WEG Electric SSW04 User Guide

Soft-Starter

Arrancador Suave

Chave de Partida Soft-Starter

44

User´s

Guide

Guia del

Usuario

Manual

do usuário

ADDENDUM TO THE MANUAL 0899.5629 E/5 - SSW-04

Thisaddendumreferstothefollowingchangesthathavebeenmade on the SSW-04

softwarefrom Version4.XXto Version5.XX.

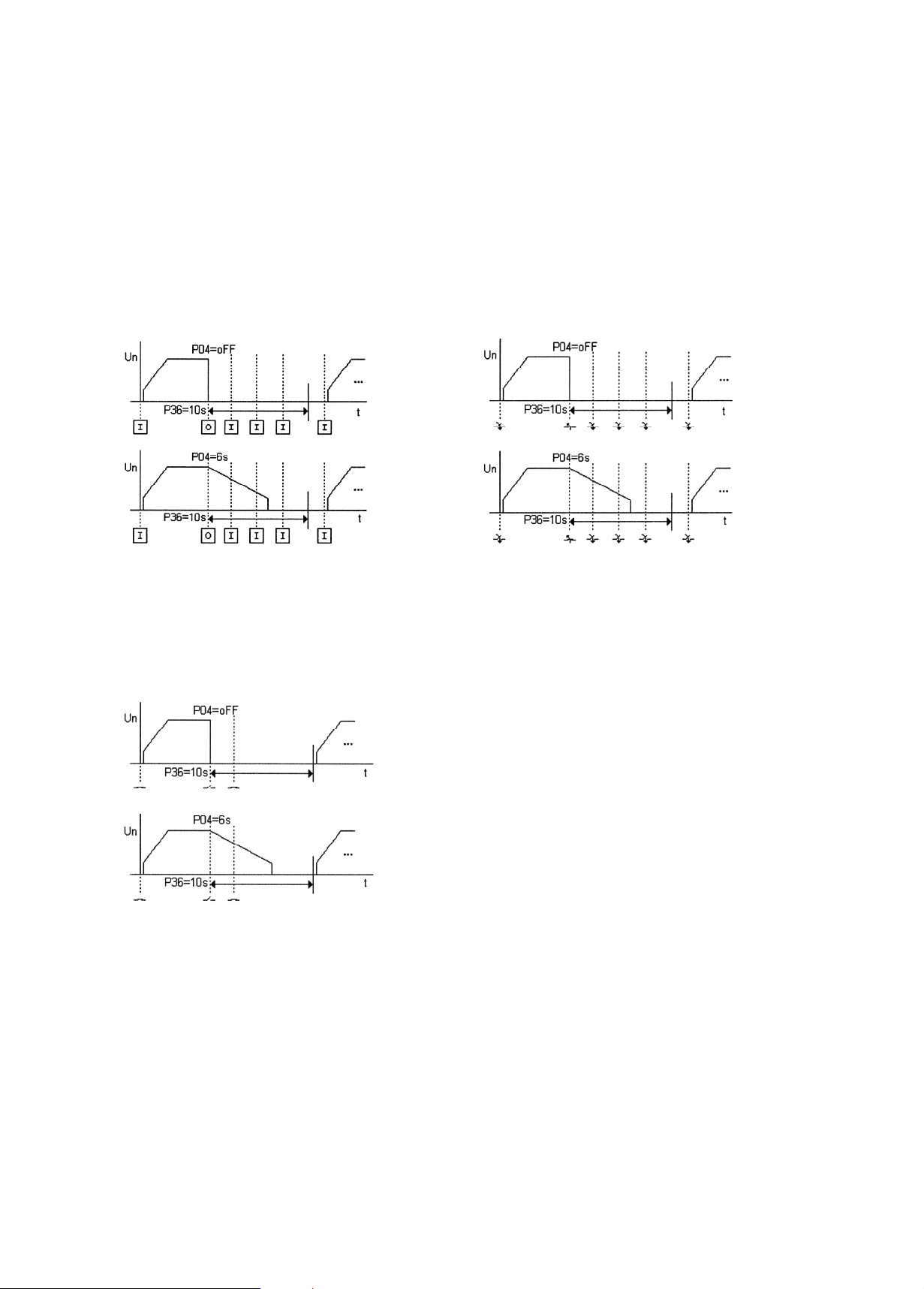

1. Inclusionofthetimeintervalbetweenstartsfunction.

Thisprotectionactslimitingthetimeminimumintervalbetweenstartstoavoidexcessive

startingand stopping according tothe timeadjusted in parameter P36.

- P36: TimeInterval Between Starts(oFF,1...999s). Factory Standard:“oFF”.

OperationbyHMI

(I/O)

Attention:

The SSW controller will not accept a new Start command during the time, adjusted in P36,

elapsedafterStop.Identicallytoserialinterfacecommunication.

Operationbytwo wire digital input

(E.D.1)

Operationbythreewiredigitalinput

(E.D.1and E.D.2)

Attention.:

The SSW controller will not accept a new Start command during the time, adjusted in P36,

elapsedafter Stop.

NOTE!

1) Usethisfunctiononlyif youneed to avoidexcessivestartingandstopping.

2) Thetime counterstartsafteraStopcommand,withorwithoutsoftstop.

3) ThetimeadjustedinP36mustbegreaterthanthetimeadjustedinP04forthisfunctionto

workproperly.

4) Thisfunctiondoesn’tworkfortheJogfunction.

5) Duringthe reversalofthe motor direction,thenewstartof the motorwillbeonlyrealized

afterthe timeadjusted in P36elapses.

ADDENDUM TO THE MANUAL 0899.5629 E/5 - SSW-04

Thisaddendumreferstothefollowingchangesthathave been made on theSSW-04 software

from Version3.XX to Version 4.XX

1. AdditionofthefunctionWatch Dog of the Serial Communication.

This protection acts when the serial communicationbetweenthemaster and the Soft-Starter is

interrupted, causing indication and action as set in parameters P63 and P64.

- P63: Watch Dog Time of the Serial Communication(oFF, 1 ... 5s). Factory Standard:“oFF”.

- P64: Action After Watch Dog Time is Elapsed (1,2 and 3). Factory Standard: 1.

1 = Indicates only error E29.

2 =IndicateserrorE29anddisablesthemotorbyramp, if P04 is programmeddifferentfrom “oFF”

and motor is stopped by inertia if equal “oFF”.

3 = Indicates error E29 and cause general disabling of the Soft-Starter. Its cats as emergency.The

motor is stopped by inertia.

NOTE!

Error E29 is reset when the correct serial communicationreturned.

NOTE!

Enable this function only if there is cyclic serial communication with a Master.

Set the watch dog time according to the time between telegrams sent by the master.

2. Change in the setting range of P15 to: off,1 ... 200s.

3. AdditionthefollowingNOTE!intheitem 6.3.19-Pump Control.

NOTE!

Before the first start of the Pump, disable the Pump Control function. P45 must be set at “oFF”.

Setthefollowing parameters:

P01 = 30 ( Initial Voltage)

P02=15(AccelerationRamp Time)

P03 = 80 (Voltage Fall StepduringDeceleration)

P04=15 (DecelerationRampTime)

P11=OFF(CurrentLimitation)

After setting the values above start and stop the Pump.Thencheck the correct direction of rotation,

pump flow andthecurrentof themotor.

After the above step youcanenablethePump Control (P45 = “on”).

4.Additionthe following items 10.2, 10.3 e 10.4 in the accessories chapter.

10.2-RS-485.

Optionallythe SSW-04canoperatein serial interface RS-485 byWeg Interface Module MIW-02.

ModuleType WEG Item

NOTE!

Formoredetails see MIW-02 Manual (0899.4430).

10.3-FieldbusNetwork.

OptionallytheSSW-04 can operate in communication network “FieldBus”, by a gateway, Weg Fieldbus

ModuleMFW-01.

ModuleType Protocol WEG Item

MFW-01/PD ProfiBusDP 417100540

MFW-01/DN DeviceNet 417100541

MFW-01/MR ModBusRTU 417100542

MIW-02 417100543

NOTE!

Formoredetailssee MFW-01 Manual (0899.4429).

10.4- SuperDrive.

ProgrammingsoftwareformicrocomputerPC, forwindows environment.Permitsparameter

programming,commandandmonitoringof the Soft-StarterSSW-04.It edits parameters“on-line”,

directlytotheSoft-Starter or it edits parameters files“off-line”,savinginthe microcomputer.The

communication between Soft-Starter and Microcomputer is by serial interface RS232 (Point to Point)or

RS485(NetworkLine).

Product WEG Item

SuperDrive 417102505

24/04/2001

SOFT-STARTER

SOFT-STARTER

SOFT-STARTER

MANUAL

MANUAL

MANUAL

SSW-04 Series

Software: version 5.XX

0899.5629 E/5

NOTE!

It is very important to check if

the Soft-Starter Software is the

same as the above.

