SERIAL

COMMUNICATION

MANUAL

SSW-03 and 04

SERIAL INTERFACE

Series SSW-03 and 04

CODE 0899.4457 E/2

0899.4657 E/2

email: astec@weg.com.br

MANUAL OF THE

SERIAL

COMMUNICATION

SSW-03 and 04

Series: SSW-03 and 04

Software: Version 4.XX

ATTENTION!

It is very important to

check if the Soft-Starter

Software version is the

same as indicated above.

WEG AUTOMAÇÃO

Av. Pref. Valdemar Grubba, 3000

89256-900 Jaraguá do Sul, SC – Brasil

Tel.(047)372-4000 – Fax(047)372-4020

_______ CONTENTS______

1 1 2

3

7 7 7 8 8

8 8 9 9

10 10 10 13 13 13 14 15 16 16 17

18

SAFETY NOTICES

1

1.1 Safety Notices in the Manual.......................................

1.2 Safety Notice on the Product.......................................

1.3 Preliminary Recommendations....................................

INTRODUCTION

2

COMMUNICATION

INTERFACES

3

DEFINITIONS

4

TELEGRAM EXAMPLES

5

2.1 About this Manual........................................................

2.2 About WEG Protocol....................................................

3.1 Interface RS-485 .........................................................

3.2 Interface RS-232 .........................................................

3.2.1 Electrical characteristics of the RS-232...............

3.2.2 Cares with the RS-232........................................

3.2.3 RS-232 connections............................................

3.2.4 Description of the Serial communication of the

Soft-Starter

3.2.5 Definition of the Cable for the RS-232 ................

3.2.6 Description of the Master Connector (RJ)...........

3.2.7 Definition of the Cable for the RS-232 PC..........

3.2.8 Description of the PC Connector (DB9)...............

4.1 Used Terms.................................................................

4.2 Block Diagram .............................................................

4.3 Magnitude Standardization..........................................

4.4 Character Format.........................................................

4.5 Protocol........................................................................

4.5.1 Reading Telegram...............................................

4.5.2 Writing Telegram.................................................

4.6 Execution and Telegram Test......................................

4.7 Telegram Sequence.....................................................

4.8 Variable Code..............................................................

4.9 Times...........................................................................

5.1 Example 1....................................................................

5.2 Example 2....................................................................

3

5

18

19 19 20

21 21

VARIABLES OF THE

SERIAL

COMMUNICATION

6

ERRORS AND

PARAMETERS

RELATED TO THE

SERIAL

COMMUNICATION

7

FAULTS AND

CORRECTIVE ACTIONS

8

6.1.1 V00 Indication of the Equipment Type......................

6.1.2 V01 Status Indication of the Soft-Starter...................

6.1.3 V02 Indication of the Soft-starter Errors....................

6.1.4 V03 Selection of the Logic Command.......................

7.1 Parameters Related to the Serial Communication.......

7.2 Errors Related to the Serial Communication................

Faults and Corrective Actions............................................ 22

19

1

SAFETY NOTICES 1

This Manual contains all necessary information for the correct use of the Serial

Communication of the Soft-Starters SSW-03 and SSW-04

This Manual has been written for qualified personnel with suitable training or technical

qualification to operate serial interfaces and theirs respective communications protocols.

1.1 SAFETY NOTICES IN

THE MANUAL

1.2 SAFETY NOTICES ON

THE PRODUCT

The following Safety Notices will be used in this Manual:

DANGER!

If the recommended Safety Instructions are not strictly

observed, this can lead to serious or fatal injuries of

equipment damage.

ATTENTION!

Failure to observe the recommended Safety Procedures

can lead to material damage.

NOTE!

The purpose of this Manual is to supply important

information about the understanding of operation and

good performance of the equipment.

The Following symbols may be attached on the product,

giving information about the safety:

High voltage

Components are sensitive to electrostatic discharge.

Do not touch them

Mandatory connection to ground protection (PE)

Shielded connection to the ground

1 SAFETY NOTICES

2

1.3 PRELIMINARY

RECOMMENDATIONS DANGER!

Only qualified personnel should plan or implement the

installation, start-up, operation and maintenance of serial

interfaces.

Personnel must review the entire Manual of this SoftStarter before, following carefully all safety notices there

indicated.

