Page 1

Motors | Automation | Energy | Transmission & Distribution | Coatings

Frequency Inverter

CFW701 V2.0X

Programming Manual

Page 2

Page 3

Programming Manual

Series: CFW701

Language: English

Document Number: 10001461481 / 01

Software Version: 2.0X

Publication Date: 04/2014

Page 4

Page 5

Summary

QUICK PARAMETER REFERENCE, FAULTS AND ALARMS .................0 -1

1 SAFETY NOTICES ................................................................................. 1-1

1.1 SAFETY NOTICES IN THIS MANUAL ............................................................................................1-1

1.2 SAFETY NOTICES ON THE PRODUCT ......................................................................................... 1-1

1.3 PRELIMINARY RECOMMENDATIONS ..........................................................................................1-2

2 GENERAL INFORMATION ......................................................................2-1

2.1 ABOUT THIS MANUAL ...................................................................................................................2-1

2.2 TERMINOLOGY AND DEFINITIONS..............................................................................................2-1

2.2.1 Terms and Definitions Used in the Manual ......................................................................2-1

2.2.2 Numerical Representation ................................................................................................ 2-3

2.2.3 Symbols for the Parameter Properties Description ...................................................... 2-3

3 ABOUT THE CFW701 .............................................................................3 -1

4 KEYPAD (HMI) .........................................................................................4 -1

5 PROGRAMMING BASIC INSTRUCTIONS .............................................5 -1

5.1 PARAMETERS STRUCTURE ......................................................................................................... 5-1

5.2 GROUPS ACCESSED IN THE OPTION MENU IN THE MONITORING MODE .......................... 5 -1

5.3 PASSWORD SETTING IN P0000 ................................................................................................... 5-1

5.4 HMI .................................................................................................................................................. 5-2

5.5 INDIRECT ENGINEERING UNITS ................................................................................................. 5-6

5.6 DISPLAY INDICATIONS IN THE MONITORING MODE SETTINGS ..........................................5 -14

5.7 INCOMPATIBILITY BETWEEN PARAMETERS ..........................................................................5 -14

6 INVERTER MODEL AND ACCESSORIES IDENTIFICATION ...............6-1

6.1 INVERTER DATA ........................................................................................................................... 6 -1

7 STARTING-UP AND SETTINGS ............................................................. 7-1

7.1 BACKUP PARAMETERS ................................................................................................................. 7-1

8 AVAILABLE CONTROL TYPES ..............................................................8 -1

9 SCALAR CONTROL (V/f) ........................................................................ 9-1

9.1 V/f CONTROL .................................................................................................................................. 9-2

9.2 ADJUSTABLE V/f CURVE .............................................................................................................. 9-5

9.3 V/f CURRENT LIMITATION ........................................................................................................... 9-6

9.4 V/f DC VOLTAGE LIMITATION ....................................................................................................... 9-8

9.5 START-UP IN THE V/f CONTROL MODE ....................................................................................9 -11

10 V VW CONTROL .................................................................................10-1

10 .1 V VW CONTROL ........................................................................................................................ 10-3

10.2 MOTOR DATA ............................................................................................................................ 10-3

10. 3 V VW CONTROL MODE START-UP ........................................................................................ 10-4

11 VECTOR CONTROL ............................................................................ 11-1

11.1 SENSORLESS CONTROL .......................................................................................................... 11-1

11.2 I/f MODE (SENSORLESS) ..........................................................................................................11- 3

11.3 SELF-TUNING .............................................................................................................................11- 3

Page 6

Summary

11.4 OPTIMAL FLUX FOR SENSORLESS VECTOR CONTROL ....................................................11- 4

11.5 TORQUE CONTROL ....................................................................................................................11- 4

11.6 OPTIMAL BRAKING ...................................................................................................................11- 6

11.7 MOTOR DATA ..............................................................................................................................11-7

11.7.1 Adjustment of the Parameters P0409 to P0412 Based on the Motor Data Sheet .. 11-11

11.8 VECTOR CONTROL ................................................................................................................. 11-12

11.8.1 Speed Regulator ...........................................................................................................11-12

11.8.2 Current Regulator ......................................................................................................... 11-14

11.8.3 Flux Regulator ............................................................................................................... 11-14

11.8.4 I/f Control ...................................................................................................................... 11-16

11.8.5 Self-Tuning ...................................................................................................................... 11-17

11.8.6 Torque Current Limitation ............................................................................................11-2 0

11.8.7 Supervision of Motor Real Speed ................................................................................ 11-2 1

11.8.8 DC Link Regulator .........................................................................................................11-22

11.9 START-UP IN THE VECTOR MODES SENSORLESS .............................................................11- 2 4

12 FUNCTIONS COMMON TO ALL THE CONTROL MODES ............... 12-1

12 .1 R A MPS ......................................................................................................................................... 12-1

12.2 SPEED REFERENCES .............................................................................................................. 12-3

12.3 SPEED LIMITS ........................................................................................................................... 12-5

12.4 ZERO SPEED LOGIC ................................................................................................................. 12-6

12.5 FLYING START / RIDE-THROUGH ............................................................................................ 12- 8

12.5.1 V/f or VV W Flying Start .................................................................................................. 12-8

12.5.2 Vector Flying Start.......................................................................................................... 12-9

12.5.2.1 P0202 = 4 ........................................................................................................... 12-9

12 . 5 .3 V V W or V/f Ride-Through ........................................................................................... 12-11

12.5.4 Vector Ride-Through ..................................................................................................... 12-13

12.6 DC BRAKING ............................................................................................................................. 12-15

12.7 SKIP SPEED .............................................................................................................................12-18

13 DIGITAL AND ANALOG INPUTS AND OUTPUTS .............................13 -1

13.1 I/O CONFIGURATION .................................................................................................................13 -1

13.1.1 Analog Inputs ...................................................................................................................13 -1

13.1.2 Analog Outputs ............................................................................................................... 13- 6

13.1.3 Digital Inputs ................................................................................................................... 13-9

13.1.4 Digital Outputs / Relays ................................................................................................13 -14

13.1.5 Frequency Input ............................................................................................................ 13 -23

13.2 LOCAL AND REMOTE COMMAND ........................................................................................ 13-24

14 DYNAMIC BRAKING ........................................................................... 14-1

15 FAULTS AND ALARMS ....................................................................... 15 -1

15.1 MOTOR OVERLOAD PROTECTION ...........................................................................................15 -1

15.2 MOTOR OVERTEMPERATURE PROTECTION ........................................................................ 15-2

15.3 PROTECTIONS ........................................................................................................................... 15-4

16 READ ONLY PARAMETERS ............................................................... 16 -1

16.1 FAULT HISTORY ......................................................................................................................... 16 -7

17 COMMUNICATION ............................................................................. 17-1

17.1 RS-485 SERIAL INTERFACE ...................................................................................................... 17-1

17.2 COMMUNICATION BACNET ...................................................................................................... 17-1

17.3 COMMUNICATION METASYS N2 .............................................................................................. 17-1

17.4 COMMUNICATION STATES AND COMMANDS .......................................................................17-2

Page 7

Summary

18 SOFTPLC [50] ...................................................................................... 18 -1

19 HVAC FUNCTIONS ..............................................................................19-1

19.1 FIRE MODE ..................................................................................................................................19 -1

19.2 BYPASS MODE .......................................................................................................................... 19-4

19.3 ENERGY SAVING MODE ............................................................................................................19 -7

19.4 SHORT CYCLE PROTECTION ................................................................................................... 19-9

19.5 DRY PUMP .................................................................................................................................. 19-9

19.6 BROKEN BELT ..........................................................................................................................19 -11

19.7 FILTER MAINTENANCE ALARM ..............................................................................................19 -12

19.8 MAIN PID CONTROLLER .........................................................................................................19 -13

19.8.1 Sleep Mode .................................................................................................................... 19-21

19.9 EXTERNAL PID CONTROLLER 1 ........................................................................................... 19 -24

19.10 EXTERNAL PID CONTROLLER 2 .......................................................................................... 19 -31

19.11 HVAC FUNCTIONS LOGICAL STATUS ................................................................................. 19-38

19.12 VERSION OF THE HVAC APPLICATION ............................................................................... 19-39