SUMMARY

SUMMARY

QUICK PARAMETER

REFERENCES, ERROR

MESSAGES AND STATUS

MESSAGES

1

SAFETY NOTICE

2

INTRODUCTION

1 Parameters .................................................... 09

2 Error Messages .............................................. 12

3 Soft-Starter Status ........................................ 12

1.1 Safety Notices in the Manual ....................... 13

1.2 Safety Notices on the Product ..................... 13

1.3 Preliminary Recommendations .................... 13

2.1 About this Manual ........................................ 15

2.2 Version of Software ....................................... 15

2.3 Abbreviations Used....................................... 16

2.4 About the SSW-04 ......................................... 16

2.4.1 Introduction ....................................... 16

2.4.2 Simplified Block Diagram of the

SSW-04 ............................................... 18

2.4.3 Description of the control

board - CCS4.00 or CCS4.01 .............. 19

2.5 Product identification ................................... 20

2.6 Receiving ...................................................... 20

3

INSTALLATION

4

POWER UP/

COMMISSIONING

3.1 Mechanical Installation ............................... 21

3.1.1 Environment ....................................... 21

3.1.2 Location/Mounting ............................ 22

3.2 Electrical Installation ................................... 23

3.2.1 Power/grounding connections........... 23

3.2.2 Location of the Power/grounding/fans

connections ........................................ 26

3.2.3 Signal and control connections ........ 27

3.2.4 Fan connections ................................. 29

3.2.5 Combination Drive "A"operation

by HMI-3P .......................................... 30

3.2.6 Combination Drive "B"operation

through terminals .............................. 32

3.3 Installation of Optional Devices .................. 34

3.3.1 HMI-3P on the Panel Door ................. 34

3.3.1.1 Mechanical Installation ........ 34

3.3.1.2 Electrical Installation ............ 35

4.1 Power-up preparations ................................. 36

4.2 Power-up ....................................................... 37

4.3 Commissioning ............................................. 37

4.3.1 Preparation ........................................ 38

5

SUMMARY

SUMMARY

4.3.2 Commissioning and Operation via

HMI-3P ............................................... 38

4.3.3 Commissioning and Operation via

Terminals ............................................ 39

4.4 Settings during the Commissioning ............. 40

USE OF THE HMI

6

DETAILED

PARAMETER

DESCRIPTION

5.1 Description of the HMI-3P Interface ............ 42

5.2 Use of the HMI-3P ........................................ 43

5.2.1 Use of the HMI-3P for operation ....... 43

5.2.2 Signalling / Indications of the HMI-3P

(display) ............................................. 44

5.3 Parameter changing ..................................... 47

5.3.1 Selection/changing parameters ........ 48

6.1 Standard parameter set at factory .............. 50

6.2 Read Parameters - P71...P77, P81, P82,

P96...P99 ....................................................... 51

6.2.1 P71 - Software Version ........................ 51

6.2.2 P72 - Motor Current %IN .......................... 51

6.2.3 P73 - Motor Current(A) ....................... 51

6.2.4 P74 - Active Power .............................. 51

6.2.5 P75 - Apparent Power ......................... 51

6.2.6 P76 - Load power factor ..................... 51

6.2.7 P77 - Output voltage ........................... 51

6.2.8 P81 - Heatsink temperature ................ 51

6.2.9 P82 - Motor thermal protection status.. 51

6.2.10 Last errors .......................................... 52

6.3 Regulation Parameters P00...P15,

P22...P42,P45, P47 ....................................... 52

6.3.1 P00 - Parameter Access ....................... 52

6.3.2 P01 - Initial Voltage ............................ 52

6.3.3 P02 - Time of the acceleration ramp .. 53

6.3.4 P03 - Voltage steps during

deceleration ............................. 53

6.3.5 P04 - Time of deceleration ramp ........ 54

6.3.6 P11 - Current limitation ...................... 54

6.3.7 P12 - Immediate overcurrent .............. 56

6.3.8 P14 - Immediate undercurrent............ 57

6.3.9 P13 - Immediate overcurrent time ...... 58

6.3.10 P15 - Immediate undercurrent time... 58

6.3.11 P22 - Rated current of the Soft-Starter 58

6.3.12 P23 - Rated voltage of the Soft-Starter 59

6.3.13 P31 - Phase rotation .......................... 59

6.3.14 P33 - Voltage level of the JOG function 59

6.3.15 P34 - DC braking time (s) .................. 60

6.3.16 P35 - DC braking voltage level (%UN) 60

6.3.17 P41 - Voltage pulse time at the start 60

7

SUMMARY

SUMMARY

6.3.18 P42 - Voltage pulse level at the start 61

6.3.19 P45 - Pump control ........................... 61

6.3.20 P47 - Auto-reset time ........................ 63

6.4 Configuration parameters P43, P44, P46,

P50...P55,P61, P62 ....................................... 64

6.4.1 P43 - By-pass relay ............................. 64

6.4.2 P44 - Energy save ................................ 64

6.4.3 P46 - Default values (it loads factory

parameters) ........................................ 65

6.4.4 P50 - Function of the relay RL3 .......... 65

6.4.5 P51 - Function of the relay RL1 .......... 66

6.4.6 P52 - Function of the relay RL2 .......... 67

6.4.7 P53 - Programming of the digital

input 2 ................................................ 68

6.4.8 P54 - Programming of the digital

input 3 ................................................ 69

6.4.9 P55 - Programming of the digital

input 4 ................................................ 69

6.4.10 P61 - Control enabling ...................... 70

6.4.11 P62 - Address of the Soft-Starter at

the communication network ............. 71

6.5 Motor Parameters - P21, P25, P26, P27 ....... 72

6.5.1 P21 - Motor current setting

(%IN of the switch) ................... 72

6.5.2 P25 - Thermal class of the

motor protection ...................... 73

6.5.3 P26 - Motor service factor................... 78

6.5.4 P27 - Auto-reset of the thermal

motor image ...................................... 78

MAINTENANCE

8

TECHNICAL

CHARACTERISTICS

9

APPENDIX

7.1 Error and possible causes ............................. 80

7.1.1 Programming error (E24) .................... 80

7.1.2 Serial Communication Error ............... 80

7.1.3 Hardware errors (E0X) ......................... 80

7.2 Preventive maintenance ............................... 84

7.2.1 Cleaning instructions .......................... 85

7.3 Changing supply fuse ................................... 85

7.4 Spare part list ............................................... 86

8.1 Power Data ................................................... 87

8.2 Power / current table .................................... 87

8.3 Mechanical data ........................................... 87

8.4 Electronics data / general ............................ 88

9.1 Comformity ................................................... 89

9.1.1 EMC and LVD directives ..................... 89

9.1.2 Requirements for conforming

installations ....................................... 89

9.1.3 Filter installation ............................... 91

SUMMARY

SUMMARY

9.2 Recommended application with terminals for two

wire control.................................................. 92

9.3 Recommended application with terminals for

three wire control ......................................... 93

9.4 Recommended application with terminals for three

wire control and power isolation contactor 94

9.5 Recommended application with terminals for

three wire control and by-pass contactor ... 95

9.6 Recommended application with terminals for

three wire control and DC braking ............... 96

9.7 Recommended application with terminals for

three wire control and motor speed reversal 97

9.8 Recommended application with PC or PLC

command ...................................................... 98

9.9 Recommended application with terminals for

three wire control for several motors ........... 99

9.10 Symbols ........................................................ 101

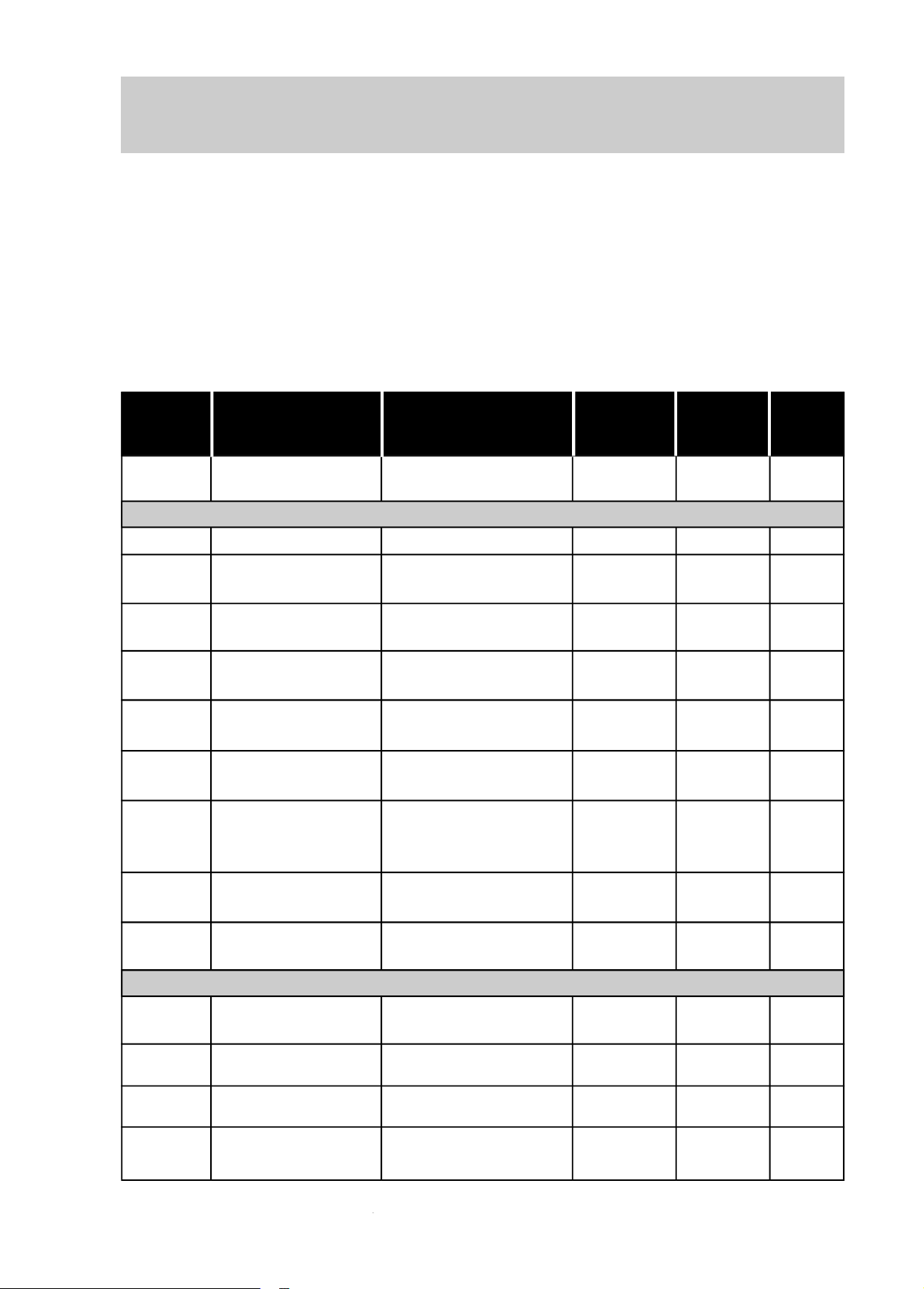

QUICK PARAMETER REFERENCES,

ERROR MESSAGES AND STATUS MESSAGES

Software: V5.XX

Application: _______________________________________________________

Type: _____________________________________________________________

Serial Number: ____________________________________________________

Responsable: _____________________________ Date: _____/_____/_____.