These personnel must follow all safety instructions

included in the Soft-Starter Manual and/or defines by local

regulations.

If there is any possibility of personnel injury and equipment

damage, that are related to motors driven by motor

starters, please install electromechanical safety devices.

In case of use of remote control (via serial

communication), consider eventual injuries and damages

that can be caused to persons and machines.

Failure to comply with these instruction may result in

personnel injury and/or equipment damage.

DANGER!

Never open energized equipment.

Always connect the frame of the equipment to the ground

(PE) at the suitable connection point.

ATTENTION

The electronic boards have components that are sensitive

to electrostatic discharges. You should never touch any of

the electrical components or connectors. If you find it

necessary to do so, touch before the metallic frame or use

a suitable grounded metallic bracelet.

NOTE!

Communications networks are generally sensitive to

interferences generated by other equipment. In order to

reduce this interference, adopt all recommended

measures.

3

ult identification related to the serial interface of WEG

INTRODUCTION 2

2.1 ABOUT THIS

MANUAL

This Manual describes the installation, start-up, operation

and fa

Soft-Starters.

For more details, training and servicing, please contact:

Servicing:

WEG AUTOMAÇÃO

Tel. (0800) 475767

Fax: (047) 372-4020

NOTE!

For request of information or servicing, please provide

always de following information:

þ Type of WEG equipment;

þ Serial number and manufacturing date indicated on WEG

equipment nameplate;

Software version that is installed in WEG equipment.