Page 8

Summary

Page 9

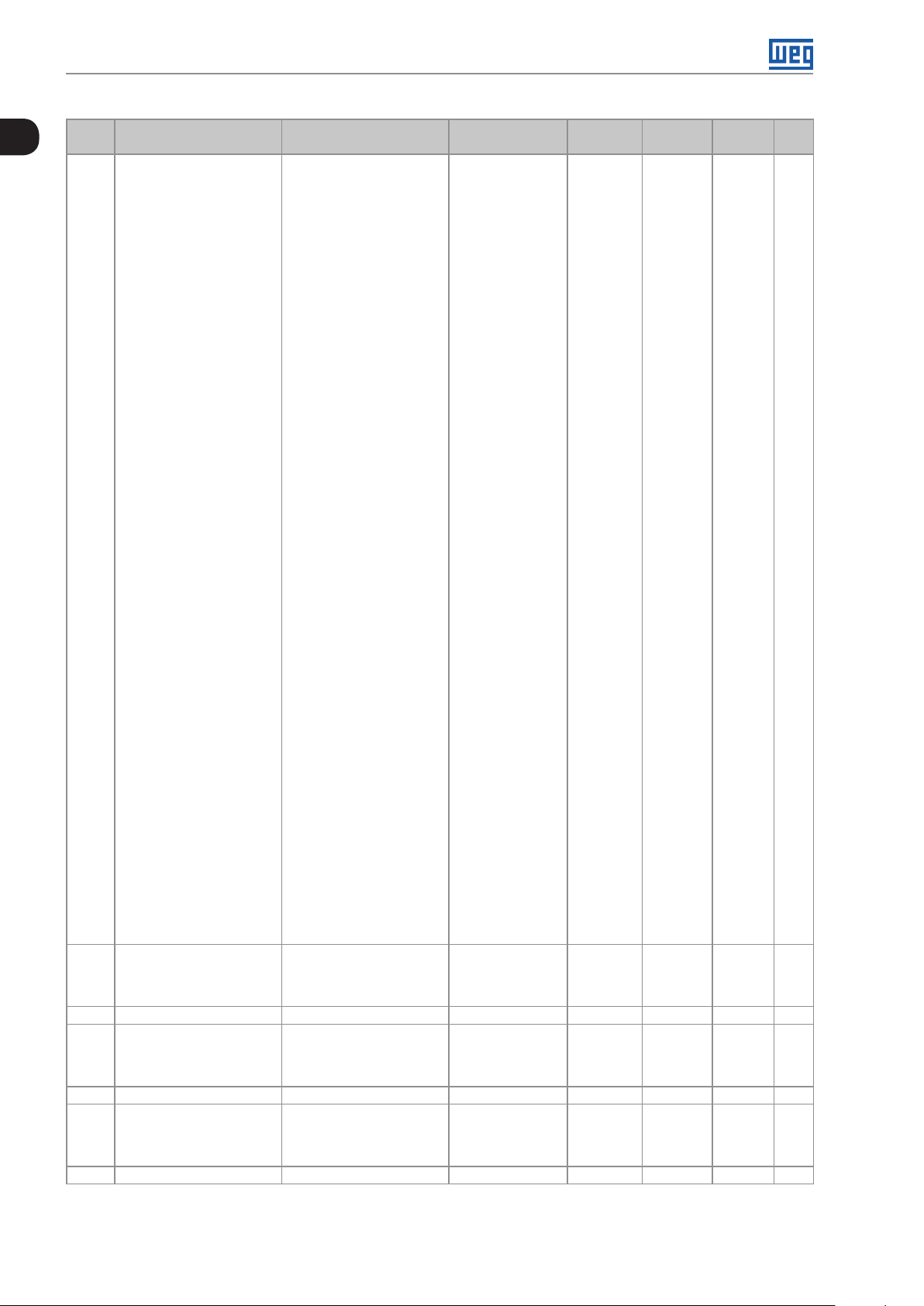

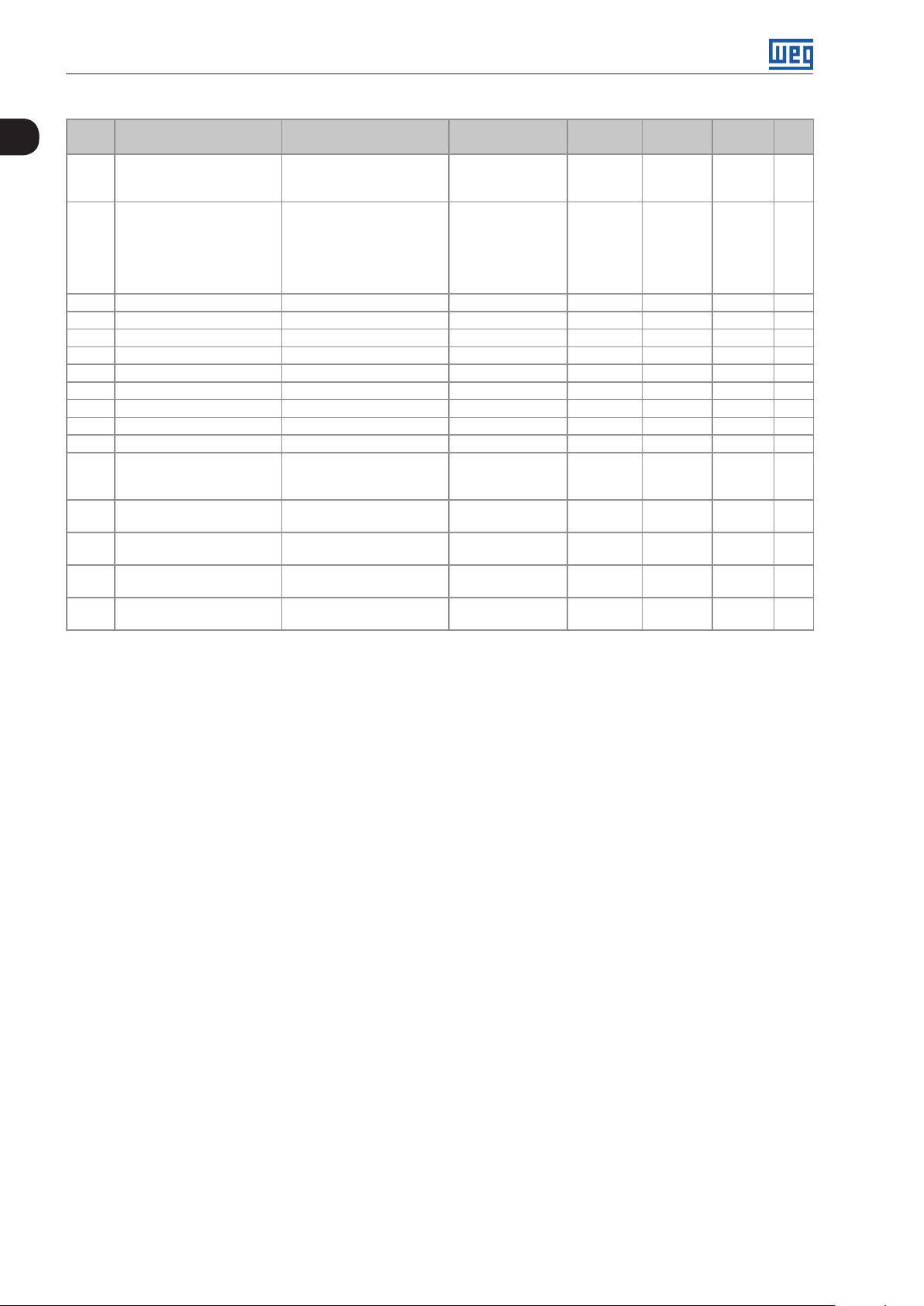

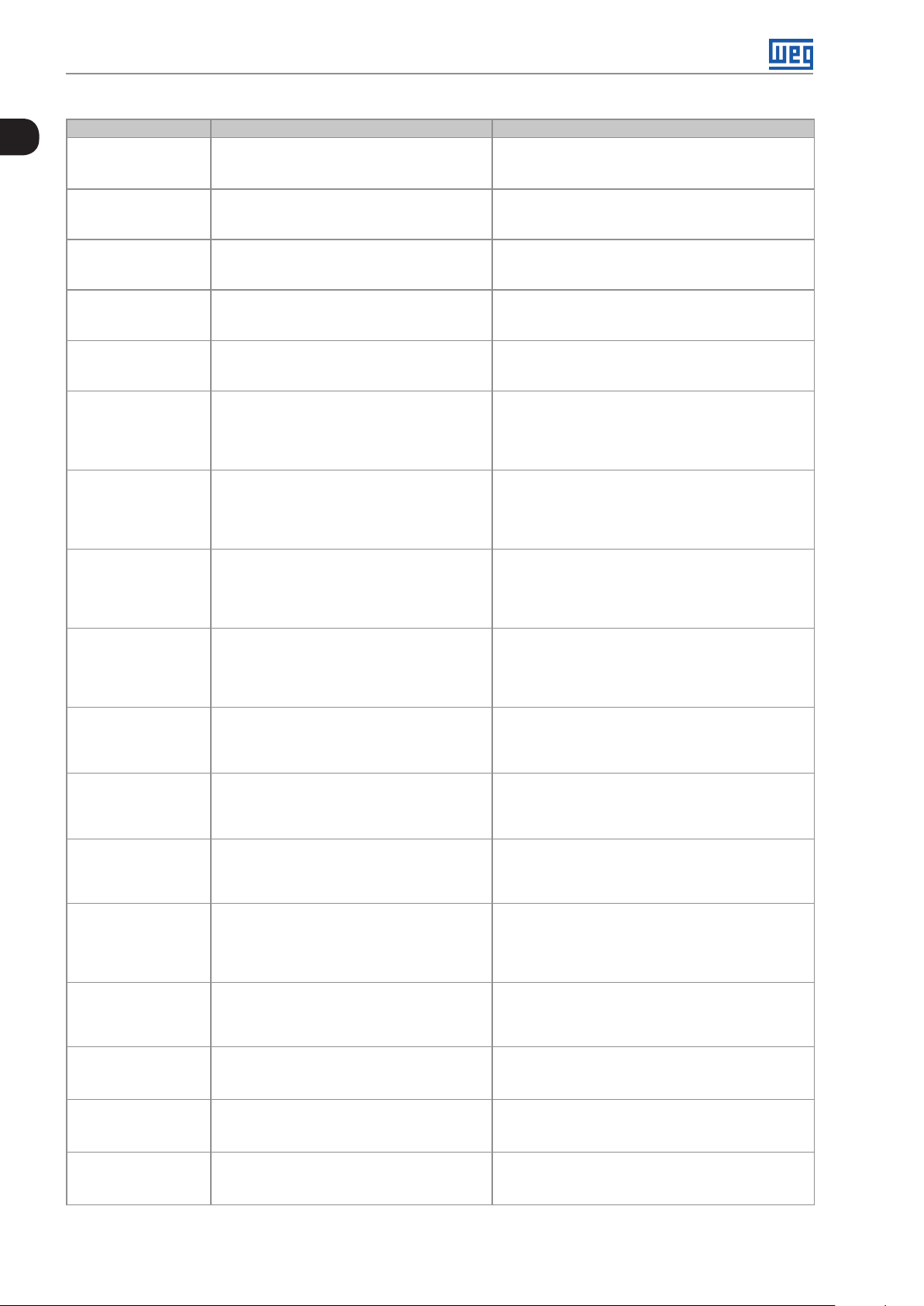

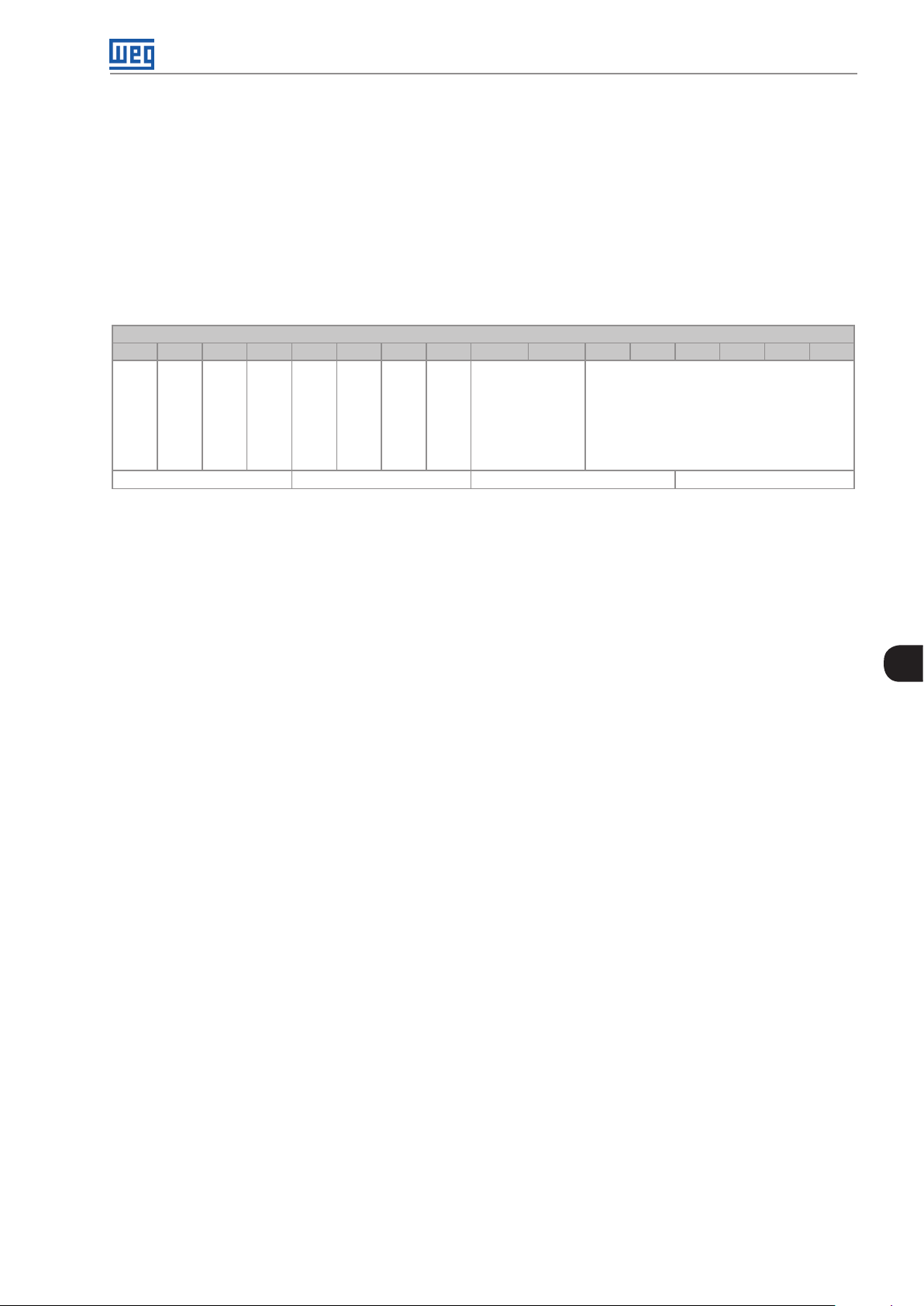

Quick Parameter Reference, Faults and Alarms

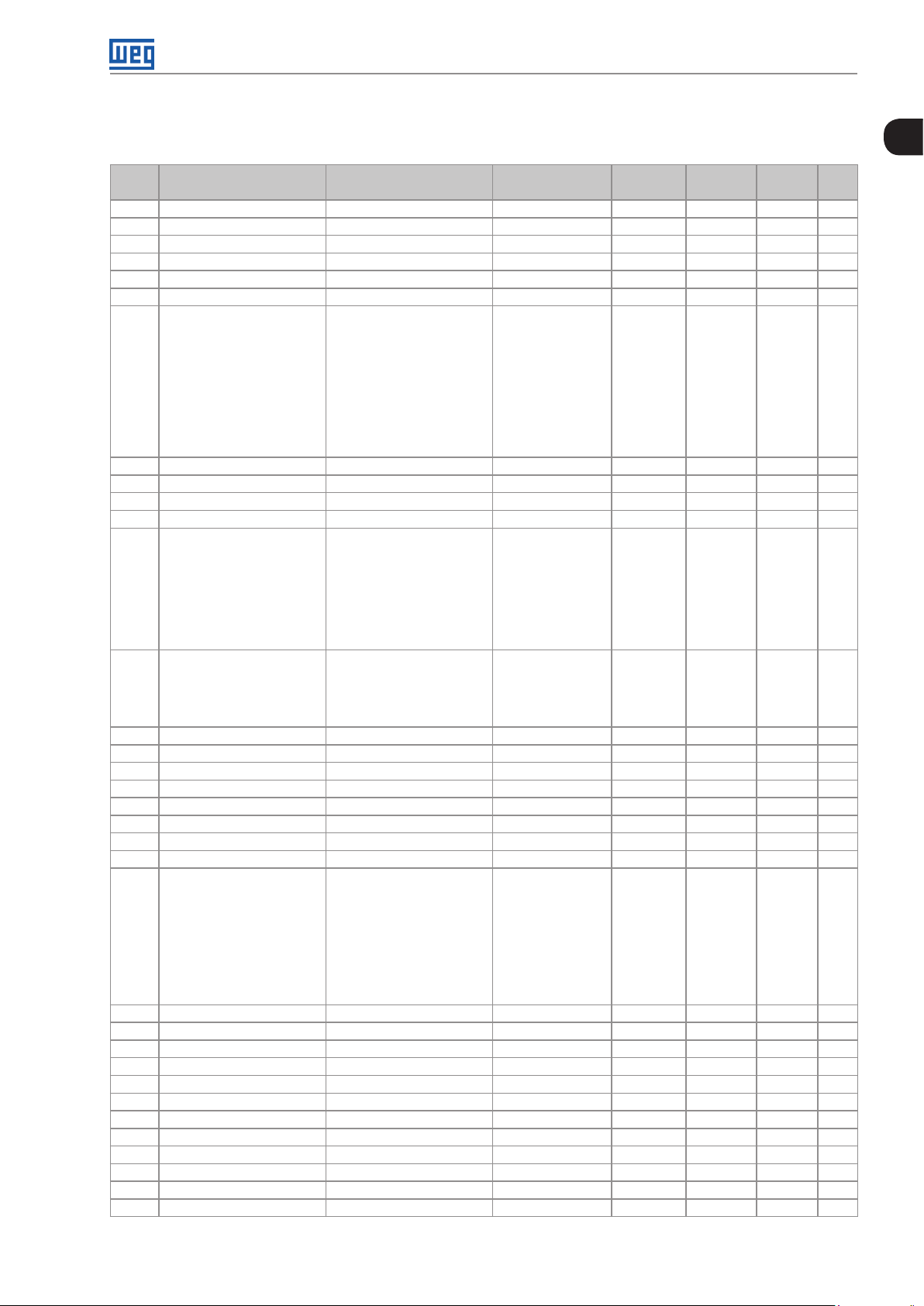

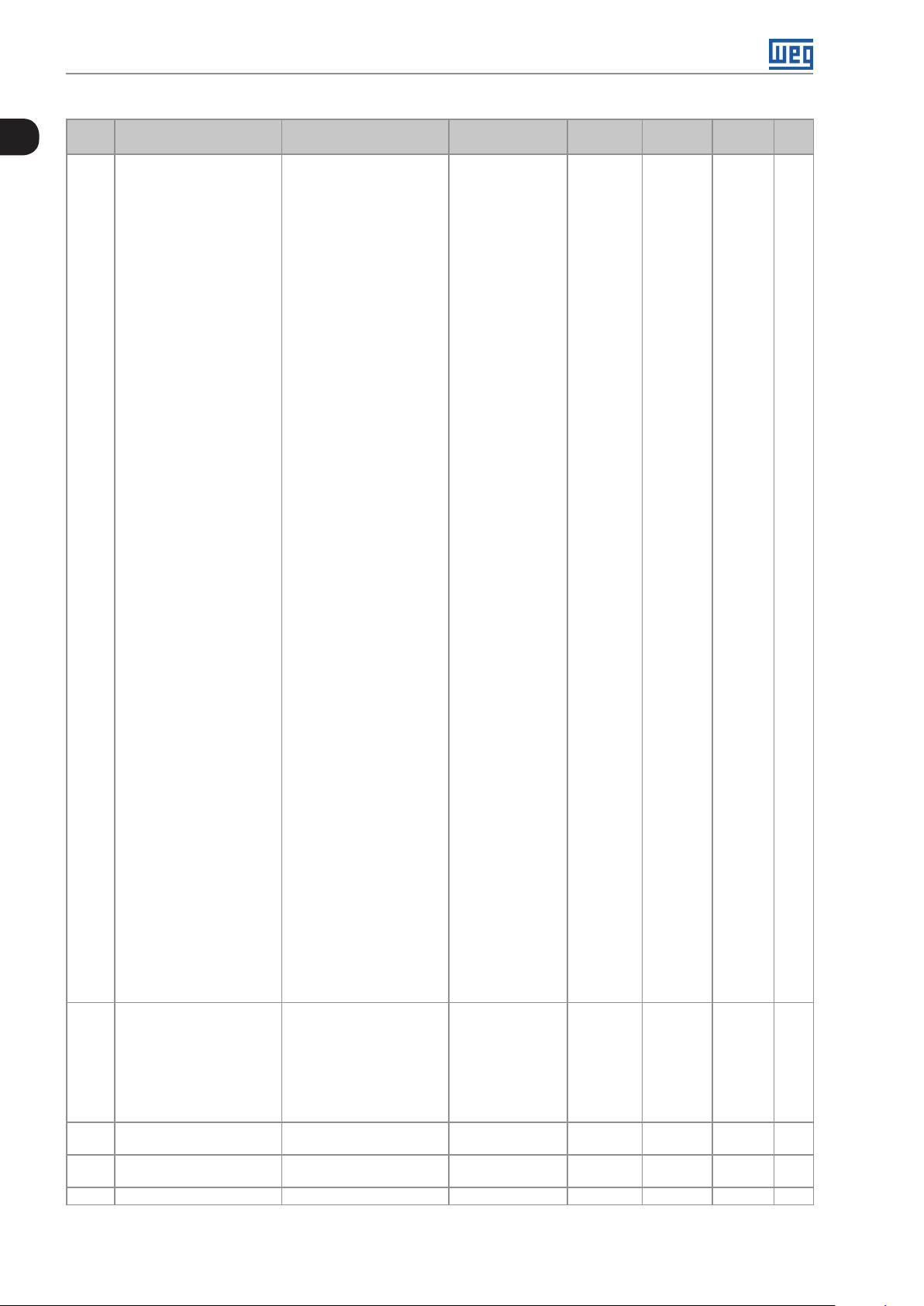

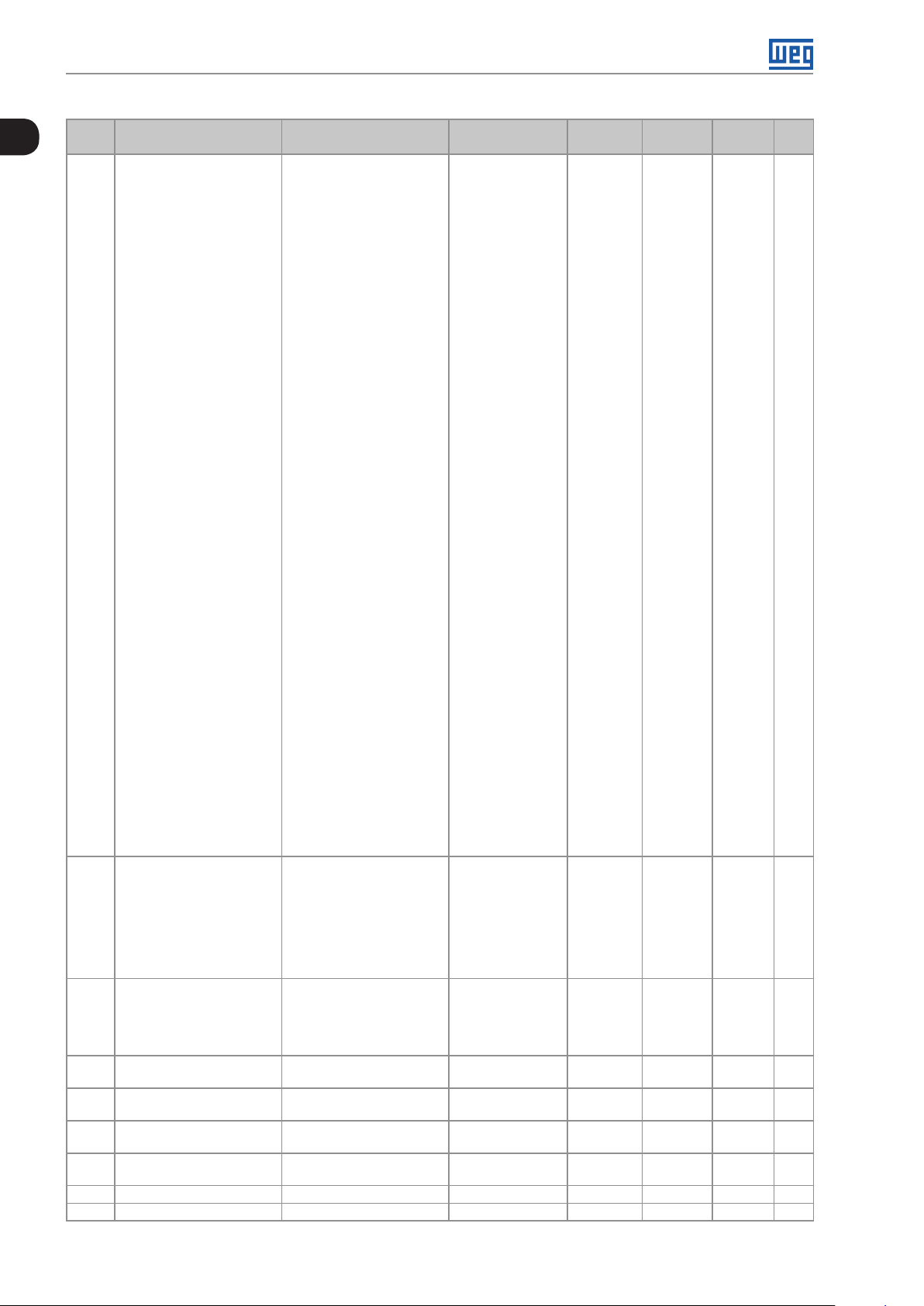

QUICK PARAMETER REFERENCE, FAULTS AND ALARMS

Param. Function

P0000 Access to Parameters 0 to 9999 0 5-1

P0001 Speed Reference 0 to 18000 rpm ro READ 16 -1

P0002 Motor Speed 0 to 18000 rpm ro READ 16 -1

P0003 Motor Current 0.0 to 4500.0 A ro READ 16-1

P0004 DC Link Voltage (Ud) 0 to 2000 V ro READ 16-2

P0005 Motor Frequency 0.0 to 1020.0 Hz ro READ 16-2

P0006 VFD Status 0 = Ready

P0007 Motor Voltage 0 to 2000 V ro READ 16-3

P0009 Motor Torque -1000.0 to 1000.0 % ro READ 16-3

P0 010 Output Power 0.0 to 6553.5 kW ro READ 16-4

P0 0 11 Output Cos φ 0.00 to 1.00 ro READ, I/O 16-4

P0 012 DI8 to DI1 Status Bit 0 = DI1

P0 013 DO5 to DO1 Status Bit 0 = DO1

P0 014 AO1 Value 0.00 to 100.00 % ro READ, I/O 13-6

P0 015 AO2 Value 0.00 to 100.00 % ro READ, I/O 13-6

P0 018 AI1 Value -100.00 to 100.00 % ro READ, I/O 13-1

P0 019 AI2 Value -100.00 to 100.00 % ro READ, I/O 13-1

P0020 AI3 Value -100.00 to 100.00 % ro READ, I/O 13-1

P0022 Frequency Input 3.0 to 6500.0 Hz ro READ, I/O 13-23

P0023 Software Version 0.00 to 655.35 ro READ 6-1

P0028 Accessories Config. 0000h to FFFFh ro READ 6-2

P0029 Power Hardware Config Bit 0 to 5 = Rated Current

P0030 IGBTs Temperature -20.0 to 150.0 °C ro READ 15-4

P0034 Internal Air Temp. -20.0 to 150.0 °C ro READ 15- 4

P0036 Fan Heatsink Speed 0 to 15000 rpm ro READ 16-5

P0037 Motor Overload Status 0 to 100 % ro READ 16-5

P0042 Powered Time 0 to 65535 h ro READ 16-6

P0043 Enabled Time 0.0 to 6553.5 h ro READ 16-6

P0044 kWh Output Energy 0 to 65535 kWh ro READ 16-6

P0045 Enabled Fan Time 0 to 65535 h ro READ 16-7

P0048 Present Alarm 0 to 999 ro READ 16 -7

P0049 Present Fault 0 to 999 ro READ 16-7

P0050 Last Fault 0 to 999 ro READ 16-8

P0054 Second Fault 0 to 999 ro READ 16-8

Adjustable

Range

1 = Run

2 = Undervoltage

3 = Fault

4 = Self-Tuning

5 = Configuration

6 = DC-Braking

7 = STO

8 = Fire Mode

9 = Bypass

Bit 1 = DI2

Bit 2 = DI3

Bit 3 = DI4

Bit 4 = DI5

Bit 5 = DI6

Bit 6 = DI7

Bit 7 = DI8

Bit 1 = DO2

Bit 2 = DO3

Bit 3 = DO4

Bit 4 = DO5

Bit 6 and 7 = Rated Voltage

Bit 8 = RFI Filter

Bit 9 = Safety Relay

Bit 10 = (0)24 V/(1)DC Link

Bit 11 = Always 0

Bit 12 = Dyn. Brak. IGBT

Bit 13 = Special

Bit 14 and 15 = Reserved

Factory

Setting

User

Setting

Propr. Groups Pág.