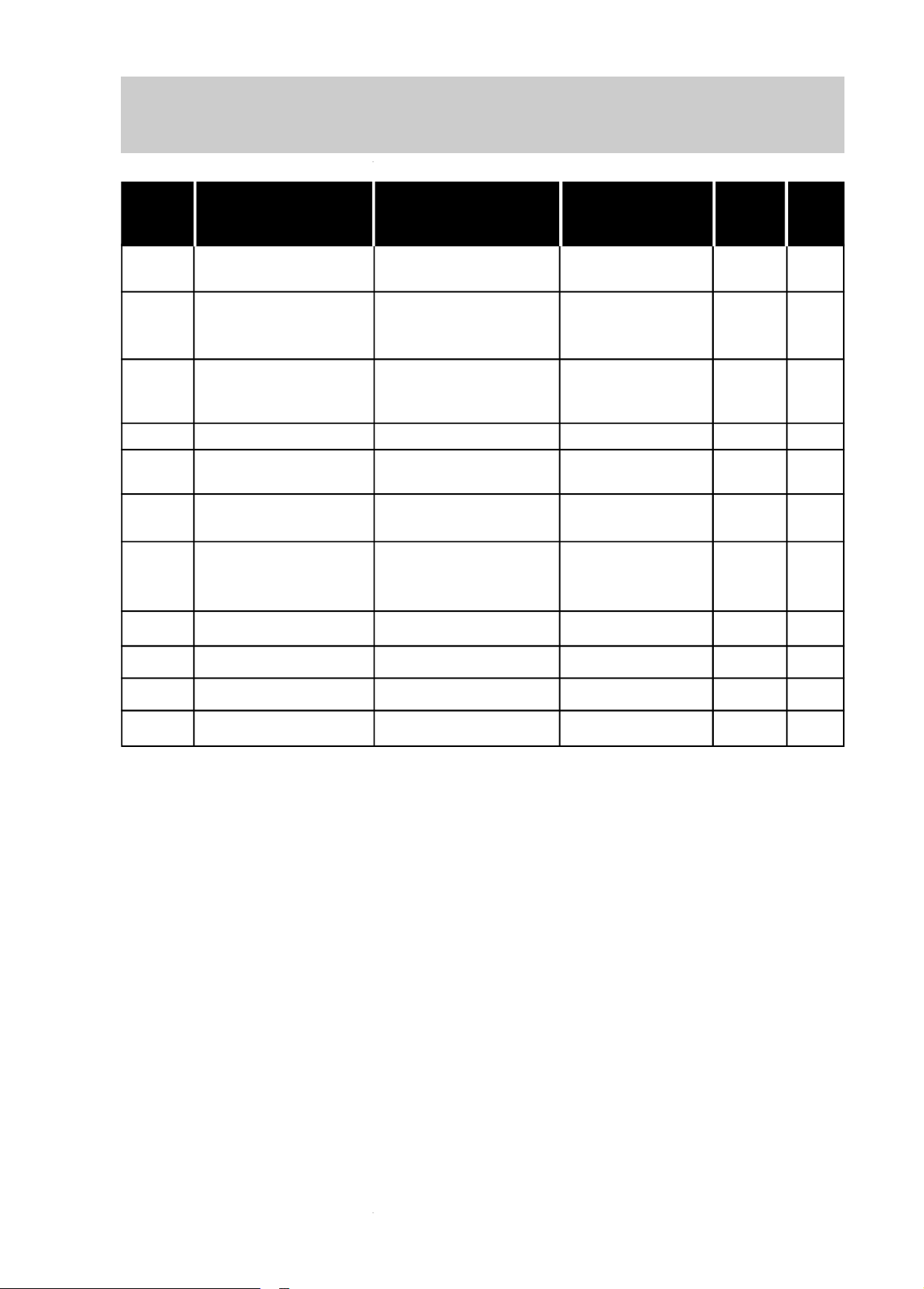

1. Parameters

Para- Function Adjustable Factory User's Page

meter Range Setting Setting

P00

P01

P02

P03

P04

P11

P12

P13

P14

Permits parameter

changing

Regulation Parameter

Initial Voltage

Acceleration ramp

time

Voltage ramp during

deceleration

Ramp time during

deceleration

Current limit during

starting

Immediate over

current

Immediate over

current time

Immediate

undercurrent

OFF, ON

25...90% UN

1...240 s

100... 40%UN

OFF,2...240s

OFF, 150...500%IN

32...200%IN

OFF, 1...20s

20...190%IN

OFF

30%UN

20s

100%UN

OFF

OFF

120%IN

OFF

70%IN

52

52

53

53

54

54

56

58

57

P15

P21

P25

P26

P27

Immediate

undercurrent time

Motor Parameter

Motor current setting

Overload class

Service factor

Auto-reset of the

thermal memory

OFF, 1...30s

OFF, 30.0...200.00%IN

5, 10, 15, 20, 25, 30

0.80...1.50

OFF, 1...600s

OFF

OFF

30

1.00

OFF

58

72

73

78

78

9

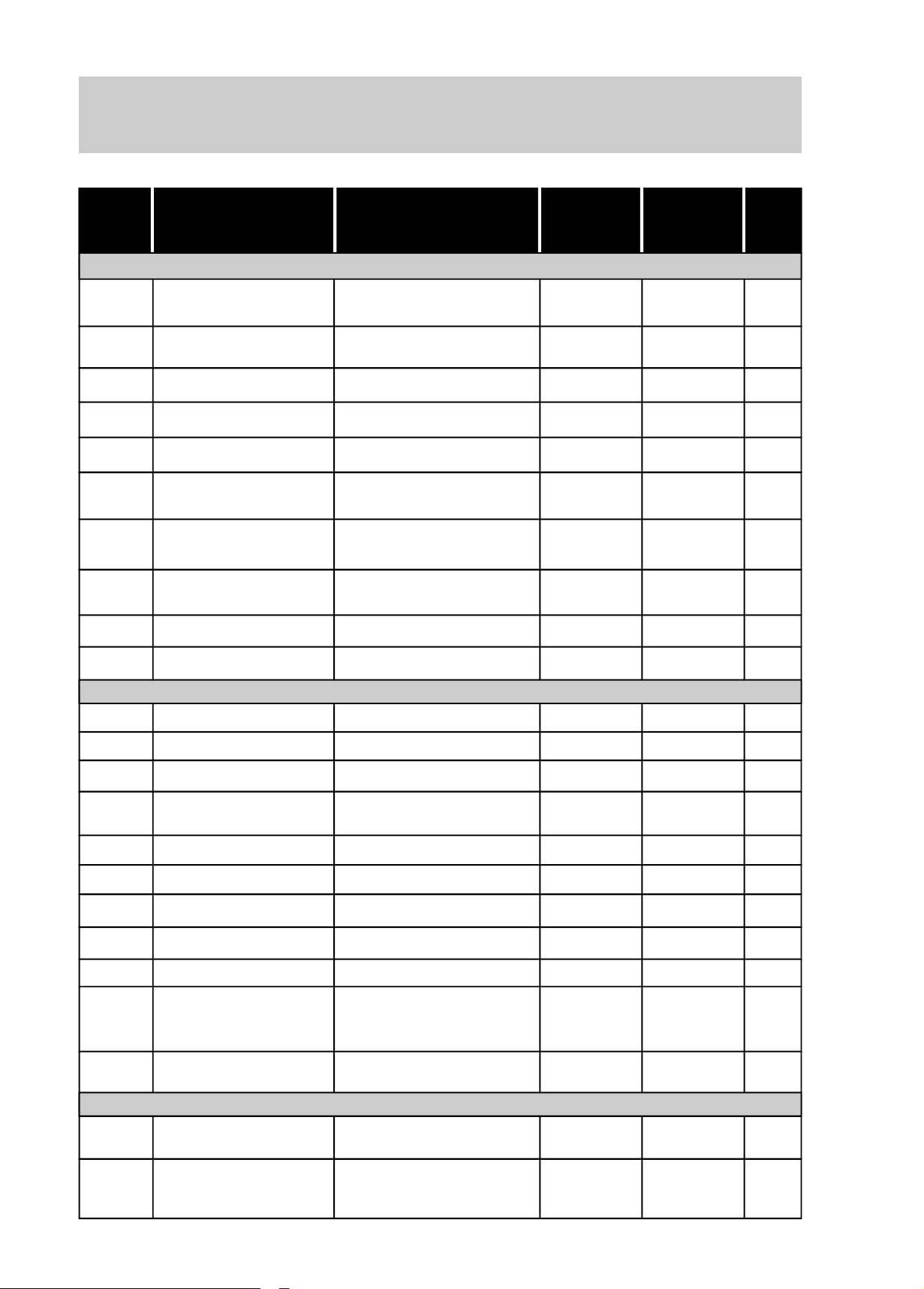

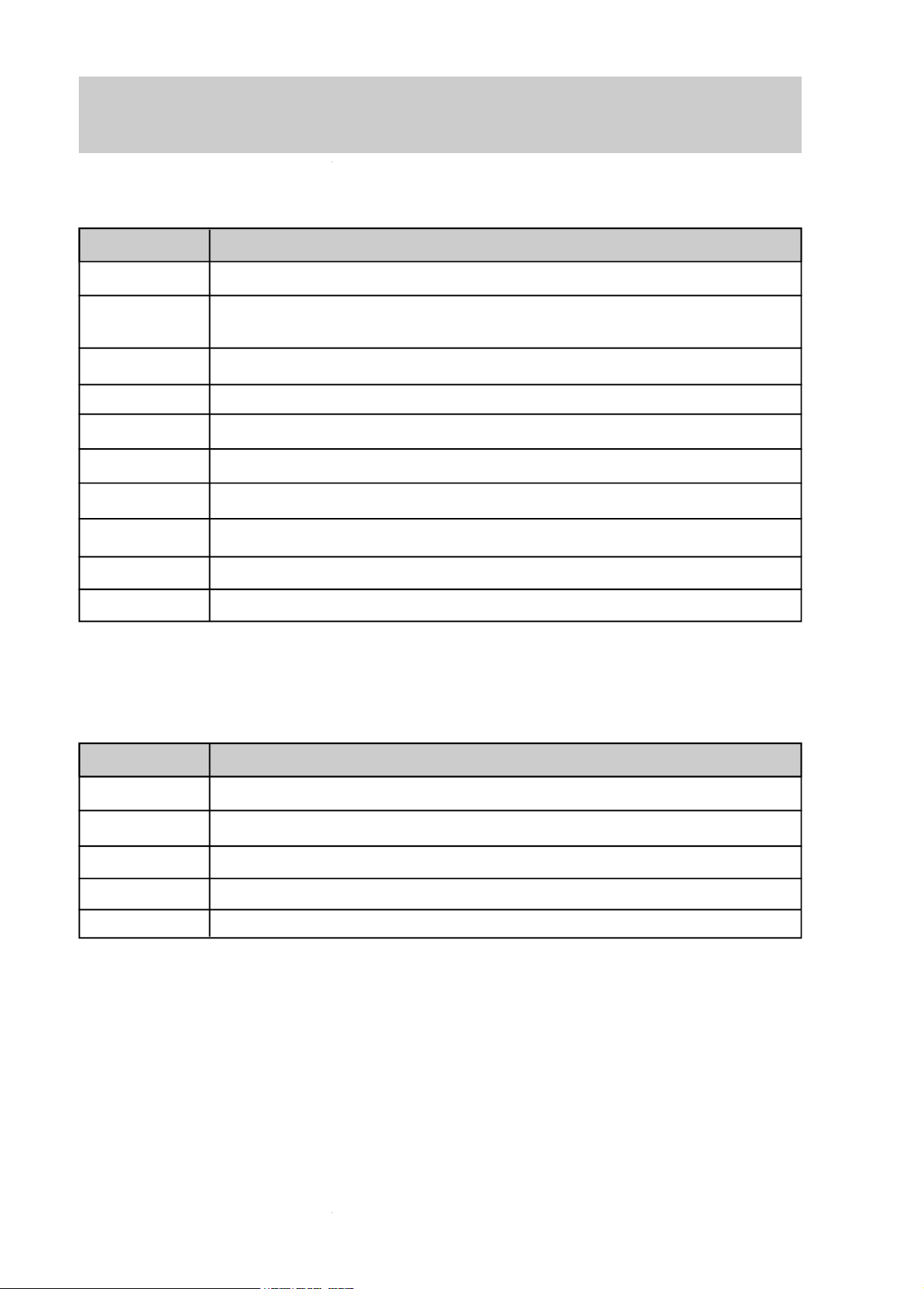

QUICK PARAMETER REFERENCES,

ERROR MESSAGES AND STATUS MESSAGES

Para- Function Adjustable Factory User's Page

meter Range Setting Setting

Regulation Parameter

P22

P23

P31

Rated current

Rated mains voltage

Phase rotation

16, 30, 45, 60, 85A

220, 230, 240, 380, 400, 415,

440, 460, 480, 525, 575V

OFF, ON

According to

the Model

380V

OFF

58

59

59

P33

P34

P35

P41

P42

P45

P47

P43

P44

P46

P50

P51

Voltage jog level

DC braking time

DC braking voltage

level

Voltage pulse at start

(kick start)

Voltage pulse level

during starting

Pump control

Errors auto-reset

Configuration Parameter

By-Pass relay

Energy save

Default values

Programming of the

Relay RL3

Function of the RL1 relay

25...50%UN

OFF, 1...10s

30...50%UN

OFF; 0.2...2s

70...90%UN

OFF, ON

OFF, 10...600s

OFF, ON

OFF, ON

1- disables with fault

2- enables with fault

1, 2, 3

25%UN

OFF

30%UN

OFF

70%UN

OFF

OFF

OFF

OFF

OFFOFF, ON

1

1

59

60

60

60

61

61

63

64

64

65

65

66

P52

P53

P54

P55

P61

P62

P71

P72

10

Function of the RL2 relay 1, 2, 3

Digital input 2 program OFF, 1...4

Digital input 3 program OFF, 1...4

Digital input 4 program OFF, 1...4

Set the command

through HMI/Serial or

digital inputs

Soft-Starter address in

the comunication NET

Reading Parameters

Switch Software version

Indication of the %IN

motor current of the

switch

OFF, ON

1...30

XXX %IN

2

1

2

OFF

ON

1

67

68

69

69

70

71

51

51

QUICK PARAMETER REFERENCES,

ERROR MESSAGES AND STATUS MESSAGES

Para- Function Adjustable Factory User's Page

meter Range Setting Setting

P73

P74

P75

P76

P77

P81

P82

P96

P97

P98

Motor current indication (A)

Active power indication

supplied to the load

(KW)

Apparent power indication supplied to the

load (KVA)

Load power factor

Soft-Starter output

voltage indication % UN

Heatsink Temperature

(ºC)

Indication of motor

Thermal Protection

Status

Last hardware error

Second hardware error

Third hardware error

0.0...999.9A

0.0...999.9kW

0.0...999.9kVA

0.00...0.99

0...100% UN

10...110ºC

0...250%

1...8

1...8

1...8

51

51

51

51

51

51

51

52

52

52

P99

Fourth hardware error

1...8

52

11

QUICK PARAMETER REFERENCES,

ERROR MESSAGES AND STATUS MESSAGES

2. Error Messages

Display

E01

E02

E03

E04

E05

E06

E07

E08

E24

E2X

Meaning

Phase failure or thyristor fault or motor not connected

At the end of time of the programmed acceleration time, the voltage does

not reach 100% UN due to the current limit.

Overtemperature at the thyristors and in the heatsink

Motor overload

Undercurrent (applicable to pumps)

Immediate overcurrent

Phase rotation

External fault

Programming error

Serial communication error

3. Soft-Starter Status

Display

rdy

PuP

EEP

On

OFF

Soft-Starter is ready to be enabled

Loading pump control parameters

Loading "Default" values

Function enabled

Function disabled

Definition

12

1

SAFETY NOTICE

This Manual contains all necessary information for the correct installation and operation

of the SSW-04 Soft-Starter.

This Manual has been written for qualified personnel with suitable training or technical

qualifications to operate this type of equipment.

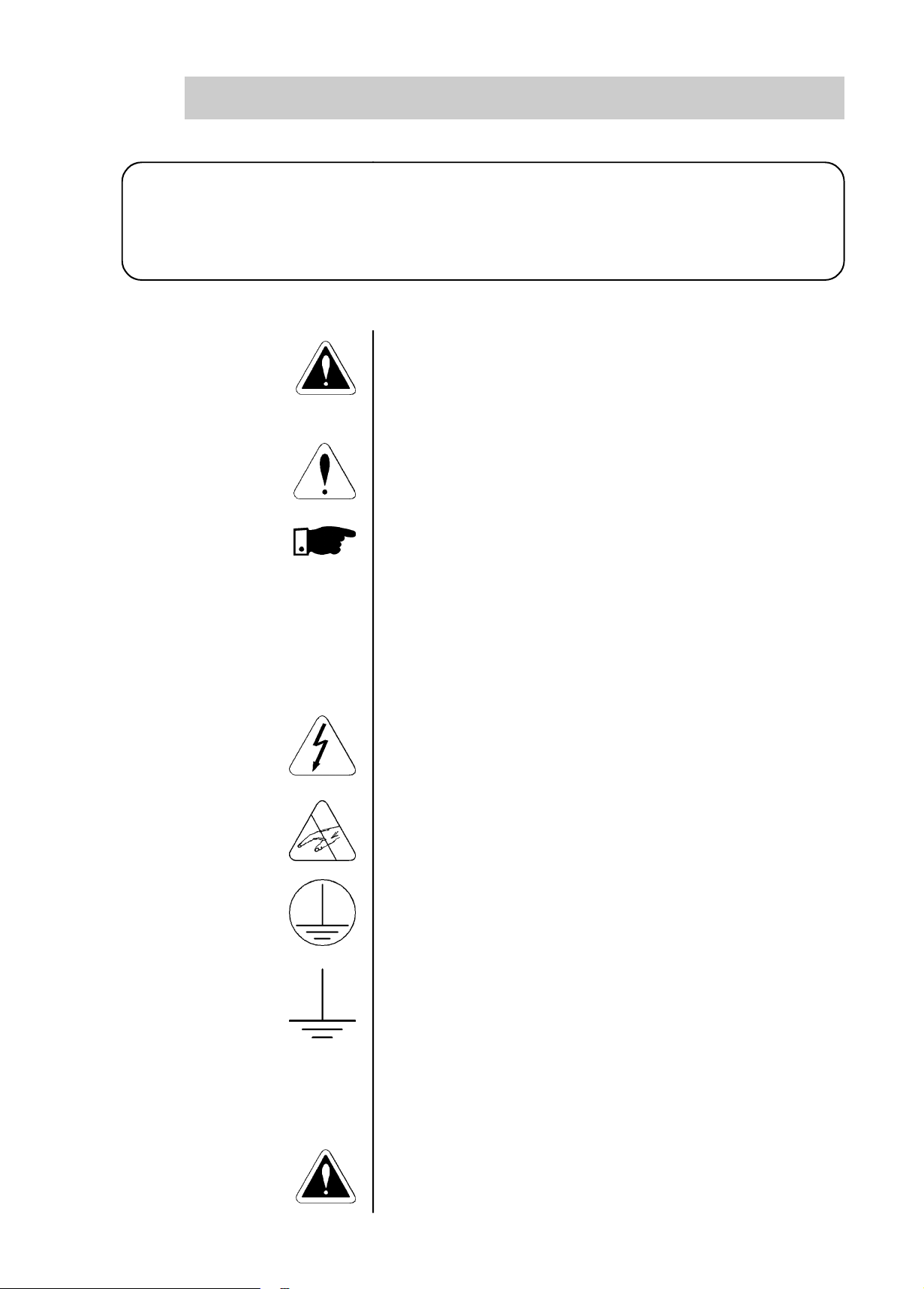

1.1 SAFETY NOTICES IN THE MANUAL

1.2 SAFETY NOTICES ON THE PRODUCT

The following Safety Notices will be used in this Manual:

DANGER!

