WEG Electric CFW701 Product Flyer

CFW701 HVAC

Variable Speed Drive

In order to be present in the world’s biggest drives market WEG

developed a product dedicated to heating, ventilation, air conditioning

and refrigeration applications. Beyond a specific hardware designed for

this purpose the CFW701 also brings in specific functions to perform

according to market needs.

The Full HVAC Potential

Fire Mode

This function makes the drive to inhibit

its internal faults making the motor run

at adverse conditions without stopping

the process.

Sleep / Wake-Up Mode

It prevents the operation of the motor

at low speeds for certain amount of

time to be previously programmed.

Also the instant when the motor has to

be restar ted can determined by using

the wake-up mode.

Broken Belt

It monitors motor torque and prevents

it from running with no load in case of a

broken belt.

Energy Saving

Depending on the motor speed and

load conditions the flux is reduced

decreasing losses and therefore

efficiency is improved causing energy

saving.

Filter Maintenance Alarm

It warns about the need to replace the filter.

Bypass

Using one of its output relay the

CFW701 HVAC allows the motor

to be started cross the line.

An external circuitry is needed for

this operation.

USB Por t

Ready to conect with a computer.

Dry Pump

It prevents the pump from running

with no load.

PTC

Possibility for monitoring PTC

se nsor.

Short Cycle Protection

It prevents a compressor/motor

from being switched on and off in

short period of times.

Motor Power Range

0.18 to 110 kW (0.25 to 150 HP)

Certifications

Characteristics

g

Focus on HVAC Duty

Overload current: 150% during 60s

Ambient temperature: up to 50 ºC

g

RFI Filter Built-In

RFI Filter complying with IEC 61800-3

Category C3

g

Low Harmonic Distortion

Meets the standard IEC 61000-3-12

g

SoftPLC

PLC functions: making it a flexible and

optimized solution

g

Advanced PID

Main PID control the process by itself

and 2 additionals PID for use to control

an independent process

g

Communication Protocols

BACnet MS/TP, Metasys N2 and

Modbus-RTU

g

Conformal Coating as Standard

Accessories

g

Intuitive HMI

Built-in as standard and

remote for the panel door

g

Inputs and Outputs (I/O):

g

8 Isolated digital inputs

g

3 Differential analog inputs

(0-10 V/4-20 mA (2) and 4-20 mA (1))

g

5 Digital outputs (2 relays with NA

contacts, 3 isolated transistors)

g

2 Non-isolated analog outputs

g

1 Dedicated input for PTC

Specific Engineering

Units for HVAC for both HMI.