ro READ 16-2

ro READ, I/O 13-9

ro READ, I/O 13-14

ro READ 6-2

0

CFW701 | 0-1

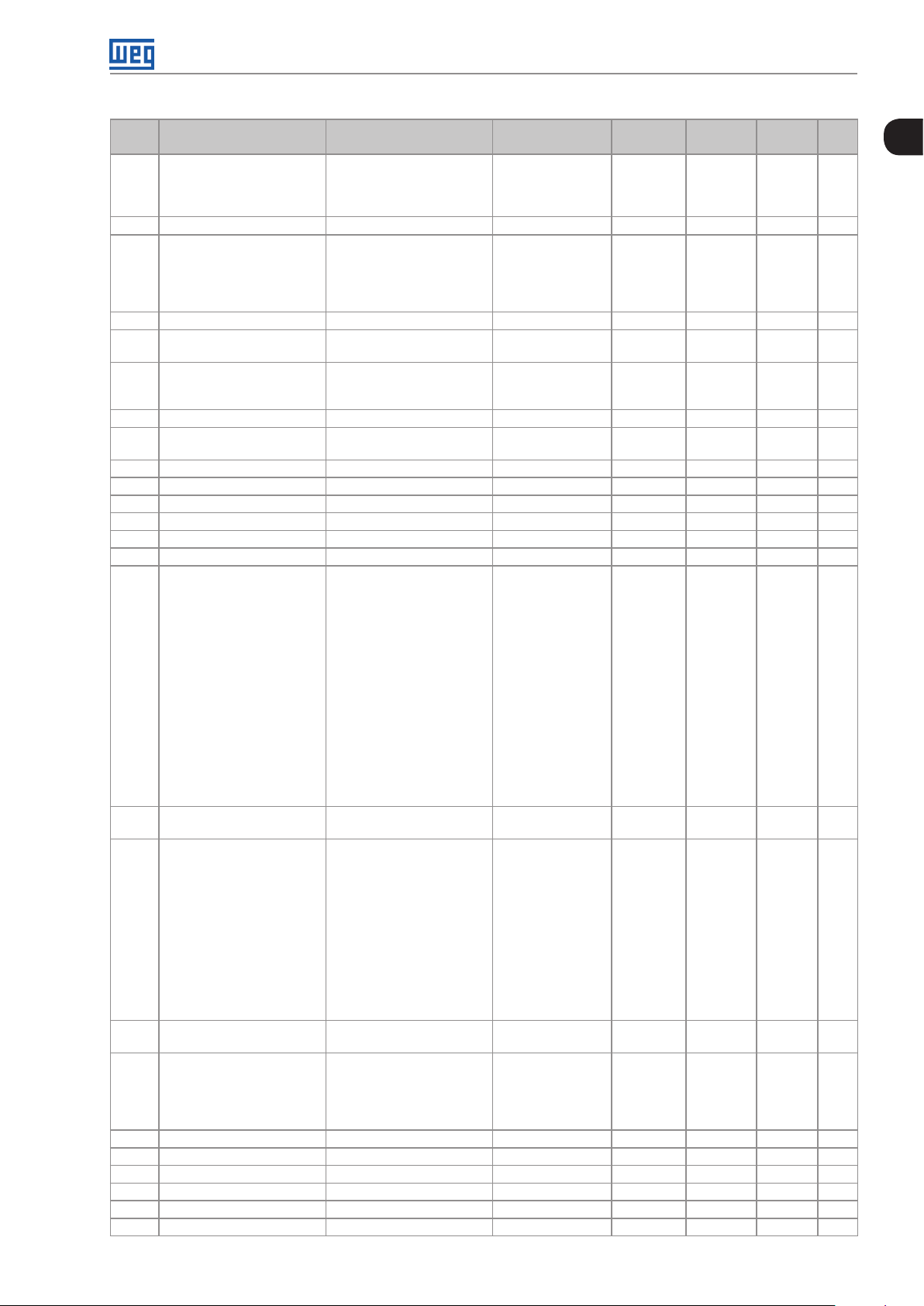

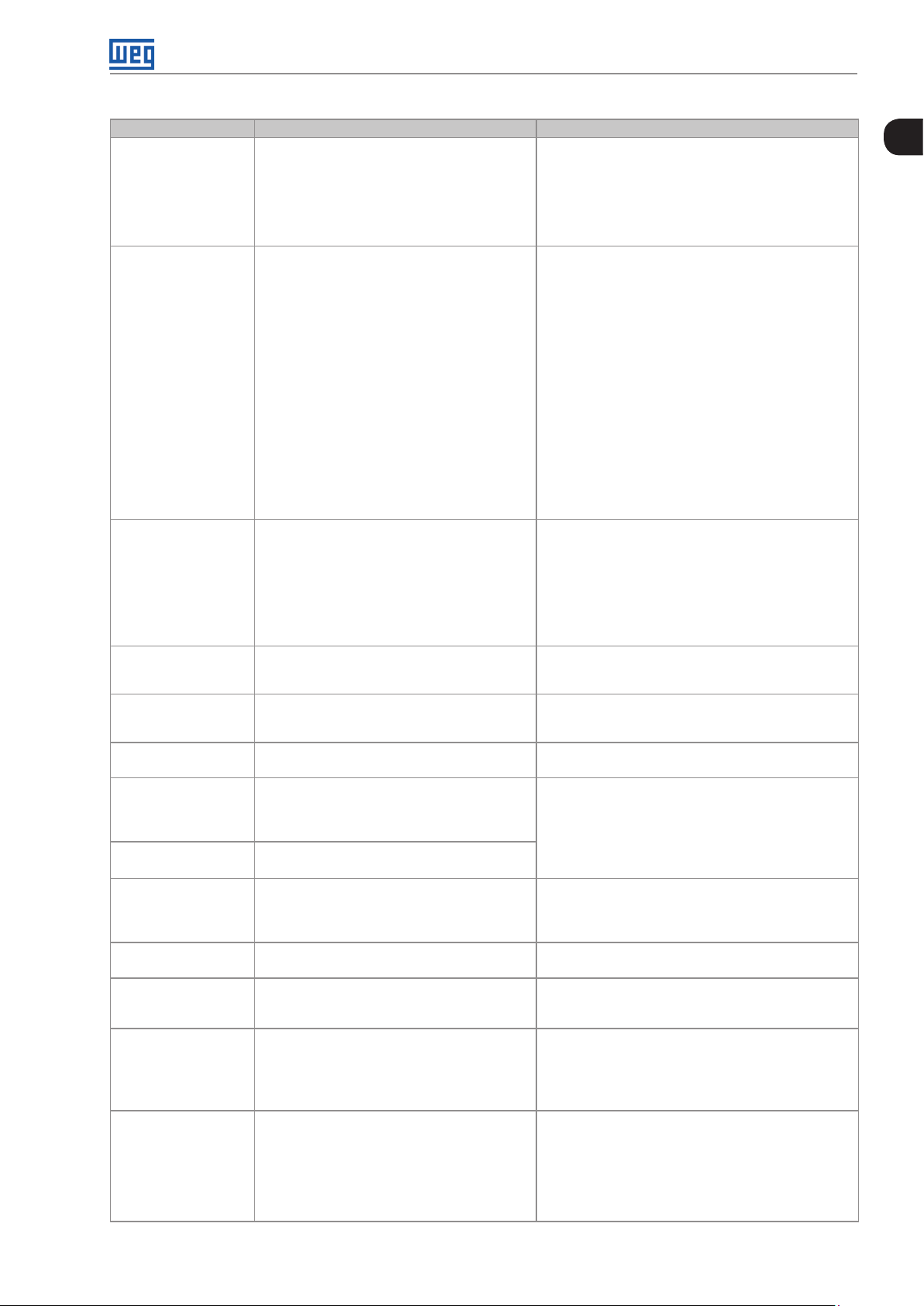

Page 10

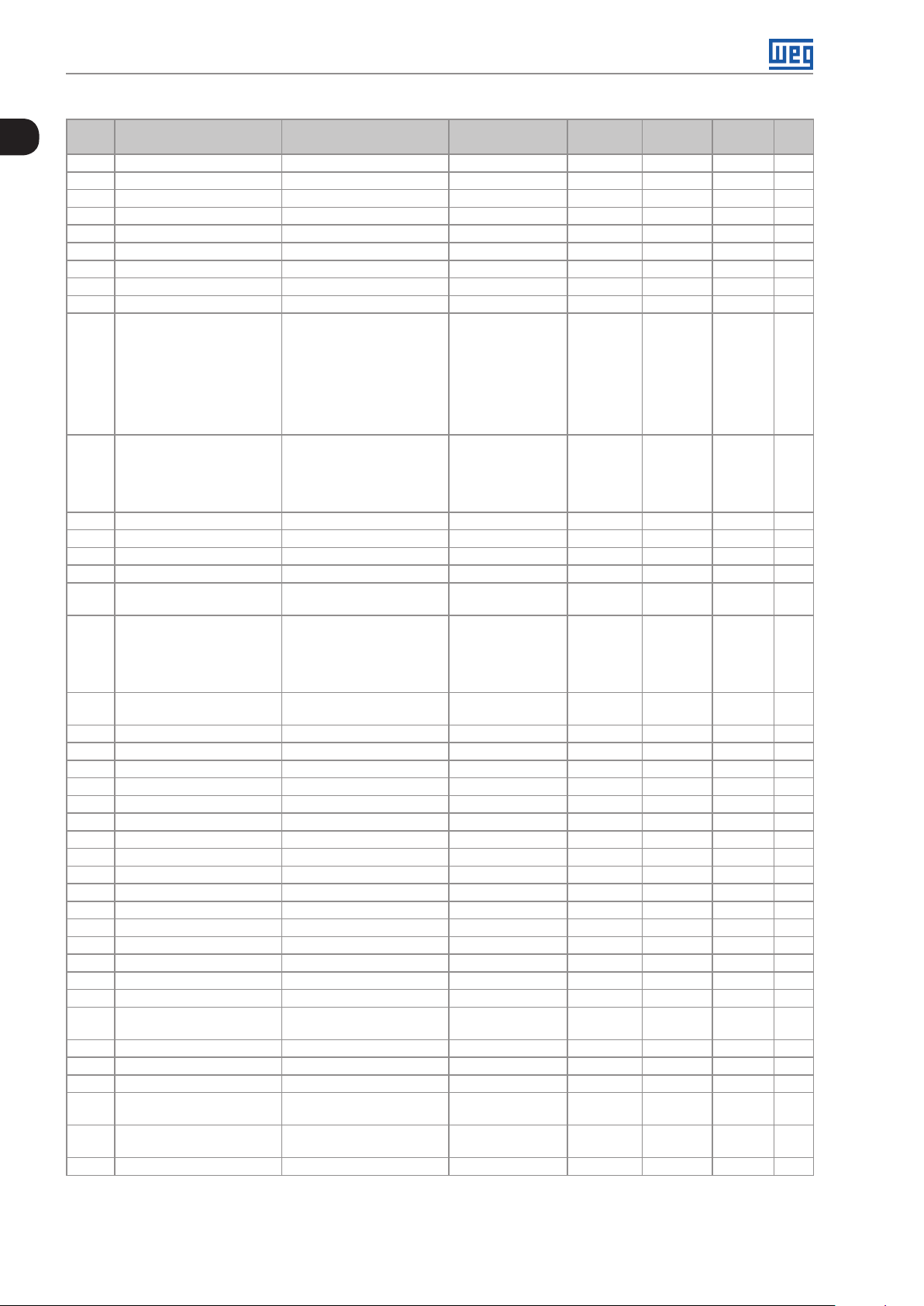

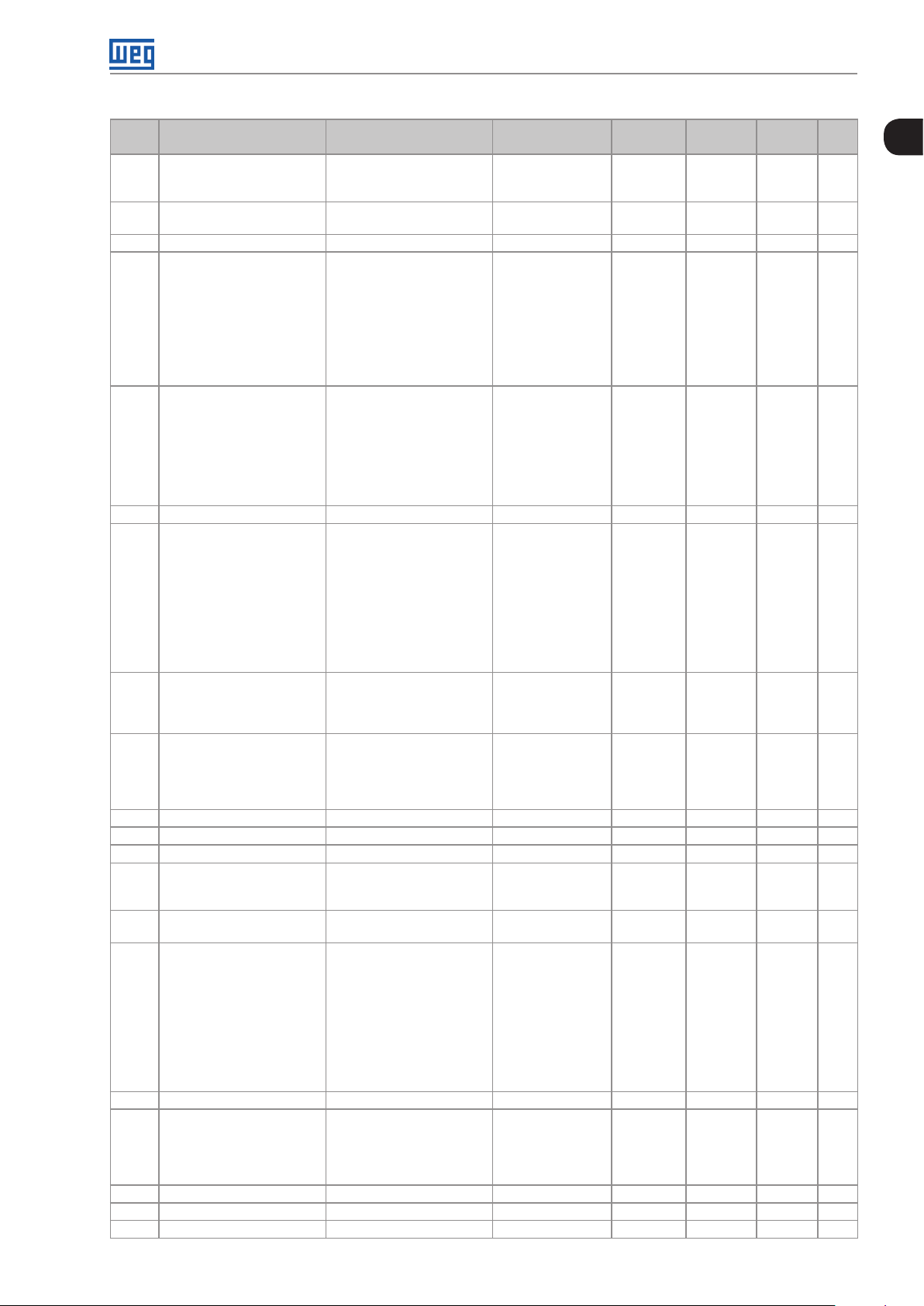

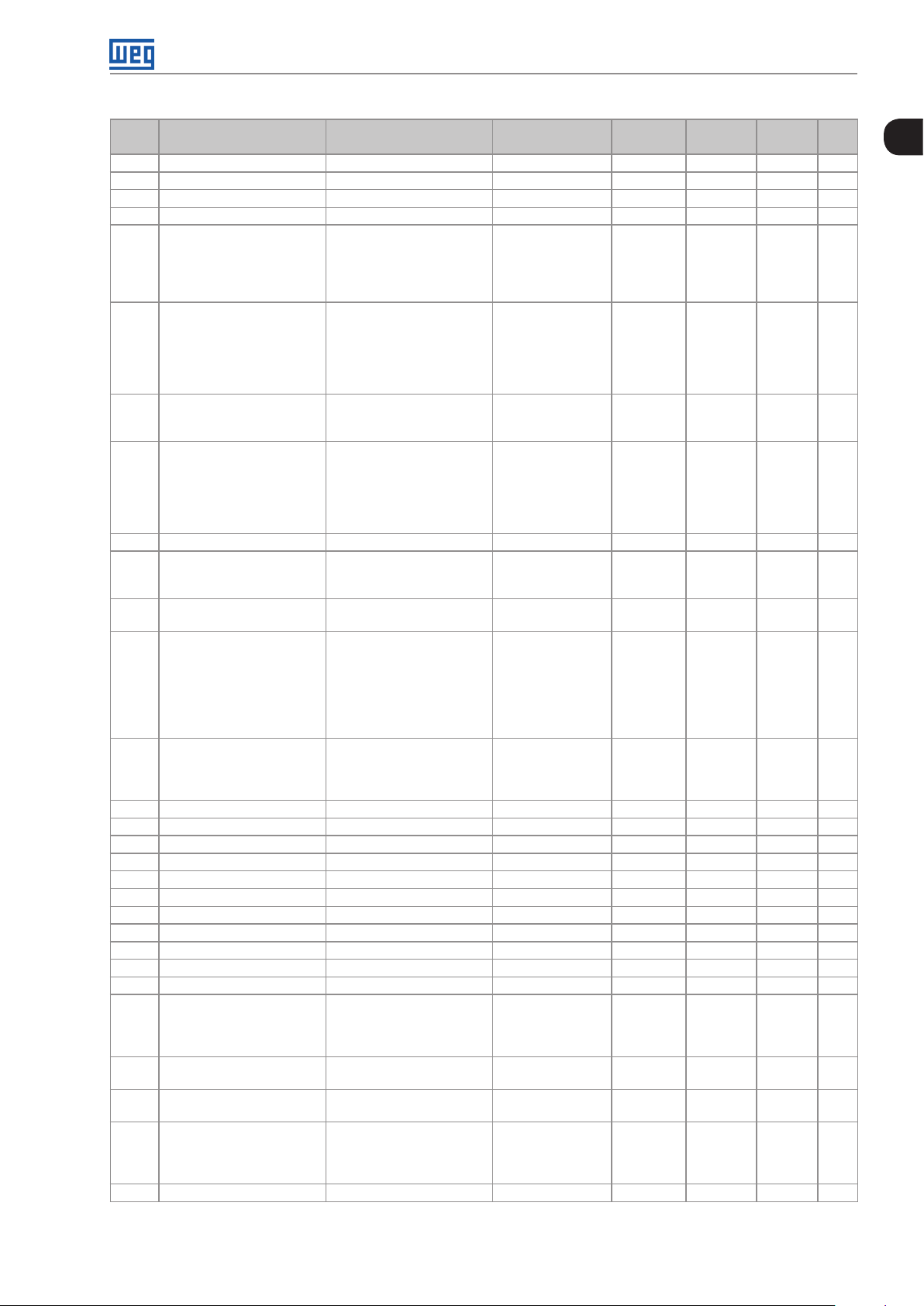

Quick Parameter Reference, Faults and Alarms

0

Param. Function

Adjustable

Range

Factory

Setting

User

Setting

Propr. Groups Pág.

P0058 Third Fault 0 to 999 ro READ 16- 8

P0062 Fourth Fault 0 to 999 ro READ 16-8

P0066 Fifth Fault 0 to 999 ro READ 16- 8

P0090 Current At Last Fault 0.0 to 4500.0 A ro READ 16 -8

P0091 DC Link At Last Fault 0 to 2000 V ro READ 16-8

P0092 Speed At Last Fault 0 to 18000 rpm ro READ 16-9

P0093 Reference Last Fault 0 to 18000 rpm ro READ 16 -9

P0094 Frequency Last Fault 0.0 to 1020.0 Hz ro READ 16-9

P0095 Motor Volt. Last Fault 0 to 2000 V ro READ 16-9

P0096 DIx Status Last Fault Bit 0 = DI1

ro READ 16 -10

Bit 1 = DI2

Bit 2 = DI3

Bit 3 = DI4

Bit 4 = DI5

Bit 5 = DI6

Bit 6 = DI7

Bit 7 = DI8

P0097 DOx Status Last Fault Bit 0 = DO1

ro READ 16 -10

Bit 1 = DO2

Bit 2 = DO3

Bit 3 = DO4

Bit 4 = DO5

P010 0 Acceleration Time 0.0 to 999.0 s 20.0 s BASIC 12-1

P0101 Deceleration Time 0.0 to 999.0 s 20.0 s BASIC 12-1

P010 2 Acceleration Time 2 0.0 to 999.0 s 20.0 s 12-1

P010 3 Deceleration Time 2 0.0 to 999.0 s 20.0 s 12-1

P010 4 Ramp Type 0 = Linear

0 12-2

1 = S Ramp

P010 5 1st/2nd Ramp Select. 0 = 1st Ramp

2 cfg 12- 3

1 = 2nd Ramp

2 = DIx

3 = Serial

4 = SoftPLC

P0120 Speed Ref. Backup 0 = Inactive

1 12-3

1 = Active

P0121 Keypad Reference 0 to 18000 rpm 90 rpm 12-4

P0122 JOG/JOG + Reference 0 to 18000 rpm 150 (125) rpm 12-4

P0123 JOG - Reference 0 to 18000 rpm 150 (125) rpm Vector 12-5

P0132 Max. Overspeed Level 0 to 100 % 10 % cfg 12- 5

P0133 Minimum Speed 0 to 18000 rpm 90 (75) rpm BASIC 12-6

P0134 Maximum Speed 0 to 18000 rpm 1800 (1500) rpm BASIC 12-6

P0135 Max. Output Current 0.2 to 2xI

nom-HD

1.5xI

nom-HD

V/f, V VW BASIC 9-6

P0136 Manual Torque Boost 0 to 9 1 V/f BASIC 9-2

P0137 Autom. Torque Boost 0.00 to 1.00 0.00 V/f 9-2

P0138 Slip Compensation -10.0 to 10.0 % 0.0 % V/f 9-3

P0139 Output Current Filter 0.0 to 16.0 s 0.2 s V/f, V VW 9-4

P0142 Max. Output Voltage 0.0 to 100.0 % 10 0.0 % cfg, Adj 9-5

P0143 Interm. Output Voltage 0.0 to 100.0 % 50.0 % cfg, Adj 9-5

P0144 3 Hz Output Voltage 0.0 to 100.0 % 8.0 % cfg, Adj 9-5

P0145 Field Weakening Speed 0 to 18000 rpm 1800 r pm cfg, Adj 9-5

P0146 Intermediate Speed 0 to 18000 rpm 900 rpm cfg, Adj 9-5

P0150 V/f DC Regulation Type 0 = Ramp Hold

1 = Ramp Accel.

0 cfg, V/f,

VVW

9-10

P0151 V/f DC Regulation Level 339 to 1000 V 800 V V/f, V VW 9-10

P0152 DC Link Regul. P Gain 0.00 to 9.99 1.50 V/f, V VW 9 -11

P0153 Dyn. Braking Level 339 to 1000 V 748 V 14-1

P0156 100 % Speed Overload

Current

P0157 50 % Speed Overload

Current

P0158 5 % Speed Overload Current 0.1 to 1.5xI

0.1 to 1.5xI

0.1 to 1.5xI

nom-ND

nom-ND

nom-ND

1.0 5xI

0.9xI

0.65xI

nom-ND

nom-ND

nom-ND

15- 4

15- 4

15- 4

0-2 | CFW701

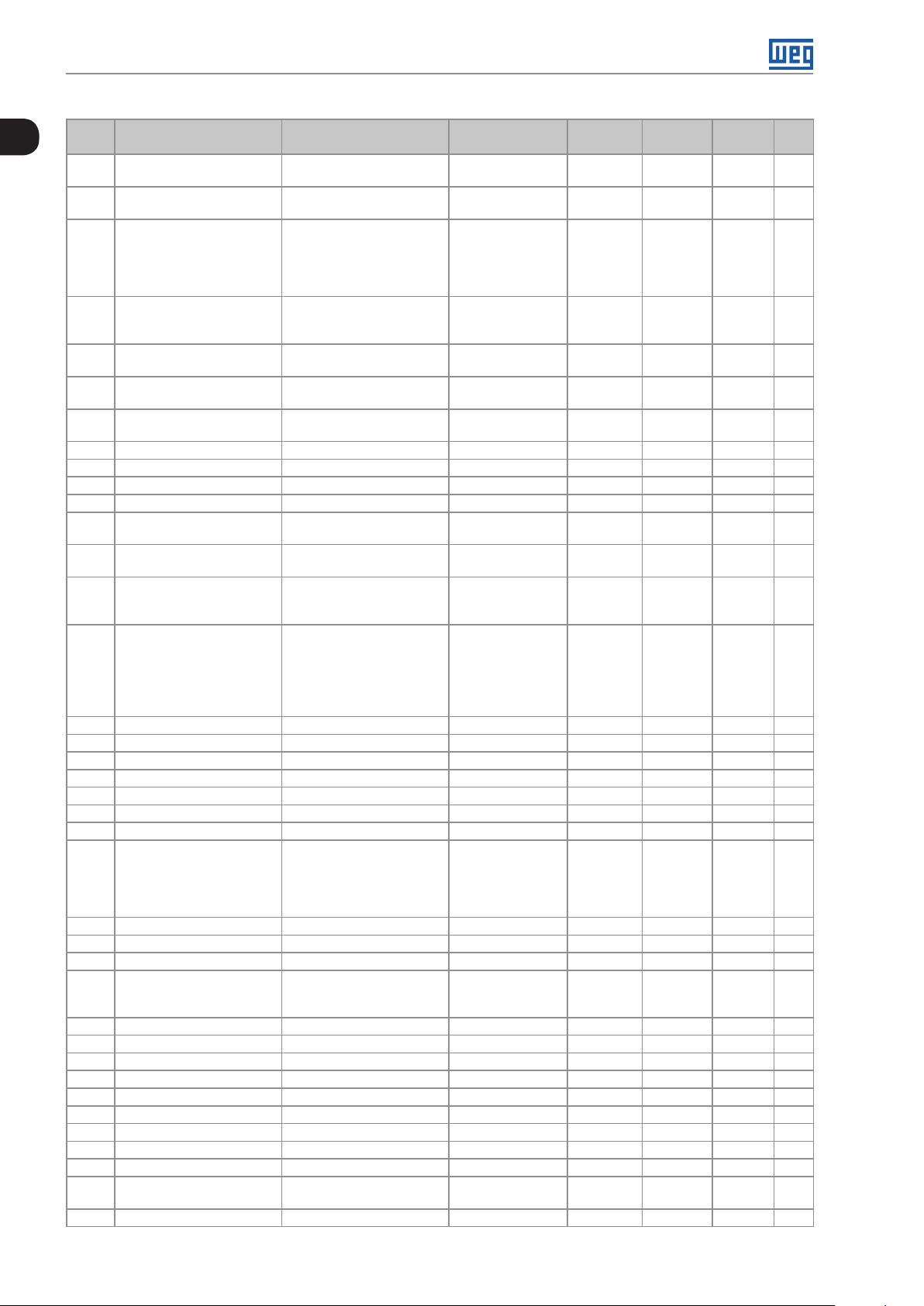

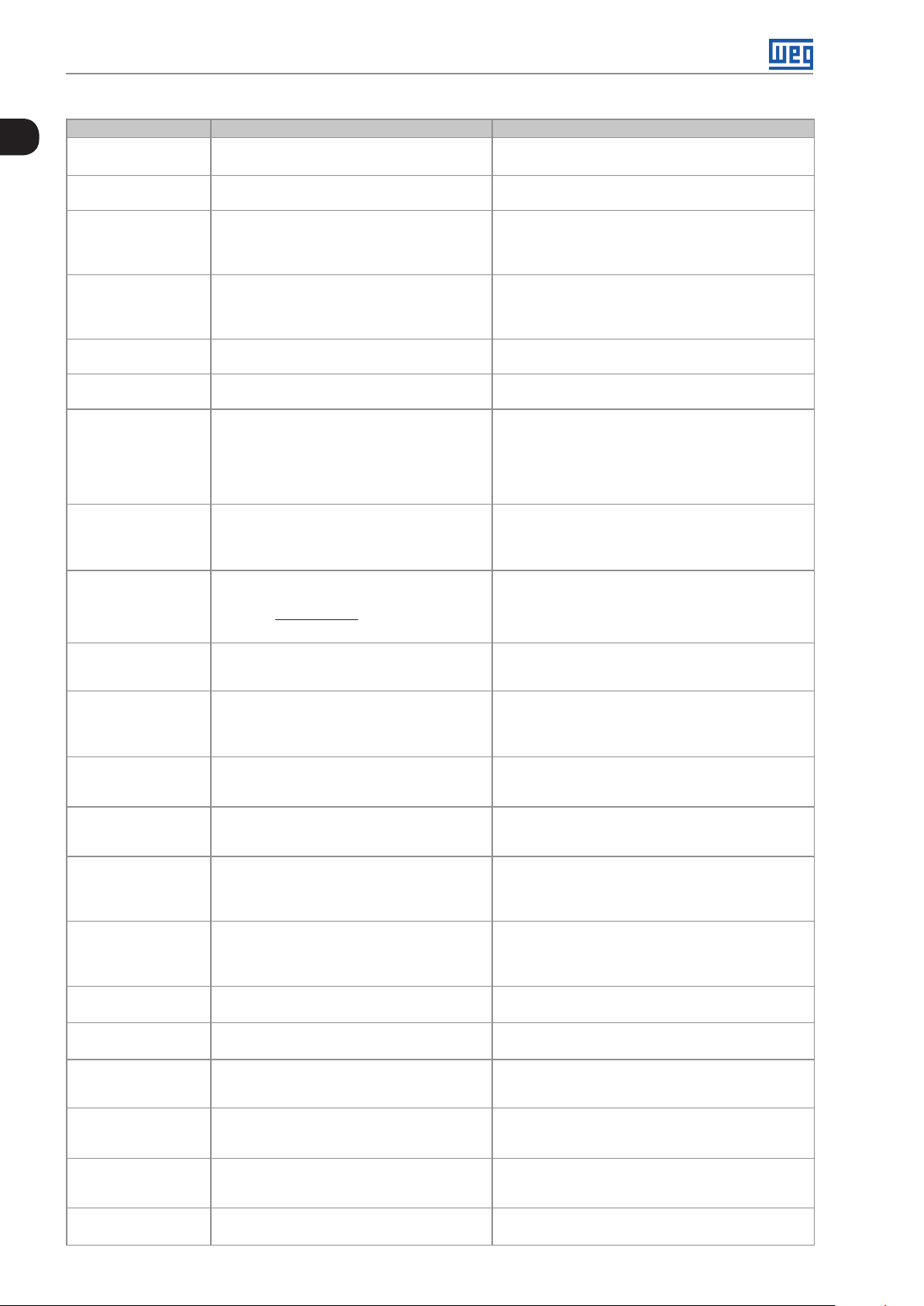

Page 11

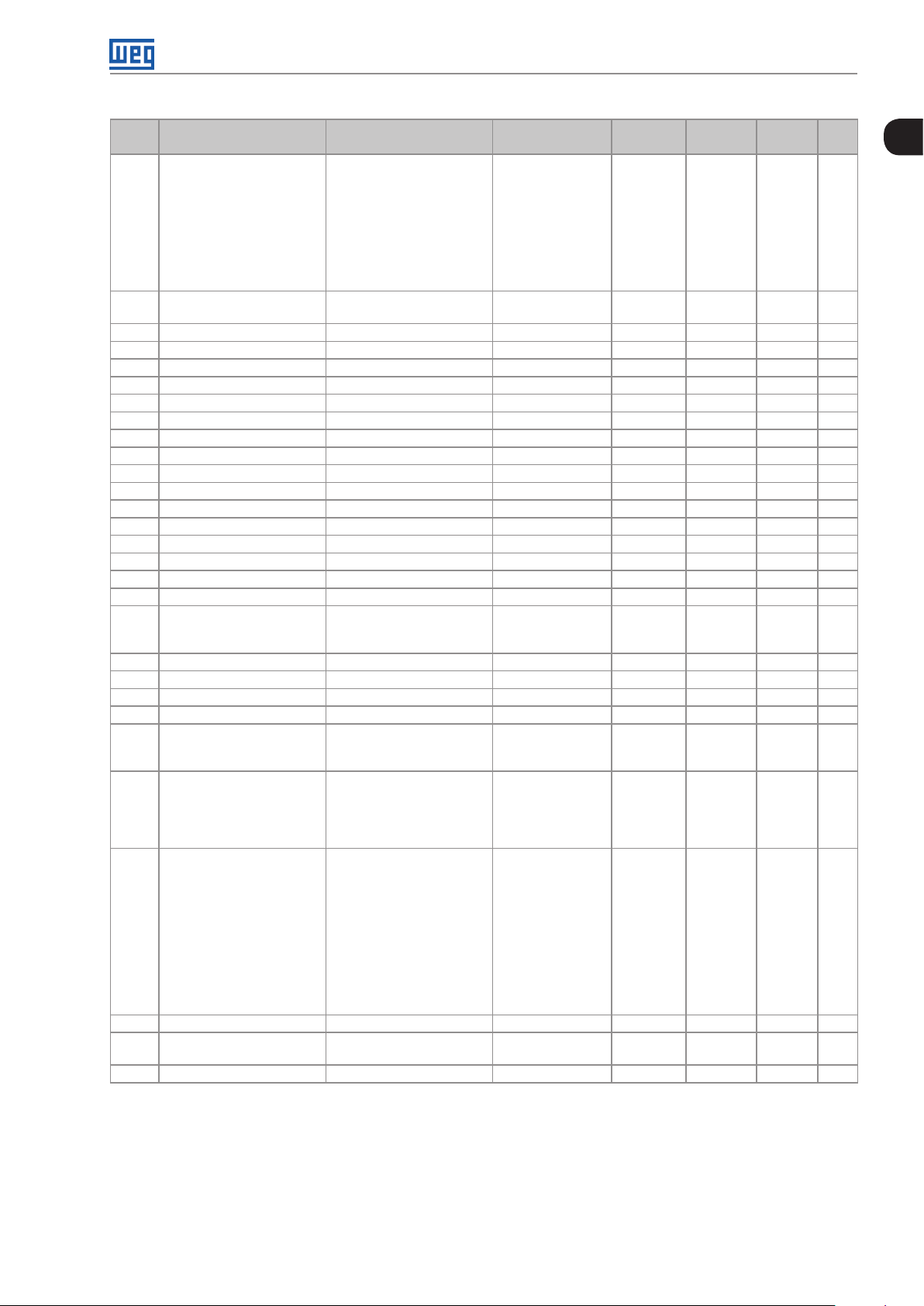

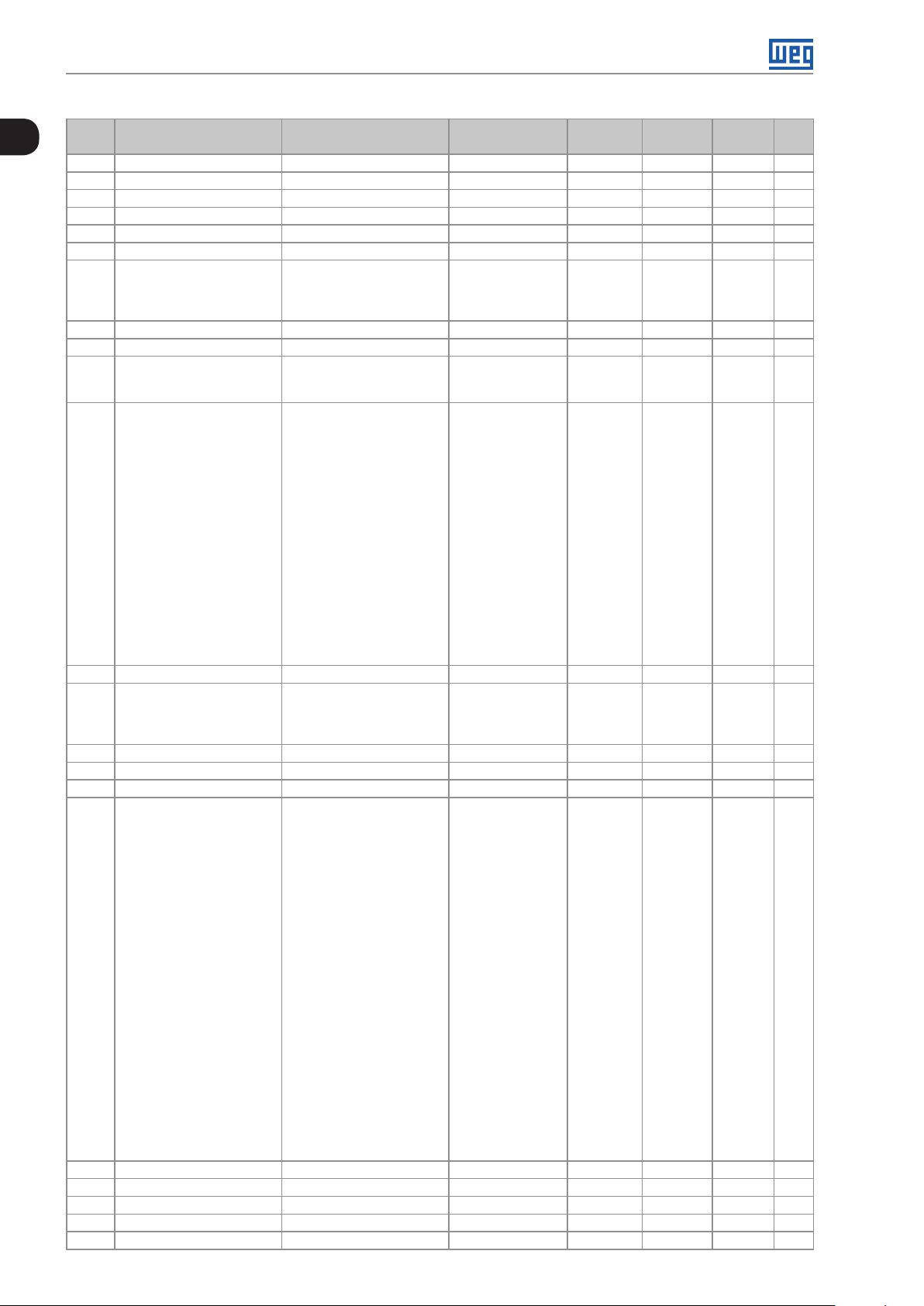

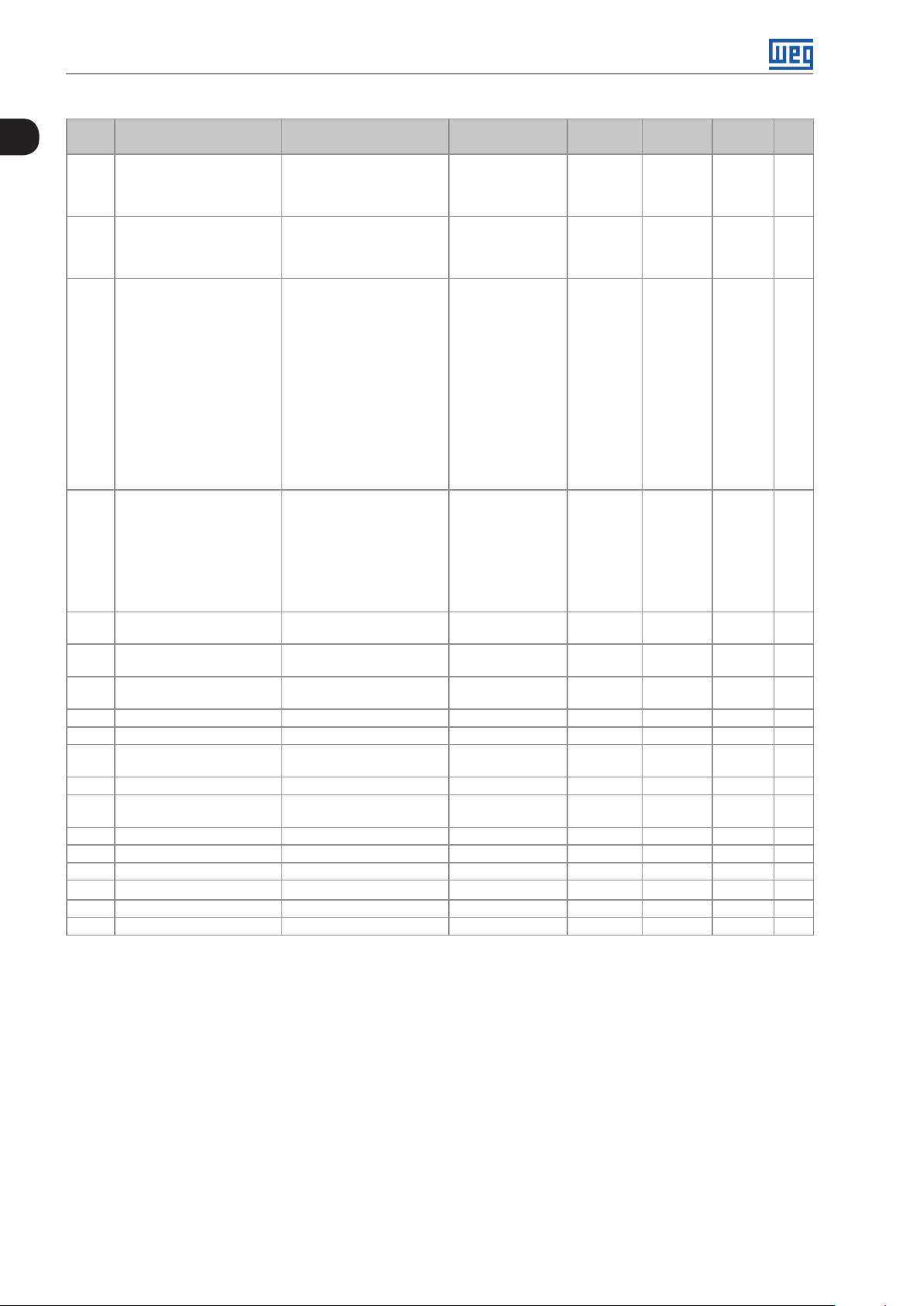

Quick Parameter Reference, Faults and Alarms

Param. Function

P0159 Motor Thermal Class 0 = Class 5

P0160 Speed Regul. Config. 0 = Normal

P0161 Speed Prop. Gain 0.0 to 63.9 7.4 Vector 11-12

P0162 Speed Integral Gain 0.000 to 9.999 0.023 Vector 11-12

P0163 LOC Reference Offset -999 to 999 0 Vector 11-13

P0164 REM Reference Offset -999 to 999 0 Vector 11-13

P0165 Speed Filter 0.012 to 1.000 s 0.012 s Vector 11-13

P0166 Speed Diff. Gain 0.00 to 7.99 0.00 Vector 11-14

P0167 Current Prop. Gain 0.00 to 1.99 0.50 Vector 11-14

P0168 Current Integral Gain 0.000 to 1.999 0.010 Vector 11-14

P0169 Max. + Torque Curr. 0.0 to 350.0 % 125.0 % Vector 11-20

P0170 Max. - Torque Curr. 0.0 to 350.0 % 125. 0 % Vector 11- 2 0

P0175 Flux Proport. Gain 0.0 to 31.9 2.0 Vector 11-14

P0176 Flux Integral Gain 0.000 to 9.999 0.020 Vector 11-15

P0178 Rated Flux 0 to 120 % 100 % Vector 11-15

P0180 Iq* After I/f 0 to 350 % 10 % Sless 11-16

P0182 Speed for I/f Activ. 0 to 90 rpm 18 rpm Sless 11-16

P0183 Current in I/f Mode 0 to 9 1 Sless 11-16

P0184 DC Link Regul. Mode 0 = With losses

P0185 DC Link Regul. Level 339 to 1000 V 800 V Vector 11- 2 3

P0186 DC Link Prop. Gain 0.0 to 63.9 26.0 Vector 11- 2 3

P0187 DC Link Integral Gain 0.000 to 9.999 0.010 Vector 11- 2 3

P0190 Max. Output Voltage 0 to 600 V 440 V Vector 11-15

P0200 Password 0 = Inactive

P0202 Control Type 0 = V/f 60 Hz

P0204 Load/Save Parameters 0 = Not Used

P0205 Main Display Parameter Sel. 0 to 1199 2 HMI 5-3

P0206 Secondary Display

Parameter Sel.

P0208 Main Display Scale Factor 0.1 to 1000.0 % 100.0 % HMI 5-3

Adjustable

Range

1 = Class 10

2 = Class 15

3 = Class 20

4 = Class 25

5 = Class 30

6 = Class 35

7 = Class 40

8 = Class 45

1 = Saturated

1 = Without losses

2 = Enab/Disab DIx

1 = Active

2 = Change Pass.

1 = V/f 50 Hz

2 = V/f Adjustable

3 = V V W

4 = Sensorless

1 = Not Used

2 = Reset P0045

3 = Reset P0043

4 = Reset P0044

5 = Load 60 Hz

6 = Load 50 Hz

7 = Load User 1

8 = Load User 2

9 = Save User 1

10 = Save User 2

0 to 1199 3 HMI 5-3

Factory

Setting

1 cfg 15-5

0 cfg, Vector 11-12

1 cfg, Vector 11- 2 2

1 HMI 5-2

0 cfg 9-5

0 cfg 7-1

User

Setting

Propr. Groups Pág.