If the recommended Safety Instructions are not strictly

observed, it can lead to serious or fatal injuries of personnel

and/or equipment damage.

ATTENTION!

Failure to observe the recommended Safety Procedures can

lead to material damage.

NOTE!

The content of this Manual supplies important information

for the correct understanding of operation and proper

performance of the equipment.

The followingsymbols maybe attachedto the product,serving

as Safety Notice:

High Voltages

1.3 PRELIMINARY RECOMMENDATIONS

Components are sensitive to electrostatic discharge. Do not

touch them without following proper grounding procedures.

Mandatory connection to ground protection (PE)

Shield connection to ground

DANGER!

Onlyqualifiedpersonnelshouldplanorimplement theinstallation,

startup, operation and maintenance of this equipment.

13

1

SAFETY NOTICE

Personnel must review this entire Manual before attempting

to install, operate or troubleshoot the SSW-04. These personnel

mustfollow all safety instructions included in this Manual and/

or defined by local regulations.

Failure to comply with these instructions may result in

personnel injury and/or equipment damage.

NOTE!

In this Manual, qualified personnel are defined as peoplethat

are trained to:

1. Install, ground, power up and operate the SSW-04

according to this manual and the local required safety

procedures;

2. Use of safetyequipment according tothelocalregulations;

3. Administer Cardio Pulmonary Resuscitation (CPR) and

First Aid.

DANGER!

Always disconnect the supply voltage before touching any

electrical component inside the Soft-Starter.

Many components are charged with high voltages, even after

the incoming AC power supply has been disconnected or

switched OFF. Wait at least 3 minutes for the total discharge

of the power capacitors.

Always connect the frame of the equipment to the ground

(PE) at the suitable connection point.

ATTENTION!

All electronic boards have components that are sensitive to

electrostatic discharges. Never touch any of the electrical

components or connectors without following proper

grounding procedures. If necessary to do so, touch the

properly grounded metallic frame or use a suitable ground

strap.

Do not apply High Voltage (High Pot) Test on the Soft-Starter!

If this test is necessary, contact the Manufacturer.

14

NOTE!

Read this entire Manual carefully and completely before

installing or operating the SSW-04.

2

INTRODUCTION

2.1 - ABOUT THIS MANUAL

This Manual describes how to install, start-up, operate and

identify the problems of the SSW-04 Soft-Starters series.

Should you require any training or further info, please contact

WEG.

This Manual is divided into 9 Chapters, providing information

to the user on how to receive, install, start-up and operate

the SSW-04:

Chapter 1- Safety Notices;

Chapter 2 - Introduction;

Chapter 3 - Installation;

Chapter 4 - Power-up / Commissioning;

Chapter 5 - Use of the HMI;

Chapter 6 - Detailed Parameter Description;

Chapter 7 - Maintenance;

Chapter 8 - Technical Characteristics;

Chapter 9 - Appendix.

This Manual provides information for the correct use of the

SSW-04. The SSW-04 is very flexible and allows for the

operation in many different modes as described in this manual.

2.2 VERSION OF

SOFTWARE

As the SSW-04 can be applied in several ways, it is impossible

to describe here all of the application possibilities. WEG does

not accept any responsibility when the SSW-04 is not used

according to this Manual.

No part of this Manual may be reproduced in any form,

without the written permission of WEG.

It is important to note the Software Version installed in the

Version SSW-04, since it defines the functions and the

programming parameters of the Soft-Starter.

This Manual refers to the Software version indicated on the

inside cover. For example, the Version 1.XX applies to versions

1.00 to 1.99, where “X” is a variable that will change due to

minor software revisions. The operation of the SSW-04 with

these software revisions are still covered by this version of

the Manual.

The Software Version can be read in the Parameter P71.

15

2

INTRODUCTION

2.3 - ABBREVIATIONS USED

2.4 - ABOUT THE SSW-04

HMI - Human machine interface (keypad + display)

HMI-3P - Keypad + Display interface - Linked via parallel

cable

RLX - Relay output No X

DIX - Digital input No X

IN - Soft-Starter nominal output current

UN - Rated mains voltage

LED - Light Emitting Diode

The SSW-04 series is a totally microprocessor controlled SoftStarter series which controls the starting current of threephase induction motors. In this way mechanical inmpacts on

the load and current peaks on the supply network are

prevented.

2.4.1 - Introduction

This series includes models from 16 to 85A, being supplied

from 220V, 230V, 240V, 380V, 400V, 415V, 440V, 460V, 480V,

525V or 575V. (The available types are listed in Section 8).

The models up to 45A are with natural cooling and isolated

heatsink (thyristor-thyristor modules). The models from 60A

and 85A have forced cooling and isolated heatsink (ThyristorThyristor Modules).

The electronic control circuit uses a 16 bit microprocessor with

high performance, allowing settings and displaying by means

of the interface (keypad + display) of all needed parameters.

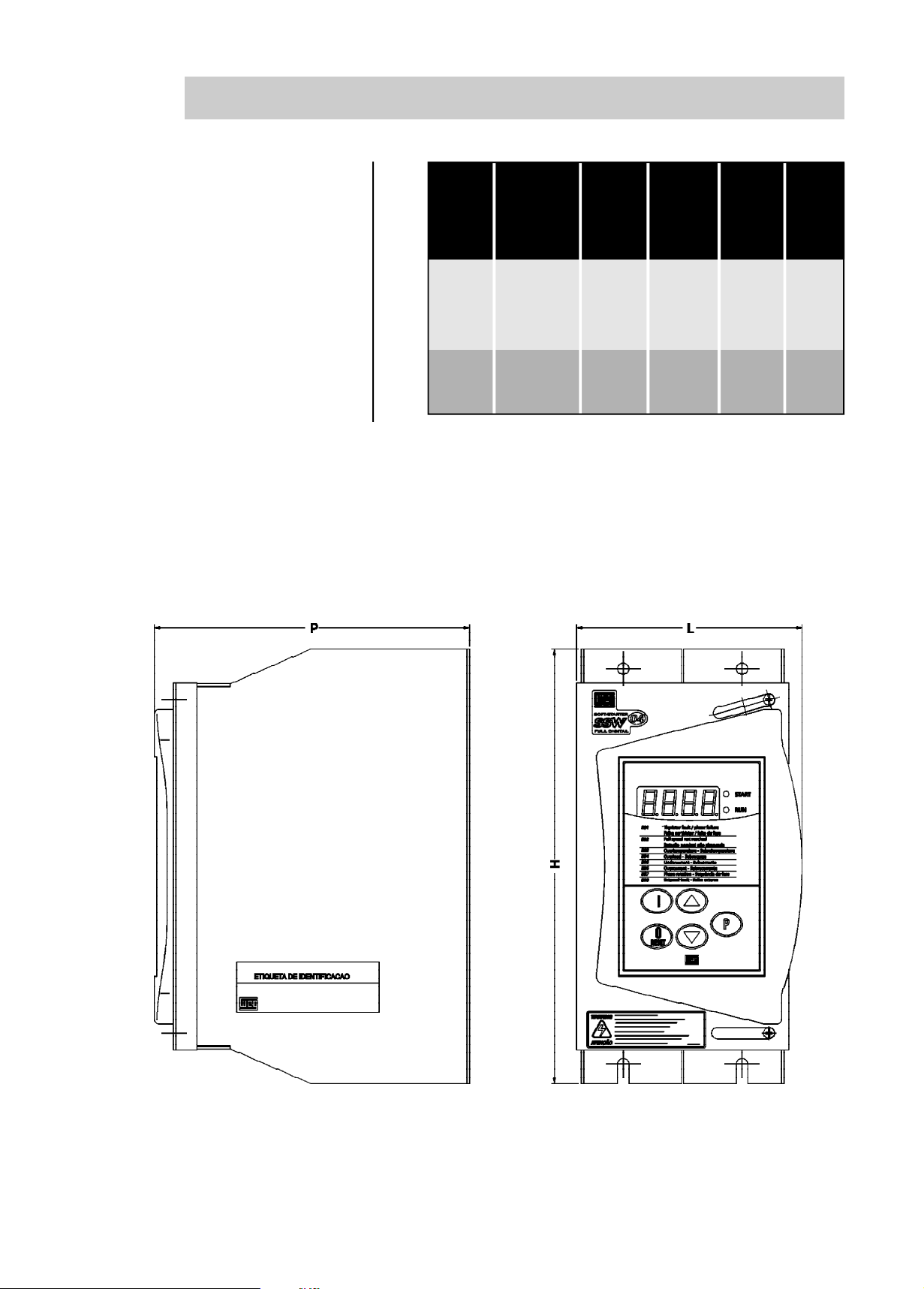

Depending on the power, this series (SSW-04) has 2 different

construction forms, as shown in Figure 2.1.

16

2

INTRODUCTION

Width Depth Height

MEC Rated L P H Weight

Current mm mm mm kg

(in) (in) (in) (lb)

16A

1 30A 140 199 275 5.2

45A (5.51) (7.83) (10.83) (11.46)

SIDE VIEW

2

60A 140 283 275 9.0

85A (5.51) (11.06) (10.83) (19.84)

