Page 1

www�weg�net

Controls

Thermal Overload Relays - RW Series

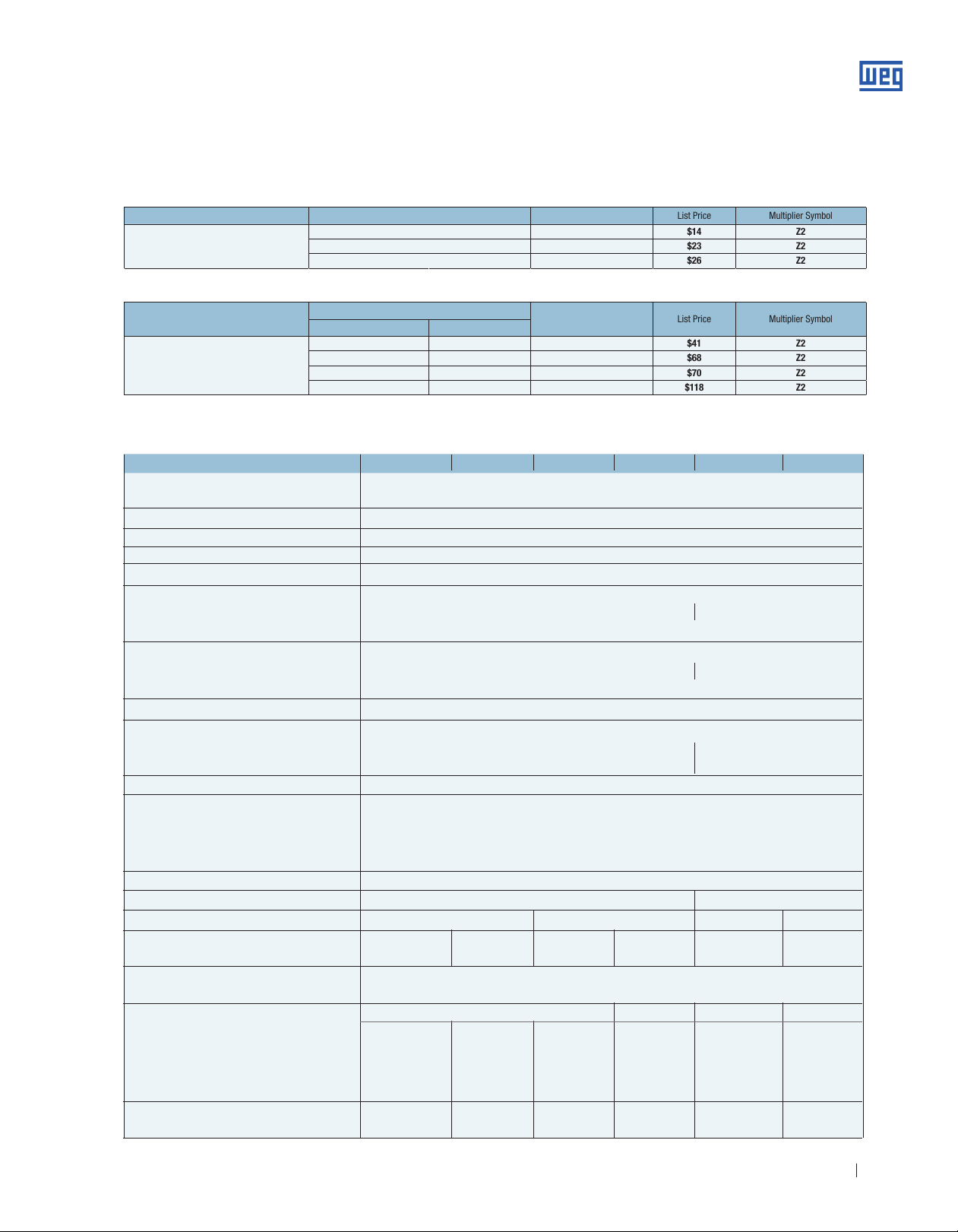

Separate mounting kit

Description Mounting on Overload Relays Catalog Number List Price Multiplier Symbol

Enables overload relay to be directly mounted

to a back panel via screws or DIN rail

Connector links

Description

Link connectors for easier CWM contactors and

RW overload relays assembly

Contactor Overload Relay

CWM112E RW117-2D3 GA117D $41 Z2

CWM112E/150E RW317-1D3 GA317-1D $68 Z2

CWM180E RW317-1D3 GA317-2D $70 Z2

CWM250E/300E RW317-1D3 GA317-3D $118 Z2

General Ratings

TYPE RW17D RW27D RW67D RW117D RW317D RW407D

Standards

Number of Poles 3

Tripping Class 10

Phase Failure Sensitivity Yes

Temperature Compensation Yes

Rated Insulation Voltage Ui

Acc. IEC 60947-4-1 [V] 690 1000

Acc. UL; CSA [V] 600

Rated Operation Voltage Ue

Acc. IEC 60947-4-1 [V] 690 1000

Acc. UL; CSA [V] 600

Rated Impulse Voltage Uimp [kV] 6

Current

Direct YES NO

Alternating [Hz] up to 400 50/60

Degree of Protection Protection against direct contact acc. VDE 0160 - Part 100 - IP20

Ambient Temperature

Storage -50 to +80ºC (-58 to 176ºF)

Operating -20 to +70ºC (-4 to 158ºF)

Ambient temperature compensation -20 to +60ºC (-4 to 140ºF)

Pollution Degree 3

Mounting Direct on contactor or separately with accessory Separate

Power Dissipation per Pole [W] up to 3 up to 5.5 - -

Weight [kg] 0.15 0.15 0.31 0.52 2.30 3.12

[lb] 0.33 0.32 0.68 1.15 5.06 6.88

Shock Resistance

IEC 60 068 part 2-27 [g/ms] 8/10

Main Terminals Capacity Cross / Slotted Combination1) Allen Head Slide Bar Slide Bar

Fine - Stranded with Sleeve [mm2] 1.5 - 10 1.5 - 10 6.0 - 35 6.0 - 35 - -

Coarse - Stranded / Solid [mm2] 1.5 - 6.0 1.5 - 6.0 6.0 - 35 25 - 35 - -

Slide Bars [mm2] - - - - 2x(25x5) 2x(60x10)

Stranded / Solid (UL / CSA) [AWG] 14 - 6 14 - 6 18 - 2 8 – 1/0 8 – 1/0 8 – 1/0

Tightening Torque [N.m] 1.4 - 2.3 1.4 - 2.3 4.0 - 6.0 4.0 - 6.0 14 - 26 23 - 26

[lb-in] 12.4 - 20.4 12.4 - 20.4 35.4 - 53.1 35.4 - 53.1 123.9 - 230.1 203.6 - 230.1

1) For RW67-2D power terminal screws are Allen Head

RW27-1D3 BF27D $14 Z2

RW67-1D3 and RW67-2D3 BF67.1D $23 Z2

RW117-1D3 BF117D $26 Z2

Assembles with

Devices according to International Standards IEC 60947-1 / 60947-4-1, European Standards EN 60947-1 / 60947-4-1,