2.2 ABOUT WEG

PROTOCOL

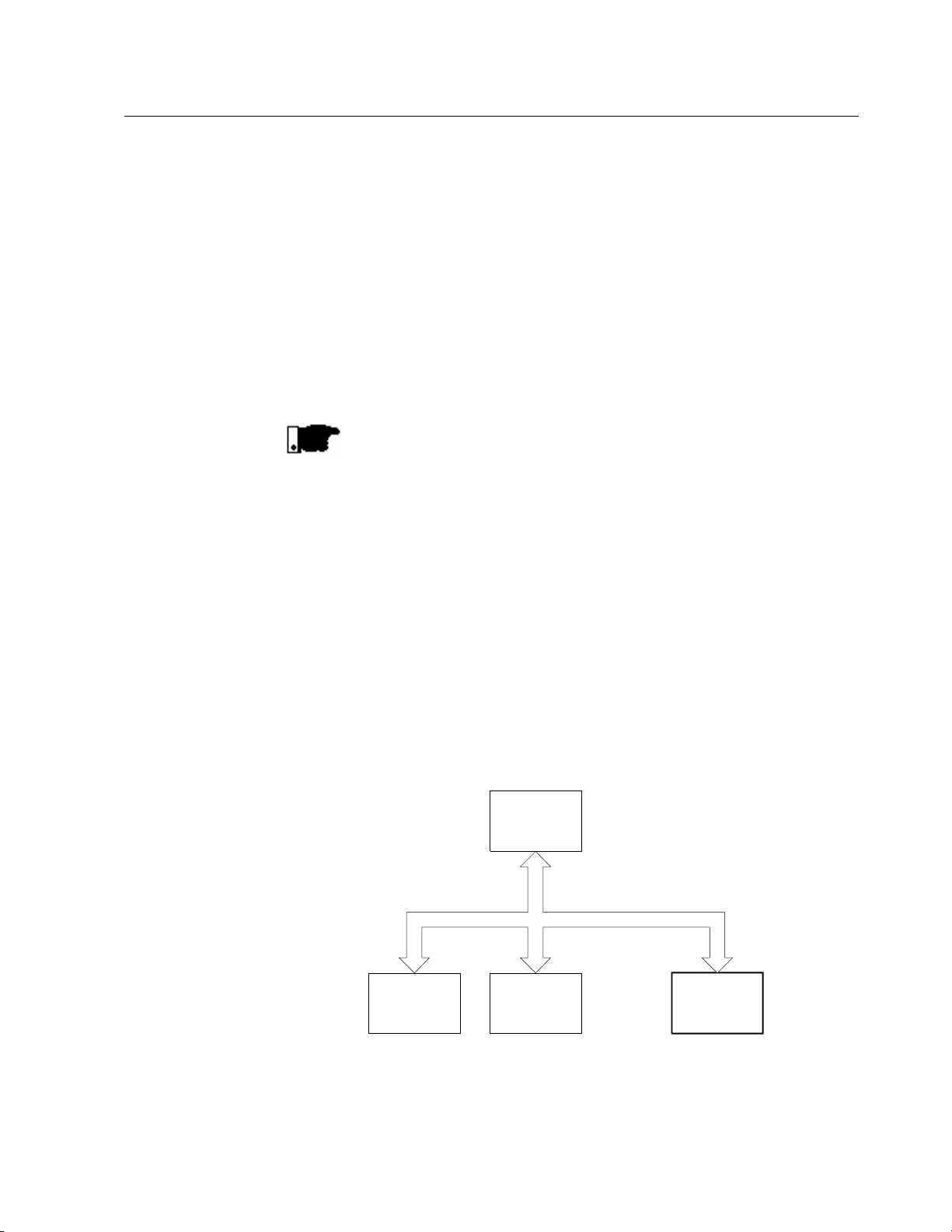

The main purpose of the serial network communication is

the physical connection of several equipment to one or more

masters that so will control though one or two wire pairs all

equipment that are connected do this network:

Master

MESTRE

PC, CLP, etc.

Slave 1

ESCRAVO 1

(converter)

(conversor)

Slave 2

ESCRAVO 2

(converter)

(conversor)

. . .

Slave n

ESCRAVO n

(converter)

(conversor)

n <= 30

WEG Soft-Starters have a Software to control data

transmission and reception though the serial interface, thus

enabling the reception of data sent by the master and the

transmission of data requested by it.

2 INTRODUCTION

4

The baud rate is 9.600Bps and it used an exchange protocol

of enquiry/answer type that meet standard ISO 1745 for

code data transmission.

The mater can perform the following operations related to

each WEG equipment that is connected to the network:

þ Identifications:

• Network number;

• Soft-Starter type;

• Software version.

þ Controls:

• General enabling/disabling;

• Error Reset.

þ Status Recognition:

• Enabling / Disabling;

• Acceleration;

• Current limitation;

• Full voltage;

• Energy saving;

• Deceleration;

• Error.

þ Parameter reading or changing.

Typical examples of WEG network use

• Monitoring at the same time several variables of WEG

Soft-Starters;

• PLC controlling the operation of several WEG SoftStarters in an industrial process.

NOTE!

WEG protocol is the same for all W EG equipment, but the

words for the logic command, basic variables, as well as

parameters can differ from one equipment to other.

5

COMMUNICATION INTERFACES 3

3.1 RS-485 INTERFACE

The physical connection between WEG Soft-Starter WEG is

performed according to one of the standards below:

þ RS-232 (point-to-point, up to 10m);

þ RS-485 (multipoint, with the use of the MIW-02 serial

interface module, with galvanic isolation, up to 1000m.

For the serial communication of the Soft-Starter at WEG

network.

þ This interface allows the connections up to 30 WEG Soft-

Starters to a Master, attributing to each WEG equipment

and address (1 to 30) that must be set at each one.

þ In addition to these 30 addresses, there as two other

addresses to perform special tasks:

• Address 0: any WEG Soft-Starter connected to the

network is required, independently of its address. Only

one Soft-Starter can be connected to network (point-topoint) in order to prevent shot-circuits in the line interface.

• Address 31: a control can be transmitted to all WEG Softstarters in the network simultaneously, without

acceptance recognition.

3 COMMUNICATION INTERFACES

6

standard

þ List of addresses and corresponding ASCII characters:

þ The connection between the network participants is

Address ASCII Address ASCII

0 @ 16 P

1 A 17 Q

2 B 18 R

3 C 19 S

4 D 20 T

5 E 21 U

6 F 22 V

7 G 23 W

8 H 24 X

9 I 25 Y

10 J 26 Z

11 K 27 [

12 L 28 \

13 M 29 ]

14 N 30 ^

15 O 31 _

performed through a pair of wires.

þ The signal levels are accordin g to EIA STANDARD RS-

485 with differential receivers and transmitters.

NOTE!

WEG Soft-Starters SSW-03 and SSW-04 have only serial

interface RS-232. Thus you must use the module of the

serial interface MIW-02 when a serial interface RS-485 is

required.

Module WEG Item No.

MIW-02 417100543

NOTE!