FRONT VIEW

Figure 2.1 - Construction forms

17

2

INTRODUCTION

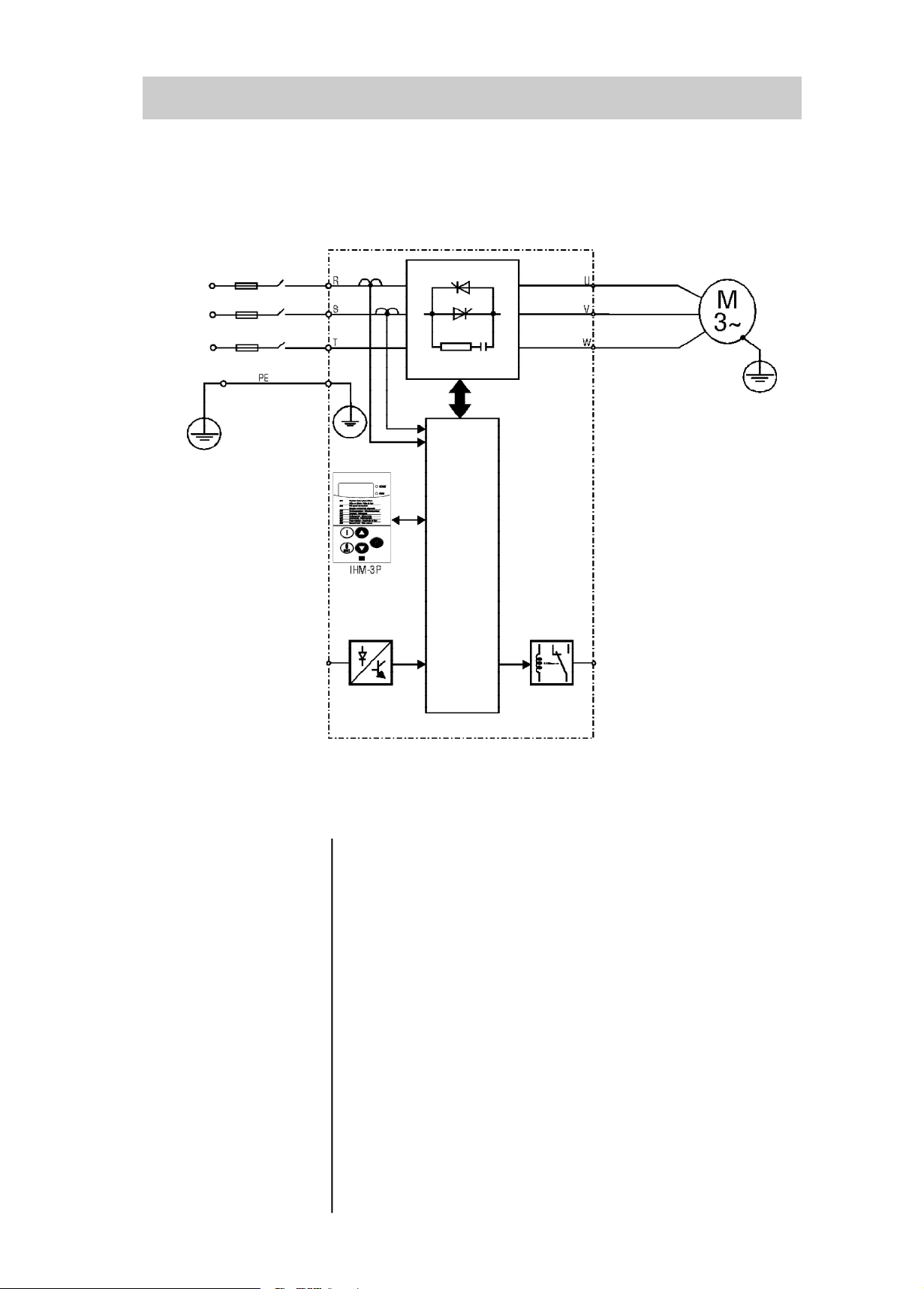

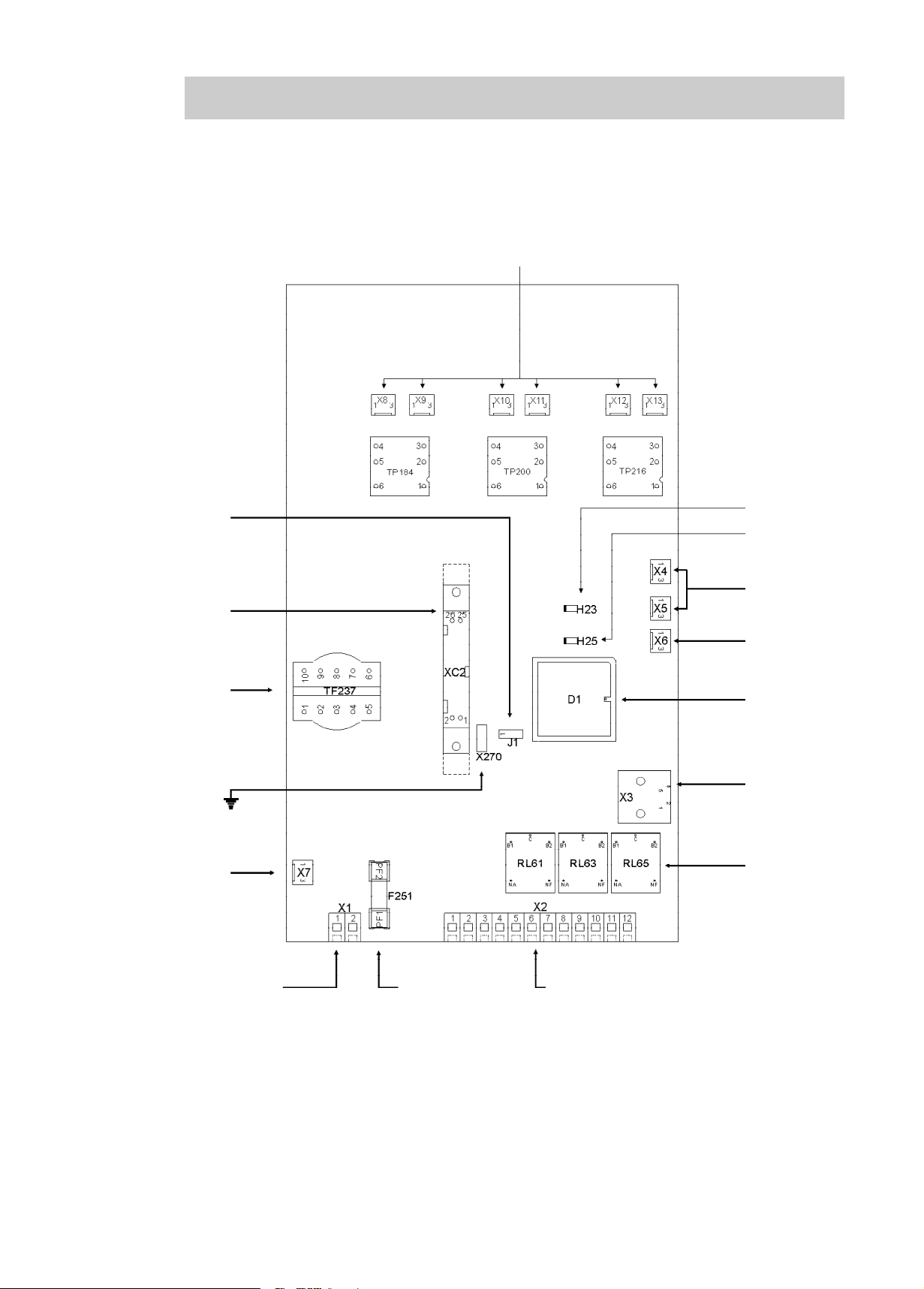

2.4.2 - Simplified Block Diagram of the SSW-04

CT

LINE

3~

DIGITAL

INPUT

CT

ELECTRONIC

CONTROL BOARD

CCS4.0X

RELAY OUTPUT

RL1, RL2,RL3

Figure 2.2 - Simplified Block Diagram of the SSW-04

In the power stage, the line voltage is controlled by means of

6 SCR’s that allow the variation of the conduction angle of

the voltage supplied to the motor.

For the internal supply of the electronics, a switched source is

used with several voltages, fed independently of the power

supply.

The control board contains the circuits responsible for the

control, monitoring and protection of the power components.

This board also contains the control and signalling circuit to

be used by the user according to its application as a relay

output.

All parameters or controls for the operation of the Soft-Starter

can be displayed or changed through the HMI.

18

2

INTRODUCTION

2.4.3 - Description of the control board - CCS 4.00 or CCS 4.01

Firing connection of the thyristors

Communication

Selection

Connector for

HMI-3P

Supply

transformer

Connection

ground

Internal fan

connector

Power on LED

Fault LED

Current

transformers Input

Heatsink Thermistor Input

Microcontroller

with software

version label

Input for serial

RS232

Relays

Supply and fan connector

Figure. 2.3 - Layout of the electronic control board CCS 4.00 or CCS4.01

Supply Fuse

User Connector

19

2

INTRODUCTION

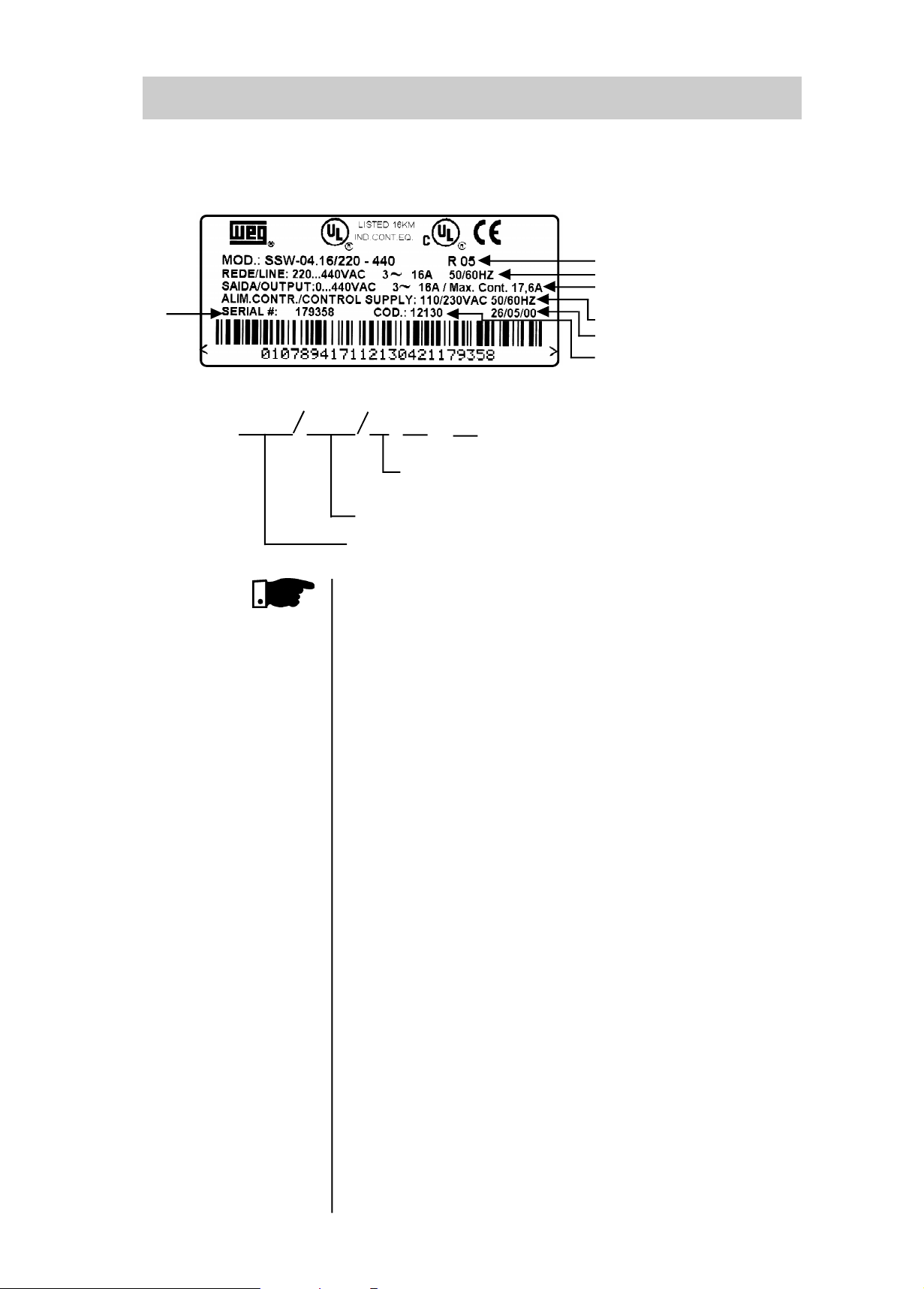

2.5 - PRODUCT

IDENTIFICATION

SERIAL NUMBER

SOFT-STARTER MODEL

INPUT DATA

OUTPUTDATA/MAXIMUM CURRENT RATINGFOR

CONTINUOUSDUTY

ELECTRONIC/FAN DATA

FABRICATION DATE

WEGITEM

Soft-Starter Type

SSW-04.

2.6 - RECEIVING

+

Voltage of the electronics

Three-phase supply voltage (220 - 440, 460 - 575).

Rated output current (A)

Max. Cont.: It's the maximum current that the Soft-Starter

can have in continuous duty. For this current the Soft-Starter

can only have 1 start per hour.

EXTERN HMI

HMI-3P.1: HMI with LEDs, 1 m (3.28ft) cable

HMI-3P.2: HMI with LEDs, 2 m (6.56ft) cable

HMI-3P.3: HMI with LEDs, 3 m (9.84ft) cable

The SSW-04 is supplied in cardboard boxes.

The outside of the packing container has a nameplate that is

the identical to that on the SSW-04. Please check if the SSW04 is the one you ordered.

Options : + I with remote HMI

1- 110/120 V

{

2- 220/230 V

20

Open the box, remove the foam and then remove the SSW-04.

SSW-04 nameplate data matches the purchase order;

The equipment has not been damaged during transport.

If any problem is detected, contact the carrier immediately.

If the SSW-04 is not to be installed immediately, store it in a

clean and dry room (Storage temperatures between - 25°C

and 60°C). Cover it to prevent dust, dirt or other contamination

of the drive.

3

INSTALLATION

3.1 - MECHANICAL INSTALLATION

3.1.1 - Environment

The location of the SSW-04 installation is a determinaning

factor for obtaining a good performance and a normal useful

life of its components.

Regarding the installation of the Soft-Starter we make the

following recommendations:

Avoid directexposureto sunlight, rain, high moistureandsea air.

Avoid exposure to gases or explosive or corrosive liquids;

Avoid exposure to excessive vibration, dust, oil or any

(conductive particles or materials).

Environmental Conditions:

Temperature: 32...104º F (0 ... 40º C) - nominal conditions.

104...131º F (40 ... 55º C) - see table 8.2.

Relative Air Humidity: 5% to 90%, non-condensing.

Maximum Altitude: 3,300 ft(1000m) - nominal conditions.

3,300 ... 13,200 ft (1000 ... 4000m) - with 10% current

reduction for each 3,300 ft (1000m) above 3,300 ft(1000m).

Pollution Degree: 2 (according to EN50178 and UL508)

(It is not allowed to have water,

condensation or conductive dust/

particles in the air)

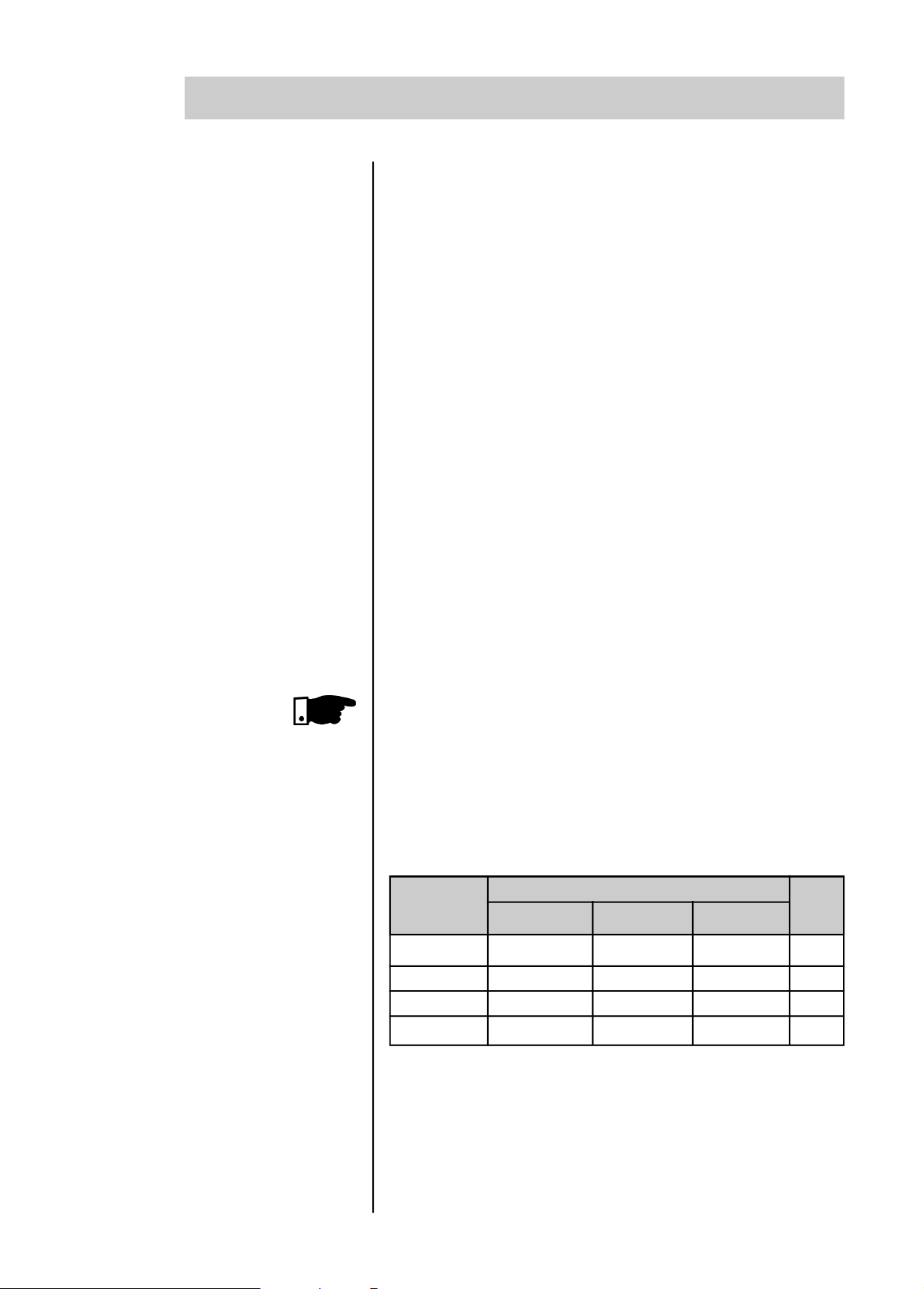

NOTE!

When Soft-Starter is installed in panels or closed metallic boxes, adequate cooling is required to ensure that the

temperature around the Soft-Starter will not exceed the

maximum allowed temperature. See Dissipated Power in

Section 8.2.

Please meet the minimum recommended panel dimensions

and its cooling requirements:

SSW-04 PanelDimensions Blower

type Width Height Depth CFM

16A 600 (23.62) 1000 (39.37) 400 (15.75) 30A 600 (23.62) 1200 (47.24) 400 (15.75) -

45A and 60A 600 (23.62) 1200 (47.24) 400 (15.75) 226

85A 600 (23.62) 1500 (59.05) 400 (15.75) 226

All dimensions in mm (inches)

21

3

INSTALLATION

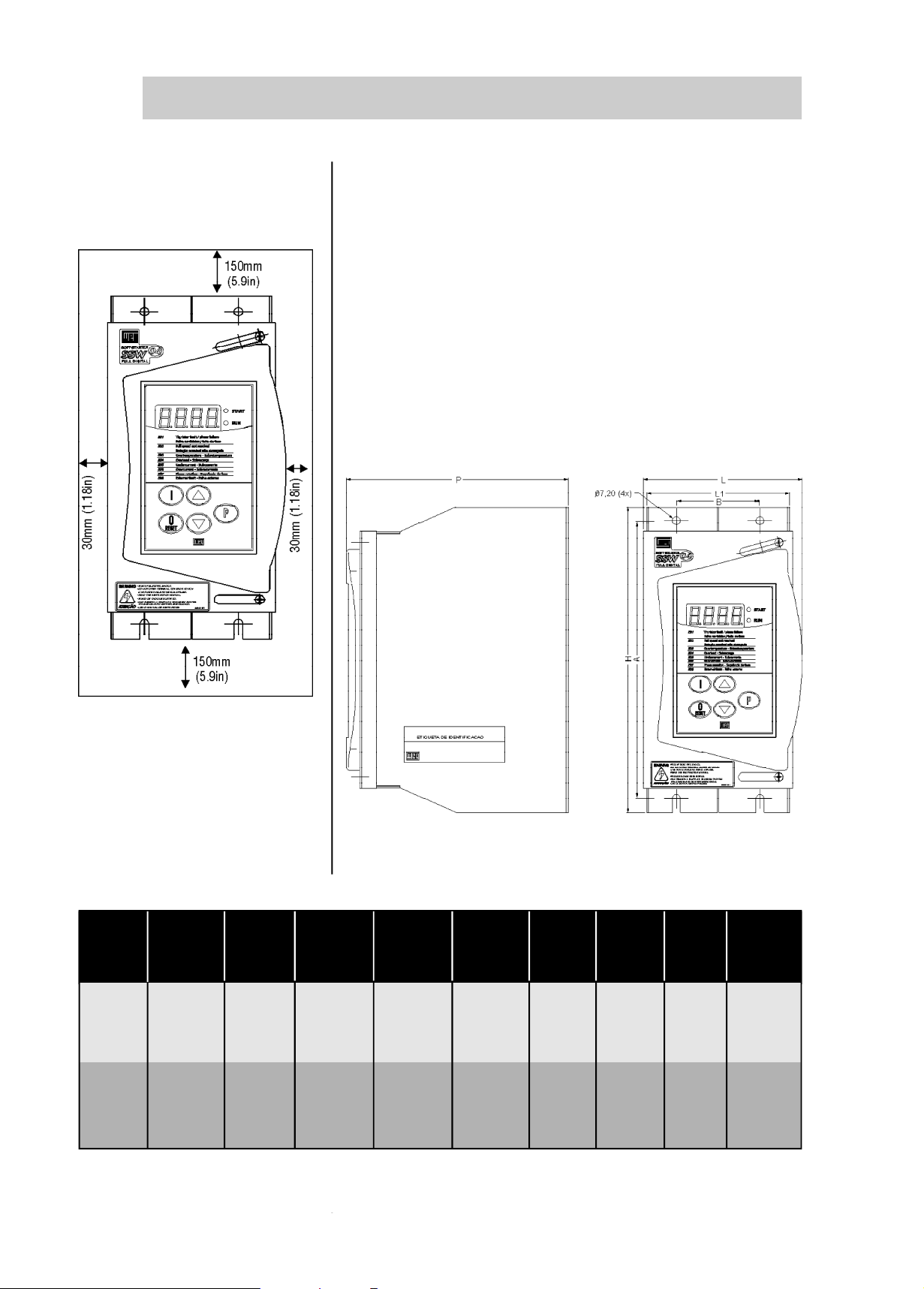

3.1.2 - Location /

Mounting

Install the Soft-Starter in Vertical Position:

Allow for free space around the SSW-04, as shown in Fig.

3.1.

Install the Soft-Starter on a flat surface.

External dimensions, fastenings drillings, etc. according to

Figure 3.2.

First install and partially tighten the mounting bolts, then

install the Soft-Starter and tighten the mounting bolts.

Provide independent conduits for physical separation for

signal conductors, control and power conductors (See

Electrical Installation).

Figure 3.1 - Free space for

ventilation

Figure 3.2 -

Type Width Width Height Depth Fasten. Fasten. Fasten Weight Degree

L1 L H P A B bolt kg Protect.

mm (in) mm (in) mm (in) mm (in) mm (in) mm (in) (lb)

128 140 275 199 250 75 (1/4") 5.2 IP20

16...45A (5.0) (5.51) (10.83) (7.83) (9.84) (2.95) M6 (11.46)

60A and 128 140 275 283 250 75 (1/4") 9.0 IP20

85A (5.0) (5.51) (10.83) (11.06) (9.84) (2.95) M6 (19.84)

External dimensions for the SSW-04 and its

screwing drillings

22

3

INSTALLATION

3.2 - ELECTRICAL INSTALLATION

3.2.1 - POWER/

GROUNDING

CONNECTIONS

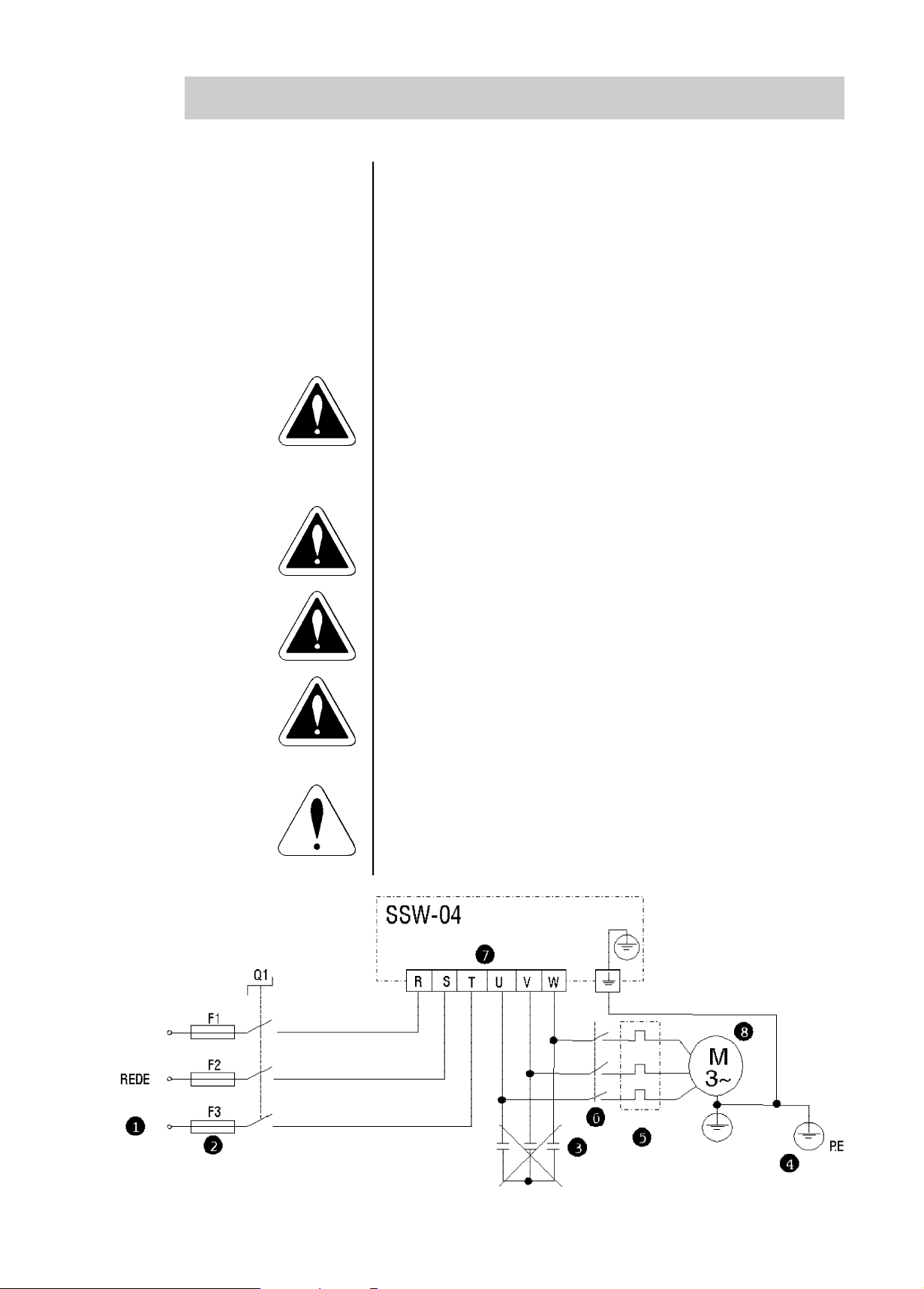

DANGER!