Underwriters Laboratories - UL 508; CSA C.22.2/14; VDE 0660/102

Catalog Number List Price Multiplier Symbol

8/10

WEG Automation - Products and Solution 103

Page 2

www�weg�net

Controls

Thermal Overload Relays - RW Series

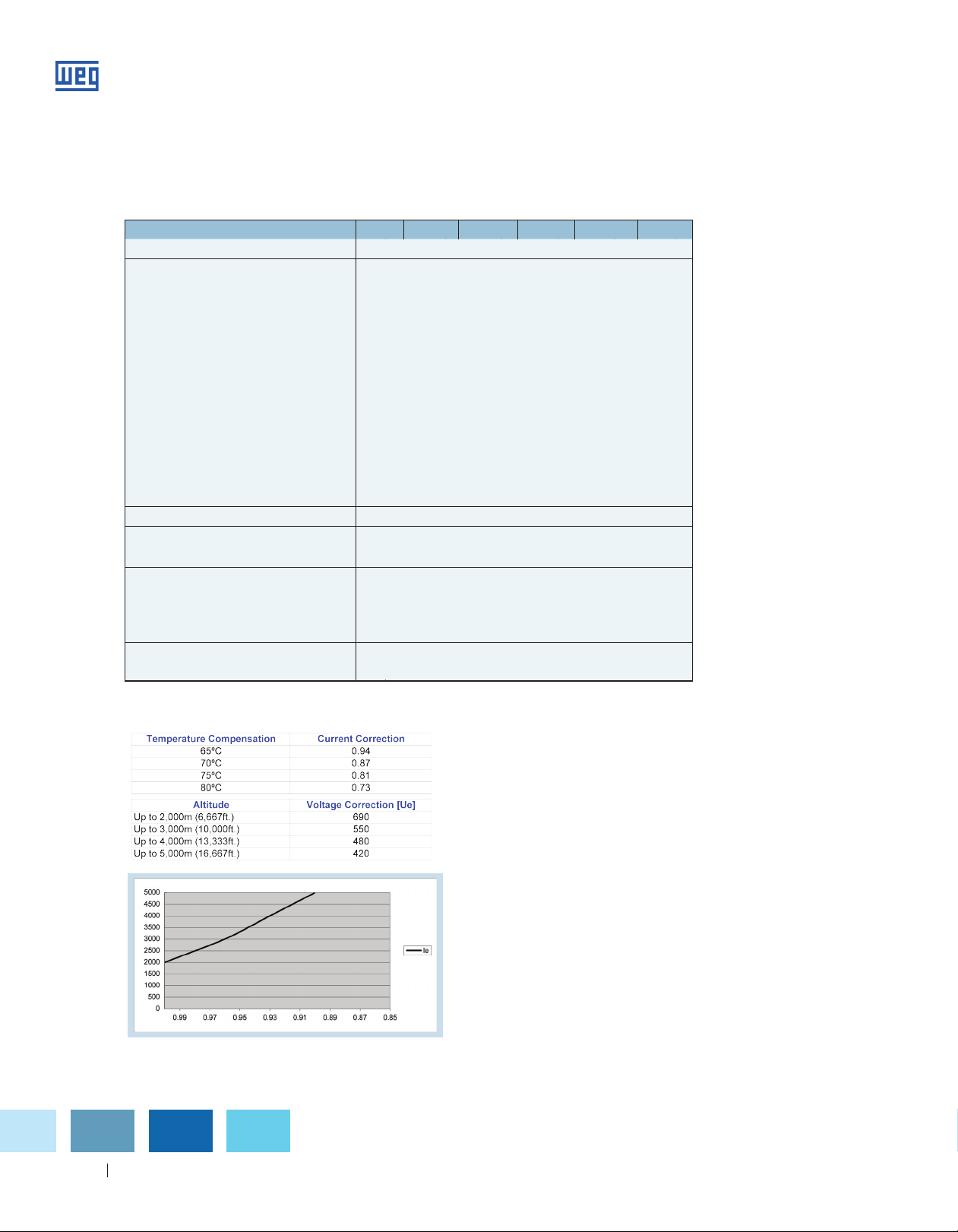

General Ratings

TYPE RW17D RW27D RW67D RW117D RW317D RW407D

Front Auxiliary Contact 1 NO + 1 NC

Rated Auxiliary Contacts

AC-14/15 24V [A] 4.0

60V [A] 3.5

125V [A] 3.0

230V [A] 2.0

400V [A] 1.5

500V [A] 0.5

690V [A] 0.3

DC-13/14 24V [A] 1.0

60V [A] 0.5

110V [A] 0.25

220V [A] 0.1

UL508 C600 ; R300

Rated Thermal Current [A] 6

Short Circuit Protection

Fuses Type D or NH gL/gG [A] 6

Auxiliar Terminals Capacity

Fine - Stranded with Sleeve [mm2] 1.0 - 2.5

Coarse - Stranded / Solid [mm2] 1.0 - 2.5

Stranded / Solid (UL / CSA) [AWG] 16 - 12

Tightening Torque [N.m] 1.0 - 1.5

[lb-in] 8.9 - 13.3

NOTE:

The derating of a RW overload

relay has two possible factors:

1) Ambient temperature

• Temperature compensation

considers a factor according

to which the rated current

must be reduced when ambient temperature is higher

than 60ºC (140ºF).

2) Altitude

• Altitude compensation

involves both, rated current

and voltage.

• Current compensation

considers a factor according to the rated current

must be reduced.

• For voltage, altitude limits

the higher operating voltage

we can use the overload

relay.

The derating of the permissible operating current for installation altitudes above 2,000m

(6,667 ft) and ambient temperatures over 60ºC (140ºF) is calculated according to:

Total derating = Derating

x Derating

altitude

ambient temperature

Example;

Altitude: 3,000 m (10,000 ft) K1 = 0.96

Ambient temperature: 70ºC (158ºF) K2 = 0.87

Meters

Total current derating = 0.96 x 0.87 = 0.84 x Ie

In this case, the maximum rated voltage we can connect to our RW overload relay is

550V.

In order to select the proper overload relay, you have to choose a device with a current range that accommodates:

Derating Factor

Overload Setting Point = FLA

/ (K1 x K2)

motor

As in the example above, K1 x K2 = 0.84

For a motor with FLA = 20Amps

Overload Setting Point = 20 / 0.84 = 23.8Amps

1-800-ASK-4WEG104

Loading...

Loading...