When the Master is fitted with only serial interface RS-232, you must use serial interface module MIW-02, RS232/RS-485, if it has the RTS signal, Request To Send. If the

RTS signal is not available on the Master, you must use a

module that can generate the RTS signal.

For more details, please contact WEG.

7

COMMUNICATION INTERFACES 3

3.2 RS-232 INTERFACE

For communication with WEG Soft-Starters (point-to-point).

þ In this case we have the connection of a Master to a

WEG Soft-Starter.

þ The logical levels meet EIA STANDARD RS-232C that

requires the use of balanced signals.

þ For RS-232 is used one communication cable.

3.2.1 Electrical

Characteristics of

RS-232

þ RS-232:

• Standard: EIA Standard RS-232C.

• Transmission speed: 9.600Bps.

• Max. cable length: 10 metros.

þ Receiver:

Max. input voltage: ± 30V;

Input resistance: > 3KΩ

Level 1 (MARK): < -3V;

Level 0 (SPACE): > +3V.

þ Transmitter:

Current limitation: ~ 10mA;

Output voltage – level 1: < -7V (RL = 3K);

Output voltage – level 0: > +7V (RL = 3K).

3.2.2 Cares with the

RS-232

þ Note please that this interface is not isolated against the

internal electronics from the equipment to which is

connected.

þ Take care with the wiring location, by separating them at

least a distance of 10 cm from the power and control

wiring.

þ It is also a good practice to install the Master as near as

possible to the Serial interface RS-232 of WEG SoftStarter.

3 COMMUNICATION INTERFACES

8

TERMINAL

SYMBOL

DESCRIPTION

1 +5V

+5V

±5%

4 Rx Data reception

5 GND

0V

6 Tx Data Transmission

Length

WEG Item

-

No.

Serial cable RS

-

232 with 0.17m

0307.4790

Serial cable RS

-

232 with 1m

0307.4820

Serial cable RS

-

232 with 3m

0307.4846

T

ERMINAL

SYMBOL

DESCRIPTION

1 Rx Data reception

4 GND

0V

5 nc Free

6 nc Free

3.2.3 RS-232

Connection

3.2.4 Description of the

Serial

communicat ion of

the Soft-Starter

3.2.5 Definition of the

cable for the

RS-232

þ This interface must be connected point-to-point directly.

þ There are two standard WEG cables as described below.

þ Connector of the SSW-03 (XC2) and SSW-04 (X3) for

the RS-232.

2 RTS Request To Send

3 GND 0V

þ The cable that must be used is the standard cable for

WEG serial communication, equipment x serial HMI of

WEG inverters (Human Machine Interface).

3.2.6 Description of the

Master Connector

(RJ)

Serial cable RS-232 with 0.23m 0307.4803

Serial cable RS-232 with 0.32m 0307.4811

Serial cable RS-232 with 2m 0307.4838

þ Master connector with RJ.

2 GND 0V

3 Tx Data transmission

9

Length

WEG Item

-

No.

Serial Cable RS

-

232 PC with 3m

0307.5460

TERMINAL

SYMBOL

DESCRIPTION

1

Free

4

Free

5 0V

6

Free

7 Free

8

Free

9

Free

3.2.7 Definition of the

Cable for RS-232

PC

COMMUNICATION INTERFACES 3

þ The cable that must be used is the standard cable for

WEG serial communication, equipment x PC.

þ It must be connected directly to the PC serial interface.

3.2.8 Description of the

PC connector

(DB9)

þ Serial connector of the PC (DB9).

2 Data reception

3 Data transmission

NOTE!

Avoid to connect equipment to different grounds, since there

can be voltage differences between them and when

connected by their interfaces, this voltage difference can

damage the equipment.

ATTENTION!

Do not use the neutral conductor for grounding purpose.

Use always serial interfaces in RS-485 for long distances.

4 DEFINITIONS

10

4.1 USED

TERMS

4.2 BLOCK DIAGRAM

4.3 MAGNITUDE

STANDARDIZATION

The protocol used for the serial communication between

WEG equipment.

þ Parameters: are those existing in WEG equipment whose

visualization or alteration is possible through the HMI

interface;

þ Variables: are values that have specific functions in W EG

equipment and that can be read, and in some cases,

modified by the master;

þ Basic Variables: are those that can be accessed only

through the serial interface.