AC input disconnect: providean AC input disconnectingswitch

to switch OFF input power to the Soft-Starter.

This device shall disconnect the Soft-Starter from the AC input

supply when required (e.g. during maintenance services).

DANGER!

The AC input disconnect cannot be used as an emergency

stop device.

DANGER!

Be sure that the AC input power is disconnected before

making any terminal connection.

DANGER!

The information below will be a guide to achieve a proper

installation. Follow also all applicable local standards for

electrical installations.

ATTENTION!

Provide at least 10 in (0.25m) spacing between low voltage

wiring and the Soft-Starter, line or load reactors, AC input

power, and AC motor cables.

Figure 3.3 -

Power and Grounding Connections

23

3

INSTALLATION

The line voltage must be compatible with the rated voltage

of the Soft-Starter.

For installation use the cable cross sections and the fuses

recommended in Table 3.1, maximum torque as indicated in

table 3.2

Power factor correction capacitors most never be installed

on the Soft-Starter output.

The Soft-Starters must be grounded. For this purpose use

a cable with a cross section as indicated in Table 3.1.

Connect it to a specific grounding bar or to the general

grounding point (resistance 10 ohms).

Do not share the grounding wiring with other equipment

which operate at high currents (for instance, high voltage

motors, welding machines, etc.).

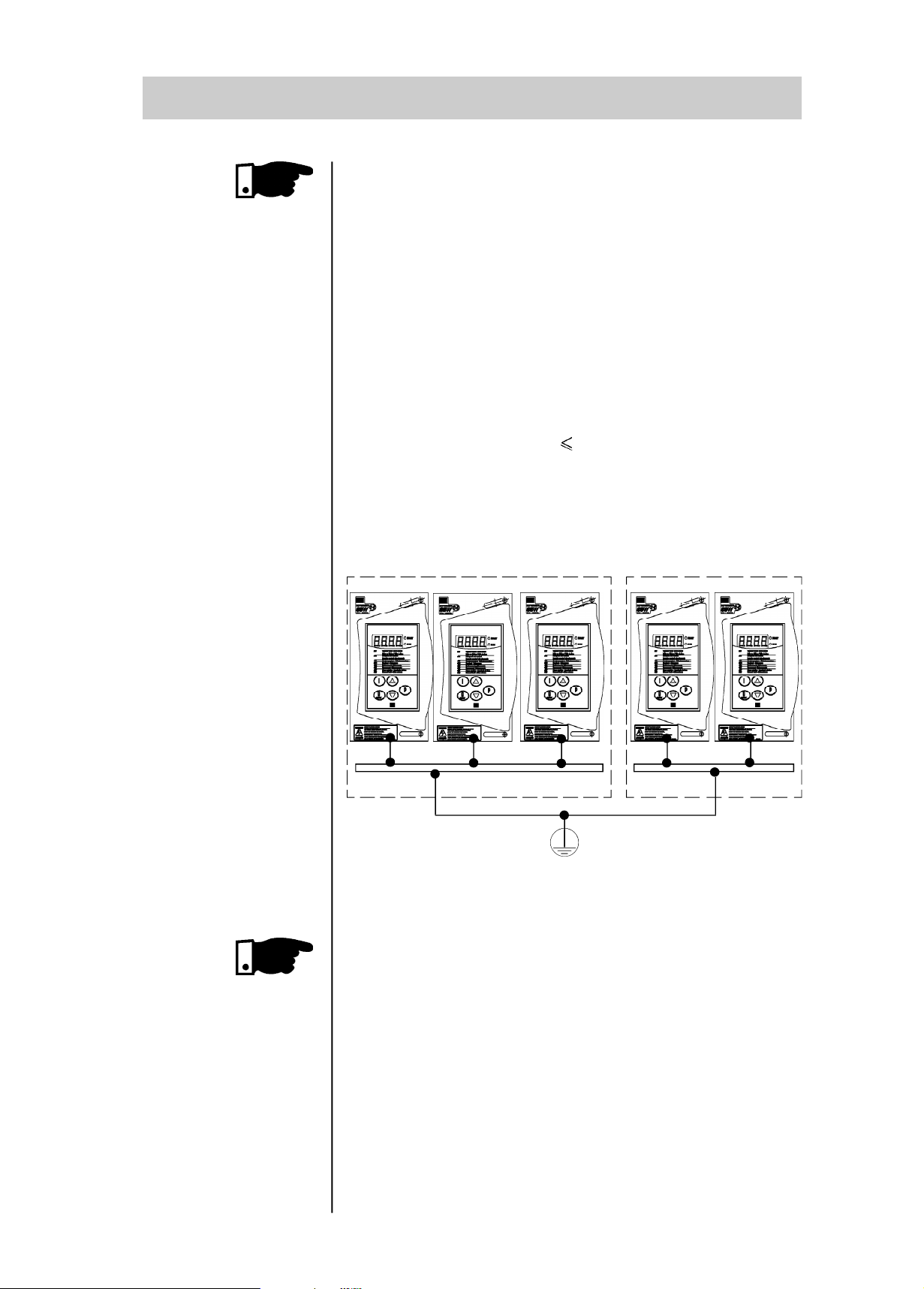

If several Soft-Starters are used together, see Figure 3.4.

SSW-04 I SSW-04 IISSW-04 I SSW-04 II SSW-04 n

Grounding bar intern to the panel

Figure 3.4 -

Do not use the neutral conductor for grounding purpose.

The Soft-Starter is fitted with electronic protection

against motor overloads. This protection must be set

according to the specific motor.

When several motors are connected to the same SoftStarter, use individual overload relays for each motor.

Grounding connection for more than one

Soft-Starter

24

If a isolating switch or a contactor is inserted in the motor supply, do not operate them with running motor or

when the Soft-Starter is enabled.

3

INSTALLATION

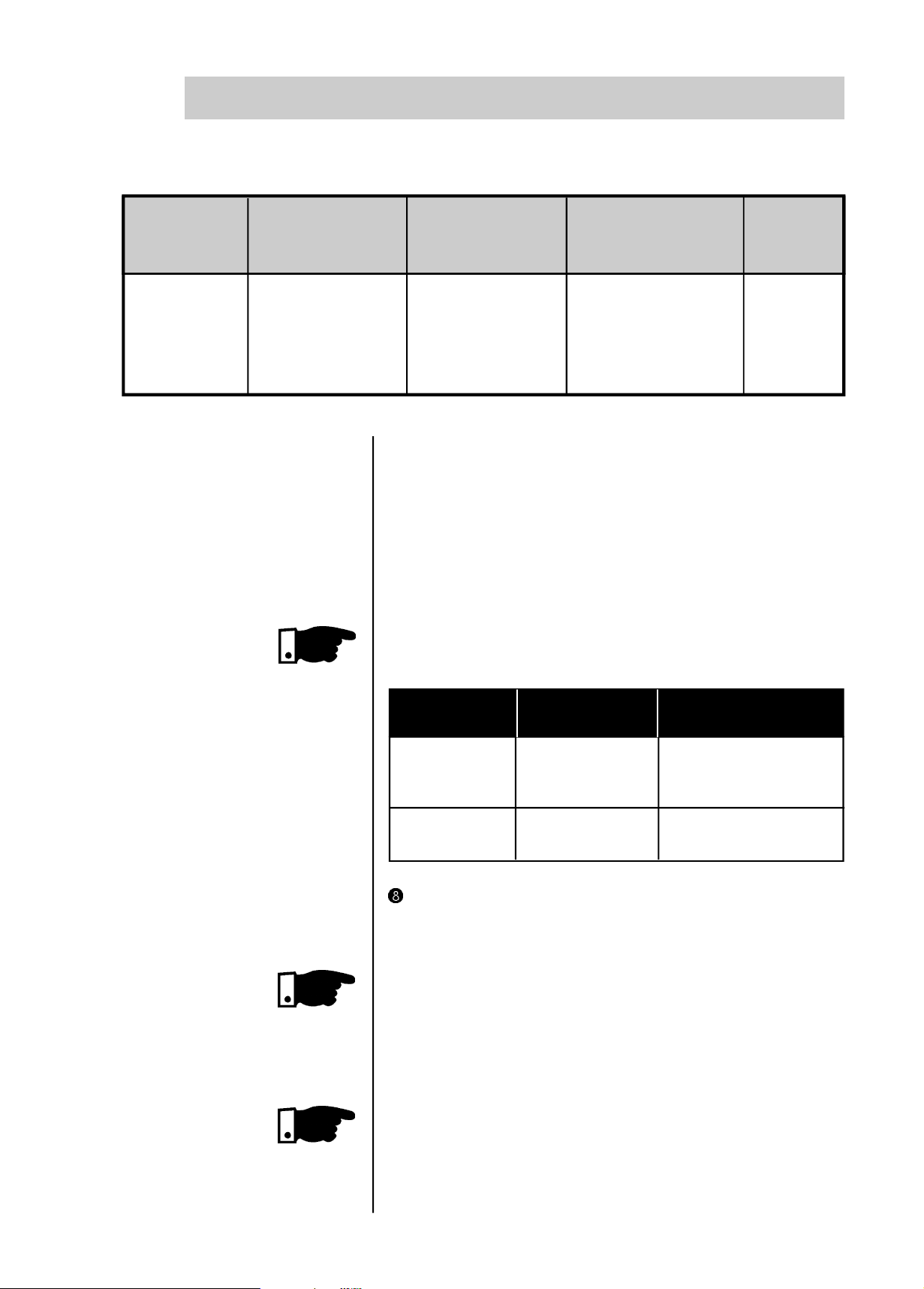

Table 3.1 - Recommended Cables/Fuses - Use 75ºC Copper Wire Only

Rated Power Grounding Ultra fast acting I2t of

current of Wiring Wiring Fuse for SCR's SCR

the SSW-04 mm² (AWG) mm² (AWG) protection (A²s)

16A

30A

45A

60A

85A

2.5mm2(12)

6mm2(8)

8mm2(8)

16mm2(4)

25mm2(3)

6mm2(8)

6mm2(8)

6mm2(8)

8mm2(8)

10mm2(6)

The cross sections indicated in Table 3.1 are orientative values

only. For correct cables dimensioning consider the installation

condition and the maximum allowable voltage drop.

The recommended fuse connected at the input side must be

a ultra rapid type (UR) with I2t smaller than 75% of the value

indicated in Table 3.1 (I2t of the SCR).

When a short circuit occurs the ultra rapid fuse protects the

SCR.

Normal fuses can also be used, in that case the installation is

protected against short circuit, but the SCR isn't protected.

Recommended torque on the power terminals:

Table 3.2 - Maximum torque

Soft-Starter

Type

Grounding wiring

Nm(Lb.in)

50A

80A

125A

160A

200A

1,150

8,000

15,000

15,000

125,000

Power wiring

Nm(Lb.in)

16A

30A

45A

60A

85A

It is Recommended to use motors with load above 30%

rated motor load.

1.2 - 1.4

(10.6-12.3)

5.0

(43.9)

1.2 - 1.4

(10.6 - 12.3)

2.5 - 3.0

(21.8 - 26.1)

NOTE!

The rated motor current shall not be less than 30% of the softstarter rated current, in order that the overload protection

works properly.

The SSW-04 is suitablefor use on a circuit capable of delivering

not more than X Arms (see below) symmetrical amperes, Y

volts maximum, when protected by Ultra-fast Semiconductor

Fuses.

25

3

INSTALLATION

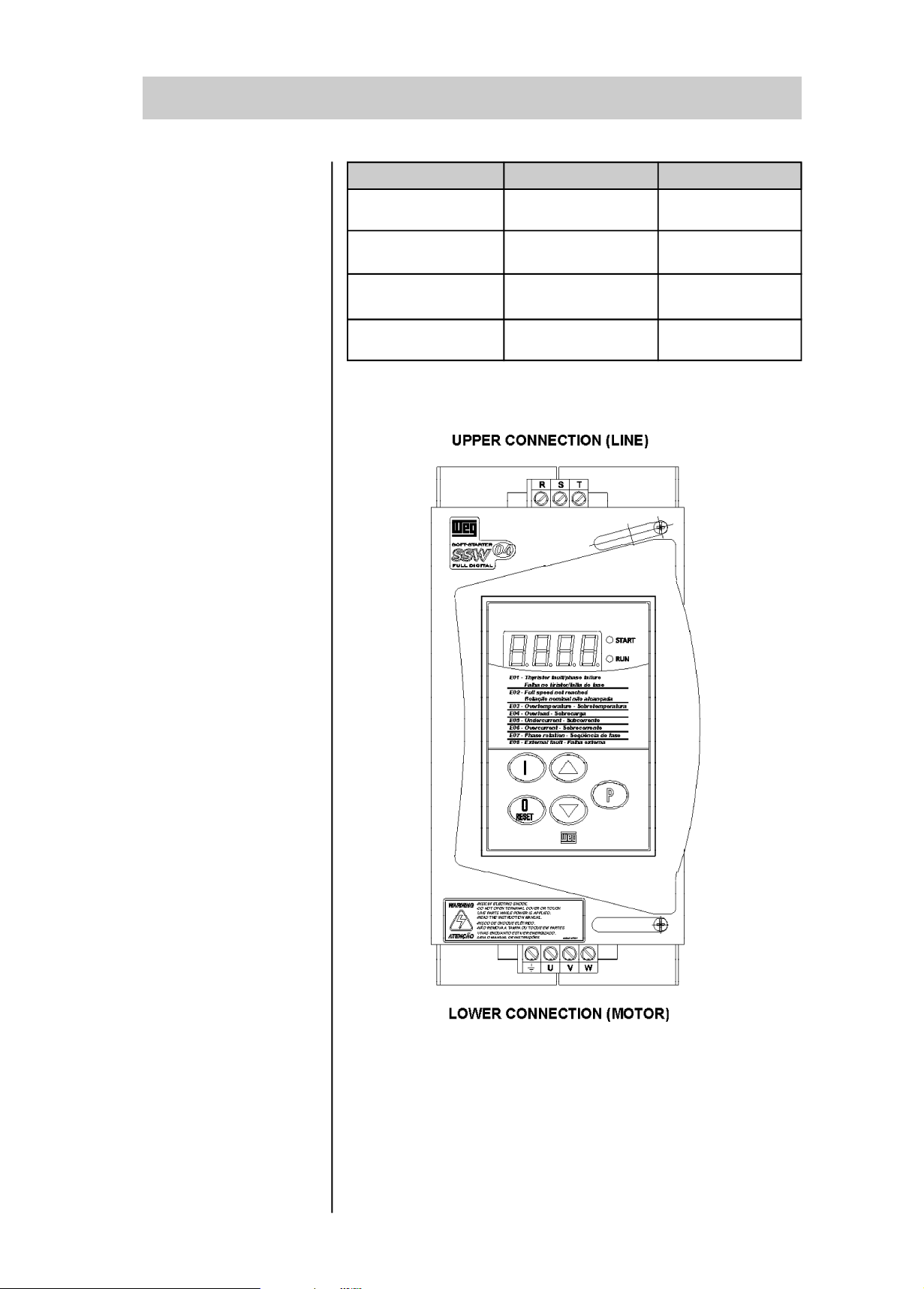

3.2.2 - Location of the

power/

grounding/fans

connection

Type

16 - 45A

460 - 575V

60 - 85A

460 - 575V

16 - 60A

220 - 440V

85A

220 - 440V

X Y

5,000

10,000

5,000

10,000

575

575

440

440

26

Figure 3.5- Location of the power/grounding connection

3

INSTALLATION

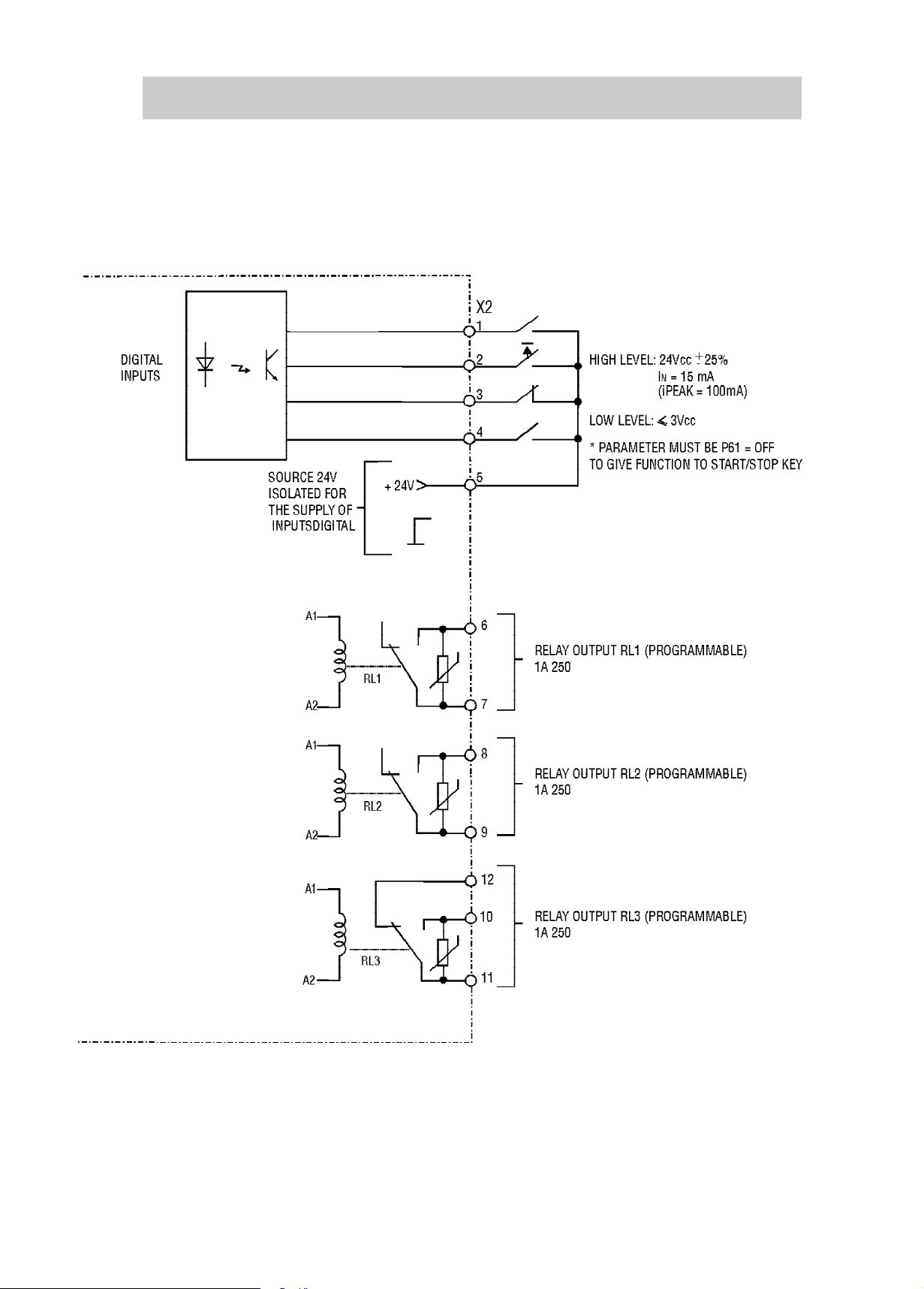

3.2.3 - Signal and

Control

Connections

The signal (digital inputs/outputs by relay) are performed

through the following connectors of the Control Board

CCS4.0X (see location in Figure 2.3).

X2 : Digital input and output by relay

X1 : Electronics and Fan supply

XC2 : connection to HMI-3P

X3 : connection to serial communication

NOTE!

Soft-starters types 60A and 85A the fan current pass also

through the connector X1. Thus the total current is:

274.5mA for 110Vac or 140mA for 220Vac.

27

3

INSTALLATION

3.2.3.1 - Description of the X2 Connector

DI1

DI2

DI3

DI4

Vac

Vac

Vac

28

Figure 3.6 - Description of the X2 (CCS4.00 or CCS4.01 connector)

3

INSTALLATION

When installing the signal and control wiring, please note

the following:

Cable cross-section: 0.5...1.5mm2;

Relays, contactors, solenoid valves or breaking coils

installed near to Soft-Starters can generate interferences in

the control circuit. To eliminate this , you must install

RC supressors connected in parallel with the coils of these

devices, when fed by alternate current and free wheel

diodes when fed by direct current.

When an extern HMI is used, the connection cable to the

Soft-Starter should be passed through the slot at the bottom

of the Soft-Starter. This cable must be laid separate from the

other cables existing in the installation, maintaining a

distance of 100mm (3.94in) each other.

3.2.4 - FAN

CONNECTIONS

Max. recommended torque in the terminals X2 and X1:

Maximum 0.4 Nm or 3.5lb.in.

The control wiring (X2:1...5) must be laid separate from

the power wiring.

The fan connections must be done through X1:1 and X1:2

connector according to the voltage defined by the SoftStarter code:

Ex.: SSW-04. 60/220-440/

Electronic / fan voltage:

1 = 110Vac

2 = 220Vac

29

3

INSTALLATION

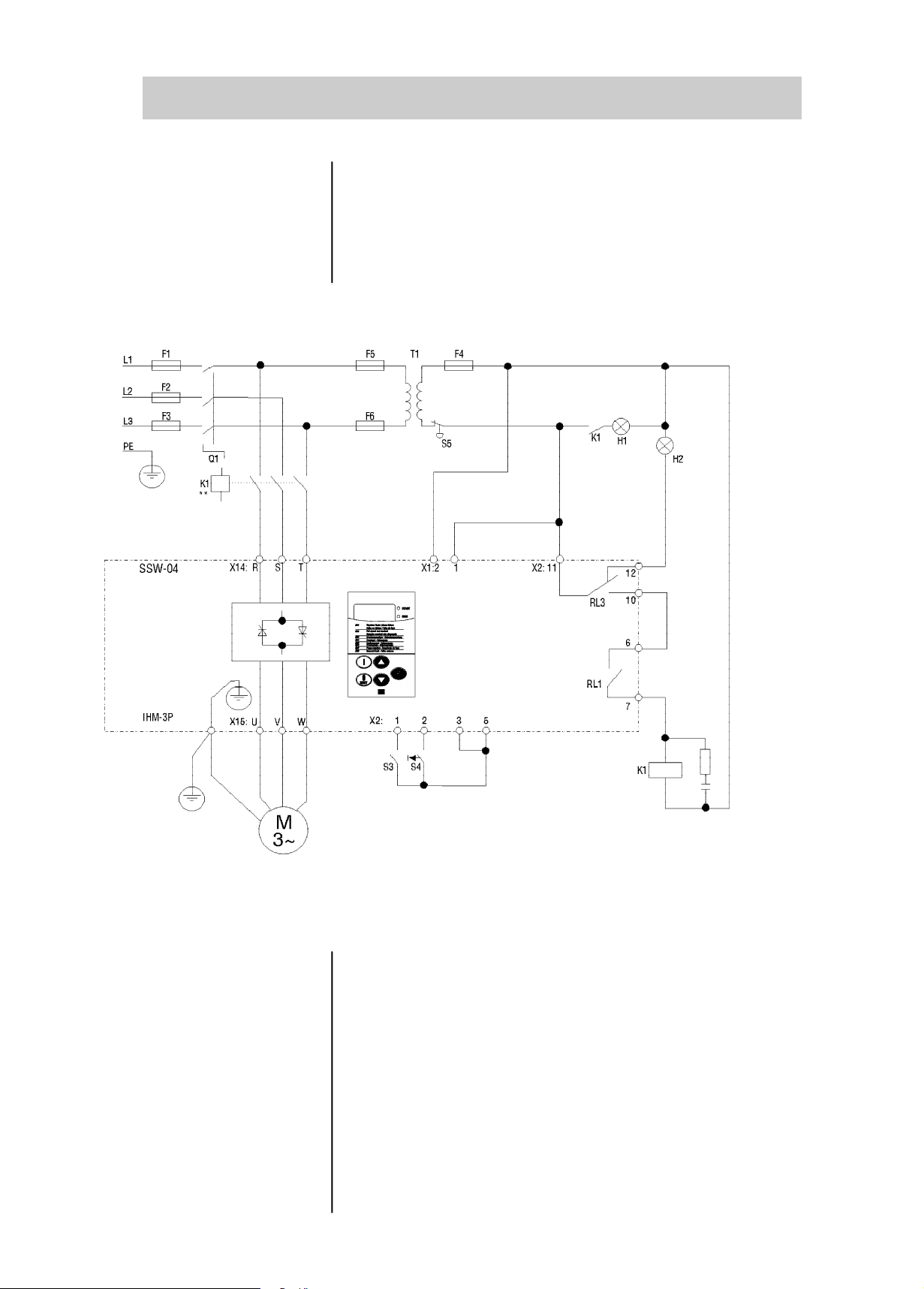

3.2.5 - Combination

drive "A" Operation

by HMI-3P

With the factory standard programming, you can operate

the Soft-Starter with the minimum connection shown in Figure 3.7.

This operation mode is recommended for users who

operate the Soft-Starter by first time, as initial training

form.

30

Figure 3.7 -

Minimum connections for operation through HMI

Note: It's necessary to use normal fuses or breaker to protect

the installation. Ultra-Rapid fuses are not necessary for

the SSW-04 operation, but they are recommended for

SCR protection.

The transformer "T" is optional and must be utilized

when the line voltage is different than the electronics

and fan voltage.

The isolation contactor "K1" is optional, and is not

necessary for the SSW-04 operation. However due to

protection and safety reasons it's recommended. In case

Loading...

Loading...