the R, S, and T connections on the power terminal and connect

the GROUND lead to PE on the chassis (Refer to Figure 1). Connect the motor leads to the U, V, and W

connections on the power terminal an d connect the GROUND lead to PE on the chassis (Refer to Figure 1).

Note: Only three-phase AC motors can be used.

3. Connect control power (110Vac) hot and neutral leads to pins 1 & 2 of the X1 connector respectively.

4. Apply Control Power followed by Input Power. The soft starter will run self-diagnostics and if no proble ms are

found it will display “rdy” on the LED display.

Minimum Parameters to Set:

P21 – Motor Current Setting - Factory def ault position is “OFF” so there is no motor overload protection. To protect the

motor from overload, obtain the full load amperage (FLA) off the motor and soft-starter name plates, and using the

following formula, calculate the percentage of current that the motor will draw from the soft-starter.

– INof the soft-starter = 170A

– INof the motor = 140A

– INof the motor / INof the switch = 140A / 170A = 0.823

– P21 = 82.3%

P25 – Thermal Class of Overload Protection - Set to factory default of 30 if not specified on the motor name plate.

P26 – Motor Service Factor – obtain from motor name plate.

Notes: (1) To change the value of p arameters set parameter P000=ON.

(2) Soft Starters are shipped with factory default values. If parameters have been changed it is advisable to reset to

factory default values prior to a new installation by setting P46= ON.

(3) These are the minimum parameters for a perfect adaptation between soft starter and motor. For a complete

description of Parameters and Error codes refer to Chapters 6 and 7 in the SSW04 User’s Guide.

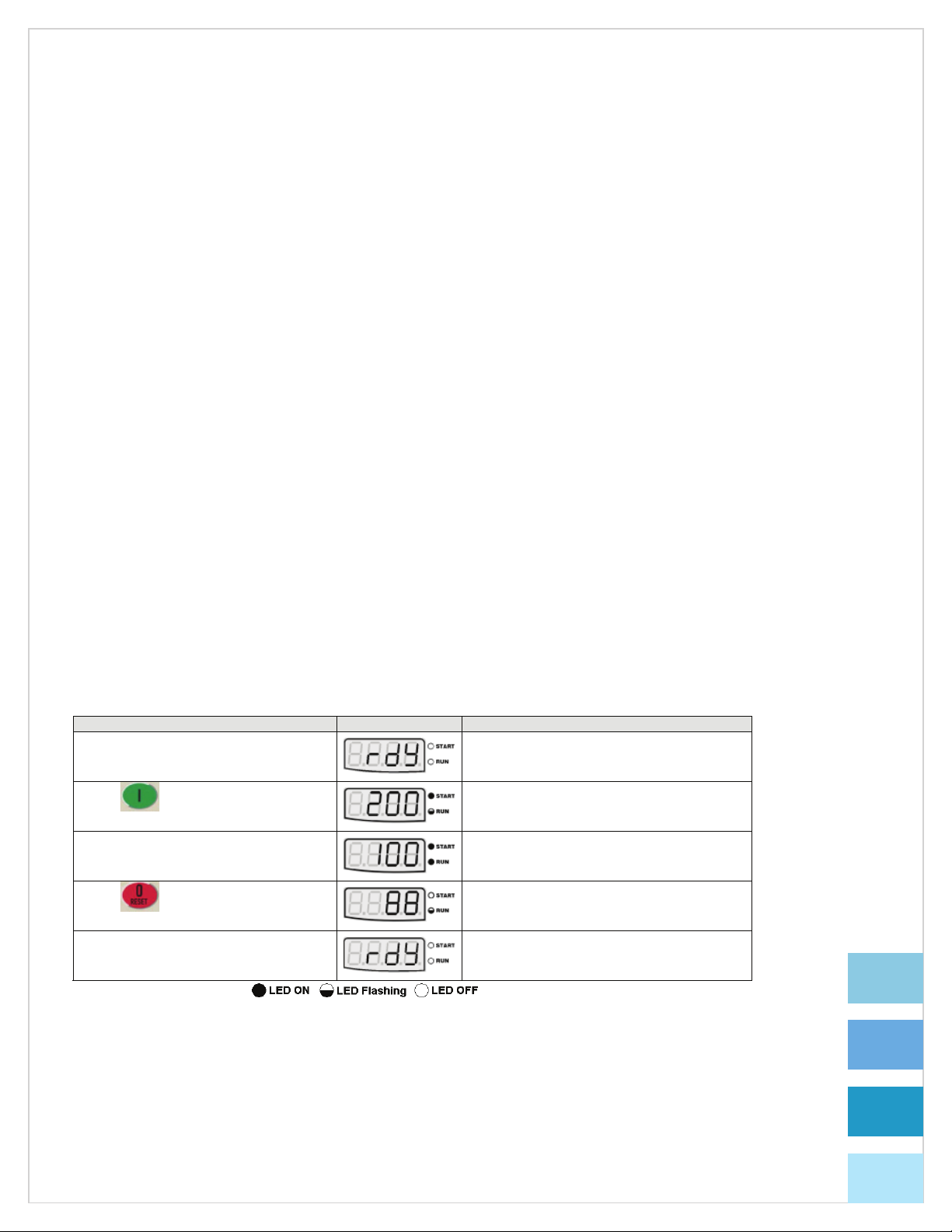

Keypad Start/Stop O peration (Local Mode):

Action

LED Display

Description

After power- up, the display shows the

following message.

Soft Starter powered-up.

Press “Start”

Motor begins to accelerate.

Motor current (P72) = 200%

When end of Acceleration ramp (P02) is

reached the Motor Current (P72) = 100%

Press “Stop”

By default, motor coasts to rest. For a

decelerated stop, program P04 for desir ed

deceleration time.

Soft Starter is turned off in “rdY” condition.

Start/Run LED Symbols: