Motors | Automation | Energy | Transmission & Distribution | Coatings

CFW701

HVAC-R Drives

Quick Setup Guide

CFW700 HVAC-R Drives

CFW701 HVAC-R Drives

1 - Installation and Power Connections

Refer to CFW701 user guide chapter 3.

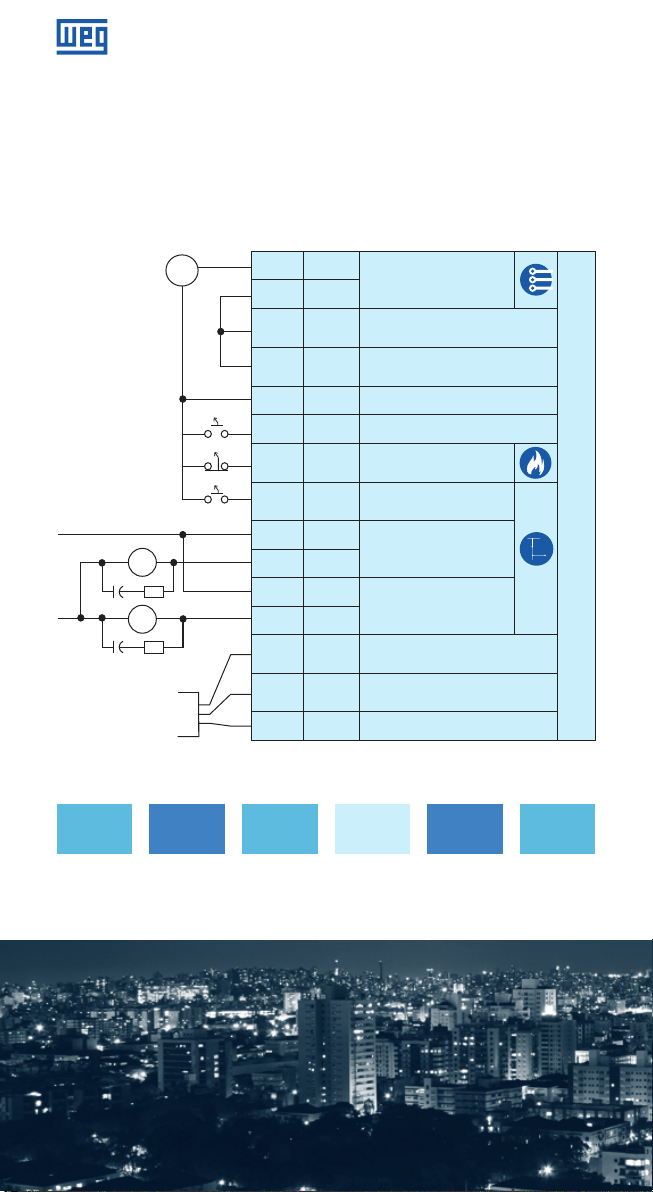

1.1 - Control Connections

4-20 mA

Sensor

-

+

OFF

OFF

OFF

120 V ac

1)

RS485

22 AI1+

23 AI1-

Analog input 1 (4-20 mA):

Control Process Variable

35 COM Common point of the digital inputs

36 DGND

15 / 34 24 V dc 24 V dc power supply

0N

Reference (0 V) for the 24 V dc

power supply

37 D1 Digital input 1: Start/Stop

0N

0N

19 DI7

20 DI8

32 C1

33 NO1

11 C2

31 NO2

10

9

Digital input 7:

Fire Mode Command

Digital input 8:

Bypass Command

Digital output 1 DO1 (RL1):

VFD Contactor

Digital output 2 DO2 (RL2):

Bypass Contactor

A-line

RxD/TxD negative

(-)

B-line

RxD/TxD positive

(+)

8 GND 0 V isolated from the RS485 circuit

Product XC1 terminal

Note: 1) BACnet MS/TP, Metasys N2 and Modbus-RTU

2

CFW700 HVAC-R Drives

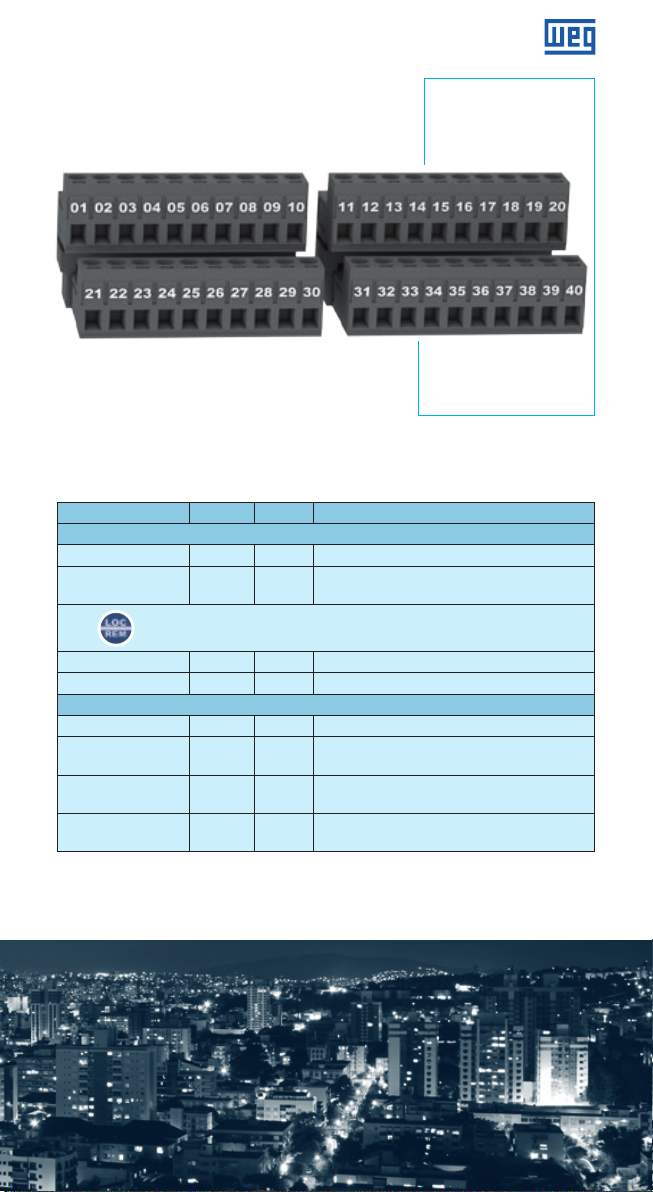

Active high / low digital inputs

NC

PTC

PTCNCNC

AI3+

AI3-

GND

A - RS485

B - RS485

RL2- C

DO3

DO4

DO5

+24 V

GND (24 V)

DI5

DI6

DI7

DI8

AI1-

AI1+

REF+

AI2-

AO1

AI 2+

REF-

AO2

AGND (24 V)

AGND (24 V)

RL1 -C

RL1 -N A

RL2- NA

1.2 - Control Configuration

PROG DEF User Description

2 - Wire start/stop

P0000 0 5 Access to parameters

P0220 2 3

Press to select remote mode

P0227 1 1 Remote run/stop = DIx

P0263 1 1 DI1 = start/stop

BACnet communication

P0308 1 Δ Serial address (0 to 255)

P0310 1 1

P0311 1 0

P0312

1)

2 3

Notes: Δ Setting depe nds on user/network.

1) Refer to the respective protocol manual for more details.