0

CFW701 | 0-3

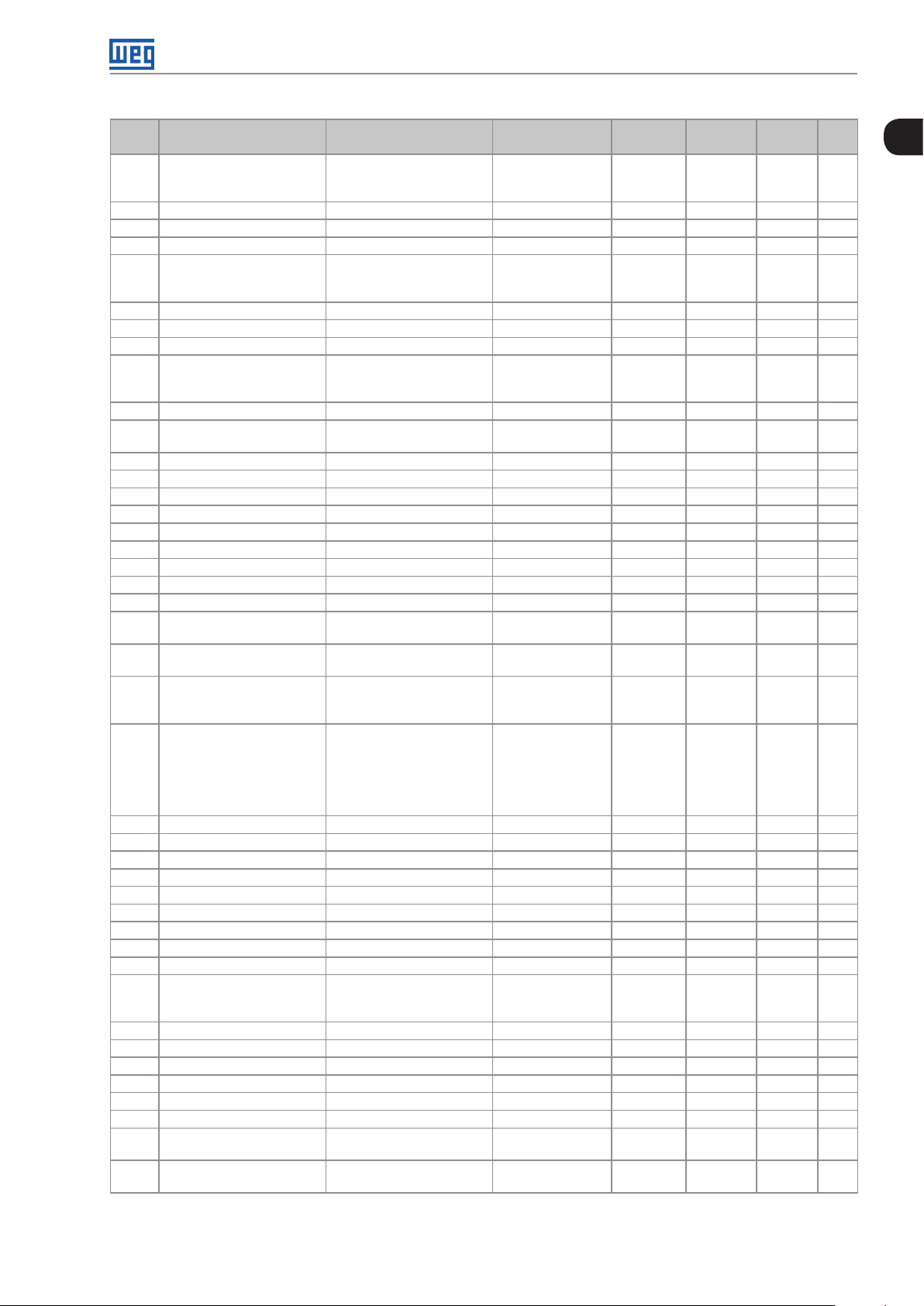

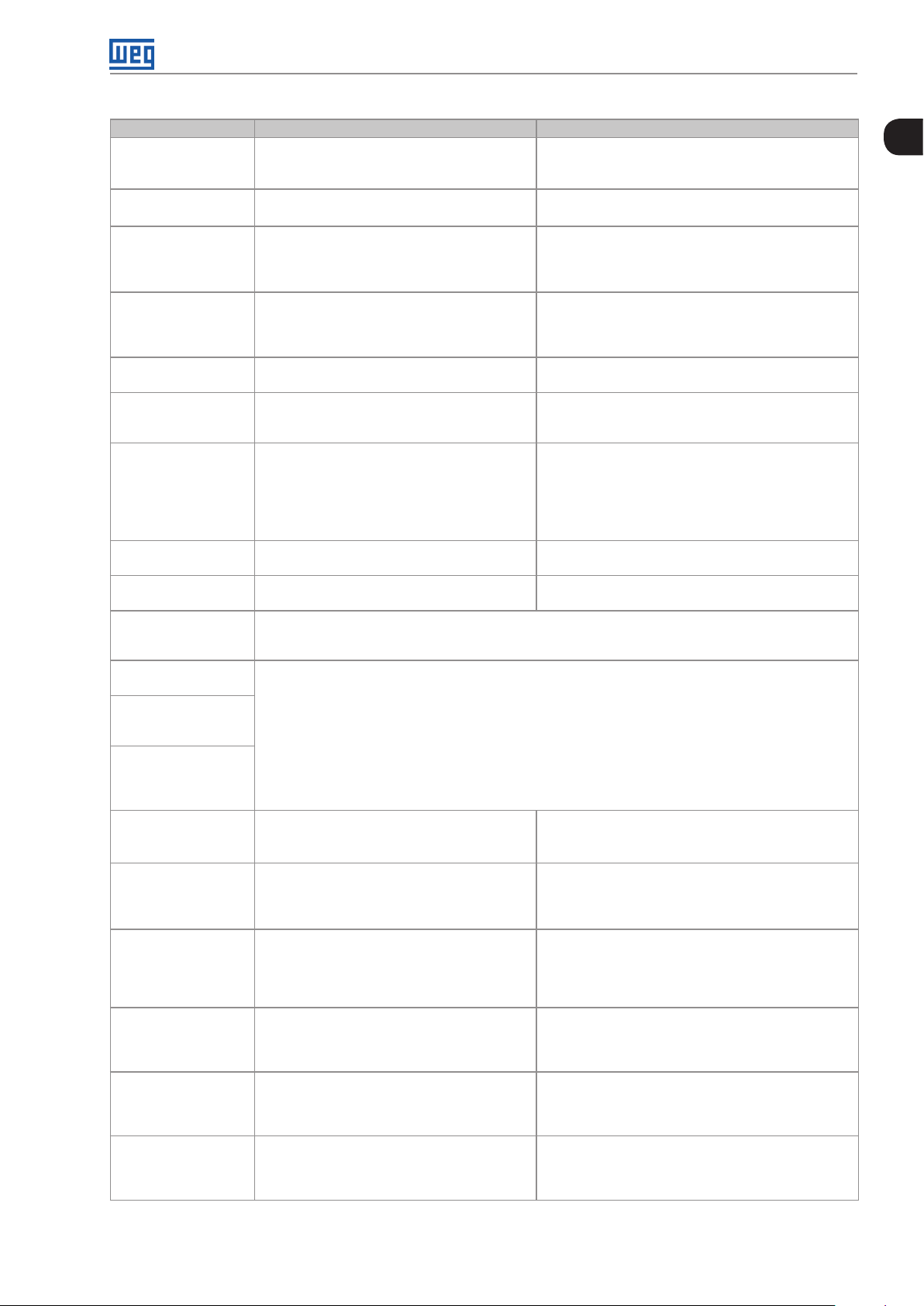

Page 12

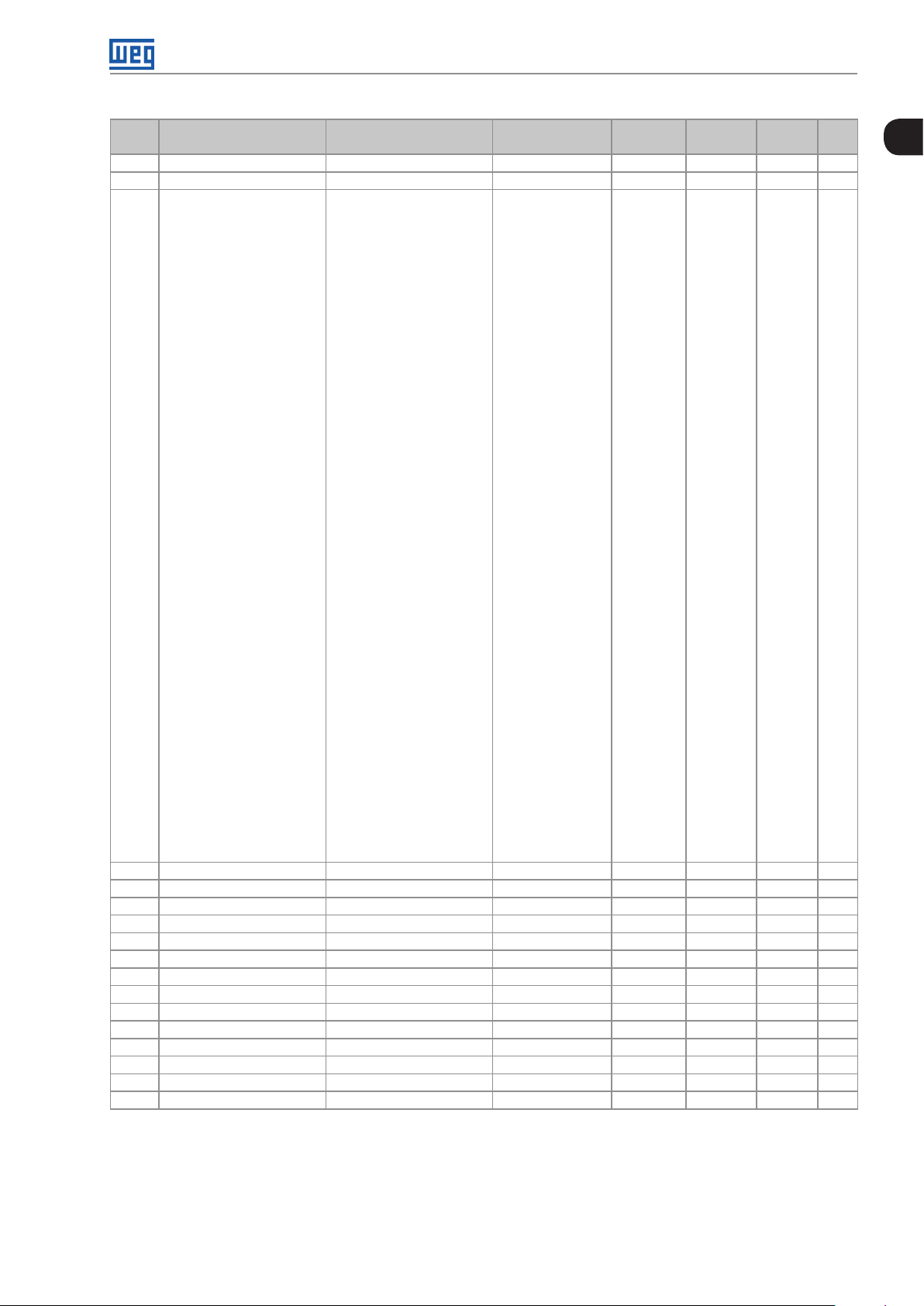

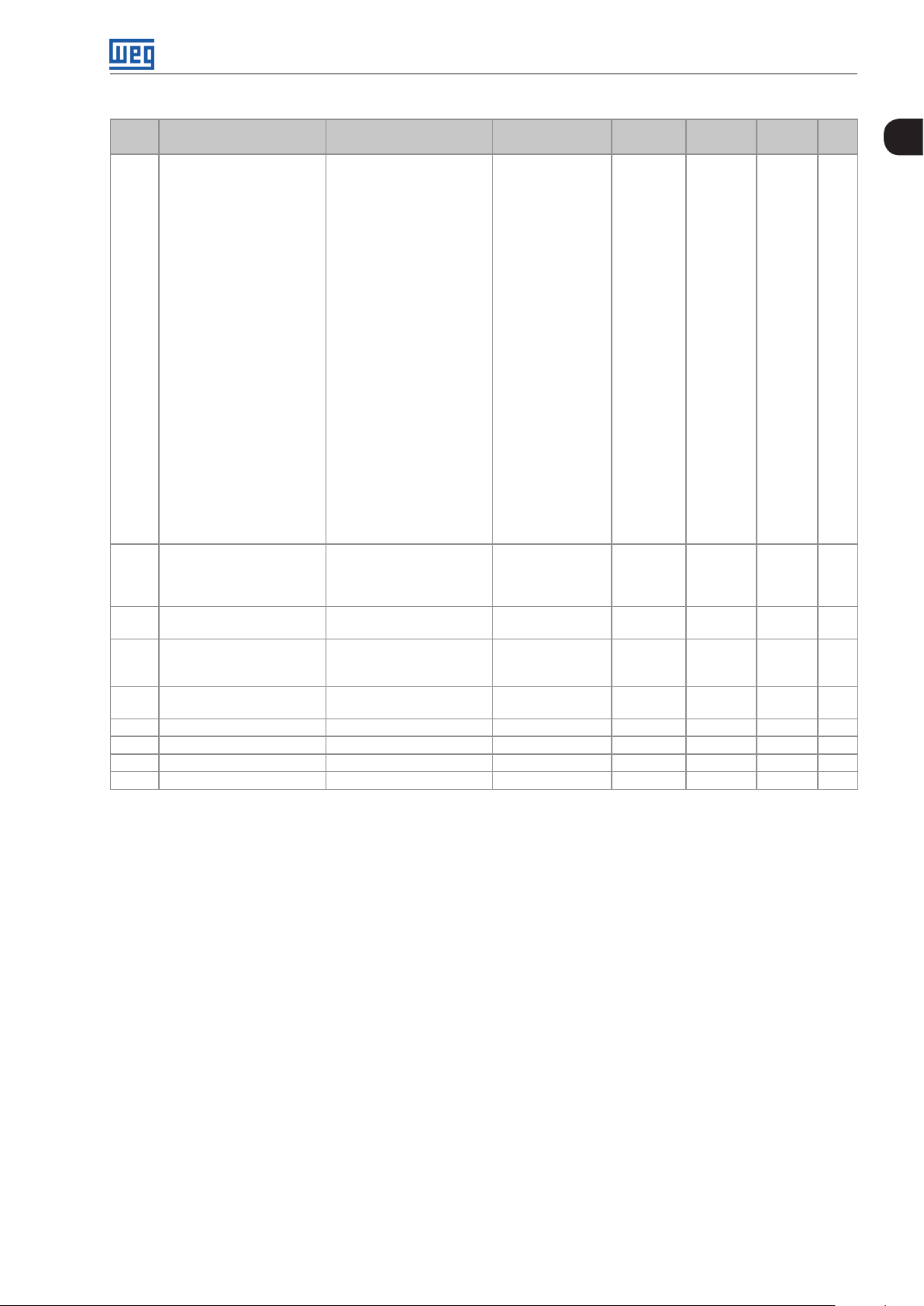

Quick Parameter Reference, Faults and Alarms

0

Param. Function

P0209 Main Display Eng. Unit 0 = None

P0210 Main Display Decimal Point 0 = wxyz

P0 211 Secondary Display Scale

Factor

P0 212 Secondary Display Decimal

Point

P0216 HMI Backlighting 0 to 15 15 HMI 5-6

Adjustable

Range

1 = V

2 = A

3 = rpm

4 = s

5 = ms

6 = None

7 = m

8 = None

9 = None

10 = %

11 = °C

12 = None

13 = Hz

14 = None

15 = h

16 = W

17 = kW

18 = None

19 = None

20 = min

21 = °F

22 = bar

23 = mbar

24 = psi

25 = Pa

26 = kPa

27 = MPa

28 = mwc

29 = mca

30 = gal

31 = l

32 = in

33 = ft

34 = m³

35 = ft³

36 = gal/s

37 = gal/min

38 = gal/h

39 = l/s

40 = l/min

41 = l/h

42 = m/s

43 = m/min

44 = m/h

45 = ft/s

46 = ft/min

47 = ft/h

48 = m³/s

49 = m³/min

50 = m³/h

51 = ft³/s

52 = ft³/min

53 = ft³/h

54 = As per P0510

55 = As per P0512

56 = As per P0514

57 = As per P0516

1 = wxy.z

2 = wx.yz

3 = w.xyz

4 = As per P0511

5 = As per P0513

6 = As per P0515

7 = As per P0517

0.1 to 1000.0 % 100.0 % HMI 5-3

See options in P0210 1 HMI 5-4

Factory

Setting

3 HMI 5-5

0 HMI 5-4

User

Setting

Propr. Groups Pág.

0-4 | CFW701

Page 13

Quick Parameter Reference, Faults and Alarms

Param. Function

P0217 Zero Speed Disable 0 = Inactive

P0218 Zero Speed Dis. Out 0 = Ref. or Speed

P0219 Zero Speed Time 0 to 999 s 0 s 12-8

P0220 LOC/REM Selection Src 0 = Always LOC

P0221 LOC Reference Sel. 0 = HMI

P0222 REM Reference Sel. See options in P0221 1 cfg I/O 13-24

P0223 LOC FWD/REV Selection 0 = Forward

P0224 LOC Run/Stop Sel. 0 = I,O Keys

P0225 LOC JOG Selection 0 = Disable

P0226 REM FWD/REV Sel. See options in P0223 4 cfg I/O 13-25

P0227 REM Run/Stop Sel. See options in P0224 1 cfg I/O 13-25

P0228 REM JOG Selection See options in P0225 2 cfg I/O 13-26

P0229 Stop Mode Selection 0 = Ramp to Stop

P0230 Dead Zone (AIs) 0 = Inactive

P0231 AI1 Signal Function 0 = Speed Ref.

P0232 AI1 Gain 0.000 to 9.999 1.000 I/O 13-3

P0233 AI1 Signal Type 0 = 0 to 10 V / 20 mA

P0234 AI1 Off set -100.00 to 100.00 % 0.00 % I/O 13-3

P0235 AI1 Filter 0.00 to 16.00 s 0 .15 s I/O 13-4

P0236 AI2 Signal Function See options in P0231 8 cfg I/O 13-2

Adjustable

Range

1 = Active (N* and N)

2 = Active (N*)

1 = Reference

1 = Always REM

2 = LR Key LOC

3 = LR Key REM

4 = DIx

5 = Serial LOC

6 = Serial REM

7 = SoftPLC LOC

8 = SoftPLC REM

1 = AI1

2 = AI2

3 = AI3

4 = Sum AIs > 0

5 = Sum AIs

6 = Serial

7 = SoftPLC

1 = Reverse

2 = FR Key FWD

3 = FR Key REV

4 = DIx

5 = Serial FWD

6 = Serial REV

7 = SoftPLC FWD

8 = SoftPLC REV

9 = AI2 Polarity

1 = DIx

2 = Serial

3 = SoftPLC

1 = JOG Key

2 = DIx

3 = Serial

4 = SoftPLC

1 = Coast to Stop

2 = Fast Stop

1 = Active

1 = No Ramp Ref.

2 = Max. Torque Cur

3 = SoftPLC

4 = PTC

5 = Main PID Feedback 1

6 = Main PID Feedback 2

7 = Main PID Feedback 3

8 = External PID 1 Feedback

9 = External PID 2 Feedback

1 = 4 to 20 mA

2 = 10 V / 20 mA to 0

3 = 20 to 4 mA

4 = -10 to +10 V

Factory

Setting

0 cfg 12-7

0 12-7

2 cfg I/O 13-24

0 cfg I/O 13-24

2 cfg I/O 13-25

0 cfg I/O 13-25

1 cfg I/O 13-2 6

0 cfg 13-26

0 I/O 13-1

5 cfg I/O 13-2

0 cfg I/O 13-5

User

Setting

Propr. Groups Pág.

0

CFW701 | 0-5

Page 14

Quick Parameter Reference, Faults and Alarms

0

Param. Function

P0237 AI2 Gain 0.000 to 9.999 1.000 I/O 13-3

P0238 AI2 Signal Type See options in P0233 0 cfg I/O 13- 5

P0239 AI2 Offset -100.00 to 100.00 % 0.00 % I/O 13-3

P0240 AI2 Filter 0.00 to 16.00 s 0.15 s I/O 13-4

P0 241 AI3 Signal Function See options in P0231 9 cfg I/O 13-2

P0242 AI3 Gain 0.000 to 9.999 1.000 I/O 13- 3

P0243 AI3 Signal Type 0 = 0 to 20mA

P0244 AI3 Offset -100.00 to 100.00 % 0.00 % I/O 13- 3

P0245 AI3 Filter 0.00 to 16.00 s 0.15 s I/O 13-4

P0246 Frequency Input

Configuration

P0 251 AO1 Function 0 = Speed Ref.