CFW701 HVAC

Variable Speed Drive

Applications

g

Hospitals

g

Shoppings

g

Commecial buildings

g

Universities

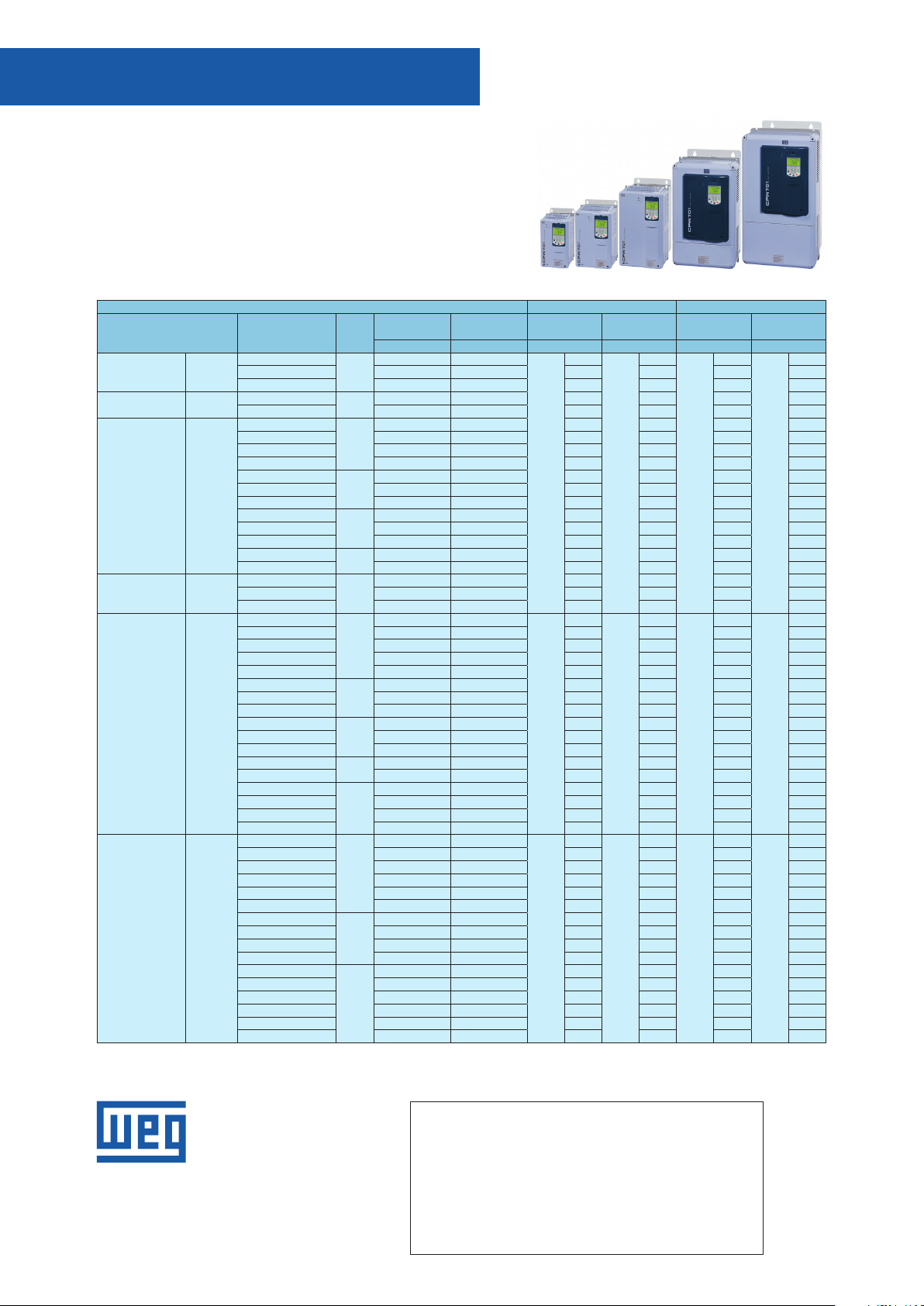

Drive Ratings

Power supply (V) Model

Single-phase 200-240

Single-phase or

three-phase

Three-phase 200-240

Three-phase 380-480

Three-phase 380-480

Three-phase 500-600

Note: 1) Use motor power ratings above only as a guideline. Motors are rated for 400 V, 50 Hz, 4-pole. The right way to size a VSD is matching its output

current with the rated motor current.