LOC/REM selection = LR key

(REM when turn on CFW701)

Serial baud rate - bits/s

(0 = 9,600; 1 = 1,920; 2 = 38,400; 3 = 57,600)

Serial bytes

(0 = 8 data bits, no parity, 1 stop bit)

Serial protocol

(2 = Modbus-RTU, 3 = BACnet MS/TP, 4 = N2)

DI1

COM

+24 V

GND (24 V)

DI4

DI2

DI3

3

CFW700 HVAC-R Drives

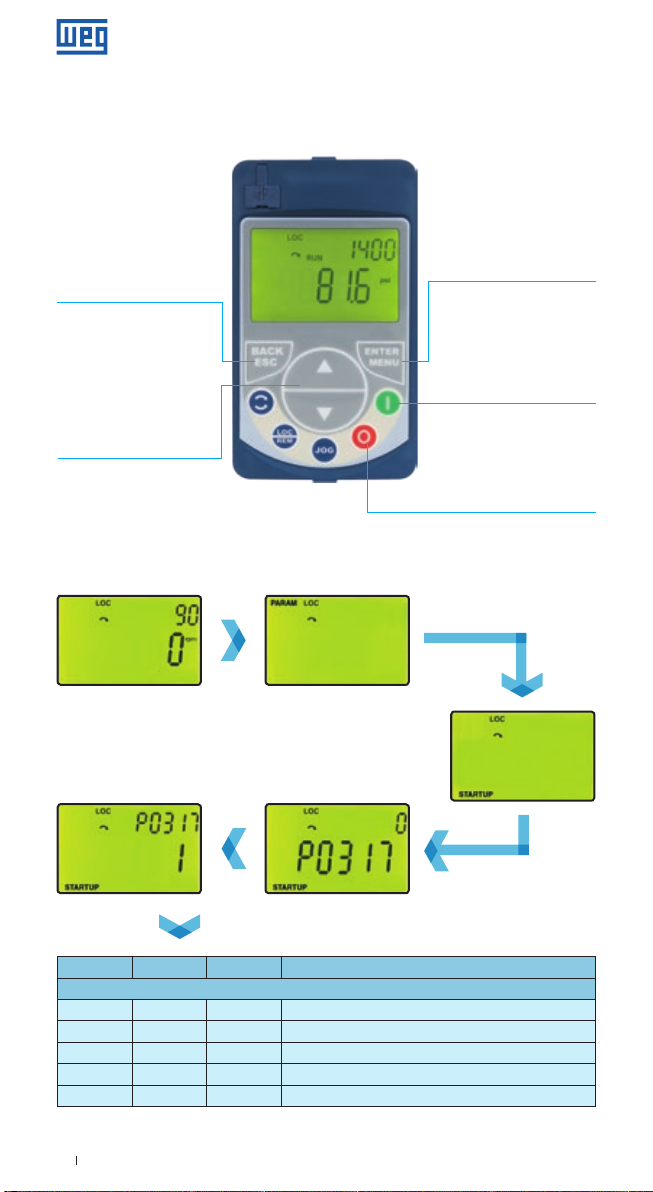

2 - Programming

2.1 - CFW701 Keypad

Back/ESC

J

Return to

monitoring mode

J

Return to previous

J

Enter programming

mode

J

Use to select/save

programming level

Up/Down

J

Adjust speed

in local mode

J

Navigate through

J

Run in local mode

parameters

J

Stop in local mode

J

Reset

2.2 - Motor and Keypad Settings

2.2.1 - Oriented Star tup Routine (STARTUP Group)

Press the

ENTER/MENU

Select

STA RT U P

Enter/Menu

Run

Stop

Press the

ENTER/MENU

PROG DEF User Description

Oriented startup (scalar - V/F mode) - STARTUP group

P0298 0 0 Normal duty

P0202 0 0 Control type V/F

P0401 -

P0403 60

P0402 1,710

Note: ■ Set as per motor nameplate data.