P0252 AO1 Gain 0.000 to 9.999 1.000 I/O 13-7

P0253 AO1 Signal Type 0 = 0 to 10 V / 20 mA

P0254 AO2 Function See options in P0251 17 I/O 13-6

P0255 AO2 Gain 0.000 to 9.999 1.000 I/O 13-7

P0256 AO2 Signal Type See options in P0253 0 cfg I/O 13-8

P0263 DI1 Function 0 = Not Used

P0264 DI2 Function See options in P0263 4 cfg I/O 13 -10

P0265 DI3 Function See options in P0263 0 cfg I/O 13 -10

P0266 DI4 Function See options in P0263 20 cfg I/O 13 -10

P0267 DI5 Function See options in P0263 21 cfg I/O 13 -10

P0268 DI6 Function See options in P0263 22 cfg I/O 13 -10

Adjustable

Range

1 = 4 to 20 mA

2 = 20 to 0 mA

3 = 20 to 4 mA

0 = Off

1 = DI3

2 = DI4

1 = Total Ref.

2 = Real Speed

3 = Torque Cur. Ref

4 = Torque Current

5 = Output Current

6 = Active Current

7 = Output Power

8 = Torque Cur. > 0

9 = Motor Torque

10 = SoftPLC

11 = PTC

12 = Motor Ixt

13 = P0696 Value

14 = P0697 Value

15 = Id* Current

16 = External PID 1 Output

17 = External PID 2 Output

1 = 4 to 20 mA

2 = 10 V / 20 mA to 0

3 = 20 to 4 mA

1 = Run/Stop

2 = General Enable

3 = Fast Stop

4 = FWD/REV

5 = LOC/REM

6 = JOG

7 = SoftPLC

8 = Ramp 2

9 = Speed/Torque

10 = JOG+

11 = JOG12 = No Ext. Alarm

13 = No Ext. Fault

14 = Reset

15 = Disab.FlyStart

16 = DC Link Regul.

17 = Progr. Off

18 = Load User 1

19 = Load User 2

20 = Main PID Aut/Man

21 = External PID 1 Aut/Man

22 = External PID 2 Aut/Man

23 = Bypass Mode

24 = Fire Mode

Factory

Setting

0 cfg I/O 13-5

0 cfg 13-23

16 I/O 13-6

0 cfg I/O 13-8

1 cfg I/O 13 -10

User

Setting

Propr. Groups Pág.

0-6 | CFW701

Page 15

Quick Parameter Reference, Faults and Alarms

Param. Function

P0269 DI7 Function See options in P0263 0 cfg I/O 13 -10

P0270 DI8 Function See options in P0263 0 cfg I/O 13-10

P0275 DO1 Function (RL1) 0 = Not Used

P0276 DO2 Function (RL2) See options in P0275 24 cfg I/O 13 -16

P0277 DO3 Function See options in P0275 0 cfg I/O 13 -16

P0278 DO4 Function See options in P0275 0 cfg I/O 13 -16

P0279 DO5 Function See options in P0275 0 cfg I/O 13 -16

P0281 Fx Frequency 0.0 to 300.0 Hz 4.0 Hz 13-21

P0282 Fx Hysteresis 0.0 to 15.0 Hz 2.0 Hz 13-21

P0287 Nx/Ny Hysteresis 0 to 900 rpm 18 (15) rpm 13-21

P0288 Nx Speed 0 to 18000 rpm 120 (100) rpm 13-21

P0289 Ny Speed 0 to 18000 rpm 1800 (1500) rpm 13-21

P0290 Ix Current 0 to 2xI

P0291 Zero Speed 0 to 18000 rpm 18 (15) rpm 13-22

P0292 N = N* Band 0 to 18000 rpm 18 (15) rpm 13-22

P0293 Tx To r q u e 0 to 200 % 100 % 13-22

P0294 Hx Time 0 to 6553 h 4320 h 13-23

Adjustable

Range

1 = N* > Nx

2 = N > Nx

3 = N < Ny

4 = N = N*

5 = Zero Speed

6 = Is > Ix

7 = Is < Ix

8 = Torque > Tx

9 = Torque < Tx

10 = Remote

11 = Run

12 = Ready

13 = No Fault

14 = No F0070

15 = No F0071

16 = No F0006/21/22

17 = No F0051

18 = No F0072

19 = 4-20 mA OK

20 = P0695 Value

21 = Forward

22 = Ride-Through

23 = Pre-Charge OK

24 = Fault

25 = Enabled Time > Hx

26 = SoftPLC

27 = N>Nx/Nt>Nx

28 = F > Fx (1)

29 = F > Fx (2)

30 = STO

31 = No F0160

32 = No Alarm

33 = No Fault/Alarm

34 = Dry Pump Alarm/Fault

35 = Broken Belt Alarm/Fault

36 = Filter Mainten. Alarm/

Fault

37 = Sleep Mode

38 = Not Used

39 = Drive Bypass Contactor

40 = Mains Bypass

Contactor

41 = Fire Mode

42 = Self-Tuning

nom-ND

Factory

Setting

11 cfg I/O 13 -16

1.0 x I

nom-ND

User

Setting

Propr. Groups Pág.

13-22

0

CFW701 | 0-7

Page 16

Quick Parameter Reference, Faults and Alarms

0

Param. Function

P0295 ND/HD VFD Rated Curr. 0 = 2 A / 2 A

P0296 Line Rated Voltage 0 = 200 / 240 V

P0297 Switching Frequency 0 = 1.25 kHz

P0298 Application 0 = Normal Duty

P0299 DC-Braking Start Time 0.0 to 15.0 s 0.0 s V/f, V V W,

P0300 DC-Braking Stop Time 0.0 to 15.0 s 0.0 s V/f, V V W,

P0301 DC-Braking Speed 0 to 450 rpm 30 rpm V/f, VV W,

P0302 DC-Braking Voltage 0.0 to 10.0 % 2.0 % V/f, V VW 12-18

P0303 Skip Speed 1 0 to 18000 rpm 600 rpm 12-19

Adjustable

Range

1 = 3.6 A / 3.6 A

2 = 5 A / 5 A

3 = 6 A / 5 A

4 = 7 A / 5.5 A

5 = 7 A / 7 A

6 = 10 A / 8 A

7 = 10 A / 10 A

8 = 13 A / 11 A

9 = 13.5 A / 11 A

10 = 16 A / 13 A

11 = 17 A / 13.5 A

12 = 24 A / 19 A

13 = 24 A / 20 A

14 = 28 A / 24 A

15 = 31 A / 25 A

16 = 33.5 A / 28 A

17 = 38 A / 33 A

18 = 45 A / 36 A

19 = 45 A / 38 A

20 = 54 A / 45 A

21 = 58.5 A / 47 A

22 = 70 A / 56 A

23 = 70.5 A / 61 A

24 = 86 A / 70 A

25 = 88 A / 73 A

26 = 105 A / 86 A

27 = 105 A / 88 A

28 = 142 A / 115 A

29 = 180 A / 142 A

30 = 211 A / 180 A

31 = 2.9 A / 2.7 A

32 = 4.2 A / 3.8 A

33 = 7 A / 6.5 A

34 = 10 A / 9 A

35 = 12 A / 10 A

36 = 17 A / 17 A

37 = 22 A / 19 A

38 = 27 A / 22 A

39 = 32 A / 27 A

40 = 44 A / 36 A

41 = 53 A / 44 A

42 = 63 A / 53 A

43 = 80 A / 66 A

44 = 107 A / 90 A

45 = 125 A / 107 A

46 = 150 A / 122 A

1 = 380 V

2 = 400 / 415 V

3 = 440 / 460 V

4 = 480 V

5 = 500 / 525 V

6 = 550 / 575 V

7 = 600 V

1 = 2.5 kHz

2 = 5.0 kHz

3 = 10.0 kHz

4 = 2.0 kHz

1 = Heavy Duty

Factory

Setting

According to

inverter model

According to

inverter model

0 cfg 6-8

User

Setting

Propr. Groups Pág.

ro READ 6-6

cfg 6-7

cfg 6-7

Sless

Sless

Sless

12-16

12-16

12-18

0-8 | CFW701

Page 17

Quick Parameter Reference, Faults and Alarms

Param. Function

P0304 Skip Speed 2 0 to 18000 rpm 900 rpm 12-19

P0305 Skip Speed 3 0 to 18000 rpm 120 0 r pm 12-19

P0306 Skip Band 0 to 750 rpm 0 rpm 12-19

P0308 Serial Address 1 to 247 1 NET 17-1

P0310 Serial Baud Rate 0 = 9600 bits/s

P0 311 Serial Bytes Config. 0 = 8 bits, no, 1

P0 312 Serial Protocol 2 = Modbus RTU

P0 313 Comm. Error Action 0 = Off

P0 314 Serial Watchdog 0.0 to 999.0 s 0.0 s NET 17-1

P0316 Serial Interf. Status 0 = Off

P0317 Oriented Start-up 0 = No

P0 318 Copy Function MMF 0 = Off

P0320 FlyStart/Ride-Through 0 = Off

P0321 DC Link Power Loss 178 to 770 V 505 V Vector 12-14

P0322 DC Link Ride-Through 178 to 770 V 490 V Vector 12-14

P0323 DC Link Power Back 178 to 770 V 535 V Vector 12-14

P0325 Ride-Through P Gain 0.0 to 63.9 22.8 Vector 12-15

P0326 Ride-Through I Gain 0.000 to 9.999 0.12 8 Vector 12-15

P0327 F.S. I/f Current Ramp 0.000 to 1.000 s 0.070 s Sless 12-10

P0328 Flying Start Filter 0.000 to 1.000 s 0.085 s Sless 12-10

P0329 Frequency Ramp F. S. 2.0 to 50.0 20.0 Sless 12-10

P0331 Voltage Ramp 0.2 to 60.0 s 2.0 s V/f, V VW 12-12

P0332 Dead Time 0.1 to 10.0 s 1.0 s V/f, V VW 12-12

P0340 Auto-reset Time 0 to 255 s 0 s 15- 8

P0 3 41 AIPTC Configuration 0 = Off

P0343 Ground Fault Config. 0 = Off

P0344 Current Lim. Conf. 0 = Hold

P0348 Motor Overload Conf. 0 = Off

P0349 Ixt Alarm Level 70 to 100 % 85 % cfg 15-10

Adjustable

Range

1 = 19200 bits/s

2 = 38400 bits/s

3 = 57600 bits/s

4 = Reserved

1 = 8 bits, even, 1

2 = 8 bits, odd, 1

3 = 8 bits, no, 2

4 = 8 bits, even, 2

5 = 8 bits, odd, 2

3 = BACnet

4 = N2

1 = Ramp Stop

2 = General Disab.

3 = Go to LOC

4 = LOC Keep Enab.

5 = Cause Fault

1 = On

2 = Watchdog Error

1 = Yes

1 = VFD → MMF

2 = MMF → VFD

3 = Sync VFD → MMF

4 = Format MMF

5 = Copy SoftPLC Program.

6 = SoftPLC Program Save

1 = Flying Start

2 = FS/RT

3 = Ride-Through

1 = Fault/Alarm

2 = Fault

3 = Alarm

1 = On

1 = Decel.

1 = Fault/Alarm

2 = Fault

3 = Alarm

Factory

Setting

1 NET 17-1

1 NET 17-1

2 NET 17-1

1 NET 17-2

0 cfg STARTUP 7-2

0 cfg 7- 2

0 cfg 12- 8

0 cfg I/O 15-8

1 cfg 15-9

1 cfg, V/f,

1 cfg 15-9

User

Setting

Propr. Groups Pág.

ro NET 17-1

VVW

9-6

0

CFW701 | 0-9

Page 18

Quick Parameter Reference, Faults and Alarms

0

Param. Function

P0350 IGBTs Overload Conf. 0 = F, w/ SF rd.

P0 3 51 Motor Overtemp. Conf. 0 = Off

P0352 Fan Control Config. 0 = HS-OFF, Int-OFF

P0353 IGBTs/Air Overtemp. Cfg 0 = HS-F/A, Air-F/A

P0354 Fan Speed Config. 0 = Inactive

P0355 F0185 Fault Config. 0 = Off

P0356 Dead Time Compens. 0 = Off

P0357 Line Phase Loss Time 0 to 60 s 3 s 15-14

P0360 Speed Hysteresis 0.0 to 100.0 % 10.0 % Vector 11-21

P0361 Time with Speed Different

from Reference

P0372 DC-Braking Curr. Sless 0.0 to 90.0 % 40.0 % Sless 12 -18

P0397 Slip Compens. Regen. 0 = Off

P0398 Motor Service Factor 1.00 to 1.50 1.00 cfg MOTOR 11-7

P0399 Motor Rated Eff. 50.0 to 99.9 % 67. 0 % cfg, V VW MOTOR 10-3

P0400 Motor Rated Voltage 0 to 600 V 440 V cfg MOTOR 11- 8

P0401 Motor Rated Current 0 to 1.3xI

P0402 Motor Rated Speed 0 to 18000 rpm 1750 (1458) rpm cfg MOTOR 11- 8

P0403 Motor Rated Frequency 0 to 300 Hz 60 (50) Hz cfg MOTOR 11- 9

Adjustable

Range

1 = F/A, w/ SF rd.

2 = F, no SF rd.

3 = F/A, no SF rd.

1 = Fault/Alarm

2 = Fault

3 = Alarm

1 = HS-ON, Int-ON

2 = HS-CT, Int-CT

3 = HS-CT, Int-OFF

4 = HS-CT, Int-ON

5 = HS-ON, Int-OFF

6 = HS-ON, Int-CT

7 = HS-OFF, Int-ON

8 = HS-OFF, Int-CT

9 = HS-CT, Int -CT *

10 = HS-CT, Int -OFF *

11 = HS-CT, Int -ON *

12 = HS-ON, Int -CT *

13 = HS-OFF, Int -CT *

1 = HS-F/A, Air-F

2 = HS-F, Air-F/A

3 = HS-F, Air-F

4 = HS-F/A, Air-F/A *

5 = HS-F/A, Air-F *

6 = HS-F, Air-F/A *

7 = HS-F, Air-F *

1 = Fault

1 = On

1 = On

0.0 to 999.0 s 0.0 s Vector 11-22

1 = On

nom-ND

Factory

Setting

1 cfg 15-10

1 cfg 15-11

2 cfg 15-11

0 cfg 15-12

1 cfg 15-13

1 cfg 15-13

1 cfg 15-14

1 cfg, V VW 10-3

1.0 x I

nom-ND

User

Setting

Propr. Groups Pág.

cfg MOTOR 11 - 8

0-10 | CFW701

Page 19

Quick Parameter Reference, Faults and Alarms

Param. Function

Adjustable

Range

P0404 Motor Rated Power 0 = 0.33 hp / 0.25 kW

1 = 0.5 hp / 0.37 kW

Factory

Setting

Motor

max-ND

User

Setting

Propr. Groups Pág.

cfg MOTOR 11 - 9

2 = 0.75 hp / 0.55 kW

3 = 1 hp / 0.75 kW

4 = 1.5 hp / 1.1 kW

5 = 2 hp / 1.5 kW

6 = 3 hp / 2.2 kW

7 = 4 hp / 3 kW

8 = 5 hp / 3.7 kW

9 = 5.5 hp / 4 kW

10 = 6 hp / 4.5 kW

11 = 7.5 hp / 5.5 kW

12 = 10 hp / 7.5 kW

13 = 12.5 hp / 9 kW

14 = 15 hp / 11 kW

15 = 20 hp / 15 kW

16 = 25 hp / 18.5 kW

17 = 30 hp / 22 kW

18 = 40 hp / 30 kW

19 = 50 hp / 37 kW

20 = 60 hp / 45 kW

21 = 75 hp / 55 kW

22 = 100 hp / 75 kW

23 = 125 hp / 90 kW

24 = 150 hp / 110 kW

25 = 175 hp / 130 kW

P0406 Motor Ventilation 0 = Self-Vent.

0 cfg MOTOR 11-10

1 = Separate Vent.

2 = Optimal Flux

3 = Extended Protection

P0407 Motor Rated Power Fac 0.50 to 0.99 0.68 cfg, V/f,

VVW

P0408 Run Self-Tuning 0 = No

1 = No Rotation

2 = Run for I

m

0 cfg, VV W,

Vector

P0409 Stator Resistance 0.000 to 9.999 Ω 0.000 Ω cfg, V VW,

MOTOR 10-4

19-7

MOTOR 11-17

MOTOR 11-18

Vector

P0 410 Magnetization Current 0 to 1.25xI

nom-ND

I

nom-ND

MOTOR 11-18

P0 411 Leakage Inductance 0.00 to 99.99 mH 0.00 mH cfg, Vector MOTOR 11-19

P0 412 Tr Time Constant 0.000 to 9.999 s 0.000 s Vector MOTOR 11-19

P0 413 Tm Time Constant 0.00 to 99.99 s 0.00 s Vector MOTOR 11- 2 0

0

CFW701 | 0-11

Page 20

Quick Parameter Reference, Faults and Alarms

0

Param. Function

P0 510 Ind. Eng. Unit 1 0 = None

P0 511 Ind. Decimal Point 1 0 = wxyz

P0 512 Ind. Eng. Unit 2 See options in P0510 11 HMI 5-9

P0 513 Ind. Decimal Point 2 0 = wxyz

P0 514 Ind. Eng. Unit 3 See options in P0510 10 HMI 5 -11

P0 515 Ind. Decimal Point 3 0 = wxyz

P0 516 Ind. Eng. Unit 4 See options in P0510 13 HMI 5-13

Adjustable

Range

1 = V

2 = A

3 = rpm

4 = s

5 = ms

6 = None

7 = m

8 = None

9 = None

10 = %

11 = °C

12 = None

13 = Hz

14 = None

15 = h

16 = W

17 = kW

18 = None

19 = None

20 = min

21 = °F

22 = bar

23 = mbar

24 = psi

25 = Pa

26 = kPa

27 = MPa

28 = mwc

29 = mca

30 = gal

31 = l

32 = in

33 = ft

34 = m³

35 = ft³

36 = gal/s

37 = gal/min

38 = gal/h

39 = l/s

40 = l/min

41 = l/h

42 = m/s

43 = m/min

44 = m/h

45 = ft/s

46 = ft/min

47 = ft/h

48 = m³/s

49 = m³/min

50 = m³/h

51 = ft³/s

52 = ft³/min

53 = ft³/h

1 = wxy.z

2 = wx.yz

3 = w.xyz

1 = wxy.z

2 = wx.yz

3 = w.xyz

1 = wxy.z

2 = wx.yz

3 = w.xyz

Factory

Setting

22 HMI 5-7

1 HMI 5-8

1 HMI 5 -10

1 HMI 5 -12

User

Setting

Propr. Groups Pág.

0-12 | CFW701

Page 21

Quick Parameter Reference, Faults and Alarms

Param. Function

P0517 Ind. Decimal Point 4 0 = wxyz

P0579 Reference to Fire Mode 0 to 18000 rpm 1800 (1500) rpm HVAC 19-2

P0580 Fire Mode Configuration 0 = Disabled

P0581 Fire Mode PID Setpoint -32768 to 32767 0 HVAC 19-3

P0582 Auto-reset Configuration 0 = Limited

P0583 Bypass Mode Configuration 0 = Off

P0584 Bypass Contactor Time 0.00 to 300.00 s 0.30 s HVAC 19-7

P0585 Short Cycle Protection

Config.