200-240

g

Schools

g

Airports

g

Hotels

g

Clean rooms

CFW701 - variable speed drive Maximum ND motor power

CFW701 A 06PO S2

CFW701 A 07PO S2 7 7 1.5 2 1.5 2

CFW701 A 10PO S2 10 10 2.2 3 2.2 3

CFW701 A 06PO B2

CFW701 A 07PO B2 7 7 1.5 2 1.5 2

CFW701 A 07PO T2

CFW701 A 10PO T2 10 8 2.2 3 1.5 2

CFW701 A 13PO T2 13 11 3 3 2.2 3

CFW701 A 16PO T2 16 13 4 5 3 3

CFW701 B 24PO T2

CFW701 B 28PO T2 28 24 7.5 10 5.5 7.5

CFW701 B 33PO T2 33.5 28 9.2 10 7.5 10

CFW701 C 45PO T2

CFW701 C 54PO T2 54 45 15 20 11 15

CFW701 C 70PO T2 70 56 18.5 25 15 20

CFW701 D 86PO T2

CFW701 D 0105PO T2 105 86 30 40 22 30

CFW701 E 0142PO T2

CFW701 E 0180PO T2 180 142 55 60 37 50

CFW701 E 0211PO T2 211 180 55 75 55 60

CFW701 A 03P6 T4

CFW701 A 05P0 T4 5 5 2.2 3 2.2 3

CFW701 A 07P0 T4 7 5.5 3 3 2.2 3

CFW701 A 10P0 T4 10 10 4 5 4 5

CFW701 A 13P5 T4 13.5 11 5.5 7.5 4 7.5

CFW701 B 17P0 T4

CFW701 B 24P0 T4 24 19 11 15 9.2 10

CFW701 B 31P0 T4 31 25 15 20 11 15

CFW701 C38P0 T4

CFW701 C45P0 T4 45 38 22 30 18.5 25

CFW701 C58P5 T4 58.5 47 30 40 22 30

CFW701 D 70P5 T4

CFW701 D 88P0 T4 88 73 45 60 37 50

CFW701 E 0105 T4

CFW701 E 0142 T4 142 115 75 100 55 75

CFW701 E 0180 T4 180 142 90 150 75 100

CFW701 E 0211 T4 211 180 110 150 90 150

CFW701 B 02P9 T5

CFW701 B 04P2 T5 4.2 3.8 2.2 3 2.2 2

CFW701 B 07P0 T5 7 6.5 4 5 4 5

CFW701 B 10P0 T5 10 9 5.5 7.5 5.5 7.5

CFW701 B 12P0 T5 12 10 7.5 10 5.5 7.5

CFW701 B 17P0 T5 17 17 11 15 11 15

CFW701 D 22P0 T5

CFW701 D 27P0 T5 27 22 18.5 25 15 20

CFW701 D 32P0 T5 32 27 22 30 18.5 25

CFW701 D 44P0 T5 44 36 30 40 22 30

CFW701 E 53P0 T5

CFW701 E 63P0

CFW701 E 80P0 T5 80 66 55 75 45 60

CFW701 E 0107 T5 107 90 75 100 55 75

CFW701 E 0125 T5 125 107 90 125 75 100

CFW701 E 0150 T5 150 122 110 150 90 100

T5 63 53 45 60 37 50

Frame

sizes

A

A

A

B

C

D

E

A

B

C

D

E

B

D

E

g

Pump and fan

applications in general

1)

Normal Duty

(ND)

A A kW HP kW HP

6 5

6 5 1.1 1.5 1.1 1

7 5.5 1.5 2 1.1 1

24 20 5.5 7.5 5.5 5

45 36 11 15 9.2 10

86 70 22 30 18.5 25

142 115 37 50 30 40

3.6 3.6

17 13.5 7.5 10 5.5 7.5

38 33 18.5 25 15 20

70.5 61 37 50 30 40

105 88 55 75 45 60

2.9 2.7

22 19 15 20 11 15

53 44 37 50

Heavy Duty

(HD)

IEC NEMA IEC NEMA

1.1

60 Hz - 230 V

50 Hz - 220 V / 230 V

1.5

60 Hz - 460 V

50 Hz - 380 V / 415 V

1.5

60 Hz - 575 V

50 Hz - 525 V / 575 V

Maximum HD motor power

1.5

50 Hz - 220 V / 230 V

2

50 Hz - 380 V / 415 V

2

50 Hz - 525 V / 575 V

1.1

1.5

1.5

30 40

60 Hz - 230 V

60 Hz - 460 V

60 Hz - 575 V

1)

1

2

2

Cod: 50021178 | Rev: 00 | Date (m/ y): 08/2014

The values shown are subject to chan ge without pr ior notice.

Loading...

Loading...