4

■

■

■

P0317 to “1”

Motor FLA (A)

Motor frequency nameplate data

Motor speed (RPM)

CFW700 HVAC-R Drives

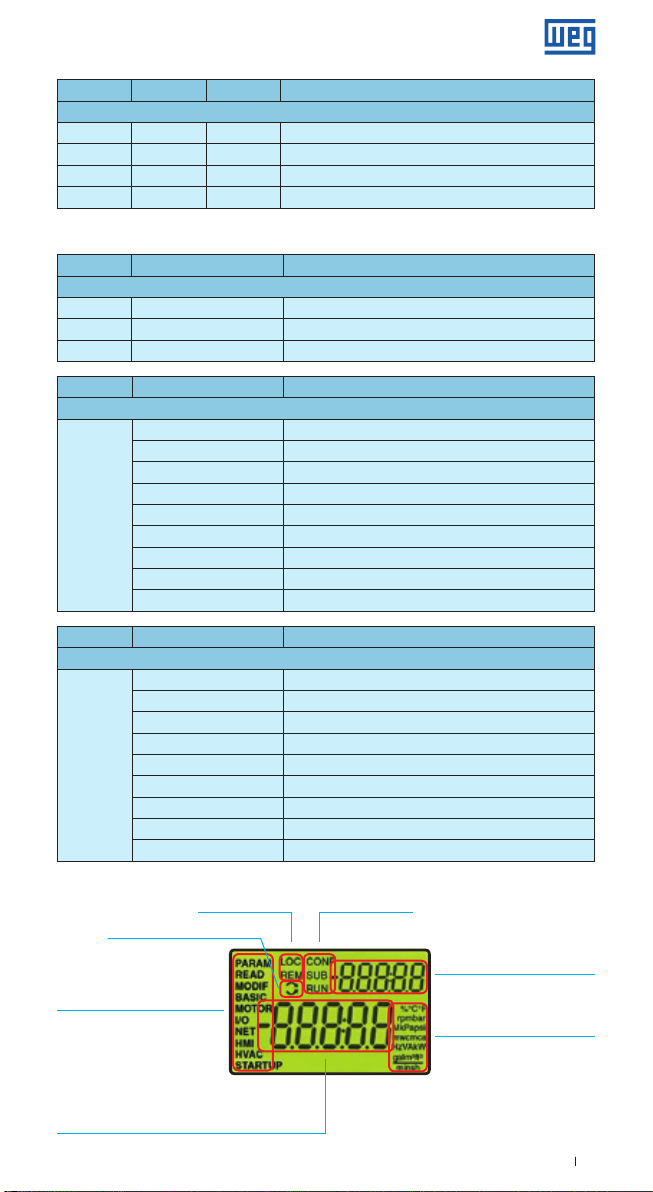

PROG DEF User Description

Basic application - BASIC group

P0100 20s Δ Acceleration time (s)

P0101 20s Δ Deceleration time (s)

P0133 90 rpm Δ Minimum speed (Hz)

P0134 1,800 rpm Δ Maximum speed (Hz)

Note: Δ Setting depends on application.

PROG DEF Description

Motor overload settings - PARAM group

P0156 1.05 x Inom-ND Overload current at 105% speed

P0157 0.9 x Inom-ND Overload current at 50% speed

P0158 0.65 x Inom-ND Overload current at 5% speed

DEF User Description

Changing monitor display parameter - HMI group

1 Speed reference (rpm)

2 Output speed (rpm)

3 Motor current (A)

P0205 = 2

P0206 = 1

5 Output frequency (Hz)

7 Output voltage (V)

42 Time powered (h)

44 Output energy (kWh)

1011 Control setpoint 1

1015 Control process variable

DEF User Description

Changing main display unit - HMI group

3 rpm

11 °C

21 °F

22 bar

P0209 = 3

24 psi

36 gal/s

37 gal/min

40 l/min

50 m³/h

Rotation

Parameters

group

Main display unit

P0205

Local/Remote Status

Secondary display

P0206

Main display unit

P0209

5

Loading...

Loading...