P0586 Minimum RUN Time 0.00 to 650.00 s 5.00 s HVAC 19-9

P0587 Minimum STOP Time 0.00 to 650.00 s 5.00 s HVAC 19-9

P0588 Maximum Torque Level 0 to 85 % 0 % cfg, V/f HVAC 19- 8

P0589 Energy Saving Min. Mag. 40 to 80 % 40 % cfg, V/f HVAC 19-8

P0590 Energy Saving Min. Speed 0 to 18000 rpm 600 (525) rpm cfg, V/f HVAC 19-8

P0591 Energy Saving Histeresis 0 to 30 % 10 % cfg, V/f HVAC 19-8

P0680 Logical Status Bit 0 = Not Used

P0681 Speed in 13 bits -32768 to 32767 ro READ,

P0682 Serial Control Word Bit 0 = Ramp Enable

P0683 Serial Speed Ref. -32768 to 32767 ro READ,

P0695 DOx Value Bit 0 = DO1

P0696 AOx Value 1 -32768 to 32767 0 NET 17-2

P0697 AOx Value 2 -32768 to 32767 0 NET 17- 2

P0760 BACnet Dev Inst High 0 to 419 0 NET 17-1

P0761 BACnet Dev Inst Low 0 to 9999 0 NET 17-1

P0762 Max. Number of Master 0 to 127 127 NET 17-1

P0763 MS/TP Max. Info Frame 1 to 65535 1 NET 17-1

Adjustable

Range

1 = wxy.z

2 = wx.yz

3 = w.xyz

1 = Enabled

2 = Enabled/P0579

3 = Enabled/P0581

4 = Enabled/Gen. Disable

1 = Unlimited

1 = On/DIx

2 = On/DIx+Fault

0 = Off

1 = On

Bit 1 = Run Command

Bit 2 = Fire Mode

Bit 3 = Bypass

Bit 4 = Quick Stop ON

Bit 5 = 2nd Ramp

Bit 6 = Config. Mode

Bit 7 = Alarm

Bit 8 = Running

Bit 9 = Enabled

Bit 10 = Forward

Bit 11 = JOG

Bit 12 = Remote

Bit 13 = Subvoltage

Bit 14 = Not Used

Bit 15 = Fault

Bit 1 = General Enable

Bit 2 = Run Forward

Bit 3 = JOG Enable

Bit 4 = Remote

Bit 5 = 2nd Ramp

Bit 6 = Quick Stop

Bit 7 = Fault Reset

Bit 8 to 12 = Reserved

Bit 13 = Internal PID

Bit 14 = External PID 1

Bit 15 = External PID 2

Bit 1 = DO2

Bit 2 = DO3

Bit 3 = DO4

Bit 4 = DO5

Factory

Setting

1 HMI 5 -14

0 cfg HVAC 19-3

0 cfg HVAC 19-3

0 cfg HVAC 19-6

0 cfg HVAC 19-9

Bit 4 NET 17-2

User

Setting

Propr. Groups Pág.

ro RE AD,

NET

NET

ro RE AD,

NET

NET

17-2

17-2

17-1

17-2

17-1

17-2

0

CFW701 | 0-13

Page 22

Quick Parameter Reference, Faults and Alarms

0

Param. Function

P0764 I-AM Msg Transmition 0 = Power Up

P0765 Token RX Qtde 0 to 65535 ro READ,

P1000 SoftPLC Status 0 = No Application

P1001 SoftPLC Command 0 = Stop Application

P1002 Scan Cycle Time 0.0 to 999.9 ms ro RE AD,

P1003 SoftPLC Appl. Sel. 0 = User

P1010 Version of the HVAC

Application

P10 11 Main PID Aut. Setpoint -32768 to 32767 0 HVAC 19 -14

P1012 SoftPLC Parameter 3 -32768 to 32767 0 HVAC 18-2

P1013 SoftPLC Parameter 4 -32768 to 32767 0 HVAC 18-2

P1014 Main PID Man. Setpoint 0.0 to 100.0 % 0.0 % HVAC 19-14

P1015 Main PID Process Variable -32768 to 32767 ro RE AD,

P1016 MainPID Output 0.0 to 100.0 % ro RE AD,

P1017 MainPID Act. Control 0 = Disable PID

P1018 Main PID Operation Mode 0 = AlwaysAutomatic

P1019 Main PID Sampling Time 0.10 to 60.00 s 0 .1 0 s HVAC 19 -16

P1020 Main PIDP. Gain 0.000 to 32.767 1.000 HVAC 19 -17

P1021 Main PIDI. Gain 0.000 to 32.767 0.430 HVAC 19 -17

P102 2 Main PIDD. Gain 0.000 to 32.767 0.000 HVAC 19 -17

P1023 Main PID Output Min. Value 0.0 to 100.0 % 0.0 % HVAC 19 -17

P1024 Main PID Output Max. Value 0.0 to 100.0 % 100.0 % HVAC 19 -18

P1025 SoftPLC Parameter 16 -32768 to 32767 0 HVAC 18-2

P1026 Main PID Feedback Conf. 0 = Sum Feed. 1, 2 and 3

P1027 Main PID Min. Feedback -32768 to 32767 0 HVAC 19-18

P1028 Main PID Max. Feedback -32768 to 32767 1000 H VAC 19-19

P102 9 SoftPLC Parameter 20 -32768 to 32767 0 HVAC 18-2

P1030 Main PID Fdbck Alarms

Conf.

P1031 M. PID Fdbck Alarm Low V. -32768 to 32767 50 HVAC 19 -20

P1032 M. PID Fdbck Alarm Low T. 0.00 to 650.00 s 5.00 s HVAC 19-20

P1033 M. PID Fdbck Alarm High V. -32768 to 32767 900 H VAC 19 -20

P1034 M. PID Fdbck Alarm Hig T. 0.00 to 650.00 s 5.00 s HVAC 19-21

P1035 SoftPLC Parameter 26 -32768 to 32767 0 HVAC 18-2

P1036 Sleep Mode Speed 0 to 18000 350 HVAC 19 -21

P1037 Sleep Mode Time 0.00 to 650.00 s 5.00 s HVAC 19-22

P1038 Wake Up Main Deviation 0.0 to 100.0 % 5.0 % HVAC 19-22

P1039 Wake Up Main Time 0.00 to 650.00 s 10.0 0 s HVAC 19 -22

P1040 HVAC Fun. Log. Status 0000h to FFFFh ro RE AD,

P10 41 SoftPLC Parameter 32 -32768 to 32767 0 HVAC 18-2

Adjustable

Range

1 = Continuos

1 = Install. App.

2 = Incompat. App.

3 = App. Stopped

4 = App. Running

1 = Run Application

2 = Delete Application

1 = HVAC

0.00 to 10.00 ro HVAC 19- 39

1 = Direct Mode

2 = Reverse Mode

1 = Always Manual

2 = A/M DI w/o bumpless

3 = A/M Net w/o bumpless

4 = A/M DI w/ bumpless

5 = A/M Net w/ bumpless

1 = Difference Feed. 1 and 2

2 = Average Feed. 1, 2 and 3

3 = Minimum Feed. 1, 2 and 3

4 = Maximum Feed. 1, 2 and 3

0 = Disable

1 = Enable Alarm

2 = Enable Fault

Factory

Setting

0 NET 17-1

1 HVAC 18-1

1 cfg HVAC 18-2

0 cfg HVAC 19 -15

0 HVAC 19 -16

0 cfg HVAC 19 -18

0 HVAC 19-19

User

Setting

Propr. Groups Pág.

NET

ro RE AD,

HVAC

HVAC

HVAC

HVAC

HVAC

17-1

18 -1

18 -1

19 -14

19 -15

19- 38

0-14 | CFW701

Page 23

Quick Parameter Reference, Faults and Alarms

Param. Function

P1042 Dry Pump Config. 0 = Disable

P1043 Dry Pump Speed 0 to 18000 400 HVAC 19-10

P1044 Dry Pump Torque 0.0 to 350.0 % 20.0 % HVAC 19 -10

P1045 Dry Pump Time 0.00 to 650.00 s 20.00 s HVAC 19 -11

P1046 Broken Belt Config. 0 = Disable

P1047 Broken Belt Speed 0 to 18000 400 HVAC 19 -11

P1048 Broken Belt Torque 0.0 to 350.0 % 20.0 % HVAC 19 -12

P1049 Broken Belt Time 0.00 to 650.00 s 20.00 s HVAC 19 -12

P1050 Filter Mainten. Alarm Conf. 0 = Disable

P10 51 Filter Mainten. Alarm Time 0 to 32000 h 5000 h HVAC 19-13

P1052 Filter Mainten. Alarm

Counter

P1053 SoftPLC Parameter 44 -32768 to 32767 0 HVAC 18-2

P1054 SoftPLC Parameter 45 -32768 to 32767 0 HVAC 18-2

P1055 SoftPLC Parameter 46 -32768 to 32767 0 HVAC 18-2

P1056 SoftPLC Parameter 47 -32768 to 32767 0 HVAC 18-2

P1057 SoftPLC Parameter 48 -32768 to 32767 0 HVAC 18-2

P1058 SoftPLC Parameter 49 -32768 to 32767 0 HVAC 18-2

P1059 SoftPLC Parameter 50 -32768 to 32767 0 HVAC 18-2

P1060 Ext. PID 1 Aut. Setpoint -32768 to 32767 0 HVAC 19-24

P1061 Ext. PID 1 Man. Setpoint 0.0 to 100.0 % 0.0 % HVAC 19 -24

P1062 Ext. PID 1 Feedback -32768 to 32767 ro READ,

P1063 Ext. PID 1 Output 0.0 to 100.0 % ro RE AD,

P1064 Ext. PID 1 Act. Control 0 = Disable PID

P1065 Ext. PID 1 Operation Mode 0 = AlwaysAutomatic

P1066 Ext. PID 1 Sampling Time 0.10 to 60.00 s 0.10 s HVAC 19-27

P1067 Ext. PID 1 P. Gain 0.000 to 32.767 1.000 HVAC 19-27

P1068 Ext. PID 1 I. Gain 0.000 to 32.767 0.430 HVAC 19-27

P1069 Ext. PID 1 D. Gain 0.000 to 32.767 0.000 HVAC 19-27

P1070 Ext. PID 1 Output Min. Value 0.0 to 100.0 % 0.0 % HVAC 19 -28

P1071 Ext. PID 1 Output Max. Value 0.0 to 100.0 % 100.0 % HVAC 19 -28

P1072 SoftPLC Parameter 63 -32768 to 32767 0 HVAC 18-2

P1073 Ext. PID 1 Min. Feedback -32768 to 32767 0 HVAC 19-28

P1074 Ext. PID 1 Max. Feedback -32768 to 32767 1000 HVAC 19 -28

P1075 Ext. PID 1 Fdbck Alarms

Conf.

P1076 Ext. PID 1 Fdbck Alarm Low V. -32768 to 32767 2 HVAC 19-29

P1077 Ext. PID 1 Fdbck Alarm Low T. 0.00 to 650.00 s 5.00 s HVAC 19-3 0

P1078 Ext. PID 1 Fdbck Alarm High V. -32768 to 32767 900 HVAC 19-3 0

P1079 Ext. PID 1 Fdbck Alarm Hig T. 0.00 to 650.00 s 5.00 s HVAC 19 -30

P1080 Ext. PID 2 Aut. Setpoint -32768 to 32767 0 HVAC 19-31

P1081 Ext. PID 2 Man. Setpoint 0.0 to 100.0 % 0.0 % HVAC 19-32

P1082 Ext. PID 2 Feedback -32768 to 32767 ro READ,

P1083 Ext. PID 2 Output 0.0 to 100.0 % ro READ,

Adjustable

Range

1 = Enable Alarm

2 = Enable Fault

1 = Enable Alarm

2 = Enable Fault

1 = Enable Alarm

2 = Enable Fault

0 to 32000 h ro READ,

1 = Direct Mode

2 = Reverse Mode

1 = Always Manual

2 = A/M DI w/o bumpless

3 = A/M Net w/o bumpless

4 = A/M DI w/ bumpless

5 = A/M Net w/ bumpless

0 = Disable

1 = Enable Alarm

2 = Enable Fault

Factory

Setting

0 cfg HVAC 19 -10

0 cfg HVAC 19 -11

0 cfg HVAC 19 -12

0 cfg HVAC 19 -25

0 HVAC 19-26

0 HVAC 19-29

User

Setting

Propr. Groups Pág.

HVAC

HVAC

HVAC

HVAC

HVAC

19 -13

19-25

19-25

19- 32

19- 32

0

CFW701 | 0-15

Page 24

Quick Parameter Reference, Faults and Alarms

0

Param. Function

P1084 Ext. PID 2 Act. Control 0 = Disable PID

P1085 Ext. PID 2 Operation Mode 0 = AlwaysAutomatic

P1086 Ext. PID 2 Sampling Time 0.10 to 60.00 s 0.10 s HVAC 19-3 4

P1087 Ext. PID 2 P. Gain 0.000 to 32.767 1.000 HVAC 19 - 34

P1088 Ext. PID 2 I. Gain 0.000 to 32.767 0.430 HVAC 19 -34

P1089 Ext. PID 2 D. Gain 0.000 to 32.767 0.000 HVAC 19-35

P1090 Ext. PID 2 Output Min. Value 0.0 to 100.0 % 0.0 % HVAC 19-35

P1091 Ext. PID 2 Output Max. Value 0.0 to 100.0 % 100.0 % HVAC 19-35

P1092 SoftPLC Parameter 83 -32768 to 32767 0 HVAC 18-2

P1093 Ext. PID 2 Min. Feedback -32768 to 32767 0 HVAC 19-35

P1094 Ext. PID 2 Max. Feedback -32768 to 32767 1000 HVAC 19- 36

P1095 Ext. PID 2 Fdbck Alarms

Conf.

P1096 Ext. PID 2 Fdbck Alarm

Lo w V.

P1097 Ext. PID 2 Fdbck Alarm

Low T.

P1098 Ext. PID 2 Fdbck Alarm

High V.

P1099 Ext. PID 2 Fdbck Alarm

Hig T.

Adjustable

Range

1 = Direct Mode

2 = Reverse Mode

1 = Always Manual

2 = A/M DI w/o bumpless

3 = A/M Net w/o bumpless

4 = A/M DI w/ bumpless

5 = A/M Net w/ bumpless

0 = Disable

1 = Enable Alarm

2 = Enable Fault

-32768 to 32767 2 HVAC 19-37

0.00 to 650.00 s 5.00 s HVAC 19 -37

-32768 to 32767 900 HVAC 19-37

0.00 to 650.00 s 5.00 s HVAC 19-38

Factory

Setting

0 cfg HVAC 19-32

0 HVAC 19-3 3

0 HVAC 19-3 6

User

Setting

Propr. Groups Pág.

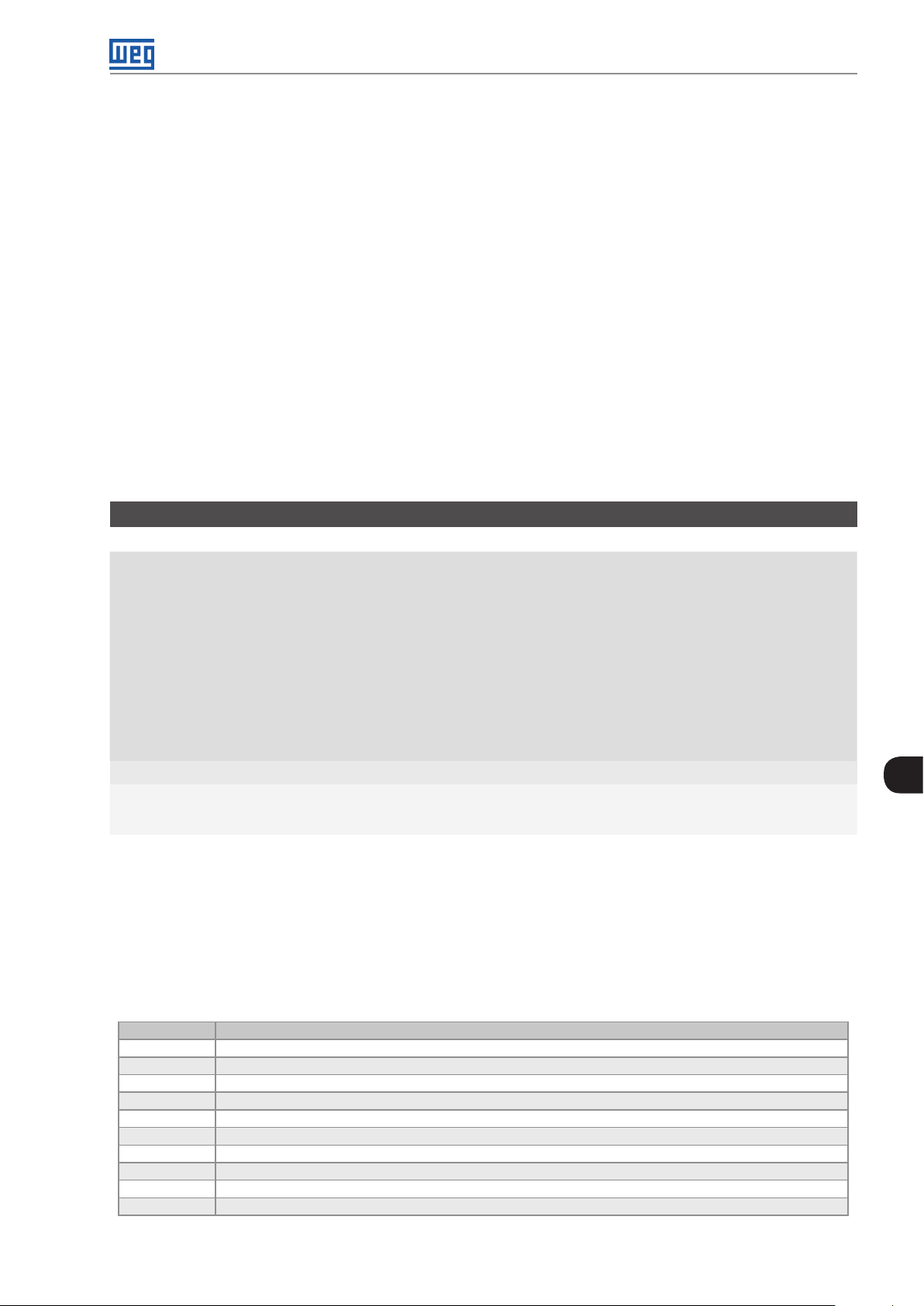

Notes:

ro = Read-only parameter

rw = Reading/writing parameter

cfg = Configuration parameter, it can be changed only with stopped motor

V/f = Parameter available in V/f mode

Adj = Parameter available only in adjustable V/f mode

VVW = Parameter available in VV W mode

Vector = Parameter available in vector mode

Sless = Parameter available only in sensorless mode

0-16 | CFW701

Page 25

Quick Parameter Reference, Faults and Alarms

Fault/Alarm Description Possible Causes

F0006:

Input Voltage Imbalance

or Phase Loss

The mains voltage imbalance is too high or phase

loss at the supply line has occurred.

Note:

A Phase Loss at the inverter input.

The input voltage imbalance is > 5 %.

- This fault may not occur if the load at the motor

shaft is too low or nonexistent.

P0357 sets the time for the trip, and P0357 = 0

disables this fault.

F0 021:

DC Link Undervoltage

A DC link undervoltage condition has occurred. The input voltage is too low and the DC link voltage

dropped below the minimum permitted value (monitor

the P0004 parameter value):

Ud < 223 V - 200 / 240 V three-phase input voltage;

Ud < 170 V - 200 / 240 V single-phase input voltage

(CFW701XXXXS2 or CFW701XXXXB2 models)

(P0296 = 0);

Ud < 385 V - 380 V input voltage (P0296 = 1);

Ud < 405 V - 400 / 415 V input voltage (P0296 = 2);

Ud < 446 V - 440 / 460 V input voltage (P0296 = 3);

Ud < 487 V - 480 V input voltage (P0296 = 4);

Ud < 530 V - input voltage 500 / 525 V (P0296 = 5);

Ud < 580 V - input voltage 550 / 575 V (P0296 = 6);

Ud < 605 V - input voltage 600 V (P0296 = 7).

Phase loss at the inverter input.

Pre-charge circuit failure.

Parameter P0296 was set to a value higher than the

power supply rated voltage.

F0022:

DC Link Overvoltage

A DC link overvoltage condition has occurred. Too high input voltage, resulting in a DC link voltage higher

than the maximum permitted value:

Ud > 400 V - 220 / 230 V models (P0296 = 0);

Ud > 800 V - 380 / 480 V models (P0296 = 1, 2, 3, or 4);

Ud > 1000 V - 500 / 600 V models (P0296 = 5, 6 or 7).

The inertia of the driven-load is too high or the

deceleration time is too short.

The parameter P0151, P0153 or P0185 setting is too high.

A0046:

High Load at the Motor

A0 047:

IGBT Overload Alarm

It is the motor overload alarm.

Note:

It can be disabled by setting P0348 = 0 or 2.

It is the IGBT overload alarm.

Note:

The settings of P0156, P0157 and P0158 are too low for

the used motor.

There is excessive load at the motor shaft.

The inverter output current is too high.

It can be disabled by setting P0350 = 0 or 2.

F0048:

It is the IGBT overload fault. The inverter output current is too high.

IGBT Overload Fault

A0050:

IGBT High Temperature

F0 051:

IGBT Overtemperature

F0070:

Overcurrent/

Short-circuit

F0 071:

Output Overcurrent

F0072:

Motor Overload

F0 0 74:

Ground Fault

The NTC temperature sensors located in the

IGBTs detected a high temperature alarm.

Note:

It can be disabled by setting P0353 = 2 or 3.

High surrounding air temperature (>50 °C (122 °F)) and

high output current.

Blocked or defective fan.

Very dirty heatsink.

The NTC temperature sensors located in the

IGBTs detected a high temperature fault.