SOFT STARTER

VARIÁVEIS

BÁSICAS

PARÂMETROS

The variable change is subject to the following

standardization.

LIGAÇÃO SERIAL MESTRE

VARIÁVEIS

Table of values and function of the parameter content of the Software version V4.XX for

implementation of: changes, monitoring and control through the serial communication.

Parameter

Parameter Function

P00

P01 Initial starting voltage 25 ... 90 (% Un)

P02 Ramp time for voltage increment 1 ... 240 (s)

P03 Voltage step during deceleration 100 ... 40 (% Un)

P04 Ramp time during voltage decrement 1 , 2 ... 240 (s) 1 = oFF

P11 Current limitation during starting 149 , 150 ... 500 (% Un)

P12 Protection against immediate overcurrent 32 ... 200 (% In)

P13

P14 Protection against immediate undercurrent 20 ... 190 (% In)

P15

P21 Motor current setting at % of the In of the switch 49 , 50 ... 200 (% In) 49 = oFF

P22 Rated current of the SSW-04 switch 0 ... 4

It allows to change the parameters via parallel

HMI

Actuation time of the protection against immediate

overcurrent

Actuation time of the protection against immediate

undercurrent

Internal value

range

0 , 1

0 , 1 ... 20 (s) 0 = oFF

0 , 1 ... 200 (s) 0 = oFF

HMI

Indication

0 = oFF

1= on

149 = oFF

0 = 16 A

1 = 30 A

2 = 45 A

3 = 60 A

4 = 85 A

11

DEFINITIONS 4

Rated current of the SSW-03 switch 0 ... 8

P23 Rated voltage of the power supply network 0 ... 9

P24 Analog input gain of the switch current 1 ... 999 X /100 = X,XX

P25 Thermal class of the motor protection 0 ... 5

P26 Motor service factor 80 ... 150 X /100 = X,XX

P27 Self-reset of the thermal memory 0 , 1 ... 600 0 = oFF

P28

P31 Phase sequence 0 , 1

P33 Jog voltage level 25 ... 50 (% Un)

P34 DC braking time 0 , 1 ...10 (s) 0 = oFF

P35 Voltage level of the DC braking 30 ... 50 (% Un)

P41 Pulse time of the starting voltage 1 , 2 ... 20

P42 Pulse level of the starting voltage 70 ... 90 (% Un)

P43 By-pass relay enabling 0 , 1

P44 Energy saver enabling 0 , 1

P45 Pump Control 0 , 1

P46 Parameters for Factory Setting 0 , 1

P47 Auto reset 9 , 10 ... 600 9 = oFF

P50 Fault relay output RL3 1 , 2

Operation mode

(available only in the SSW-03)

0 , 1

0 = 120 A

1 = 170 A

2 = 205 A

3 = 255 A

4 = 290 A

5 = 340 A

6 = 410 A

7 = 475 A

8 = 580 A

9 = 670 A

10 = 800 A

11= 950 A

12= 1100 A

13= 1400 A

0 = 220 V

1 = 230 V

2 = 240 V

3 = 380 V

4 = 400 V

5 = 415 V

6 = 440 V

7 = 460 V

8 = 480 V

9 = 575 V

0 = 5

1 = 10

2 = 15

3 =20

4 = 25

5 = 30

0 = oFF

1 = on

0 = oFF

1 = on

1 = oFF

2 /10 = 0,2 s

0 = oFF

1 = on

0 = oFF

1 = on

0 = oFF

1 = on

0 = oFF

1 = on

1 = disables with

error

2 = enables with

error

4 DEFINITIONS

12

1 = in operation

P51 Programmable relay output RL1 1 ... 3

P52 Programmable relay output RL2 1 ... 3

P53 Programmable digital input 2 0 , 1 ... 3

P54 Programmable digital input 3 0 , 1 ... 4

P55 Programmable digital input 4 0 , 1 ... 4

P56

P57

P61 Start / Stop enabling via HMI or serial com. 0 , 1

P62 Switch address in the communication network 1 ... 30

P63 Verification time of the serial communication 0 , 1 ... 5 (s)

P64 Verification action of the serial communication 1 ... 3

P71 Indication of the Software version XXX XXX /100 = X.XX

P72 Motor current indication (%) of the In of the switch 0 ... 9999 (% In)

P73 Motor current indication (A) 0 ... 9999 (A)

P74 Indication the active power supplied to the load (kW) 0 ... 65535 X /10 = X, X kW

P75 Indication of the Apparent power supplied to the load (kVA) 0 ... 65535 X /10 = X, X kVA

P76

P77 Indication of the voltage applied by the switch (% Un) 0 ... 100 (% Un)

P81

P82 Status indication of the thermal protection of the motor 0 ... 250 250 = error

P96 Back-up of the last activated Hardware error 1 ... 8

P97 Back-up of the penultimate activated Hardware error 1 ... 8

P98 Back-up of the last but two activated Hardware 1 ... 8

P99 Back-up of the first of the four last activated errors 1 ... 8

Programmable analog output

(available only in SSW-03)

Analog output gain

((available only in SSW-03)

Indication of the cos ϕ of the load

Temperature of the heat sinker

(available only in the SSW-04)

0 , 1 ... 4

1 ... 999 X /100 = X,XX

0 .. 99 X /10 = X,X

0 ... 130 (°C)

2 = full voltage

3 = direct.of rot.

1 = in operation

2 = full voltage

3 = DC braking

0 = oFF

1 = error reset

2 = external error

3 =gen. enabling

4 = three wire

communication

0 = oFF

1 = error reset

2 = external error

3 =gen. enabling

4 = direct.of rot.

0 = oFF

1 = error reset

2 = external error

3 =gen. enabling

4 = Jog function

0 = oFF

1 = current (%)

2 = voltage (%)

3 = cos u

4 = therm. status

0 = oFF

1 = on

1 = only E29

2 = ramp disabl.

3 = gen disabling

13

arity

(even parity). Two types of messages are used (by the

4.4 CHARACTER

FORMAT

4.5 PROTOCOL

DEFINITIONS 4

þ 1 start bit;

þ 8 information bits [codify the text character and the

transmission character, taken from the 7 bit code,

according to ISO 646 and supplemented to even p

(eighth bit)];

þ 1 stop bit;

After the start bit follows the less significant bit:

start

bit

The transfer protocol meets ISO 1745 requirements for the

code data transfer.

Are used only text character sequences without header.

The error monitoring is realized by means of the

transmission related the parity of the individual 7 bit

characters, according to ISO 646.

The parity monitoring is realized according to DIN 66219

B2 B3 B4 B5 B6 B7 B8B1START

8 bits of information

STOP

stop

bit

4.5.1 Reading Telegram

Master):

þ READING TELEGRAM: to enquiry the variable content of

the starting switch

þ WRITING TELEGRAM: to change the variable content or

to sent commands to the starting switch.

Note.: Transmission between two inverters is not possible.

The master has the access control to the bus bar.

This telegram allows that the master receives from the SoftStarter the content corresponding to the enquiry code.

In the answer telegram, the Soft-Starter transmits the data

requested by the master and the it completes the

transmission with EOT.

4 DEFINITIONS

14

1) Mestre:

EOT ADR ENQ

CÓDIGO

2) Soft Starter:

ADR STX = ETX BCC

CÓDIGO VAL

TEXTO

þ Reading telegram format:

• EOT: control character End Of Transmission;

• ADR: inverter address (ASCII@, A, B, C, ...) (ADRess);

• CÓDIGO: address of the 5 digit variable codified in

ASCII;

• ENQ: ENQuiry control character;

þ Format of the answer telegram of the Soft-Starter:

• ADR: 1 character – Soft-Starter address;

• STX: control character - Start of TeXt;

• TEXTO: consists in:

• CÓDIGO: variable address;

• " = ": separation character;

• VAL: 4 digit value HEXADECIMAL;

• ETX: control character - End of TeXt;

• BCC: Byte of CheCksum - EXCLUSIVE OR of all bytes

between STX (excluded) and ETX (included.

Note: In some cases the switch answer can be given with:

ADR

NAK

4.5.2 Writing Telegram

This telegram sends data to the variables of the starting

switch.

The switch will answer by indicating if the data were receipt

or not.

15

DEFINITIONS 4

1) Mestre:

1) Mestre:

EOT ADR STX = ETX BCC

2) Soft Starter:

ADR ACK ADR NAK

CÓDIGO VAL

OU

þ Writing telegram format:

• EOT: control character End Of Transmission;

• ADR: address of the Soft-Starter;

• STX: control character Start of TeXt;

TEXTO: consists in:

• CÓDIGO: address of the variable;

• " = ": separation character;

• VAL: value if formed by 4 digits HEXADECIMAL;

• ETX: control character End of TeXt;

• BCC: Byte of CheCksum - EXCLUSIVE OR of all bytes

between STX (excluded) and ETX (included).

þ Format of the answer telegram of the Soft-Starter:

TEXTO

4.6 EXECUTION AND

TEST TELEGRAM

Accepting:

• ADR: Soft-Starter address;

• ACK: control character ACKnowledge;

Non accepting:

• ADR: Soft-Starter address;

• NAK: control character Not AcKnowledge.

This means that the data were not accepted and that the

addressed variable retains its old value.

The Soft-Starters and the master test the telegram syntax.

Below are defined the answers for the respective verified

condition:

þ Reading Telegram:

• Without answer: with wrong telegram structure, control

characters were wrongly received, or the Soft-Starter was

wrong;

4 DEFINITIONS

16

Starters at determined

use longer than the time

address and the basic variables formed by 5 digits (ASCII

4.7 TELEGRAM

SEQUENCE

4.8 VARIABLE CODE

• NAK: CODE corresponding to an inexisting variable or

read-only variable;

• TEXTO: with valid telegrams.

þ Writing Telegram:

• Without answer: with wrong telegram structure, received

control characters are wrong or Soft-Starter address is

wrong;

• NAK: with code corresponding to an inexisting variable,

wrong BCC (Byte of CheckSum), read-only variable, VAL

outside the permitted range for the variable at issue,

operation parameter outside the changing mode.

• ACK: with valid telegrams;

The telegram is processed in the Softtime intervals. Thus, between two telegrams for the same

Soft-Starter it must be assured a pa

sum of the involved telegrams. (see Item 4.9).

The filed designated by CODE contains the parameter

Characters), as follows:

17

Starter, a wait time

4.9 TIMES

Baud rate of data reception / transmission: 9600bps 1bit / 104,2us

Each data word has 10bits 1,04ms

One enquiry telegram has 8 words 8,33ms

One answer telegram to an enquiry has 14 words 14,58ms

One changing telegram has 15 words 15,63ms

One answer telegram to a changing has 2 words 2,08ms

One updating of a requested variable (with immediate answer) 22,91ms

One changing of a written variable (with immediate answer) 17,71ms

NOTE!

DEFINITIONS 4

þ The baud rate of the serial communication of WEG Soft-

Starters WEG is 9600bps.

þ Times of WEG protocol:

The master should maintain between two variable

transmissions to the same Softcompatible with the telegram types to be processed and their

respective answers.

5 TELEGRAM EXAMPLES

18

5.1 EXAMPLE 1 þ Starting time change(P02) to 20s in the Soft-Starter 7 (“;”

= SSW-03).

1) Mestre:

EOT G STX 0 1 ; 0 2 = 0 0 1 4 ETX BCC

end. 7

2) Soft Starter:

2) Soft Starter:

G ACK

5.2 EXAMPLE 2 þ Reading of the inverter output current 10, presuming it

was 100A at the enquiry moment. (“;” = SSW-03).

1) Mestre:

EOT J 0 1 ; 7 3 ENQ

end. 10

2) Soft Starter:

2) Soft Starter:

J STX 0 1 ; 7 3 = 0 0 6 4 ETX BCC

end. 10

NOTE!

The examples above presume that the used Soft-Starter is a

SSW-03. When a SSW -04 is used, the value “;” of the code

should be changed to “<”.

VARIABLES OF THE SERIAL COMMUNICATION 6

19

0 =

0 =

0 =

0 =

0 =

0 =

0 =

0 =

0 =

0 =

0 =

0 =

0 =

6.1 BASIC VARIABLES

6.1.1 V00

6.1.2 V01

6.1.3 V02

(code 00x00)

þ Indication of the equipment type.

þ Reading variable;

(code 00x01)

þ Indication of the Soft-Starter status.

Reading variable, which bits have the following meaning:

LSB

0 0 = disabled 1 = enabled

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

MSB

general disabling 1 = general enabling

free 1 = in jog

free 1 = In acceleration

free 1 = in current limiting

free 1 = at full voltage

free 1 = in energy saver

free 1 = in deceleration

reserved

free 1 = in DC braking

free 1 = In changing the direction of

clockwise 1 = Counter-clockwise

reserved

free 1 = with hardware error

without power supply 1 = with power supply

without error 1 = with error

(code 00;02)

rotation

þ Indication of the Soft-Starter error.

þ Reading variable which bits have the following meaning:

Serial Error (byte-high)

Hardware Error (byte-low)

Errors:

Serial Error Hardware Error

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

MSB LSB

6 VARIABLES OF THE SERIAL COMMUNICATION

20

0 =

0 =

0 =

0 =

0 =

1 =

1 =

1 =

1 =

Error code: error number in hexadecimal

6.1.4 V03

Ex.: E00 Ü 00H

E01 Ü 01H

E10 Ü 0AH

(code 00;03)

þ Selection of the logic control.

þ Writing variables, which bits have the following meaning::

MSB

0

1

2

3

4

5

6

7

8 1 = Enabling/disabling

9

10

11

12

13

14

15

MSB

Disables 1 = enables

General enabling 1 = General disabling

Without jog 1 = com jog

Clockwise 1 = Counter-clockwise

Reserved

Reserved

Reserved

free 1 = resetting

General enabling/disabling

jog

clockwise

reserved

reserved

reserved

Switch " reset " when error occurs

þ BYTE HIGH (8-15): desired action mask. The

corresponding bit should be set to 1 to enable this

action.

þ BYTE LOW (0-7): logic level of the desired action.

NOTE!

The reset acts only when the Soft-Starter has hardware

error.

NOTE!

To use the Jog control and the reversal of the direction of

rotation via serial communication, you must set the following

parameters: P54=4, P55=4 and P61=on.

21

7.1 PARAMETERS

RELATED TO THE

SERIAL

COMMUNICATION

ERRORS AND SERIAL PARAMETERS 7

þ P61 – Controls via HMI and Serial or via Digital Inputs.

þ P62 – Switch address on the communication network.

þ P63 – Verification time of the Serial Communication.

þ P64 – Verification Action of the Serial Communication.

7.2 ERRORS RELATED

TO THE SERIAL

COMMUNICATION

þ They do not cause WEG Soft-Starter lockout;

þ They do not deactivated the fault relay;

þ The inform only on the display and in the logic status

word.

Types of errors:

• E22: longitudinal parity error (BCC);

• E24: parameter changing attempt can be realized only

with stopped motor;

• E25: inexisting variable;

• E26: desired value outside the permitted limits;

• E27: writing attempt on read -only variable or logic control

is disabled;

• E29: cyclic serial communication error interrupted.

Note:

These errors can be observed through the reading if the

status variable of WEG equipment.

NOTE!

Error E29 may lockout the Soft-Starters.

This protection is used in installations where the Soft-Starter

has to take a decision when a communication fault occurs

between the master and the Soft-Starter.

NOTE!

Please take car with the parameter compatibility. For more

details about parameter incompatibilities, see please Manual

of WEG Soft-Starters.

8 FAULTS AND CORRECTIVE ACTIONS

22

No communication with

Master reads but does not

change the Soft-Starter

Problems:

Soft-Starter:

parameters:

Corrective Actions:

þ Check if telegram format is correct.

• Equipment Code;

• Byte of BCC is correct;

• Parity;

• Word length.

þ Check all ca ble connections of the serial communication

e and check if power supply of all connected equipment

is correct.

þ Check if the baud rate of the master is 9600bps.

þ Check if the Soft-Starter address (P62) is the same to

which the master is sending the telegrams.

þ When a RS-485 is used and the master is using RS-

232/RS-485 inverter, check if there is present a RTS

signal.

þ Check if the format of the changing telegrams is correct.

þ Check if there is no writing attempt on a read-only

variable.

þ Check if this variable can be changed with enabled

motor.

Random indications of serial

errors in the serial

communication:

þ When installed in communication network with RS-485:

• Check all serial communication cables in the network

and their shields;

• Check if all grounding points are grounded correctly;

• Check if only the network terminal points are fitted with

termination resistors;

þ Check the cables of all RS-232-connections. They

should be as short as possible and be laid separately

from the serial communication cables.

Loading...

Loading...