An overcurrent or a short-circuit at the output,

at the DC link or at the braking resistor, has

occurred.

Short-circuit between two motor phases.

Short-circuit between the dynamic braking resistor

connection cables.

Shorted IGBT modules.

An output overcurrent has occurred. Excessive load inertia or too short acceleration ramp.

P0135, or P0169 and P0170 settings are too high.

The motor overload protection has tripped.

Note:

It can be disabled by setting P0348 = 0 or 3.

A ground fault occurred either in the cable

between the inverter and the motor or in the

motor itself.

The settings of P0156, P0157 and P0158 are too low for

the used motor.

There is excessive load at the motor shaft.

Short-circuit to the ground in one or more output phases.

Motor cable capacitance is too large, resulting in current

peaks at the output.

Note:

It can be disabled by setting P0343 = 0.

F0078:

Motor Overtemperature

Fault related to the PTC temperature sensor

installed in the motor.

Note:

- It can be disabled by setting P0351 = 0 or 3.

- An analog input and an analog output must be

set for the PTC function.

Excessive load at the motor shaft.

Severe duty cycle (too many starts / stops per minute).

Too high surrounding air temperature.

Loose connection or short-circuit (resistance < 100 Ω) in

the wiring connected to the motor thermistors.

Not installed motor thermistors.

Blocked motor shaft.

0

CFW701 | 0-17

Page 26

Quick Parameter Reference, Faults and Alarms

0

Fault/Alarm Description Possible Causes

F0080:

Microcontroller watchdog fault. Electrical noise.

CPU Watchdog

F0084:

Auto-Diagnosis Fault

A0090:

External Alarm

Auto-Diagnosis Fault. Defect in the inverter internal circuitry.

Firmware incompatible with an accessory.

External alarm monitored through a digital input.

Note:

A digital input (DI1 to DI8) programmed for “No external

alarm” is open.

It is necessary to program a digital input for “No

external alarm”.

F0 091:

External Fault

External fault monitored through a digital input.

Note:

A digital input (DI1 to DI8) programmed for “No external

fault” is open.

It is necessary to program a digital input for “No

external fault”.

A0098:

Activate General Enable

F0099:

Invalid Current Offset

A0110 :

High Motor Temperature

General Enable signal is missing during the

self-tuning.

The current measurement circuit is presenting an

abnormal value for null current.

Fault detected through PTC type temperature

sensors installed in the motor.

Note:

- It can be disabled by setting P0351 = 0 or 2.

- An analog input and an analog output must be

The digital input programmed for “General Enable” is

open.

Defect in the inverter internal circuitry.

Excessive load at the motor shaft.

Severe duty cycle (too many starts / stops per minute).

Too high surrounding air temperature.

Not installed motor thermistors.

Blocked motor shaft.

set for the PTC function.

A0128:

Serial Communication

Timeout

It indicates that the inverter stopped receiving

valid telegrams during a certain period.

Note:

Check the wiring and the ground installation.

Make sure that the inverter has sent a new message

within the time interval set at P0314.

It can be disabled by setting P0314 = 0.0 s

F0150:

Motor Overspeed

Overspeed fault.

It trips when the actual speed exceeds the value

(100 % + P0132)

of

P0134 x

100%

for more than 20 ms.

Wrong settings of P0161 and/or P0162.

Problem with a hoist-type load.

F0151:

FLASH Memory Module

Fault

A0152:

High Internal Air

Temperature

F0153:

Internal Air

Overtemperature

F0156:

Undertemperature

F0 15 7:

Parameter Table Data

Loss

F0158:

Parameter Table Fault

A0159:

Incompatible HMI

F016 0:

Safety Stop Relays

A016 3:

AI1 Broken Cable

A016 4:

AI2 Broken Cable

A016 5:

AI3 Broken Cable

A016 8:

Speed Error too High

0-18 | CFW701

FLASH Memory Module (MMF-01) fault. Defective FLASH memory module.

Check the connection of the FLASH memory module.

This alarm indicates that the internal air

temperature is too high.

Note:

It can be disabled by setting P0353 = 1 or 3.

High surrounding air temperature (>50 °C (122 °F)) and

high output current.

Defective internal fan (if existent).

High temperature (> 45 ºC) inside the cabinet.

It indicates internal air overtemperature fault. High surrounding air temperature (>50 °C (122 °F)) and

high output current.

Defective internal fan (if existent).

The temperature sensors located in the IGBTs or

Surrounding air temperature ≤ -30 °C (-22 °F).

in the rectifier detected a low temperature, below

-30 °C ( -22 °F), fault.

There was a problem during the initialization,

during the parameter table loading routine. Some

The control was switched off very fast while a parameter

was being modified.

recent parameter modifications may have been

lost.

There was a problem during the initialization,

during the parameter table loading routine. All

Firmware updating fault.

Defective control board.

the parameters were lost and the factory settings

were loaded.

Incompatible HMI HMI of another product being used.

Safety stop relay fault. One of the relays is defective or it does not have +24 V

applied to its coil.

It indicates that the AI1 current (4-20 mA or

20-4 mA) reference is out of the 4 to 20 mA range.

Broken AI1 cable.

Bad contact at the connection of the signal to the

terminal strip.

It indicates that the AI2 current (4-20 mA or

20-4 mA) reference is out of the 4 to 20 mA range.

Broken AI2 cable.

Bad contact at the connection of the signal to the

terminal strip.

It indicates that the AI3 current (4-20 mA or

20-4 mA) reference is out of the 4 to 20 mA range.

Broken AI3 cable.

Bad contact at the connection of the signal to the

terminal strip.

Difference between speed reference and effective

Inverter in torque current limitation.

speed greater than the setting in P0360.

Page 27

Quick Parameter Reference, Faults and Alarms

Fault/Alarm Description Possible Causes

F016 9:

Speed Error too High

A0 170:

Safety Stop

A0 177:

Fan Replacement

F0 179:

Heatsink Fan Speed

Fault

F018 2:

Pulse Feedback Fault

F018 3:

IGBT Overload +

Temperature

F018 5:

Pre-Charge Contactor

Fault

A0210:

Drive in Bypass mode

A0211:

Drive in Fire Mode

F0228:

Serial Communication

Timeout

A0702:

Disabled Inverter

A0704:

Two Enabled

Movements

A0706:

Reference not

Programmed for

SoftPLC

F0711:

Fault in the Execution of

the SoftPLC

A0750:

Programming AIx for

Main PID Controller

Feedback

A0752:

Programming DIx for

Main PID Controller

Automatic/Manual

Selection

A0754:

Programming Local

Reference (P0221) for

SoftPLC

A0756:

Programming Remote

Reference (P0222) for

SoftPLC

A0758:

Programming Indirect

Engineering Unit 4

(P0516) for Hz or rpm

Difference between speed reference and effective

speed greater than the setting in P0360 for longer

than P0361.

The Safety Stop function is active. The CFW701 went to the STO state.

Fan replacement alarm (P0045 > 50000 hours).

Note:

This function can be disabled by setting

P0354 = 0.

This fault indicates a problem with the heatsink fan.

Note:

This function can be disabled by setting

P0354 = 0.

It indicates a fault in the output pulses feedback. Defect in the inverter internal circuitr y.

Overtemperature related to the IGBT overload

protection.

It indicates a fault at the pre-charge contactor. Defective pre-charge contactor.

Indicates that the drive is in Bypass mode. The digital input programmed for activating the Bypass

Indicates that the drive is in Fire Mode. The digital input programmed for activating the Fire Mode

Refer to the RS-232 / RS-485 Serial Communication Manual.

Refer to the SoftPLC Manual.

Fault in the execution of the SoftPLC. Incompatible applicative.

It indicates to the user there is not analog input

programmed for Main PID controller feedback.

It indicates to the user there is not digital input

programmed for Main PID controller

Automatic/Manual selection.

It indicates to the user that the origin of the speed

reference in the Local situation is not programmed

for SoftPLC .

It indicates to the user that the origin of the

speed reference in the Remote situation is not

programmed for SoftPLC.

It indicates to the user that the engineering unit

parameters for motor speed is not programmed

for Hz or rpm.

Inverter in torque current limitation for too long.

The heatsink fan maximum number of operating hours

has been reached.

Dirt on the blades and in the bearings of the fan.

Defective fan.

Defective fan power supply connection.

Too high inverter surrounding temperature.

Operation with frequencies < 10 Hz with overload.

Open command fuse.

Phase loss at the L1/R or L2/S input.

P0355 = 1 (incorrect setting for mechanical models “E”

powered by the DC Link. For these models should be

set P0355 = 0).

mode is active.

is active.

Fault during upload of the applicative.

Parameter P0231 or P0236 or P0241 is not programmed

in 5, 6 or 7.

Parameter P0263 or P0264 or P0265 or P0266 or P0267

or P0268 or P0269 or P0270 is not programmed in 20.

Main PID controller is enabled (P1017 in 1 or 2) and

CFW701 frequency inverter run the motor in Local

situation and parameter P0221 is not programmed in 7.

Main PID controller is enabled (P1017 in 1 or 2) and

CFW701 frequency inverter run the motor in Remote

situation and parameter P0222 is not programmed in 7.

Parameter P0516 is not programmed in 13 (Hz) or 3 (rpm).

0

CFW701 | 0-19

Page 28

Quick Parameter Reference, Faults and Alarms

0

Fault/Alarm Description Possible Causes

A0760:

Low Level for Main PID

Controller Feedback

F0761:

Low Level for Main PID

Controller Feedback

A0762:

High Level for Main PID

Controller Feedback

F0763:

High Level for Main PID

Controller Feedback

A0764:

CFW701 in Sleep Mode

A0766:

Dry Pump Detected

F0 767:

Dry Pump Detected

A0768:

Broken Belt Detected

F0769:

Broken Belt Detected

A0770:

Filter Maintenance

F0771:

Filter Maintenance

A0780:

Programming AIx for

External PID Controller 1

Feedback

A0782:

Programming DIx for

External PID Controller

1 Automatic/Manual

Selection

A0784:

Programming AOx for

External PID Controller 1

Output

A0786:

Low Level for External PID

Controller 1 Feedback

F0787:

Low Level for External PID

Controller 1 Feedback

A0788:

High Level for External PID

Controller 1 Feedback

It indicates to the user that the Main PID controller

feedback is low.

It indicates to the user that the Main PID controller

feedback is low.

It indicates to the user that the Main PID controller

feedback is high.

It indicates to the user that the Main PID controller

feedback is high.

It indicates to the user that the CFW701 frequency

inverter is in Sleep mode.

It indicates to the user that the dry pump

condition was detected for the pump driven by

CFW701 frequency inverter.

It indicates to the user that the dry pump

condition was detected for the pump driven by

CFW701 frequency inverter.

It indicates to the user that the broken belt

condition was detected for the motor driven by

CFW701 frequency inverter.

It indicates to the user that the broken belt

condition was detected for the motor driven by

CFW701 frequency inverter.

It indicates to the user that the need to change

the filter system.

It indicates to the user that the need to change

the filter system.

It indicates to the user there is not analog input

programmed for External PID controller 1

feedback.

It indicates to the user there is not digital input

programmed for External PID controller 1

Automatic/Manual selection.

It indicates to the user there is not analog output

programmed for External PID controller 1 output.

It indicates to the user that the External PID

controller 1 feedback is low.

It indicates to the user that the External PID

controller 1 feedback is low.

It indicates to the user that the External PID

controller 1 feedback is high.

Parameter P1030 is programmed in 1 and the Main PID

controller feedback value is remaining below the value

programmed in P1031 for the time programmed in P1032.

Parameter P1030 is programmed in 2 and the Main PID

controller feedback value is remaining below the value

programmed in P1031 for the time programmed in P1032.

Parameter P1030 is programmed in 1 and the Main PID

controller feedback value is remaining above the value

programmed in P1033 for the time programmed in P1034.

Parameter P1030 is programmed in 2 and the Main PID

controller feedback value is remaining above the value

programmed in P1033 for the time programmed in P1034.

Main PID controller is enabled and in Automatic mode

and the motor speed is remaining below the speed value

programmed in P1036 for the time programmed in P1037.

Parameter P1042 is programmed in 1 and the pump

driven by CFW701 frequency inverter is running faster

than speed programmed in P1043 and the motor torque

is remaining below the torque value programmed in

P1044 for the time programmed in P1045.

Parameter P1042 is programmed in 2 and the pump

driven by CFW701 frequency inverter is running faster

than speed programmed in P1043 and the motor torque

is remaining below the torque value programmed in

P1044 for the time programmed in P1045.

Parameter P1046 is programmed in 1 and the motor

driven by CFW701 frequency inverter is running faster

than speed programmed in P1047 and the motor torque

is remaining below the torque value programmed in

P1048 for the time programmed in P1049.

Parameter P1046 is programmed in 2 and the motor

driven by CFW701 frequency inverter is running faster

than speed programmed in P1047 and the motor torque

is remaining below the torque value programmed in

P1048 for the time programmed in P1049.

Parameter P1050 is programmed in 1 and the operation

time of motor driven by CFW701 frequency inverter

displayed in P1052 is greater than the time programmed

in P10 51.

Parameter P1050 is programmed in 2 and the operation

time of motor driven by CFW701 frequency inverter

displayed in P1052 is greater than the time programmed

in P10 51.

Parameter P0231 or P0236 or P0241 is not programmed

in 8.

Parameter P0263 or P0264 or P0265 or P0266 or P0267

or P0268 or P0269 or P0270 is not programmed in 21.

Parameter P0251 or P0254 is not programmed in 16.

Parameter P1075 is programmed in 1 and the External PID

controller 1 feedback value is remaining below the value

programmed in P1076 for the time programmed in P1077.

Parameter P1075 is programmed in 2 and the External PID

controller 1 Feedback value is remaining below the value

programmed in P1076 for the time programmed in P1077.

Parameter P1075 is programmed in 1 and the External PID

controller 1 feedback value is remaining above the value

programmed in P1078 for the time programmed in P1079.

0-20 | CFW701

Page 29

Quick Parameter Reference, Faults and Alarms

Fault/Alarm Description Possible Causes

F0789:

High Level for External PID

Controller 1 Feedback

A0790:

Programming AIx for

External PID Controller 2

Feedback

A0792:

Programming DIx for

External PID Controller

2 Automatic/Manual

Selection

A0794:

Programming AOx for

External PID Controller 2

Output

A0796:

Low Level for External PID

Controller 2 Feedback

F0 797:

Low Level for External PID

Controller 2 Feedback

A0798:

High Level for External PID

Controller 2 Feedback

F0799:

High Level for External PID

Controller 2 Feedback

It indicates to the user that the External PID

controller 1 feedback is high.

It indicates to the user there is not analog

input programmed for External PID controller 2

feedback.

It indicates to the user there is not digital input

programmed for External PID controller 2

Automatic/Manual selection.

It indicates to the user there is not analog output

programmed for External PID controller 2 output.

It indicates to the user that the External PID

controller 2 feedback is low.

It indicates to the user that the External PID

controller 2 feedback is low.

It indicates to the user that the External PID

controller 2 feedback is high.

It indicates to the user that the External PID

controller 2 feedback is high.

Parameter P1075 is programmed in 2 and the External PID

controller 1 feedback value is remaining above the value

programmed in P1078 for the time programmed in P1079.

Parameter P0231 or P0236 or P0241 is not programmed

in 9.

Parameter P0263 or P0264 or P0265 or P0266 or P0267

or P0268 or P0269 or P0270 is not programmed in 22.

Parameter P0251 or P0254 is not programmed in 17.

Parameter P1095 is programmed in 1 and the External PID

controller 2 feedback value is remaining below the value

programmed in P1096 for the time programmed in P1097.

Parameter P1095 is programmed in 2 and the External PID

controller 2 feedback value is remaining below the value

programmed in P1096 for the time programmed in P1097.

Parameter P1095 is programmed in 1 and the External PID

controller 2 feedback value is remaining above the value

programmed in P1098 for the time programmed in P1099.

Parameter P1095 is programmed in 2 and the External PID

controller 2 feedback value is remaining above the value

programmed in P1098 for the time programmed in P1099.

0

Notes:

(1) Very long motor cables, with more than 100 m (328.08 ft), presents a high parasitic capacitance to the ground.

The circulation of a leakage current through this capacitance may cause the activation of the ground fault circuit,

and consequently an F0074 trip immediately after the inverter enabling.

POSSIBLE SOLUTION:

To reduce the switching frequency (P0297).

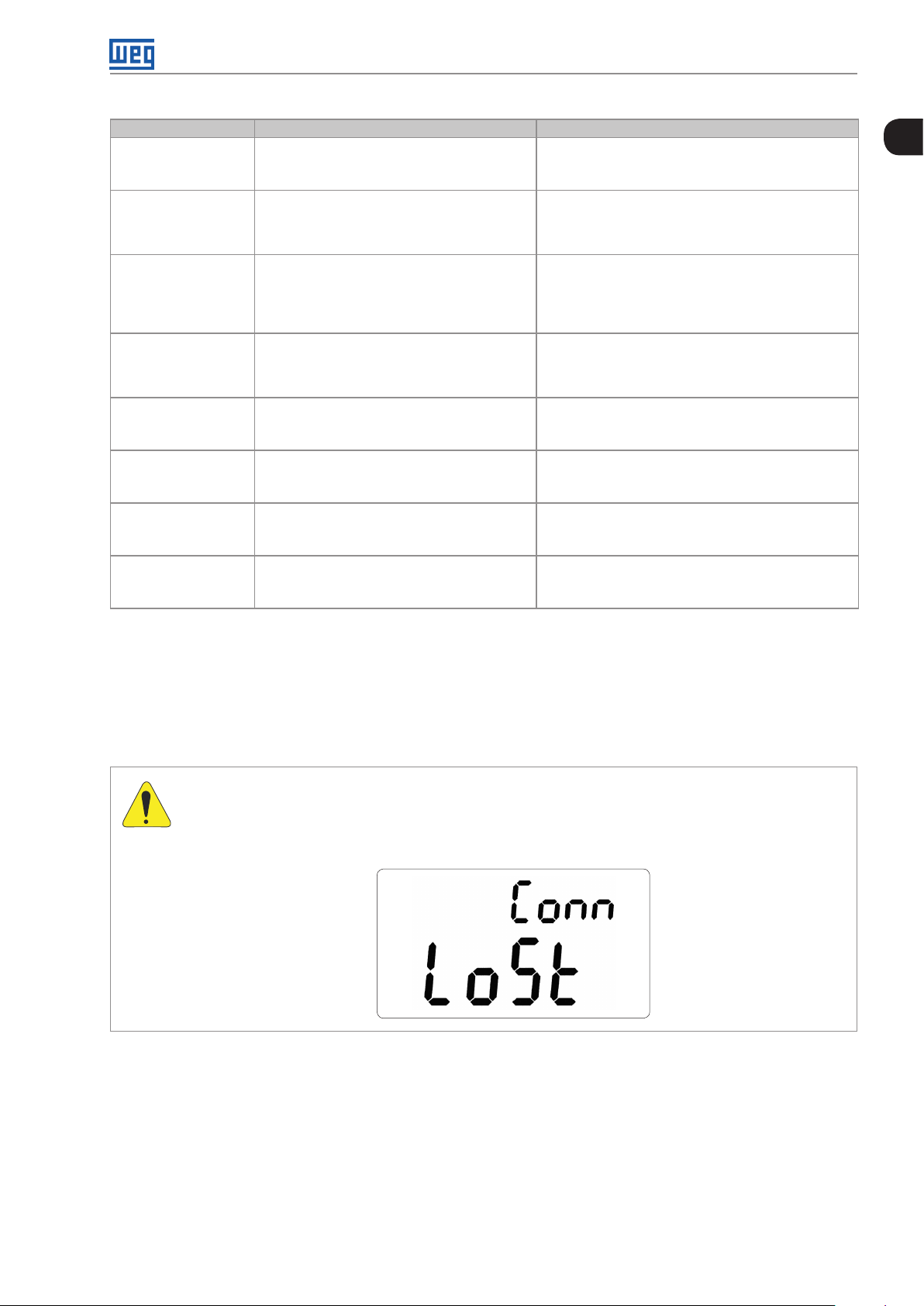

ATTENTION!

A bad contact in the HMI cable, or electric noise in the installation, can cause a failure in the

communication between the HMI and the control board. In such case, the operation through the HMI

becomes impossible and the HMI indicates the following message on the display:

CFW701 | 0-21

Page 30

Quick Parameter Reference, Faults and Alarms

0

0-22 | CFW701

Page 31

Safety Notices

1 SAFETY NOTICES

This Manual contains the information necessary for the correct use of the CFW701 Frequency Inverter.

It has been developed to be used by qualified personnel with suitable training or technical qualification for operating

this type of equipment.

1.1 SAFETY NOTICES IN THIS MANUAL

The following safety notices are used in this manual:

DANGER!

The procedures recommended in this warning have the purpose of protecting the user against dead,

serious injuries and considerable material damage.

DANGER!